Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Improve anti-slump performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

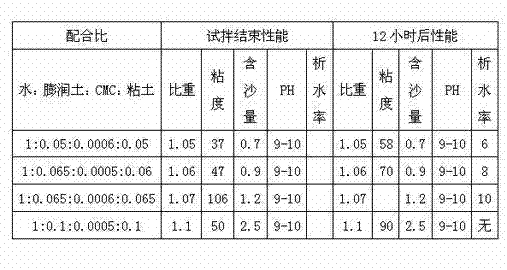

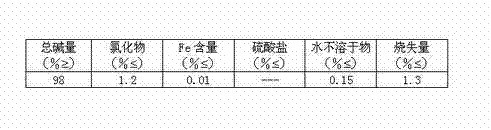

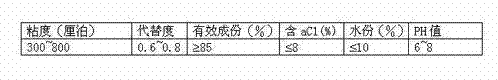

Construction slurry for rotary pile drilling

InactiveCN102226077ARich and stableEnrich and perfect mechanicsDrilling compositionSlurry wallSodium Bentonite

The invention discloses a type of construction slurry for rotary pile drilling. The slurry is a type of compound slurry comprising water, bentonite, hydroxypropyl methyl cellulose solution, clay and soda ash. The construction slurry provided by the present invention can be widely applied in fields of well drilling, rotary pile drilling, and underground diaphragm wall. During a preparing process, the slurry can be mixed quickly and well. The slurry also has advantages of high efficiency, low pollution, low energy consumption and low cost.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HIGHWAY ENG

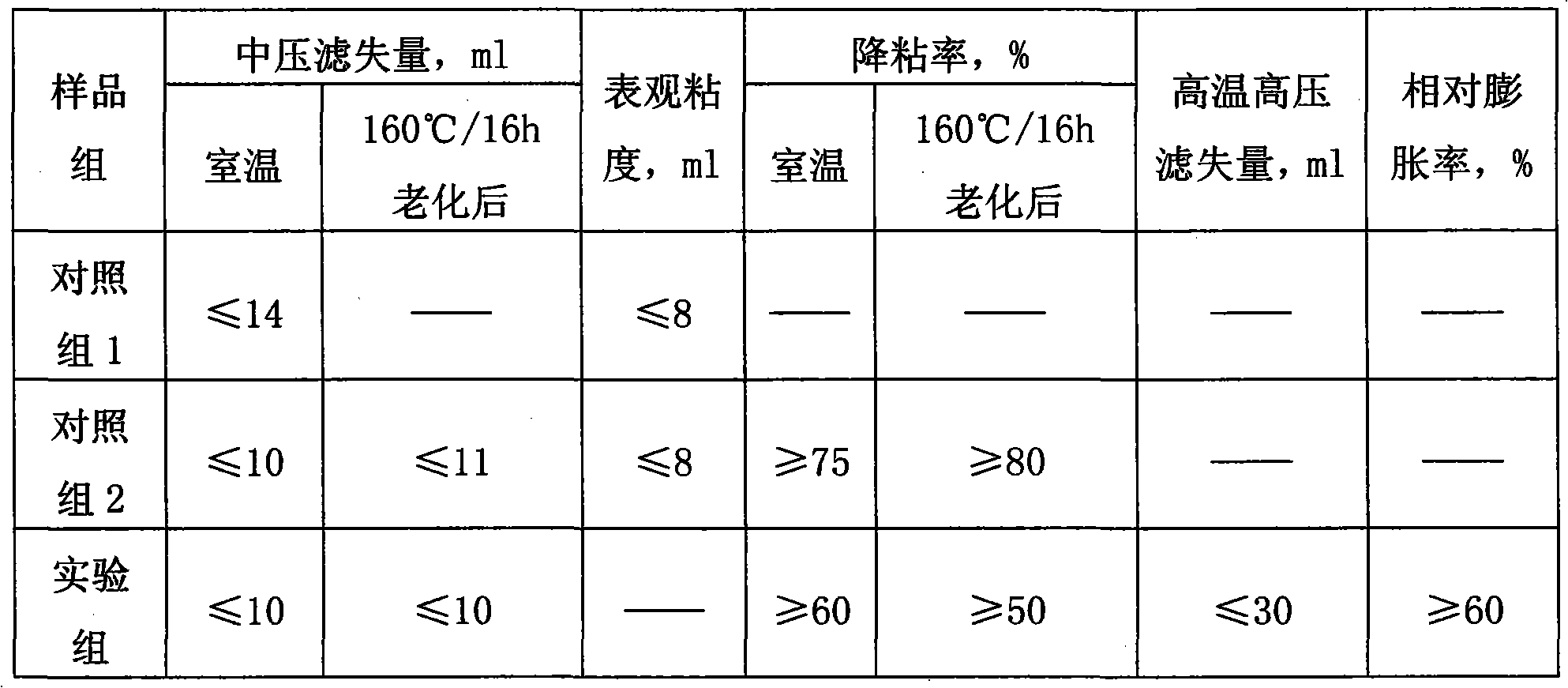

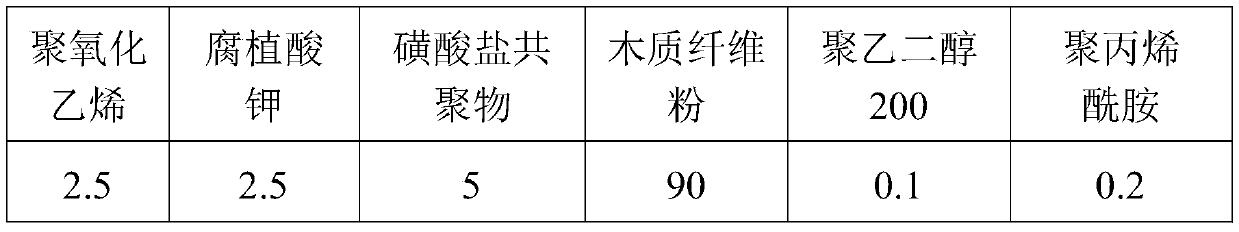

Process for preparing drilling fluid for preventing polycrystalline diamond compact (PDC) bit balling

InactiveCN101892036AImprove anti-slump performanceImprove integrityDrilling compositionCelluloseWater dispersible

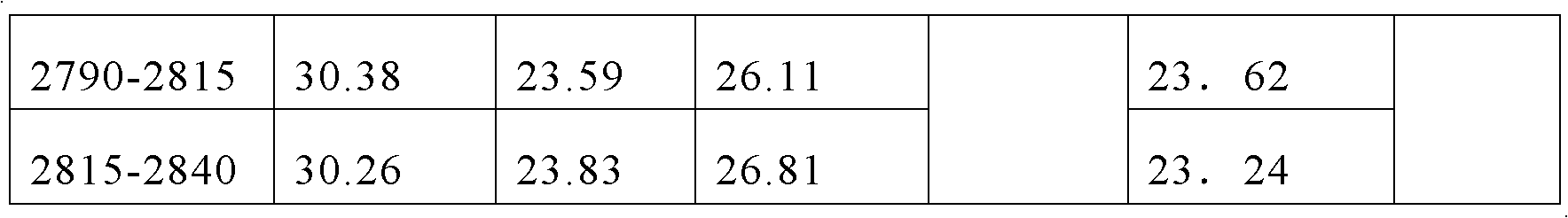

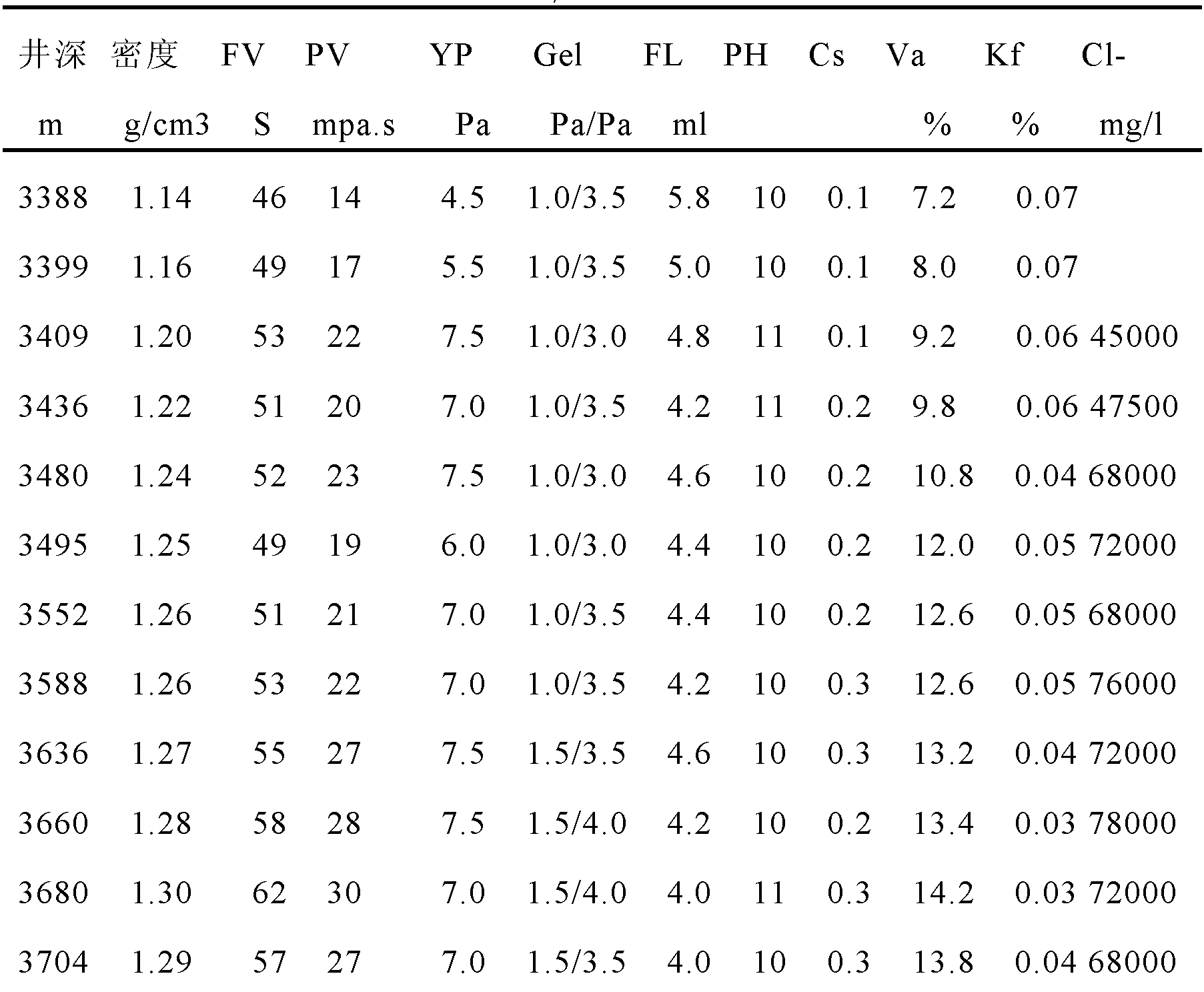

The invention relates to a process for preparing drilling fluid, in particular to a process for preparing the drilling fluid for preventing polycrystalline diamond compact (PDC) bit balling. The process comprises a construction process and a dosage formula of treating agents and is characterized in that: according to the dosage formula, the treating agents are prepared by mixing clear water polymer original slurry, poly anionic cellulose (PAC), calcium carbonate (QS-4), carboxymethyl starch (CMS), sulfonated phenolic resin(SMP-2), water dispersible cation emulsified asphalt powder (SFT-1), sodium chloride(NaCL) and sodium formate (WT-1) in a mass ratio of 1,000:2-3:30-40:20-30:2-3:1.5-2:50-100:20; and the construction process comprises the following steps of: according to a circulation circle, uniformly mixing a coating agent PAC, a filtrate reducer CMS, a salt and high-temperature resistant filtrate reducer SMP-2 and an anti-sloughing lubricant SFT-1 for 12h at first; adding QA-4, NaCL, WT-1 into the mixture and uniformly mixing the mixture; and regulating the mixture to have a density Rho of 1.06 to 1.10g / cm<3>, a funnel viscosity T of 38 to 45s and an API water loss FL of 4 to 6ml. The process has the advantages of effectively preventing the balling of a sticking bit and a PDC bit at a lower curved section, reducing a frictional resistance and a torque, eliminating a sticking phenomenon, improving a mechanical drilling rate and ensuring downhole safety.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

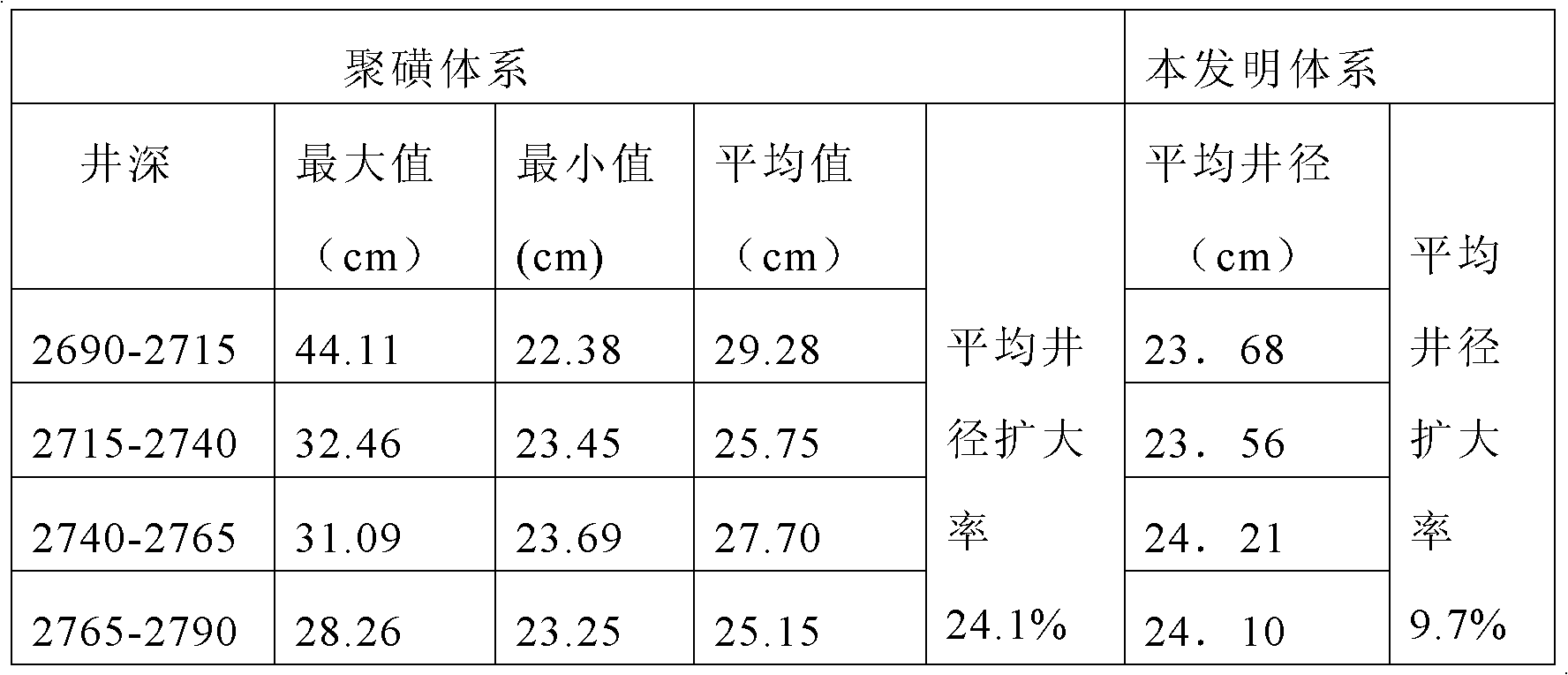

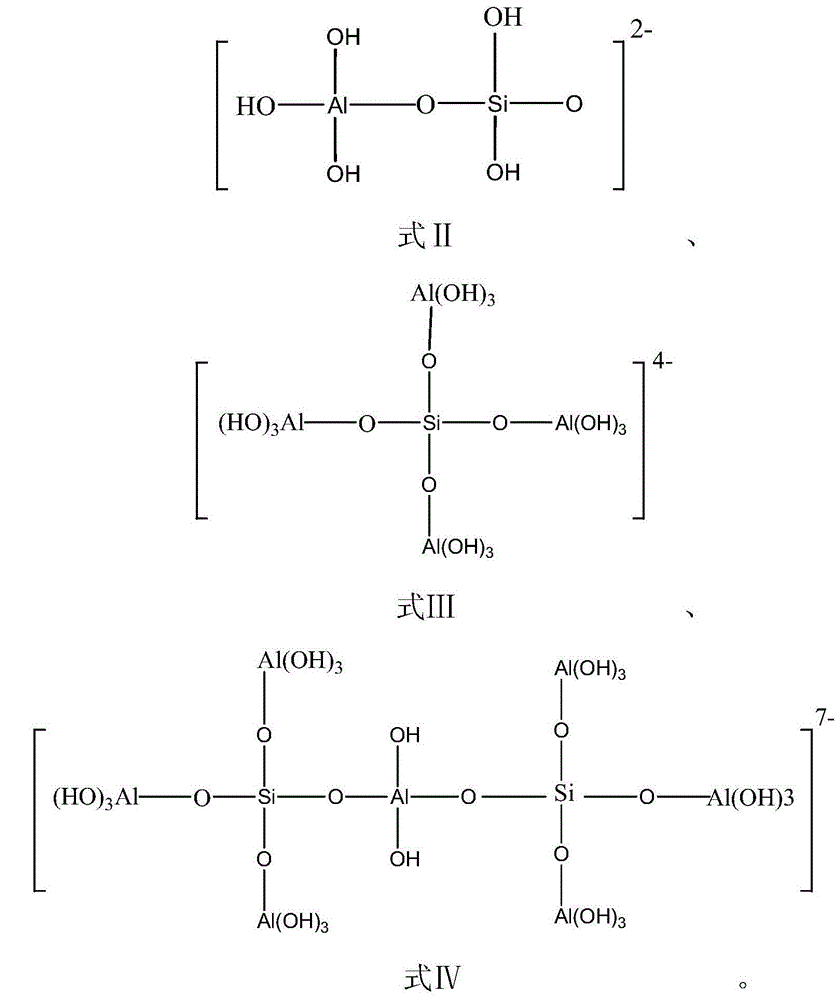

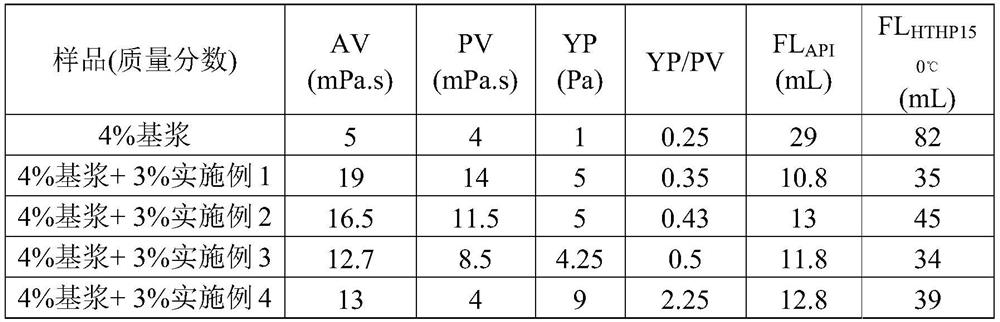

Silicate-aluminate anti-sloughing drilling fluid

InactiveCN106318347AImprove anti-slump performanceProcess stabilityDrilling compositionBlocking layerInorganic salts

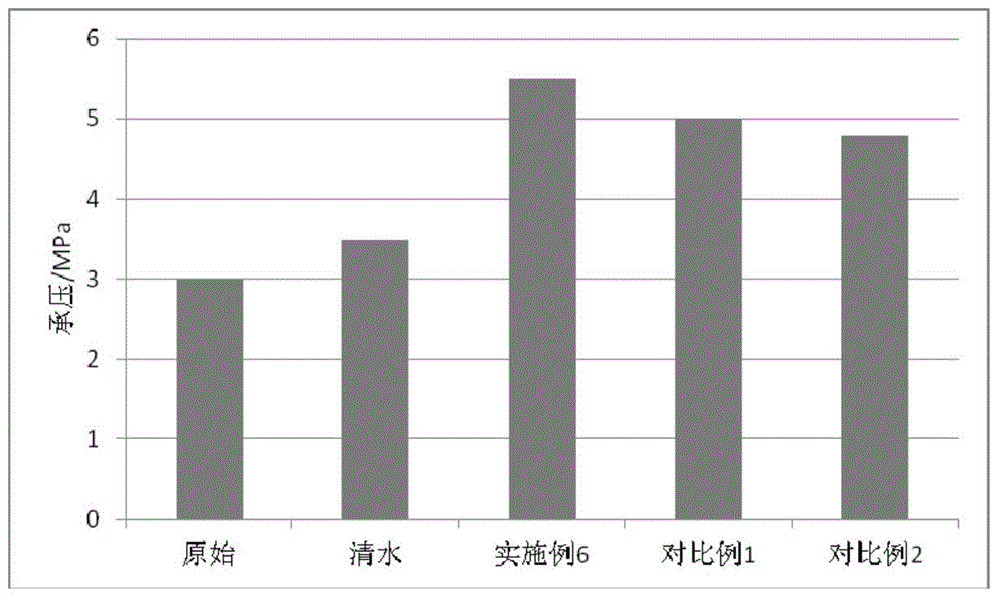

The present invention relates to the technical field of chemical oil field drilling fluids, and in particular discloses a silicate-aluminate system anti-sloughing drilling fluid, the drilling fluid is prepared from raw bentonite base slurry, a viscosity and shear strength improving agent, a filtrate loss reducer A, a high temperature filtrate loss reducer B, a flow type regulator, an organic inhibitor, an inorganic salt, a plugging agent, sodium hydroxide, barite, a silicate and sodium metaaluminate, by compounding of the low modulus silicate and the aluminate, in the conversion process of filtrate from high pH value environment to neutral environment, the low modulus silicate and the aluminate generate a silicate gel and a new material aluminosilicate precipitate to play chemical wall fixing and physical formation plugging roles, namely an inorganic mineral dense blocking layer is formed immediate vicinity of a wellbore, the collapse pressure of an easy-to-slump formation can be significantly reduced, the bearing capacity is effectively improved, anti-sloughing inhibition capacity of the drilling fluid can be improved, and the silicate-aluminate system anti-sloughing drilling fluid can better satisfy the requirements of borehole wall stability and safe drilling, and achieves the purpose of inhibiting, plugging and chemical wall fixing.

Owner:SINOPEC SSC +1

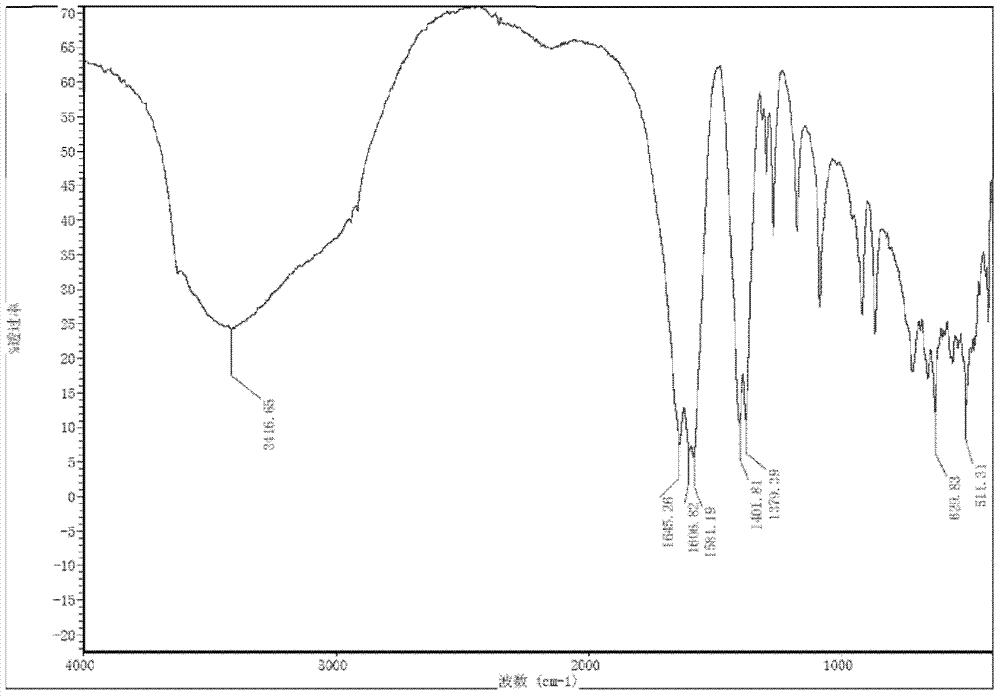

Wall fixing agent for drilling fluid as well as preparation method and application of wall fixing agent

The invention provides a wall fixing agent for drilling fluid as well as a preparation method and application of the wall fixing agent and belongs to the technical field of drilling fluid. The wall fixing agent for the drilling fluid is prepared from the following raw materials in parts by weight: 10 to 25 parts of acrylamide; 10 to 25 parts of an adhesive; 10 to 25 parts of dimethyl diallyl ammonium chloride; 1 to 5 parts of acrylic acid; 1 to 5 parts of 2-acrylamide-2-methylpropanesulfonic acid; 1 to 5 parts of a chain transfer agent; 2 to 5 parts of an initiator; 5 to 12 parts of sodium hydroxide; and 80 to 100 parts of distilled water. According to the wall fixing agent provided by the invention, the strength of well wall rock is improved by enhancing cohesive force and adhesive forceamong rock particles, so that the anti-collapse performance of the drilling fluid is improved. Particularly, the hydration force and the like of the shale during hydration expansion can be weakened orcompletely counteracted by the cohesion of a bionic shell, so that the stability of a well wall is improved, and the wall fixing agent has relatively good adhesion performance in a water environment.

Owner:BEIJING SHIDABOCHENG TECH

Organic-inorganic composite silicate high-temperature-resistant film-forming drilling fluid system

ActiveCN109735314AImprove performanceImprove anti-slump performanceDrilling compositionSodium BentoniteReducer

The invention discloses an organic-inorganic composite silicate high-temperature-resistant film-forming drilling fluid system, relates to drilling fluid, and belongs to the technical field of geological resource exploration and development. The drilling fluid system comprises bentonite base slurry, thickening agents, filtrate reducers, blocking agents, weighting agents, inorganic silicate and organic silicate, the dosage of raw materials is calculated according the weight of the bentonite base slurry, the weight percent of the bentonite base slurry is 1%-4%, the concentration of the organic silicate is 0.05mol / L-0.5mol / L, and the weight percent of the inorganic silicate is 0.1%-5%. According to the organic-inorganic composite silicate high-temperature-resistant film-forming drilling fluidsystem, the inhibition and anti-collapse ability of the drilling fluid is improved, the requirements of borehole stability and safe drilling are more effectively met, and inhibition, blocking and chemical wall fixation are achieved.

Owner:JILIN UNIV

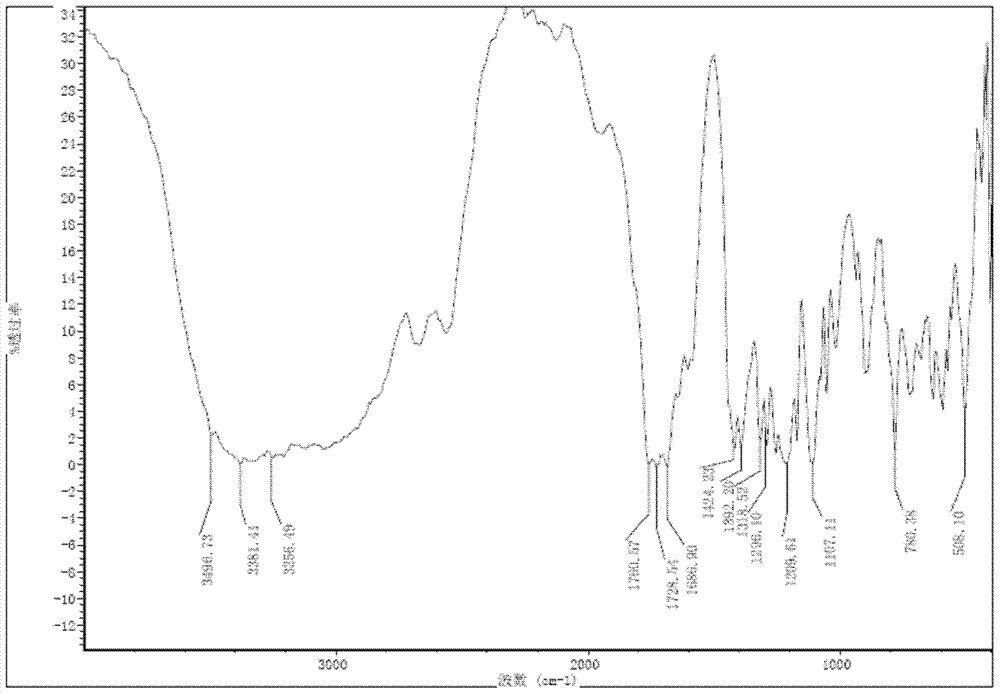

pH-responsive drilling fluid aluminum-based anti-sloughing agent and preparation method thereof

ActiveCN106947439APH responsiveSolve the outstanding problems of compatibilityDrilling compositionThroatPolyol

The present invention relates to a pH-responsive drilling fluid aluminum-based anti-sloughing agent and a preparation method thereof. According to the present invention, the pH-responsive drilling fluid aluminum-based anti-sloughing agent prepared by carrying out a reaction on polyether polyol, a lactone monomer, an initiator, an aluminum compound and a pH value adjuster has pH responsiveness, stably exists in the drilling fluid (the pH value is more than 8) in the form of a dissolved state, can rapidly respond within a pH responsive range (the pH value is more than or equal to 5 and is less than or equal to 7.5) to form aluminum hydroxide precipitate, and can block stratum bore throat and micro-cracks through physical and chemical action, can improve the collapse resistance of the aluminum-based drilling fluid, can strengthen the stability of the borehole wall, and can meet the complex stratum exploration and development requirements; and the preparation method has characteristics of simpleness, easy reaction control, low production cost, stable product quality, and easy industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Construction method of underground diaphragm wall in water-rich silty-fine sand layer

InactiveCN112281810AReduce side pressureImprove stabilityExcavationsBulkheads/pilesSlurry wallSodium Bentonite

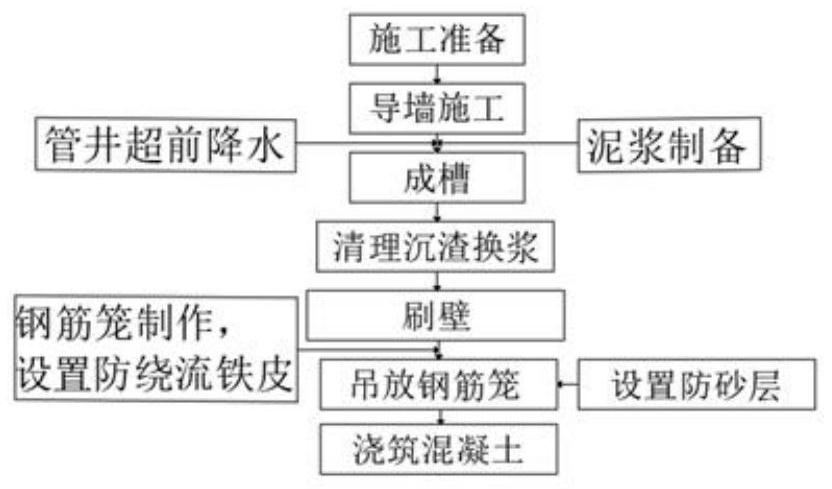

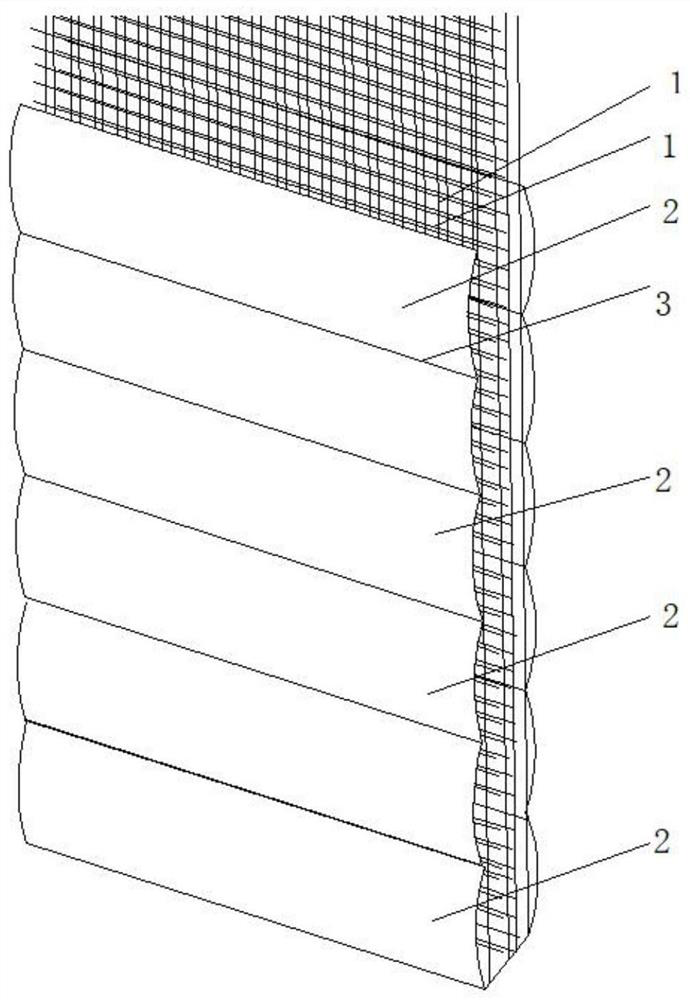

The invention discloses a construction method of an underground diaphragm wall in a water-rich silty-fine sand layer. The construction method comprises the following steps of guide wall construction,tube well advanced precipitation, slurry preparation, grooving, groove cleaning and slurry replacement, wall brushing, reinforcement cage manufacturing, reinforcement cage hoisting, sand prevention layer arrangement and concrete pouring. According to the construction method of the underground diaphragm wall in the water-rich silty-fine sand layer, firstly, the self-stability of groove walls is improved through advanced precipitation of tube wells in a foundation pit which are constructed in advance; and during grooving, sodium bentonite is adopted for slurry manufacturing, and thin and tough slurry cakes are formed on the groove walls, so that the collapse resistance is improved.

Owner:江苏旭辰交通科技发展有限公司

Anti-collapse agent of zwitterionic emulsified asphalt for drilling fluid

ActiveCN103980868AWith anti-collapse performanceImprove stabilityDrilling compositionBetaineIndustrial Additive

The invention provides an anti-collapse agent of zwitterionic emulsified asphalt for drilling fluid. The anti-collapse agent comprises the following raw material components in percentage by weight: 20.0-35.0% of industrial additive oil, 15.0-30.0% of asphalt, 7.0-18.0% of sulfonated asphalt, 0.4-0.8% of dodecyldimethylsulfopropyl betaine, 1.0-2.0% of organic stabilizer, 8.0-15.0% of aviation kerosene and 5.0-42.0% of water. According to the invention, an emulsifying agent is reselected, the organic stabilizer is also added, so that the anti-collapse agent has anti-collapse performance and relatively high storage stability and is capable of avoiding the layering phenomenon; the anti-collapse agent can be used for obtaining high-quality products by adding relatively few raw materials and has relatively strong anti-frost property; the quality of the products can be regulated within a certain range, and the anti-collapse agent has a wide market popularization value.

Owner:YUMEN OIL FIELD KEDA CHEM

Low-density water-based drilling fluid and preparation method thereof

InactiveCN109868123AMeet the requirements of safe drillingGood settlement stabilityDrilling compositionWater basedInorganic salts

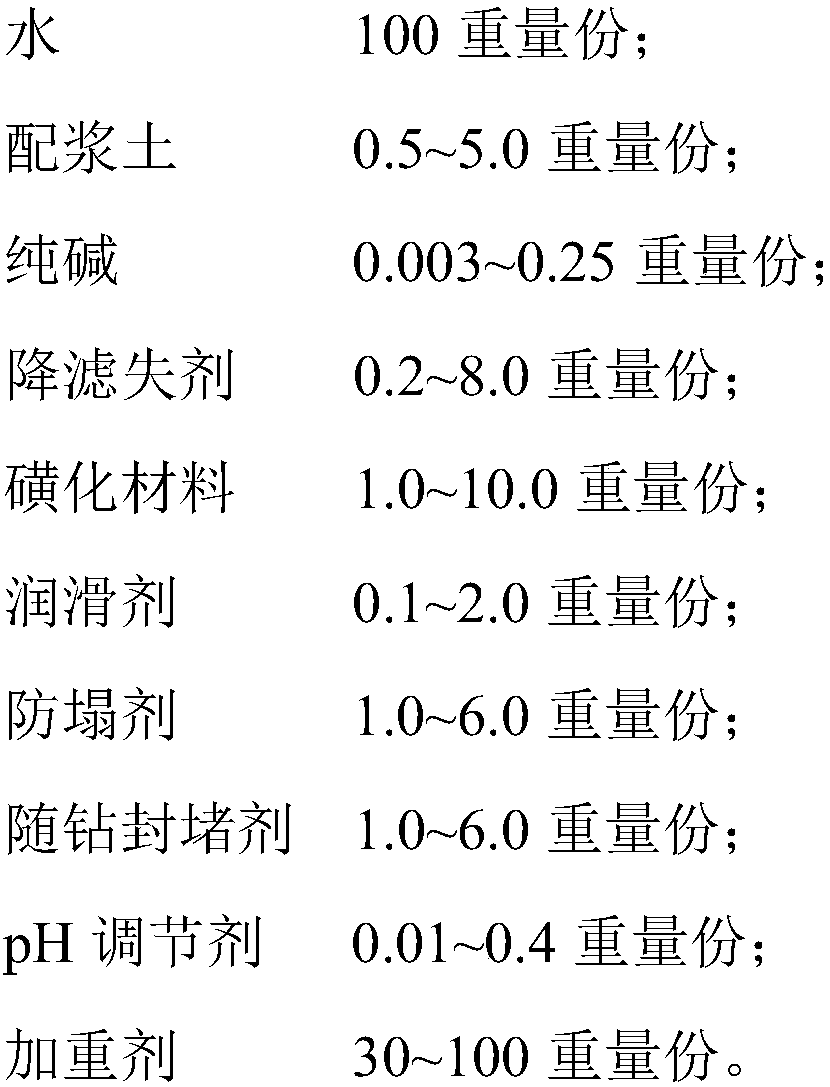

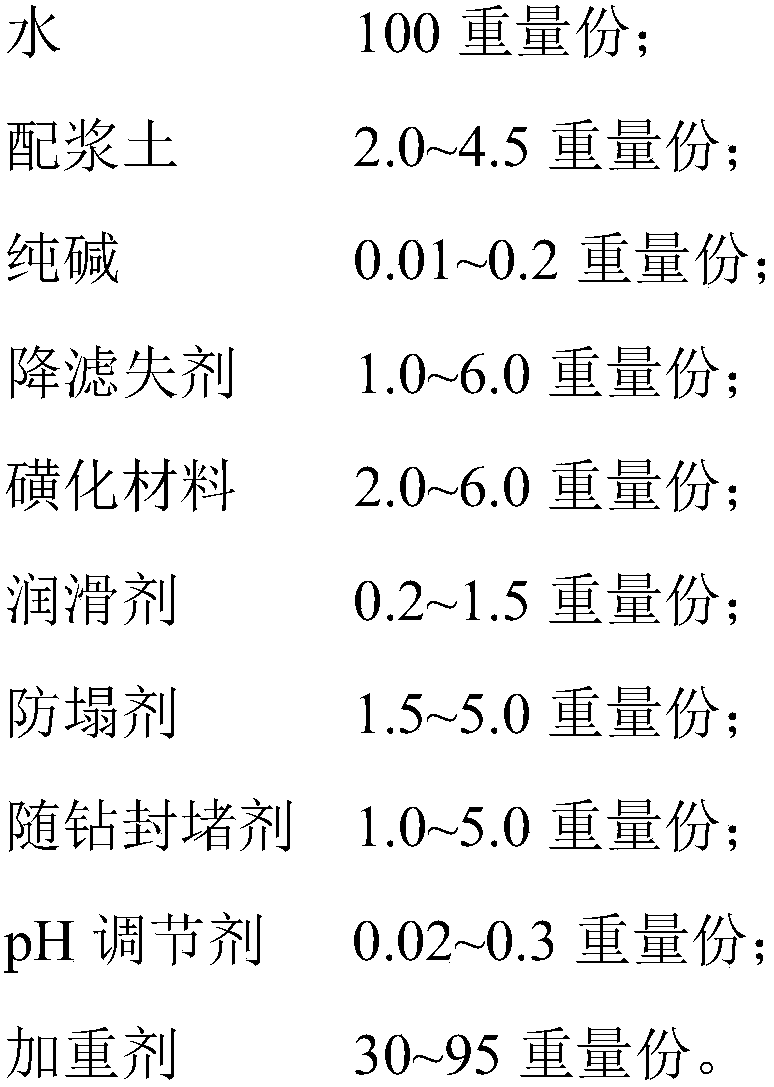

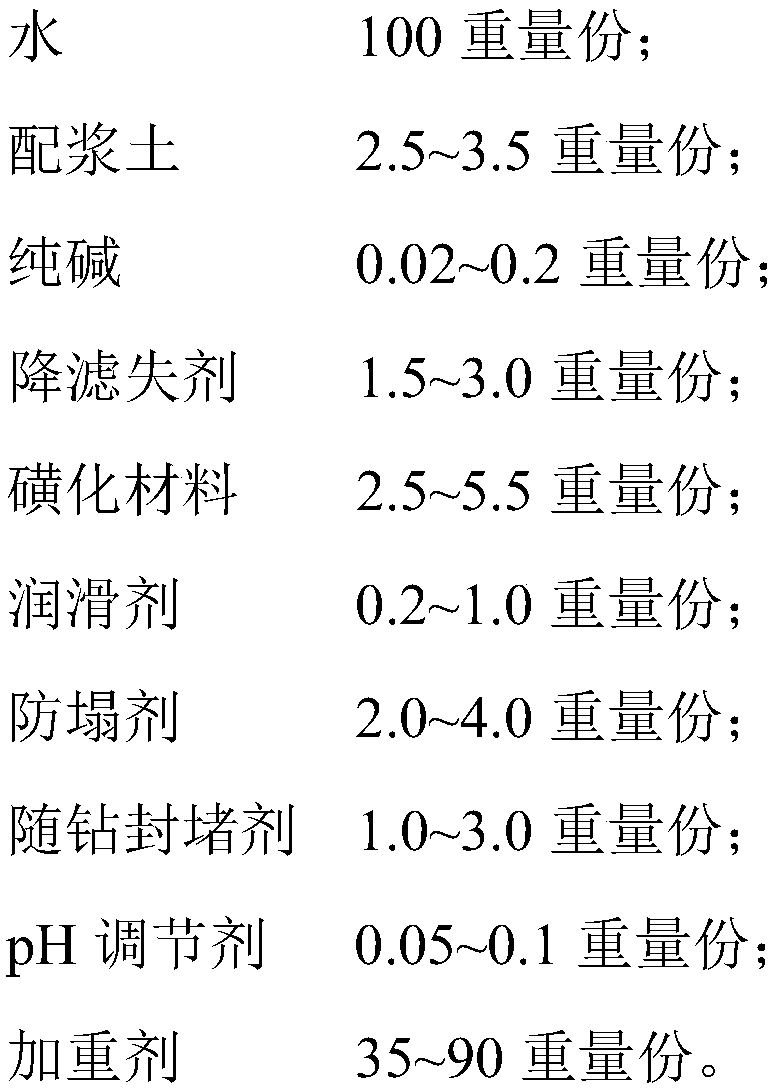

The invention provides a low-density water-based drilling fluid system for safely drilling through a long open-hole diabase formation. The drilling fluid system comprises the following components, inparts by weight: 100 parts by weight of water, 0.5-5.0 parts by weight of slurry mixing soil, 0.003-0.25 part by weight of sodium carbonate, 0.2-8.0 parts by weight of a fluid loss agent, 1.0-10.0 parts by weight of a sulfonated material, 0.1-2.0 parts by weight of a lubricant, 1.0-6.0 parts by weight of an anti-collapse agent, 1.0-6.0 parts by weight of a plugging agent while drilling, 0.01-0.4 part by weight of a pH adjusting agent and 40-80 parts by weight of a weighting agent; and the drilling fluid system further comprises 0.1-10.0 parts by weight of an inorganic salt. The drilling fluidprovided by the invention has good rheological performance and rock-carrying capacity; the drilling fluid can not only safely drill through the diabase formation, but also can meet the purpose that fallen diabase returns to the ground in time, effectively avoid stuck drilling, ensure safe drilling and shorten a well construction period through improvement of plugging while drilling and collapse resistance of the system.

Owner:CHINA PETROLEUM & CHEM CORP +1

Emulsified residual oil type lubricant for drilling fluid and production process thereof

ActiveCN103013463ALow raw material costReduce manufacturing costDrilling compositionParaffin waxResidual oil

The invention discloses an emulsified residual oil type lubricant for a drilling fluid and a production process thereof. The emulsified residual oil type lubricant for the drilling fluid comprises the following components in parts by weight: 40 to 60 parts of residual oil, 10 to 20 parts of No.15 technical white oil, 10 to 20 parts of paraffin, 20 to 30 parts of an anti-freezing agent, 1 to 5 parts of sorbitan oleate and 1 to 5 parts of sulfonic acid. The emulsified residual oil type lubricant prepared by adopting the production process is used in the drilling fluid and has the advantages of low friction resistance, good immersion effect and high anti-collapse performance; and by adopting the emulsified residual oil-type lubricant, the quality of mud cakes can be effectively improved.

Owner:河北华运鸿业化工有限公司

Environment-friendly anti-collapse plugging drilling fluid as well as preparation method and application thereof

ActiveCN111793483AImprove anti-slump performanceImprove the blocking effectProductsReagentsGeotechnical engineeringInorganic salts

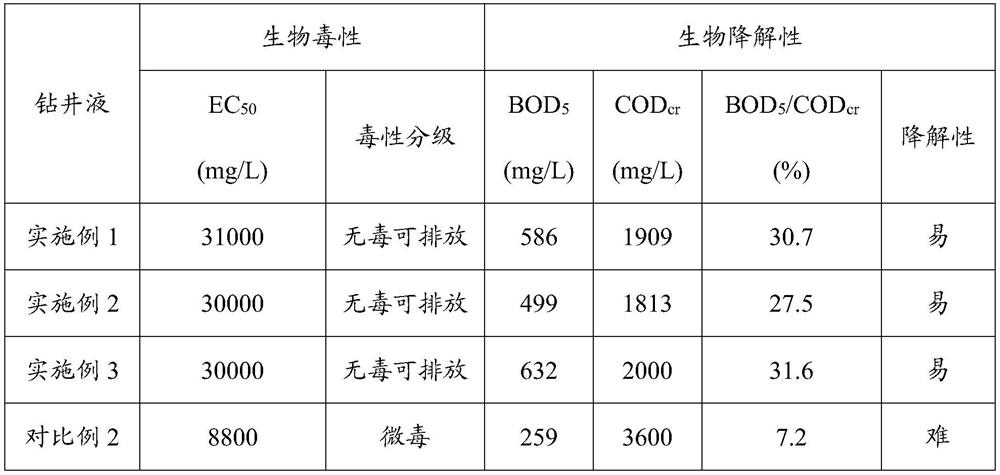

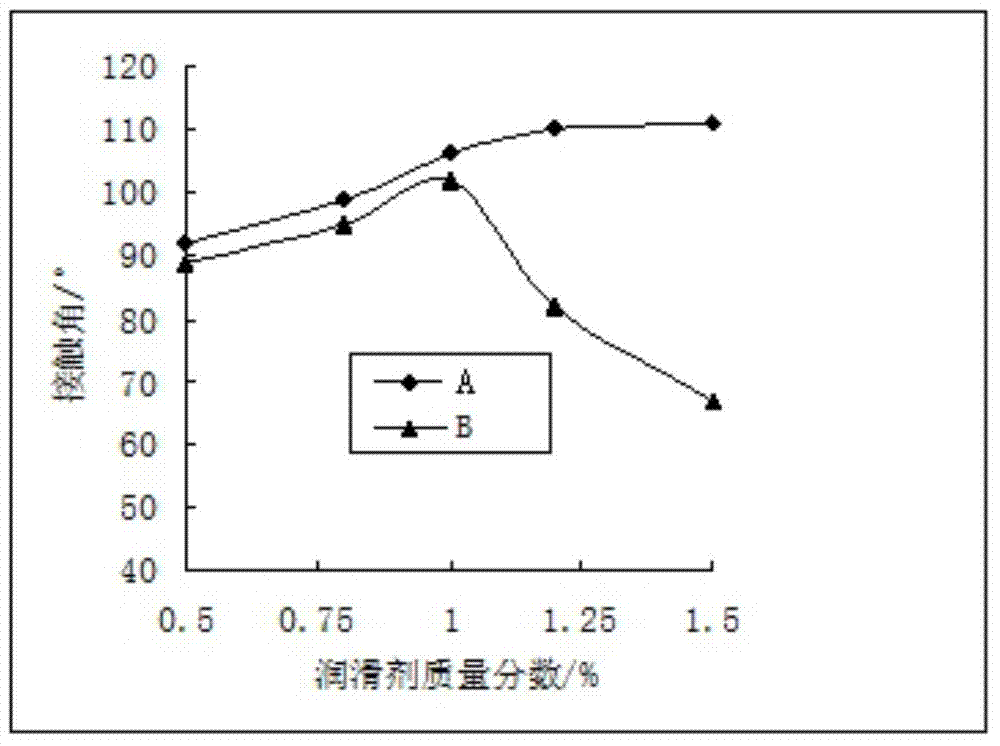

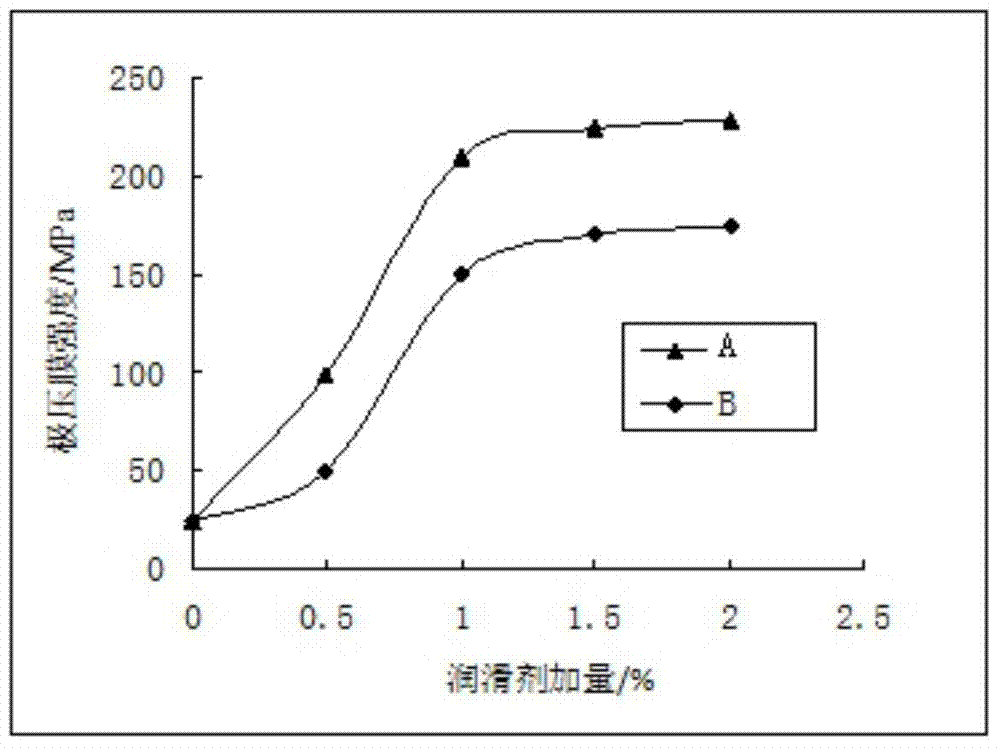

The invention provides an environment-friendly anti-collapse plugging drilling fluid as well as a preparation method and an application thereof, which belong to the field of drilling fluids for petroleum drilling engineering. The invention provides the environment-friendly anti-collapse plugging drilling fluid, which comprises: 100 parts of water, 1-3 parts of sodium bentonite, 0.2-0.4 parts of apH value regulator, 0.3-0.5 part of a glue protecting agent, 0.1-0.2 part of a coating agent, 1-2 parts of a filtrate reducer, 4-6 parts of inorganic salt, 1-3 parts of an inhibitor, 1-3 parts of a lubricant, 2-4 parts of a blocking agent, 0.3-0.8 part of an anti-collapse agent, 0.1-0.15 part of a flow pattern regulator and 0-100 parts of a weighting agent. The drilling fluid provided by the invention is good in rheological property and filtrate loss reduction property, the HTHP filtrate loss and PPT filtrate loss at 150 DEG C are remarkably reduced, a mud cake is thin and compact, borehole wall instability caused by pore pressure increase due to the fact that too much drilling fluid filtrate enters a stratum can be prevented, and the drilling fluid is non-toxic and easy to degrade.

Owner:XINJIANG BEIKEN ENERGY ENG +1

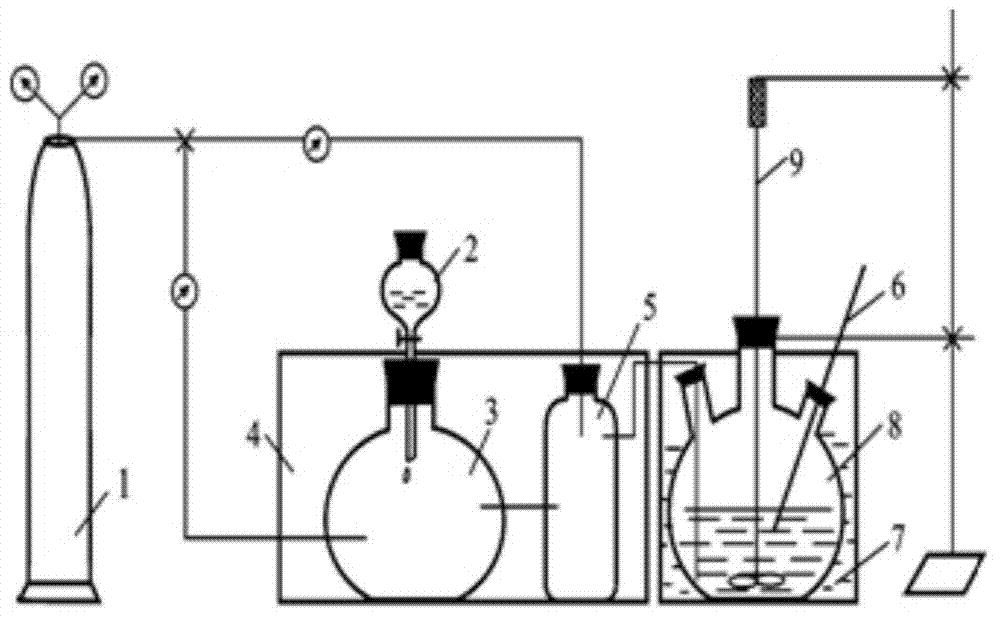

Method for preparing multifunctional lubricant of drilling fluid by using waste oil

The invention discloses a method for preparing a multifunctional lubricant of drilling fluid by using waste oil. The method comprises the following steps: (1) firstly, weighing the waste oil and putting into a reactor, and putting the reactor into an electrothermal constant-temperature water bath kettle; (2) then weighing liquid SO3 and putting into a dropping funnel, in order to change the liquid SO3 dripping from the dropping funnel into a gas SO3, and keeping a gas generator connected with the dropping funnel at 50-70 DEG C by a thermal cycling effect of a jacket water bath; (3) mixing with N2 before the gas SO3 enters a reactor; and (4) controlling the reaction temperature at 50 DEG C, enabling the gas SO3 to react with the waste oil for 2-4 hours, and then adding an organic alkali to the reactor, adjusting the pH to 8-9, and then adding a composite surfactant to the reactor, so as to obtain the lubricant after agitating for 3-10 minutes. Compared with the similar lubricant, the lubricant prepared by the method disclosed by the invention is simple in production technology, and low in cost, has good high-temperature extreme pressure lubricity, also has good fluid loss effect and anti-collapse performance, and is applicable to horizontal well and complicated stratum drilling.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparation method of polyalcohol anti-collapse inhibitor for environment-friendly drilling fluid salt slurry system

InactiveCN111454699ASimple production processReduce investmentDrilling compositionSide productProcess engineering

The invention relates to a polyalcohol anti-collapse inhibitor for a drilling fluid salt slurry system and a preparation method of the polyalcohol anti-collapse inhibitor for the environment-friendlydrilling fluid salt slurry system. The preparation method comprises the following preparation steps: (1) weighing ethylene oxide or / and propylene oxide, ethylene glycol or glycerol as reactants, uniformly stirring the components at room temperature, and slowly pouring the mixture into a high-pressure reaction kettle; (2) adding a proper amount of catalyst, continuously introducing nitrogen for protection, controlling the reaction temperature at 75-125 DEG C and the pressure at 0.1-0.3 MPa, and continuously stirring the components; (3) after reaction for 60 minutes, opening a safety relief valve, removing residual pressure in the high-pressure reaction kettle, and discharging a synthetic product everywhere; (4) washing the by-product and redundant reactants with distilled water or a hydrochloric acid solution or NaOH solution with the concentration of 0.1% until the pH value is neutral; and (5) removing water from the product obtained in the step (4) to obtain the polyalcohol anti-collapse inhibitor. The product has excellent anti-sloughing inhibition performance, and the lubricity of the drilling fluid is remarkably improved.

Owner:扬州润达油田化学剂有限公司

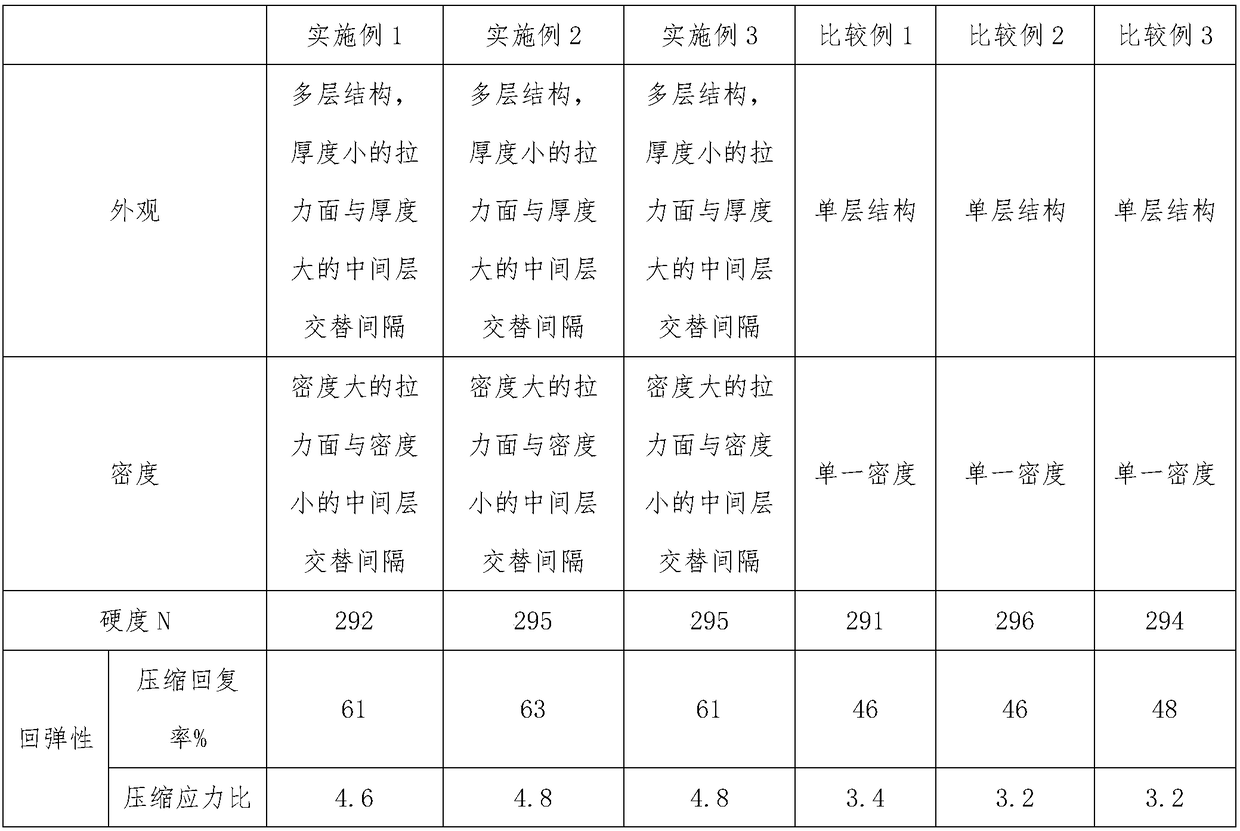

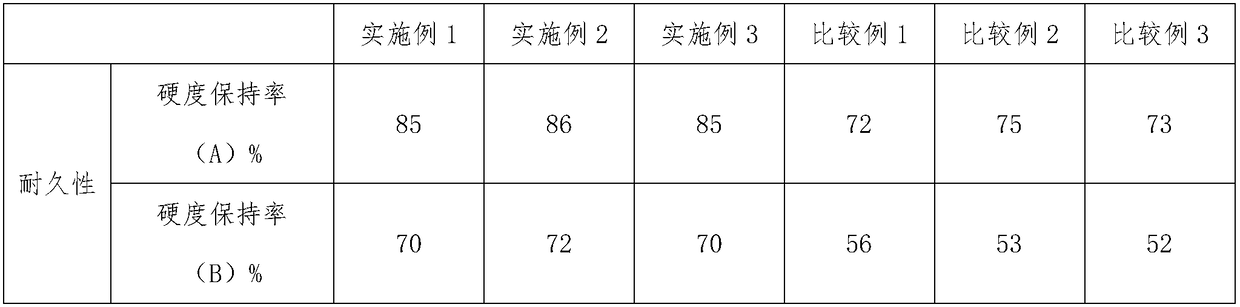

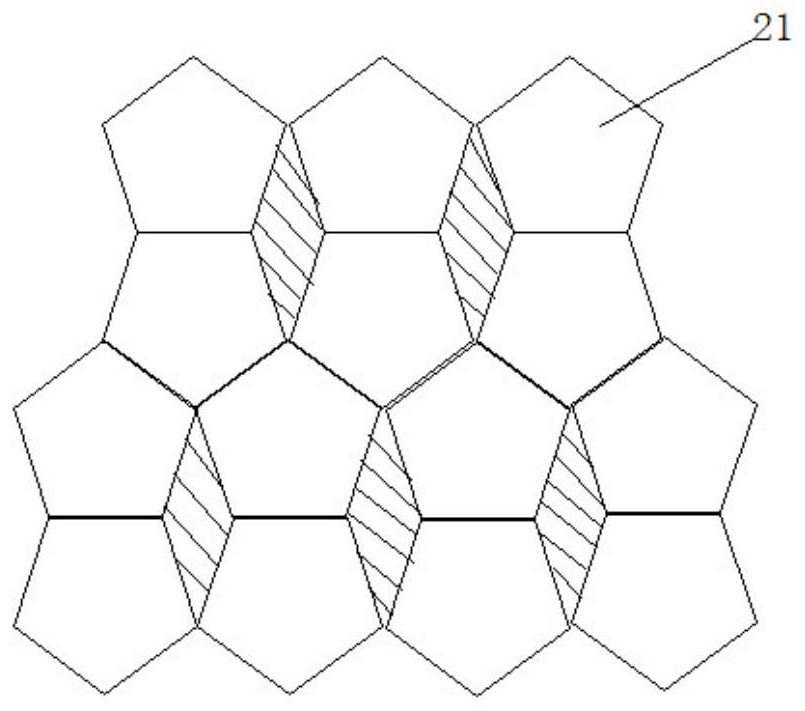

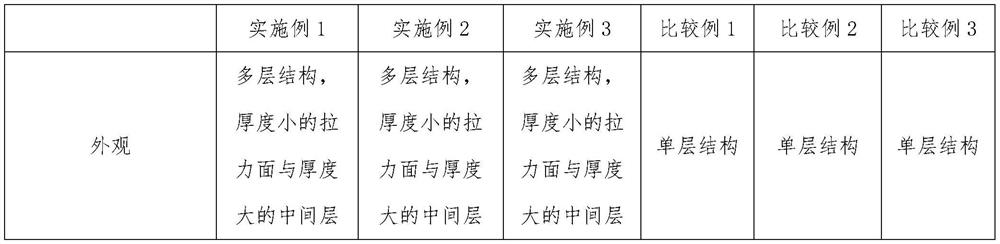

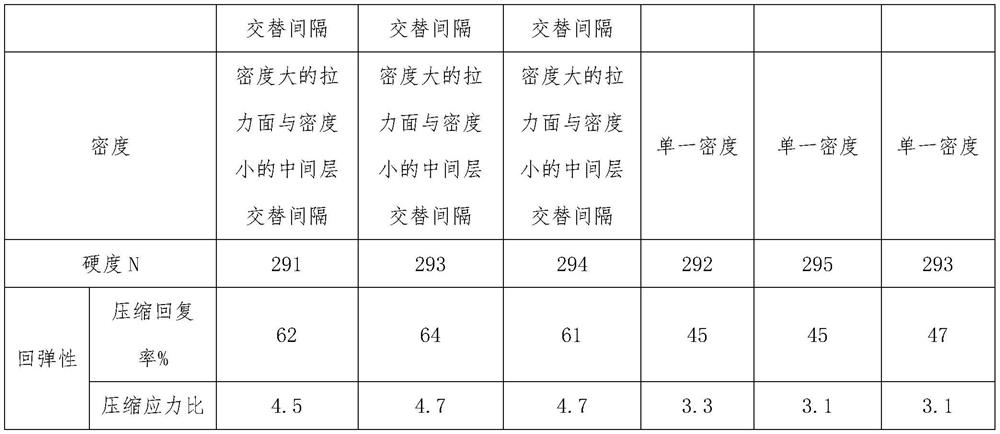

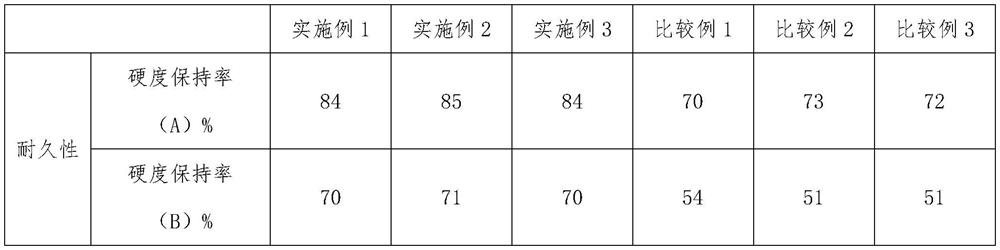

Preparing method of multi-layer tension surface fiber mat and fiber mat

PendingCN109385747AImprove anti-slump performanceGuaranteed lightweightNon-woven fabricsElastomerEngineering

The invention discloses a preparing method of a fiber mat. With elastomer fiber as the raw material, unit fiber layers with upper tension surfaces, lower tension surfaces and middle layers are formedthrough the steps of opening, carding, lapping, needling and the like, the overlapped unit fiber layers are hot-pressed, and finally the finished fiber mat of a multi-layer tension surface structure is prepared. The fiber mat prepared through the method has the multi-layer tension surface structure, the pressure exerted on the fiber mat can be buffered by multiple stages, the anti-collapsing performance is greatly improved, the light weight of the fiber mat is ensured, no glue is used in the production process, and no harm is caused to a human body.

Owner:昆山吉美川纤维科技有限公司

Anti-sloughing diluted filtration reducing agent for drilling fluid and preparation method thereof

ActiveCN101560378BImprove sexual functionHigh cost performanceDrilling compositionFiltrationPotassium hydroxide

Owner:石家庄华莱鼎盛科技有限公司

A technology for preparing mineral composite solid lubricants for drilling based on chemical by-products

InactiveCN102199417BEase of environmental protectionPromote cleaner productionDrilling compositionChemical industrySodium dithionite

The invention relates to a technology for preparing a mineral composite solid lubricant for well drilling on the basis of by-products in chemical industry. The solid lubricant is prepared by taking by-product residue (or residual liquid) of sodium dithionite powder distillation as a main ingredient, adopting graphite and / or expanded graphite mineraloid as a loading material, taking animal oil or vegetable oil or oil based surfactants derived from the animal oil or the vegetable oil as a lubricating property regulator, and adding a certain amount of a combined drilling-fluid property regulator prepared by matching special fluid loss additive for drilling fluid, a collapse preventing agent and an emulsifying agent according to a specific proportion through processes such as mixing, extrusion, kneading, and the like. The preparation method comprises a cross blending method, a kneading method, a twin-screw-rod extrusion method, a single-screw-rod extrusion method, and the like. Compared with the prior art, the invention has the advantages of simultaneously enhancing two lubricating properties of the adhesion coefficient reducing rate and the friction resistance coefficient reducing rate of the drilling fluid lubricant, and the collapse preventing property, and has the characteristics of low price, simplicity for production process, convenience for field transport and storage of petroleum drilling and geological prospecting drilling, and the like.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

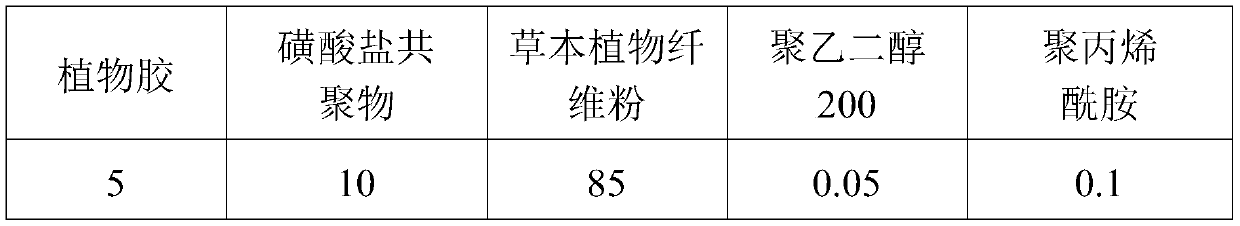

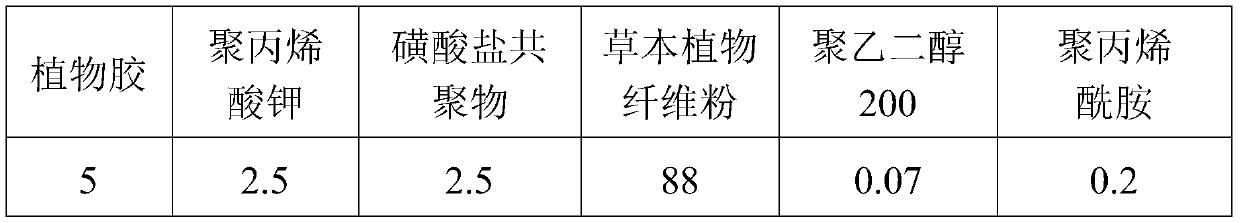

A kind of anti-collapse polymer mud powder and its preparation method and application

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD

An organic-inorganic composite silicate high temperature resistant film-forming drilling fluid system

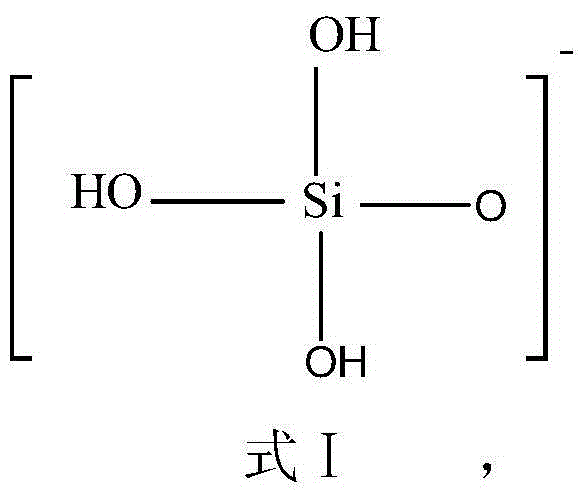

ActiveCN109735314BImprove performanceImprove anti-slump performanceDrilling compositionPhysical chemistrySlurry

The invention discloses an organic-inorganic composite silicate high-temperature-resistant film-forming drilling fluid system, which belongs to the drilling fluid used in the technical field of geological resource exploration and development. The drilling fluid system is composed of the following raw materials: bentonite base slurry, viscosity increasing agent, fluid loss reducer, plugging agent, weighting agent, inorganic silicate and organic silicate, the amount of each raw material is based on the weight of the bentonite base slurry, and the mass fraction of the bentonite base slurry is 1% to 4%. The concentration of the organic silicate is 0.05mol / L-0.5mol / L, and the mass fraction of the inorganic silicate is 0.1%-5%. The organic-inorganic composite silicate high-temperature-resistant film-forming drilling fluid system proposed by the present invention improves the ability of the drilling fluid to inhibit and prevent collapse, better meets the needs of well wall stability and safe drilling, and achieves inhibition, plugging and chemical purpose of solidification.

Owner:JILIN UNIV

Potassium salt polymer drilling fluid

InactiveCN105131916AImprove salt toleranceStrong inhibitoryDrilling compositionCalcium EDTASalt resistance

The invention relates to potassium salt polymer drilling fluid and belongs to the field of oilfield chemistry. The potassium salt polymer drilling fluid is characterized by containing the following substances in percentage by weight: 3-10% of clay, 1-8% of weighting material, 1-3% of sulfonated lignin sulfomethyl phenol-formaldehyde resin copolymer, 1-1.5% of potassium polyacrylate, 1-2% of potassium chloride, 1-4% of lubricant and the balance of tap water. According to the potassium salt polymer drilling fluid, proportioned materials are simple and are readily available, and the potassium salt polymer drilling fluid has the advantages of high inhibition capability, calcium resistance, salt resistance and collapse prevention and is applicable to oil wells of various depths.

Owner:山东聚鑫化工有限公司

Modified alkyl glycoside high-temperature-resistant inhibitor as well as preparation method and application thereof

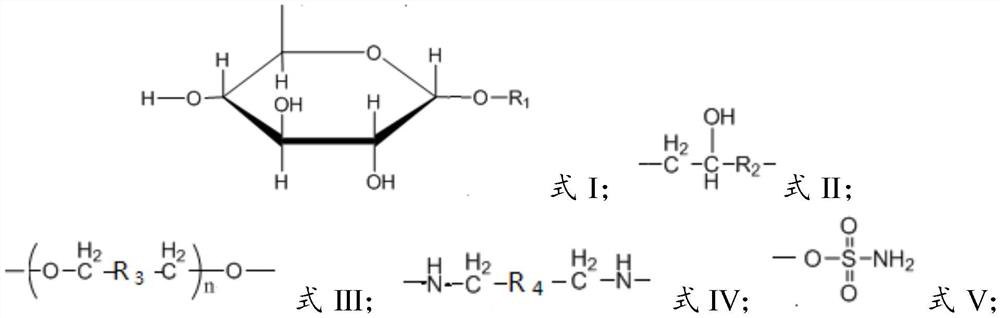

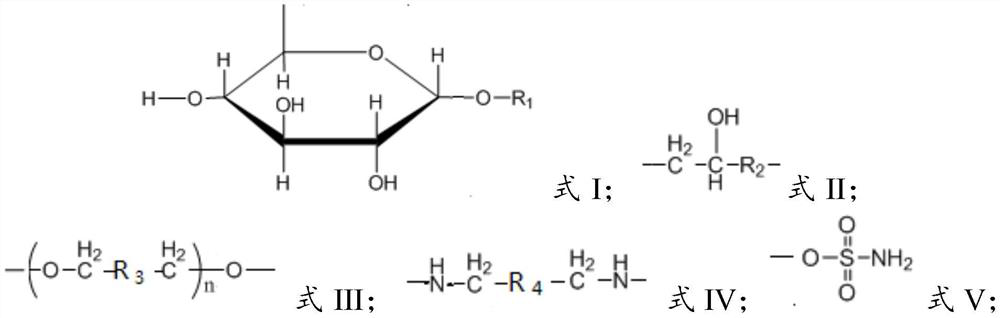

PendingCN113929899AImprove anti-slump performanceEase of field applicationDrilling compositionGlycosidePtru catalyst

The invention belongs to the technical field of oilfield chemical drilling fluid treating agents, and provides a modified alkyl glycoside high-temperature-resistant strong inhibitor and a preparation method and application thereof. The preparation method comprises the following steps: subjecting halogenated epoxide, polymeric glycol and alkyl glycoside to reacting under catalysis of an acid catalyst so as to obtain halogenated alcohol polyether alkyl glycoside; subjecting the halogenated alcohol polyether alkyl glycoside to reacting with organic amine to obtain amino polyether alkyl glycoside; and subjecting the amino polyether alkyl glycoside to reacting with sulfamic acid serving as a sulfonating agent to generate the modified alkyl glycoside high-temperature-resistant strong inhibitor. The modified alkyl glycoside provided by the invention comprises an alkyl glycoside group, a hydroxyalkyl group, a polyether group, an amido group and a sulfonic acid group, and has a relatively good collapse inhibition effect under a high-temperature condition. In addition, the modified alkyl glycoside provided by the invention has no biotoxicity. The modified alkyl glycoside provided by the invention can be applied to drilling fluids, is suitable for drilling construction of formations such as deep wells and ultra-deep wells with relatively high formation temperature and with shale easy to collapse, and meets the requirements for well wall stability and environmental protection of high-temperature formations.

Owner:中石化石油工程技术服务有限公司 +2

Emulsified residual oil type lubricant for drilling fluid and production process thereof

ActiveCN103013463BLow raw material costReduce manufacturing costDrilling compositionParaffin waxResidual oil

The invention discloses an emulsified residual oil type lubricant for a drilling fluid and a production process thereof. The emulsified residual oil type lubricant for the drilling fluid comprises the following components in parts by weight: 40 to 60 parts of residual oil, 10 to 20 parts of No.15 technical white oil, 10 to 20 parts of paraffin, 20 to 30 parts of an anti-freezing agent, 1 to 5 parts of sorbitan oleate and 1 to 5 parts of sulfonic acid. The emulsified residual oil type lubricant prepared by adopting the production process is used in the drilling fluid and has the advantages of low friction resistance, good immersion effect and high anti-collapse performance; and by adopting the emulsified residual oil-type lubricant, the quality of mud cakes can be effectively improved.

Owner:河北华运鸿业化工有限公司

Method for treating potassium amino polysulfonate drilling fluid

PendingCN113755143AEffective accumulationWide particle size distributionFlushingDrilling compositionMining engineeringWell drilling

The invention discloses a method for treating potassium amino polysulfonate drilling fluid, and relates to the technical field of drilling fluid. The method comprises the following steps: (1) geological general situation research: before drilling fluid treatment, firstly researching the drilling depth of a drilling position and the geological condition of the drilling position, and according to the difference between the drilling depth and the geological condition, targetedly formulating a drilling fluid formula of the potassium amine polysulfonate drilling fluid, wherein the drilling fluid formula specifically comprises a formula I, a formula II, a formula III and a formula IV, (2) preparation of the potassium amine polysulfonate drilling fluid; and (3) construction of the potassium amine polysulfonate drilling fluid. The treatment method of the potassium amine polysulfonate drilling fluid is suitable for petroleum drilling in mesozoic and paleozoic stratums, and during preparation, a drilling fluid treatment agent is added according to the sequence of a fluid loss agent, a 30% coating agent, an inhibitor and a 70% coating agent. The particle size distribution is wide according to the adding sequence, effective accumulation of clay particles is facilitated, a compact filter cake is formed, and the filtration wall-building performance and the rheological property are both good.

Owner:宋晓勇

A kind of cutting-lifting agent for gas stagnation plug and preparation method thereof

ActiveCN110066644BGood resistance to high temperature and saltEasy to dehydrateDrilling compositionClay mineralsWell drilling

The invention relates to a cutting agent for gas stagnation plugs in the technical field of petroleum drilling chemical materials and a preparation method. The cutting agent for air stagnation plugs is made by grafting polymerized monomers onto the surface of layered chain clay minerals after organic modification; the cutting agent for air stagnation plugs prepared by the method of the present invention has better high temperature resistance Salt resistance, cutting and water loss reducing performance; the temperature resistance of the air stagnation plug cutting agent of the present invention is better than that of organic cutting agents, and the compatibility and water loss performance are better than simple layered chain clay minerals. The excellent properties of polymers for water loss reduction and layered chain clay minerals’ resistance to temperature and shearing are suitable for use in deep high-temperature formations, and can effectively improve the gas retardation capacity of gas stagnation plugs, thereby slowing down the speed of oil and gas upward channeling and prolonging safe operation time.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of raw material composition for coating agent, coating agent and its preparation method and application

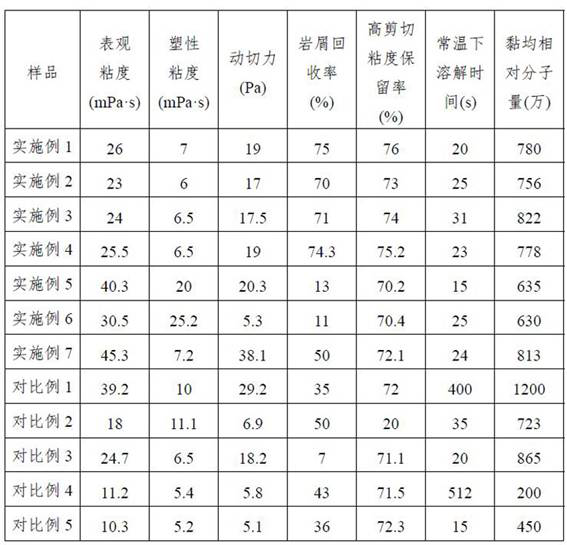

ActiveCN113265232BImprove adsorption capacityImprove shear resistanceDrilling compositionPolymer sciencePetrochemical

The present invention relates to the technical field of polymer additives in petrochemical industry, in particular to a raw material formula for a coating agent, a coating agent and its preparation method and application, the material formula of the coating agent includes acrylamide monomers, the The raw material formula for the coating agent also includes the following components: physical mixing components, chemical adjustment components and initiators; the acrylamide monomer is used as a component in the physical mixing components; the chemical adjustment components Including oxidant, polymerization inhibitor, chelating agent and molecular weight regulator; the initiator is a high-temperature initiator; the coating agent prepared by the raw material formula for the coating agent provided by the present invention has low plastic viscosity and high dynamic shear force , strong coating inhibition, good shear resistance, and fast dissolution speed. Compared with other types of coating agents, it has better comprehensive performance. When used in drilling fluids in the petroleum field, the High value and wide application prospect.

Owner:SHANDONG NUOER BIOLOGICAL TECH

A kind of silicate-cationic alkyl glucoside drilling fluid and preparation method thereof

ActiveCN104357031BImprove rheologyImprove anti-slump performanceDrilling compositionInorganic saltsReducer

The invention discloses a silicate-cation alkyl glucoside drilling fluid and a preparation method thereof, and belongs to the technical field of drilling fluids in oilfield chemistry. The silicate-cation alkyl glucoside drilling fluid is prepared by mixing the following materials of 0.1%-0.3% of a fluid pattern regulator, 1%-2.5% of a filtrate reducer A, 1%-3% of a high-temperature-resistant filtrate reducer B, 3%-10% of silicate, 5-8% of alkyl glucoside, 1%-2% of cation alkyl glucoside, 2%-6% of a blocking agent, 5%-15% of an inorganic salt, 0.2%-0.35% of sodium hydroxide, 0-51% of barite and the balance of water according to the mass to volume ratio and then ageing at a high temperature. The drilling fluid provided by the invention can resist the temperature as high as 120 DEG C, the recovery rate of shale is more than 90%, and the blockage rate is more than 90%. The drilling fluid has the advantages of excellent rheological property, lubricity, high temperature resistance, inhibition, sealing ability, clay pollution resistance, and salt tolerance, and helps to keep the borehole diameter regular and keep a borehole wall stable in the drilling process.

Owner:CHINA PETROCHEMICAL CORP +1

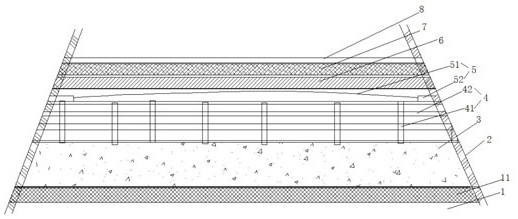

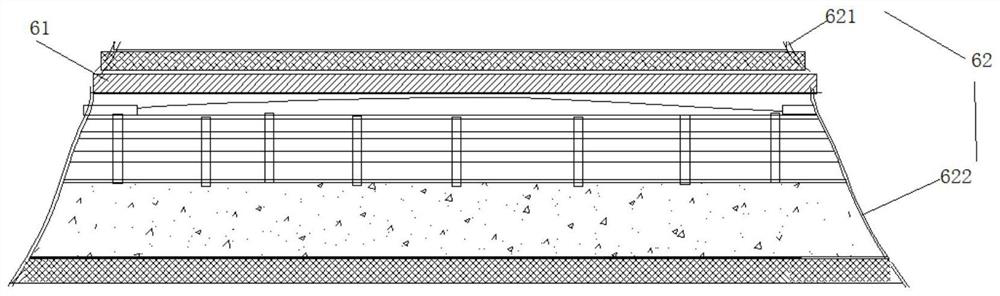

A construction method of municipal soft soil roadbed

ActiveCN110846964BPrevent collapseStable supportRoadwaysClimate change adaptationArchitectural engineeringStructural engineering

Owner:JIANGSU DONGZHU LANDSCAPE CONSTR

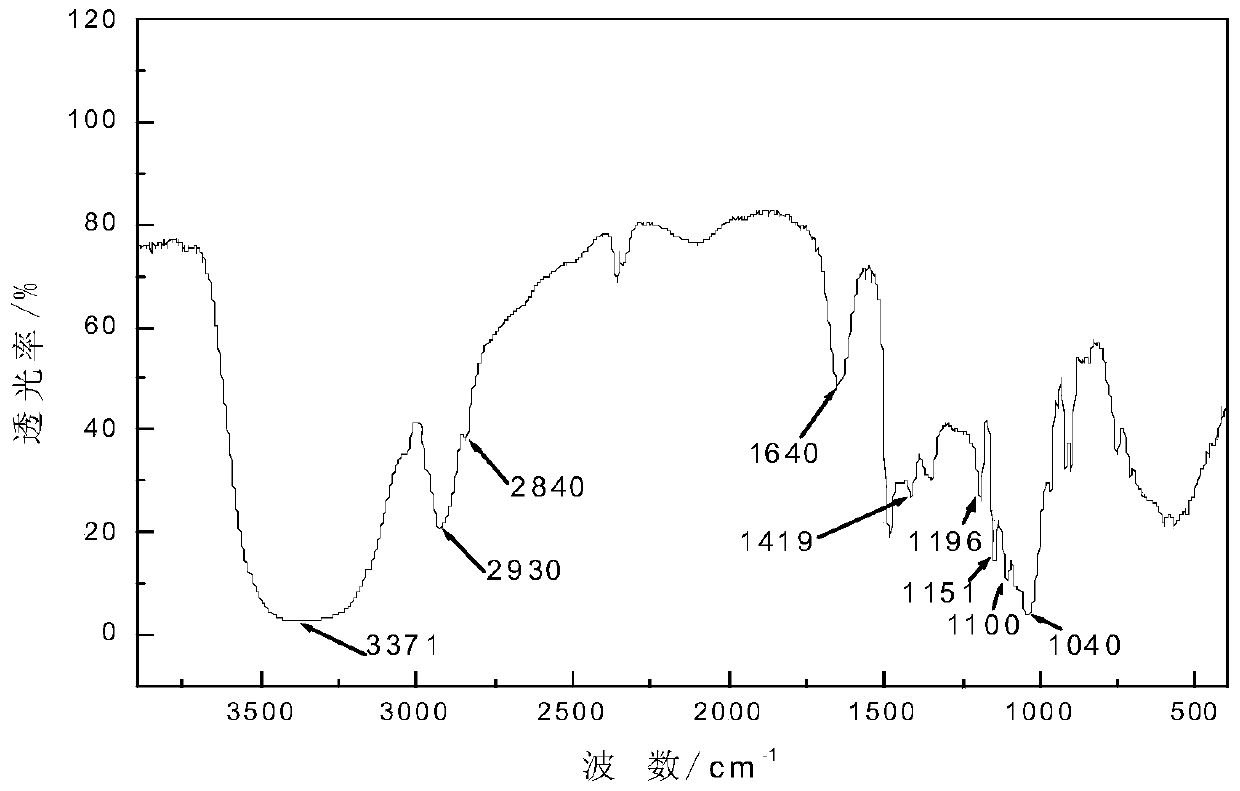

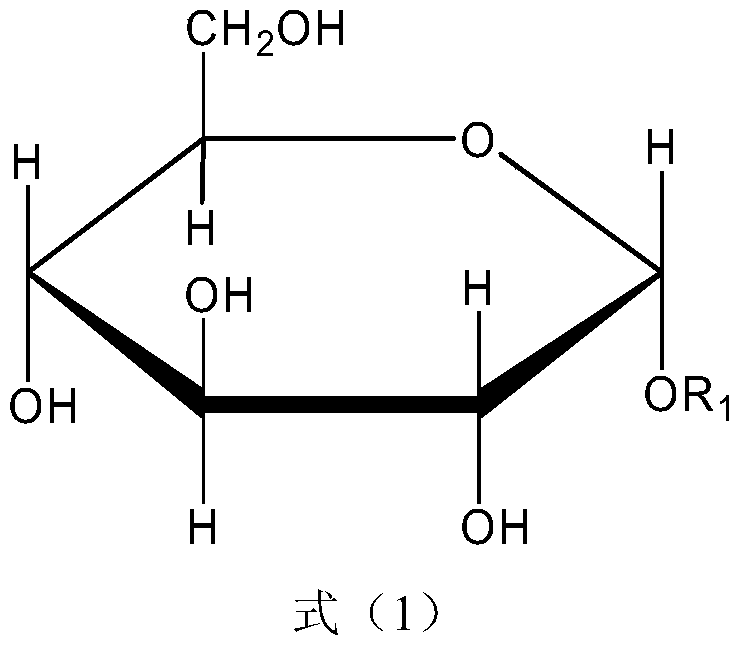

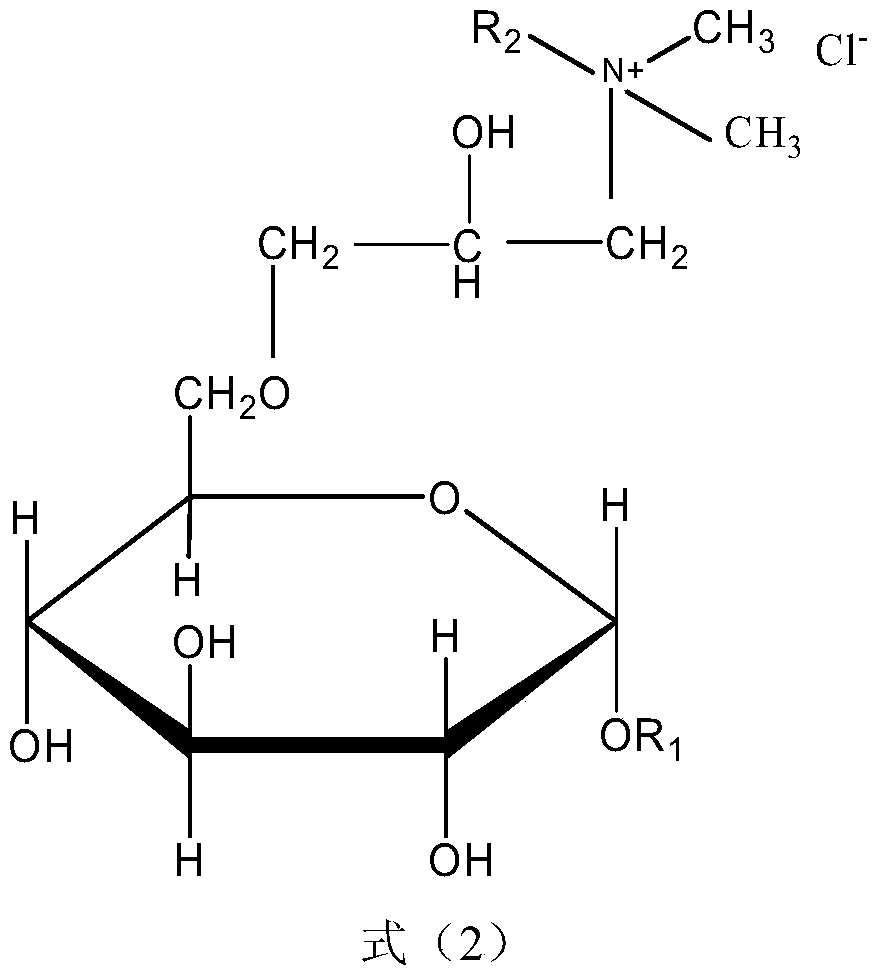

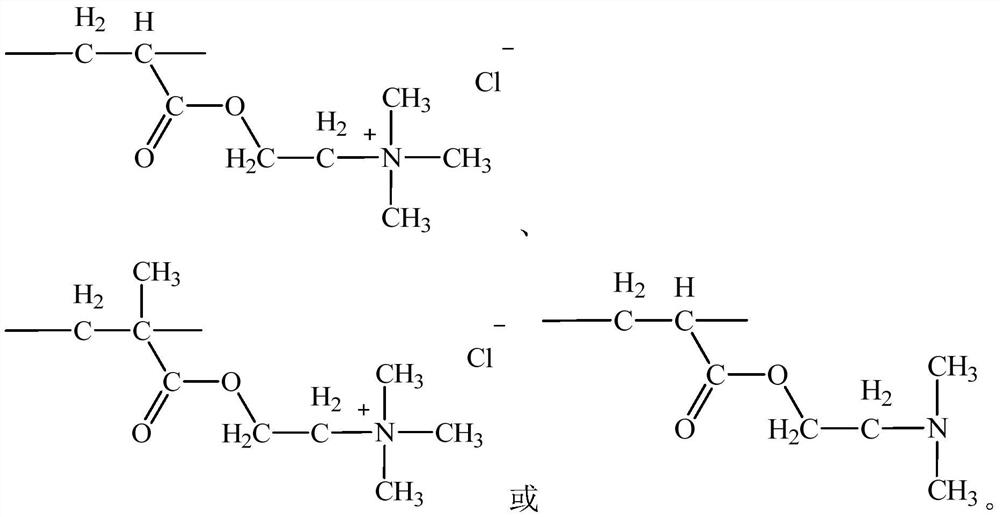

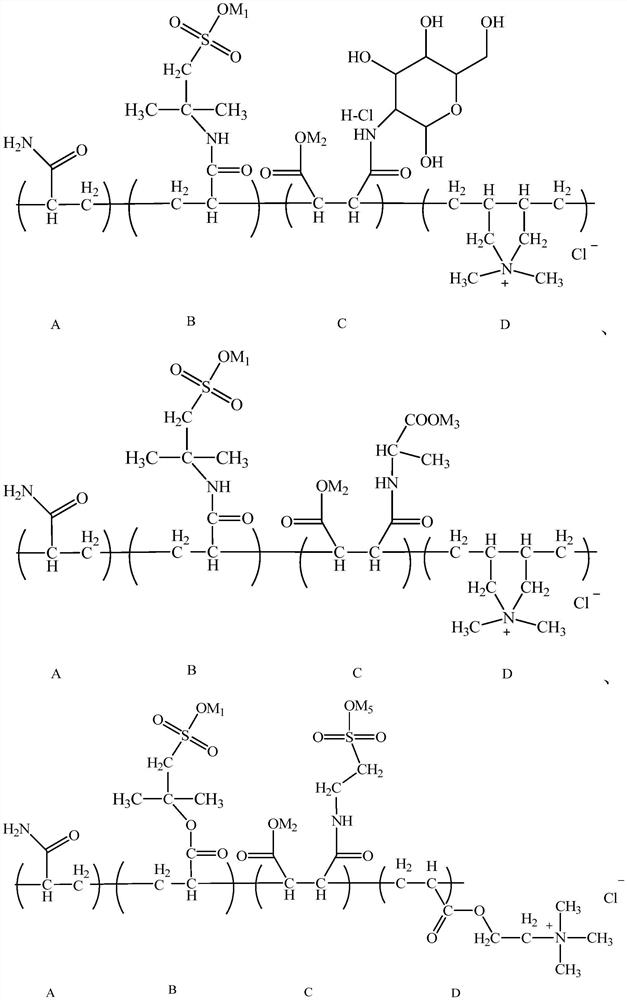

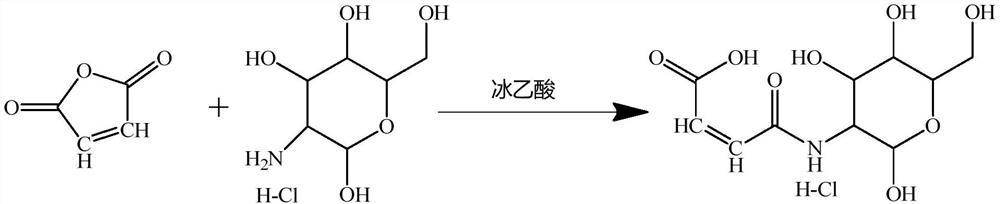

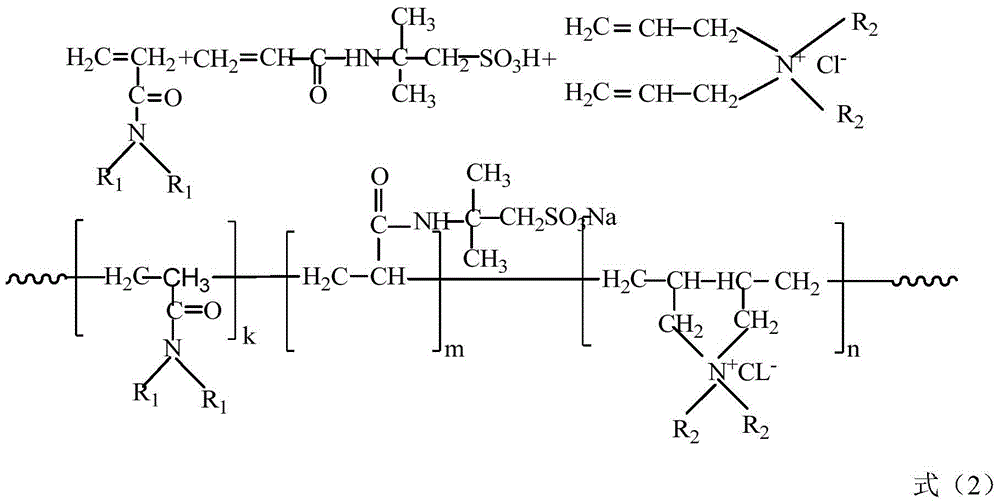

Random copolymer and its preparation method, application and drilling fluid

ActiveCN111718443BReduce fluid lossImprove anti-slump performanceDrilling compositionThermodynamicsHalogen

The invention relates to the field of reducing fluid loss in drilling fluids under high-calcium and high-temperature conditions, and discloses random copolymers and their preparation methods and applications, as well as drilling fluids and methods for reducing fluid loss in drilling fluids. The random copolymer contains structural unit (A) represented by formula (1), structural unit (B) represented by formula (2), structural unit (C) represented by formula (3), and formula (4) Or the structural unit (D) represented by formula (5), X is halogen. The random copolymer is used as a fluid loss reducer in drilling fluids to reduce the fluid loss of drilling fluids containing high calcium ions.

Owner:CHINA PETROLEUM & CHEM CORP +1

A polymer inhibitor for clay-free drilling fluid and preparation method thereof

ActiveCN104140490BInhibits hydration swellingMeet the needs of safe and fast drillingDrilling compositionWell drillingOil field

Belonging to the technical field of preparation methods for petroleum drilling oilfield chemistry macromolecular polymers, the invention discloses a polymer inhibitor for clay phase-free drilling fluid and a preparation method thereof. The polymer inhibitor is formed by copolymerization of an organic amide monomer A, an amido hydrolysis inhibiting monomer B and a cationic monomer C according to a mass percentage of (56-76):(10-25):(14-19) under the action of an initiator and a pH value regulator. The intrinsic viscosity number of the polymer inhibitor is 2.0-3.0dl / g. The shale with a clear water recovery rate of 3.6% is employed to perform shale recovery experiment on the obtained product. A 0.5% aqueous solution of the polymer inhibitor can reach a primary shale recovery rate of higher than 90% after 16h at 200DEG C and a relative shale recovery rate of higher than 98%, and a contrast example, i.e. a 2% high temperature resistant polyamine inhibitor solution only has a primary shale recovery rate of 64.2% after 16h at 200DEG C. With good sloughing inhibiting and preventing ability under high temperature conditions, the polymer inhibitor provided by the invention can be used for weak gel clay phase-free drilling fluid to effectively inhibit hydration expansion of mud shale and ensure safe and fast drilling of a special process well, thus further improving the wellbore wall stabilization capacity.

Owner:CHINA PETROCHEMICAL CORP +1

Shale inhibitor multi-branched polyamine for drilling fluid and preparation method of shale inhibitor multi-branched polyamine

InactiveCN108485617AImprove anti-slump performanceReduce penetrationDrilling compositionPolyamineChemistry

The invention belongs to the technical field of deep well and ultra deep well mining, and discloses a shale inhibitor multi-branched polyamine for drilling fluid and a preparation method thereof. Theinhibitor is prepared from the following raw materials in parts by weight: 30-40 parts of aliphatic amine, 30-40 parts of propylene oxide (PO), 20-30 parts of a butylene oxide (BO), and 20-30 parts ofa reactive group compound. The shale inhibitor is arranged in a single molecule between clay layers; in addition to the electrostatic interaction force between the inhibitor and the clay layers, theinhibitor forms hydrogen bonds with siloxane-based atoms of a clay crystal face; the inhibitor can also be combined with other treatment agents to form a synergistic effect, and through the combination with a physical plugging method and a chemical plugging method, the strength of the rock formation around the borehole wall is effectively increased, and the problem of swelling of mud shale is solved. The shale inhibitor multi-branched polyamine has a good capability of inhibiting clay from making mud, and the reduction rate of clay mud-making inhibition with the single-agent inhibitor can reach 70% or more than 70%.

Owner:TIANJIN TIANCHENG TUOYUAN TECH DEV +1

A kind of preparation method of density gradient fiber mat and fiber mat

ActiveCN109023721BImprove anti-slump performanceGuaranteed lightweightNon-woven fabricsAdhesivesElastomerPolymer science

The invention discloses a method for preparing a fiber mat. The elastomer fiber and the bonding fiber are mixed as a raw material, and a unit fiber layer with a multi-layer structure is first formed through steps such as opening, carding, laying, and presetting, and then through the steps of The stacked multiple unit fiber layers are hot-pressed to finally produce a finished fiber mat with a multi-layer density gradient structure. The fiber mat manufactured by the method has a density gradient structure, the pressure applied to it can be buffered in multiple stages, the anti-slump performance is greatly improved, and the light weight of the fiber mat is guaranteed. Glue is not used in the production process and is harmless to the human body.

Owner:爱可比(苏州)新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com