Optical system for laser precision slotting and slotting method

An optical system and laser beam technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of unclear groove boundary contour, corner ablation, wave pattern, etc., to suppress laser speckle and reduce collapse edge, enhance the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

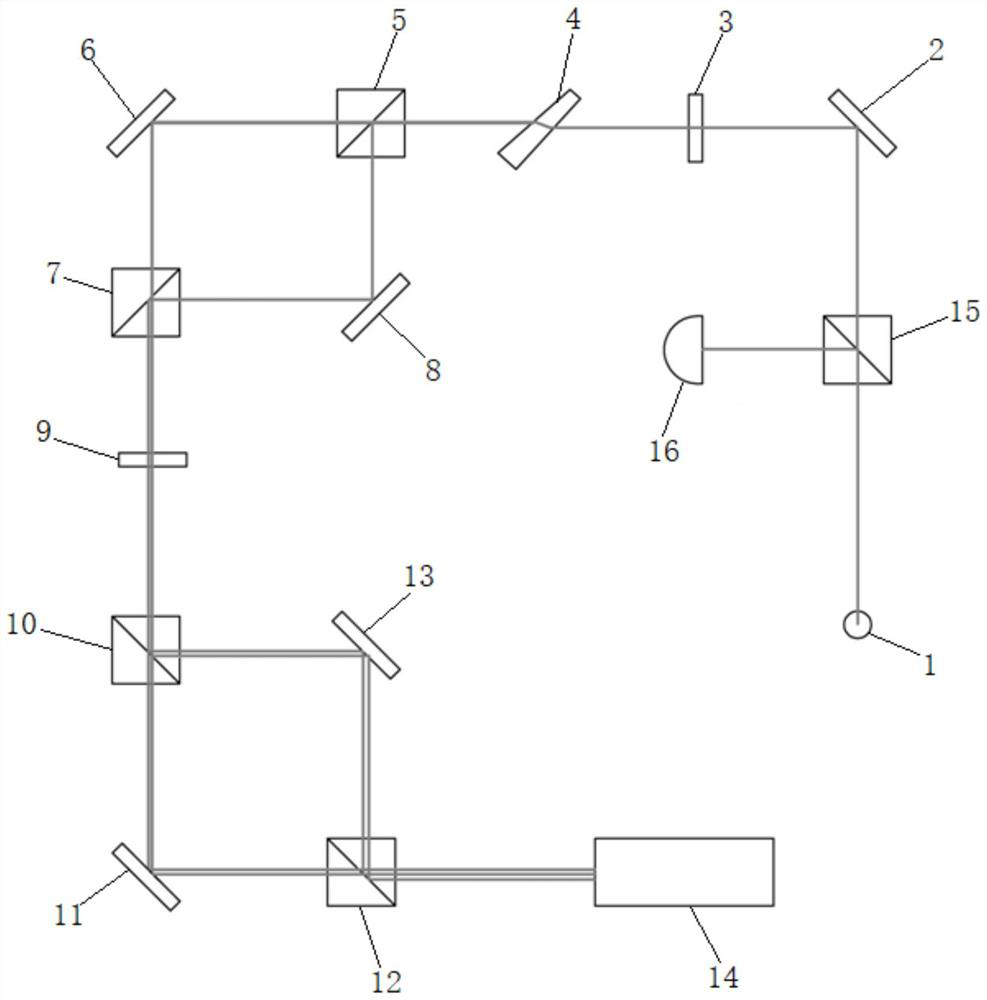

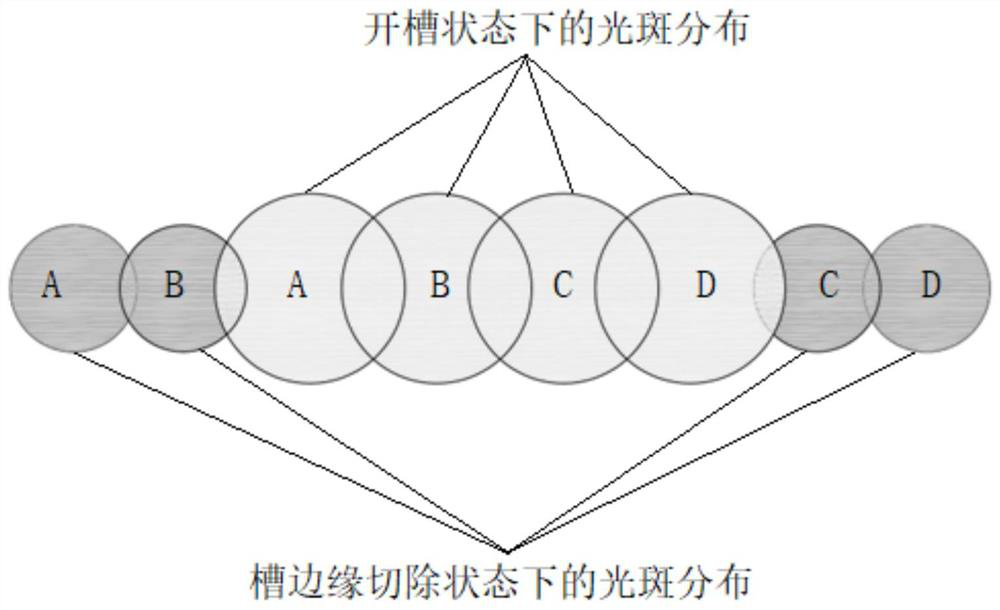

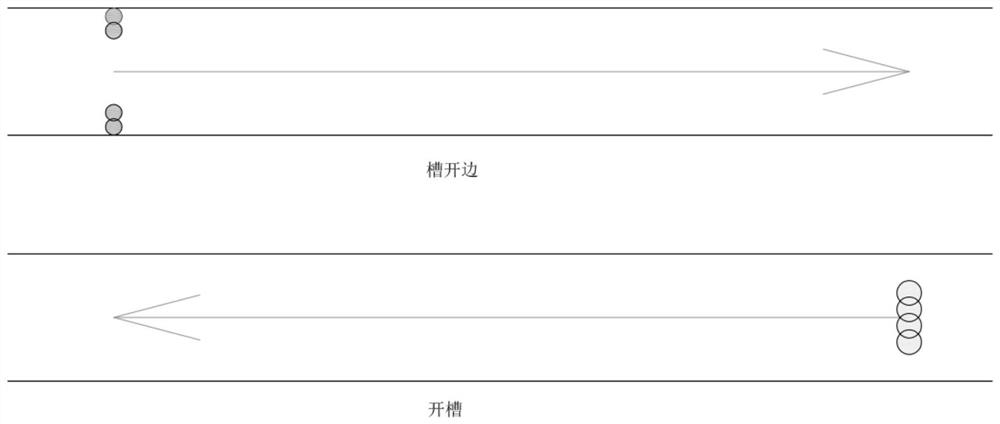

[0023] Please refer to Figure 1-Figure 3 , the present embodiment is an optical system for laser precision grooving, which includes an ultraviolet nanosecond laser 1, a first reflective mirror group 2 that totally reflects the light beam emitted by the ultraviolet nanosecond laser 1, and reflects the first reflective mirror group 2 The first half-wave plate 3 that processes the light beam into linearly polarized light, the wedge mirror 4 that reduces the interference and speckle phenomenon of linearly polarized light, and divides the light beam processed by the wedge mirror 4 evenly into two first beams with equal energy and The second dichroic prism 5 for the second light beam, the second mirror group 6 that reflects the first light beam to a first beam combining prism 7, and polarizes the second light beam and then enters the first beam combining prism The first vibrating mirror unit 8 in 7, the second half-wave plate 9 that modulates the polarization form of the first beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com