Water-based wood white primer as well as preparation method and use method thereof

A technology of white primer and woodware, applied in the field of coatings, can solve the problems of unfavorable use of water-based wood white primer, high content of organic volatiles, and restrictions on effective promotion, etc., achieve excellent wetting and wrapping ability, promote water release, and quickly Polished effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

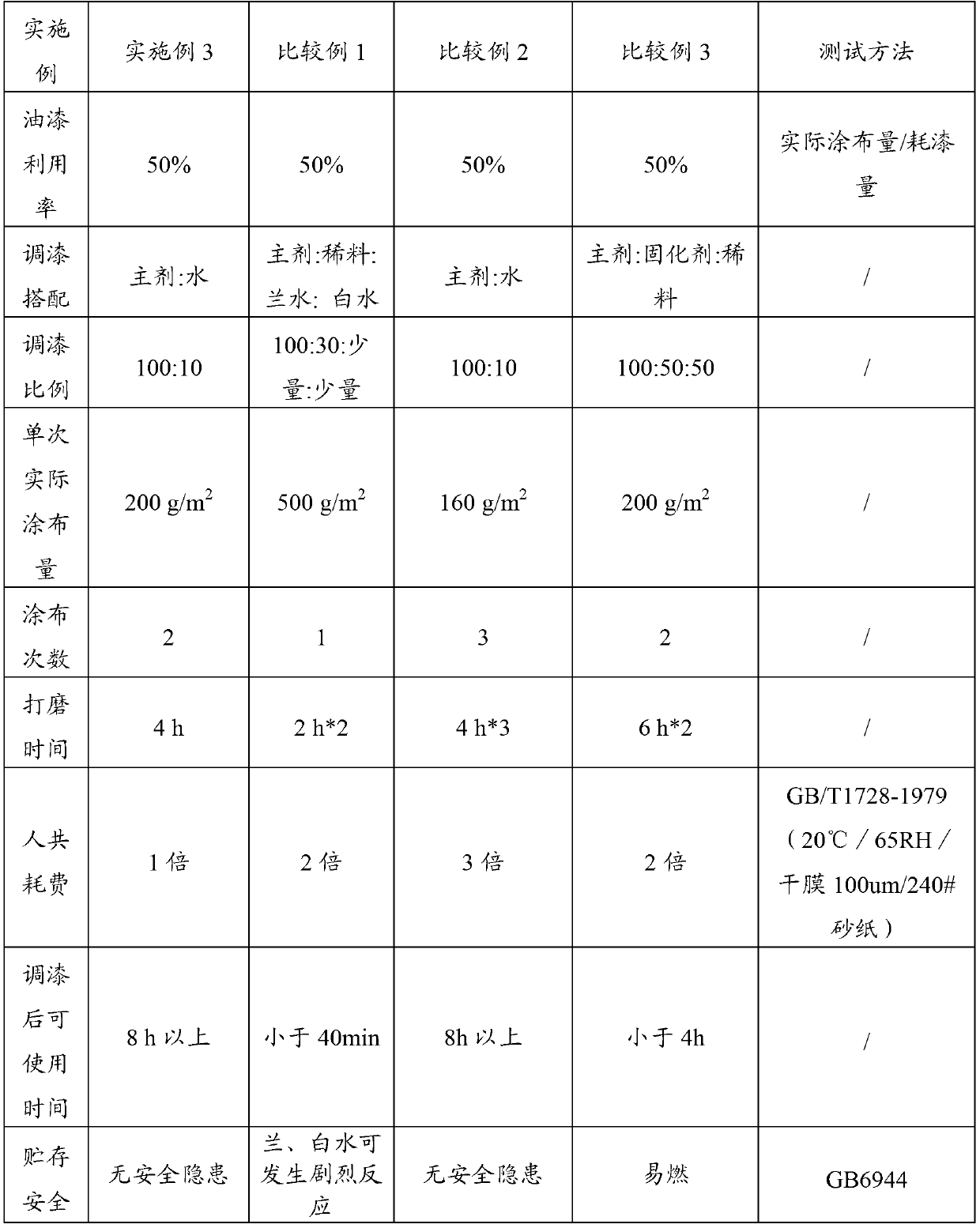

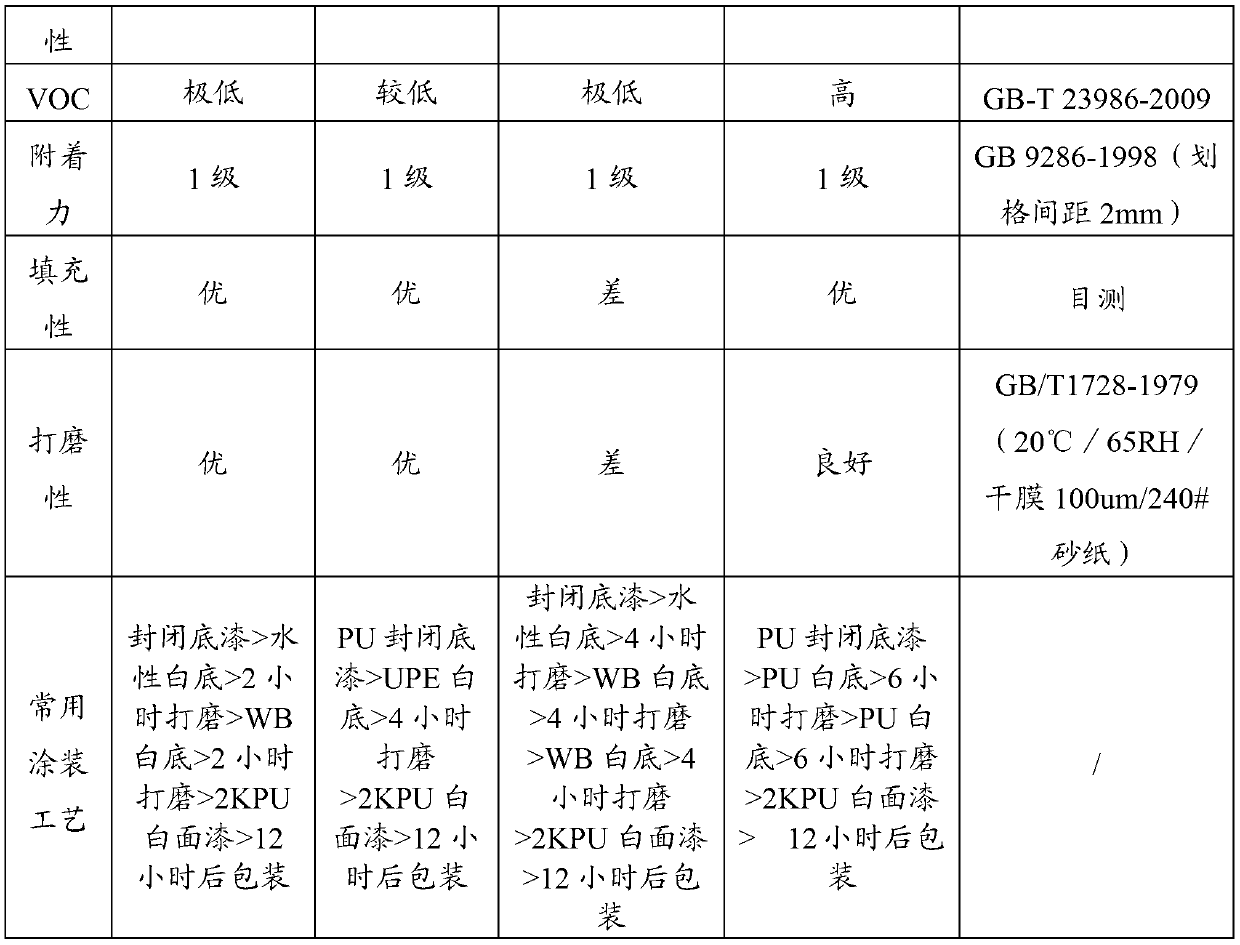

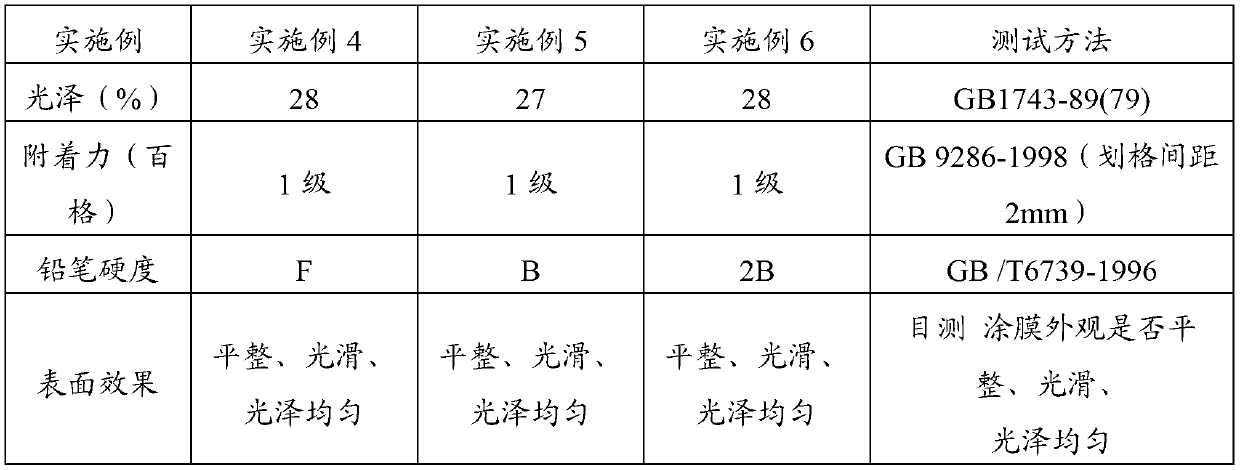

Examples

preparation example Construction

[0067] The invention provides a kind of preparation method of water-based white primer, comprising the following steps:

[0068] a) uniformly mixing the water-based resin with the defoamer and the wetting and dispersing agent to obtain the first material;

[0069] b) adding titanium dioxide, talcum powder and heavy calcium to the first material, and then adding a thickener to it after stirring at a high speed to obtain the second material;

[0070] c) Mix the second material with film-forming aids, thickeners, substrate wetting agents, bactericidal and antifungal agents, and water, and adjust the viscosity of the obtained material to 90KU-100KU to obtain a water-based wood white primer .

[0071] In the invention, the water-based resin, the defoamer and the wetting and dispersing agent are firstly mixed, and the first material is obtained after uniform mixing. In the invention, the water-based resin is placed in the dispersion tank first, and the defoamer and the wetting and...

Embodiment 1

[0101] In terms of weight percentage, 25wt% of the brand name NeoCryl A-639 and 10wt% of the brand name NeoRez R-2005 were added to the cylinder, stirred evenly at a speed of 400 rpm, and then poured into it at the above stirring speed. Add 0.3wt% of the product with the grade of TEGO810 and 1wt% of the product with the grade of TEGO752W, and stir evenly at the above stirring speed;

[0102] At the above stirring speed, add 5wt% of titanium dioxide of R996 grade, 12wt% of talc powder of TP1250 and 38wt% of heavy calcium of CC800 into the cylinder, and add 0.32wt% of grade It is a PU40W thickener, and the obtained material is dispersed for 15 minutes at a speed of 1100 rpm until the fineness of the scraper is less than 45 μm;

[0103] At a speed of 800 rpm, add 2.8wt% of a product with a grade of DPnB, 2.2wt% of a product with a grade of DPM, 0.08wt% of a thickener with a grade of PU40W to the obtained material with a fineness of less than 45 μm, 0.3wt% grade is the product of...

Embodiment 2

[0105] In terms of weight percentage, add 35w% of the product of ALBERDINK2714VP into the cylinder, stir evenly at a speed of 500 rpm, and then add 0.2wt% of the product of TEGO810 and 1wt% of the product of TEGO810 at the above stirring speed. TEGO752W products, and stir evenly at the above stirring speed;

[0106] At the above stirring speed, slowly add 5wt% of titanium dioxide with grade R996, 18wt% of talcum powder with grade TP1250 and 32wt% heavy calcium with grade CC800 into the tank for 1.5 minutes, and continue to add 0.48 The wt% grade is a thickener of PU40W, and the obtained material is dispersed for 15 minutes at a speed of 1150 rpm, until the scraper fineness of the material is less than 45 μm;

[0107] At a speed of 900 rpm, add 3wt% of a product with a grade of DPnB, 2wt% of a product with a grade of DPM, 0.12wt% of a thickener with a grade of PU40W, and 0.3wt% to the obtained material with a fineness of less than 45 μm. % grade is the product of TEGO270, 0.2w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com