Powder feeding and spreading mechanism of laser sintering 3D printer

A 3D printer and laser sintering technology, applied in the field of 3D printing, can solve the problems affecting the leveling of powder, uneven powder, and poor quality of powder spreading, and achieve the effect of improving efficiency, uniform powder feeding, and improving powder spreading quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

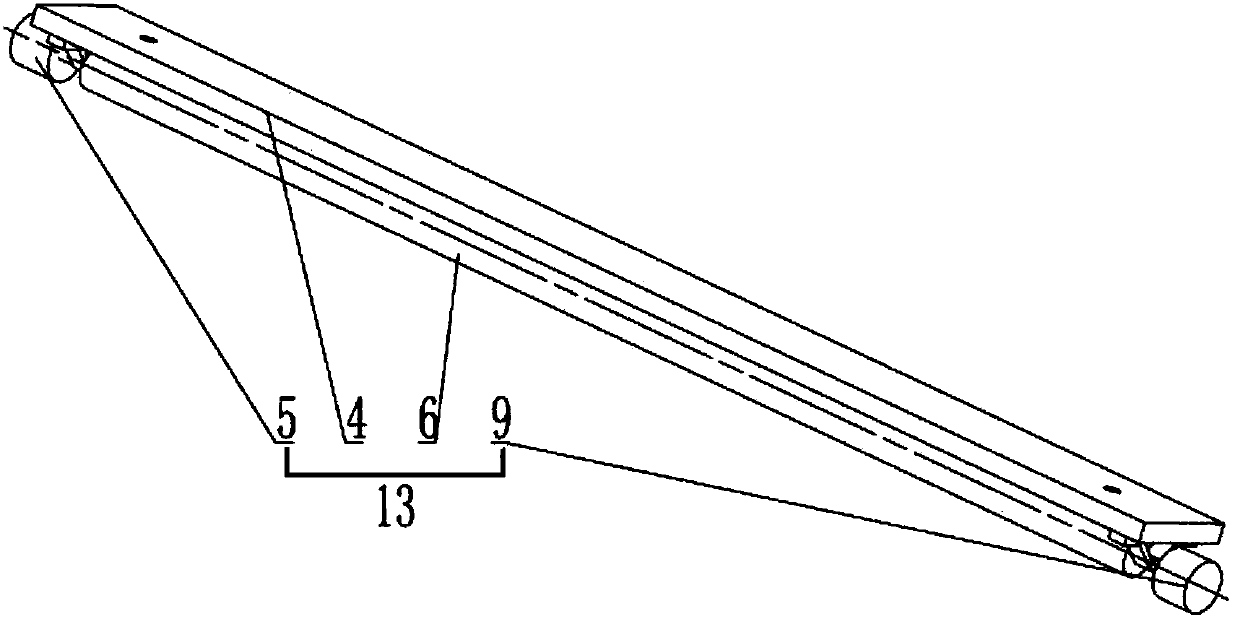

[0037] refer to Figure 1 to Figure 3 , a powder supply and spreading mechanism for a laser sintering 3D printer, comprising a control system 1, a powder supply cylinder 2, a level detector 7, a cylinder 3, a workbench 8, a guide rail 12 and a powder spreading and leveling mechanism 13.

[0038] In the present embodiment, the powder spreading and scraping mechanism 13 includes a frame 4, a first power unit 5, a second power unit 9, a powder supply and powder spreading cover 6, a powder outlet screen 14 and a screw powder feeding mechanism 15; The powder supply cover 6 is a cylindrical ring, and its length is consistent with the length of the workbench.

[0039] Any 1 / 4 circumference of the powder supplying and spreading cover 6 is provided with a powder outlet sieve 14, and its remaining 3 / 4 circumference is used as a scraper for scraping the powder on the workbench 8; powder In the powder supply and spreading set 6 , the powder outlet sieve 14 is evenly spread on the workben...

Embodiment 2

[0052] The difference between this embodiment and Example 1 is that the diameter of the powder outlet holes on the powder outlet sieve is 70um, the number of powder outlet holes on the powder outlet sieve is 2300, and the screw powder feeding mechanism and the powder outlet The gap between the insides of the powder supply and powder sets is 0.2mm; the purpose of this design is to adapt to the particle size of the powder. If the particle size of the powder is below 70um, the powder outlet sieve will filter the powder with a diameter greater than 70um, because in 3D printing Among them, the diameter of the powder that does not meet the requirements will reduce the printing quality; the powder output can be adjusted to adapt to the small area of the workbench and improve the efficiency of powder supply.

[0053] The working mode and other structures and connection modes of this embodiment are the same as those in Embodiment 1.

Embodiment 3

[0055] The difference between this embodiment and embodiment 1 is that the diameter of the powder outlet holes on the powder outlet sieve is 120um, the number of powder outlet holes on the powder outlet sieve is 546, and the screw powder feeding mechanism and the powder outlet The gap between the insides of the powder supply and powder sets is 0.1mm; its purpose is consistent with that described in Example 3, that is, if the particle size of the powder is below 120um, the powder outlet sieve will filter powders with a diameter greater than 120um, because in 3D printing , The diameter of the powder that does not meet the requirements will reduce the printing quality; the powder output can be adjusted to adapt to a large-area workbench and improve the efficiency of powder supply.

[0056] The working mode and other structures and connection modes of this embodiment are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com