Array type water waveguide laser processing device

A laser processing and water waveguide technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of insufficient processing flexibility, small processing range, low efficiency, etc., to expand the processing range, improve processing quality, beam uniform size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

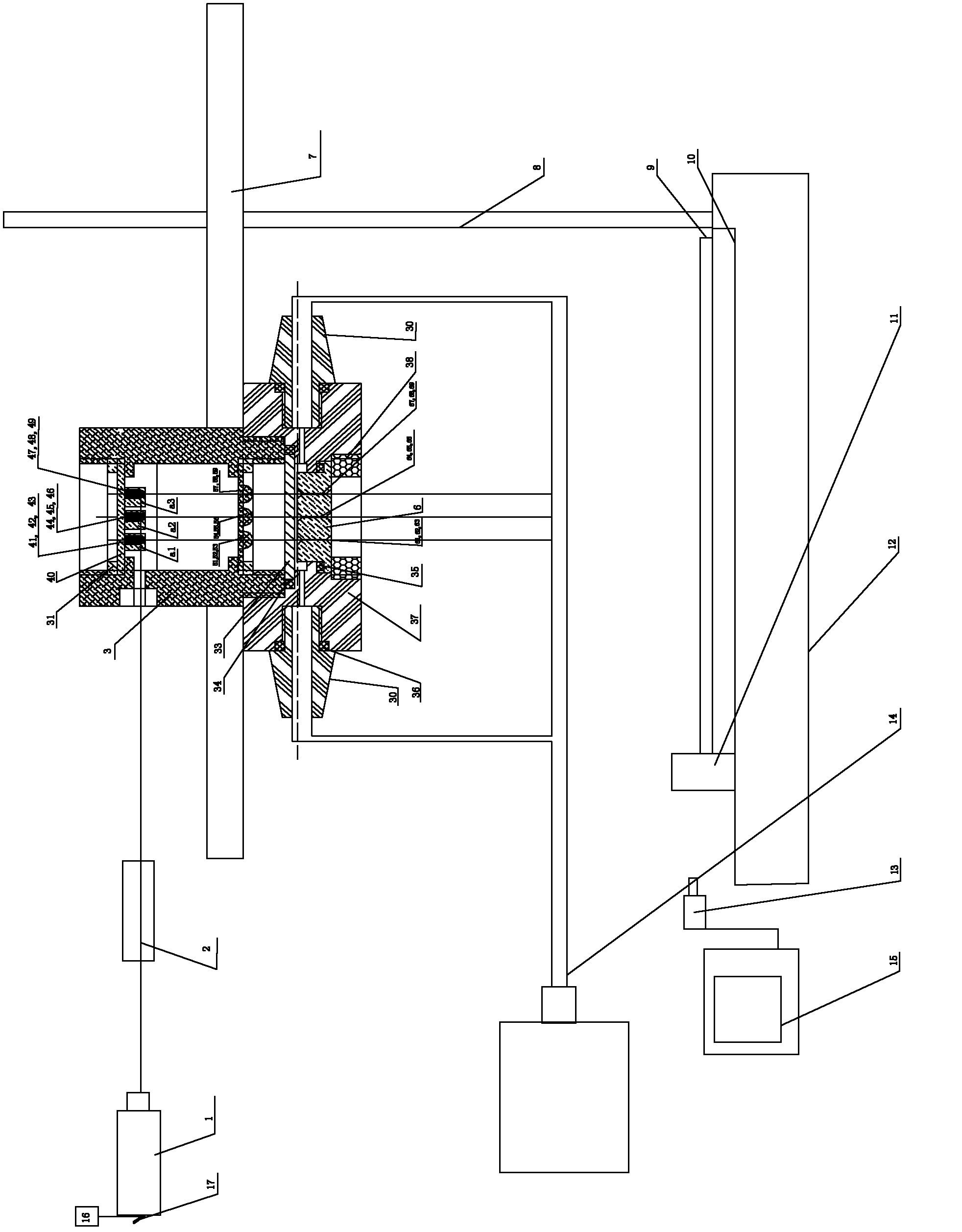

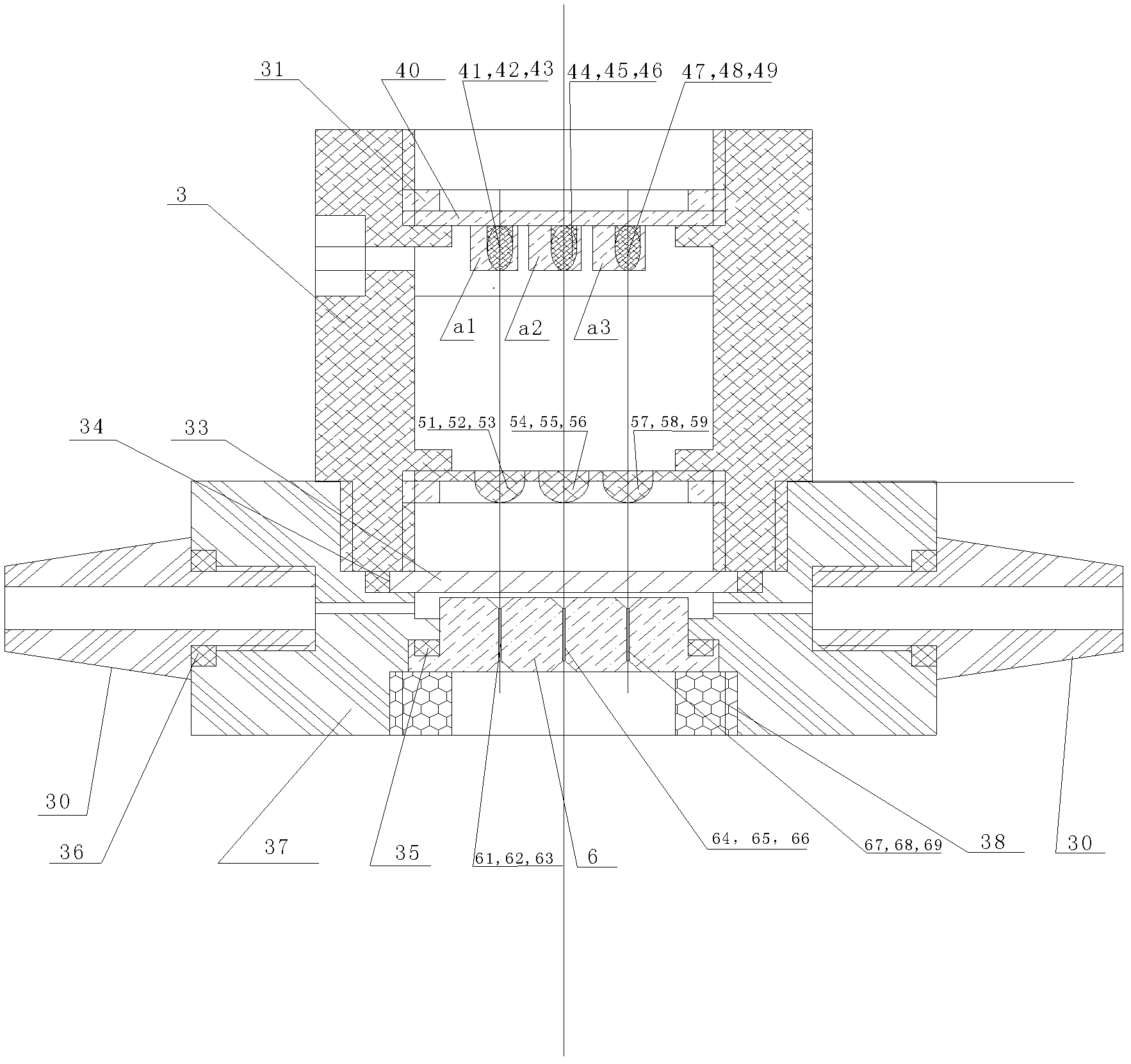

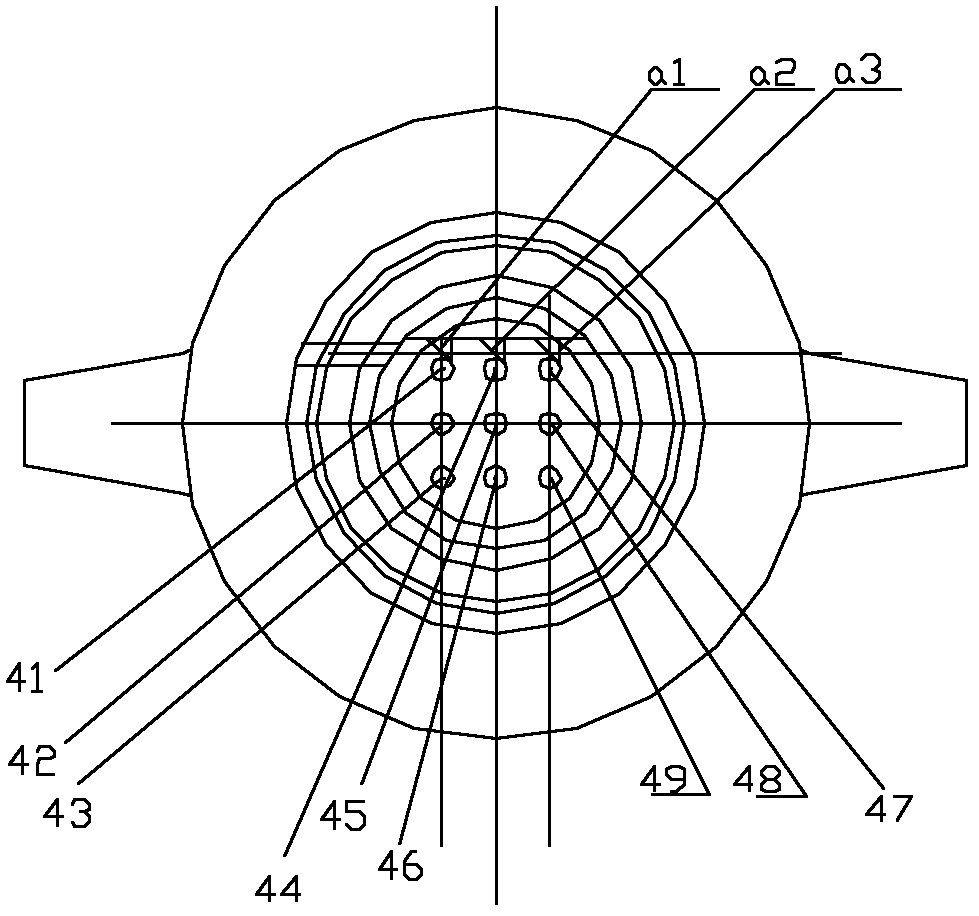

[0021] The embodiment of the present invention takes Nd:YAG laser as an example. The laser is converted into multiple beams of laser light through multiple lenses and multiple sets of transmission mirrors and coupled with multiple beams of water waveguides to form a water waveguide laser parallel processing system.

[0022] see Figure 1~4 , the embodiment of the present invention is provided with laser 1, inverted telescope 2, lens barrel 3, the first transmissive mirror array a1, a2, the second transmissive mirror array 41~48, the first reflector a3, focusing lens array 51~58 , nozzle body 6, bracket with collar 7, bracket 8, workpiece to be processed 9, water collector 10 with filter, fixture 11, numerical control platform 12, camera 13, water circulation system 14, computer numerical control device 15, observation laser 16 , the second reflector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com