Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Increase dynamic shear force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of utilizing nanometer silicon dioxide to improve properties of water-based drilling fluid at different temperatures

ActiveCN103013469AImprove the blocking effectImprove stabilityDrilling compositionWater basedFiltration

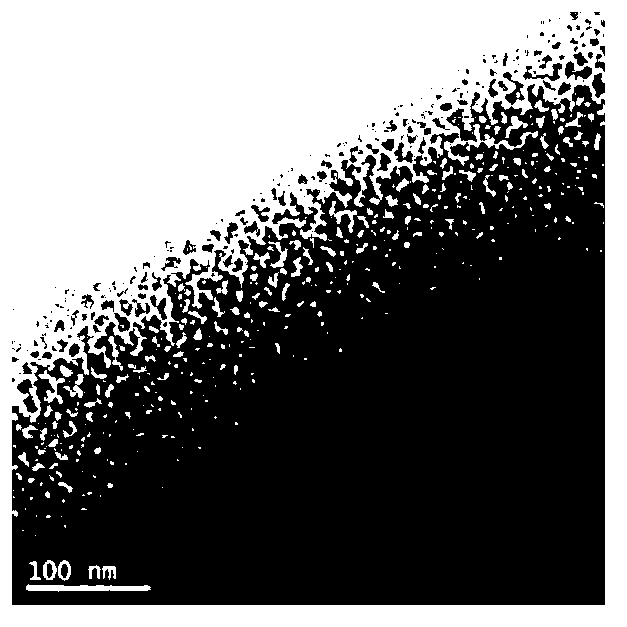

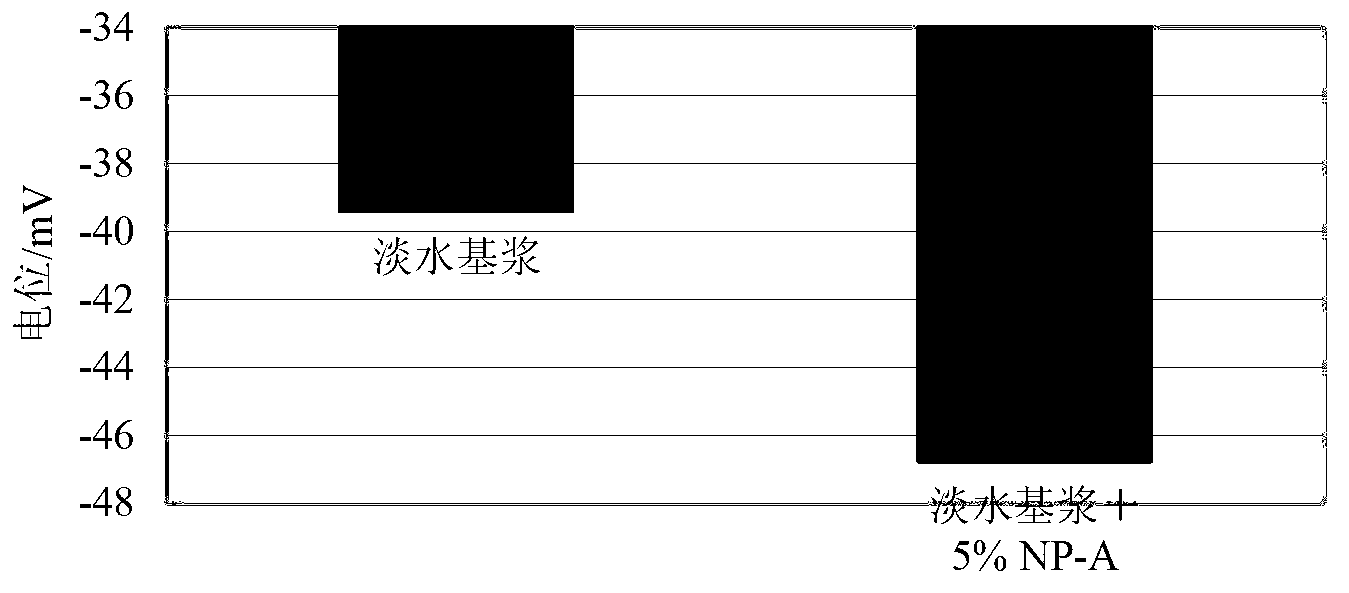

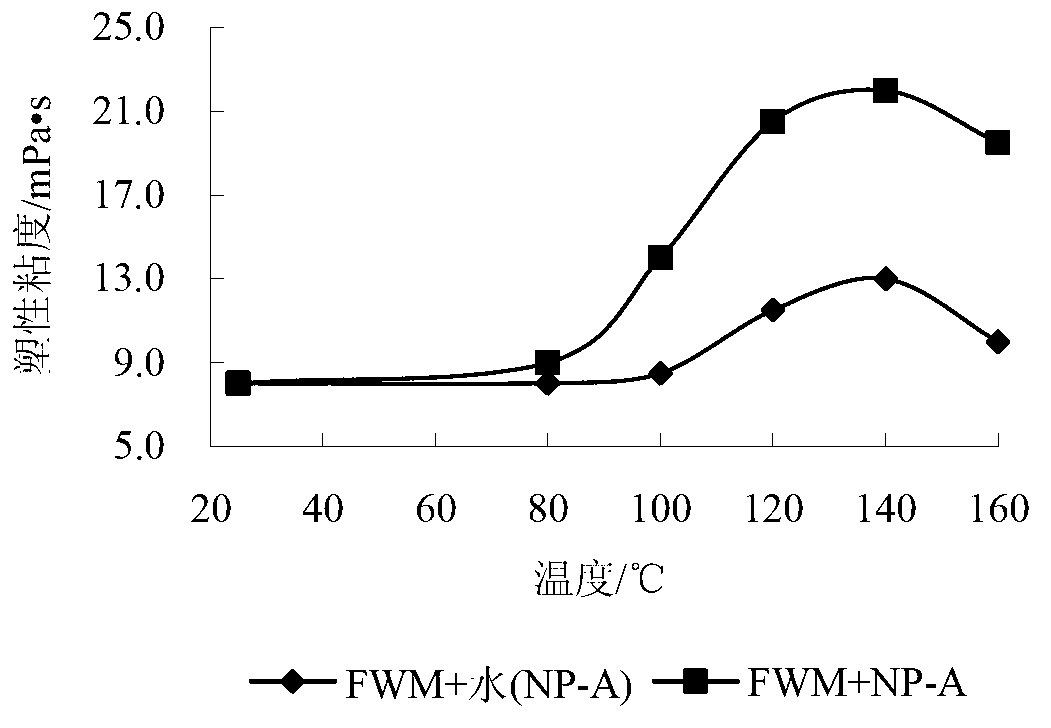

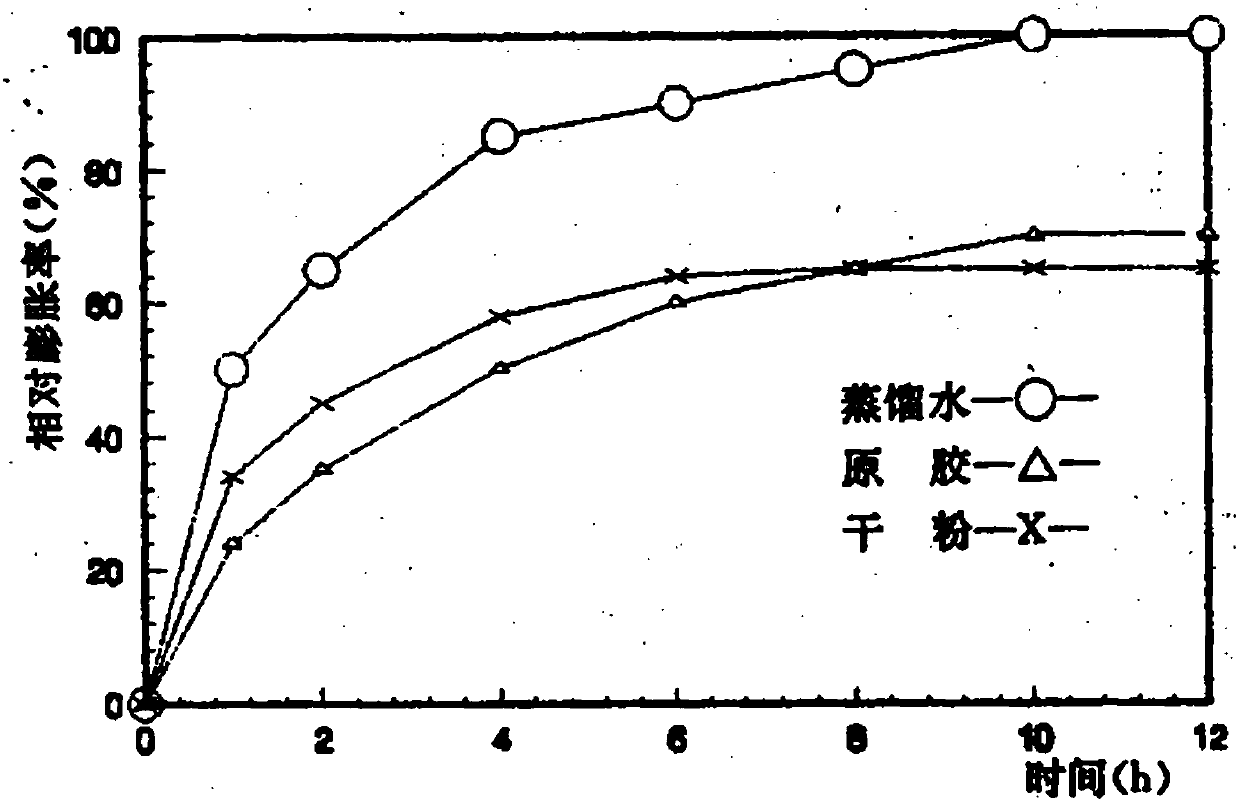

The invention provides a method of utilizing nanometer silicon dioxide to improve properties of water-based drilling fluid at different temperatures. The method comprises a step of adding a nanometer silicon dioxide dispersing agent into base mud, wherein the mass of the nanometer silicon dioxide particle in the nanometer silicon dioxide dispersing agent is 5-10% of total mass of the base mud and the nanometer silicon dioxide dispersing agent. Due to the nano-scale particle size, the nanometer silicon dioxide material can be filled into small holes and cracks of the shale stratum to improve the plugging effect of the water-based drilling fluid, slow down the trend of permeation of the drilling fluid to the stratum and expansion and chipping of the stratum after water absorption, and improve the stability of the borehole wall. The nanometer silicon dioxide can strengthen the stability of fresh-water base mud and bentonite base mud by increasing the negative charge level of the system. The nanometer silicon dioxide also can enable the base mud to form thinner and compact mud cakes and facilitate the de-filtration effect to be obvious.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

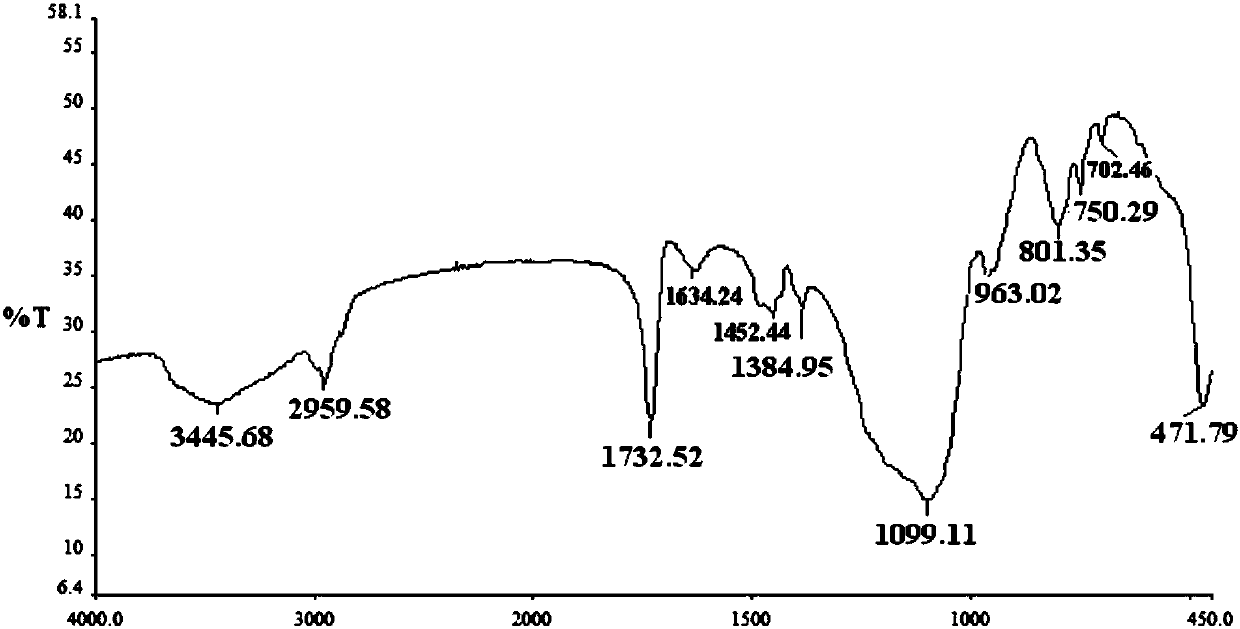

Dimer acid-organic amine copolymer, preparation method and application thereof, water-in-oil emulsified drilling fluid shear strength improving agent and drilling fluid

ActiveCN104893691AIncrease dynamic shear forceHigh ratio of dynamic plasticOrganic compound preparationCarboxylic acid amides preparationDimer acidAniline

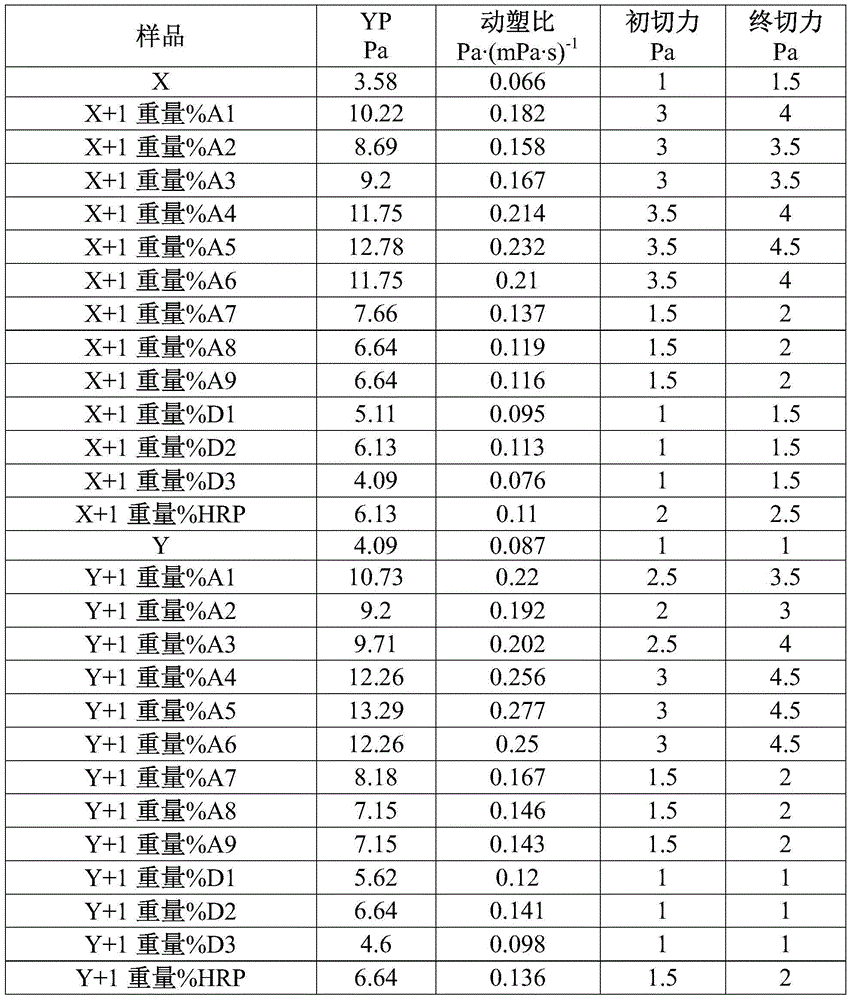

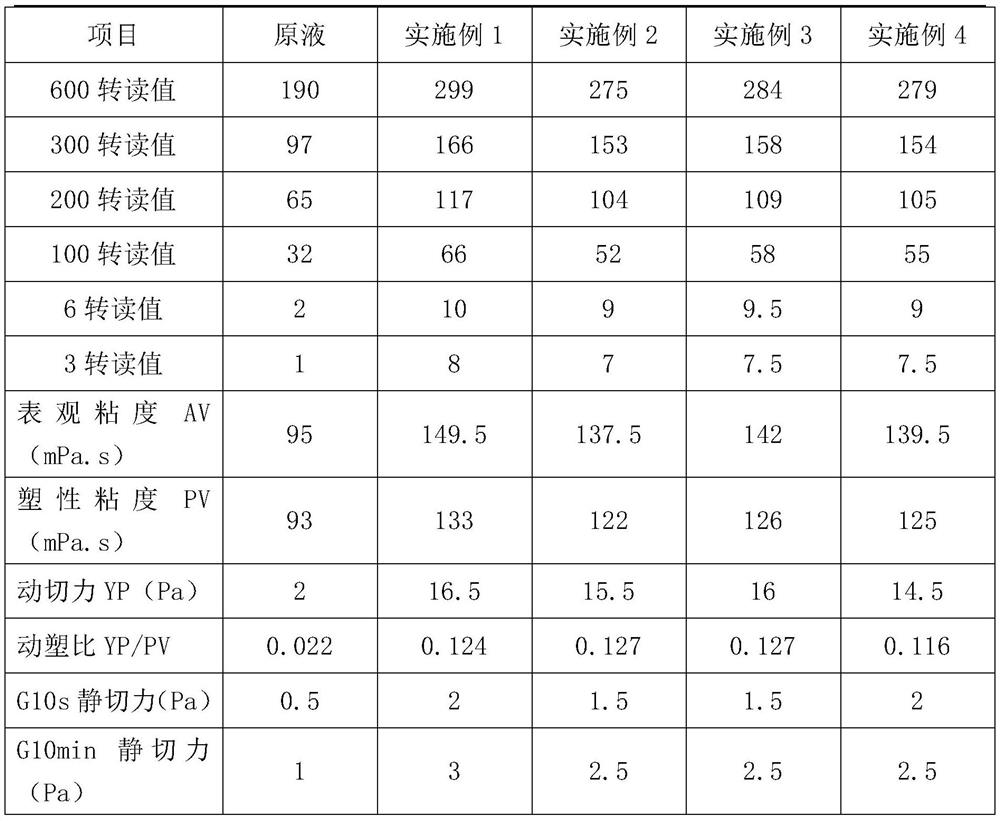

The invention relates to a dimer acid-organic amine copolymer which comprises a structural unit from dimer acid, a structural unit from alkylamine and a structural unit from aromatic amine, wherein the dimer acid is an oleic acid-linoleic acid dimer; the alkylamine is one or more of C10-C20 alkyl primary amines, and the aromatic amine is aniline and one or more of anilines of which the benzene ring is subjected to single-point substitution or multipoint substitution by C1-C3 alkyl. The invention also relates to a preparation method of the dimer acid-organic amine copolymer, application of the dimer acid-organic amine copolymer as a shear strength improving agent, a water-in-oil emulsified drilling fluid shear strength improving agent, and a drilling fluid containing the shear strength improving agent. The shear strength improving agent provided by the invention can obviously enhance the dynamic shear force, dynamic plastic ratio and static shear force of the water-in-oil emulsified drilling fluid under the condition of lower consumption, and can be used in the water-in-oil emulsified drilling fluid which contains or does not contain organic soil.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Process for preparing drilling fluid for preventing polycrystalline diamond compact (PDC) bit balling

InactiveCN101892036AImprove anti-slump performanceImprove integrityDrilling compositionCelluloseWater dispersible

The invention relates to a process for preparing drilling fluid, in particular to a process for preparing the drilling fluid for preventing polycrystalline diamond compact (PDC) bit balling. The process comprises a construction process and a dosage formula of treating agents and is characterized in that: according to the dosage formula, the treating agents are prepared by mixing clear water polymer original slurry, poly anionic cellulose (PAC), calcium carbonate (QS-4), carboxymethyl starch (CMS), sulfonated phenolic resin(SMP-2), water dispersible cation emulsified asphalt powder (SFT-1), sodium chloride(NaCL) and sodium formate (WT-1) in a mass ratio of 1,000:2-3:30-40:20-30:2-3:1.5-2:50-100:20; and the construction process comprises the following steps of: according to a circulation circle, uniformly mixing a coating agent PAC, a filtrate reducer CMS, a salt and high-temperature resistant filtrate reducer SMP-2 and an anti-sloughing lubricant SFT-1 for 12h at first; adding QA-4, NaCL, WT-1 into the mixture and uniformly mixing the mixture; and regulating the mixture to have a density Rho of 1.06 to 1.10g / cm<3>, a funnel viscosity T of 38 to 45s and an API water loss FL of 4 to 6ml. The process has the advantages of effectively preventing the balling of a sticking bit and a PDC bit at a lower curved section, reducing a frictional resistance and a torque, eliminating a sticking phenomenon, improving a mechanical drilling rate and ensuring downhole safety.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

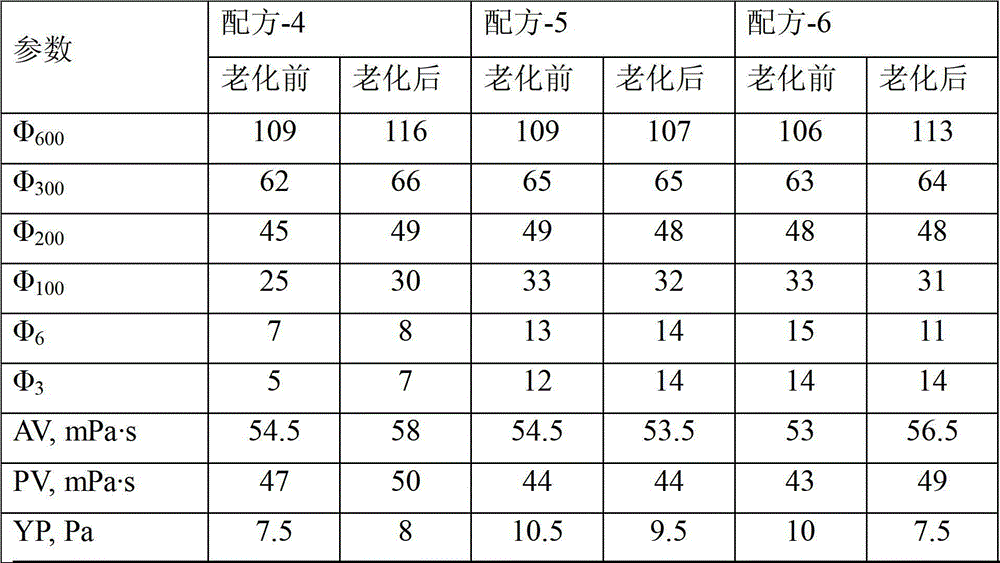

High-temperature resistant water-based drilling fluid and preparation method thereof

ActiveCN104559968APrevent problems such as stickingEasy to introduceDrilling compositionWater basedFiltration

The invention discloses a high-temperature resistant water-based drilling fluid and a preparation method thereof. The high-temperature resistant water-based drilling fluid comprises the following components in percentage by mass: 85%-97% of basic mud and 3%-15% of asphaltic liquid of a high softening point. The preparation method comprises the following steps: (1), adding asphaltic raw materials of a high softening point into water for performing crushing, adding a stable dispersant, and uniformly mixing the crushed asphaltic raw materials and the stable dispersant so as to obtain the asphaltic liquid of the high softening point; (2),uniformly mixing the asphaltic liquid of the high softening point, a performance modifying agent and the basic mud so as to obtain the high-temperature resistant water-based drilling fluid. In the water-based drilling fluid disclosed by the invention, the dispersion of asphaltic particles of a high softening point is uniform and stable; the water-based drilling liquid is high in high temperature resistance and filtration resistance; the preparation method is simple and convenient, the cost is reduced, and the applied range is wide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Whole oil-based drilling fluid viscosifier and preparation method thereof

InactiveCN106753289AThe polymerization reaction is stableFully polymerizedDrilling compositionPolyesterPolyol

The invention provides a whole oil-based drilling fluid viscosifier and a preparation method thereof. The preparation method for the whole oil-based drilling fluid viscosifier comprises the steps: 1) uniformly mixing 15-50 parts by weight of polyester polyol, 5-15 parts by weight of a polymerization promoter and 50-150 parts by weight of a solvent at room temperature so as to obtain a mixture; 2) heating the mixture to 40-60 DEG C, adding 15-80 parts by weight of isocyanate and 0.3-1.0 part of a polymerization catalyst under a stirring condition, and continuing to heat the mixture to 70-90 DEG C and enabling the mixture to react for 3-5 h so as to obtain an intermediate product; and 3) cooling the intermediate product to 40-50 DEG C, adding 5-15 parts by weight of a polymerization promoter, heating to 60-80 DEG C and continuing a reaction for 2-3 h so as to obtain the whole oil-based drilling fluid viscosifier. The whole oil-based drilling fluid viscosifier prepared by the preparation method can effectively improve suspension stability of a drilling fluid and improve the rheological property of the drilling fluid without changing the density of the drilling fluid; and therefore, the whole oil-based drilling fluid viscosifier is suitable for exploration and development of low pressure reservoirs.

Owner:PETROCHINA CO LTD

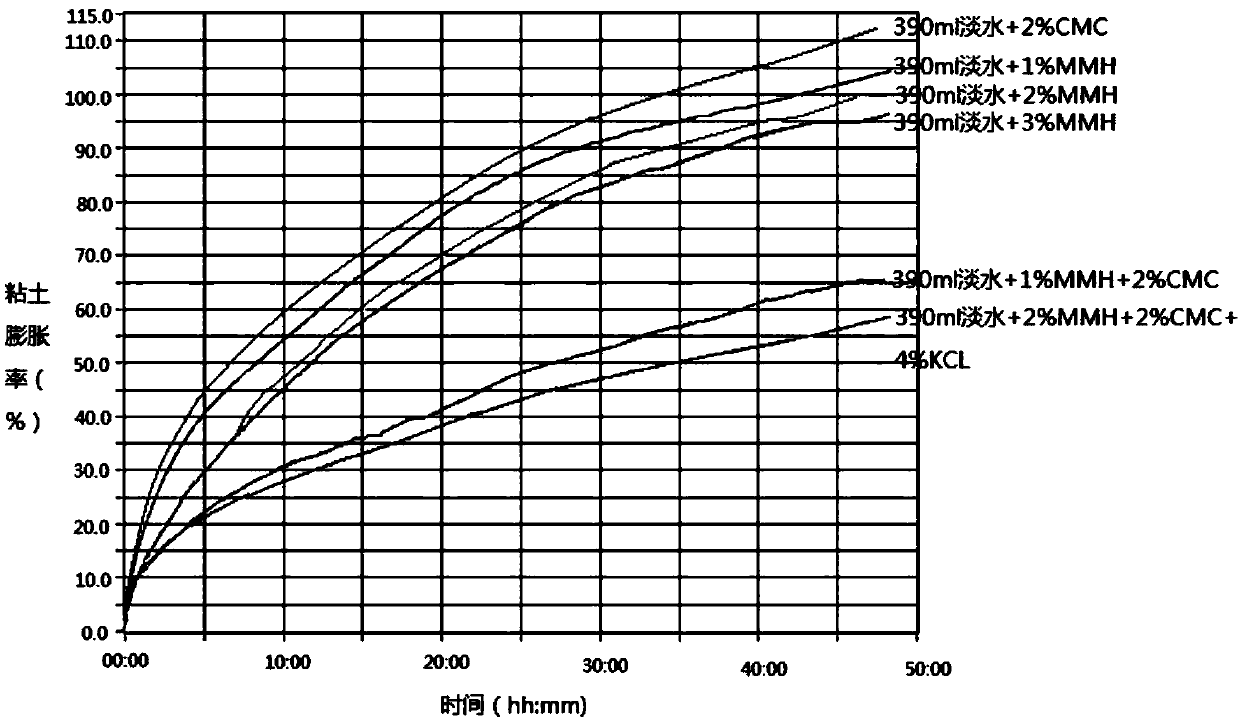

Drilling fluid and composite additive

ActiveCN102477287AIncrease dynamic shear forceAvoid high static shearDrilling compositionFiltrationTackifier

The invention belongs to the field of well drilling. Aiming at solving the problems that the water loss amount of the traditional positively-charged drilling fluid is great and the drilling fluid cannot be simultaneously used together with a filtration-reducing agent, the invention provides an MMH (mixed metal hydrides) mud composite additive. The MMH mud composite additive is prepared from the following raw materials in parts by weight: 1 part of MMH, 0.2-3 parts of xanthan gum, 0.05-0.1 part of polymer covering inhibitor, 0.05-0.15 part of tackifier, 0.1-0.3 part of organic silicon de-foaming agent and 0.2-0.3 part of superfine calcium carbonate. The invention further provides a drilling fluid which is prepared from the MMH mud composite additive.

Owner:深圳市钻通工程机械股份有限公司

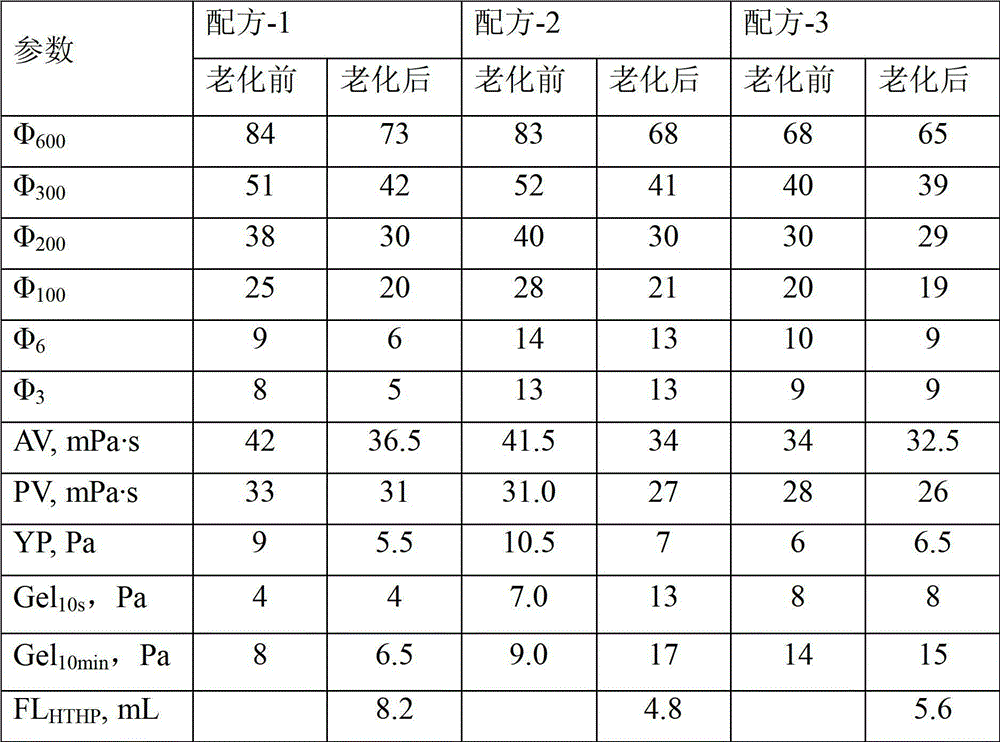

Invert-emulsion drilling fluid, preparation method and application thereof

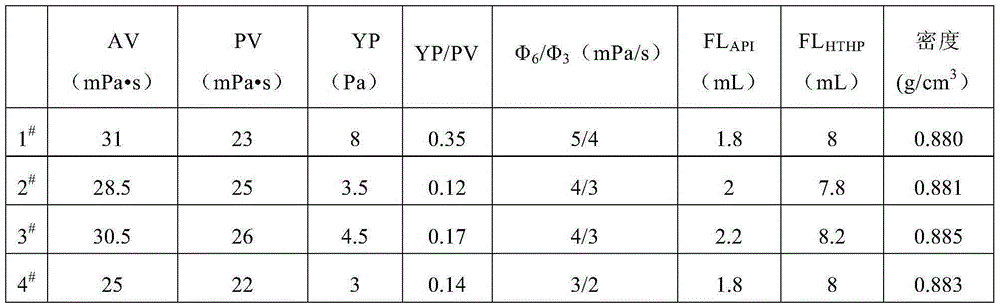

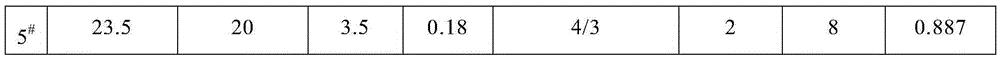

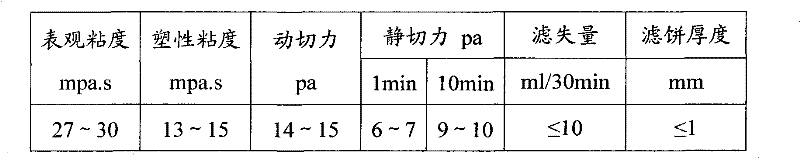

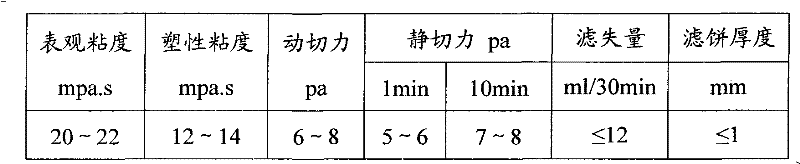

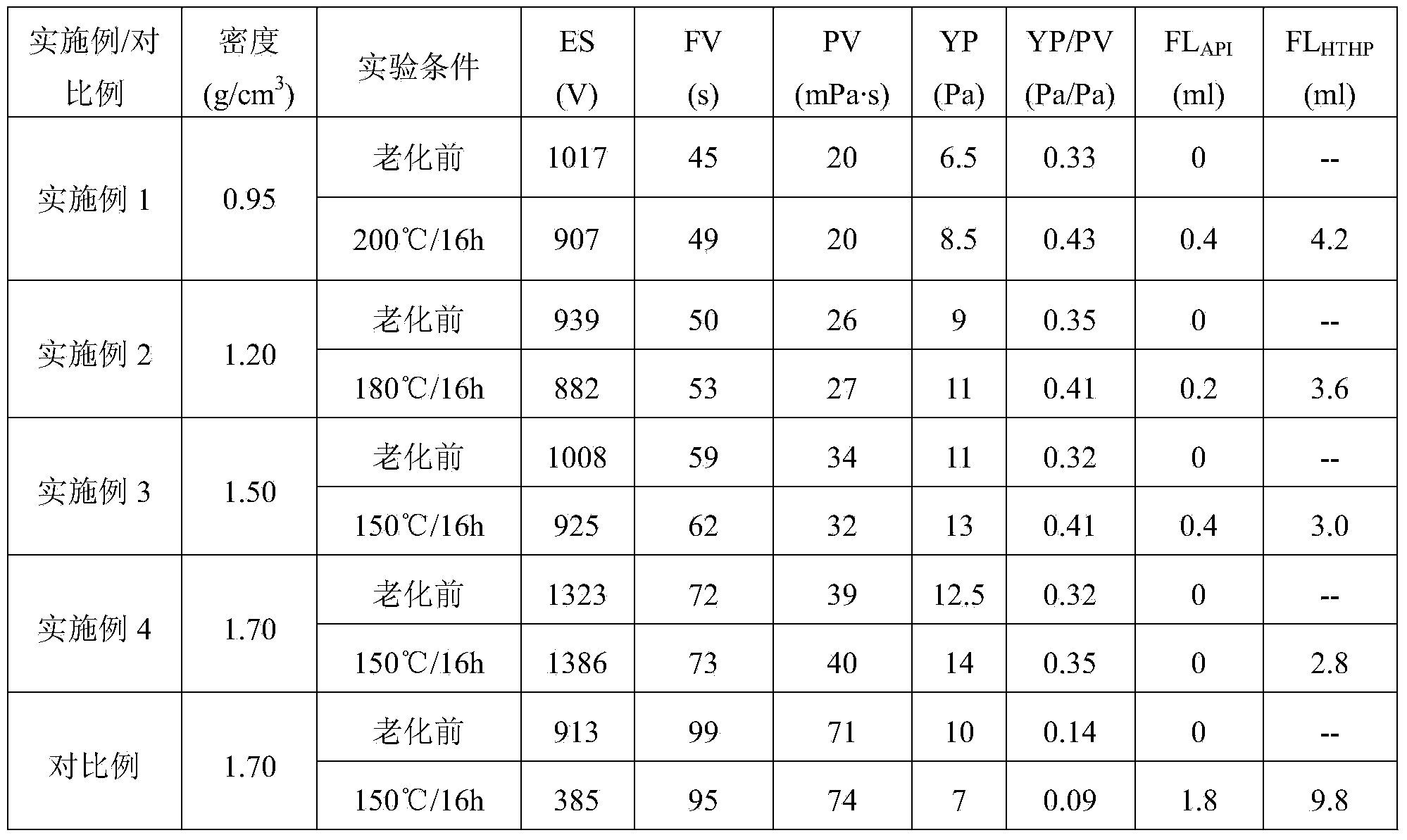

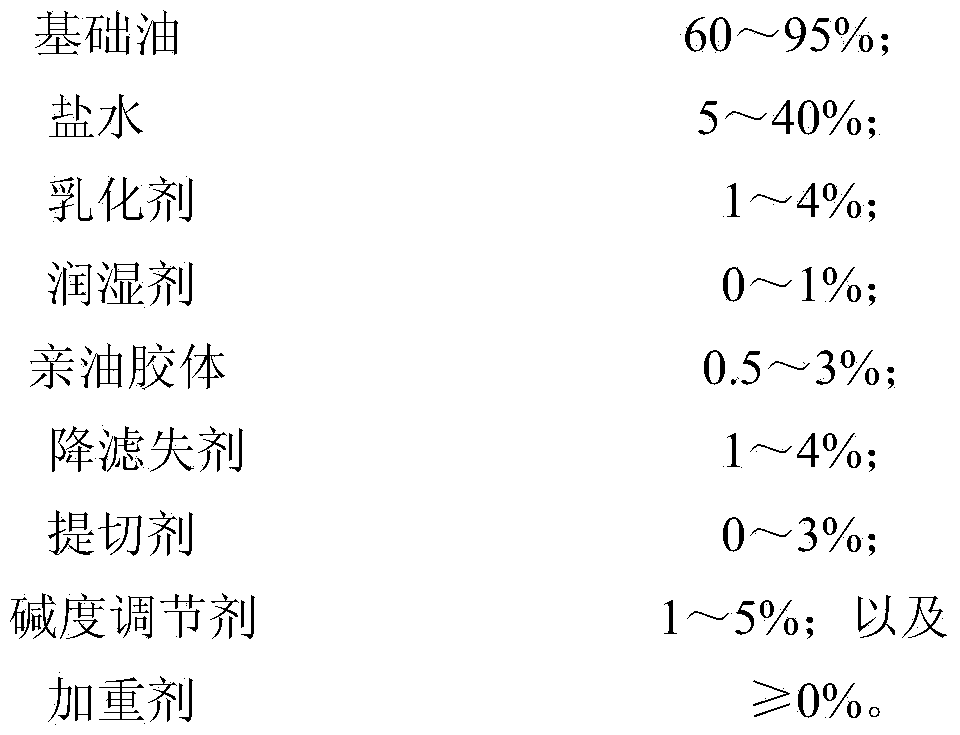

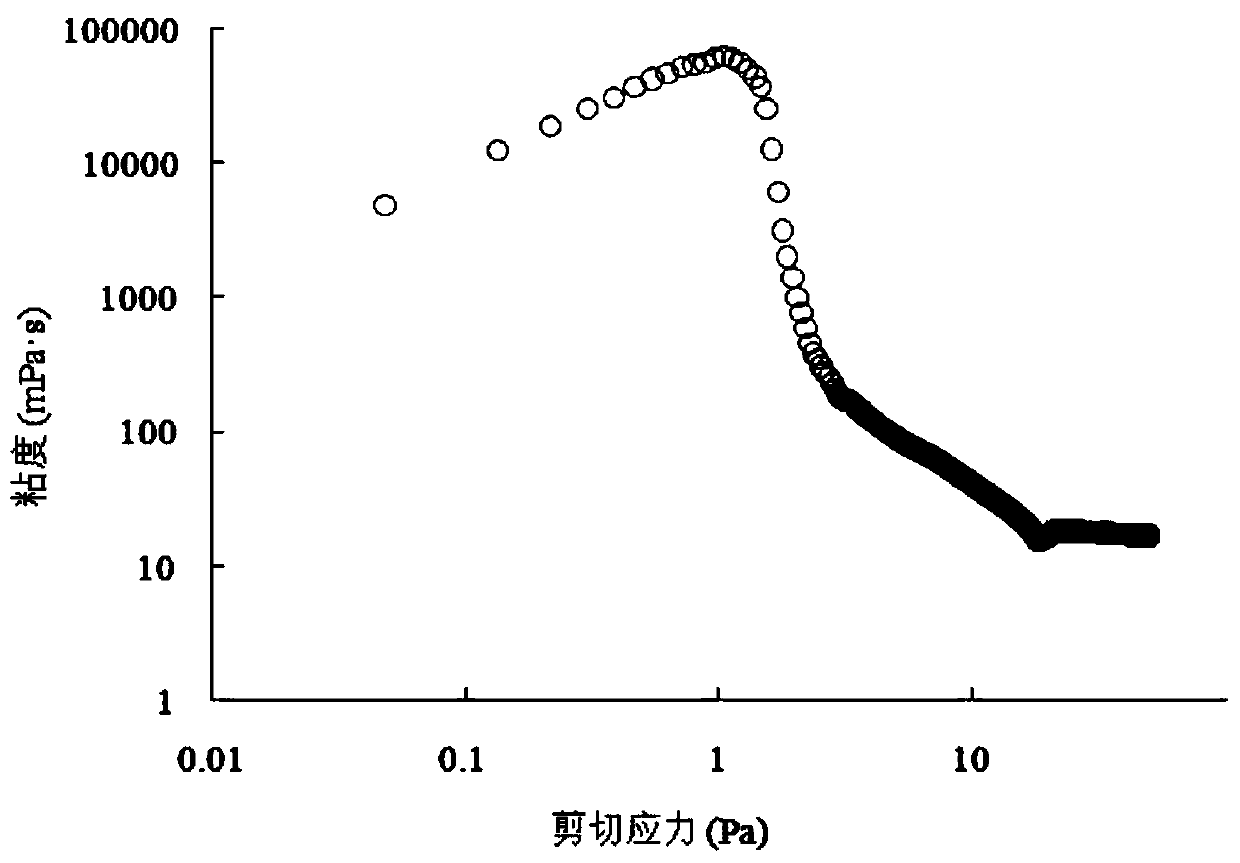

The invention provides an invert-emulsion drilling fluid, which comprises basic oil, brine, an emulsifier, a wetting agent, lipophilic colloid, a fluid loss additive, a shearing potentiator, an alkalinity conditioning agent, and a weighting agent. The invert-emulsion drilling fluid has the characteristics of low funnel viscosity and plasticity viscosity, and high dynamic shearing force and static shearing force; the yield point / plastic viscosity ratio is more than or equal to 0.30, the drilling fluid can sustain a temperature as high as 200 DEG C, so the drilling fluid is suitable for being used in a high temperature deep well, and a plurality of oils such as diesel oil, white oil, gas-liquefied oil, and the like can be used to carry out construction. Solved are the technical problems that the funnel viscosity and plasticity viscosity of the conventional invert-emulsion drilling fluid system are too high, and the dynamic shearing force and the static shearing force are too low.

Owner:CHINA PETROLEUM & CHEM CORP +1

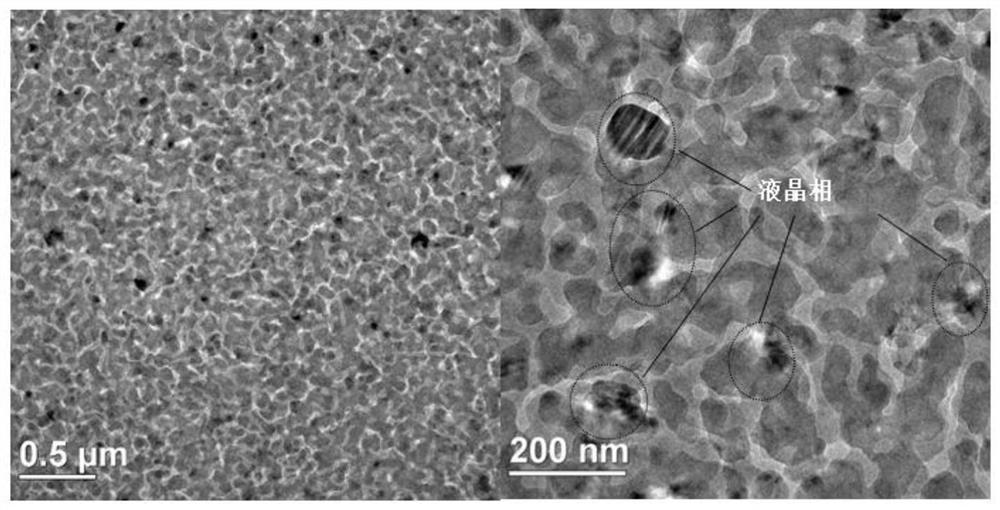

Bicontinuous phase micro-emulsion, preparation method thereof, drilling fluid containing micro-emulsion and preparation method thereof

ActiveCN109971441AImprove drilling performanceSimplify drilling proceduresOrganic compound preparationCarboxylic acid amides preparationEmulsionOil phase

The invention provides a bicontinuous phase micro-emulsion which comprises an emulsifier, a water soluble acid, an oil phase and a water phase. The emulsifier is an amine nonionic emulsifier. The invention further discloses a drilling fluid containing the micro-emulsion. The drilling fluid comprises the micro-emulsion, an oil base stabilizer, organic soil and a weighing material. The invention further discloses a preparation method of the micro-emulsion and the drilling fluid. The method comprises the steps that other raw materials are mixed, the water soluble acid is added for induction to obtain the bicontinuous phase micro-emulsion and the drilling fluid, or the other raw materials and the water soluble acid are mixed at first to obtain the bicontinuous phase micro-emulsion, a drillingfluid additive is added, and the bicontinuous drilling fluid is obtained. The bicontinuous phase micro-emulsion has the advantages that the unique oil phase and water phase bicontinuous characteristics, high shearing force, low plastic viscosity and viscoelasticity rheologic characteristics are achieved, the advantages of the oil phase and water phase drilling fluids can be shown at the same timewhen the micro-emulsion is used for the drilling fluid, and the water power transmission, suspension, rock debris carrying and well cleaning capability of the drilling fluid are enhanced.

Owner:SOUTHWEST PETROLEUM UNIV

Modified epoxy asphalt and preparation method thereof, and water-based drilling fluid and preparation method thereof

ActiveCN110922771AIncrease stickinessSmall particle sizeDrilling compositionBuilding insulationsPolymer scienceFirming agent

The invention discloses modified epoxy asphalt and a preparation method thereof, and a water-based drilling fluid and a preparation method thereof. The modified epoxy asphalt comprises the following components in parts by weight: 100 parts of matrix asphalt, 1-20 parts of a compatibilizer, 1-10 parts of a toughening agent, 5-20 parts of a curing agent, 1-5 parts of a curing accelerator and 5-30 parts of an epoxy resin, wherein the curing accelerator comprises a product obtained by reacting polyamine, phenol and an aldehyde-containing aqueous solution. According to the water-based drilling fluid, the modified epoxy asphalt liquid is added and is small in particle size and high in softening point, has a certain elastic deformation capacity and is excellent in high-temperature resistance, sothat the drilling fluid has good rheological property and high-temperature and high-pressure filtrate loss reduction effect when used at a high temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

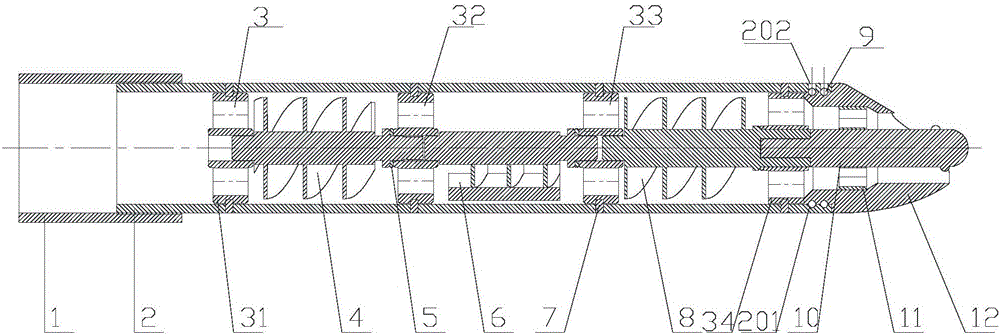

Self-guiding bushing vibration guide shoe

ActiveCN106761472BNovel structureSimple and reasonableDrilling rodsDrilling casingsCyclic processEngineering

Owner:DEZHOU HANLONG PETROLEUM EQUIP CO LTD

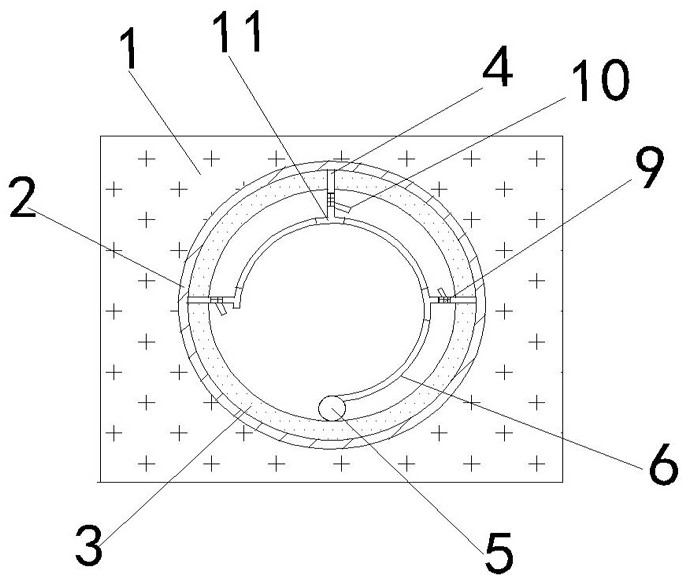

Self-steering casing vibration guiding shoe

ActiveCN106761472ANovel structureSimple and reasonableDrilling rodsDrilling casingsCarrying capacityCoupling

The invention provides a self-steering casing vibration guiding shoe. The self-steering casing vibration guiding shoe comprises a short casing, a coupling, positioning plates, a first power turbine, an eccentric block assembly, a second power turbine, an eccentric head, a plurality of balls, a positioner and a drill bit. The self-steering casing vibration guiding shoe has the advantages that the structure is novel, simple and reasonable, the self-steering casing vibration guiding shoe is especially suitable for a well high in well cementation requirement, in the casing running process, steering of the eccentric head can be adjusted at any time, the casing is guided to run, and the self-steering casing vibration guiding shoe is particularly suitable for a highly-deviated well and a horizontal well; in the circulation process, the solids carrying capacity is greatly improved, the shear breaking effect on detritus at the bottom of the well is obvious, and the cleaning and purifying effects on a well bore are improved; in the circular well cementation process, the dynamic shear force of a drilling fluid or cement is improved, the displacement efficiency is improved, and the mixing and channeling conditions in the well cementation process are reduced; during well cementation, the cementing strength of oil well cement is improved through the shear, stirring and vibration effects, and the well cementation quality is improved.

Owner:DEZHOU HANLONG PETROLEUM EQUIP CO LTD

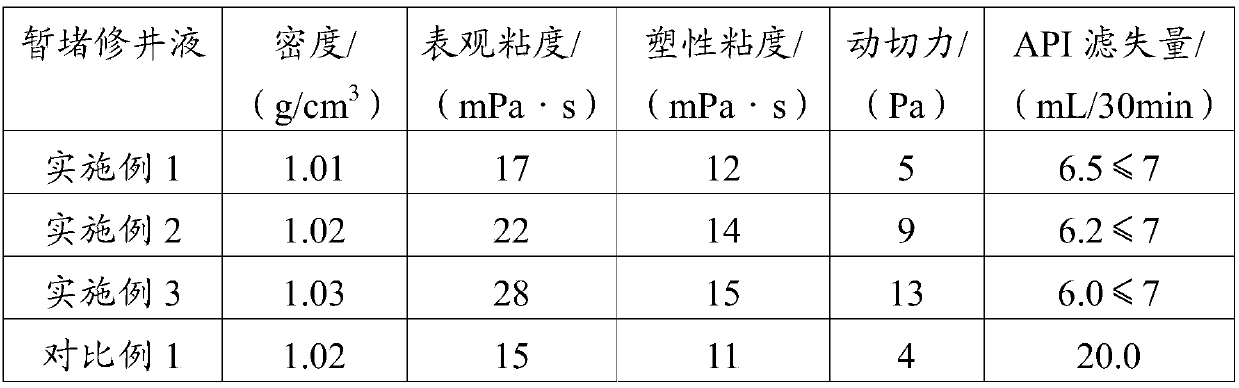

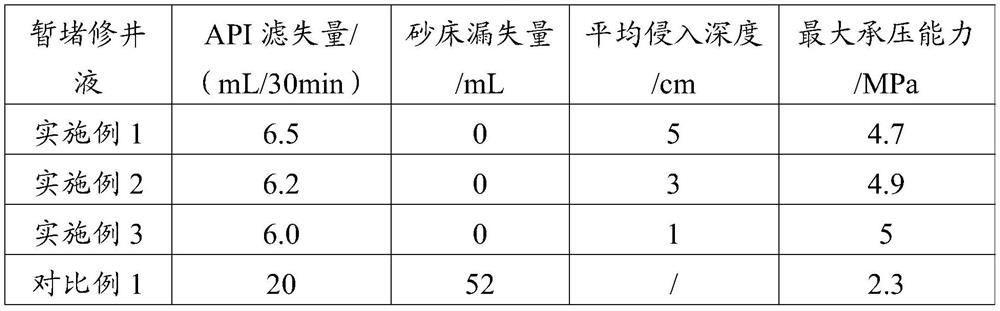

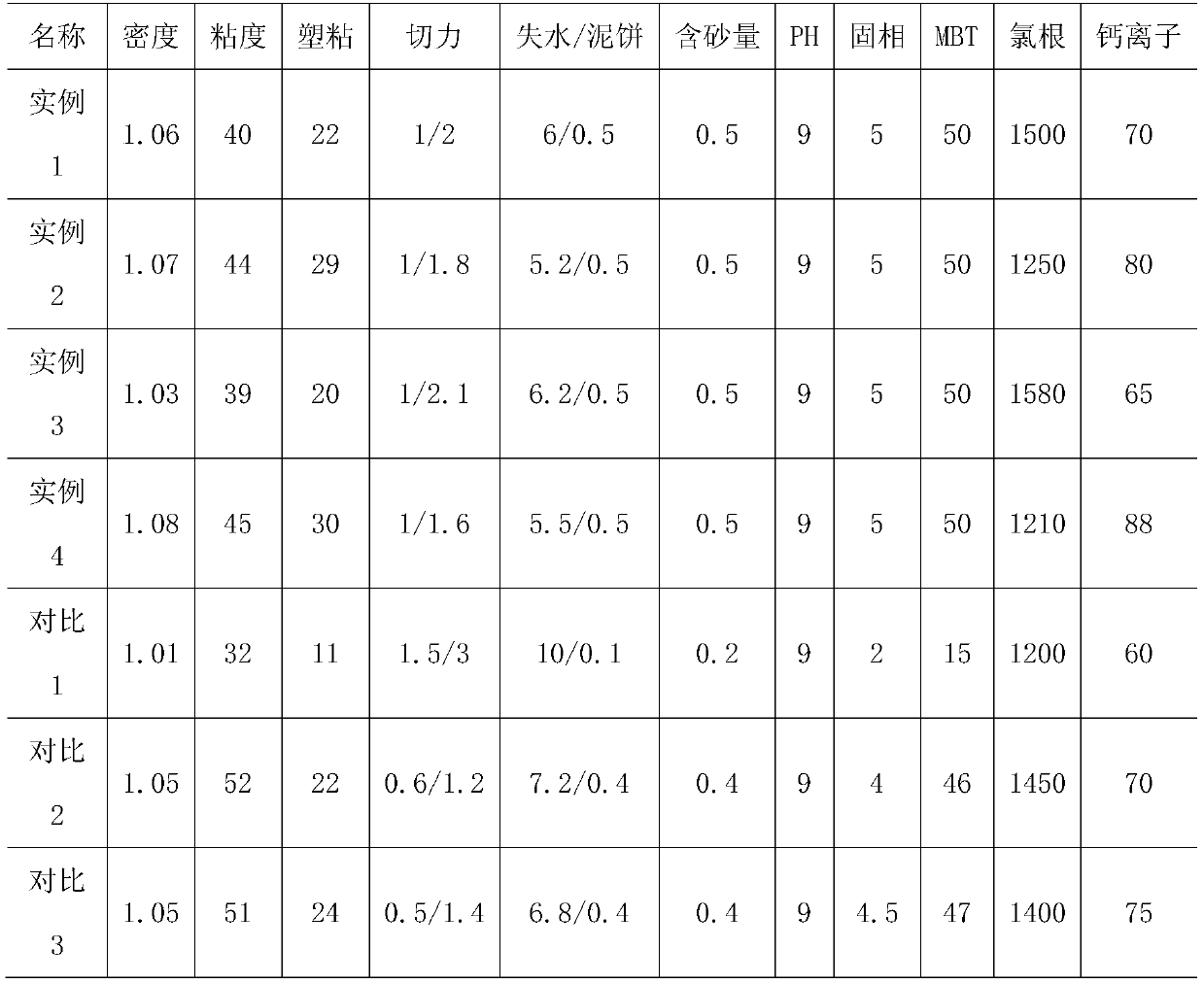

Temporary plugging workover fluid and preparation method thereof

ActiveCN111394077AImprove pressure bearing capacityStrong pressure resistanceDrilling compositionFiberPolyvinyl alcohol

The invention discloses a temporary plugging workover fluid and a preparation method thereof, and belongs to the field of oilfield chemistry. The temporary plugging workover fluid comprises, based onthe total weight being 100 parts, 0.96-2.7 parts of flour balls, 0.48-1.35 parts of resin balls, 1.92-4.5 parts of an expansion inhibitor, 0.29-0.45 parts of a suspending agent, 0.19-0.27 parts of a fiber synergist, 0.10-0.41 parts of a scale inhibitor, 0.19-0.32 parts of a degradation agent and the balance of water. The flour balls are prepared by mixing wheat flour and floating beads in a mass ratio of 6: 4 to 7: 3, adding water, and performing mixing, extruding, cutting, forming and drying. The density of the flour balls is 0.97-1.02 g / cm<3>, and the particle size of the flour balls is 2-4mm. The resin balls are prepared by mixing petroleum resin and floating beads in a mass ratio of 7: 3 to 8: 3, adding isopropanol and a silane coupling agent, and performing mixing, extruding, cutting,forming and drying. The density of the resin balls is 0.97-1.02 g / cm<3>, and the particle size of the resin balls is 3-5mm. The fiber synergist is polyvinyl alcohol fiber, the diameter of the polyvinyl alcohol fiber is 0.01-0.03mm, and the length of the polyvinyl alcohol fiber is 3-5mm. The temporary plugging workover fluid can form a temporary plugging layer which is compact in structure and excellent in mechanical strength and pressure bearing capacity, and does not damage a reservoir.

Owner:PETROCHINA CO LTD

Pipe jacking thixotropic slurry and preparation method thereof

ActiveCN112877043AStir wellReduce resistanceBuilding constructionsDrilling compositionLandslideRoad surface

The invention provides pipe jacking thixotropic slurry and a preparation method thereof, belonging to the field of building materials. The pipe jacking thixotropic slurry is prepared from the following components in parts by weight: 6%-10% of sodium bentonite, 0.2%-0.5% of an alkaline inorganic treating agent, 0.1%-0.3% of a flocculating agent, 0.5%-0.8% of a tackifier, 1%-2% of a filtrate reducer, 1%-3% of a lubricating agent and 84%-90% of water, wherein the alkaline inorganic treating agent is sodium carbonate, the flocculating agent is a high-molecular agglutinant, and the filtrate reducer is pregelatinized starch. The invention also provides a preparation method of the pipe jacking thixotropic slurry. The thixotropic slurry has good consistency, can form a high-quality slurry sleeve and has a certain supporting effect; and the components in the formula of the thixotropic slurry have a synergistic effect, so the stability and safety of existing thixotropic slurry are improved, and soil collapse and pavement subsidence are avoided.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

Pebble stratum deep and large foundation pit underground diaphragm wall retaining wall slurry and preparation method thereof

ActiveCN110066661AWall protection effect is goodImprove recycling ratesBuilding constructionsOrganic fertilisersSlurry wallMaterial consumption

The invention relates to the field of building construction, and provides pebble stratum deep and large foundation pit underground diaphragm wall retaining wall slurry. The pebble stratum deep and large foundation pit underground diaphragm wall retaining wall slurry is prepared from, by weight, 1,000 parts of water, 75-85 parts of bentonite, 3-5 parts of sodium carbonate and 0.5-1.5 parts of sodium polyacrylate. The invention further provides a preparation method of the pebble stratum deep and large foundation pit underground diaphragm wall retaining wall slurry. The pebble stratum deep and large foundation pit underground diaphragm wall retaining wall slurry has the advantages that sodium polyacrylate is adopted for replacing traditional CMC, the slurry wall protecting performance and theslurry recycling rate are greatly increased, and meanwhile corresponding environment contamination and material consumption are reduced; meanwhile, various indexes of the slurry prepared through theformula can meet the requirement of circulating slurry indexes, the wall protecting effect is good, and the groove wall stability is good.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

Novel lubricant and resistance-reducing slurry for pipe jacking construction in desert areas and preparation method of slurry

InactiveCN105950123AReduce water lossThe slurry funnel has high viscosity and dynamic shearing forceDrilling compositionSodium carboxymethylcelluloseLubrication

The invention discloses novel lubricant and resistance-reducing slurry for pipe jacking construction in desert areas. The slurry comprises machine head synchronous grouting slurry and follow-up supplement slurry along a line, wherein the machine head synchronous grouting slurry is prepared from the components in parts by weight as follow: 130-150 parts of clay, 1-1.5 parts of carboxymethyl cellulose, 0.25-0.3 parts of sodium hydroxide, 2.5-3.5 parts of a lubricant anti-collapse agent and 1,000 parts of water; the follow-up supplement slurry along the line is prepared from components in parts by weight as follows: 4.5-5 parts of hydrolysis polyacrylamide, 2.5-3.5 parts of a lubrication anti-collapse agent and 1,000 parts of water. A slurry grouting system for pipe jacking construction comprises the synchronous grouting slurry and the follow-up supplement slurry and adopts a synchronous slurry grouting process and a follow-up slurry grouting process; the synchronous grouting slurry mainly has a casing formation and wall protection function on the basis of lubrication and resistance reduction, the follow-up supplement slurry mainly has lubrication and resistance reduction properties, and accordingly, the lubricant and resistance-reducing slurry system performs the lubrication and wall-protection functions best.

Owner:CHINA TIESIJU CIVIL ENG GROUP

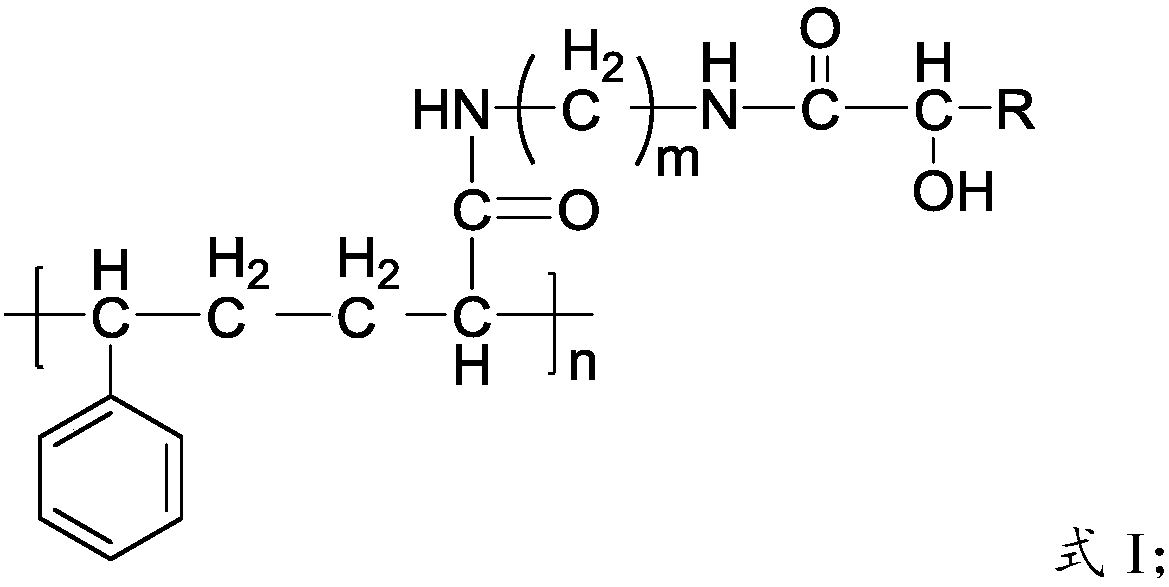

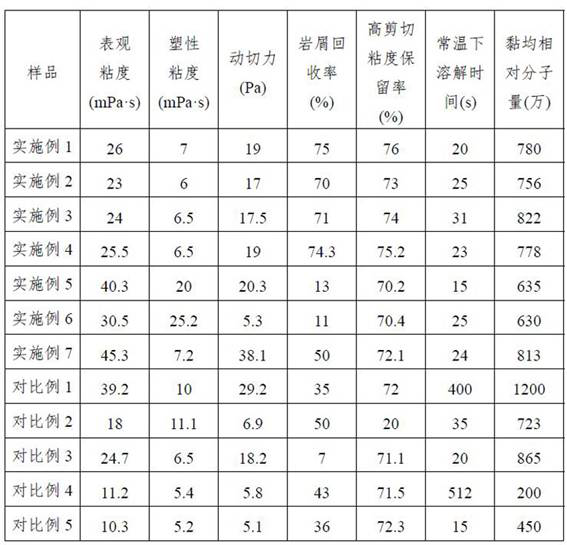

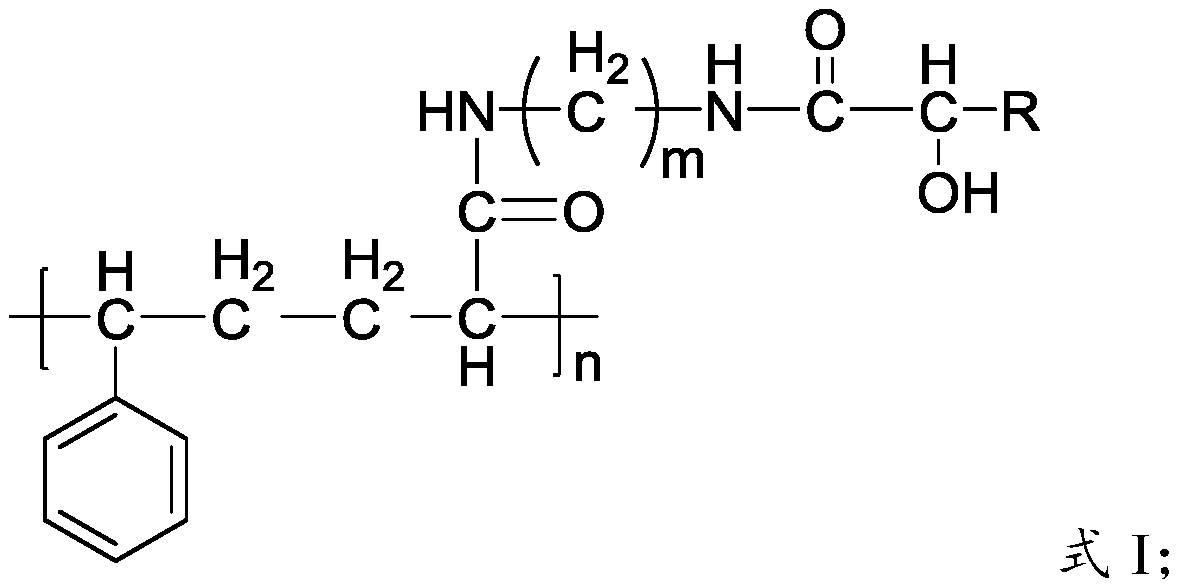

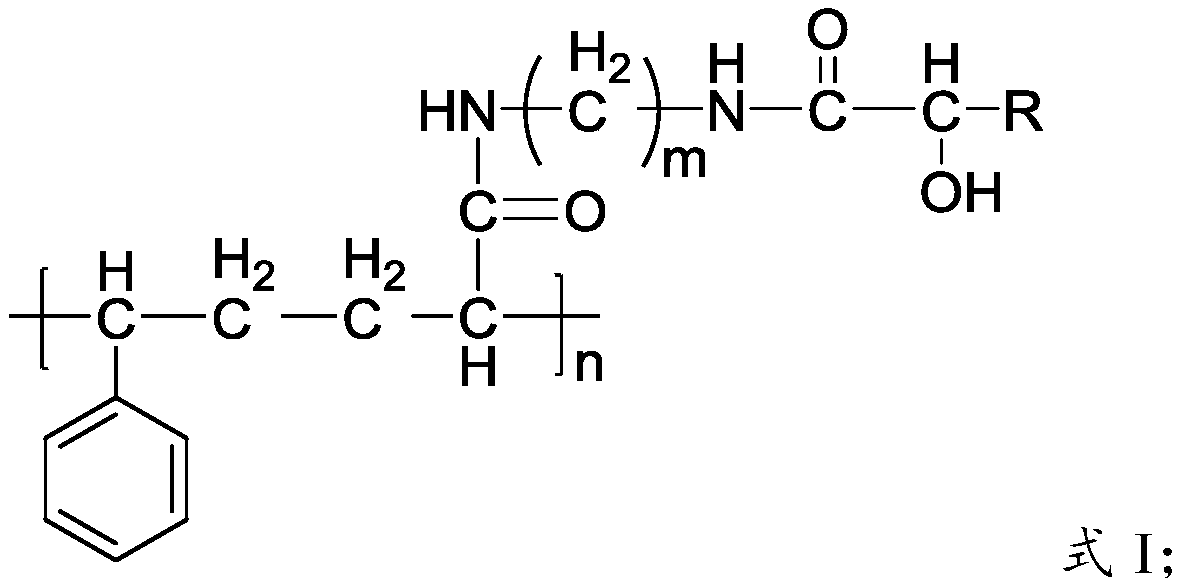

Lifted cutting agent and preparation method and oil-based drilling fluid

ActiveCN107805286AHigh cutting forceEnhance structural strengthDrilling compositionHigh liftCarboxylic acid

The invention provides a preparation method of a lifted cutting agent. The preparation method comprises the following steps: a styrene vinyl carboxylic acid copolymer, diamine and hydroxyl aliphatic acid are subjected to a reaction to obtain the lifted cutting agent. The lifted cutting agent takes the styrene vinyl carboxylic acid copolymer, diamine and hydroxyl aliphatic acid as raw materials, the lifted cutting agent has an alternative structure, can increase the structural force of drilling fluid, and has higher lifted cutting rate, the oil-based drilling fluid using the lifted cutting agent has high lifted cutting force and strong dynamic carrying and static suspension capability, and requirement of on-site construction can be better satisfied. The lifted cutting agent prepared by theabove technical scheme has a structure shown in a formula I. The invention also provides the oil-based drilling fluid of the lifted cutting agent.

Owner:中石化石油工程技术服务有限公司 +1

A kind of double continuous phase microemulsion, its preparation method and the drilling fluid containing the microemulsion and its preparation method

ActiveCN109971441BPossesses the characteristics of bicontinuous water phaseUnique water phase bicontinuous featureOrganic compound preparationCarboxylic acid amides preparationRheopectyPhysical chemistry

The invention provides a bicontinuous phase micro-emulsion which comprises an emulsifier, a water soluble acid, an oil phase and a water phase. The emulsifier is an amine nonionic emulsifier. The invention further discloses a drilling fluid containing the micro-emulsion. The drilling fluid comprises the micro-emulsion, an oil base stabilizer, organic soil and a weighing material. The invention further discloses a preparation method of the micro-emulsion and the drilling fluid. The method comprises the steps that other raw materials are mixed, the water soluble acid is added for induction to obtain the bicontinuous phase micro-emulsion and the drilling fluid, or the other raw materials and the water soluble acid are mixed at first to obtain the bicontinuous phase micro-emulsion, a drillingfluid additive is added, and the bicontinuous drilling fluid is obtained. The bicontinuous phase micro-emulsion has the advantages that the unique oil phase and water phase bicontinuous characteristics, high shearing force, low plastic viscosity and viscoelasticity rheologic characteristics are achieved, the advantages of the oil phase and water phase drilling fluids can be shown at the same timewhen the micro-emulsion is used for the drilling fluid, and the water power transmission, suspension, rock debris carrying and well cleaning capability of the drilling fluid are enhanced.

Owner:SOUTHWEST PETROLEUM UNIV

Temporary plugging workover fluid and preparation method thereof

ActiveCN111394077BImprove pressure bearing capacityStrong pressure resistanceDrilling compositionFiberPolyvinyl alcohol

The invention discloses a temporary plugging workover fluid and a preparation method thereof, belonging to the field of oil field chemistry. Based on 100 parts by weight, the temporary plugging workover fluid includes: 0.96-2.7 parts of flour balls, 0.48-1.35 parts of resin balls, 1.92-4.5 parts of swelling inhibitors, 0.29-0.45 parts of suspending agents, and 0.19-0.19 parts of fiber synergists 0.27 parts, 0.10-0.41 parts of antiscalant, 0.19-0.32 parts of degradation agent, and the balance is water; flour balls are mixed with wheat flour and floating beads with a mass ratio of 6:4-7:3, added water to mix, squeezed Made by pressing, cutting, forming and drying; the density of flour balls is 0.97‑1.02g / cm 3 , the particle size is 2‑4mm; resin balls are mixed with petroleum resin and floating beads with a mass ratio of 7:3‑8:3, then mixed with isopropanol and silane coupling agent, extruded, cut, shaped, and dried Prepared; the density of resin balls is 0.97‑1.02g / cm 3 , the particle size is 3-5mm; the fiber synergist is polyvinyl alcohol fiber; the diameter of polyvinyl alcohol fiber is 0.01-0.03mm, and the length is 3-5mm. The temporary plugging and workover fluid can form a temporary plugging layer with compact structure, excellent mechanical strength and pressure bearing capacity, and will not cause damage to the reservoir.

Owner:PETROCHINA CO LTD

A kind of high temperature resistant water base drilling fluid and preparation method thereof

The invention discloses high-temperature resistant water-based drilling fluid and a preparation method thereof. The high-temperature resistant water-based drilling fluid comprises base slurry and a modified high-softening point asphalt liquid, wherein the modified high-softening point asphalt liquid comprises modified high-softening point asphalt granules, water, a stable dispersing agent and a stabilizer; the particle size of the modified high-softening point asphalt granules is less than or equal to 120 mum; the modified high-softening point asphalt granules comprise 7-9 parts by mass of kernels consisting of basic asphalt and 1-3 parts by mass of shells formed by a modifier; the modifier comprises poly-sulfur and free sulfur; the weight ratio of the poly-sulfur to the free sulfur is (3:7)-(7:3). As the modified high-softening point asphalt liquid is added into the drilling fluid disclosed by the invention, and the asphalt granules are prepared in a mode that the base asphalt is coated by a layer of mixture of high-elasticity poly-sulfur and free sulfur, the drilling fluid is small in particle size, has a certain elastic deformation property, is excellent in high temperature resistance and can be stably stored at normal temperature, therefore, the viscosity / yield boosting of the drilling fluid and the dynamic shearing force and the high-temperature high-pressure de-filtration property of the system can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of anti-seepage wall positive electric glue wall solidification mud and its application

Owner:SINOHYDRO FOUND ENG

Shear strength improving agent for solid-free completion fluid workover fluid for oil-gas well and preparation method thereof

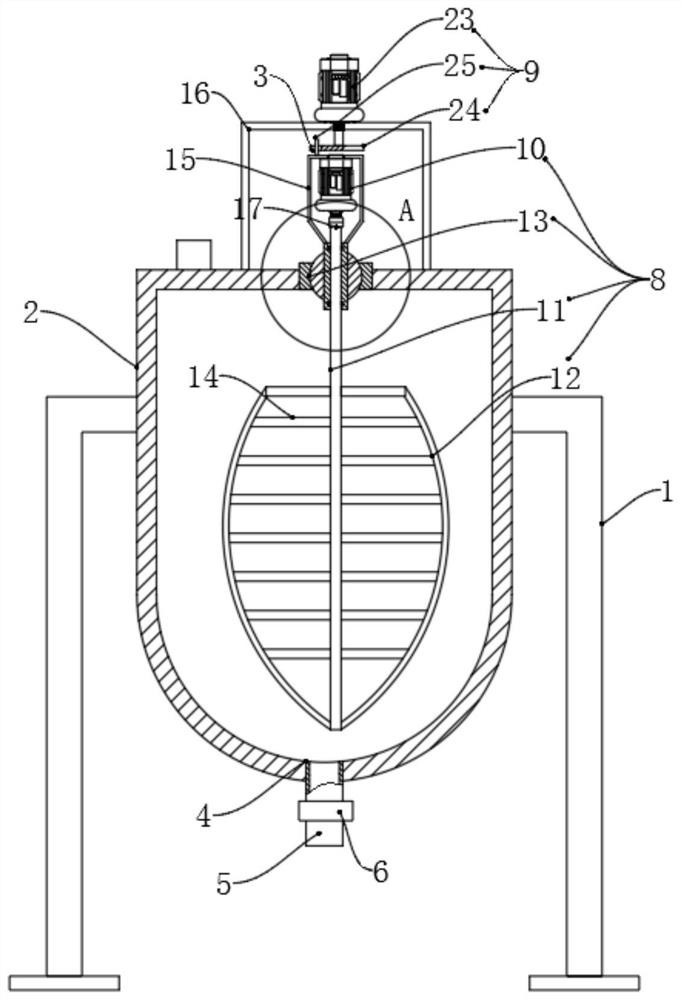

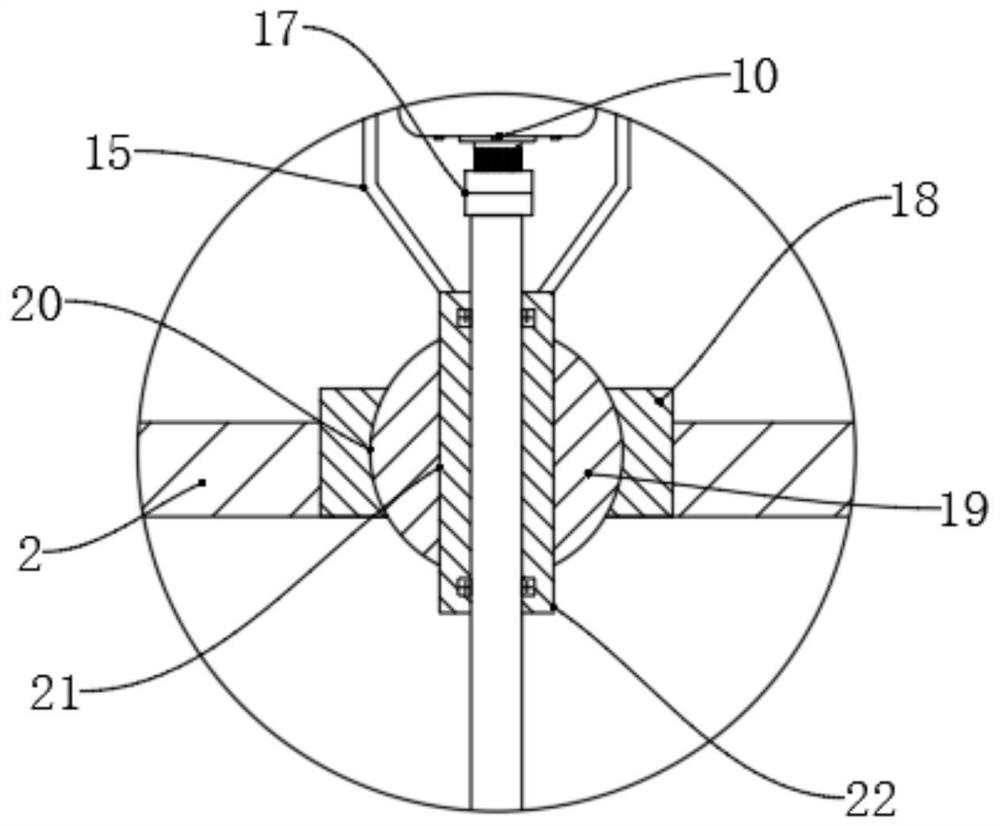

ActiveCN112552883AIncrease viscosity shearSolve the problem of poor suspension sand carryingTransportation and packagingRotary stirring mixersAlkalinitySaline water

The invention discloses a shear strength improving agent for solid-free completion fluid workover fluid for an oil-gas well. The shear strength improving agent comprises the following raw materials inpercentage by weight: 8-12% of metal salt; 28-32% of an alkalinity regulator; 8-12% of a flow pattern regulator; and the balance of water. In addition, the invention further discloses a preparation method of the shear strength improving agent for the solid-free completion fluid workover fluid for the oil-gas well, and the preparation method comprises the following steps: step 1, adding a formulaamount of water into a reaction device, then adding a formula amount of metal salt, and stirring by using a stirring device to quickly dissolve and uniformly mix the metal salt; step 2, slowly addingthe mixture into a formula amount of alkalinity regulator, and regulating the pH value to be 9-10; step 3, after the reaction is completed, adding a flow pattern regulator for stirring; and step 4, evaporating the solvent, and crushing the solvent to obtain powder. The shear strength improving agent can solve the technical problem that solid-phase composite brine completion fluid and workover fluid are poor in suspension and sand carrying.

Owner:成都西油华巍科技有限公司

Six-claw drilling fluid coating agent and preparation method thereof

ActiveCN113372515AHigh viscosityIncrease dynamic shear forceDrilling compositionMeth-Polyvinyl alcohol

The invention relates to the technical field of oil-gas field development, and provides a six-claw drilling fluid coating agent and a preparation method thereof. The six-claw drilling fluid coating agent is prepared through a polymerization reaction. The preparation raw materials of the polymerization reaction comprise the following components in parts by weight: 10 to 30 parts of acrylamide, 3 to 6 parts of six-claw prepolymer, 80 to 120 parts of N-vinyl pyrrolidone, 100 to 150 parts of 2-acrylamide-2-methylpropanesulfonic acid, 10 to 20 parts of polyvinyl alcohol, 3 to 8 parts of a conditioner, 27 to 41 parts of potassium hydroxide, 580 to 720 parts of water, 1 to 3 parts of a high-temperature initiator and 0.5 to 3 parts of a medium-temperature initiator. A molecular chain of the coating agent has a six-claw structure, so the coating agent can realize rapid adsorption of the clay surface and coating of drilling cuttings, and has strong and lasting coating capability; and each branch chain of the coating agent has a large number of sulfonic acid groups and five-membered ring structures, so that the coating agent has more excellent temperature resistance, and the temperature resistance can reach 230 DEG C.

Owner:SHANDONG NUOER BIOLOGICAL TECH

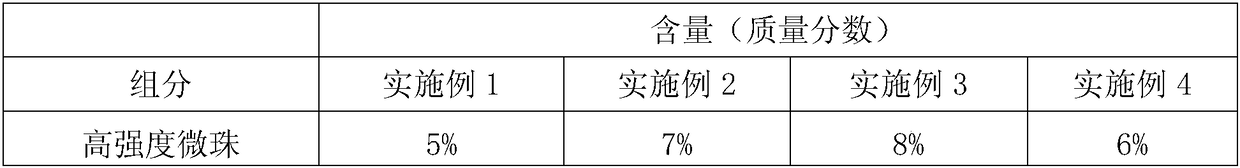

Low-density cement used for well cementation

InactiveCN108395154AImprove performanceImprove early strengthDrilling compositionHorizontal wellsVolumetric Mass Density

The invention provides low-density cement used for well cementation. The low-density cement comprises the following components in percentages by mass: 5%-8% of high-strength microbeads, 2%-7% of floating beads, 2%-3% of perlite, 55%-70% of oil wells G-grade cement, 8%-12% of silica fume, 3%-9% of fly ash, 2% of a fluid loss agent, 2%-3% of a stabilizer, 1% of an expanding agent, 0.6%-0.75% of an early strength agent, and 0.25%-0.4% of a drag reducer. The low-density cement slurry used for the well cementation provided by the invention has high high-temperature stability, a constant high-pressure density and high early strength, has higher plastic viscosity, dynamic shearing force and thixotropy at high temperature, and is suitable for a well cementing process of high-yield oil wells, gas wells, deep wells, ultra-deep wells, horizontal wells and other wells with higher requirements.

Owner:宁夏亿昀特种工程材料有限公司

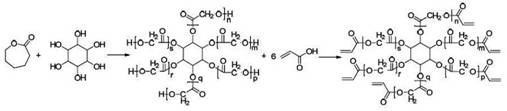

Preparation method of organic rheology modifying agent for full-oil-based drilling fluid

ActiveCN103012180BGood suspensionImprove thixotropyOrganic compound preparationCarboxylic acid amides preparationFatty acidUltimate tensile strength

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Drilling slurry for coring of highly loose stratums as well as preparation method and application of drilling slurry

The invention discloses a drilling slurry for coring of highly loose stratums as well as a preparation method and application of the drilling slurry. The drilling slurry is prepared from the followingcomponents in percentage by mass: 5%-10% of bentonite, 0.2%-0.5% of caustic soda, 0.2%-0.5% of sodium carbonate, 0.5%-0.8% of a cationic colloid, 0.3%-0.5% of a fluid loss agent, 0.3%-0.5% of a polyacrylonitrile-potassium salt, 0.5%-1% of a polyacrylonitrile composite ammonium salt and the balance water. When the formula provided by the invention is used for coring highly loose stratums, the yield can reach 80-90%, and compared with the prior art, the yield is obviously improved.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

A kind of water base drilling fluid and preparation method thereof

The invention discloses a water-based drilling fluid and a preparation method thereof. The water-based drilling fluid includes base slurry and modified epoxy asphalt fluid. The modified epoxy asphalt fluid includes modified epoxy asphalt particles, water, stable dispersant and stabilizer. The modified epoxy asphalt particles include epoxy asphalt The core formed and the shell formed by the modifier, in terms of parts by mass, the core is 7 to 9 parts, and the shell is 1 to 3 parts; the modifier includes polymerized sulfur and free sulfur, and the polymerized sulfur in the modifier The weight ratio to free sulfur is 3:7~7:3. The modified epoxy asphalt fluid is added to the water-based drilling fluid of the present invention, wherein the asphalt particles are a mixture of high-elastic polymeric sulfur and free sulfur coated with a layer of epoxy asphalt, which not only has a small particle size, but also has a certain Elastic deformation ability, and excellent high temperature resistance. The drilling fluid has good rheological properties and high temperature and high pressure fluid loss reduction effect when used at high temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of raw material composition for coating agent, coating agent and its preparation method and application

ActiveCN113265232BImprove adsorption capacityImprove shear resistanceDrilling compositionPolymer sciencePetrochemical

The present invention relates to the technical field of polymer additives in petrochemical industry, in particular to a raw material formula for a coating agent, a coating agent and its preparation method and application, the material formula of the coating agent includes acrylamide monomers, the The raw material formula for the coating agent also includes the following components: physical mixing components, chemical adjustment components and initiators; the acrylamide monomer is used as a component in the physical mixing components; the chemical adjustment components Including oxidant, polymerization inhibitor, chelating agent and molecular weight regulator; the initiator is a high-temperature initiator; the coating agent prepared by the raw material formula for the coating agent provided by the present invention has low plastic viscosity and high dynamic shear force , strong coating inhibition, good shear resistance, and fast dissolution speed. Compared with other types of coating agents, it has better comprehensive performance. When used in drilling fluids in the petroleum field, the High value and wide application prospect.

Owner:SHANDONG NUOER BIOLOGICAL TECH

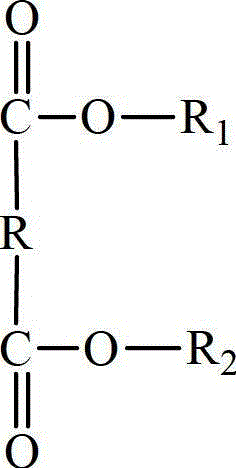

A kind of cutting agent and its preparation method and oil-based drilling fluid

ActiveCN107805286BHigh cutting rateIncrease dynamic shear forceDrilling compositionPolymer scienceCarboxylic acid

Owner:中石化石油工程技术服务有限公司 +1

Modified nano silicon dioxide, high-temperature-resistant tackifying and shear strength improving agent and preparation methods and applications of modified nano silicon dioxide and high-temperature-resistant tackifying

PendingCN114805421AImprove structural strengthIncrease dynamic shear forceSilicon organic compoundsOrganic chemistry methodsUnsaturated fatty acidSilane coupling

The invention provides modified nano silicon dioxide, a high-temperature-resistant tackifying and shear-improving agent and preparation methods and applications of the modified nano silicon dioxide and the high-temperature-resistant tackifying and shear-improving agent, and the preparation method of the modified nano silicon dioxide comprises the following steps: S1, carrying out first contact reaction on nano silicon dioxide and an amino-containing silane coupling agent in an alcohol solvent to obtain a first contact reaction product; s2, the first contact reaction product and polyfatty acid are subjected to a second contact reaction, the modified nano-silica is obtained, and the polyfatty acid is selected from C18 unsaturated fatty acid dimer or C18 unsaturated fatty acid trimer. The modified nano silicon dioxide and the high-temperature-resistant tackifying and shear-improving agent disclosed by the invention can effectively improve the structural strength of a water-in-oil emulsified drilling fluid system in an extreme high-temperature environment, especially improve the dynamic shear force and low-shear-rate viscosity of the water-in-oil emulsified drilling fluid, and further improve the sedimentation stability of the water-in-oil emulsified drilling fluid system.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A kind of oil-based drilling fluid cutting agent and preparation method thereof

ActiveCN105623625BIncrease dynamic shear forceImprove temperature stabilityDrilling compositionSolventCutting force

The invention provides an oil-based drilling fluid extracting and cutting agent and a preparation method thereof. The method comprises the following steps: maleic anhydride and styrene are subjected to a polymerization reaction under existence of a solvent and an initiator to obtain a mixture; the obtained mixture is subjected to a reaction under existence of an alcohols compound and a catalyst to obtain an extracting and cutting agent crude product; and the obtained extracting and cutting agent crude product is subjected to removal of an organic solvent, and then is dried and crushed to obtain the oil-based drilling fluid extracting and cutting agent. The oil-based drilling fluid extracting and cutting agent has a long straight chain alkyl group and contains a lot of polar groups, net structures are formed by the long chain alkyl group in an oil-based drilling fluid through association action, the polar groups in molecules are capable of interacting with other groups through electrostatic attraction or hydrogen bond, so that the net structure with larger specific surface area is formed, and the existence of the net structures effectively increases the dynamic cutting force of the drilling fluid.

Owner:BC P INC CHINA NAT PETROLEUM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com