Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Improve laser processing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

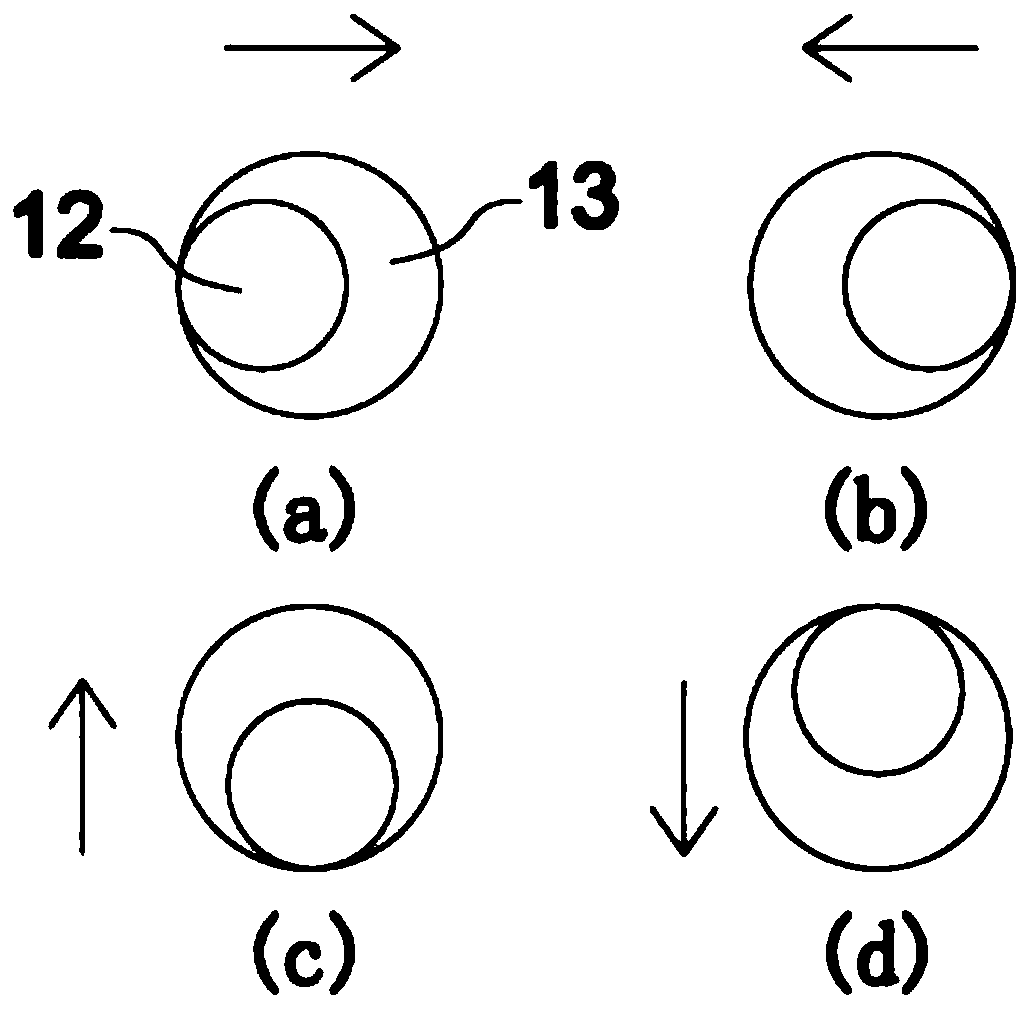

Same-wavelength double-beam narrow-spot laser quick cladding method

InactiveCN102409338AEasy loading and unloadingEasy to operateMetallic material coating processesNumerical controlHeat-affected zone

The invention discloses a same-wavelength double-beam narrow-spot laser quick cladding method, which is characterized by comprising the following steps of: (1) performing rust removing, oil removing, cleaning and sand blasting treatment on the surface of a substrate; (2) splitting a laser beam of the same wavelength into two beams of laser by using a laser beam splitter mirror; (3) applying a first beam of laser to the surface of the substrate for performing preheating treatment on the substrate; (4) blowing alloy powder into a molten pool formed on a second beam of laser on the surface of the substrate by using a powder nozzle of an automatic powder feeder; (5) moving a numerically-controlled machine too along the vertical direction of a laser scanning speed by 40-80 percent of the diameter of a laser spot; and (6) repeating the steps (2)-(5) till the thickness of a coating reaches a required thickness, or ending work. The method has the advantages: (1) the processing cost is reduced greatly; (2) the substrate has a small heat affected zone, and is not deformed; and (3) the shape and size of the substrate are unlimited.

Owner:NANCHANG HANGKONG UNIVERSITY

Laser machining equipment for parallel machining

InactiveCN107876968AImprove processing efficiencySatisfy processing operationsLaser beam welding apparatusGalvanometerOptoelectronics

The invention discloses laser machining equipment for parallel machining. The laser machining equipment comprises a multi-beam output laser device, a beam expanding device, a galvanometer and a lens,all of which are sequentially arranged. The laser machining equipment further comprises a control mechanism for controlling the laser device and the galvanometer. The beam expanding device, the galvanometer and the lens correspond to beams generated by the multi-beam laser device in a one-to-one manner. The laser device emits the multi-beam laser, the output beams are independent of one another, parameters of the output beams can be respectively set and are independent of one another, and the beams sequentially pass through the beam expanding device, the galvanometer and the lens correspondingto the beams and irradiate to the product surface for laser machining. The galvanometer can arrange to-be-machined patterns in a zoned manner according to the characteristics of the machined patterns. The machining equipment can generate multiple parallel laser machining beams at the same time, parallel machining can be conducted on to-be-machined workpieces, the laser machining equipment is suitable for large-breadth material cutting or groove carving or drilling or marking operation, the laser machining efficiency is improved, and the large-area laser machining operation can be achieved.

Owner:INNO LASER TECH CORP LTD +1

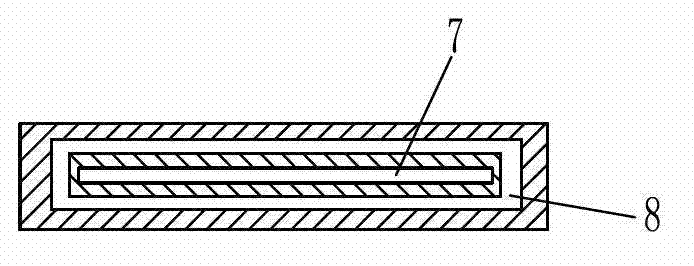

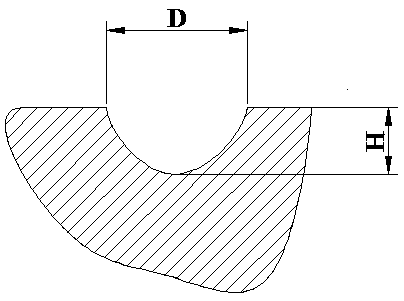

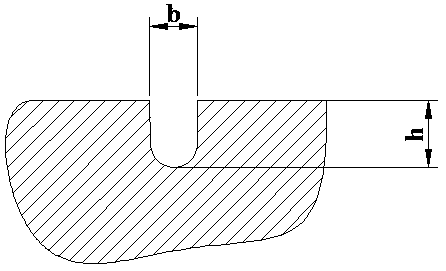

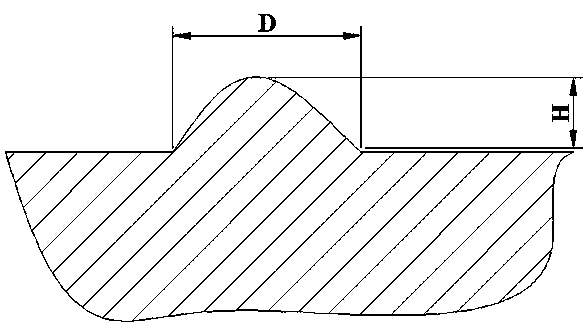

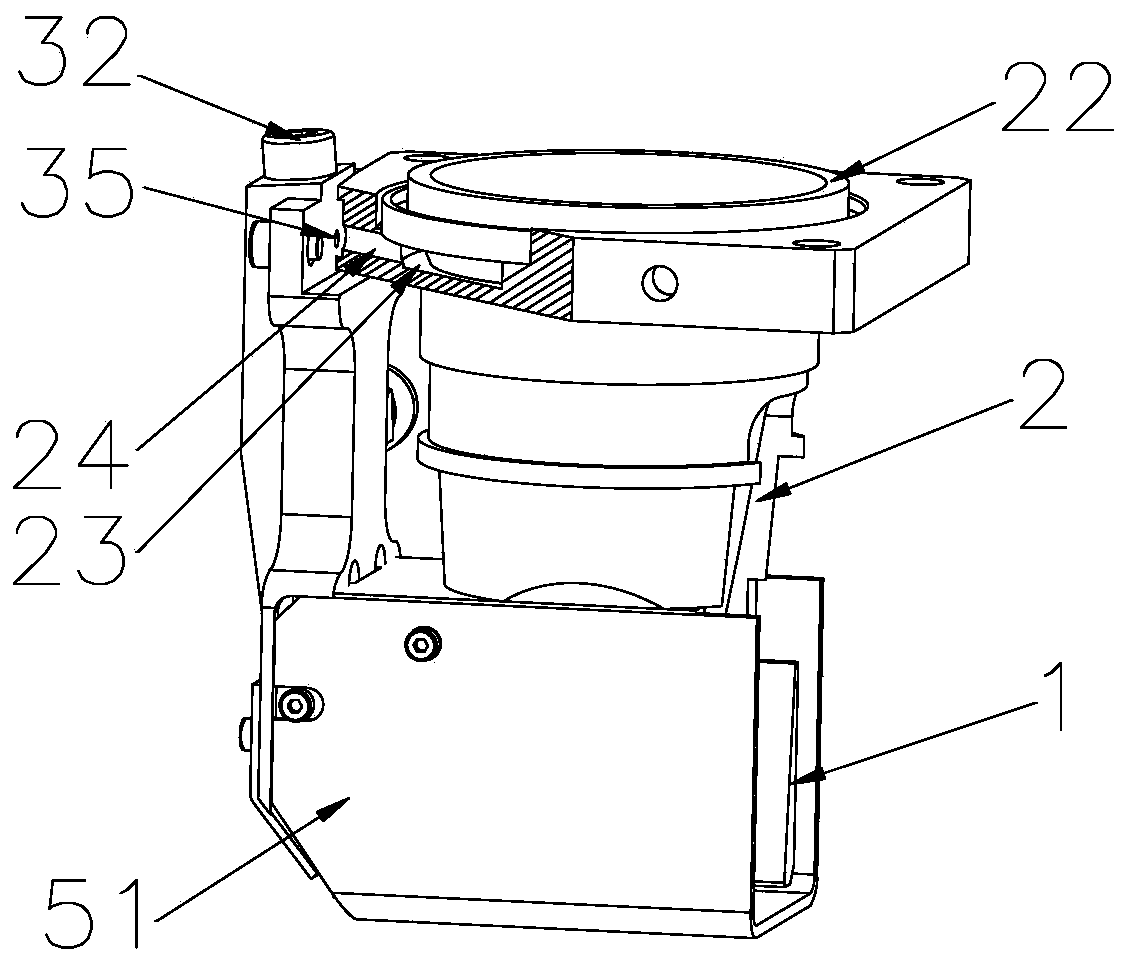

Wideband nozzle capable of uniformly feeding powder in laser processing

ActiveCN103205748AImprove continuityImprove stiffnessMetallic material coating processesLiquid spraying apparatusLaser processingMetallurgy

The invention discloses a wideband nozzle capable of uniformly feeding power in laser processing. The wideband nozzle comprises a rectangular nozzle and an annular powder cavity, the rectangular nozzle is provided with a rectangular powder feed channel and a protection gas channel, one end of the rectangular powder feed channel is a powder outlet, the protection gas channel is arranged at the periphery of the powder outlet and parallel to the powder outlet, the other end of the rectangular powder feed channel is a powder feed gas channel, the powder feed gas channel comprises a transition channel and a circular channel, the transition channel is used for realizing the smooth and uniform transition from the circular channel to the rectangular powder feed channel, the rectangular nozzle is installed and fixed in the annular powder cavity, the powder outlet end and the circular channel end of the rectangular nozzle extend out of the annular powder cavity, the powder is put in the annular powder cavity, and the gas channel is arranged in the annular powder cavity, and a powder inlet is arranged at the side of the rectangular powder feed channel of the rectangular nozzle. The nozzle disclosed by the invention can be used for greatly eliminating the phenomenon that the powder in middle is more than powder at two sides when the rectangular nozzle is used for feeding powder, the powder is capable of uniformly filling the powder outlet of the whole rectangle to realize the uniform powder feed.

Owner:HANGZHOU BOHUA LASER TECH

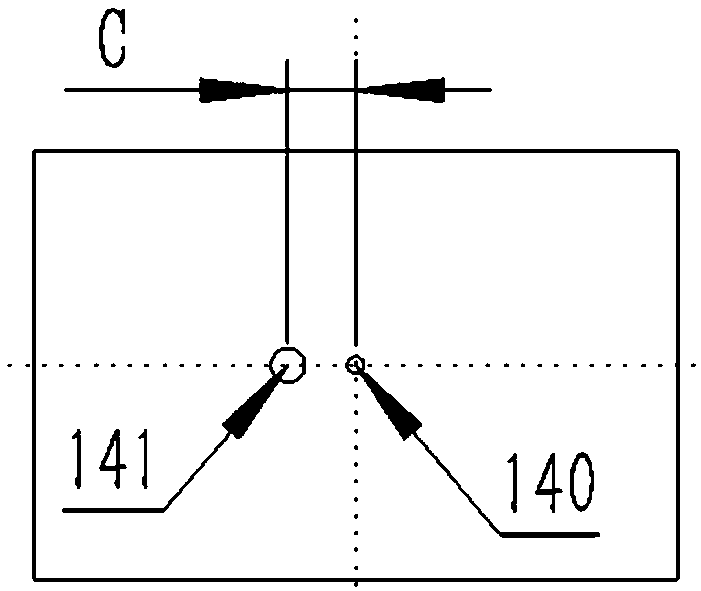

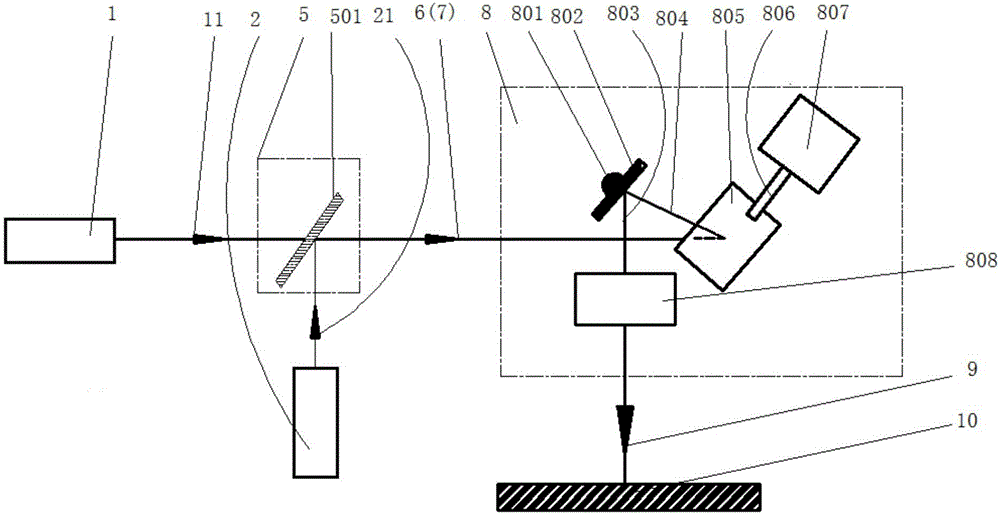

Focusing device based on inner coaxial shaft and focusing method based on inner coaxial shaft

ActiveCN109530912AImprove focusing efficiencyImprove consistencyLaser beam welding apparatusCamera lensLight beam

The invention provides a focusing device based on an inner coaxial shaft and a focusing method based on the inner coaxial shaft, and belongs to the technical field of laser machining. The device comprises a light source, a galvanometer focusing system, a spectroscope, a laser device, a camera lens and a sensor, wherein the light source is used for outputting a light beam to a workpiece, the lightbeam is irradiated on the surface of the workpiece to form a light beam state, the image information of the light beam state is transmitted to the spectroscope through the galvanometer focusing system, and the image information is transmitted to the camera lens and the sensor sequentially through the spectroscope; the imaging lens is used for transmitting the image information to the sensor, the sensor receives the image information and processes and analyzes the image information by software to obtain a mass center position of the light beam; and the laser device is used for outputting laser,the laser is reflected to the galvanometer focusing system through the spectroscope, and the laser is focused to the workpiece through the galvanometer focusing system. According to the focusing device, the problems of low focusing efficiency and poor consistency can be solved, and the laser machining efficiency is improved; and the focusing method based on the inner coaxial shaft uses the devicementioned above.

Owner:WUHAN HGLASER ENG CO LTD

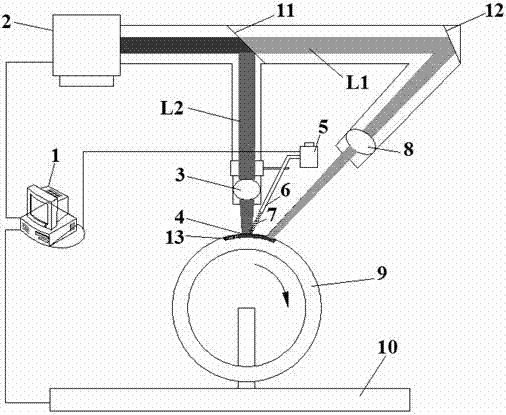

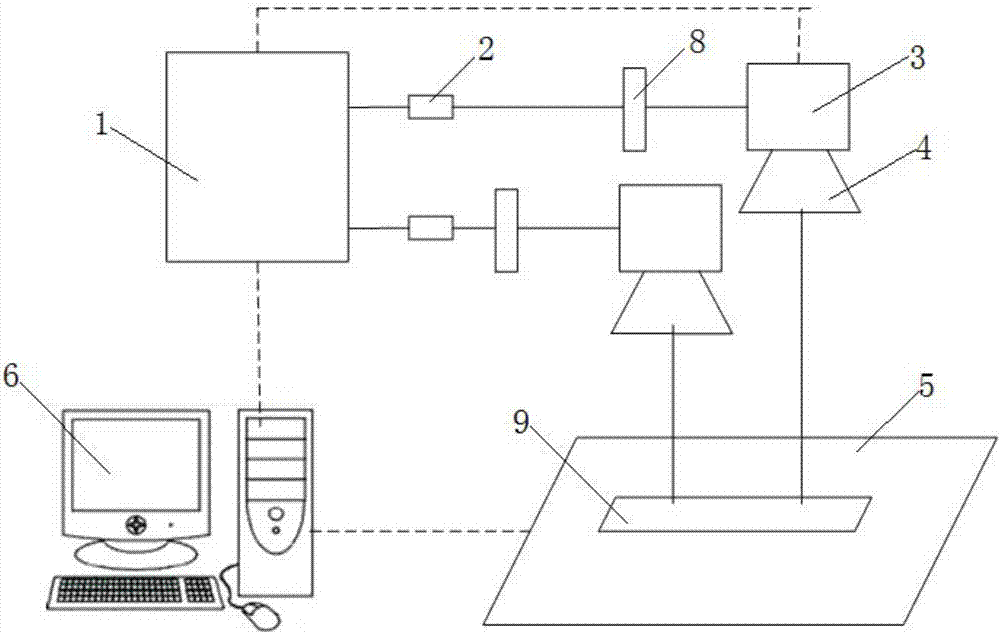

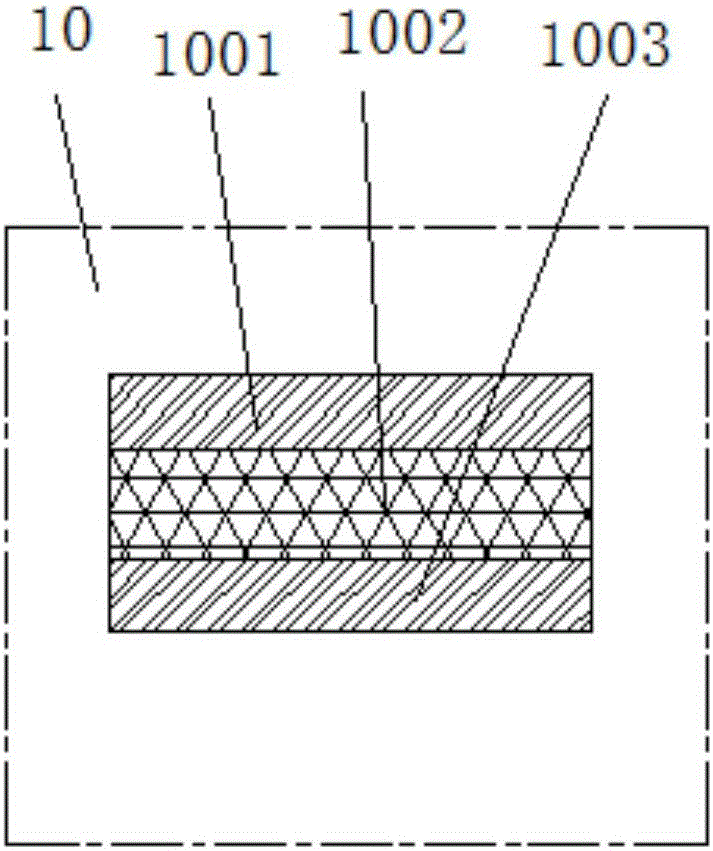

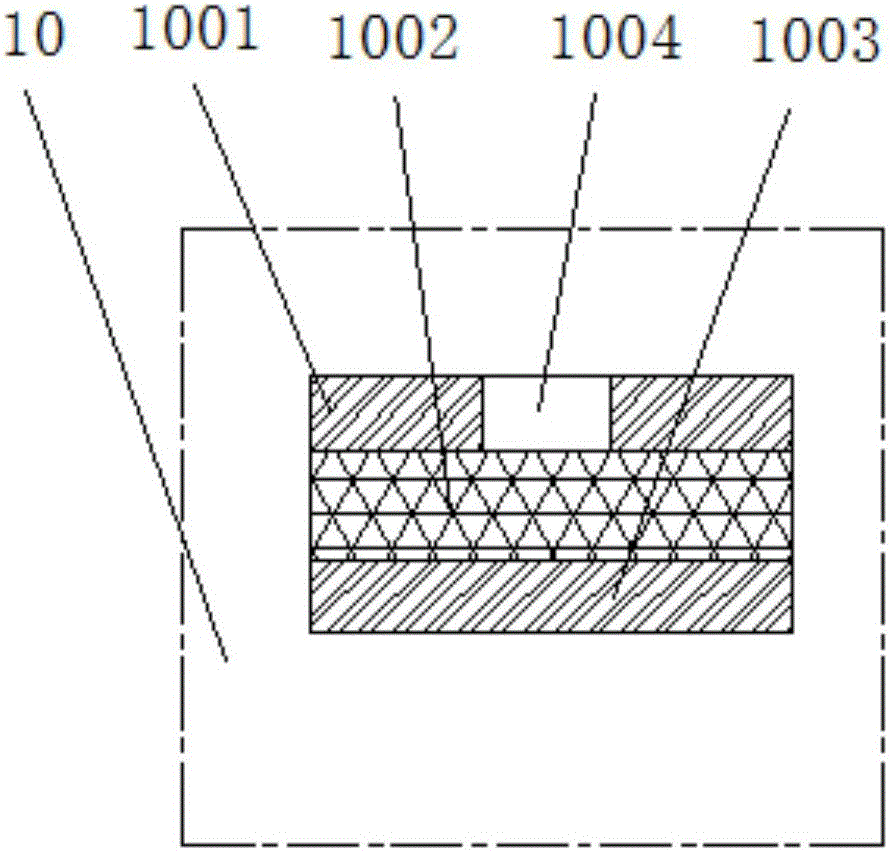

Multilayer material layered milling machining system and method based on space combination laser focal point

ActiveCN106624391AImprove laser processing efficiencyImprove efficiencyPrinted circuitsMetal working apparatusComputer moduleWindow opening

The invention discloses a multilayer material layered drilling system based on a space combination laser focal point and a drilling method. The drilling system comprises a window opening milling laser, a selective milling laser, a laser beam combiner and a laser focusing and focal point switching module; under the same one drilling optical focusing system, the laser focusing and focal point switching module is provided with the space combination laser focal point; when multiple layers of sheet plates with different materials are machined, the laser focal points with different characteristics can be used for machining the different layers of materials, so that the laser machining efficiency and the laser machining quality can be greatly improved; and in particular, when blind holes of multiple layers of laminated sheet plates with different materials are drilled, and the last layer of laser of the blind holes damage milling of the materials with low threshold, the selective milling laser focal points are used for removing the materials without worrying about damage of the materials with high threshold by the next layer of laser, so that the excellent process stable section is brought, the machining time is saved, the machining efficiency is improved, and the excellent machining effect is obtained.

Owner:张立国

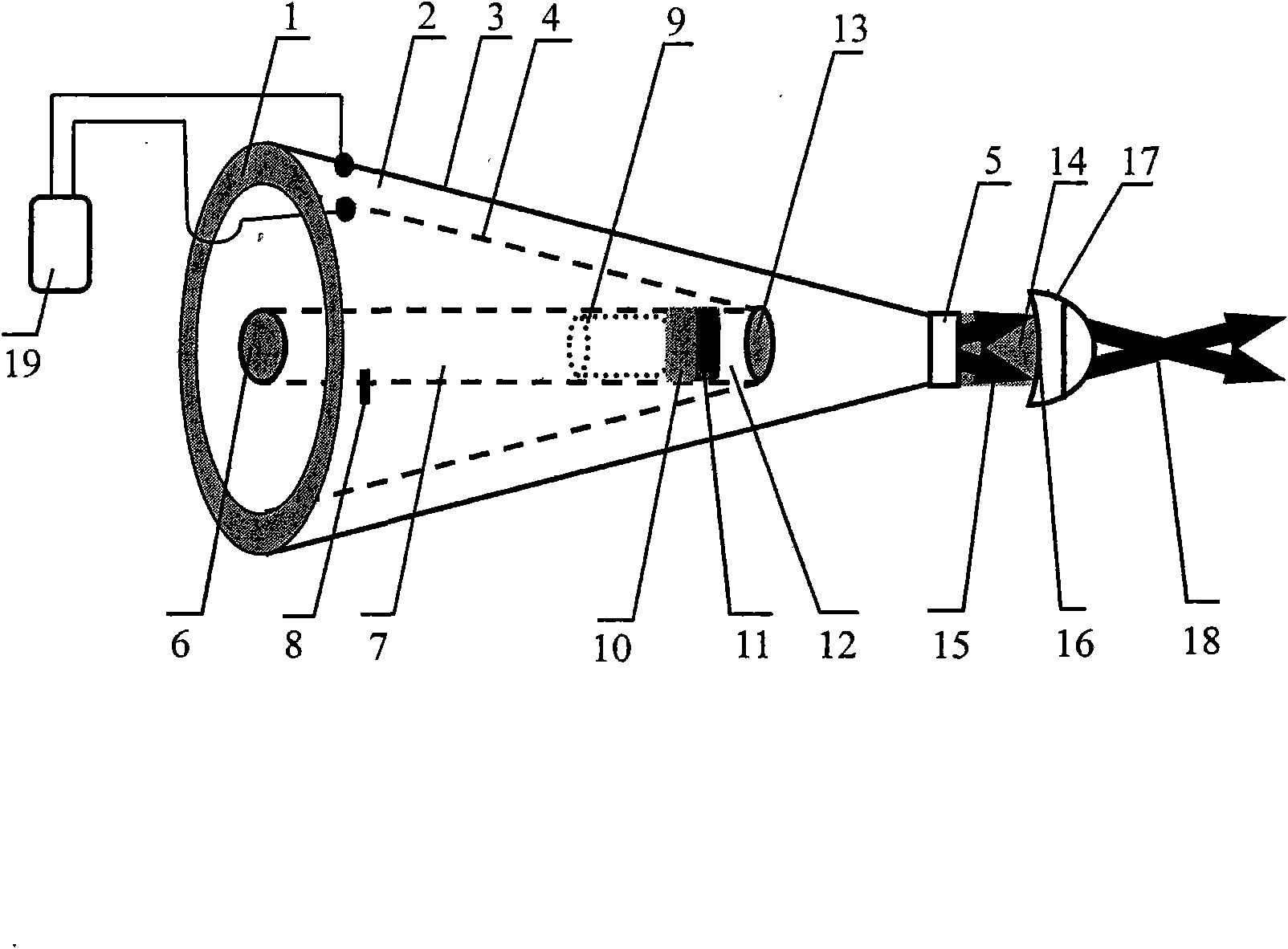

Conical phase locking carbon dioxide laser

InactiveCN101630807ASmall meeting pointNarrative convenienceOptical resonator shape and constructionGas laser constructional detailsMetallic materialsOptical engineering

The invention discloses a conical phase locking carbon dioxide laser, and belongs to the fields of optical engineering and laser application. The conical carbon dioxide laser and axially-symmetric output beams are subjected to phase locking, and then convergent beams form intense coherent superposition, so the conical phase locking carbon dioxide laser has the laser processing efficiency and property sufficiently close to that of an axial flow carbon dioxide laser or even exceeding, and has the advantages in the aspects of device volume and use convenience. The conical phase locking carbon dioxide laser has good compactness the same as a cylindrical CO2 laser and a flat waveguide CO2 laser, the quality and the coherence of the output beams of the conical phase locking carbon dioxide laser are higher than those of the cylindrical CO2 laser, and the compactness and the output level quality of the conical phase locking carbon dioxide laser are higher than those of the flat waveguide device. After being processed by a convergence system, the output beams of the conical phase locking carbon dioxide laser can be conveniently applied to surface treatment, welding, cutting, perforating and the like of metal and nonmetallic materials; and the conical phase locking carbon dioxide laser can become an important device for laser processing.

Owner:SICHUAN UNIV

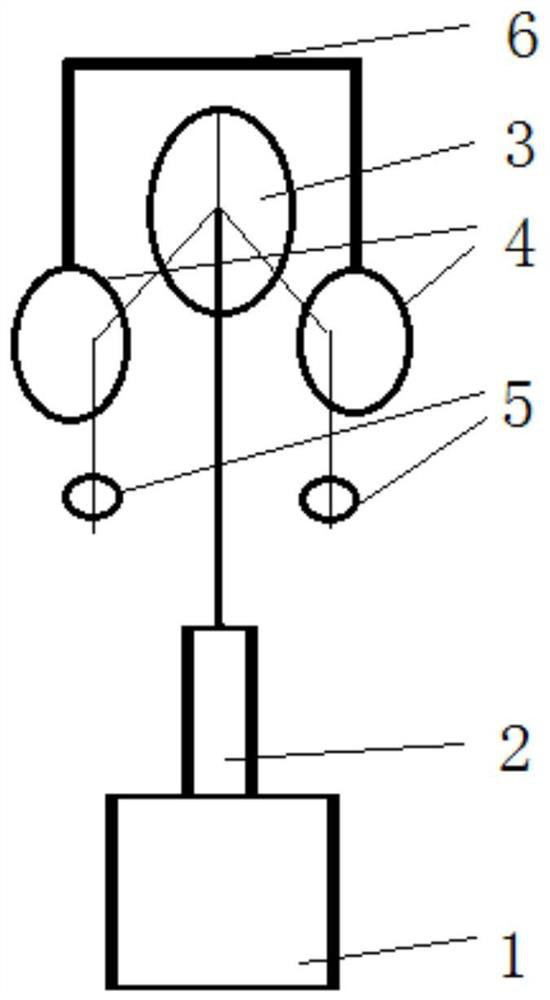

Array type water waveguide laser processing device

ActiveCN102248294AUniform sizeRealize two-dimensional processingLaser beam welding apparatusFlat glassNumerical control

The invention provides an array type water waveguide laser processing device and relates to a laser processing device. The array type water waveguide laser processing device solves the technical problems of small processing range and low efficiency in the background technology part and overcomes the defects of insufficient processing flexibility and the like. The array type water waveguide laser processing device is provided with a laser, an inverted telescope, a lens barrel, a first transmitting and reflecting mirror array, a second transmitting and reflecting mirror array, a first reflecting mirror, a focusing lens array, a nozzle body, a bracket with a lantern ring, a bracket, a water collector with a filter, a fixture, a numerical control platform, a vidicon, a water circulating system, a computer numerical control device, an observation laser, a second reflecting mirror, a pipe joint, a water cavity, plate glass and a compression ring.

Owner:XIAMEN UNIV

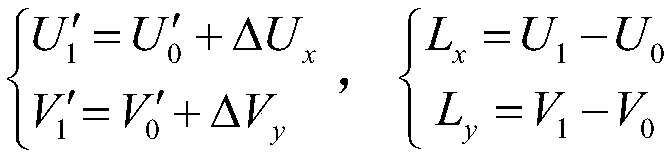

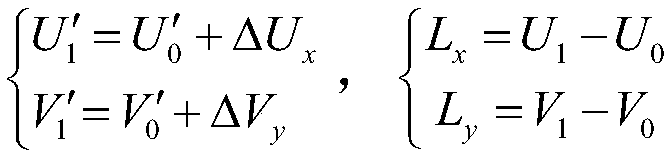

Laser processing method for infinite width and device

ActiveCN109332886ALaser processing meetsSimple structureLaser beam welding apparatusLaser processingGalvanometer

The invention discloses a laser processing method for an infinite width and a device. The process is as follows: fixing a workpiece to be processed on a servo platform, controlling the moves of the servo platform to collect and identify a positioning point on the workpiece, and determining initial coordinates of a starting point and an ending point of each line segment to be processed in a motioncoordinate system according to the positioning point; according to the initial coordinates, determining the length, the direction, and the initial processing point of each line segment to be processed, and determining the processing sequence of all line segments and the motion trajectory of the servo platform and a scanning galvanometer; and controlling a synergic movement of the servo platform and the scanning galvanometer according to the determined processing sequence and the motion trajectory to realize the processing of the workpiece to be processed. The laser processing method for the infinite width and the device have the advantages of the simple structure and the convenient use, and are suitable for continuous laser processing of large-width workpiece, so that the efficiency of thelaser processing is greatly improved. The synchronous coordinated movement of the servo platform and the scanning galvanometer achieves the advantages of precision, infinite width and high speed.

Owner:HUAZHONG UNIV OF SCI & TECH +1

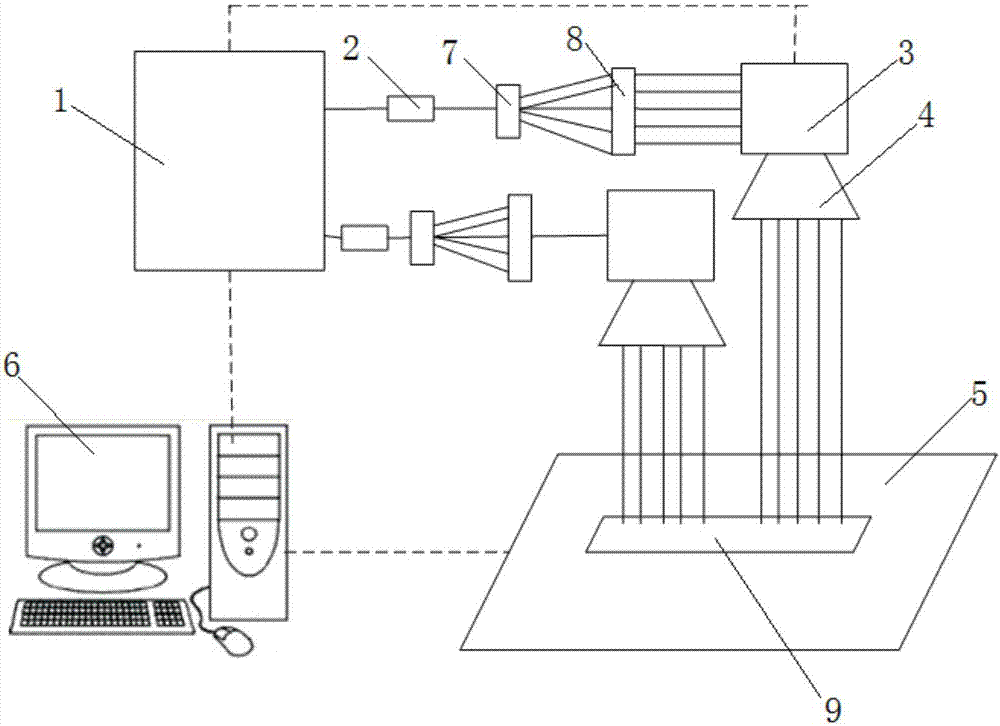

Laser processing device and method

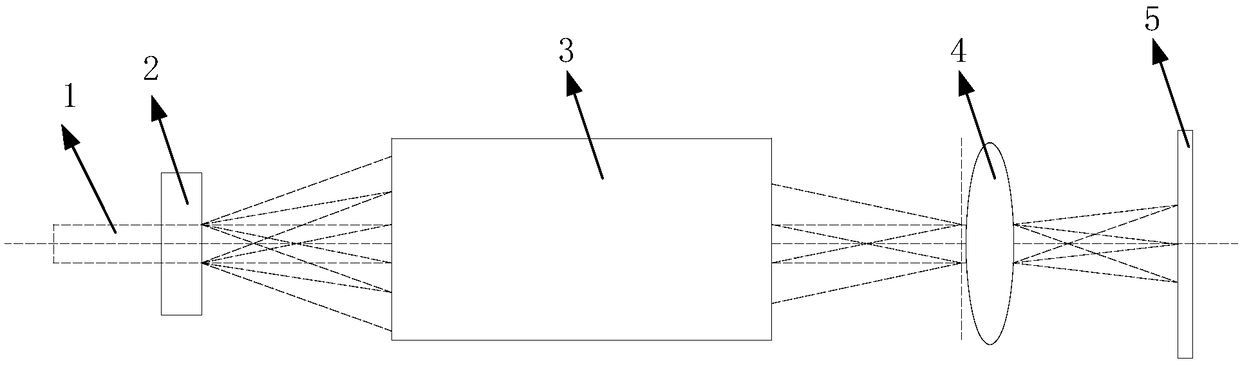

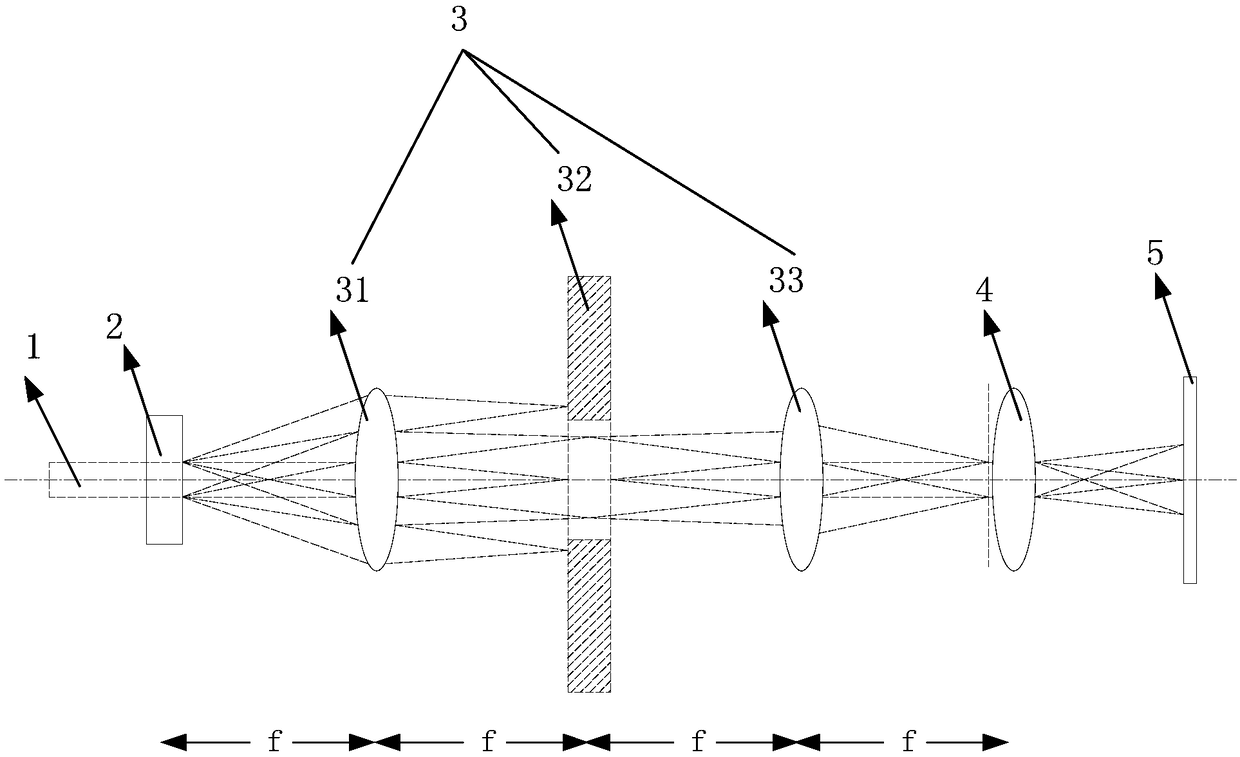

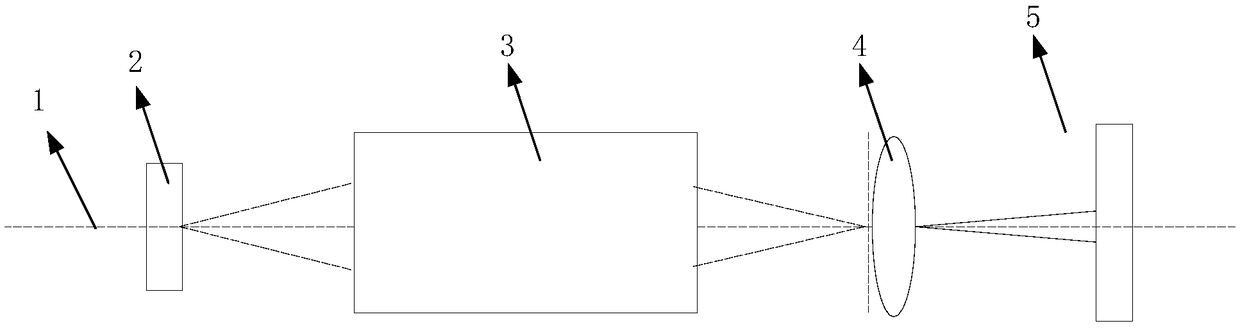

ActiveCN109434278AAchieve laser processingImprove laser processing efficiencyLaser beam welding apparatusLaser processingLaser cutting

The invention belongs to the technical field of laser processing, discloses a laser processing device, and further discloses a laser processing method. The laser processing device comprises a laser device, a laser dividing component, a laser adjusting assembly and a focus lens; the laser device is used for emitting a laser beam; the laser dividing component is used for dividing the laser beam emitted by the laser device into N sub laser beams which are at the diverging angle and are distributed at equal intervals in the direction perpendicular to the propagation direction of the laser beam, wherein N is equal to 2, 3, 4...; the laser adjusting assembly is used for converting the sub laser beams at the divergent angle into sub laser beams at the contracting angle to enable the sub laser beams at the contracting angle to enter the focus lens; and the focus lens is used for focusing the multiple incident sub laser beams and then emitting the focused sub laser beams to a to-be-processed workpiece at equal intervals to process the to-be-processed workpiece. According to the laser processing method and device provided by the invention, compared with existing monorail processing, multi-rail processing is achieved, the laser processing efficiency is improved greatly, taking wafer laser cutting as an example, a plurality of cutting ways can be cut at a time, and the processing efficiency is improved exponentially.

Owner:深圳市大族半导体装备科技有限公司

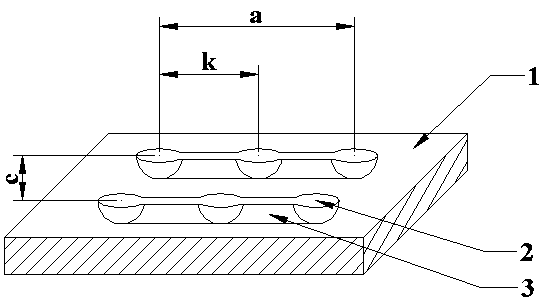

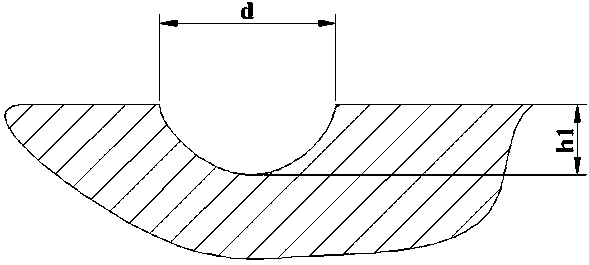

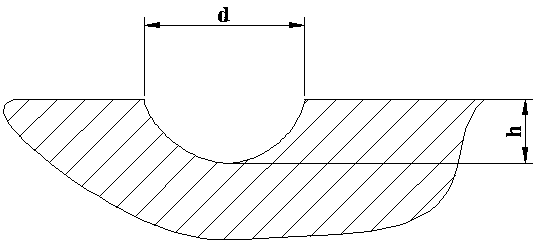

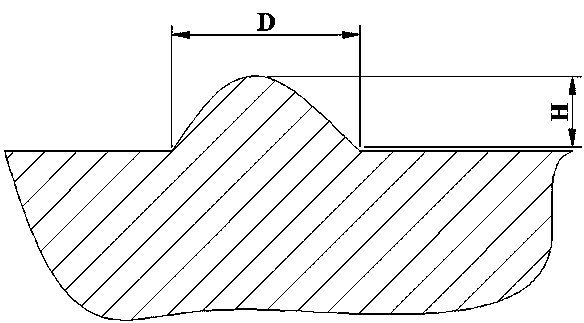

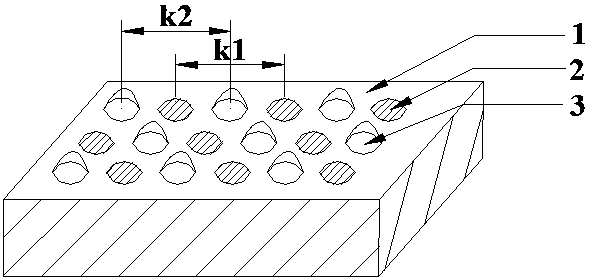

Combined microstructure guide rail and manufacturing method thereof

PendingCN108098364AAvoid crawlingImprove wear resistanceLarge fixed membersWear resistanceMachine tool

The invention discloses a combined microstructure guide rail and a manufacturing method thereof, and relates to the technical field of surface treatment of machine tool guide rails. The combined microstructure guide rail is characterized in that a combined microstructure is distributed on the surface of the guide rail; the combined microstructure is in pit morphology and micro groove morphology; and the micro groove morphology is characterized in that micro grooves connected with single pits in the length direction of the guide rail are processed in micro pit morphology arrays. According to the combined microstructure guide rail, the crawling phenomenon of the guide rail is solved, lubricating performance is improved, abrasion resistance is improved, the service life of the guide rail canbe effectively prolonged, and comprehensive performance is improved.

Owner:NANTONG UNIVERSITY +1

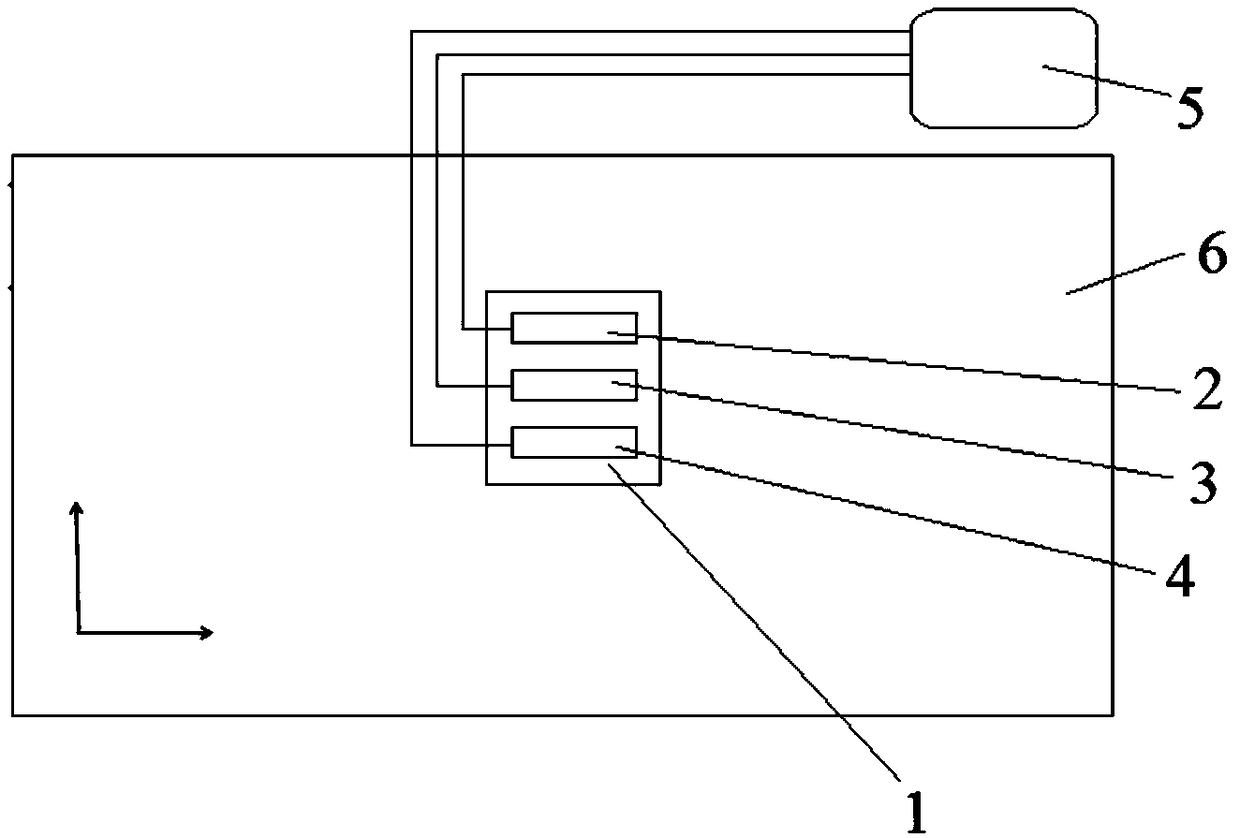

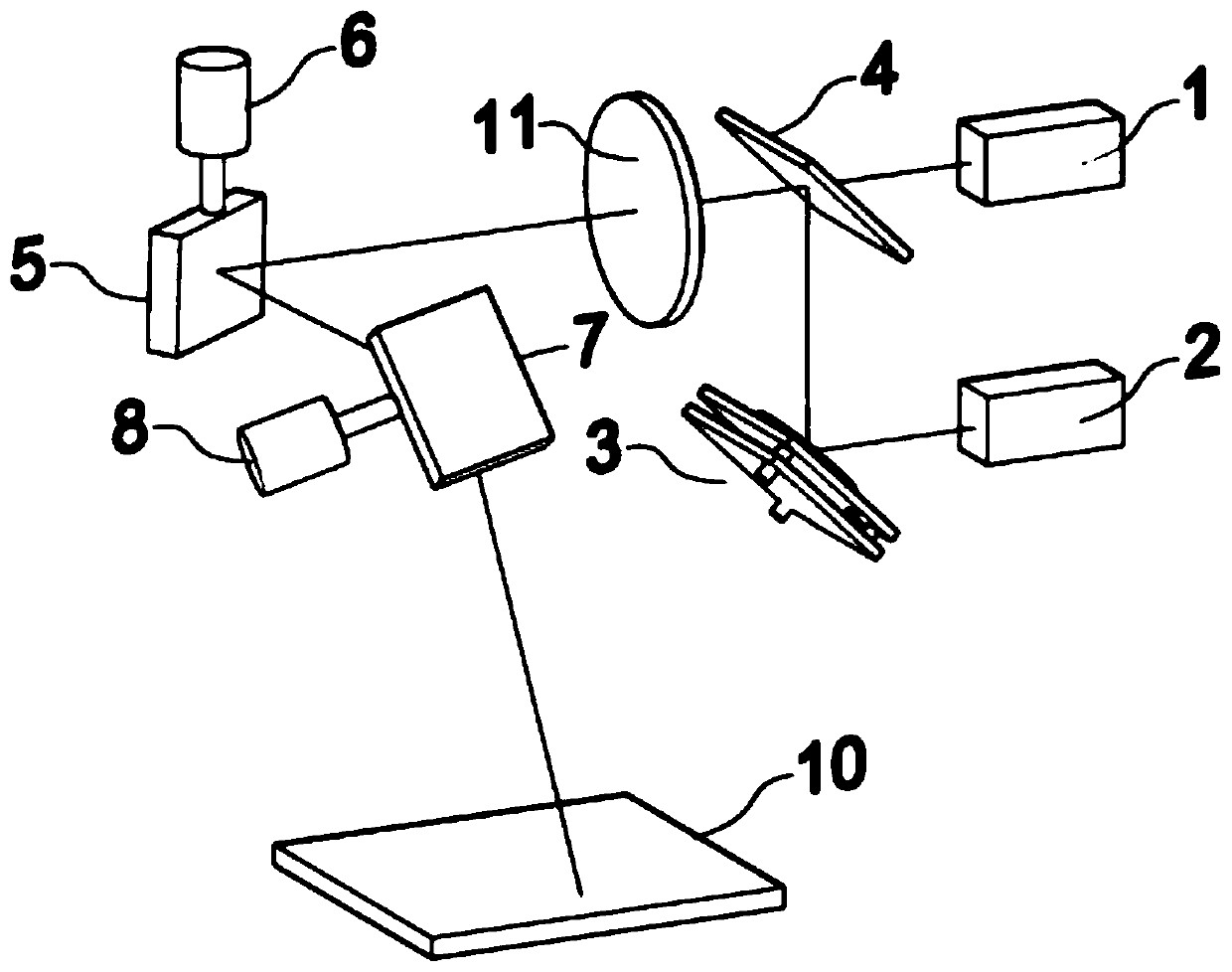

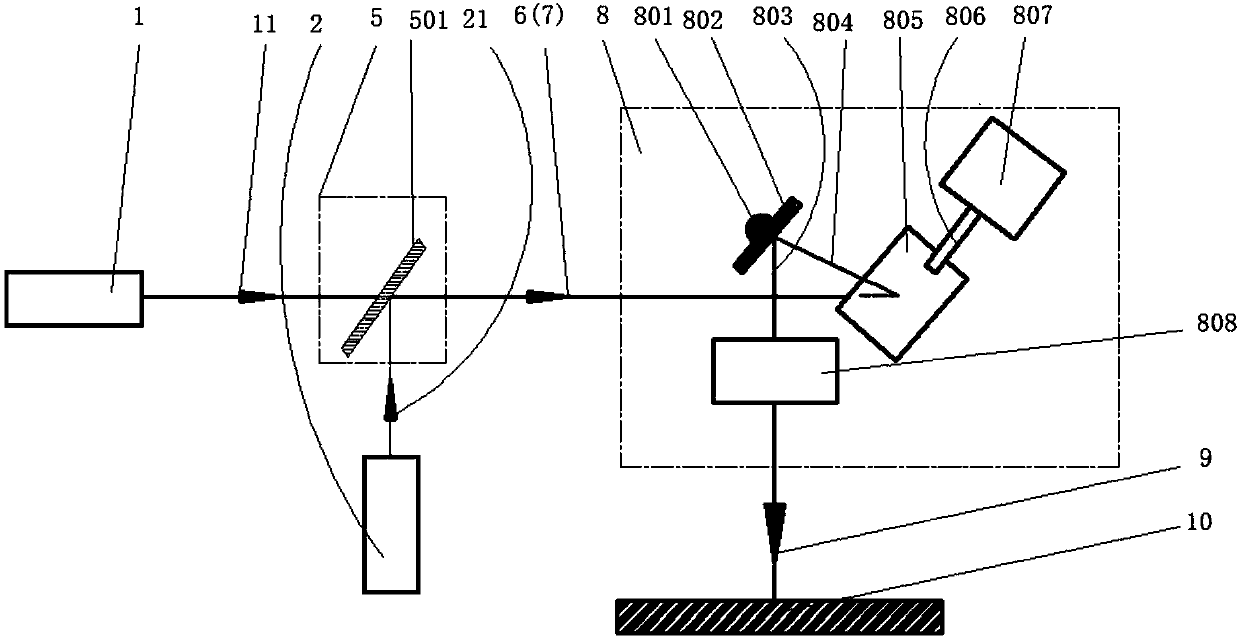

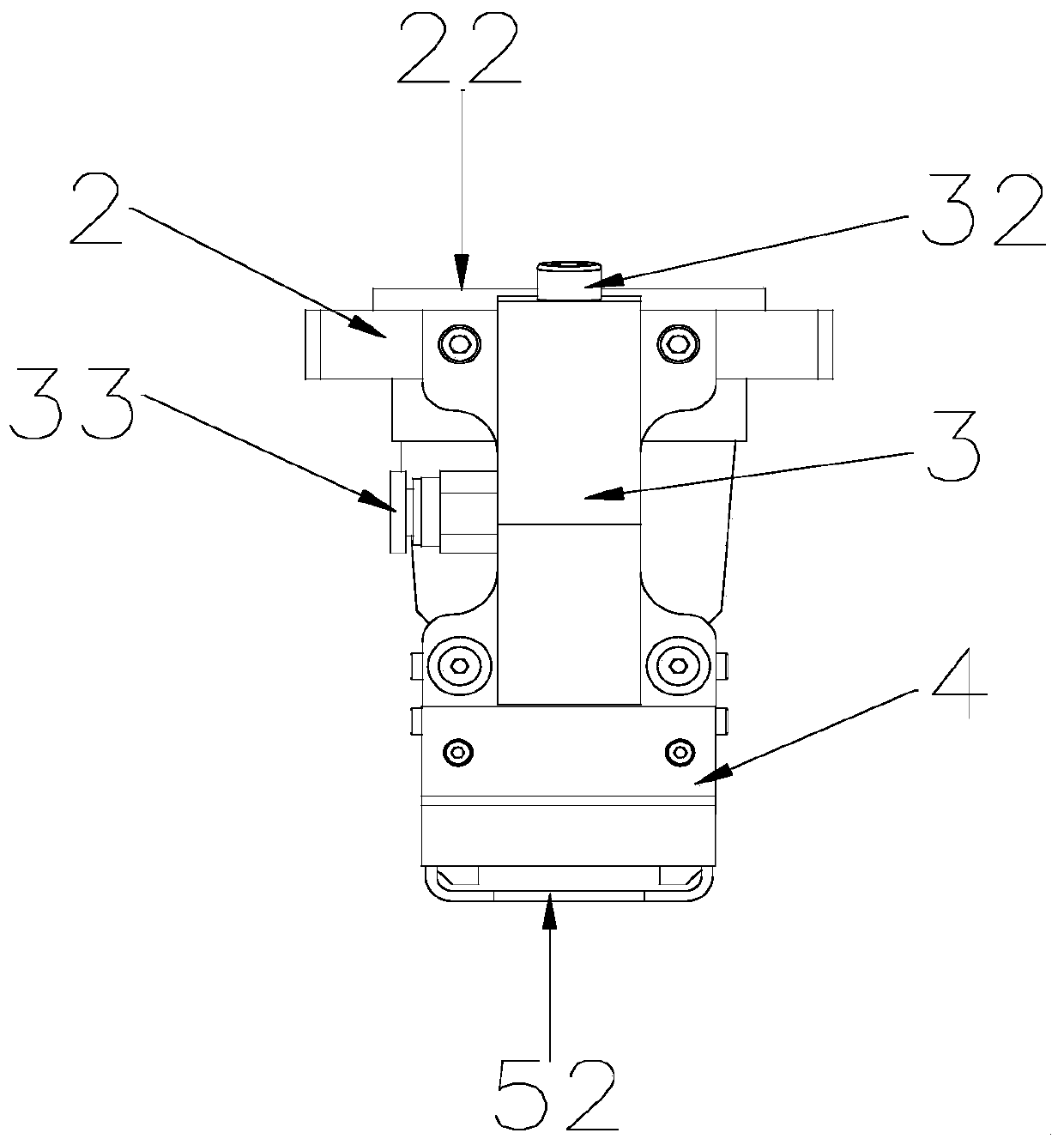

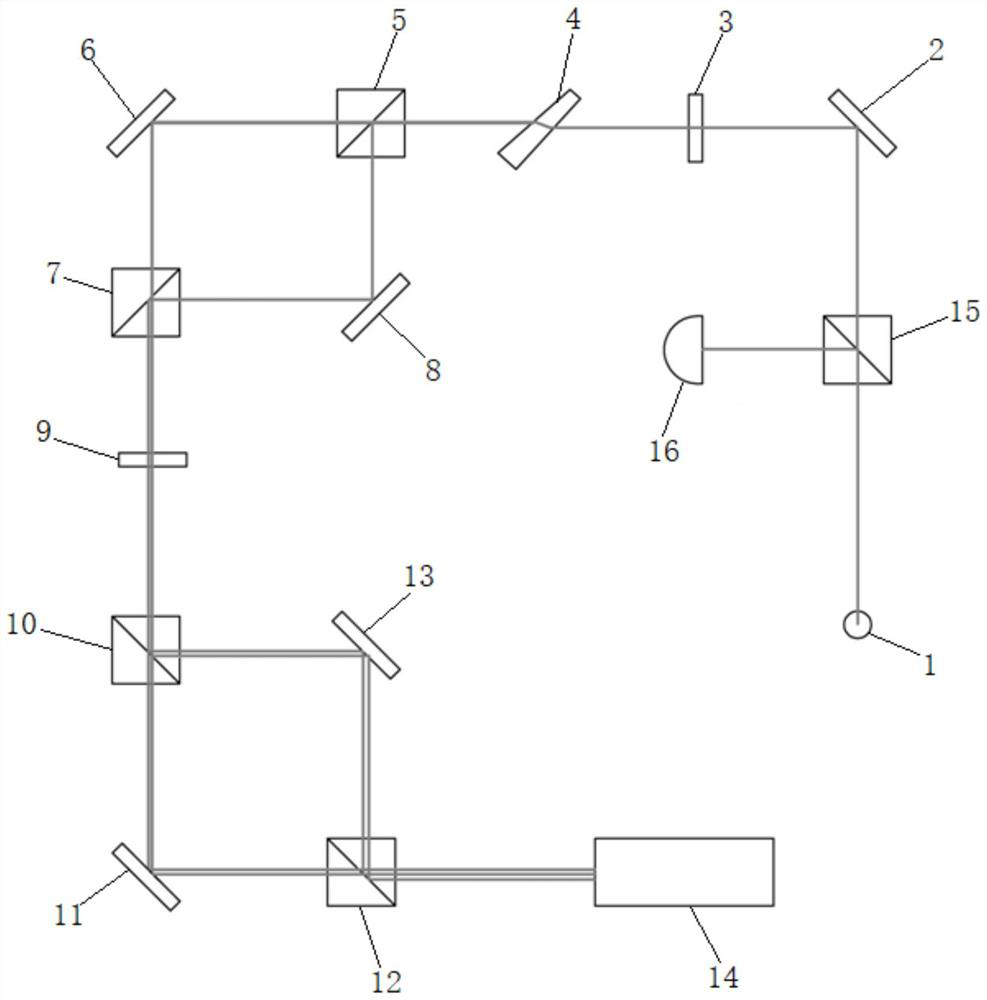

Double-beam laser processing optical system

PendingCN110076450AImprove laser processing efficiencyImprove processing efficiencyLaser beam welding apparatusLaser scanningLaser fiber

The invention belongs to the field of laser processing, and discloses a double-beam laser processing optical system. The double-beam laser processing optical system comprises a pulse fiber laser (1) used for emitting main laser, a continuous laser (2) used for emitting auxiliary laser, a reflector (3) capable of adjusting deflection direction, a beam combiner (4), a focusing assembly and a laser scanning assembly, wherein the auxiliary laser is combined with a main laser through the reflector (3) capable of adjusting the deflection direction to form a double beam laser, the double beam laser is transmitted to a to-be-processed workpiece for the laser processing, and a relative position of a focusing light spot of an auxiliary laser and a focusing light spot of a main laser is kept unchanged all the time on a workpiece laser processing path. According to the system, the composition of components in the system and interaction relation among the components are improved, the auxiliary laser which the relative position of the focusing light spot always keeps unchanged with the focusing light spot of the main laser on the workpiece laser processing path is introduced, the double beam isrealized, and the problems of high price and the like of the high-power optical fiber laser can be overcome.

Owner:HUAZHONG UNIV OF SCI & TECH

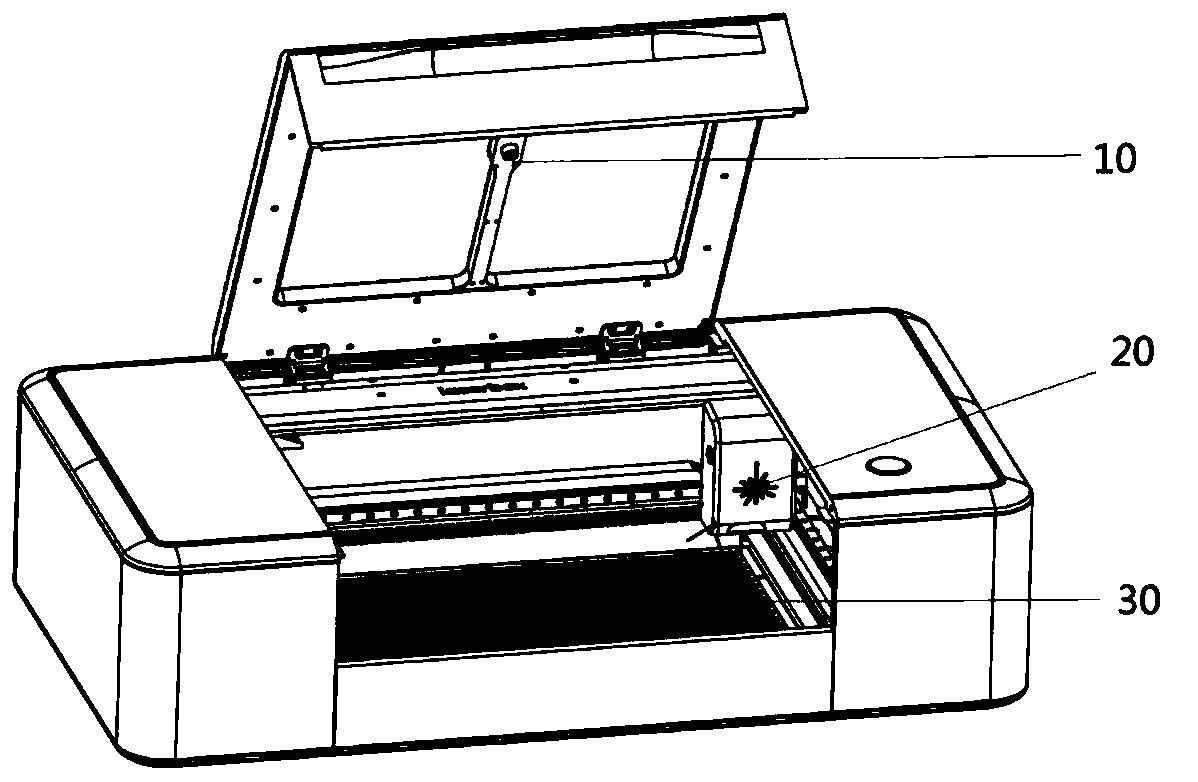

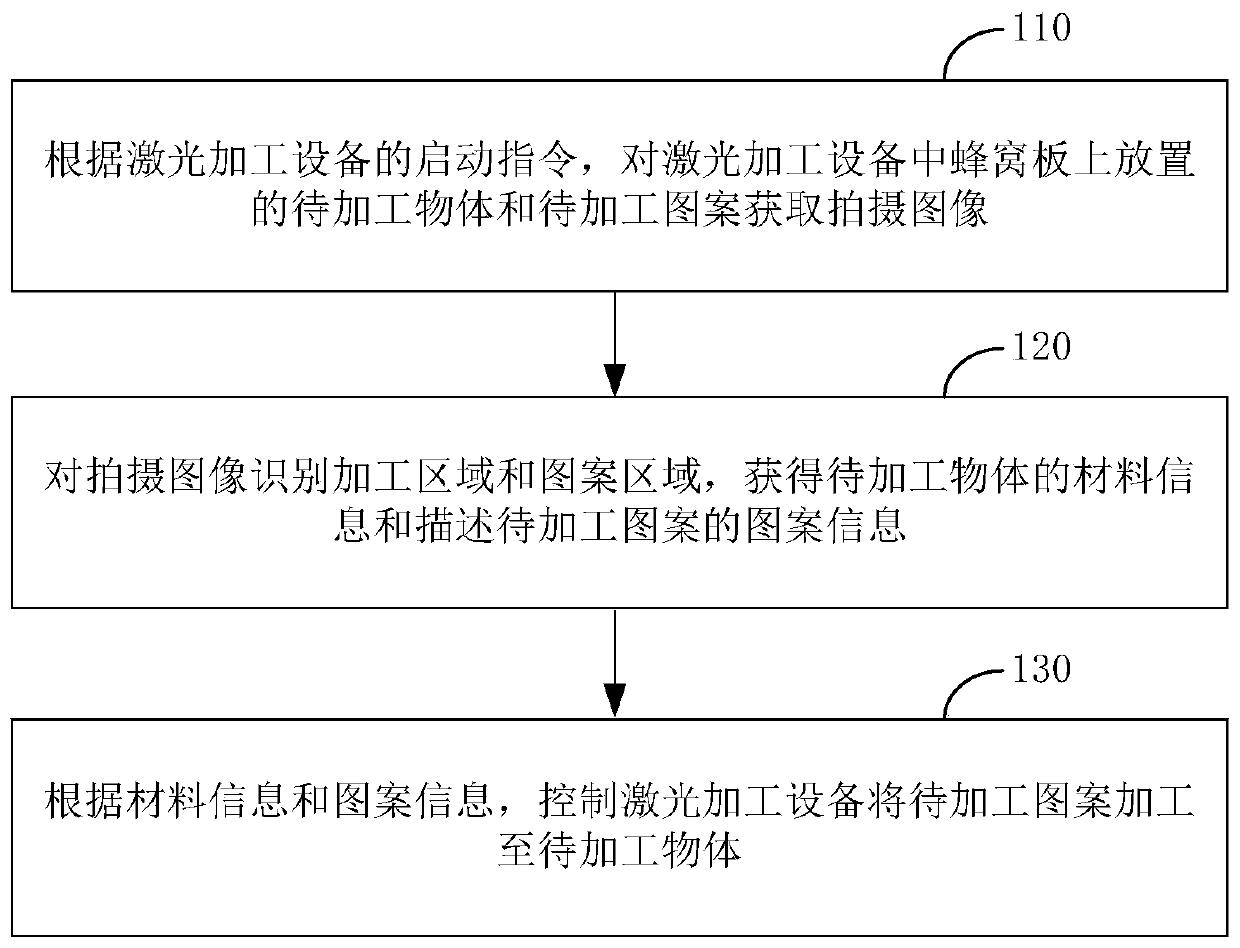

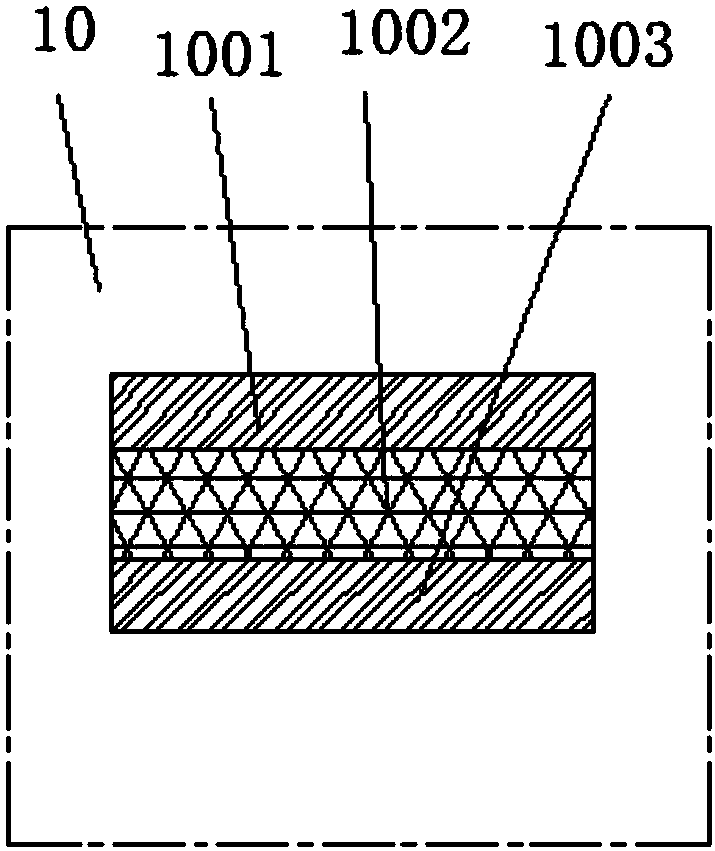

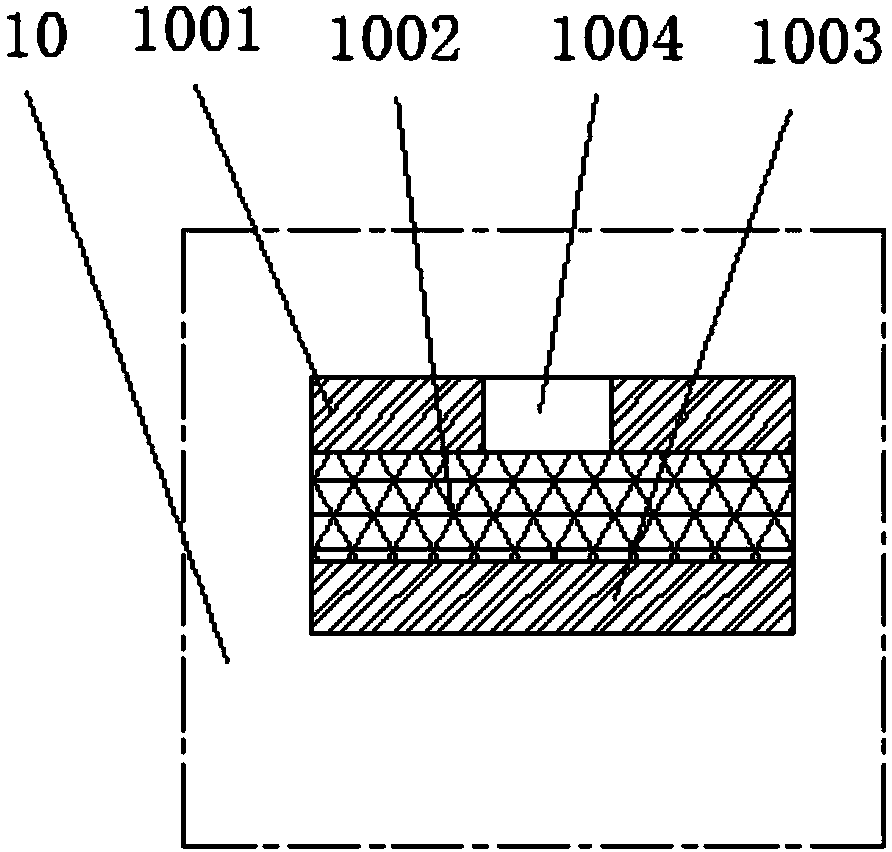

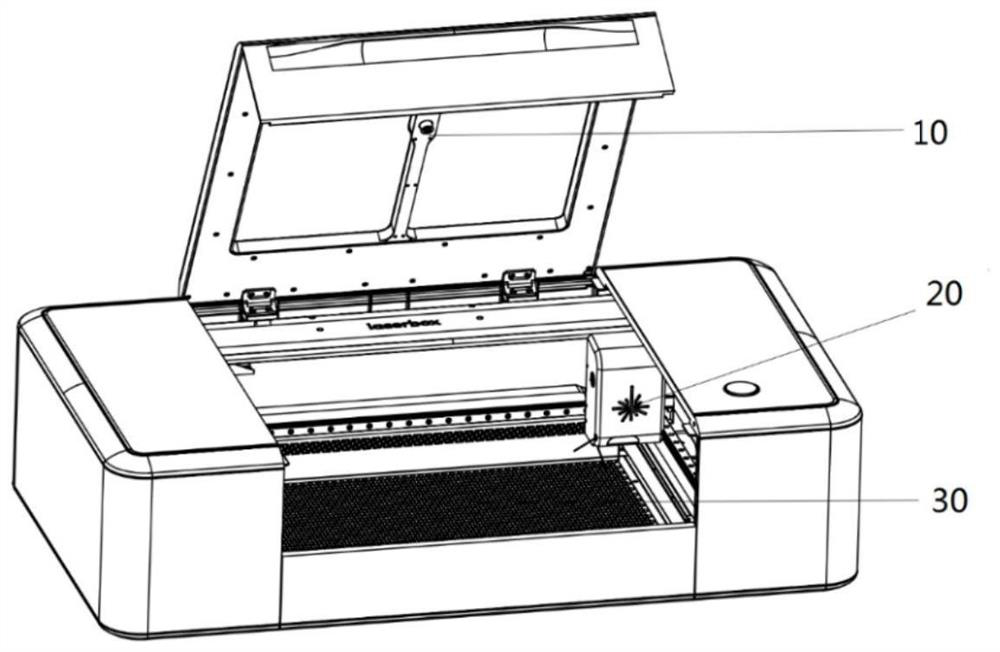

Laser machining method and device, laser machining equipment and storage medium

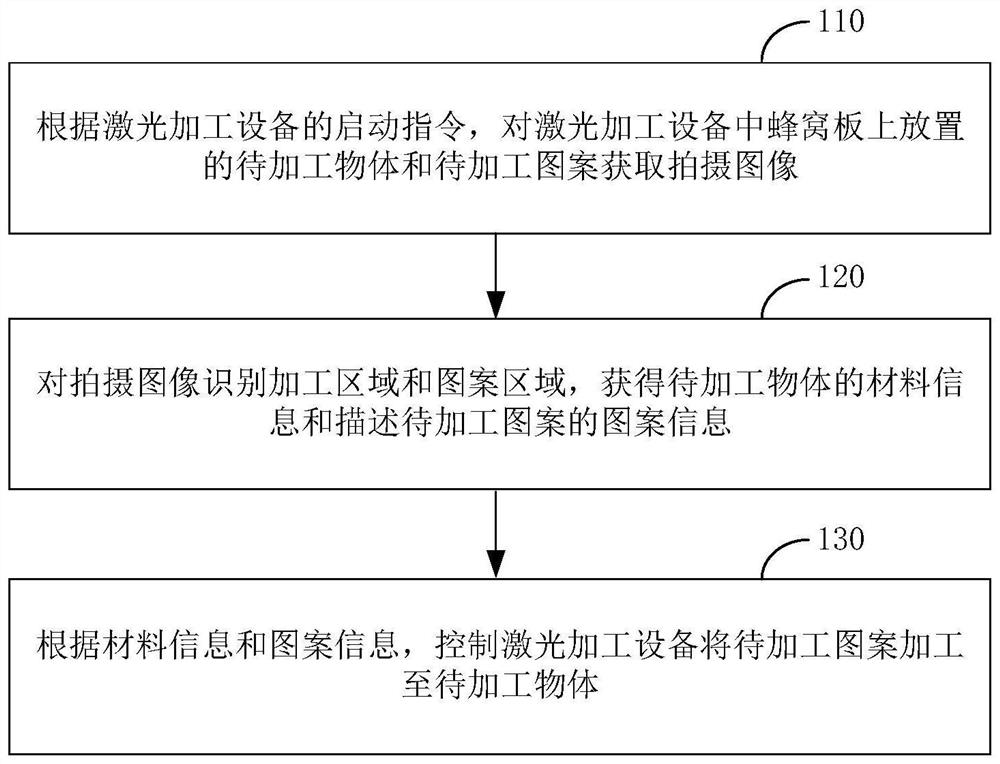

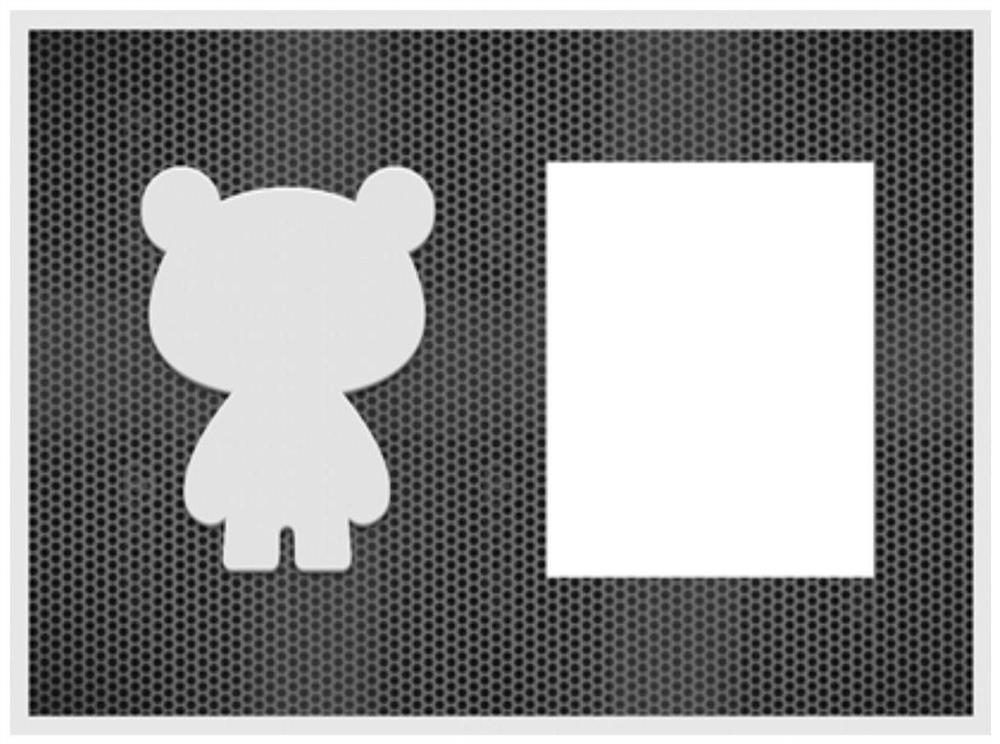

ActiveCN111515523AHigh degree of automationImprove laser processing efficiencyLaser beam welding apparatusManufacturing engineeringImage identification

The invention discloses a laser machining method and device. The method comprises the following steps of according to a starting instruction of laser machining equipment, acquiring shot images of a to-be-machined object and a to-be-machined pattern placed on a honeycomb plate in the laser machining equipment; identifying a machining region and a pattern region of the shot images to obtain materialinformation of the to-be-machined object and pattern information describing the to-be-machined pattern, wherein the machining region is an image region corresponding to the to-be-machined object in the shot image; and controlling the laser machining equipment to machine the to-be-machined pattern to the to-be-machined object according to the material information and the pattern information. By adopting the method, the automation degree of laser machining of the laser machining equipment is greatly improved.

Owner:SHENZHEN MAKER WORKS TECH CO LTD

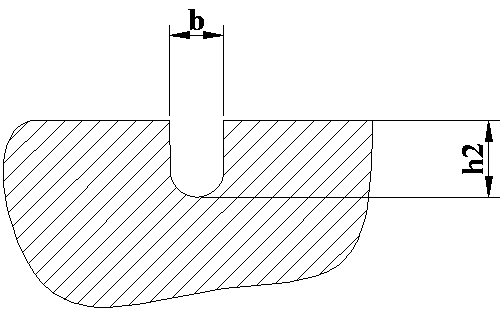

Multi-morphology combined micro-texture guide rail and manufacturing method thereof

PendingCN108098133AImprove the lubrication effectInhibit crawling phenomenonLarge fixed membersLaser beam welding apparatusMicro textureMachine tool

The invention discloses a multi-morphology combined micro-texture guide rail and a manufacturing method thereof, and relates to the technical field of machine tool guide rail surface treatment. The concave-convex alternated micro-textures are distributed on the surface of the guide rail; and the concave-convex alternated micro-textures are formed by a single-row micro-concave morphology and a single-row micro-convex morphology, the single-row micro-concave morphology and the single-row micro-convex morphology are arranged equal distance at intervals with each other; and a micro-groove which isconnected with a single micro-concave morphology in the length direction of the guide rail is machined in a micro-concave morphology array. According to the invention, the problem that a single texture composite morphology is difficult to be machined, oil is stored in the micro-concave, oil supply function in concave-convex composite morphology is difficult to play, and lubricating oil cannot flow are solved, so that the abrasion is better reduced, and crawling phenomenon of the machine tool or the guide rail are restrained.

Owner:NANTONG UNIVERSITY +1

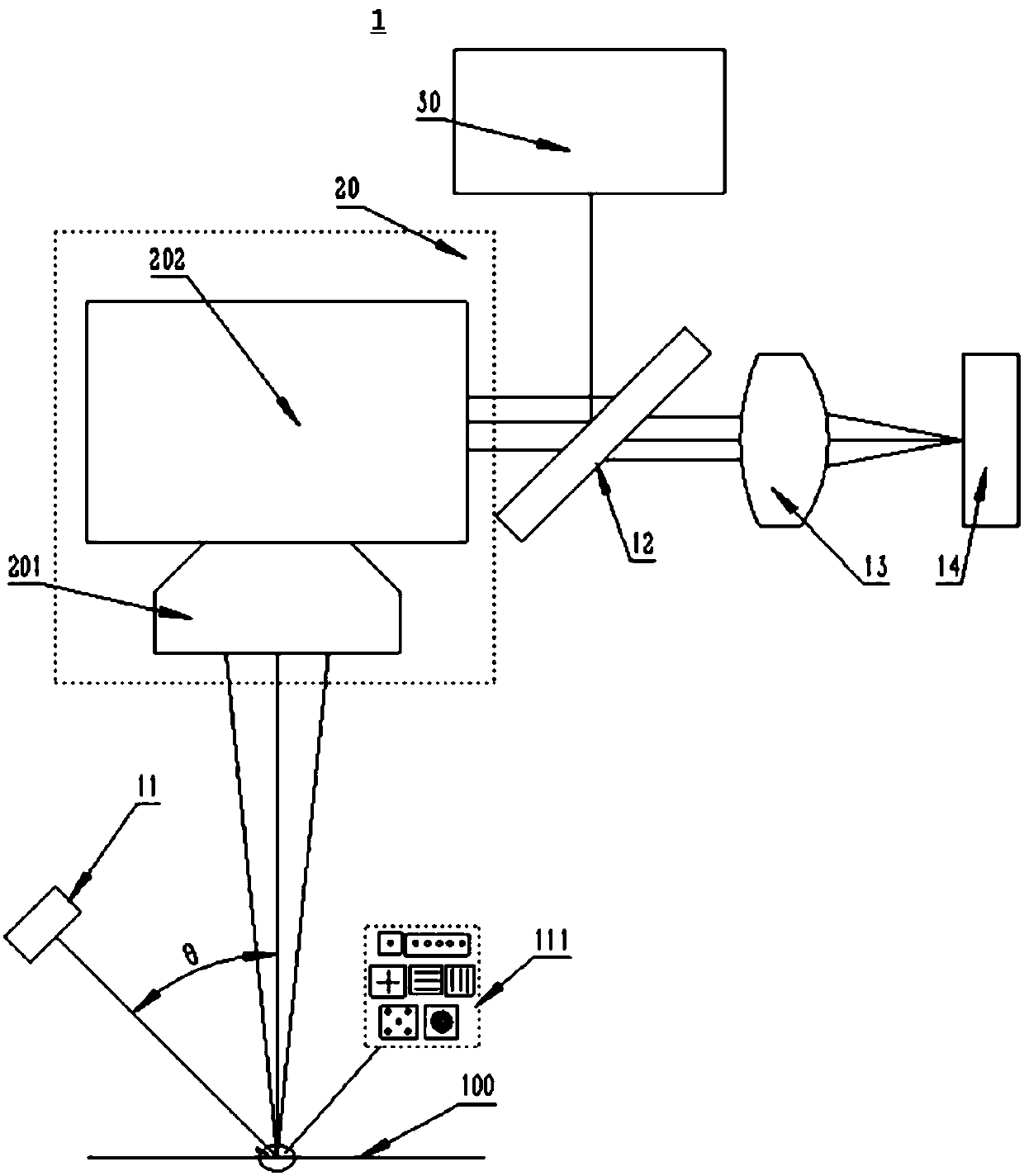

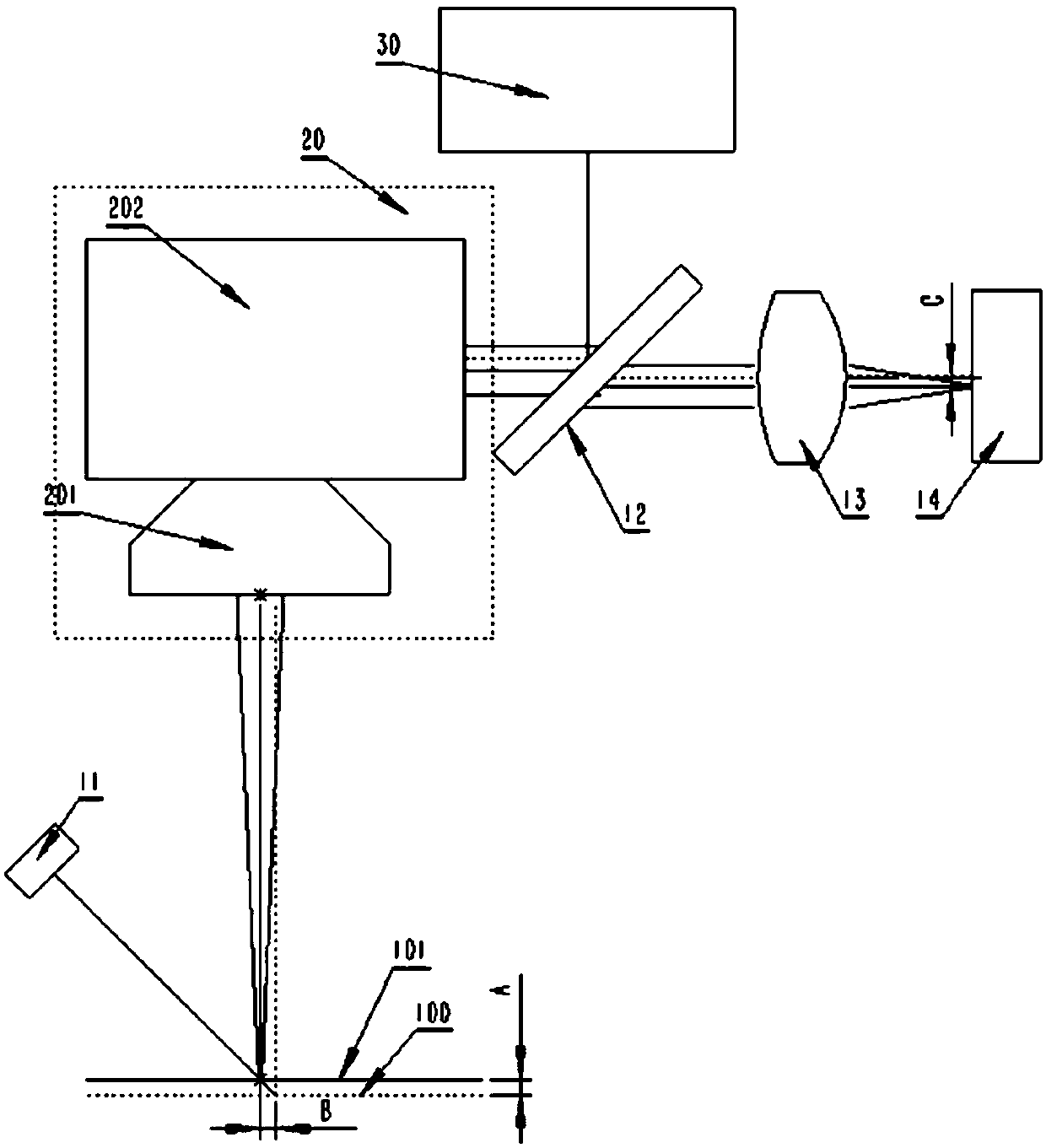

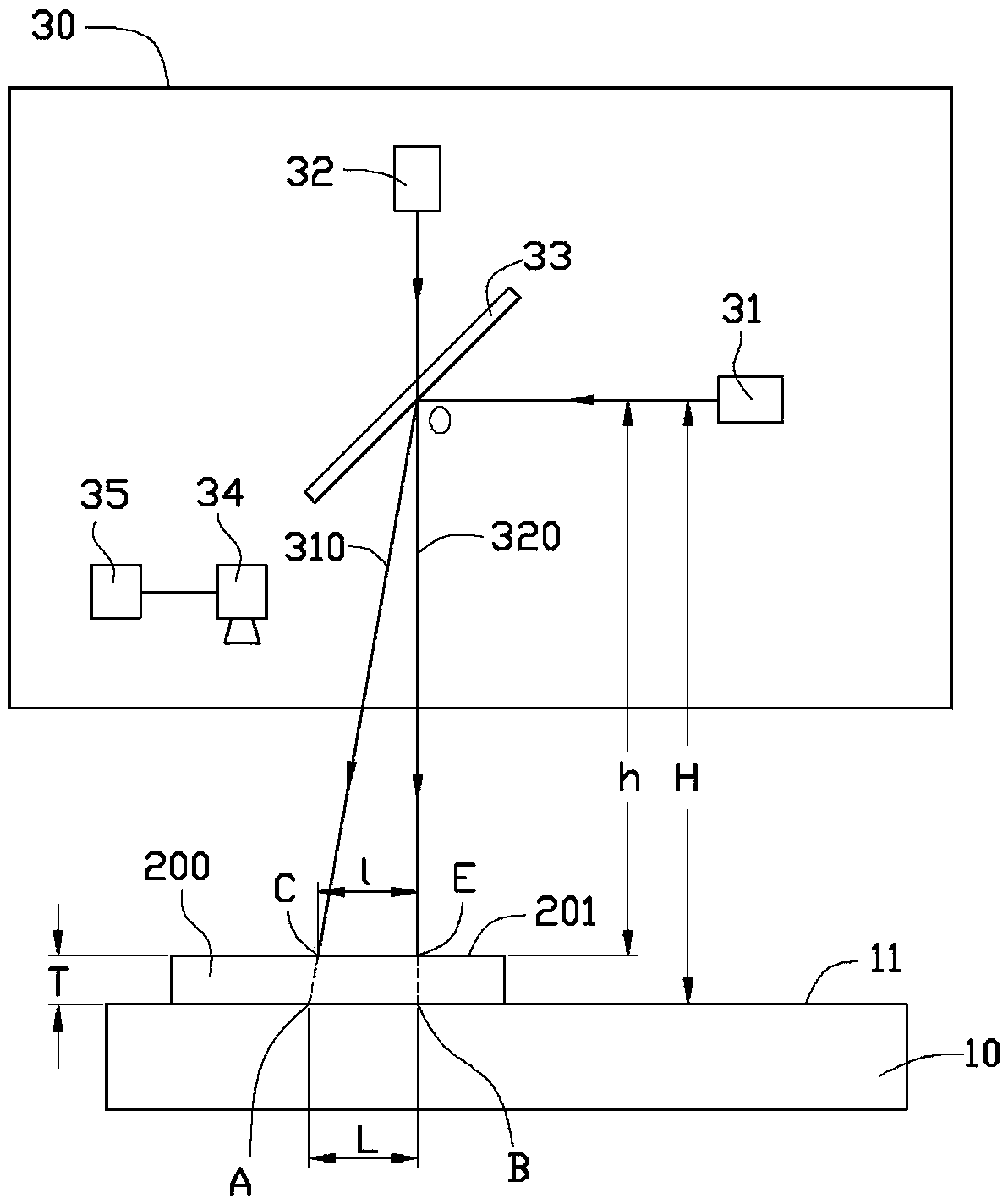

Laser processing system

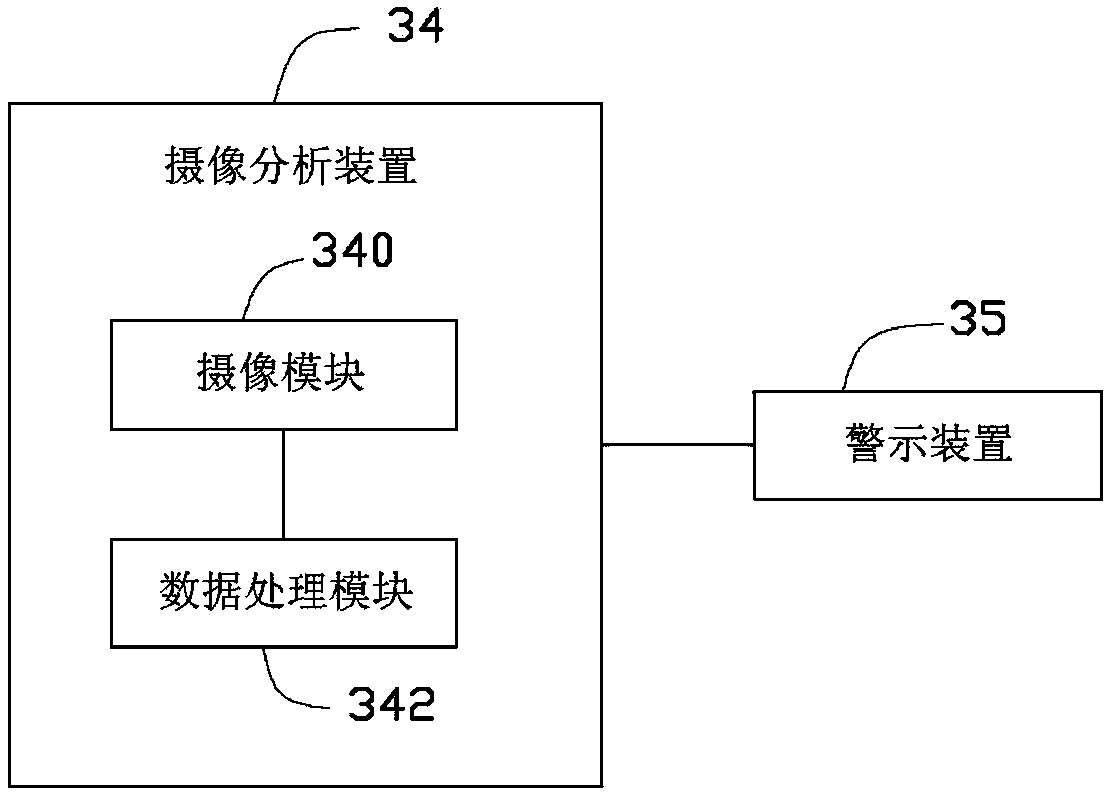

InactiveCN104227231AAvoid damageImprove laser processing efficiencyLaser beam welding apparatusLaser processingLight beam

The invention relates to a laser processing system which comprises a laser device used for laser processing, a height detection device and a platform deck. The height detection device is used for detecting the height of a workpiece to be processed and comprises a first laser light source arranged in the horizontal direction, a second laser light source arranged in the vertical direction, a light splitting element and a camera analyzing device, wherein a light beam emitted by the first laser light source is reflected by the light splitting element to reach the platform deck, and a light beam emitted by the second laser light source can penetrate through the light splitting element and directly reach the platform deck. The camera analyzing device comprise a camera module and a data processing module, wherein the camera module is used for shooting images of the first laser beam and the second laser beam on the platform deck and the surface of the workpiece to be processed, and the data analyzing module is used for analyzing the images to obtain the height of the workpiece.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

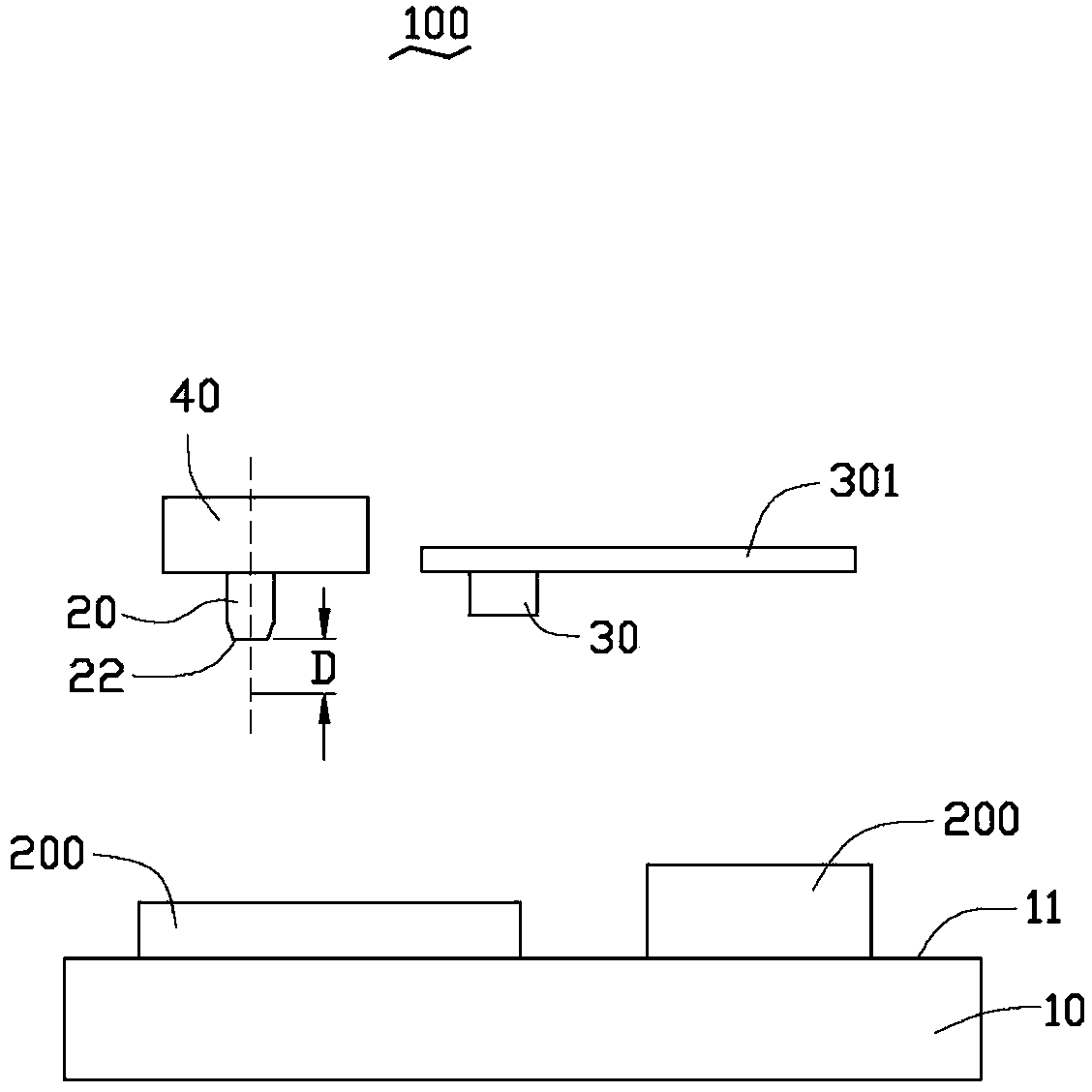

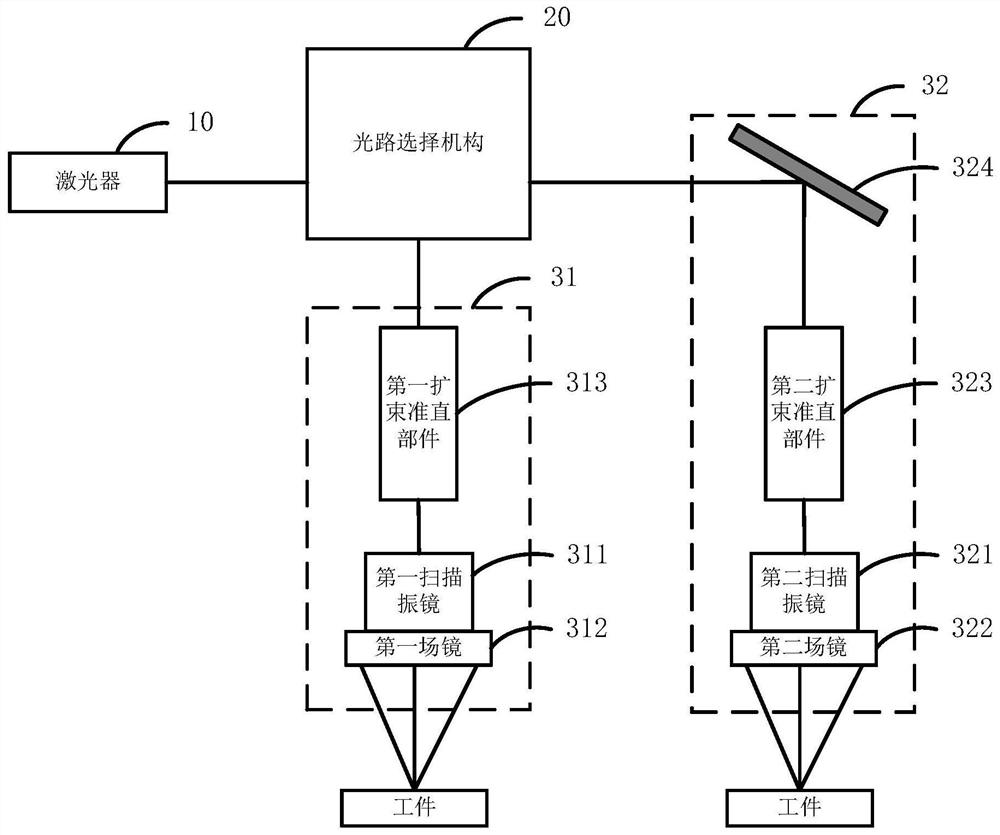

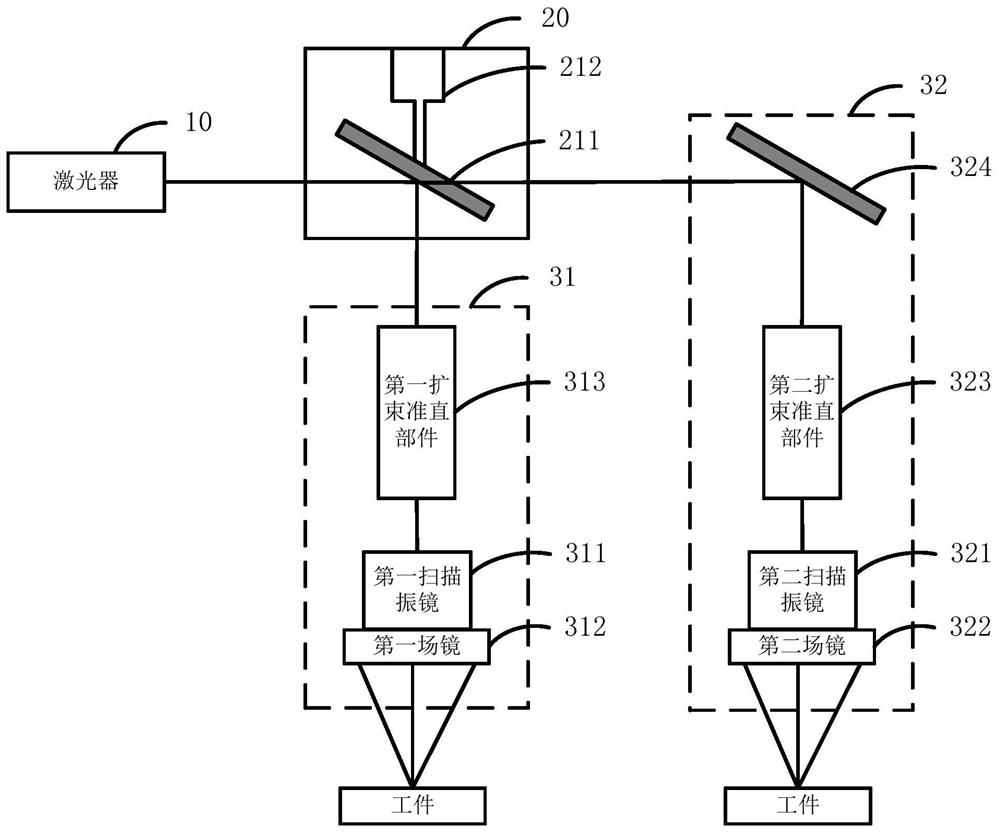

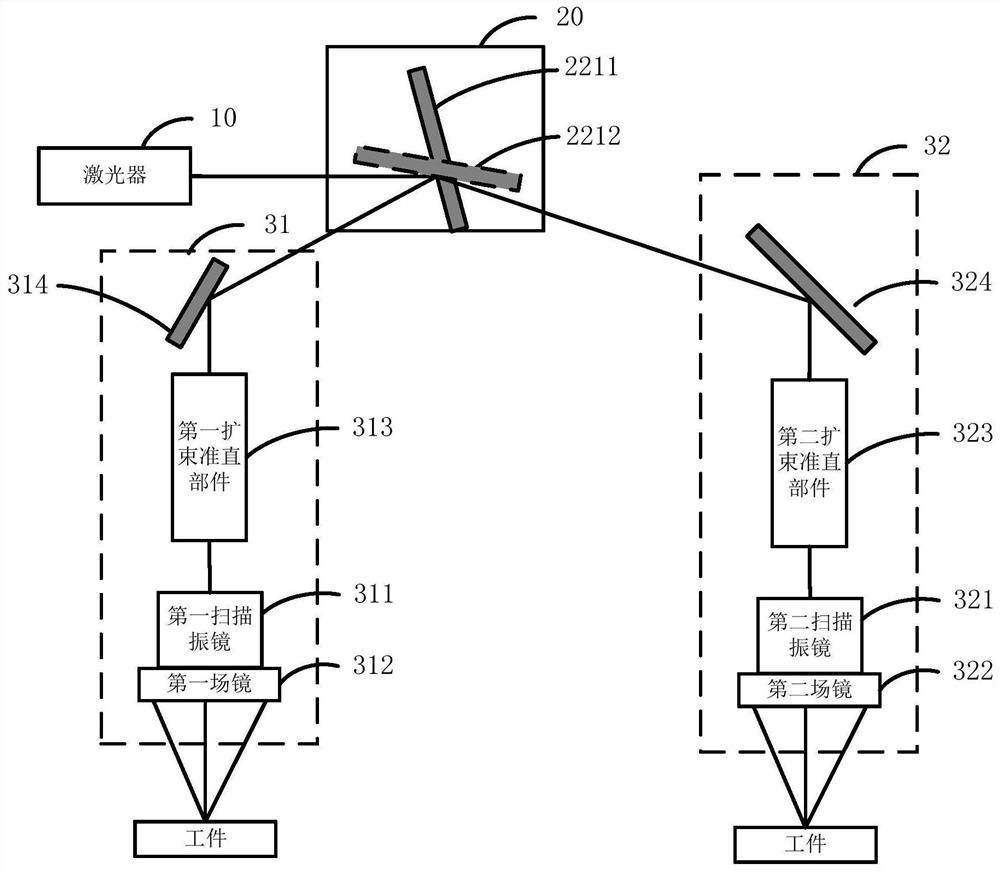

Laser machining device, machining equipment, machining system and machining method

InactiveCN111922511AIncrease profitImprove laser processing efficiencyLaser beam welding apparatusLaser processingEngineering

The embodiment of the invention discloses a laser machining device, machining equipment, a machining system and a machining method. A light path selection mechanism of the device is arranged between alaser device and a first machining mechanism and a second machining mechanism. The laser device is used for transmitting initial laser. A controller is used for being connected with the light path selection mechanism, the first machining mechanism and the second machining mechanism in a communicating manner, so that a first signal is obtained, the light path selection mechanism is controlled according to the first signal to send the initial laser to the first machining mechanism, and the first machining mechanism is controlled according to the first signal to carry out laser machining; the controller is further used for obtaining a second signal, the light path selection mechanism is controlled according to the second signal to send the initial laser to the second machining mechanism, andthe second machining mechanism is controlled according to the second signal to carry out laser machining. According to the laser machining device, the initial laser transmitted by the laser device isused for the first machining mechanism and the second machining mechanism to carry out laser machining, the utilization rate of laser energy is increased, and efficiency of laser machining is improved.

Owner:HANS LASER TECH IND GRP CO LTD

Laser electrolysis jet flow combined working time-shared control system and control method

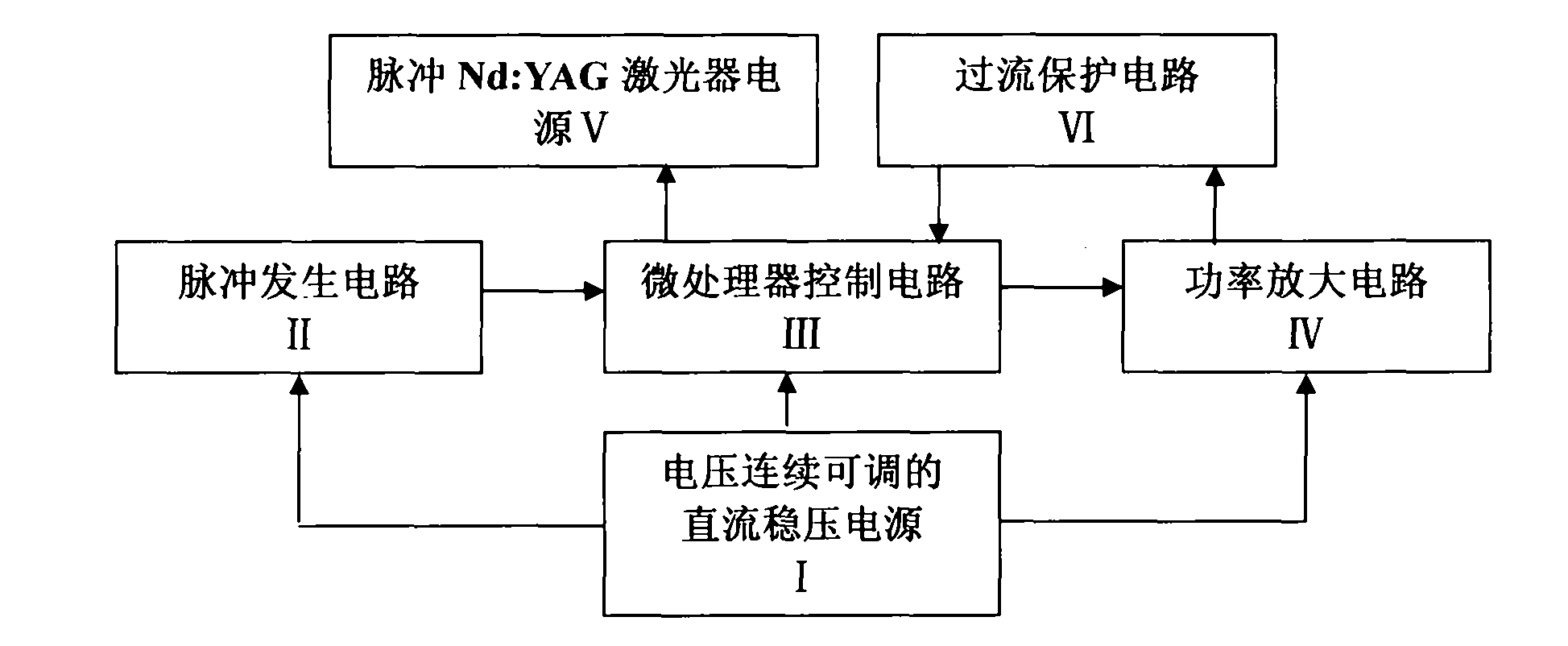

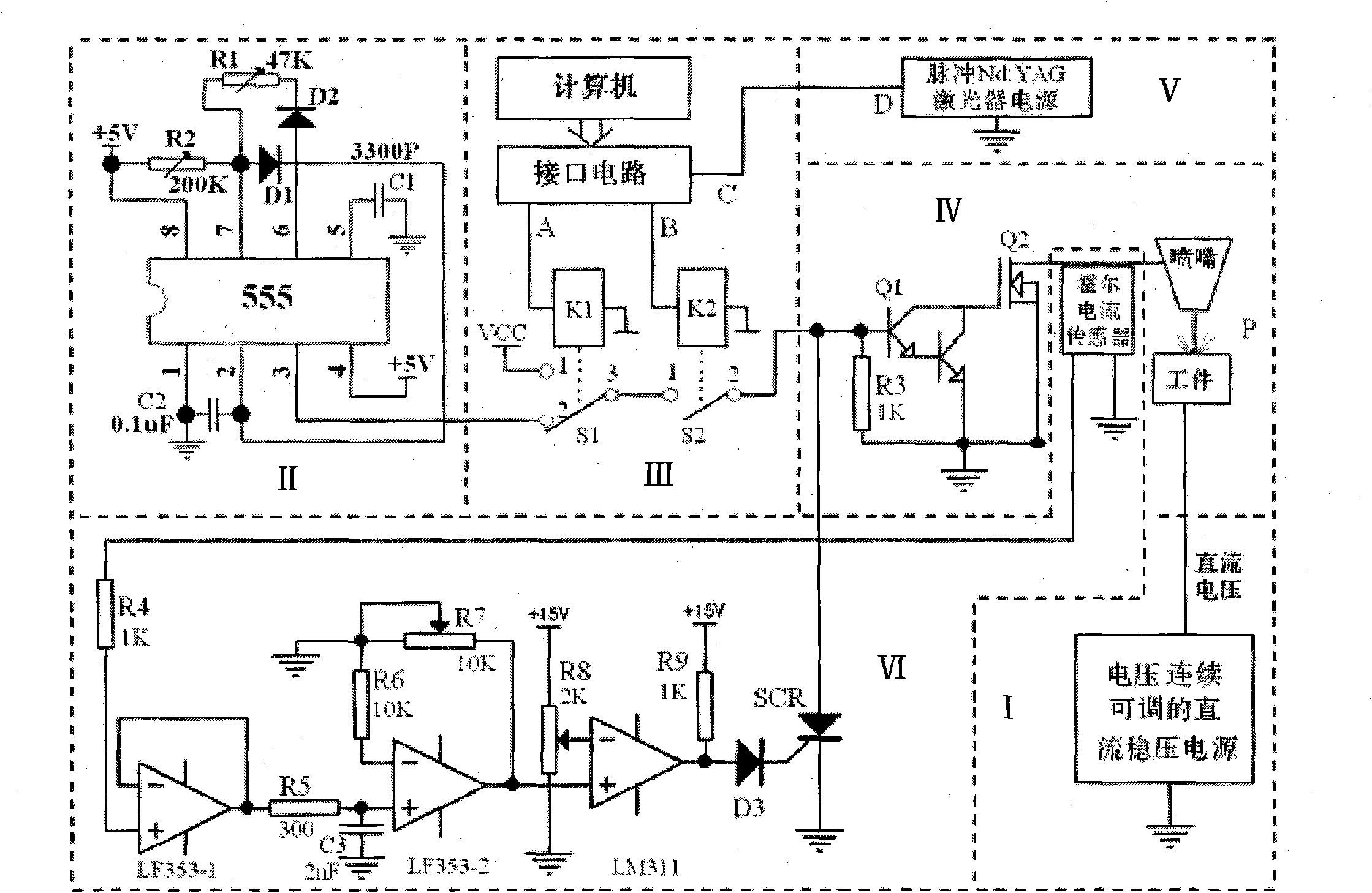

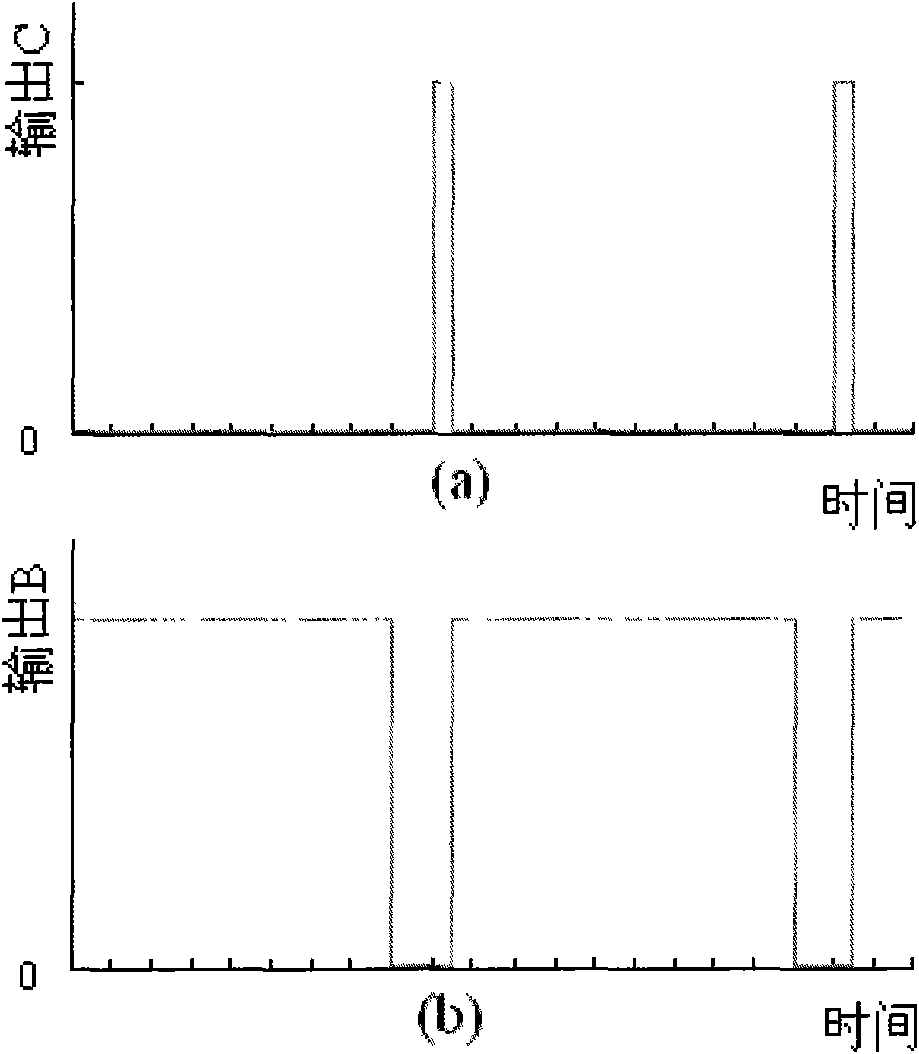

InactiveCN101829819AImprove efficiencyHigh comprehensive processing efficiencyTime-sharingHigh frequency

The invention discloses a laser electrolysis jet flow combined working time-shared control system and a control method. The system of the invention comprises a direct current stabilized power supply with continuously adjustable voltage, a pulse-generating circuit, a microprocessor control circuit, a power amplifier circuit, a pulse Nd:YAG laser power supply circuit and an overcurrent protecting circuit. In the method of the invention, the frequency and the adjusts the duty factor of a pulse power supply for electrolysis-jet processing through the adjustable potentiometer of the pulse-generating circuit, a computer controls a power supply device to output direct current or high-frequency pulse current through the output end of the microprocessor control circuit, and the time-sharing function of the electrolysis-jet processing and laser processing of high-frequency pulse can be realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Concave-convex alternate microstructure guide rail and manufacturing method thereof

PendingCN108274246ASolve the problem of no flowInhibit crawling phenomenonLarge fixed membersMachine toolMicrostructure

The invention discloses a concave-convex alternate microstructure guide rail and a manufacturing method thereof and relates to the technical field of machine tool guide rail surface treatment. Concave-convex alternate microstructures are distributed on a guide rail surface. The concave-convex alternate microstructures are structures that single-row micro concave pit morphology and single-row microconvex morphology are equidistantly and alternately arranged. According to the guide rail and the manufacturing method, the problems that machining of single texture composite morphology is difficult, the functions of micro concave pit oil storage and oil supply are difficult to play in concave-convex composite morphology, and lubricating oil cannot flow are solved, thus, abrasion is reduced better, and the phenomenon of machine tool or guide track creeping is restrained.

Owner:NANTONG UNIVERSITY +1

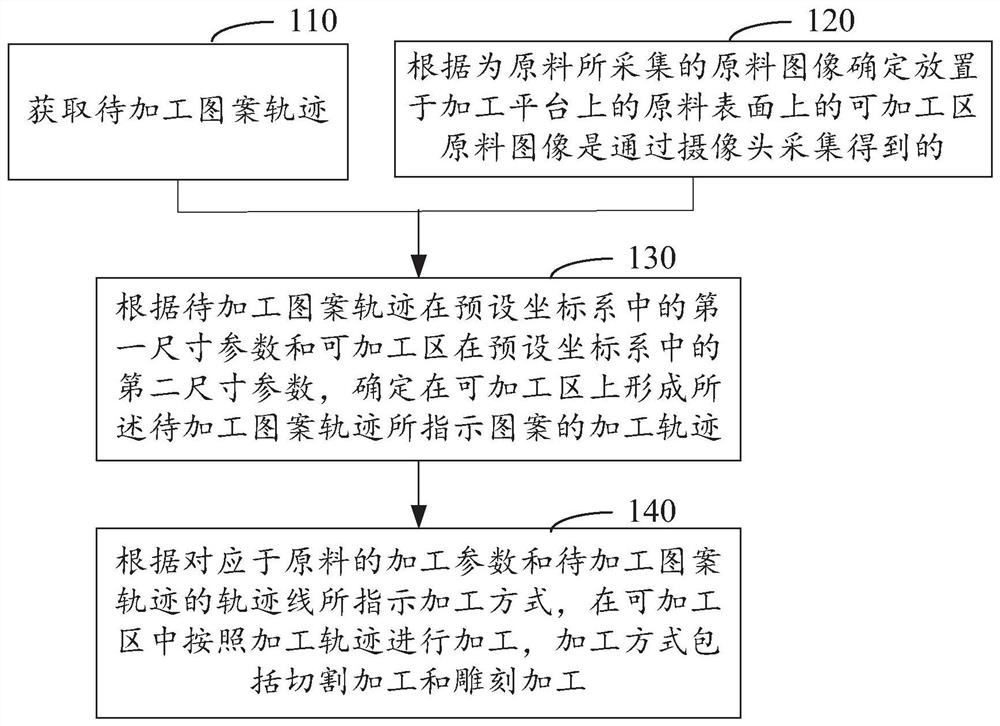

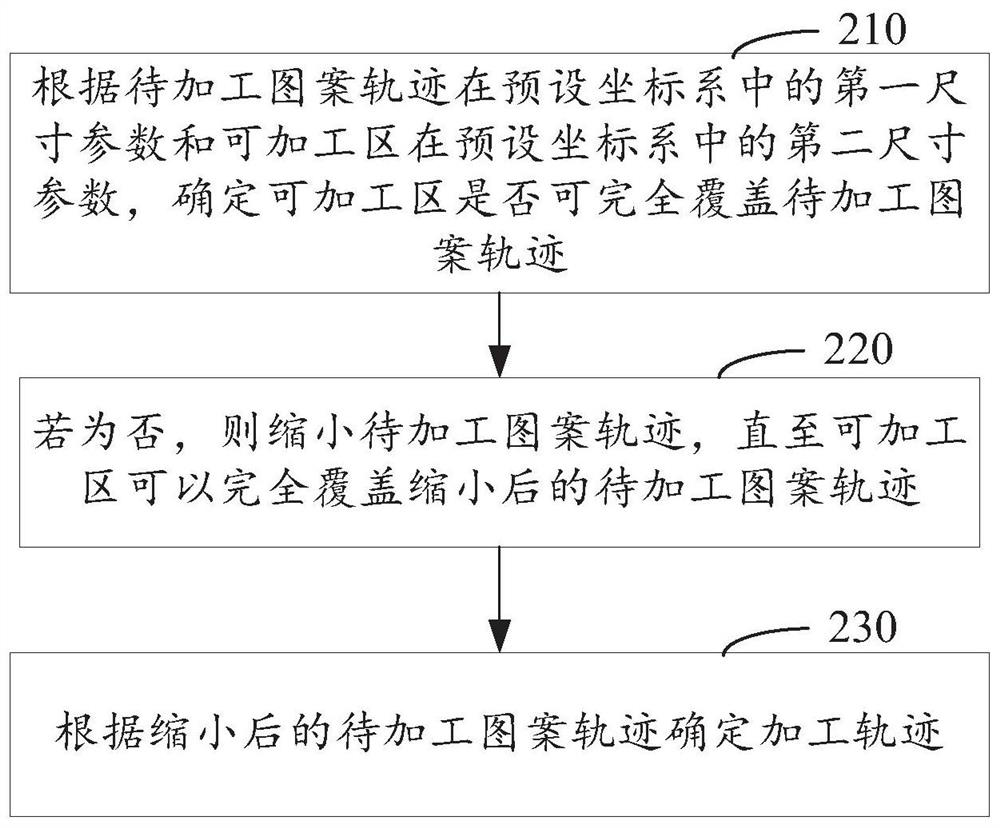

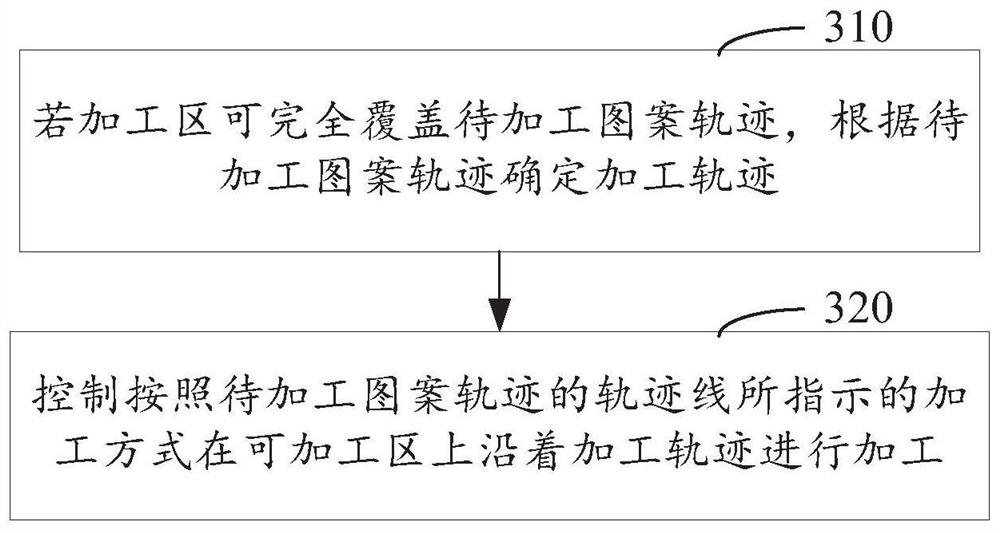

Laser processing control method and device and laser processing equipment

ActiveCN113290313AAvoid situations that are not fully formed on the feedstockProcessing automationLaser beam welding apparatusLaser processingMachining

The embodiment of the invention provides a laser processing control method. The method comprises the steps that a to-be-processed pattern track is obtained; a machinable area on the surface of a raw material placed on a processing platform is determined according to a raw material image acquired for the raw material, wherein the raw material image is acquired by a camera; according to a first size parameter of the to-be-processed pattern track in a preset coordinate system and a second size parameter of the machinable area in the preset coordinate system, a processing track of a pattern indicated by the to-be-processed pattern track on the machinable area is determined; and according to machining modes indicated by the machining parameters corresponding to the raw material and a track line of the to-be-machined pattern track, machining is conducted in the machinable area according to the machining track, wherein the machining modes comprise cutting machining and carving machining. Automatic laser processing is realized, and the processing efficiency is improved.

Owner:SHENZHEN MAKER WORKS TECH CO LTD

A system and method for layered milling of multi-layer materials based on spatially combined laser focus

ActiveCN106624391BImprove laser processing efficiencyImprove efficiencyPrinted circuitsMetal working apparatusLaser processingWindow opening

The invention discloses a multilayer material layered milling and drilling system and drilling method based on spatially combined laser focus. The milling and drilling system includes a window milling laser, a selective milling laser, a laser beam combiner, and laser focusing and focus switching The module realizes the laser focus and focus switching module under the same drilling optical focusing system, which sets the space combined laser focus. When processing multi-layer thin sheets of different materials, the laser focus with different characteristics can be used for processing Different layers of materials, which can greatly improve laser processing efficiency and laser processing quality, especially when processing blind hole drilling of multi-layer sheets of different materials, and when milling materials with a low laser damage threshold in the last layer of blind holes , the material is removed by selecting the focus of the milling laser, without worrying about damaging the next layer of laser damage threshold material, which brings a good process stability range, saves processing time, improves processing efficiency, and obtains good processing results.

Owner:张立国

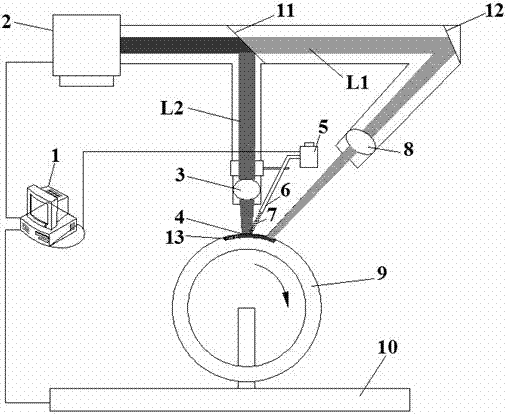

Same-wavelength double-beam narrow-spot laser quick cladding method

InactiveCN102409338BEasy loading and unloadingEasy to operateMetallic material coating processesNumerical controlHeat-affected zone

The invention discloses a same-wavelength double-beam narrow-spot laser quick cladding method, which is characterized by comprising the following steps of: (1) performing rust removing, oil removing, cleaning and sand blasting treatment on the surface of a substrate; (2) splitting a laser beam of the same wavelength into two beams of laser by using a laser beam splitter mirror; (3) applying a first beam of laser to the surface of the substrate for performing preheating treatment on the substrate; (4) blowing alloy powder into a molten pool formed on a second beam of laser on the surface of the substrate by using a powder nozzle of an automatic powder feeder; (5) moving a numerically-controlled machine too along the vertical direction of a laser scanning speed by 40-80 percent of the diameter of a laser spot; and (6) repeating the steps (2)-(5) till the thickness of a coating reaches a required thickness, or ending work. The method has the advantages: (1) the processing cost is reduced greatly; (2) the substrate has a small heat affected zone, and is not deformed; and (3) the shape and size of the substrate are unlimited.

Owner:NANCHANG HANGKONG UNIVERSITY

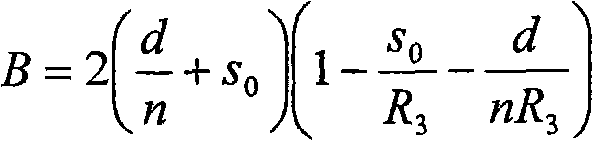

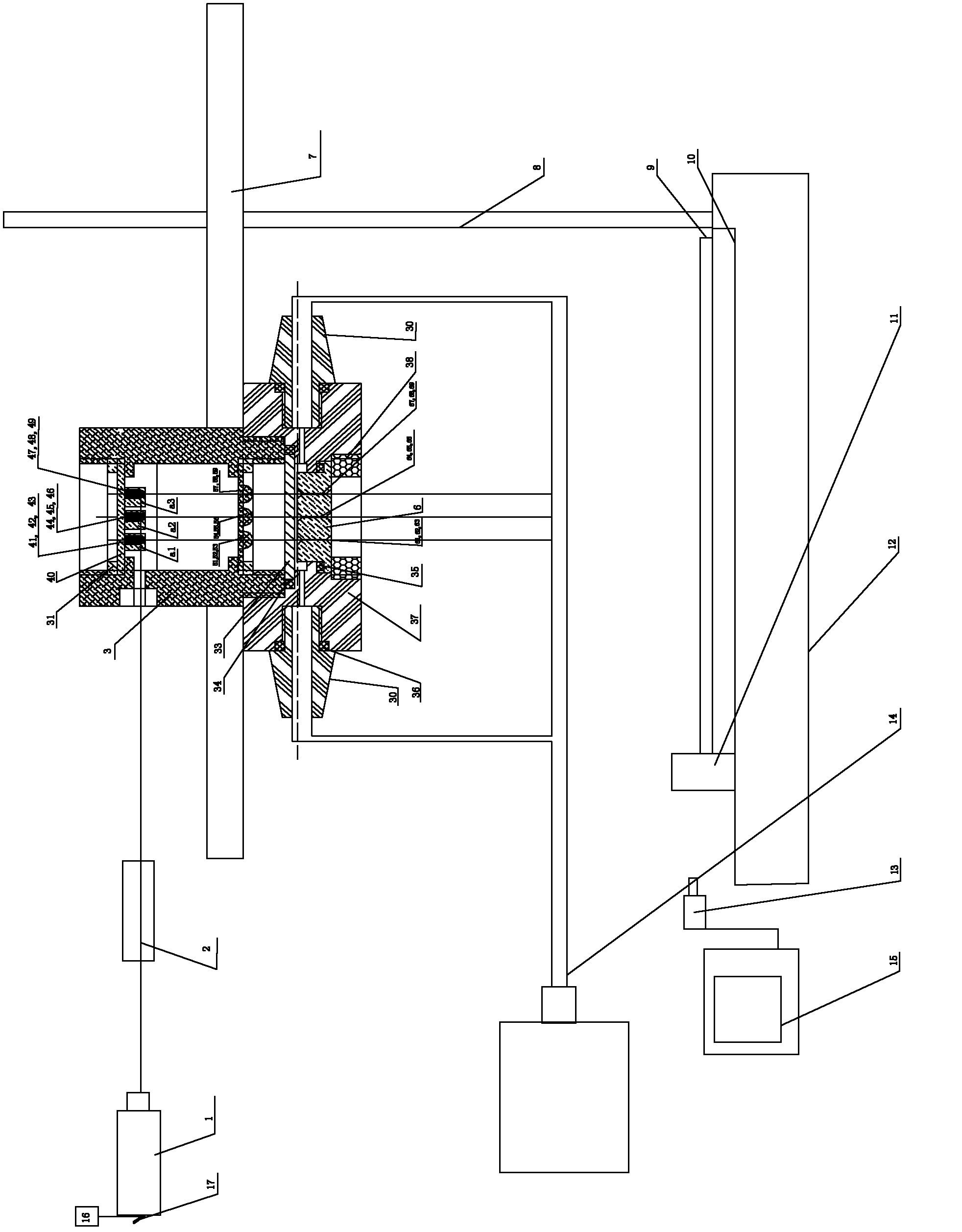

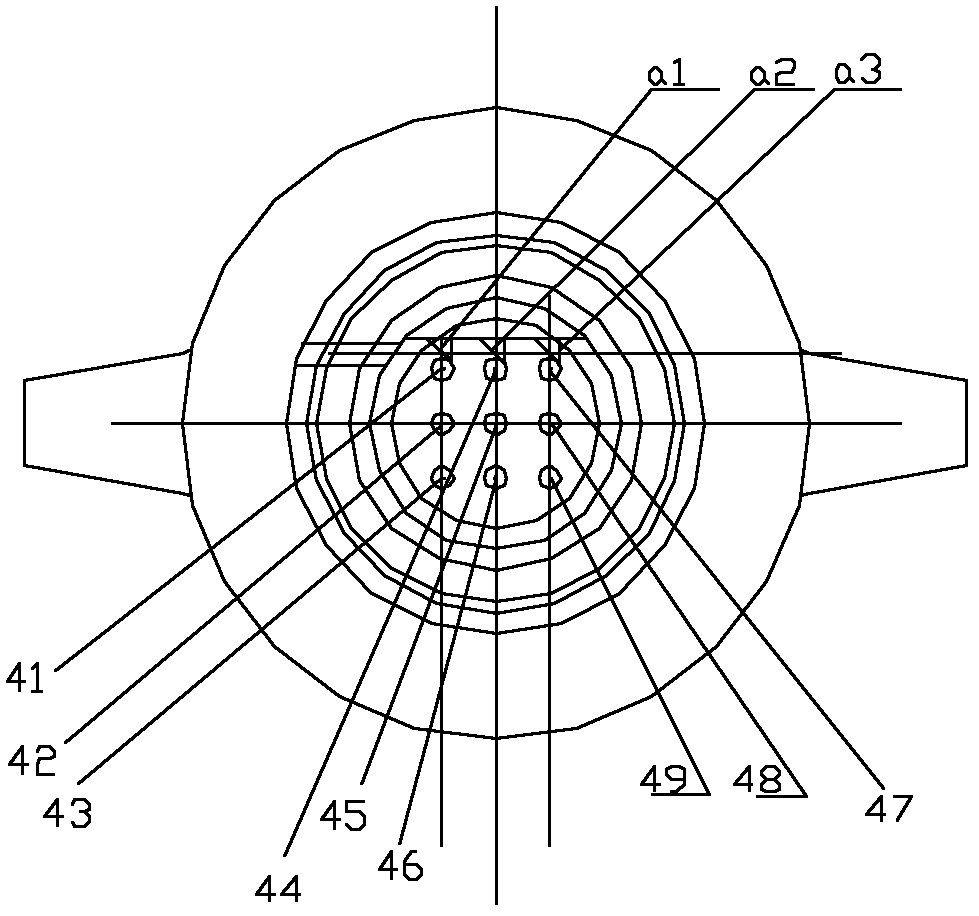

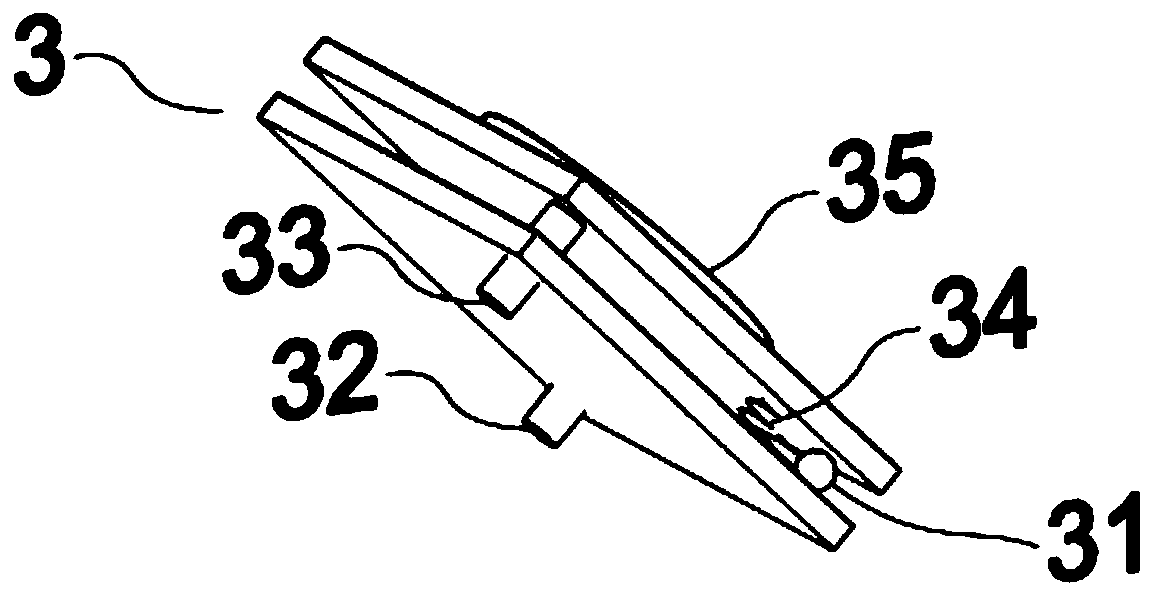

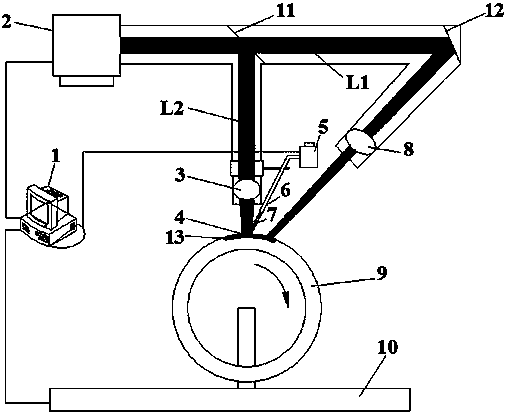

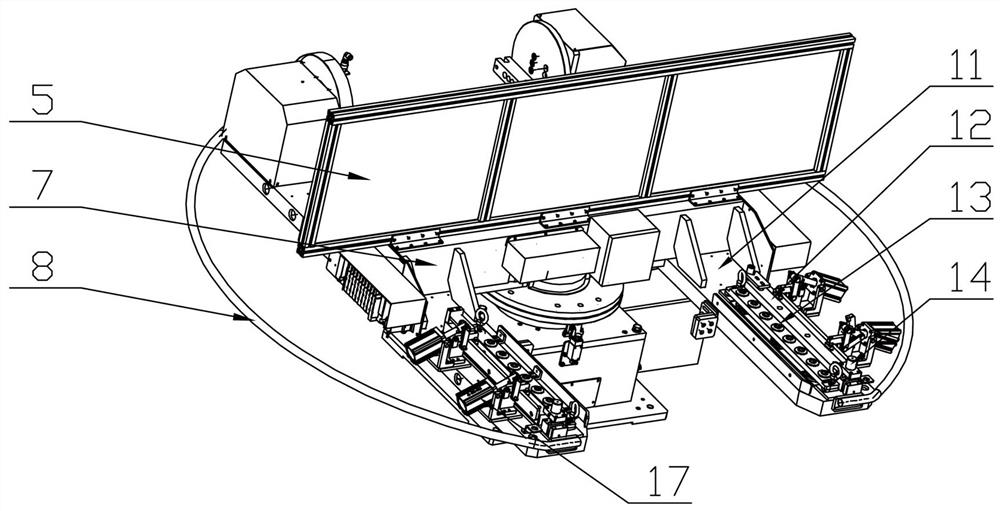

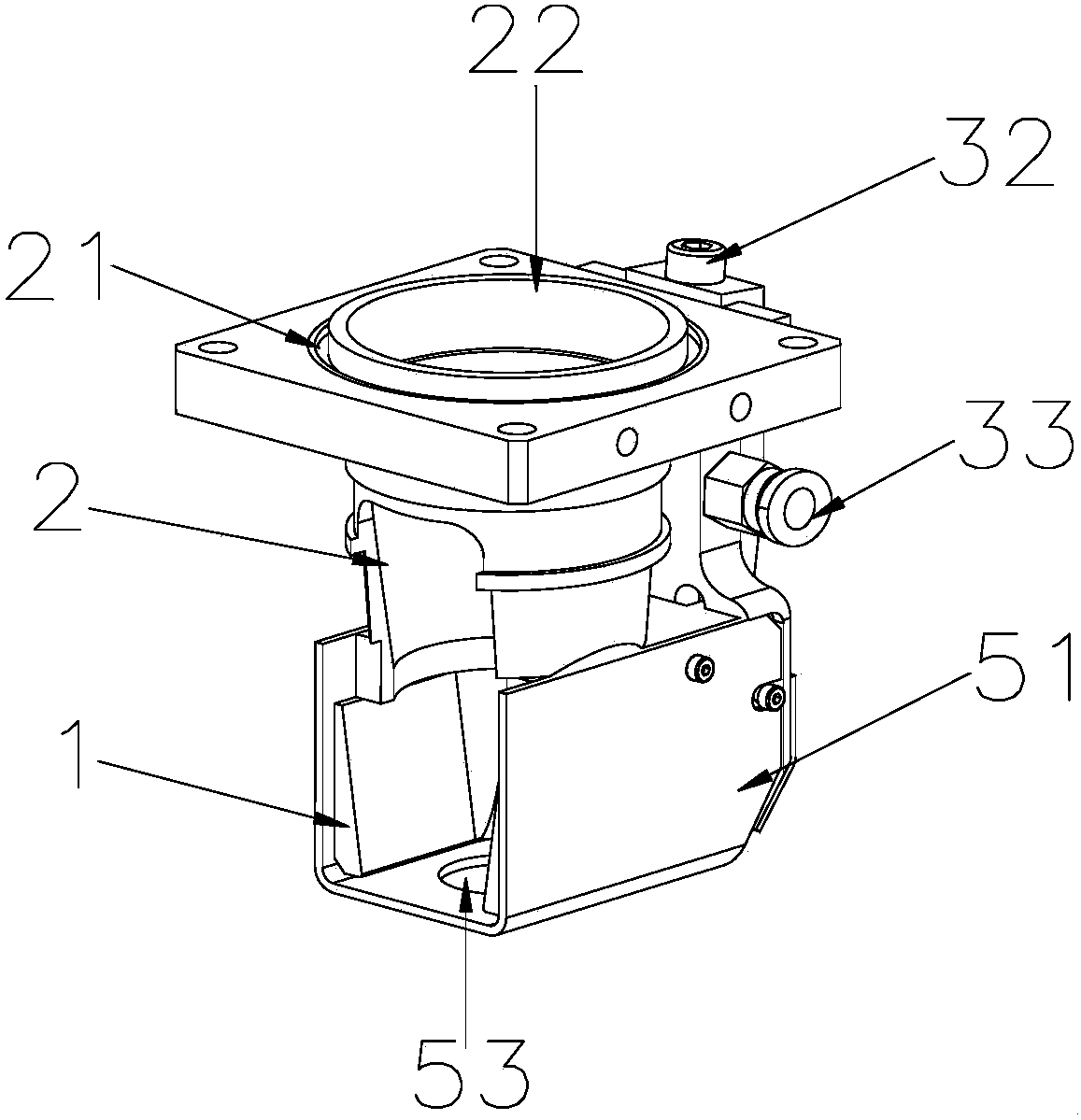

Aviation wire harness end laser processing equipment

ActiveCN112164961AEfficient processingRealize processingLine/current collector detailsApparatus for removing/armouring cablesAviationLaser processing

The invention provides an aviation wire harness end laser processing equipment, and relates to the field of aviation wire harness processing. The equipment comprises a bottom plate, a wire clamping mechanism, a rotating mechanism, a laser mechanism and an optical system arranged in the rotating mechanism, wherein the wire clamping mechanism, the rotating mechanism, and the laser mechanism are arranged on the bottom plate in sequence. Laser is adopted for machining the aviation wire harness end, an optical system is driven by a rotating mechanism to surround a machined aviation wire harness byone circle mainly based on a nanosecond short-pulse laser with the wavelength of 405 nm, and high-precision and high-efficiency aviation wire harness end machining serves as the target. And the processing of wire stripping, windowing, longitudinal cutting, regional evaporation ablation and the like of the aviation wire harness end is realized. According to the invention, the wire taking PTFE and PVC as insulating materials is taken as a processed material, the processing time is less than 5s, the fixed-length precision is not more than 0.2 mm, the processing length is 3-30mm, and the wire coreV is physically damaged, so that the equipment is compact in structure, reliable in processing quality, high in processing efficiency, high in processing precision, small in occupied space and convenient to move.

Owner:CHANGCHUN UNIV OF SCI & TECH

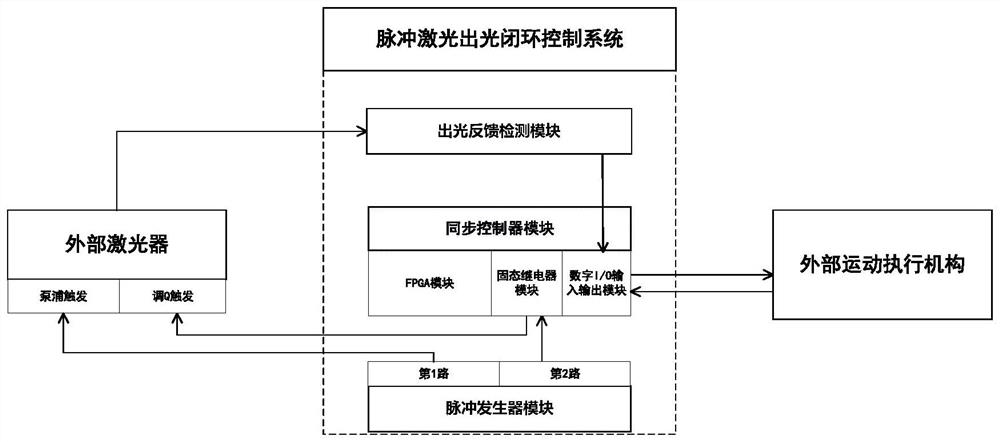

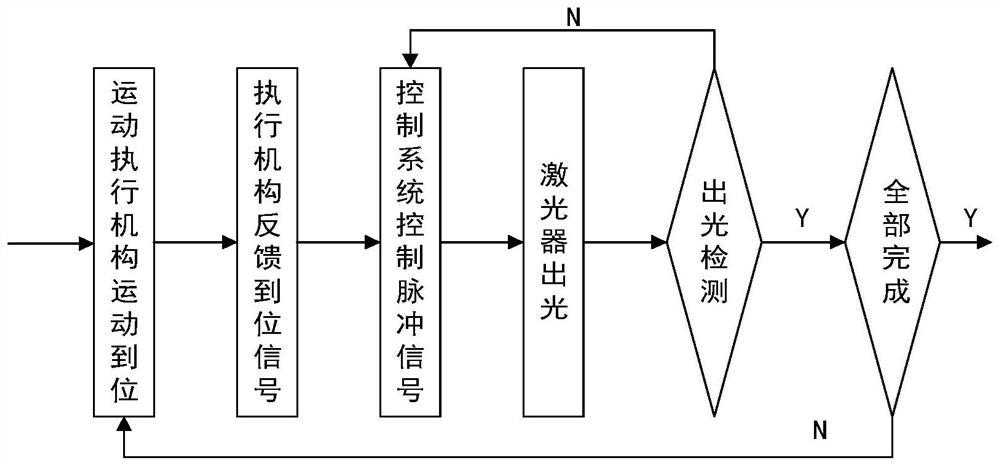

Pulse laser light emitting synchronous closed-loop control system and method, terminal and medium

PendingCN114115047ARealize closed-loop controlAchieve precise controlProgramme controlComputer controlLoop controlLaser processing

The invention provides a pulse laser light-emitting synchronous closed-loop control system, which comprises a synchronous controller module for acquiring a light-emitting signal and a light-emitting feedback signal and realizing closed-loop control of laser light-emitting and light-emitting feedback; the emergent light feedback detection module is used for detecting emergent laser and transmitting an emergent light feedback signal to the synchronous controller module; and the pulse generator module controls the triggering of an external laser. Closed-loop control over laser light emitting and light emitting feedback is achieved, the problem of no light emitting or disordered light emitting is effectively avoided, the light emitting efficiency of the laser is remarkably improved, and accurate control over the whole laser machining process is achieved.

Owner:SHANGHAI PLATFORM FOR SMART MFG CO LTD

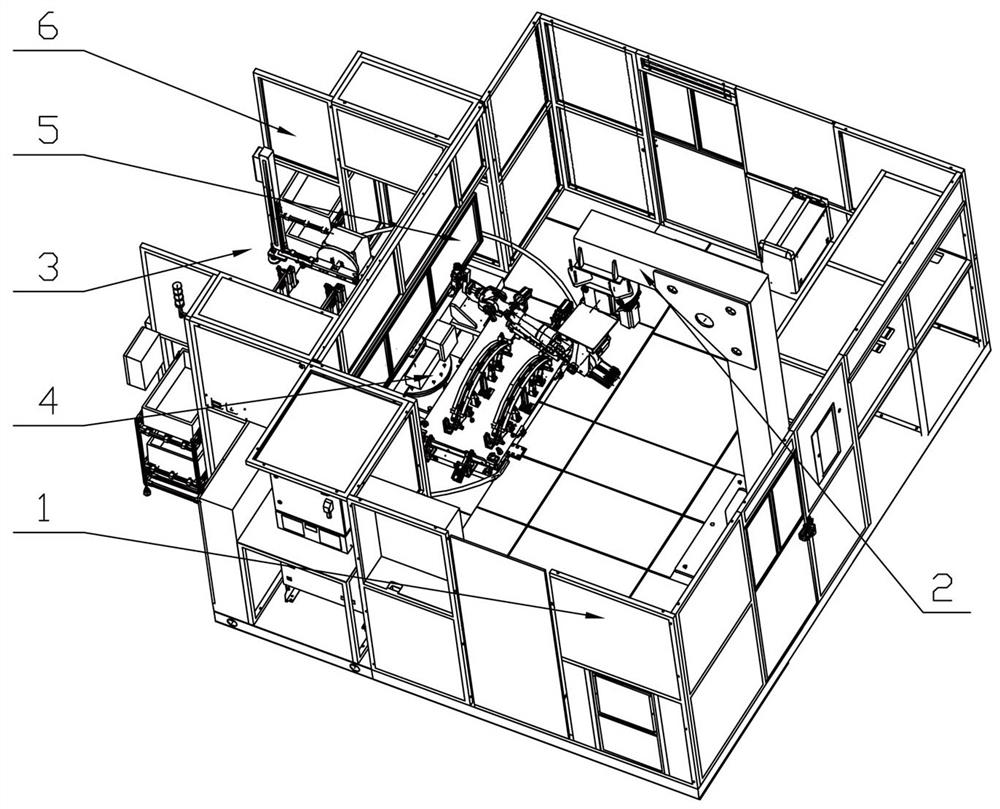

Double-station laser cutting workstation

InactiveCN113369726AImprove loading and unloading efficiencyImprove laser processing efficiencyLaser beam welding apparatusStructural engineeringLaser cutting

The invention relates to a double-station laser cutting workstation, and belongs to the technical field of laser cutting equipment. According to the structure, a protective cover is arranged on the periphery of the space of a laser workstation, and a laser cutting robot is arranged in the protective cover; a feeding opening is formed in one side of the protective cover; a circular rotary table is arranged in the protective cover, and the bottom of the circular rotary table is connected with a rotary driving device; a cross beam is arranged on the upper surface of the circular rotary table in the diameter direction, a vertical light shielding plate is arranged on the cross beam and located at the feeding opening, and the light shielding plate and the protective cover form an integral protective room; clamping tools are arranged on the two sides of the cross beam respectively, the clamping tool on one side of the cross beam is located in the protective cover, and the clamping tool on the other side of the cross beam is located outside the feeding opening. The double-station laser cutting workstation is provided with a rotary feeding structure, rotary feeding and the machining procedure are carried out at the same time, safe production is guaranteed, and the cutting efficiency is improved.

Owner:辽宁华天航空科技股份有限公司

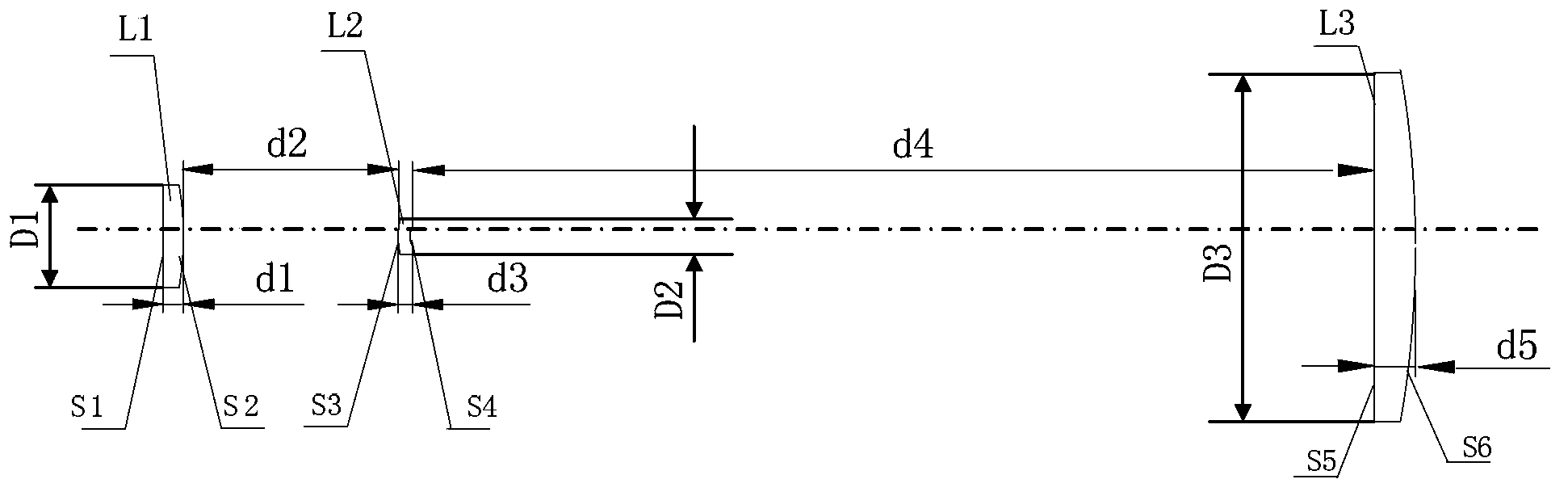

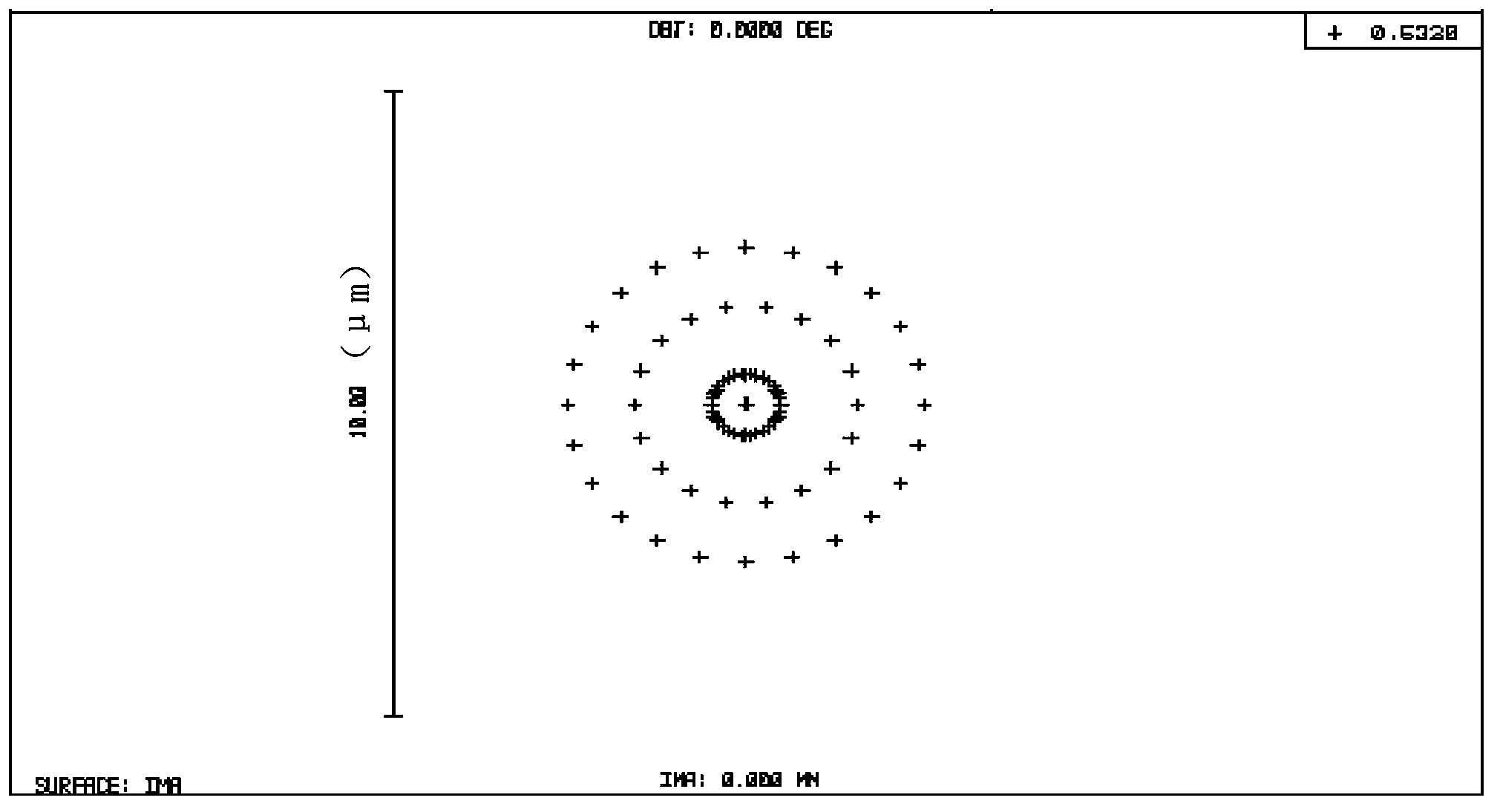

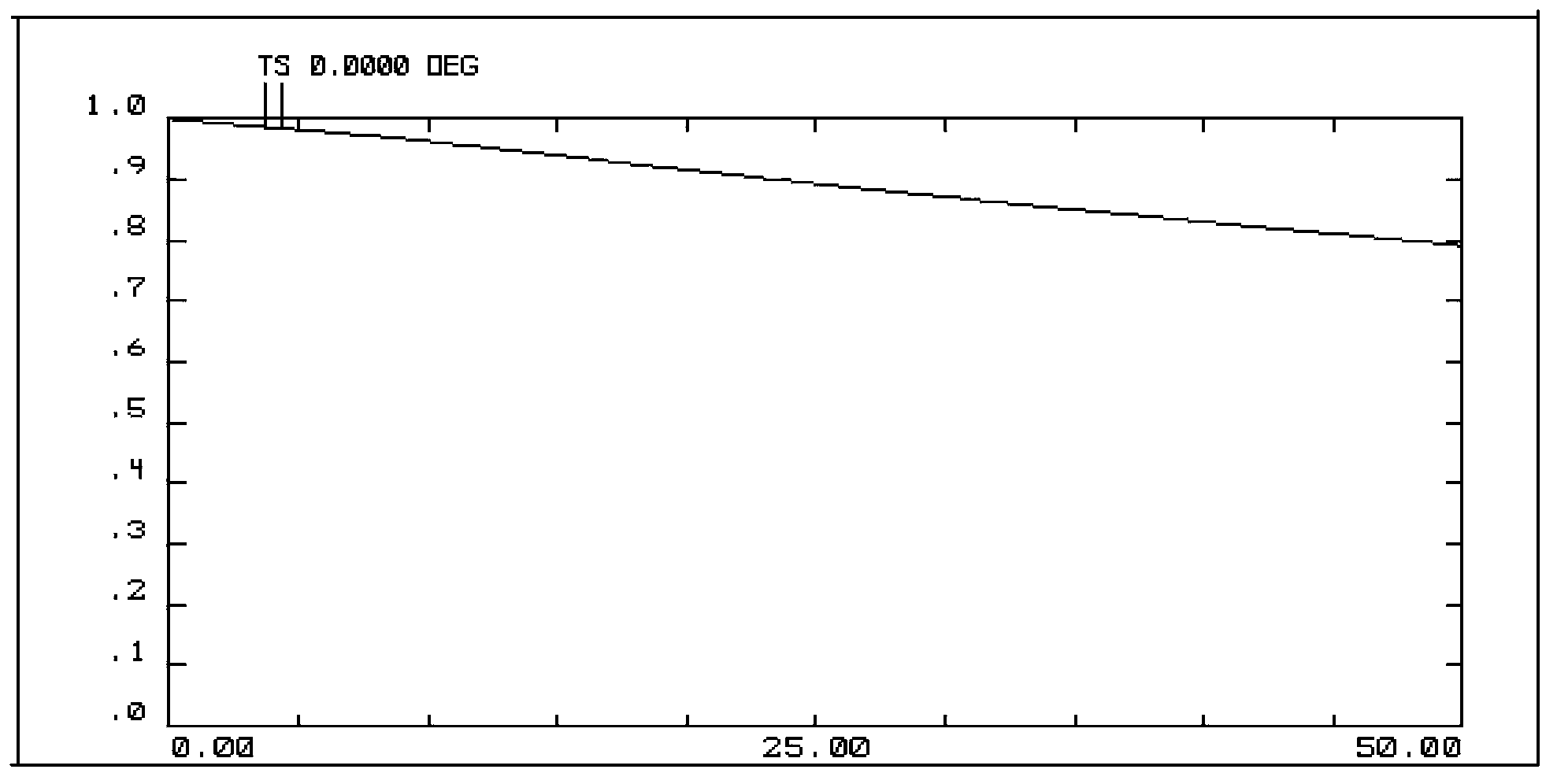

Green light laser zooming and beam expanding system and laser processing device

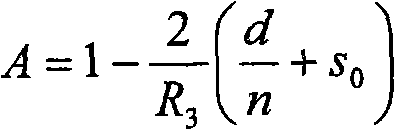

The invention is suitable for the field of laser processing, and provides a green light laser zooming and beam expanding system comprising a first lens, a second lens and a third lens. The first lens and the third lens present to be plane-convex positive lenses. The second lens presents to be a convex-concave negative lens. The first lens, the second lens and the third lens respectively comprise a first curved surface and a second curved surface, a third curved surface and a fourth curved surface, and a fifth curved surface and a sixth curved surface. Curvature radiuses of the first to the sixth curved surfaces are indefinite, -29.8, 7.2, 1.6, indefinite and -100. Center thicknesses of the first to the third lenses are 2, 1 and 4. External diameters of the first to the third lenses are 10, 3 and 34. Ratios of refractive indexes to abbe numbers of the first to the third lenses are 1.8:25, 1.48:68 and 1.8:25. Spacing distance between the second curved surface and the third curved surface is from 8 to 28mm, spacing distance between the fourth curved surface and the fifth curved surface is from 107 to 115mm, and tolerance is 5%. Beams of incident light can be expanded for 2 to 16 times by the system so that the system is applicable to lasers with different emergent diameters and divergence angles, and efficiency and accuracy of laser processing are enhanced.

Owner:HANS LASER TECH IND GRP CO LTD

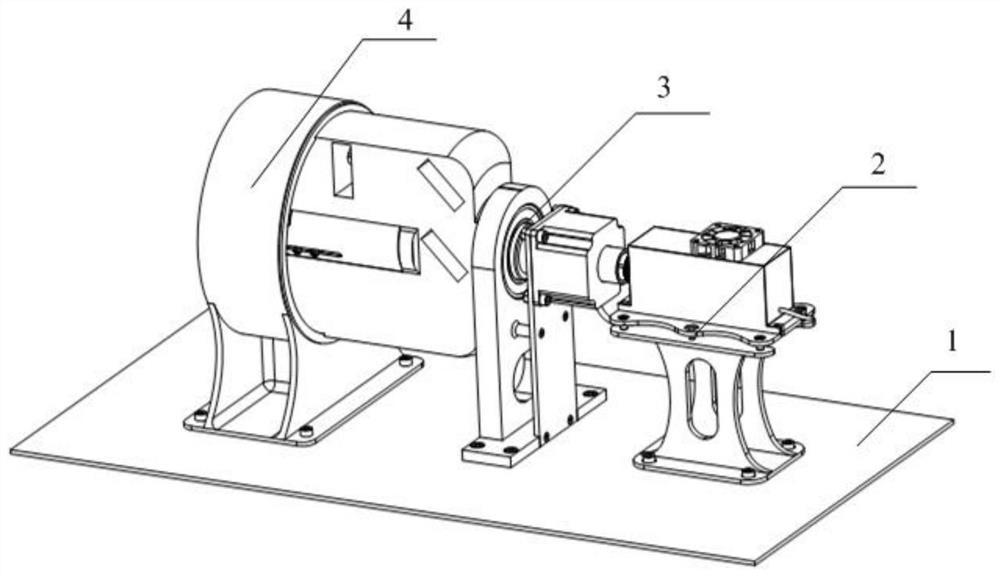

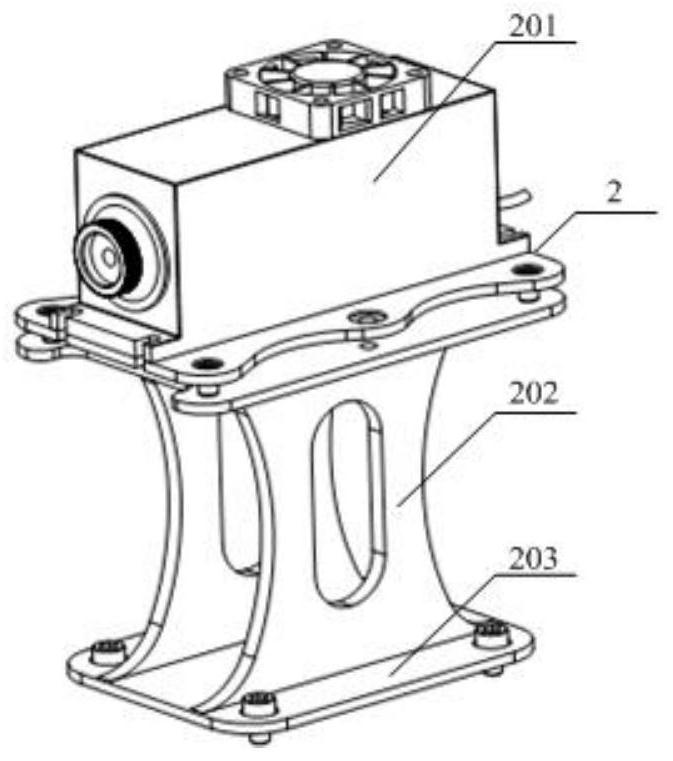

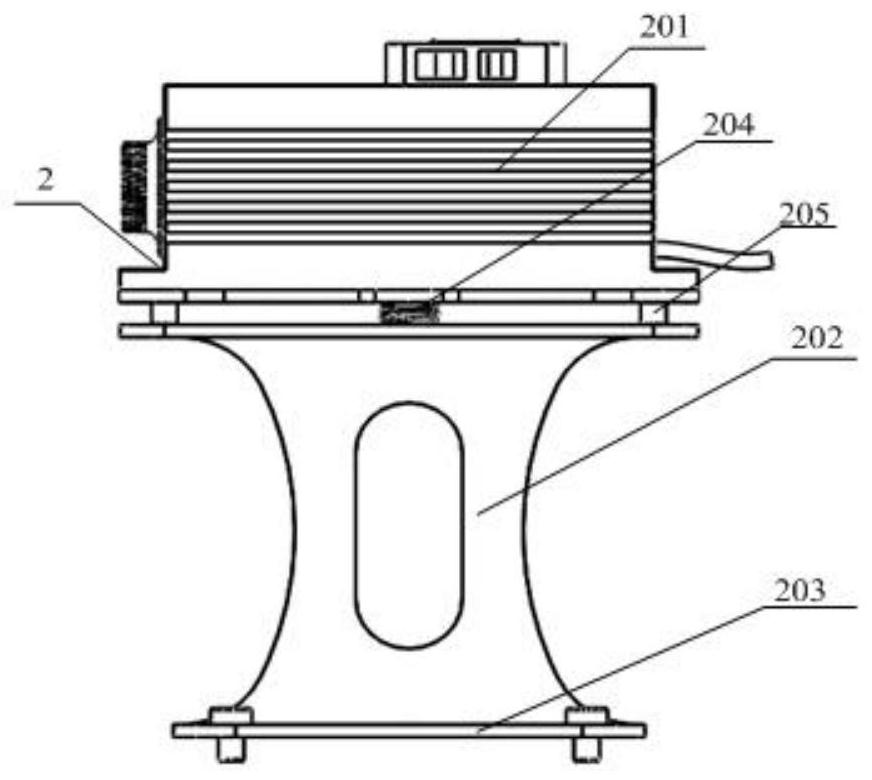

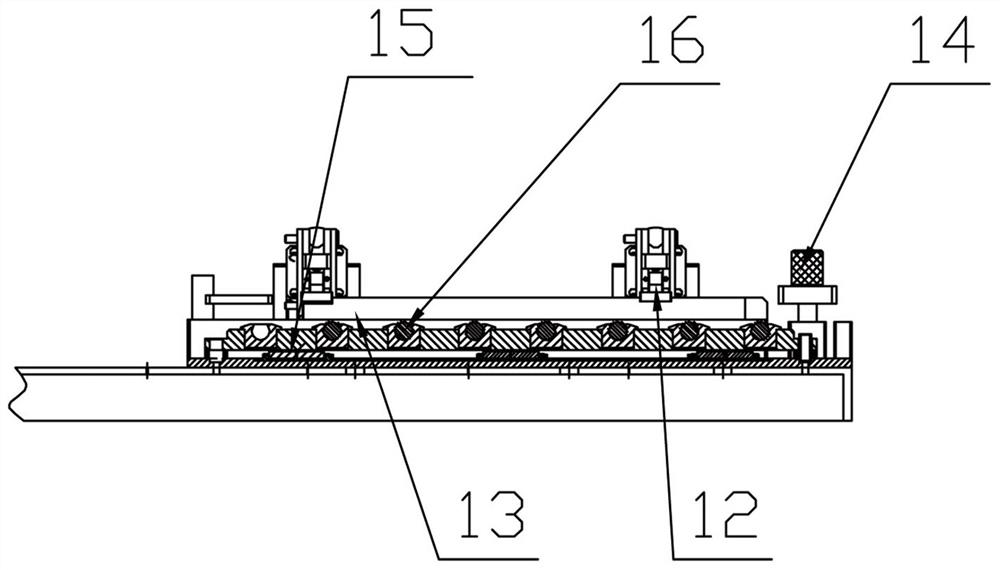

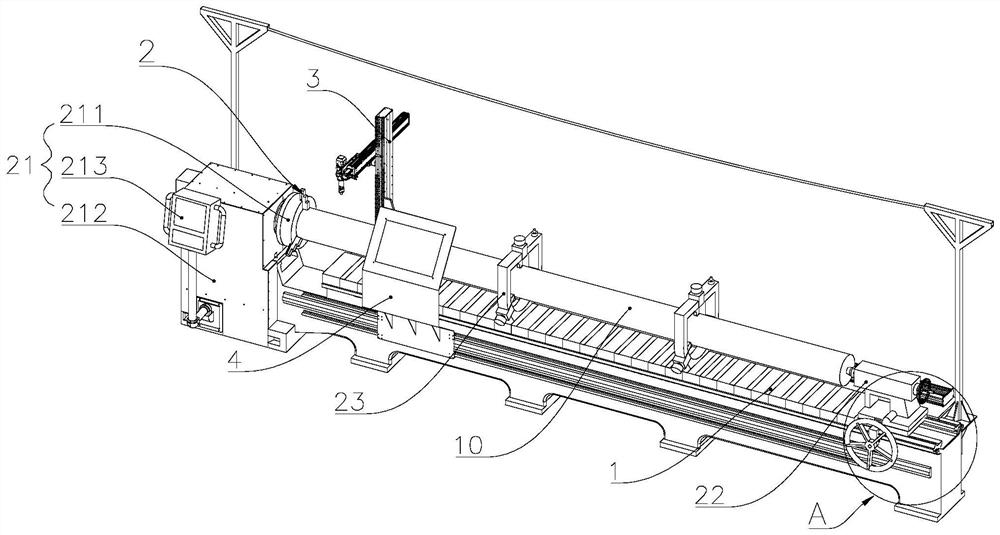

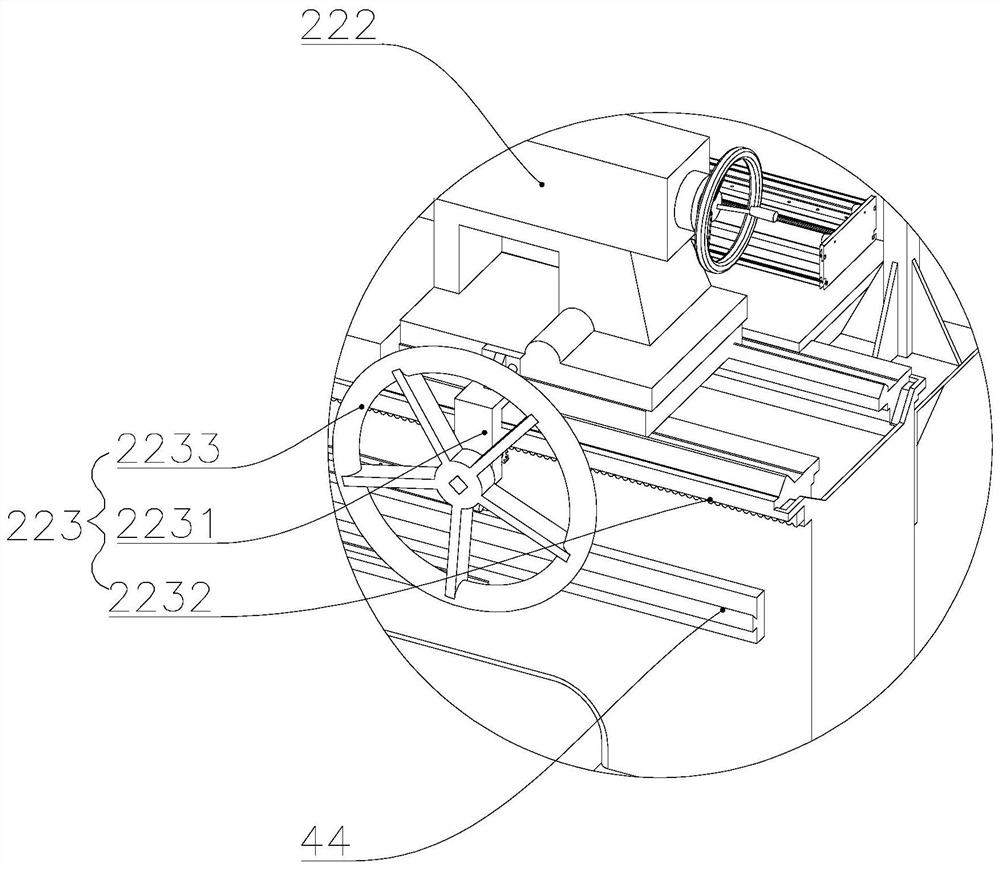

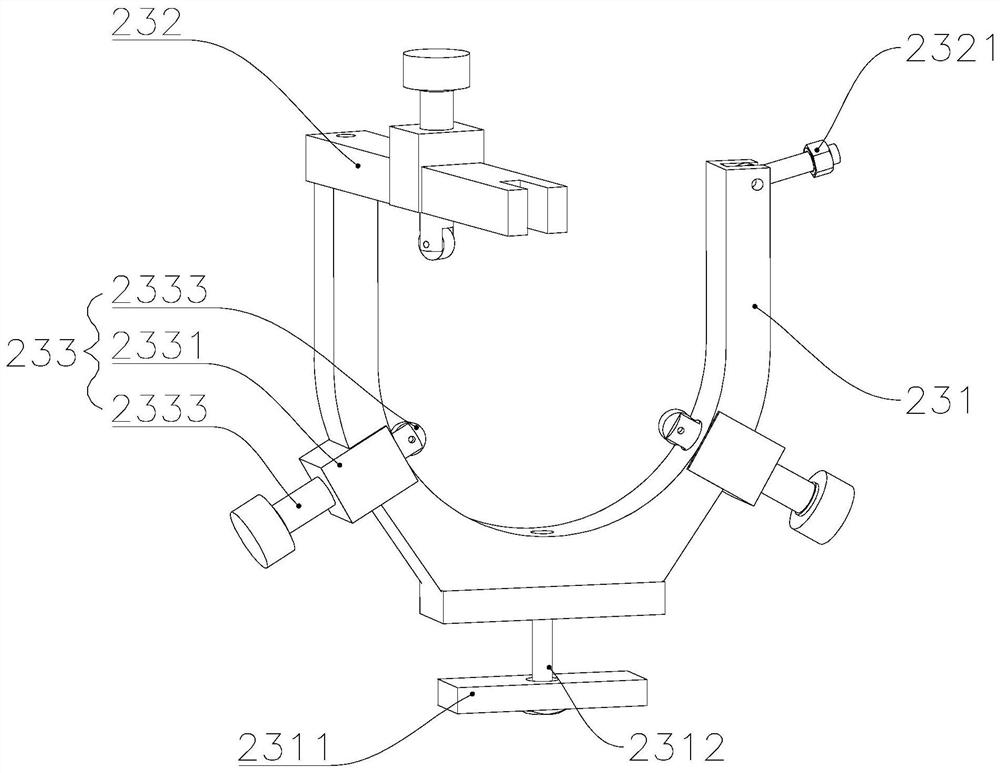

Workbench for shaft processing and laser processing system based on workbench

PendingCN113832463AStrong bearing capacityAvoid bending deformationFurnace typesMetallic material coating processesPhysicsEngineering

The invention relates to the technical field of laser cladding, in particular to a workbench for shaft processing and a laser processing system based on the workbench. The workbench comprises a horizontal lathe bed, a clamping mechanism and a laser module. The clamping mechanism is arranged on the horizontal lathe bed and used for limiting shaft parts. The laser module is arranged on one side of the horizontal lathe bed in a sliding manner and used for processing the shaft parts. The clamping mechanism comprises a three-jaw chuck, a movable tailstock and a plurality of center supporting modules. The center supporting modules are arranged between the three-jaw chuck and the movable tailstock. The three-jaw chuck and the movable tailstock limit the shaft parts from the two ends of the shaft parts. The center supporting modules limit the shaft parts from the main body portions of the shaft parts, and the shaft parts are stably arranged on the horizontal lathe bed. The center supporting modules support the shaft parts, then the movable tailstock with a centre locks the shaft parts, stable clamping of the to-be-machined shaft parts is achieved, the bearing performance is high, and stable processing is guaranteed.

Owner:江苏珠峰光电科技有限公司

Double-path gas protection device of high-power laser machining head

PendingCN110614434ARestricted refluxAvoid damageLaser beam welding apparatusShunt DeviceHigh power lasers

The invention relates to the technical field of laser machining head protection devices, specifically to a double-path gas protection device of a high-power laser machining head. The double-path gas protection device of the high-power laser machining head comprises a mounting base, an air knife I component and an air knife II component; the mounting base comprises two side plates and a bottom plate fixedly connected between the two side plates; a machining through hole is formed in the bottom plate; the lower end of the air knife II component is fixedly connected between the two side plates; the air knife I component is arranged between the two side plates and positioned at the lower end of the air knife II component; and a shunting device used for separating blown gas into two parts, which are correspondingly blown to the air knife I component and the air knife II component, is mounted on one side of the air knife I component and one side of the air knife II component. According to the double-path gas protection device of the high-power laser machining head, the problem that a lot of loss of a laser machining head protecting lens is caused by not very well limiting back flow of powder and welding slag during working of the laser machining head is solved. The double-path gas protection device of the high-power laser machining head has the advantages that the structure is simple, the possibility that the protecting lens is damaged is greatly reduced, and therefore, the production cost.

Owner:江苏珠峰光电科技有限公司

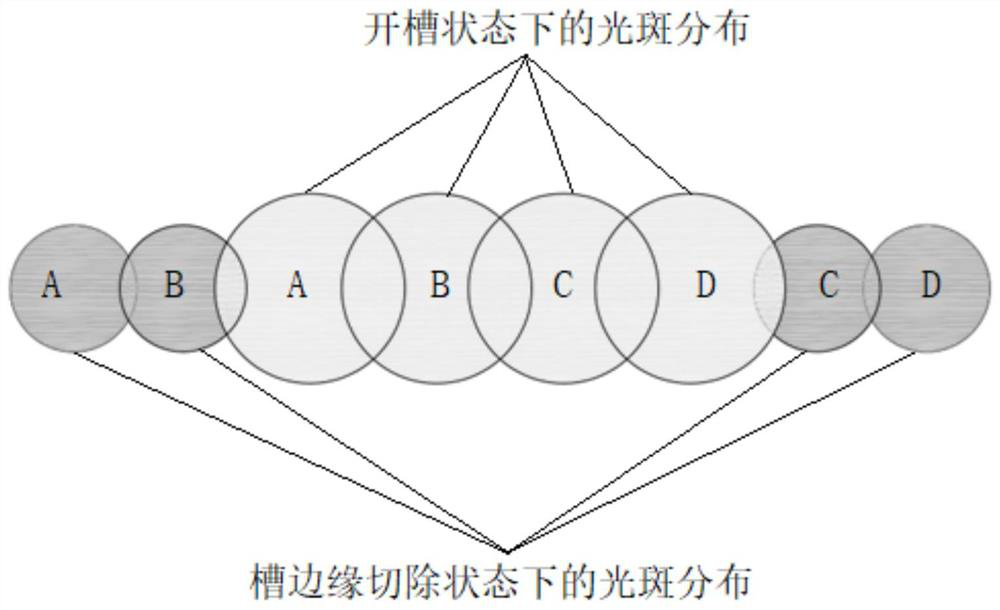

Ridge-type laser beam splitting system and method

PendingCN112658472AImprove laser processing efficiencyBroaden process adjustment windowLaser beam welding apparatusLaser solderingLaser scribing

The invention aims to provide a ridge-type laser beam splitting system and method. The ridge-type laser beam splitting system comprises a laser, a ridge-type beam splitter, reflectors and condensers, the reflectors are arranged on the output light paths of the ridge-type beam splitter, the condensers are arranged on the output light paths of the reflectors, the condensers are used for focusing laser, the two sets of reflectors and condensers are arranged in a complete set, and each set corresponds to one output light path of the ridge-type beam splitter. By reasonably designing a subsequent light path adjusting system and amplifying a subsequent reflection angle, the reflectors can adjust the laser spacing, so that the laser processing efficiency is effectively improved, and a process adjusting window is widened. The system and the method are wide in application scene and can be applied to the fields of laser scribing, laser welding, laser cutting and the like.

Owner:HUANENG NEW ENERGY CO LTD +1

Laser processing method and device, laser processing equipment, storage medium

ActiveCN111515523BHigh degree of automationImprove laser processing efficiencyLaser beam welding apparatusComputer hardwareLaser processing

The present invention discloses a laser processing method and device. The method includes: according to the start instruction of the laser processing equipment, acquiring photographed images of the object to be processed and the pattern to be processed placed on the honeycomb board in the laser processing equipment; Identifying a processing area and a pattern area in the photographed image, obtaining material information of the object to be processed and pattern information describing the pattern to be processed, the processing area being an image area corresponding to the object to be processed in the photographed image; According to the material information and pattern information, the laser processing equipment is controlled to process the pattern to be processed to the object to be processed. The adoption of the method greatly improves the automation degree of the laser processing equipment for laser processing.

Owner:SHENZHEN MAKER WORKS TECH CO LTD

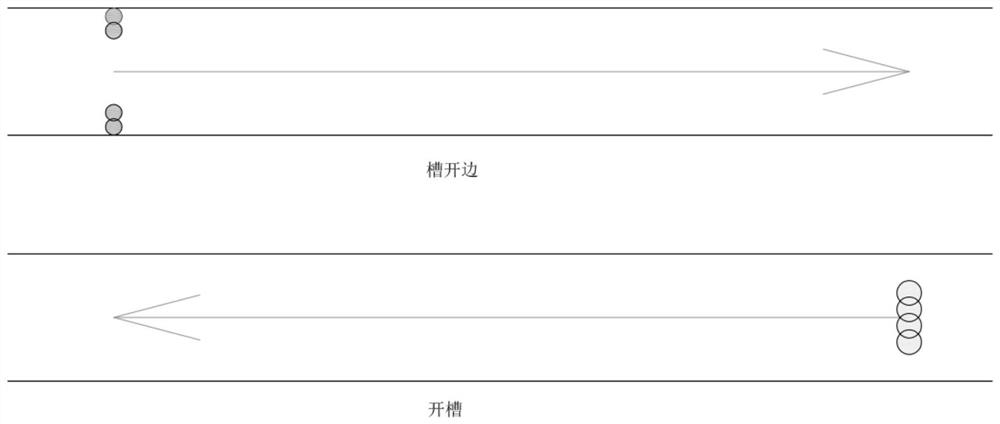

Optical system for laser precision slotting and slotting method

PendingCN112548366AImprove absorption rateSuppress interferenceLaser beam welding apparatusBeam splitterBeam energy

The invention discloses an optical system for laser precision slotting and a slotting method. The optical system comprises a laser device, a first reflector group, a first half-wave plate, a wedge-shaped mirror, a second beam splitter prism for uniformly splitting a light beam processed by the wedge-shaped mirror into a first light beam and a second light beam with equal energy, a second reflectorgroup for reflecting the first light beam to a first beam combining prism, a first galvanometer unit for polarizing the second light beam and then emitting the second light beam into the first beam combining prism, a second half-wave plate for modulating the polarization state of the light beam emitted by the first beam combining prism, a third beam splitting prism for uniformly splitting the light beam into four laser beams, a third reflector group for reflecting two of the four laser beams into a second beam combining prism, a second galvanometer unit for performing polarization processingon the other two laser beams and then emitting the laser beams into the second beam combining prism, and a laser focusing unit. The phenomena of edge breakage and raised grains are reduced, so that the groove boundary contour is clear, and corners are basically not overburnt.

Owner:SUZHOU QUICK LASER TECH +1

Laser blackening or coloring method of a material surface

ActiveCN103586578BAchieve laser blackening and coloringImprove reliabilityWelding/soldering/cutting articlesLaser beam welding apparatusLaser processingPlastic materials

The invention discloses a method for darkening or coloring the surface of a material. The surface of the material is irradiated through an ultra-short pulse laser, and a submicron-order periodic structure is formed on the surface of the material, so that the processed area of the surface of the material is darkened or colored. The method is characterized in that the material is a non-metallic solid material, the pulse width of the ultra-short pulse laser is from 20 femtoseconds to 50 picoseconds, and the wave length of the ultra-short pulse laser is 1.8-2.2 microns. By limiting the wave length and the pulse width of the pulse laser, laser darkening and coloring of the non-metallic material, especially a plastic material are achieved through the method. Compared with a processing method by adopting an ultra-fast solid laser, the method has higher reliability, laser processing efficiency can be greatly improved, and the requirements of industrialized mass production can be satisfied.

Owner:杭州银湖激光科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com