Random copolymer and its preparation method, application and drilling fluid

A technology of random copolymers and structural units, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of insufficient calcium resistance and high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The second aspect of the present invention provides a kind of preparation method of random copolymer, comprising:

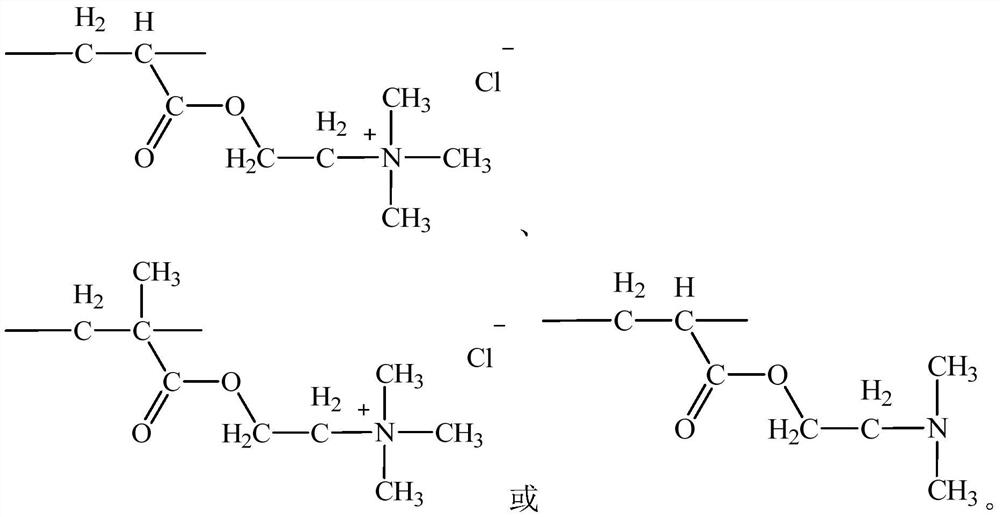

[0060] In the presence of nitrogen protection and initiator, the monomer (a) shown in formula (6), the monomer (b) shown in formula (7), the monomer (c) shown in formula (8), and The monomer (d) shown in formula (9) or formula (10) carries out radical copolymerization reaction;

[0061] Among them, R 1 and R 2 Each independently is H or C 1 -C 6 the alkyl group, R 3 and R 4 Each independently is H or C 1 -C 3 the alkyl group;

[0062] Among them, R 5 -O-R- or -NH-R-, where R is -C m h 2m -, and m=4, 5 or 6;

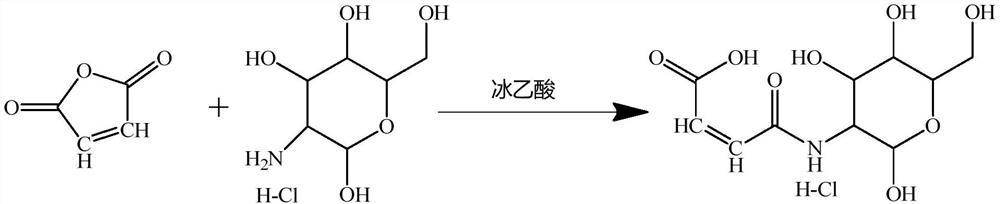

[0063] Among them, R 6 selected from

[0064] Among them, R 7 and R 8 Each independently is H or C 1 -C 6 the alkyl group, R 9 for-C n h 2n -, and the integer of n=2-6, R 10 for

[0065] X is halogen.

[0066] According to the present invention, preferably, the dosage of each monomer: the monomer (a) is 20-50 pa...

Embodiment 1

[0120] (1) 9.7g sodium hydroxide is dissolved in 100g water, obtains 109.7g lye;

[0121] (2) Add respectively 35g of acrylamide, 50g of 2-acrylamido-2-methylpropanesulfonic acid, 6g of N-glucose hydrochloride maleamic acid, 2g of dimethyl diene Propyl ammonium chloride, dissolved evenly. Pass nitrogen gas for 0.5h to remove oxygen to obtain monomer mixed solution, pH value is 8;

[0122] (3) Add 0.74 g of initiator V-044 (azobisisobutylimidazoline hydrochloride) to the monomer mixed solution at a temperature of 45 ° C and pH = 8 for free radical polymerization for 1 hour to obtain a gel product;

[0123] (4) After shearing and granulating the gel-like product, dry it at 65° C. for 36 hours to obtain a solid product, which is pulverized.

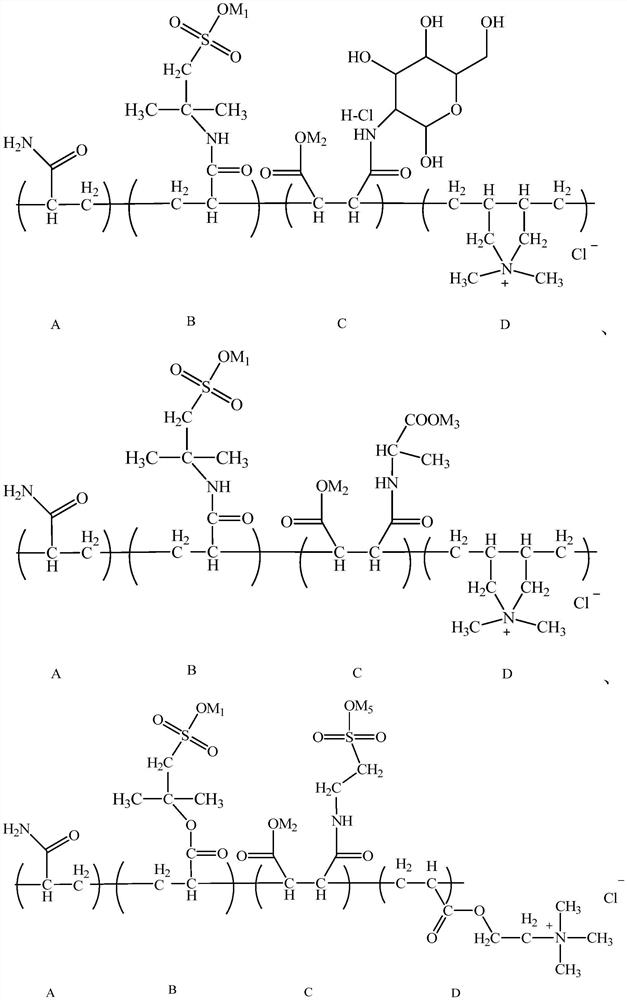

[0124] The obtained solid product is determined to be a random copolymer containing the following structural composition by analysis, Among them, M 1 and M 2 For Na. The apparent viscosity of the aqueous solution containing 1% by wei...

Embodiment 2

[0127] (1) Add 8.7g sodium hydroxide to 100g water, stir and dissolve to get 108.7g lye;

[0128] (2) Add respectively 42g of acrylamide, 45g of 2-acrylamido-2-methylpropanesulfonic acid, 7g of N-isopropionyl maleamic acid, 5g of dimethyl diene Propyl ammonium chloride, dissolved evenly, passed nitrogen gas for 0.5h to remove oxygen to obtain monomer mixed solution, pH value was 9;

[0129] (3) Add 0.74 g of APS (ammonium persulfate) and 0.66 g of sodium bisulfite to the monomer mixed solution at a temperature of 50 ° C and pH = 7, and carry out free radical polymerization for 1.5 hours to obtain a gel product;

[0130] (4) After shearing and granulating the gel-like product, dry it at 70° C. for 24 hours to obtain a solid product, which is pulverized.

[0131] The obtained solid product is determined to be a random copolymer containing the following structural composition by analysis,

[0132]

[0133] Among them, M 1 , M 2 and M 3 For Na. The apparent viscosity of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com