Wall fixing agent for drilling fluid as well as preparation method and application of wall fixing agent

A technology of wall solidifying agent and drilling fluid, applied in the field of drilling fluid, can solve the problems of incapable of sticking to the rock, and the wall solidifying agent is difficult to absorb the rock surface, etc., so as to improve the stability of the well wall, improve the anti-slump performance, and improve the rock surface. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

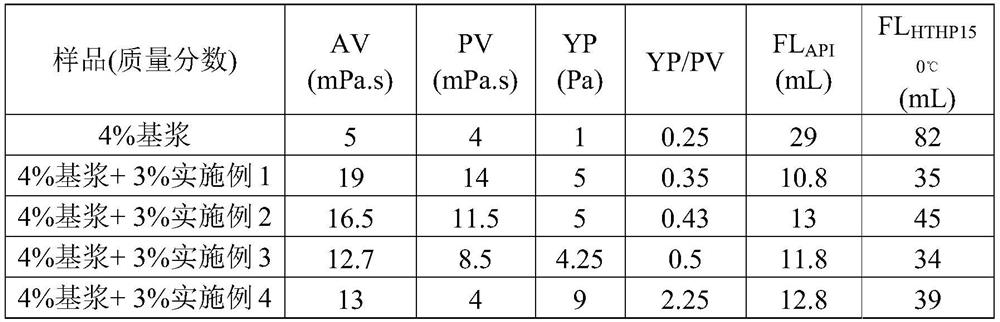

Examples

preparation example Construction

[0035] An embodiment of the present invention also proposes a method for preparing a wall-fixing agent, comprising the following steps:

[0036] (1) Mix acrylamide, DMDAAC, and part of distilled water, heat up to 65-70°C, add adhesive and part of initiator, and react at a constant temperature of 65-70°C to obtain product 1;

[0037] (2) Mix the chain transfer agent, sodium hydroxide, and the remaining distilled water, add AMPS, stir, add acrylic acid, adjust the pH value to 7-8, add the remaining initiator, react at 60-65 ° C, then granulate, dry, Pulverized product two;

[0038] (3) Mix product 1 and product 2 to obtain a wall-solidifying agent.

[0039] In one embodiment of the present invention, in step (1), the amount of distilled water added is 1 / 3-2 / 3 of the total mass.

[0040] In one embodiment of the present invention, in step (1), the amount of the initiator added is 1 / 3-2 / 3 of the total mass.

[0041] In one embodiment of the present invention, in step (1), the b...

Embodiment 1

[0047] Example 1 A method for preparing a wall-solidifying agent for drilling fluid, comprising the following steps, the raw materials used are calculated in parts by mass:

[0048] (1) Add 40 parts of distilled water, 20 parts of acrylamide, and 20 parts of DMDAAC into the reaction kettle, stir evenly, raise the temperature to 65-70°C, slowly add adhesives (10 parts of vinyl acetate and 10 parts of polyvinyl alcohol), drop Adding control time is 30 minutes, add 1 part of ammonium persulfate (make ammonium persulfate into a 5% solution), turn on the cooling water, keep the temperature of the material at 65-70°C and polymerize for 3 hours to obtain product 1.

[0049] (2) Add 50 parts of distilled water, 12 parts of sodium hydroxide, and 5 parts of sodium formate into the reaction kettle and stir until completely dissolved, then add 2 parts of AMPS and stir for 30 minutes, then add 2 parts of acrylic acid and stir evenly, and adjust the pH value to 7- 8. Stir for 60 minutes, ...

Embodiment 2

[0051] Example 2 With embodiment 1, difference is that binder is 20 parts of vinyl acetates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com