A kind of raw material composition for coating agent, coating agent and its preparation method and application

A technology of raw material composition and coating agent, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of slow dissolution rate, poor shear resistance, unstable drilling fluid system, etc., and achieve fast dissolution rate , high dynamic shear force, good application prospect and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

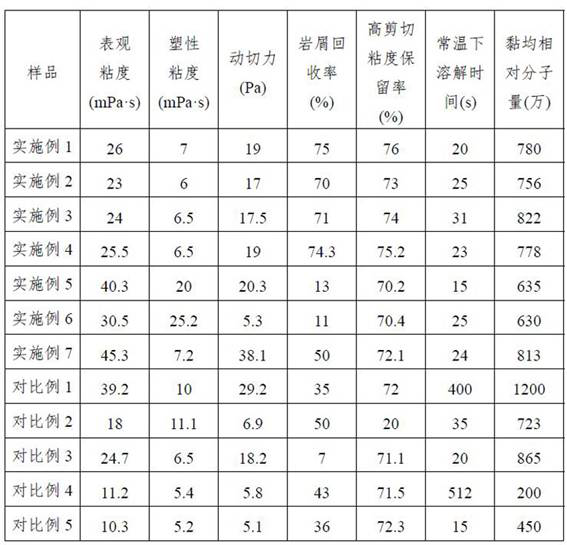

Examples

Embodiment 1

[0092] The present invention prepares the coating agent through the raw material formula and preparation method for the coating agent in the following proportions:

[0093] 153g of acrylamide, 27g of sodium carbonate, 3.1g of ammonium lauryl polyoxyethylene ether sulfate, 13g of polyoxyethylene lauryl alcohol (8) ether, 18g of α-methylstyrene, 27g of potassium chloride, polyoxypropylene polyoxyethylene 4.1g of oxyethylene glyceryl ether, 26g of dimethyl diallyl ammonium chloride, 728.8g of deionized water, 0.025g of di-tert-butyl peroxide, 0.0085g of p-tert-butylcatechol, N -Hydroxyethylethylamine triacetic acid 0.063g, dodecyl mercaptan 0.018g, azobisisobutamidine hydrochloride 1.1g, 3-[ N -tris(hydroxymethyl)methylamino]-2-hydroxypropanesulfonate sodium 15g, N - 23 g of sodium octadecyl-β-alanine, 15 g of methanol.

[0094] Concrete preparation process is as follows:

[0095] (1) Turn on the stirring in the reactor, set the speed at 200r / min, add 153g of acrylamide, 27g o...

Embodiment 2

[0101] The present invention prepares the coating agent through the raw material formula and preparation method for the coating agent in the following proportions:

[0102] 162g of acrylamide, 37g of sodium carbonate, 2.3g of laureth-4 phosphate, 17g of octylphenol polyoxyethylene ether, 21g of sodium 2-acrylamido-2-methylpropanesulfonate, 37g of potassium chloride, poly Oxypropylene polyoxyethylene glyceryl ether 3.2g, methacryloxyethyltrimethylammonium chloride 23g, deionized water 697.5g, di-tert-butyl peroxide 0.04g, p-tert-butylcatechol 0.01g, N -Hydroxyethylethylamine triacetic acid 0.07g, dodecyl mercaptan 0.02g, azobisisobutamidine hydrochloride 0.8g, 1,4-butanediol diacrylate 24g, N - 20 g of sodium octadecyl-β-alanine, 16 g of methanol.

[0103] Concrete preparation process is as follows:

[0104] (1) Turn on the stirring in the reactor, set the speed at 200r / min, mix 162g of acrylamide, 37g of sodium carbonate, 2.3g of laureth-4 phosphate, 17g of octylphenol polyo...

Embodiment 3

[0110] The present invention prepares the coating agent through the raw material formula and preparation method for the coating agent in the following proportions:

[0111] Acrylamide 147g, Sodium Carbonate 21g, Laureth Ammonium Sulfate 4.3g, Octylphenol Polyoxyethylene Ether 20g, α-Methyl Styrene 11g, Potassium Chloride 21g, Polyoxypropylene Polyoxyethylene Glyceryl Ether 6.0 g, 30g of dimethyl diallyl ammonium chloride, 739.7g of deionized water, 0.031g of ammonium persulfate, 0.0097g of p-tert-butylcatechol, 0.05g of diethylenetriaminepentaacetic acid, dodecylsulfur Alcohol 0.023g, azobisisobutyramide hydrochloride 0.96g, 3-[ N - 30 g of sodium tris(hydroxymethyl)methylamino]-2-hydroxypropanesulfonate, 30 g of dodecyldimethyl betaine, and 13 g of methanol.

[0112] Concrete preparation process is as follows:

[0113] (1) Turn on the stirring in the reactor, set the speed at 200r / min, add 147g of acrylamide, 21g of sodium carbonate, 4.3g of ammonium lauryl polyoxyethylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com