Wideband nozzle capable of uniformly feeding powder in laser processing

A nozzle and powder feeding technology, used in laser welding equipment, metal processing equipment, spraying devices, etc., can solve the problem of difficult and uniform powder feeding from nozzles, achieve good uniformity, improve efficiency and coating performance and stiffness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

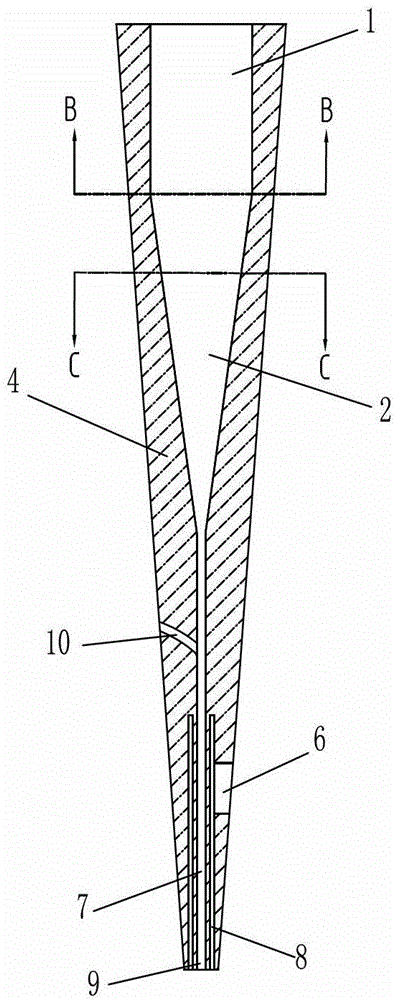

[0020] Such as figure 1 The shown broadband nozzle for uniform powder feeding for laser processing includes a rectangular nozzle 4 and an annular powder chamber 5. The rectangular nozzle 4 is provided with a rectangular powder feeding channel 7 and a protective gas channel 8. One end of the rectangular powder feeding channel 7 is The powder outlet 9 and the protective gas channel 8 are arranged in parallel on the periphery of the powder outlet 9. The other end of the rectangular powder feeding channel 7 is a powder feeding gas channel. The powder feeding gas channel includes a transition channel 2 and a circular channel 1. The transition channel 2 realizes the smooth and uniform transition from the circular channel 1 to the rectangular powder feeding channel 7; the rectangular nozzle 4 is fixedly installed in the annular powder chamber 5, and the powder outlet 9 end of the rectangular nozzle 4 and the circular channel 1 end protrude Annular powder chamber 5, powder 12 is place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com