Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

171 results about "Cutting agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cutting agent is a chemical used to "cut" (dilute or adulterate) recreational drugs with something less expensive than the drug itself.

Powder metallurgy transmission gear and manufacturing method thereof

ActiveCN102179519AHigh strengthHigh hardnessPortable liftingFurnace typesManufacturing cost reductionProduction rate

The invention discloses a powder metallurgy transmission gear which is prepared from the raw materials containing the following components in percentage by weight: 1-5% of nickel, 1-3% of copper, 0.5-2% of molybdenum, 0.5-0.9% of graphite, 0.6-0.9% of lubricant, 0.3-0.5% of cutting agent and the balance of ferrum. The invention also discloses a manufacturing method of the powder metallurgy transmission gear. The powder metallurgy transmission gear has good self-lubricating performance, can meet the requirement on different parts with various specifications of a transmission gear of an automatic overrun clutch, and can greatly reduce the manufacturing cost and increase the utilization ratio of materials and the production rate.

Owner:宁波金钟粉末冶金有限公司

Process for manufacturing main drive inner core of gasoline economizer for motorcycle

InactiveCN101733403AEasy to processHigh densityRoad transportFreewheel clutchesVolumetric Mass DensityMixed materials

The invention discloses a process for manufacturing the main drive inner core of a gasoline economizer for a motorcycle. The high-performance main drive inner core of the gasoline economizer for the motorcycle is manufactured with the powder metallurgy process including the material mixing process, the molding process and the sintering process and then with the mechanical processing process, the heat treating process, the surface treating process and the like. In the process of mixing the material, a small number of micronized wax is added to the material to be good for the molding of the work piece, and cutting agent of MnS is added to the material to be convenient for the subsequent mechanical processing of the work piece. The mixed material is molded at the high pressure of 600-800 Mpa so that the molded work piece has high density. The work piece is sintered at high temperature so that the copper powder permeates into the iron powder structure to improve the performance of the parts. In the invention, the material utilization ratio can be more than 95 percent, and the machining amount is less, thus the advantage that less cutting is needed in the powder metallurgy technology is fully reflected. The invention has the advantages of saving the material, simplifying the processing process and prolonging the service life of the work piece.

Owner:SHANDONG CHENGRUI POWDER METALLURGY

Combustion jet cutter used for steel structure member cutting

ActiveCN103182609ACombustion synthesis reaction is fastIncrease energy densityWelding apparatusPotassium nitrateEngineering

The invention discloses a combustion jet cutter used for steel structure member cutting. The combustion jet cutter consists of a jet cutter bottom, primer, a shell case, ignition agent, cutting agent and a nozzle, wherein thermite is based on plain thermit in the cutting agent; the plain thermit roughly accounts for 65-85wt% of the cutting agent; gas-forming agent is based on potassium nitrate which roughly accounts for 5-25wt% of the cutting agent; and slagging constituent and alloying agent roughly account for 7-20wt% of the cutting agent. During cutting, the combustion jet cutter is filled into a cutting gun, the cutting gun is held with a hand to aim at a cutting part, the jet cutter primer is triggered, inner ignition agent the jet cutter is ignited by the primer, the cutting agent is ignited by the ignition agent to generate high-temperature metallurgical melt and high-pressure gas, and a product is injected after being subjected to energy-gathering compression by the nozzle to locally melt the steel structure member so as to realize cutting. The jet cutter is mainly used for the quick thermal cutting and the underwater cutting of various steel structure members.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

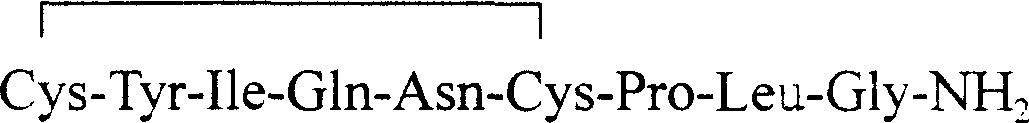

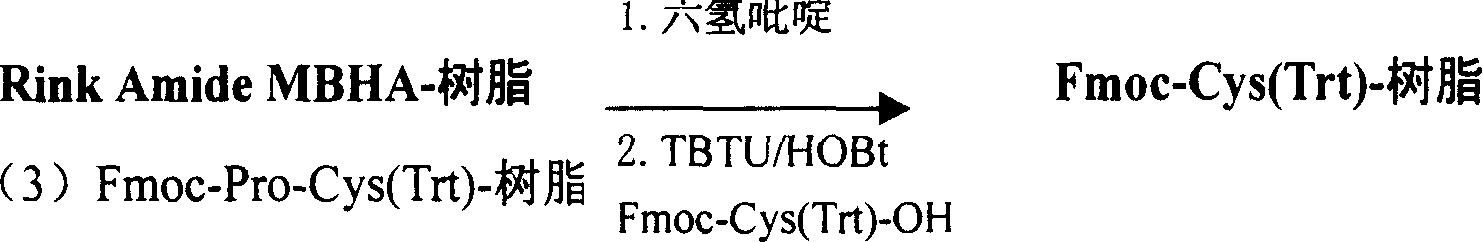

Preparation method of polypeptide solid-phase synthesis bivalirudin crude product

ActiveCN101555274ALow costHigh purityPeptide preparation methodsBlood disorderProtecting groupAmino acid supplementation

The invention discloses a preparation method of polypeptide solid-phase synthesis bivalirudin crude product. The preparation method comprises the following steps of: (1) mixing Fmoc-amino-acid resin or Fmoc-polypeptide resin and an unprotecting agent and removing Fmoc protecting group; (2) in the existence of a condensing agent, leading amino acid with Fmoc or Boc and amino acid or polypeptide onthe resin to carry out condensation; (3) repeating the step (1) and step (2) and obtaining polypeptide resin shown as formula II; and (4) in the existence of a cutting agent, leading the polypeptide and the resin on the polypeptide resin to be separated, and obtaining bivalirudin shown as formula I. The unprotecting agent contains 3 to 20 percent of piperidine and 0.5 to 10 percent of bicyclic amidine by total volume.

Owner:HAINAN SHUANGCHENG PHARMA

Preblend of microcrystalline cellulose and lactase for making tablets

A preblend for making lactase tablets is prepared containing about 1-99% (preferably about 200-60%) by weight lactase and about 1-99% (preferably about 40-80%) by weight microcrystalline cellulose. Lactase used in the preblend may be in combination with up to about 4 parts (preferably about 0.5-2 parts) by weight cutting agent such as sugars, starches, cellulose, and inorganic salts for each part by weight lactase. About 0.5-4% by weight lubricant such as magnesium stearate may be present in the preblend. A preferred preblend contains about 9.6 weight percent lactase and about 90 weight percent microcrystalline cellulose, or about 2000 to about 9000 FCC lactase units and from about 40 to about 80 weight percent microcrystalline cellulose. Another preferred preblend contains about 9.6 weight percent lactase, about 30.0 weight percent microcrystalline cellulose and about 59.4 weight percent mannitol. Each preblend may also contain magnesium stearate. A preferred lactase is from Aspergillus oryzae and the microcrystalline cellulose preferably has an average particle size of about 10-200 μm.

Owner:MCNEIL PPC INC

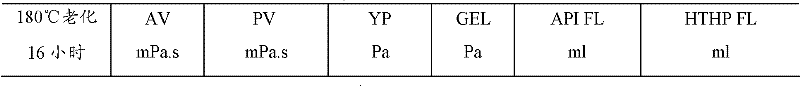

High-temperature-resistant clay-phase-free hypotonic reservoir stratum drilling fluid

The invention discloses high-temperature-resistant clay-phase-free hypotonic reservoir stratum drilling fluid, which can be absorbed quickly, has high inhibiting performance and causes little damage, which comprises the following components: 100 parts of sea water or fresh water, 0.2 to 0.5 part of fluid loss additive, 2.0 to 4.0 parts of high-temperature fluid loss additive, 0.2 to 0.5 part of extracting and cutting agent, 0.5 to 1.5 parts of high-temperature stabilizer, 0.5 to 1 part of water blocking agent and 10 to 233 parts of organic salt. The invention has the following advantages: (1) the drilling fluid can resist a temperature as high as 180 DEG C; (2) the rheological behaviour and water loss property of the drilling fluid are easy to control; (3) the drilling fluid can be well mixed with the fluid in a reservoir stratum with small damage to the reservoir stratum and is particularly suitable for hypotonic oil and gas reservoir; and (4) the drilling fluid can be applied to drilling completion operation of reservoir stratum sections of deep and medium-deep wells, particularly hypotonic reservoir stratums.

Owner:CHINA NAT OFFSHORE OIL CORP +1

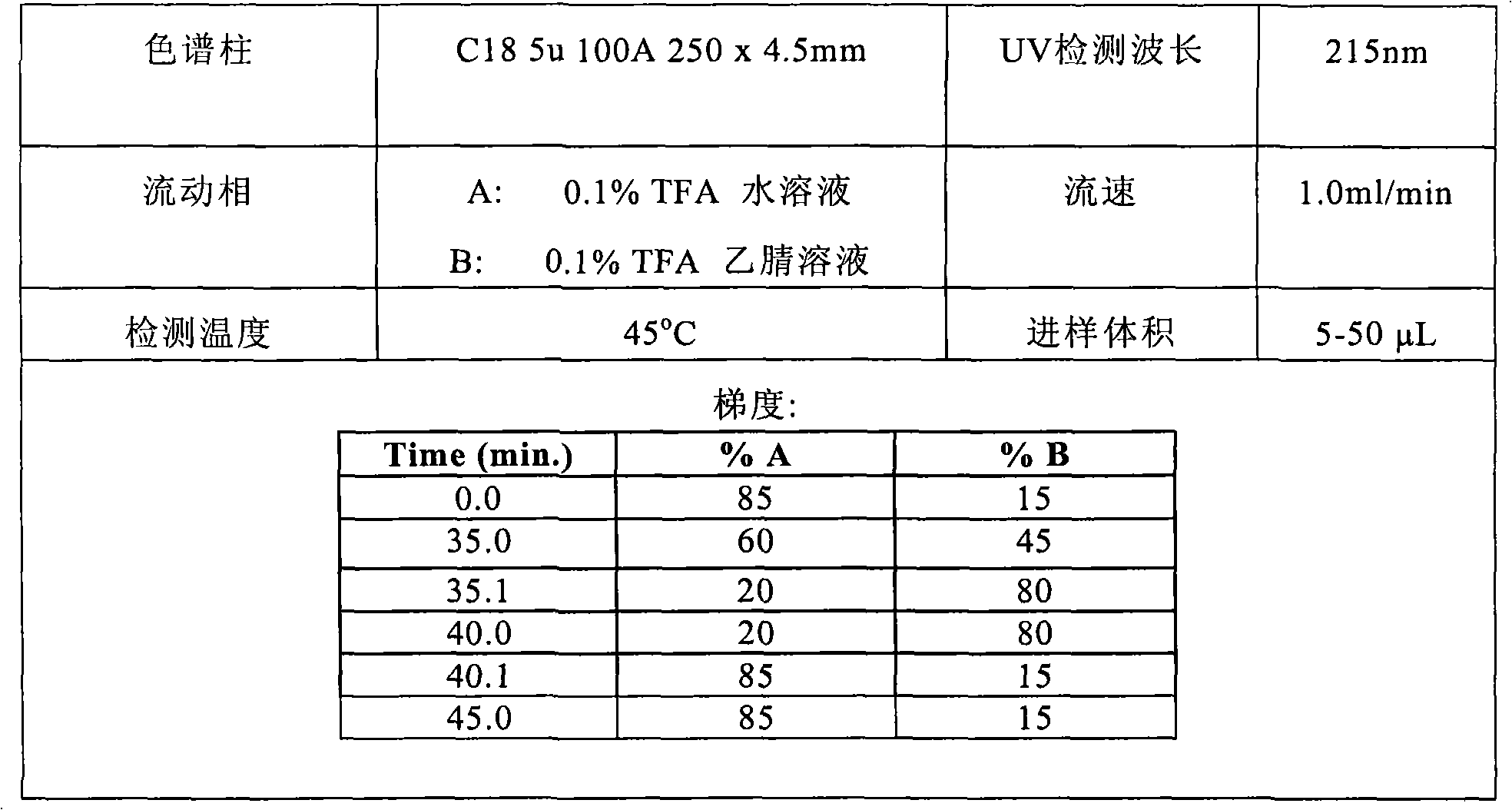

Preparing process for synthesizing oxytocin from solid-phase polypeptide

ActiveCN1990501AReduce usageSimple processOxytocins/vasopressinsPeptide preparation methodsProduction rateRink amide resin

The invention discloses a method for preparing oxytocin through solid phase polypeptide synthesis, comprising following steps: taking Rink Amide resin (comprising Rink Amide MBHA resin, Rink Amide Am resin) as raw material, taking amino acid protected by Fmoc, TBTU or HBTU / HOBt as condensing agent, making up amino acid in sequence; adding peptide cutting agent for peptide cutting, adding for precipitation and getting reduced coarse product; adding basic matter, feeding air for oxidation or oxiding with H2O2 with pH being 7.5- 10.0, getting oxidized coarse product; separating and purifying by using C18 or C 8 column and getting final product. The method is characterized by low production cost, simple process, little pollution, high production rate and convenience for industrial production.

Owner:SHANGHAI SOHO YIMING PHARMA

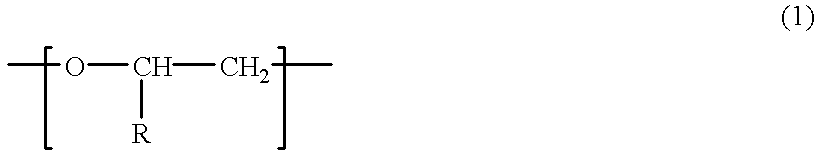

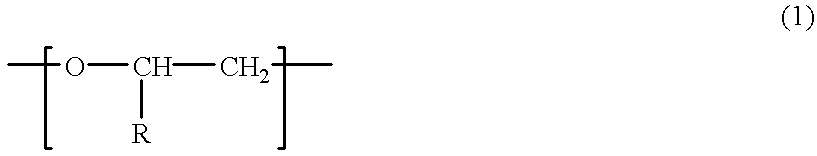

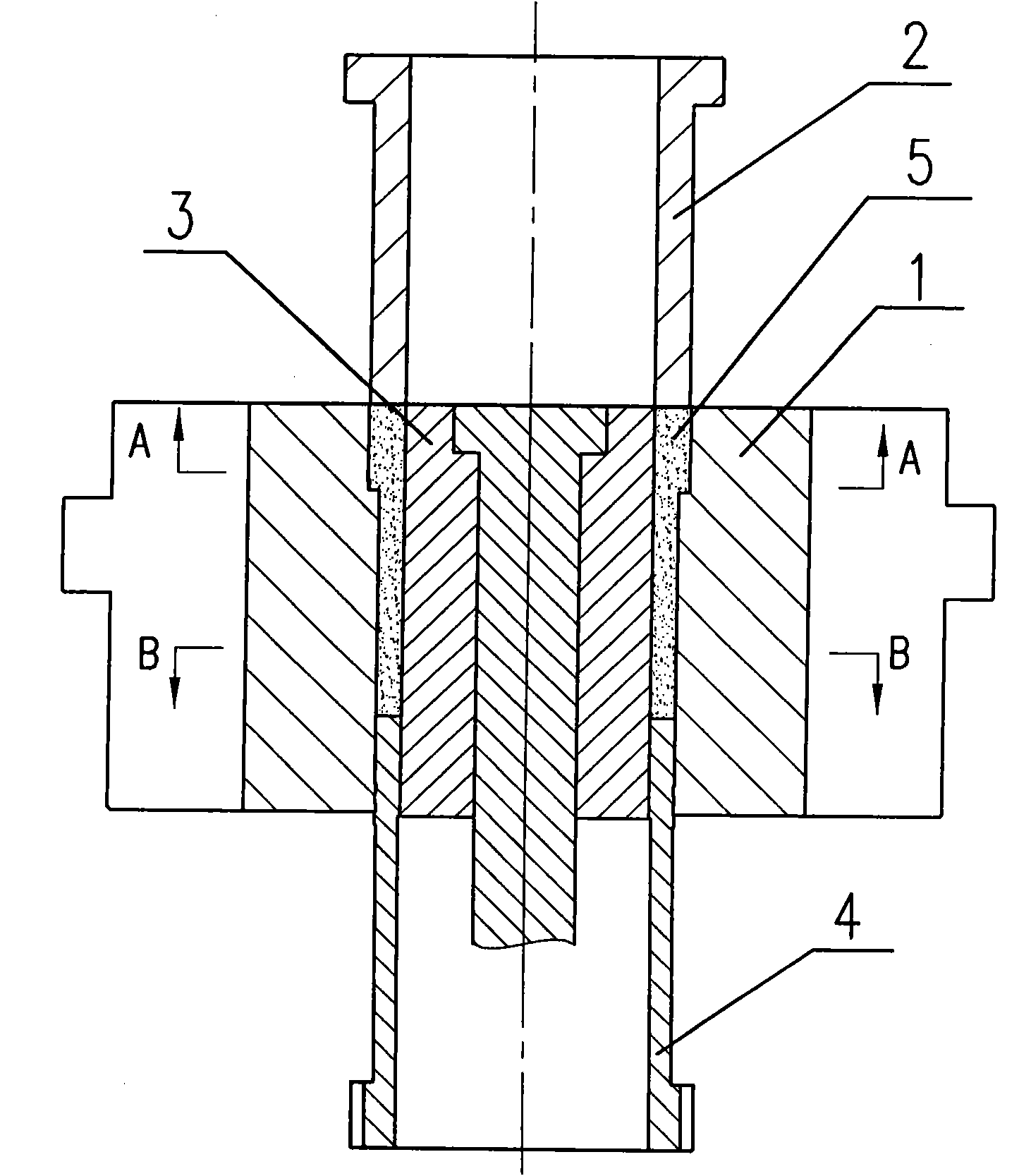

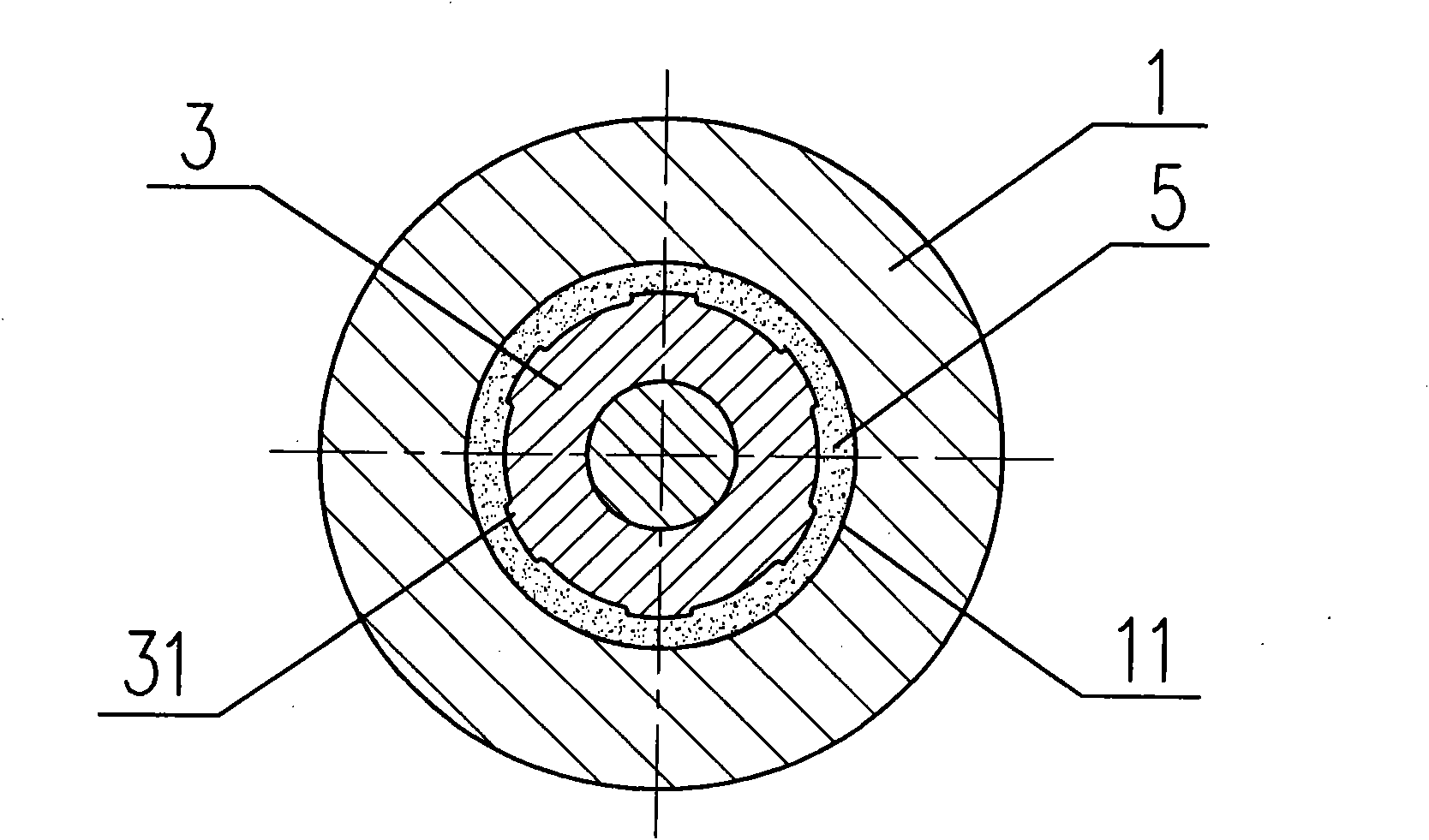

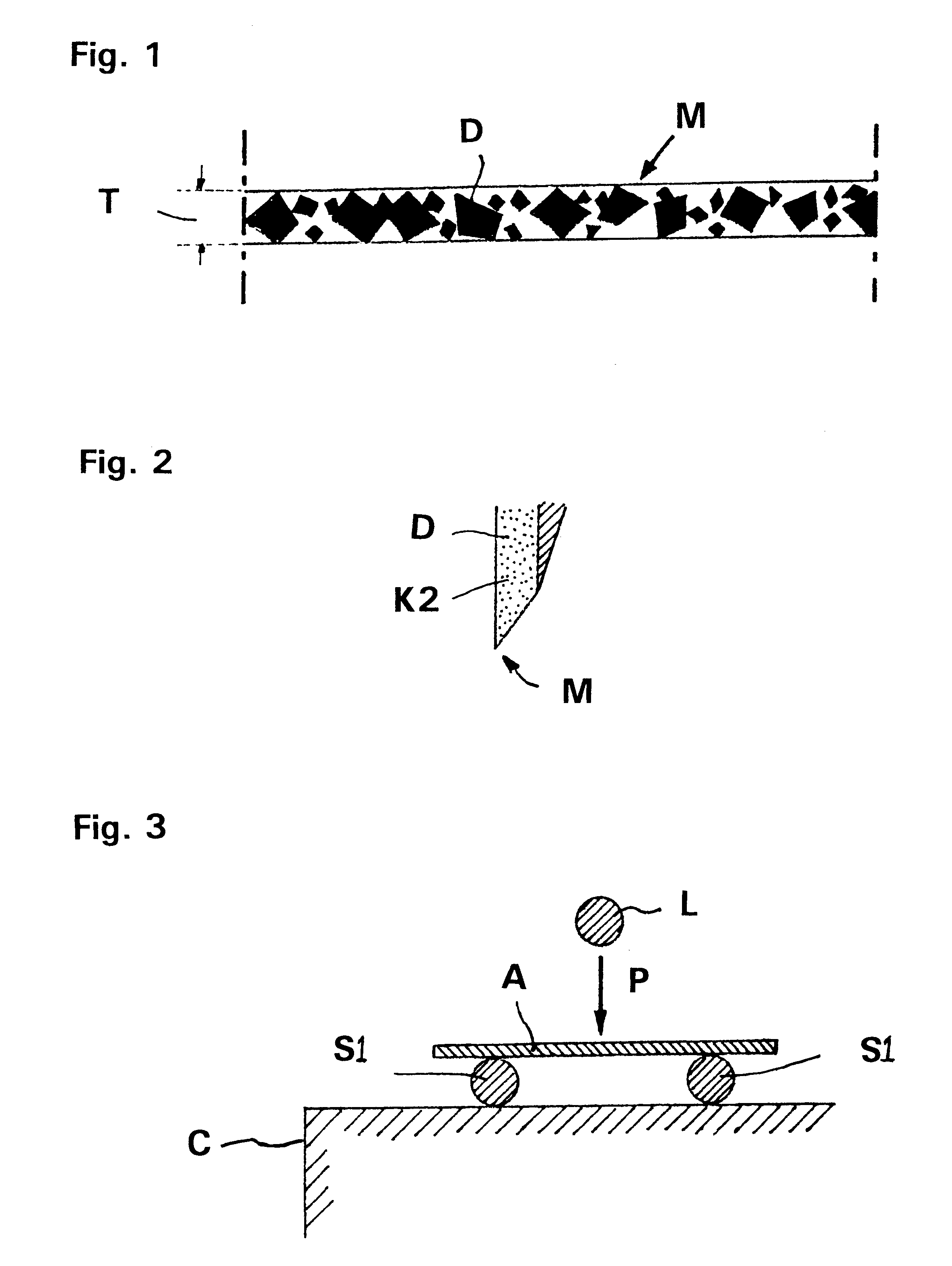

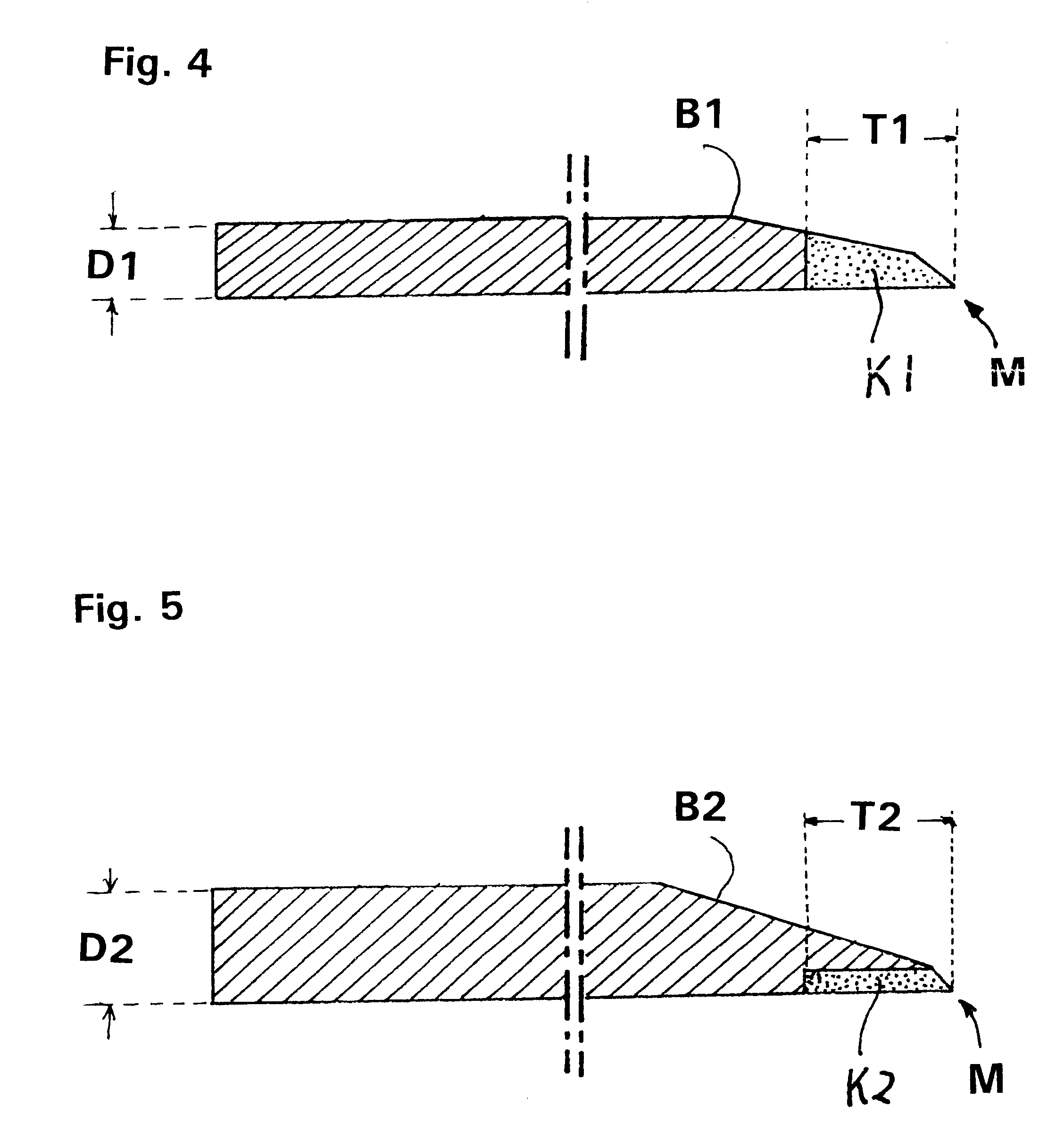

Aqueous cutting fluid, aqueous cutting agent, and process for cutting hard brittle materials with the same

InactiveUS6228816B1Good dispersionEasily re-dispersedWork treatment devicesLiquid carbonaceous fuelsDispersion stabilitySodium Bentonite

An aqueous cutting liquid comprises a cationic water-soluble resin having an amine value of 20 to 200 mgKOH / g, and at least one rheology control agent selected from the group consisting of an inorganic bentonite, an organic bentonite and an aqueous silica sol, wherein the content of a nonvolatile matter of the rheology control agent is 0.1 to 30 percent by weight of the amount of the nonvolatile matter of the cationic water-soluble resin. An aqueous cutting agent comprises the aqueous cutting liquid, and an abrasive grain, wherein the content of the abrasive grain is 100 to 1000 percent by weight of the amount of the nonvolatile matter of the aqueous cutting liquid. A hard and brittle material is cut by a cutting device using the aqueous cutting agent. The present invention provides an aqueous cutting agent which is excellent in dispersion stability of the abrasive grain and viscosity stability during cutting / slicing operations, aqueous cutting liquid usable for the aqueous cutting agent, and a cutting / slicing method excellent in cutting performance, cleanability and the like of the work material on cutting / slicing hard and brittle material by using the cutting agent.

Owner:NOF CORP +1

Lubrication cutting agent and preparation method thereof

ActiveCN103865617AImprove the finishReduce wearLubricant compositionTriethylamine phosphateSuccinic acid

The invention provides a lubrication cutting agent and a preparation method thereof. The lubrication cutting agent comprises: 10-40 parts of sulfurized cutting oil, 5-10 parts of naphthenic oil, 2-6 parts of triethyl phosphate, 1-4 parts of dinonyl naphthalene barium sulfonate, 0.2-1.5 parts of 1,2,6-butylated hydroxytoluene, 0.5-2.8 parts of dodecyl phenyl succinic acid, 1-5 parts of stearic acid, 0.1-1.2 parts of triethanolamine boric acid ester, 0.5-3.2 parts of sodium citrate, 0.3-1.2 parts of polyacrylamide, 12-18 parts of sodium dodecyl benzene sulfonate, 0.01-0.1 part of dodecenylsuccinic acid, 1-7 parts of oleamide, 5-13 parts of ethylenediamine tetraacetic acid tetrasodium, 0.2-0.8 part of chlorinated paraffin and 10-20 parts of hydrophilia polyhydric alcohols. The preparation method comprises steps of firstly, uniformly mixing a part of the components, and secondly, adding the rest components. The lubrication cutting agent provided by the invention has remarkable effects on improving the surface smoothness of a workpiece and alleviating abrasion of a cutter.

Owner:上海德润宝特种润滑剂有限公司

Iron core for engine cooling fan and manufacturing process thereof

ActiveCN102034585AIncrease profitImprove product qualityInorganic material magnetismInductances/transformers/magnets manufactureIron powderHigh volume manufacturing

The invention discloses an iron core for an engine cooling fan and a manufacturing process thereof. The iron core is a powder metallurgical material prepared from the following raw materials by weight percent: 0.01-1.0% of phosphorus, 0.1-1.5% of free cutting agents, 0.2-2% of lubricating agents, 0.01-1.5% of binding agents and the balance iron powder. The manufacturing process of the iron core comprises the steps of material mixing, forming, sintering, sealing, reshaping, auxiliary machining and surface treatment. The invention has the following beneficial effects: a powder metallurgy process is simple and reliable, ensures that the production efficiency and material utilization are greatly improved, and is especially suitable for mass production; and the iron core product formed by a mould has the advantages of stable quality, high machining precision, low manufacturing cost, good sealing property, capability of reducing the weight of the engine when the iron core is used for the engine cooling fan, low energy consumption, obvious oil saving effect, improvement of the overall property of the engine cooling fan and the like, and is convenient and safe in assembly.

Owner:LAIZHOU SANWANG POWDER METALLURGY

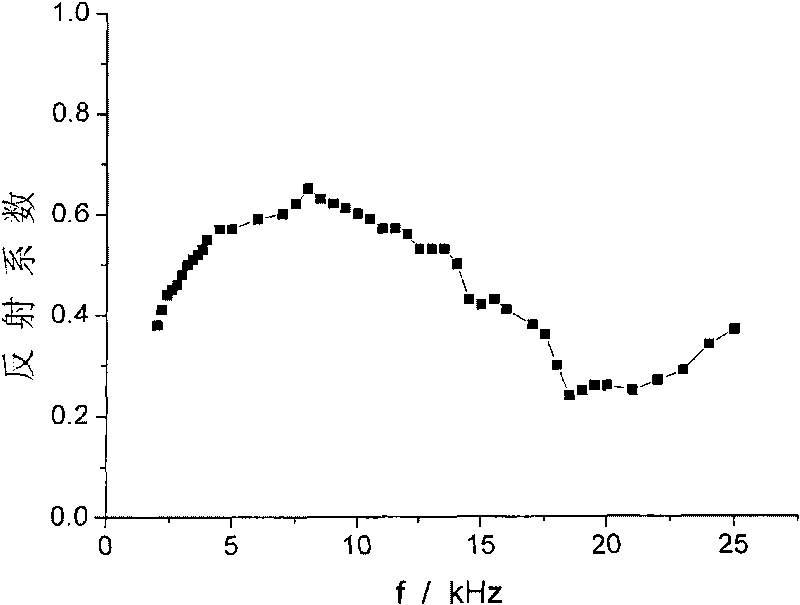

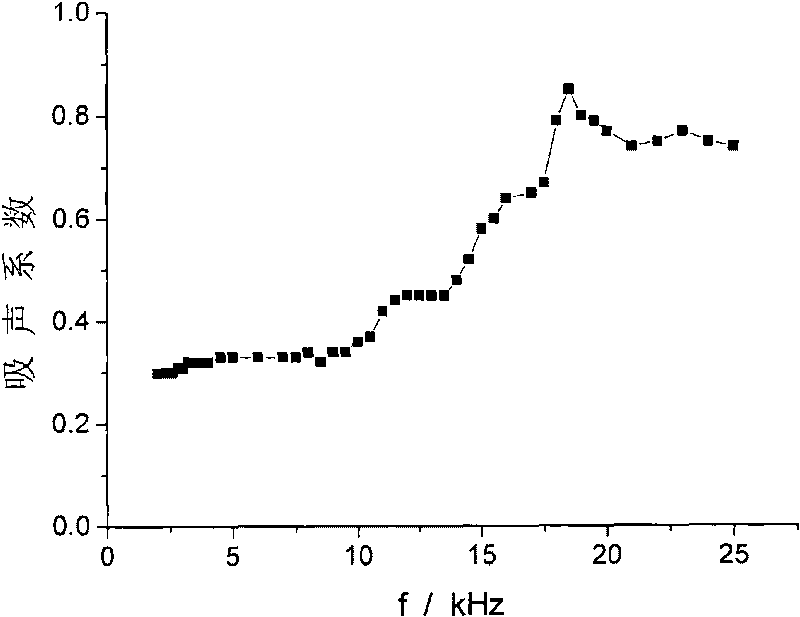

Low-density underwater sound absorbing plate and preparation method thereof

InactiveCN101719367AImprove the sound absorption coefficientLow densitySynthetic resin layered productsSound producing devicesVacuum pumpingUnderwater

The invention relates to a low-density underwater sound absorbing plate mainly used for an underwater sandwich structure core and a preparation method thereof. The sound absorbing plate effectively absorbs sound and has relatively low density. The sound absorbing plate is molded by separately pouring and curing an upper layer and a lower layer, wherein the upper layer comprises the following raw materials in percentage by weight: 55-75 percent of matrix resin, 10-20 percent of filler, 10-30 percent of curing agent and 1-5 percent of auxiliary agent; the lower layer comprises the following raw materials in percentage by weight: 40-65 percent of matrix resin, 15-30 percent of filler, 15-40 percent of cutting agent and 1-5 percent of auxiliary agent; the fillers contain hollow glass beads with grain sizes of 10-800 micrometers; and the thickness ratio of the upper layer to the lower layer is 1:(3-5). The preparation method comprises the following steps of: dewatering the raw materials of the upper layer and the lower layer; respectively proportioning and weighing the raw materials according to a range of 0.75-0.8 of the relative density of the whole plate and the content of the components of the upper layer and the lower layer; preheating the matrix resin of the upper layer and the lower layer; adding the fillers and then adding the auxiliary agents and the curing agents so as to ensure that the fillers are sufficiently dispersed in the matrix resin; initiating crosslinking and carrying out vacuum-pumping treatment on the raw materials; and then pouring the raw materials into a mold by adopting a layered pouring and curing method that the upper layer is firstly poured and then the lower layer is poured.

Owner:NAVAL UNIV OF ENG PLA

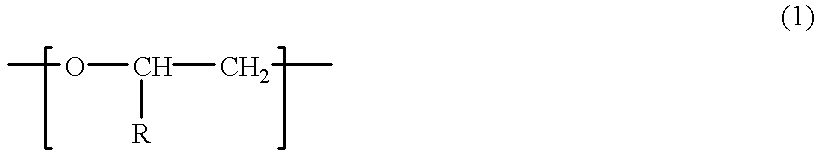

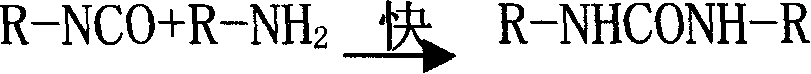

Environmentally friendly track rubber, and its production method and track construction method using same

ActiveCN1580163ALow TDI contentLow toxicityGround pavingsPolyurea/polyurethane coatingsAlcoholAdditive ingredient

The invention publishes a kind of environmental plastic raceway. It is composed by polyether diatomic alcohol, polyether triatomic alcohol, TDI, PAPI, filling, ph chain cutting agent and others accessory ingredient. The invention also publishes the manufacturing methods. The process contains polyalcohol water after polyether, prepolymerization, adding filling and accessory ingredient, filtering and packaging. The construction contains cleaning up the base, lay down bottom, laying down frade lamella, spinkling colloidal particle, coating surface glue and marking out. The invention, environmental plastic raceway, has many advantages, such as innocuity, convenient manufacture, transport and construction, and good physics capability.

Owner:深圳市奥顺达体育有限公司

Powder metallurgy material used for pressing and sintering exhaust seat ring

The invention provides a powder metallurgy material used for pressing and sintering an exhaust seat ring. The powder metallurgy used for pressing and sintering the seat ring comprises the following components in percentage by mass: 0.8 to 1.3 percent of C, 1.5 to 3.0 percent of Cr, 1.0 to 3.0 percent of Mo, 3.0 to 6.5 percent of Co, 0.5 to 2.0 percent of Ni, 0.8 to 1.5 percent of MnS, 0.05 to 0.3 percent of P, 0.2 to 0.5 percent of V, 0.2 to 3.0 percent of W, and the balance Fe and unavoidable impurities. After the W is added, a hard particles is formed, and the power metallurgy material has higher wear resistance, impact resistance, corrosion resistance, and abrasion resistance at a high temperature, so that the bench testing time of the exhaust seat ring can reach 450 hours. Due to the addition of fatty acid diamide, the problem of furnace chamber scaling in a sintering process is solved; and by adding an anti-segregation agent and a free-cutting agent, the segregation of a finished product is avoided, the cutting is facilitated, and the size precision and surface roughness of a cutting surface are ensured.

Owner:CHANGSHU SHUANGYUE MACHINERY

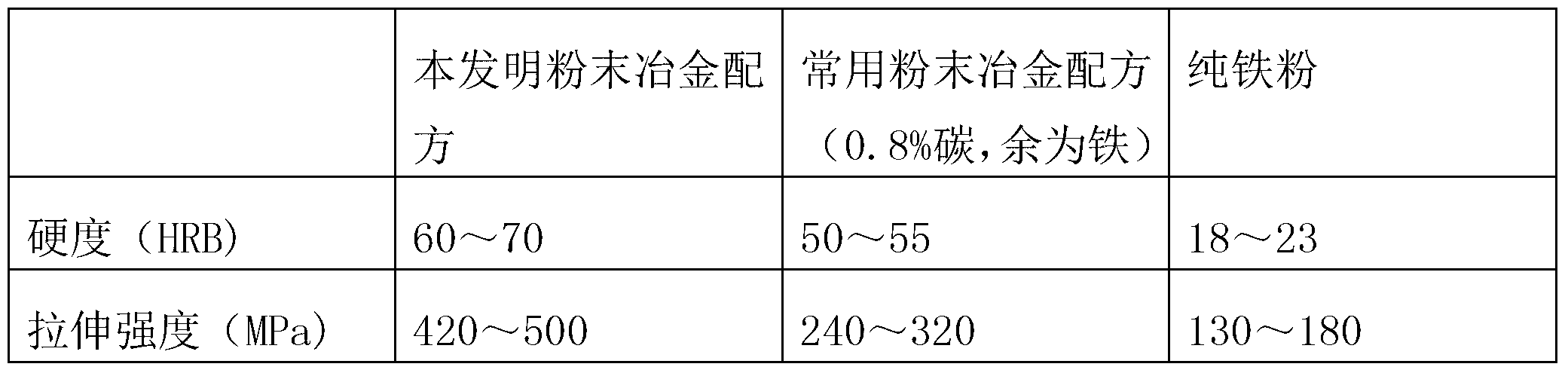

Powder metallurgical formula and technology

The invention provides a powder metallurgical formula and technology. The powder metallurgical formula comprises the following raw materials: 48-88 percent of atomized iron powder, 10-50 percent of reducing iron powder, 0.4-1.5 percent of graphite powder, 1-3.9 percent of electrolytic copper, 0.3-1.5 percent of micro powder paraffin, 0.1-0.9 percent of easily cut agent and 0.1-0.9 percent of enhancer. The powder metallurgical formula consists of the following steps of mixing, pressing, sintering, fining, deburring and steaming. According to the powder metallurgical formula and technology, the tensile strength and the hardness of a product are improved; and by optimization of the technical steps, the production efficiency is improved, and the waste of energy is reduced.

Owner:山西鑫晟新材料有限公司

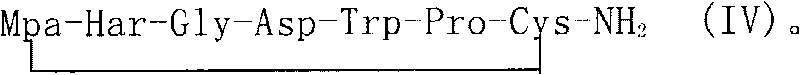

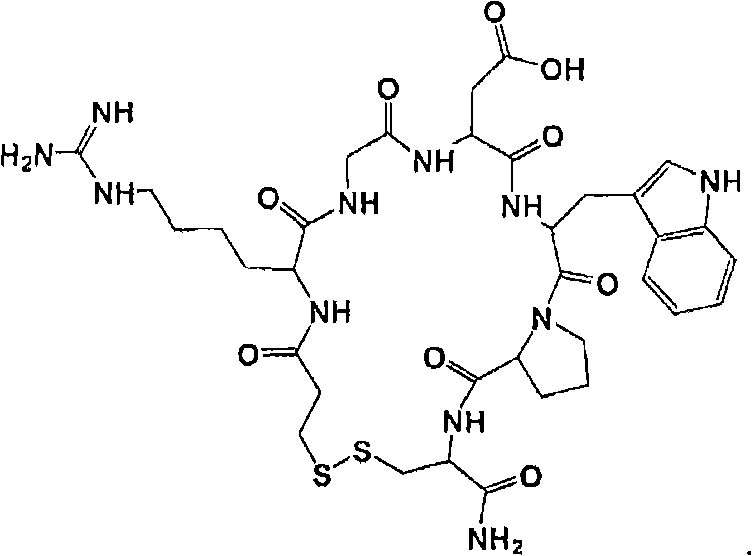

Process for preparing solid phase polypeptide synthetic eptifibatide

ActiveCN1858060AConvenient sourceHigh peptide yieldPeptide preparation methodsPropanoic acidRink amide resin

The preparation process of solid phase polypeptide synthesized eptifibatide includes the following steps: (1) connecting amino acids one by one with Rink Amide resin, Rink Amide MBHA resin or Rink Amide AM resin as initial material, and Fmoc protected amino aids as monomer, with the last peptide chain being S-benzyl mercapto propionic acid Map(SBzl); (2) adding peptide cutting agent (TFA / HBr / HAc / TIS / EDT) to cut peptide; (3) precipitating and collecting coarse reductant eptifibatide product in ether solvent; (4) dissolving coarse reductant eptifibatide product in water, regulating pH value with ammonia water to 7.5-10.0, introducing air for oxidation, and collecting coarse eptifibatide product; and (5) separating and purifying the coarse product in C18 column to obtain the target product. The present invention has high yield, and is suitable for industrial production.

Owner:SHANGHAI SOHO YIMING PHARMA

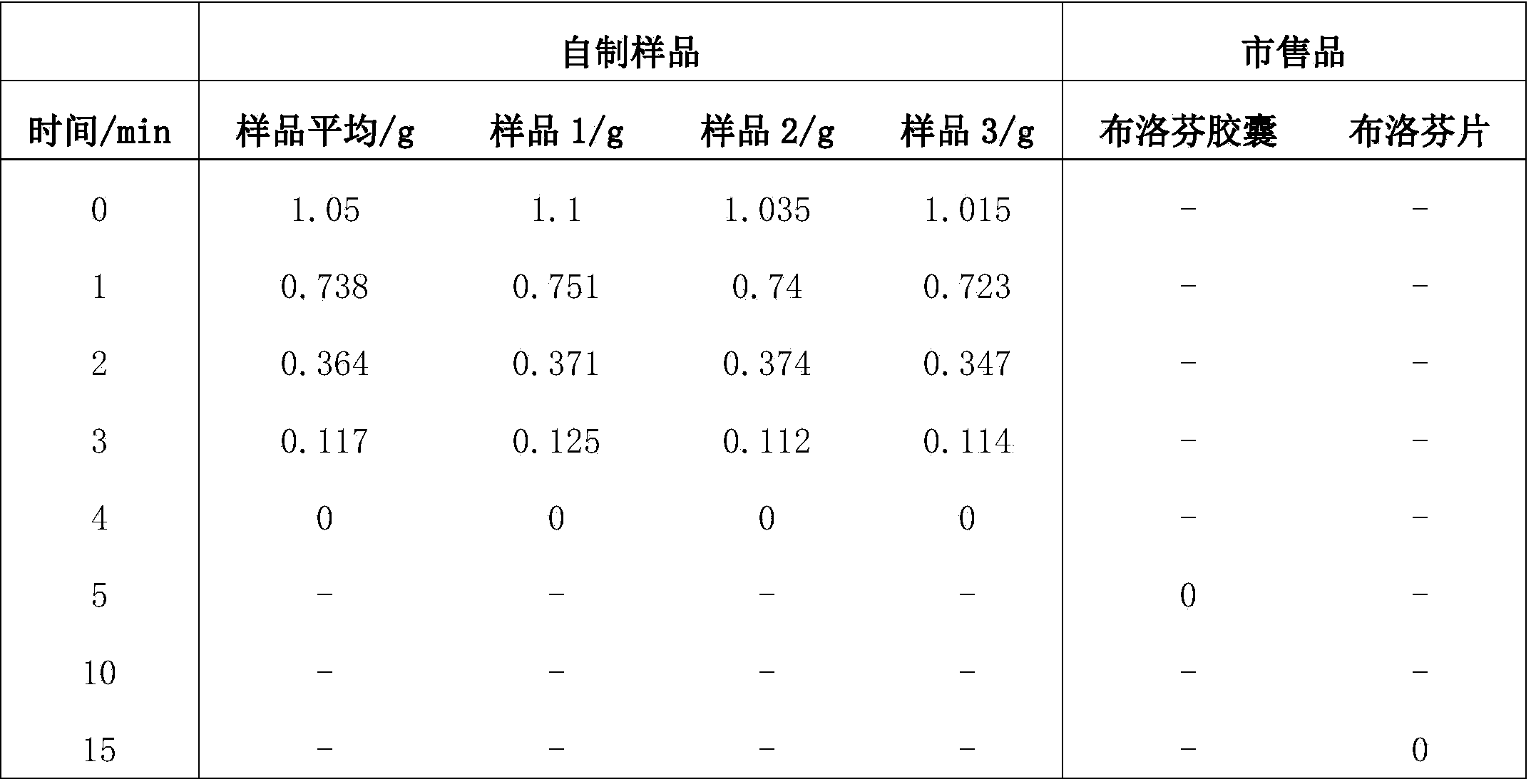

Oral ibuprofen pellet xerogel and preparation method thereof

ActiveCN103784396AGood taste masking effectImprove stabilityOrganic active ingredientsAntipyreticFiller ExcipientAdhesive

The invention relates to oral ibuprofen pellet xerogel and a preparation method thereof. The oral ibuprofen pellet xerogel comprises ibuprofen pellets evenly distributed in a xerogel matrix, wherein the xerogel matrix contains a xerogel forming agent, a curing agent, a sweetening agent, an aromatic and a preservative. The oral ibuprofen pellet xerogel consists of, by weight, raw materials including ibuprofen 20-100 parts, filler 10-100 parts, binding agent 5-60 parts, pellet coating material 2-20 parts, xerogel forming agent 100-400 parts, cutting agent 5-30 parts, sweetening agent 10-2000 parts, aromatic 10-50 parts and preservative 1-15 parts. The oral ibuprofen pellet xerogel has the advantage of being high in pharmaceutical stability, exquisite in appearance, good in taste, convenient to take, high in bioavailability, good in patient (especially children) medication compliance, accurate in dosage, simple in preparation process, convenient to carry and transport and suitable for industrial production.

Owner:黑龙江童医生儿童生物制药有限公司

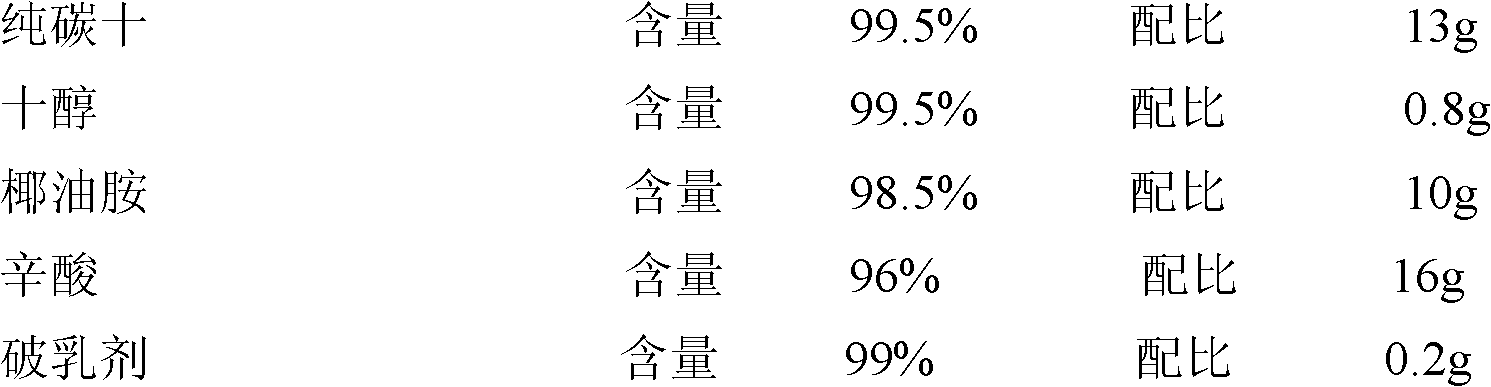

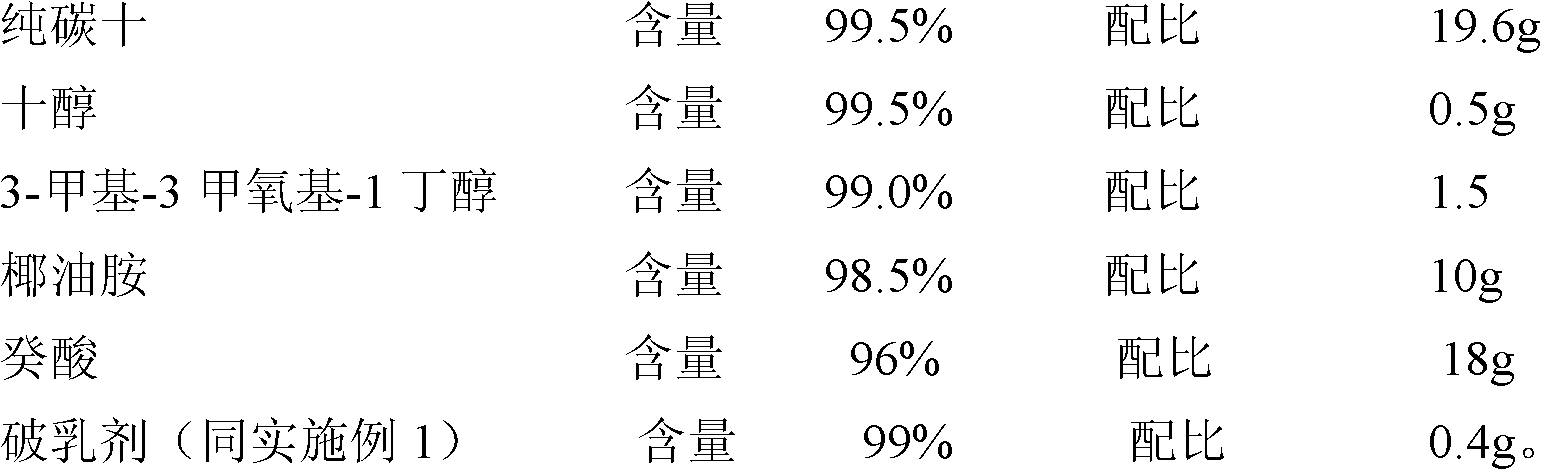

Environment-friendly type cleaning water cutting agent and preparation method thereof as well as displacer for same

ActiveCN102330106AThe mechanism of action is simple and scientificEasy to useLiquid displacementHydrocarbon solventsEmulsion

The invention relates to an environment-friendly type cleaning water cutting agent and a preparation method thereof as well as a displacer for the same. The environment-friendly type cleaning water cutting agent comprises the following components calculated according to weight percentage: 95-98 percent of solvent and 2-5 percent of displacer, wherein the displacer comprises the following components calculated according to weight percentage: 1-5 percent of alcohols solvents, 20-30 percent of filming amine, 30-40 percent of organic carboxylic acid, 0.3-0.8 percent of emulsion splitter and hydrocarbon solvent of which the amount is supplemented to 100 percent. The preparation method is realized by sequentially mixing various components. The environment-friendly type cleaning water cutting agent disclosed by the invention has strong cleaning function; more importantly, the environment-friendly type cleaning water cutting agent can be used for quickly removing water brought by a previous work procedure for cleaning parts; and the removed water is deposited at the bottom of a cleaning agent and is drained through the bottom of a rinse tank by using a pollution discharge mode, thus the service life of the cleaning agent is prolonged by over 3 months.

Owner:华阳新兴科技(天津)集团有限公司

Methods and Compositions for Screenless Completion

Methods are provided that include a method of a) placing a hydrojetting tool into a subterranean formation; b) introducing a jetting fluid that includes an aqueous base fluid, a stabilizing agent, and a cutting agent into the subterranean formation by use of the hydrojetting tool at a rate sufficient to create at least one fracture; c) introducing a slug fluid that includes an aqueous base fluid and a degradable diverting agent into an annulus formed between the hydrojetting tool and the subterranean formation; d) introducing a propping fluid that includes an aqueous base fluid and proppants coated with a consolidating agent into the annulus formed between the hydrojetting tool and the subterranean formation; and e) placing the proppants in the fracture.

Owner:HALLIBURTON ENERGY SERVICES INC

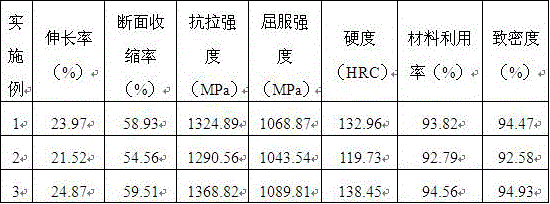

Powder metallurgical gear

InactiveCN106001548AUniform densityHigh densitySolid state diffusion coatingCarbon fibersPolyethylene glycol

The invention discloses a powder metallurgical gear. The powder metallurgical gear is prepared from water atomization iron powder, copper powder, molybdenum powder, vanadium powder, nickel powder, yttrium powder, aluminum powder, magnesium powder, cobalt powder, lead powder, steel slag powder, iron-melted furnace slag powder, ferroalloy slag powder, modified tree ash powder, graphite powder, amino resin, polyether modified silicone, hydroxypropyl methyl cellulose, zinc stearate, polyethylene glycol, ethylene bisstearamide, stearic acid, carbon fibers, glass fibers, boron nitride, epoxypropoxy propyl trimethoxysilane, silicon dioxide, manganese sulfide, acrylate, an inhibitor, a binder, an enhancer, a cutting agent, a lubricant, a coupling agent and a dispersing agent. According to the powder metallurgical gear, by means of specific composition proportion, the overall density is uniform, the compactness is high, the elongation and reduction of cross section are high, the abrasion resistance, strength and hardness are good, the material utilization rate is high, and the materials are suitable for rapidly producing high-performance gears on large scale.

Owner:黄宇

Solid phase polypeptide synthesis preparation method for thymopoietin pentapeptide

ActiveCN1865279AReduce usageReduce manufacturing costPeptide preparation methodsEtherCombinatorial chemistry

The invention discloses a preparing method of thymic pentagon through solid-phase polypeptide, which comprises the following steps: (1) adopting CTC resin (or Wang resin) as original material, Fmoc protected amino acid as monomer, TBTU / HOBt (or HBTU / HOBt) as condensing agent to connect amino acid sequently; utilizing Boc-Arg-OH for the last peptide chain; adding the endope cutting agent in the product of step (1) to cut peptide; adding ether to deposit; collecting crude product; (3) adapting C18 or C8 pillar to proceed separating and purifying the crude product in the step (2) to obtain the object product.

Owner:SHANGHAI SOHO YIMING PHARMA

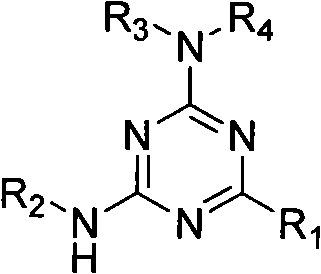

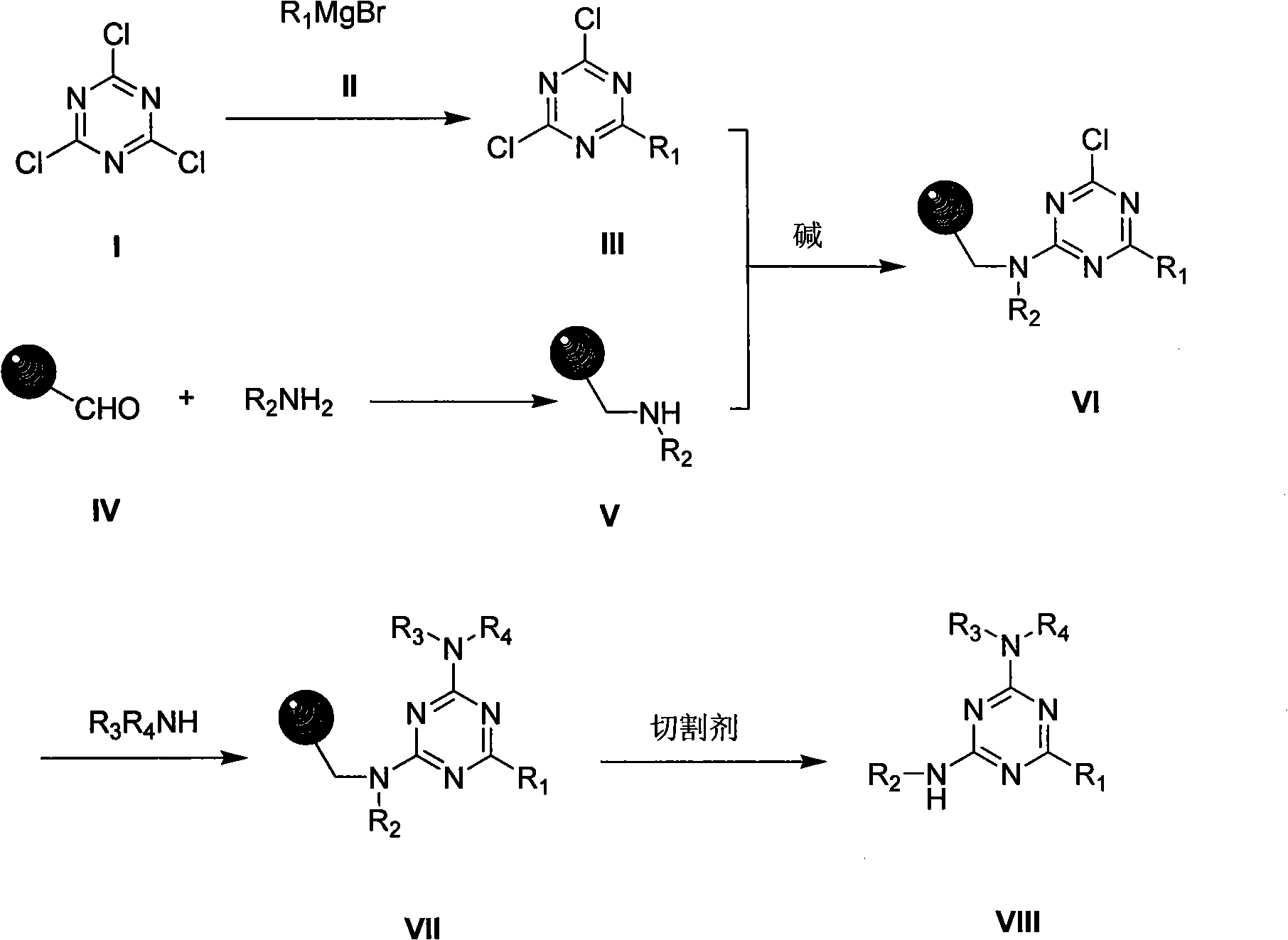

2,4,6-tri-substituted-1,3,5-triazine derivates library and preparation method

InactiveCN101307029ASynthetic conditions are mildRaw materials are easy to getOrganic chemistryOrganic compound librariesOrganic solventTriazine derivative

The invention provides a solid phase synthesis method for a 2, 4, 6-trisubstituted-1, 3, 5-triazine derivative library. The method comprises the following steps that: aldehyde group resin reacts with primary amine in organic solvent; resin containing a secondary amine structure is obtained through reductive amination; the resin reacts with 2, 4, 6-trisubstituted-1, 3, 5-triazine so as to obtain resin connected with a triazine mother ring, and then the resin reacts with primary amine or secondary amine so as to have 6-chlorine replaced; finally a formed product is cut from the resin through a cutting agent, so as to obtain a 2, 4, 6-trisubstituted-1, 3, 5-triazine derivative with molecular diversity. The 2, 4, 6-trisubstituted-1, 3, 5-triazine derivative provided by the invention is moderate in synthesis condition, easy to get raw materials, high in yield and beneficial to high-throughput screening and the discovery of anti-cancer anticancer drug lead compounds.

Owner:ZHEJIANG UNIV

High-wear-resistance automobile shaft component powder metallurgy material

InactiveCN106270495AImprove performanceHigh densityTransportation and packagingMetal-working apparatusPolyvinyl chlorideTitanium carbide

The invention discloses a high-wear-resistance automobile shaft component powder metallurgy material. The high-wear-resistance automobile shaft component powder metallurgy material comprises the following raw materials: iron powder, chromium powder, molybdenum powder, copper powder, nickel powder, lead oxide powder, yttrium powder, titanium carbide powder, tantalum carbide powder, tin powder, zinc oxide powder, alumina powder, graphene powder, tetramethylolmethane, stearic acid, polyvinyl chloride fiber, basalt fibers, ethylene glycol monoethyl ether acetate, hypromellose, ethylene bisstearamide, chlorinated paraffin, glycidoxypropyl trimethoxysilane, silicon carbide, manganous sulphide, alcohol acid resin, an inhibitor, a binding agent, a reinforcing agent, a cutting agent, a lubricant, a cross-linking agent, a dispersant and a regulator. By the specific ingredient proportion, the high-wear-resistance automobile shaft component powder metallurgy material is uniform in integral density, high in compactness, high in extend rate and percentage reduction of area, good in wear resistance, strength and hardness and high in material utilization rate, and is suitable for quickly producing the high-performance automobile shaft component powder metallurgy material on a large scale.

Owner:GUANGXI NANNING ZHICUI SCI TECH CONSULTATION CO LTD

Diamond containing edge material

InactiveUS6447569B1Edge nicking and tippingMinimal damagePigmenting treatmentOther chemical processesTitaniumTitanium alloy

A blade material, containing diamond particles below about 100 mum in diameter, is formed as a cutting material where the diamond particles serve as cutting agents while being fixed in a retaining matrix. The retaining matrix substantially includes Titanium or a Titanium alloy containing more than about 50 wt % of Titanium and fixes the diamond particles in place through a multi-step process.

Owner:SUETA KIMIKO

Novel powder metallurgy transmission gear

InactiveCN105970106AUniform densityLarge elongationTransportation and packagingMetal-working apparatusCarbon fibersSlag

The invention discloses a novel powder metallurgy transmission gear. The novel powder metallurgy transmission gear is prepared from water-atomized iron powder, copper powder, molybdenum powder, vanadium powder, nickel powder, yttrium powder, aluminum powder, magnesium powder, cobalt powder, lead powder, steel slag powder, cupola slag powder, iron alloy slag powder, modified tree ash powder, graphite powder, China wood oil-based alkyd resin, dimethyl silicone oil, ethylcellulose, zinc stearate, polyethylene glycol, ethylene bis stearamide, fatty acid, carbon fibers, glass fibers, boron nitride, epoxypropoxy trimethoxypropylsilane, silicon dioxide, manganese sulfide, acrylate, an inhibitor, a bonder, a reinforcer, a cutting agent, a lubricant, a coupling agent and a dispersant. Through the specific ingredient proportion, the novel powder metallurgy transmission gear is uniform in overall density, high in compactness, large in elongation and section shrinkage rate, good in wear resistance, strength and hardness, high in material utilization rate and suitable for large-batch rapid production of high-performance gears.

Owner:黄宇

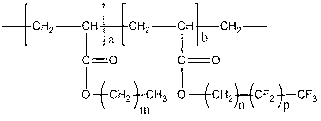

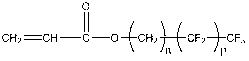

Fluorine-containing oil-based drilling fluid extracting and cutting agent and preparation method thereof

ActiveCN103289657ARaw materials are easy to getSimple manufacturing processDrilling compositionPolymer sciencePolymer solution

The invention provides a fluorine-containing oil-based drilling fluid extracting and cutting agent and a preparation method thereof. The preparation method comprises the following steps according to the ratio: a, adding 10-300g of acrylic ester and 0.1-60g of perfluoroalkyl ethyl acrylic ester into 1L of dimethyl sulfoxide solvent, and stirring at room temperature until acrylic ester and perfluoroalkyl ethyl acrylic ester are completely dissolved; b, adding 0.1-10g of azodiisobutyronitrile into a dissolved solution obtained in the step a, stirring until azodiisobutyronitrile is dissolved, then placing the dissolved solution in a thermostatic waterbath at the temperature of 25 DEG C, stirring and introducing nitrogen for 25-35 minutes; c, increasing temperature of a solution obtained in the step b to 50-80 DEG C, and reacting for 4-36 hours to obtain a polymer solution; and d, placing the polymer solution obtained in the step c into a mixed solution of absolute acetone and absolute ether in volume ratio of 1:1, and drying and smashing sediments to obtain the fluorine-containing oil-based drilling fluid extracting and cutting agent product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Automobile shaft component powder metallurgy material

InactiveCN106623891AImprove performanceHigh strengthTransportation and packagingMetal-working apparatusTitanium carbideBoron fiber

The invention discloses an automobile shaft component powder metallurgy material. The automobile shaft component powder metallurgy material comprises the following raw materials of iron powder, chromium powder, molybdenum powder, copper powder, nickel powder, lead oxide powder, yttrium powder, titanium carbide powder, tantalum carbide powder, tin powder, zinc oxide powder, aluminum oxide powder, graphene powder, pentaerythritol, stearic acid, boron fibers, basalt fibers, polypropylene resin, hydroxypropyl methylcellulose, ethylene-bis-stearamide, polyethylene wax, epoxy propoxy propyl trimethoxy silane, silicon carbide, manganous sulphide, tributoxyethyl phosphate, an inhibitor, a binder, an enhancer, a cutting agent, a lubricating agent, a cross-linking agent, a dispersing agent and an adjusting agent. According to the automobile shaft component powder metallurgy material, by means of the specific composition proportion, the automobile shaft component powder metallurgy material is uniform in overall density, high in density, large in ductility and percentage reduction of area, good in wear resistance, strength and hardness and high in material utilization rate, and high-performance automobile shaft component powder metallurgy materials can be produced fast on a large scale.

Owner:GUANGXI NANNING ZHICUI SCI TECH CONSULTATION CO LTD

Method for synthesizing eptifibatide

InactiveCN101759776ASimple stepsEasy to operatePeptide preparation methodsBulk chemical productionDegree of substitutionCutting agent

The invention provides a method for synthesizing eptifibatide. The method comprises the steps of: (1) condensing Fmoc Rinklinker with AM resin having a degree of substitution of 0.8 to 1.2 mmol / g, so as to acquire a Fmoc-polypeptide resin, (2) mixing the Fmoc-polypeptide resin with a protective agent and removing the Fmoc protecting base so as to acquire a protected polypeptide resin, (3) condensing the protected amino acid of the Fmoc with the protected polypeptide resin by using the condensing agent, (4) repeating the step (2) to step (3) so as to acquire a hexapeptide resin, (5) condensing the hexapeptide resin with Mpa(Trt)-OH so as to acquire a heptamer resin, (6) separating the heptamer from the resin by using cutting agent so as to acquire the crude product of eptifibatide, and (7) oxidizing and cyclizing the crude product of eptifibatide in order to acquire the eptifibatide. The method of the invention can promote the yield of the eptifibatide, decrease the cost and promote the purity.

Owner:SHANGHAI AMBIOPHARM

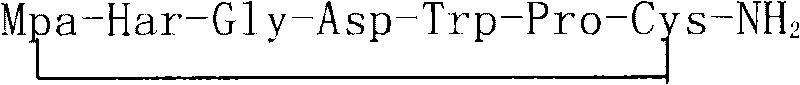

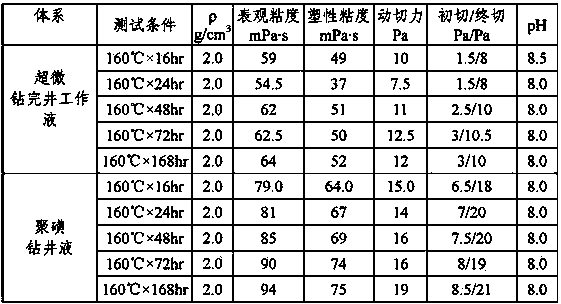

Ultrafine high-density well-drilling/completing working fluid for protecting ultra-deep tight sandstone gas reservoirs and preparation method thereof

The invention relates to an ultrafine high-density well-drilling / completing working fluid for protecting ultra-deep tight sandstone gas reservoirs and a preparation method thereof. The ultrafine high-density well-drilling / completing working fluid for protecting ultra-deep tight sandstone gas reservoirs comprises the following raw materials in parts by weight: 100 parts of water, 4-12 parts of a dispersant, 5-15 parts of formate, 2-5 parts of a high-temperature-resistant salt-resistant composite sulfonate copolymer, 0.1-0.5 part of a high-temperature-resistant lifted cutting agent, 5-12 parts of a compound plugging agent, and 120-300 parts of a mineral powder weighting agent; and the density of the ultrafine high-density well-drilling / completing working fluid is 1.7-2.3 g / cm<3>. The invention also provides the preparation method of the ultrafine high-density well-drilling / completing working fluid. The ultrafine high-density well-drilling / completing working fluid provided by the invention is suitable for drilling high-pressure gas reservoir layers of deep wells and ultra-deep wells, and under the density condition of 1.8-2.3 g / cm<3>, the temperature resistance can reach 180 DEG C; and in the stage of well completing, the working fluid has a long-term static high-temperature-resistant suspension stabilizing capacity, and satisfies oil-testing well completion operations of deep wells and ultra-deep wells, therefore, the working fluid is a high-temperature-resistant, high-pressure-resistant and hypersalinity-resistant well-drilling / completing working fluid with good performances.

Owner:BAZHOU DADE PETROLEUM TECH

Oil-based drilling fluid extracting and cutting agent and preparation method thereof

ActiveCN105623625AIncrease dynamic shear forceImprove temperature stabilityDrilling compositionCutting forceSolvent

The invention provides an oil-based drilling fluid extracting and cutting agent and a preparation method thereof. The method comprises the following steps: maleic anhydride and styrene are subjected to a polymerization reaction under existence of a solvent and an initiator to obtain a mixture; the obtained mixture is subjected to a reaction under existence of an alcohols compound and a catalyst to obtain an extracting and cutting agent crude product; and the obtained extracting and cutting agent crude product is subjected to removal of an organic solvent, and then is dried and crushed to obtain the oil-based drilling fluid extracting and cutting agent. The oil-based drilling fluid extracting and cutting agent has a long straight chain alkyl group and contains a lot of polar groups, net structures are formed by the long chain alkyl group in an oil-based drilling fluid through association action, the polar groups in molecules are capable of interacting with other groups through electrostatic attraction or hydrogen bond, so that the net structure with larger specific surface area is formed, and the existence of the net structures effectively increases the dynamic cutting force of the drilling fluid.

Owner:BC P INC CHINA NAT PETROLEUM CORP

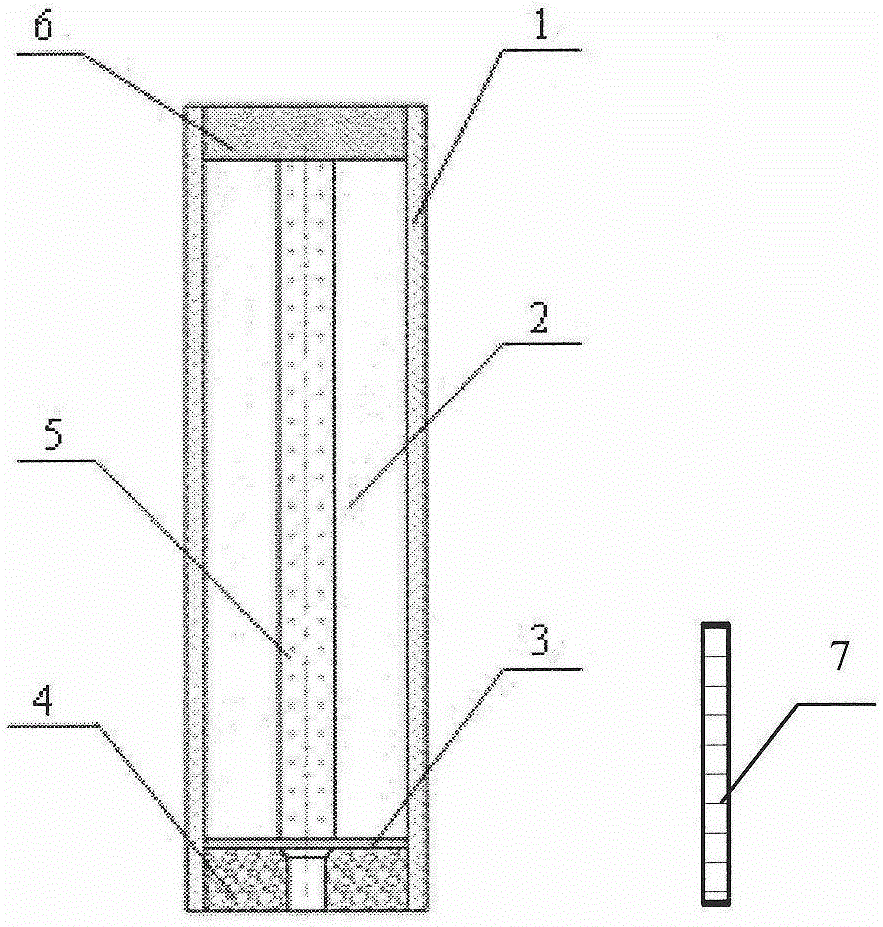

Solid thermit jet cutter

ActiveCN106238933ASimple structureStable structureWelding/cutting media/materialsSoldering mediaPlastic materialsHigh energy

The invention discloses a solid thermit jet cutter. The solid thermit jet cutter includes a shell case, a plug, a rapid combustion agent, a cutting agent, a separating sheet, a nozzle and a fuse; the shell case is a paper tube; the plug is made of a high-temperature resistance plastic material or a ceramic material; the high energy cutting agent is a hollow structure compressed by mixed solid powder; a channel is filled with the rapid combustion agent, and a solid dual-grain structure is formed; the straight-flow type nozzle made of a graphite material is arranged on the internal front end of the cutter; the separating sheet is arranged between the nozzle and the cutting agent and the rapid combustion agent; and the fuse is a special hard columnar inflammable material. During cutting, the jet cutter is arranged in a special cutting torch, the fuse is introduced from the nozzle, the rapid combustion agent is ignited after the fuse is ignited, the rapid combustion agent ignites the inner wall of the grain instantly, a high-temperature product is gathered and compressed via the nozzle and then is ejected to fuse and combust a cutting piece locally, and then the high-temperature product is blown down by high-pressure gas, and manual thermit cutting can be achieved. The jet cutter is simple in structure, is easy and reliable to operate, is high in cutting efficiency, is wide in application, and can be used for rapid emergent thermal cutting without electricity, gas, and devices.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com