A construction method of municipal soft soil roadbed

A technology of soft soil subgrade and construction method, which can be applied in basic structure engineering, roads, excavation, etc., can solve the problems of support and bearing capacity, increase the weight and pressure of the road, and have no support layer, etc., to improve the stability. and safety of use, improved connectivity, and improved waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

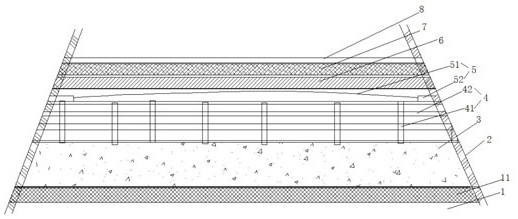

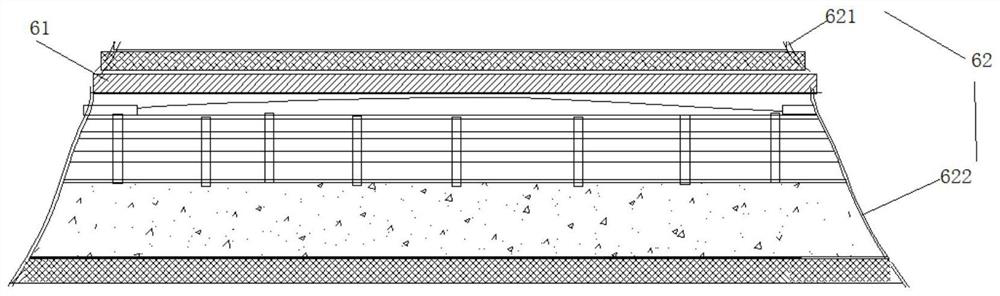

[0037] As shown in the figure, a construction method of a municipal soft soil roadbed includes: a road base 1 and an anti-slump edge 2, a sand layer 3 is arranged on the road base 1, and a support layer 4 is arranged above the sand layer 3 , the support layer 4 is provided with a water-conducting layer 5, the water-conducting layer 5 is provided with an anti-collapse layer 6, the anti-collapse layer 6 is provided with a pavement layer 7, and the top of the pavement layer 7 is provided with The waterproof layer 8, the anti-slump side 2 is arranged on both sides of the roadbed.

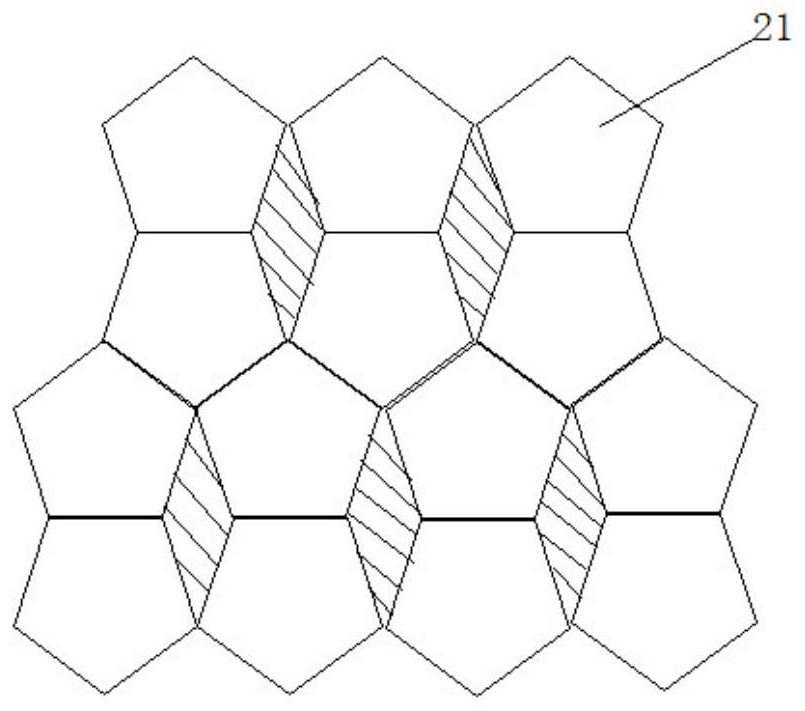

[0038] In the present embodiment, a reinforcing layer 11 is provided on the surface of the road base 1, and the reinforcing layer 11 adopts a metal mesh structure. Sand and gravel fillers are arranged in the metal mesh structure. The metal mesh is made of corrosion-resistant metal strips. woven.

[0039] In this embodiment, the support layer 4 is provided with a support column 41 and a connecting truss...

Embodiment 2

[0046] As shown in the figure, a construction method of a municipal soft soil roadbed includes: a road base 1 and an anti-slump edge 2, a sand layer 3 is arranged on the road base 1, and a support layer 4 is arranged above the sand layer 3 , the support layer 4 is provided with a water-conducting layer 5, the water-conducting layer 5 is provided with an anti-collapse layer 6, the anti-collapse layer 6 is provided with a pavement layer 7, and the top of the pavement layer 7 is provided with The waterproof layer 8, the anti-slump side 2 is arranged on both sides of the roadbed.

[0047] In the present embodiment, a reinforcing layer 11 is provided on the surface of the road base 1, and the reinforcing layer 11 adopts a metal mesh structure. Sand and gravel fillers are arranged in the metal mesh structure. The metal mesh is made of corrosion-resistant metal strips. woven.

[0048] In this embodiment, the support layer 4 is provided with a support column 41 and a connecting truss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com