Laser processing system

A laser processing and processing technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as collision, laser device processing workpiece damage, and affecting laser processing efficiency, so as to avoid damage and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

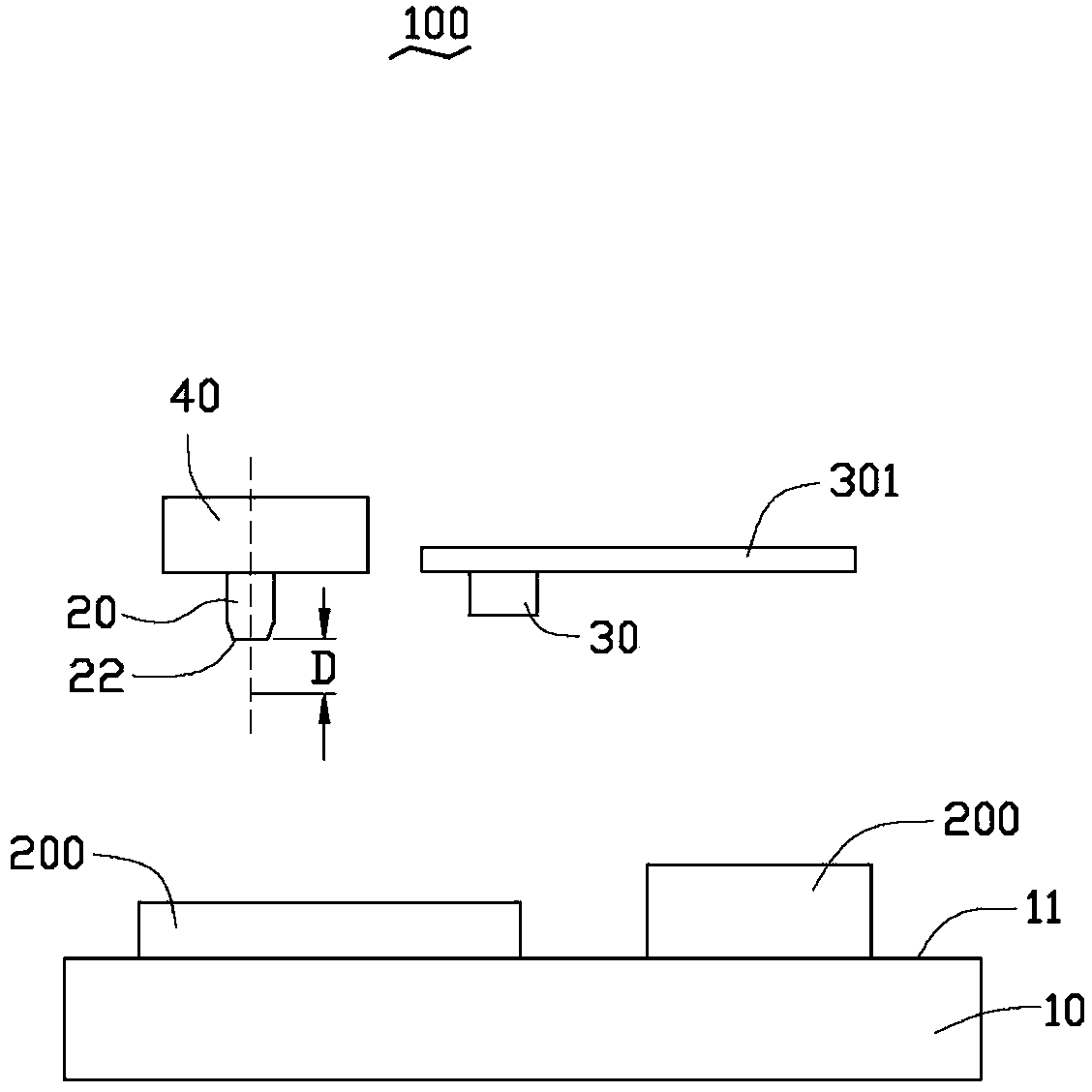

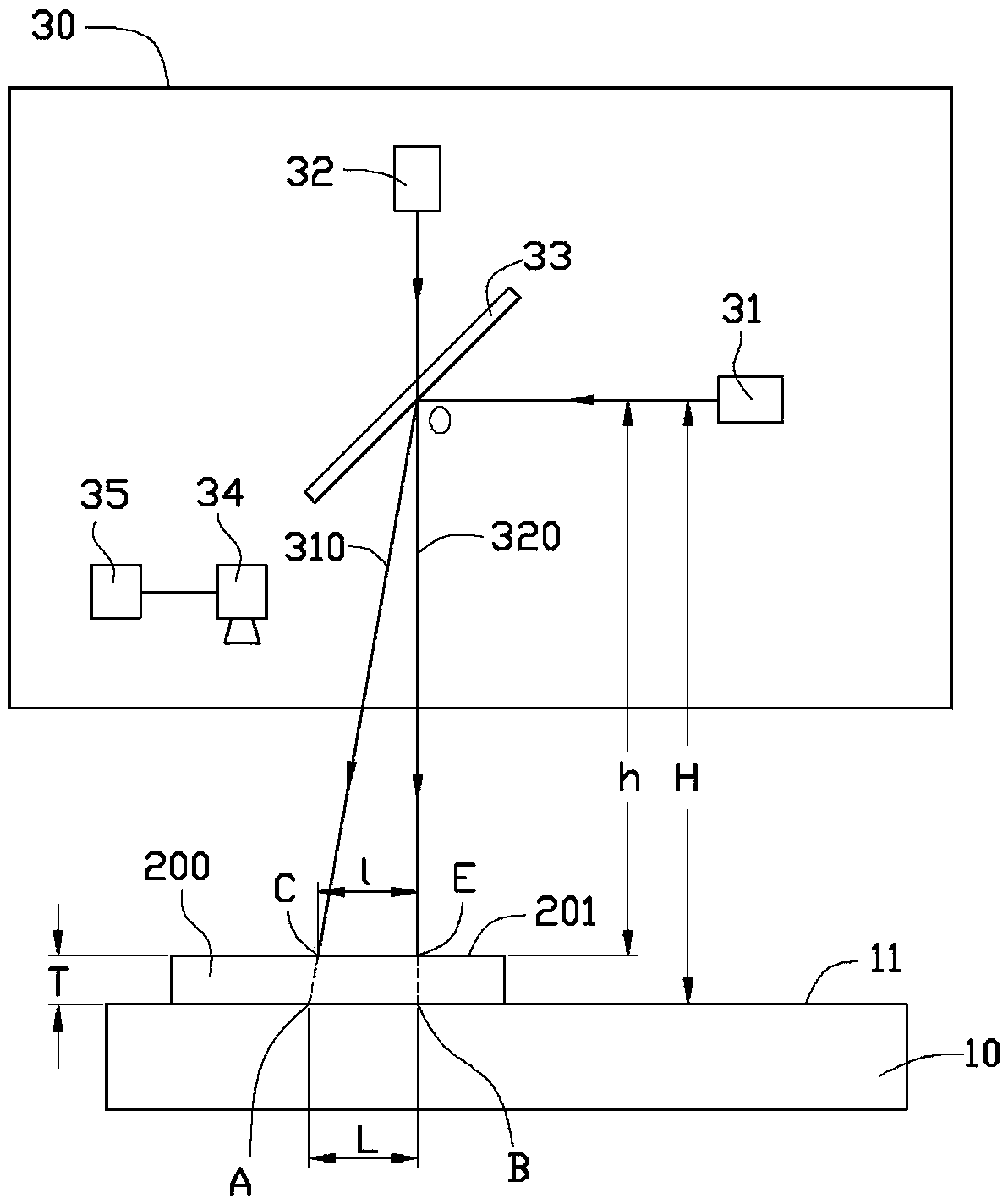

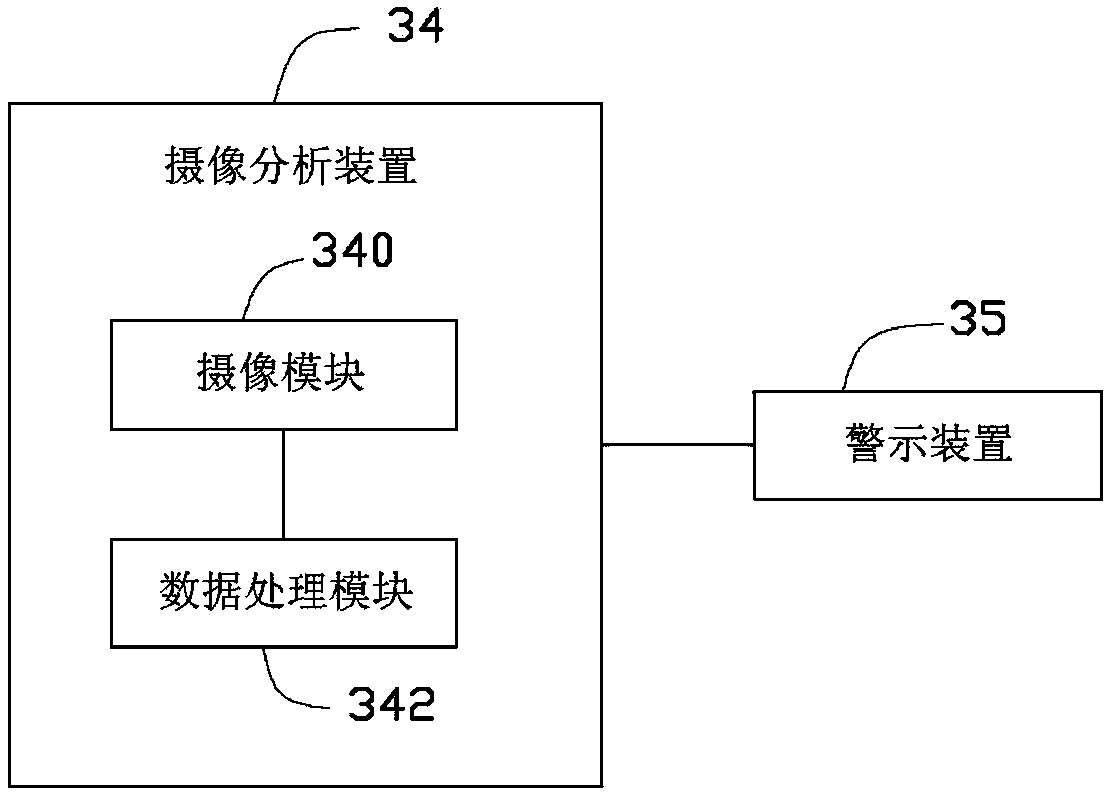

[0014] Please refer to figure 1 A laser processing system 100 according to an embodiment of the present invention includes a stage 10 , a laser device 20 for performing laser processing on a workpiece 200 to be processed, a height detection device 30 , and a driving mechanism 40 .

[0015] The stage 10 includes a working surface 11 , and the workpiece 200 to be processed is arranged at a predetermined processing position on the working surface 11 . Different workpieces 200 to be processed have different heights relative to the working surface 11 .

[0016] The laser device 20 is fixed on the drive mechanism 40, and the drive mechanism 40 is used to drive the laser device 20 to move. According to different requirements, the drive mechanism 40 can drive the laser device 20 in a plane parallel to the working surface 11. And move in a direction perpendicular to the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com