Method for preparing multifunctional lubricant of drilling fluid by using waste oil

A waste engine oil and lubricant technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of acid residue, waste water and harmful gas pollution, and achieve good filtration loss reduction, low cost, and faster less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

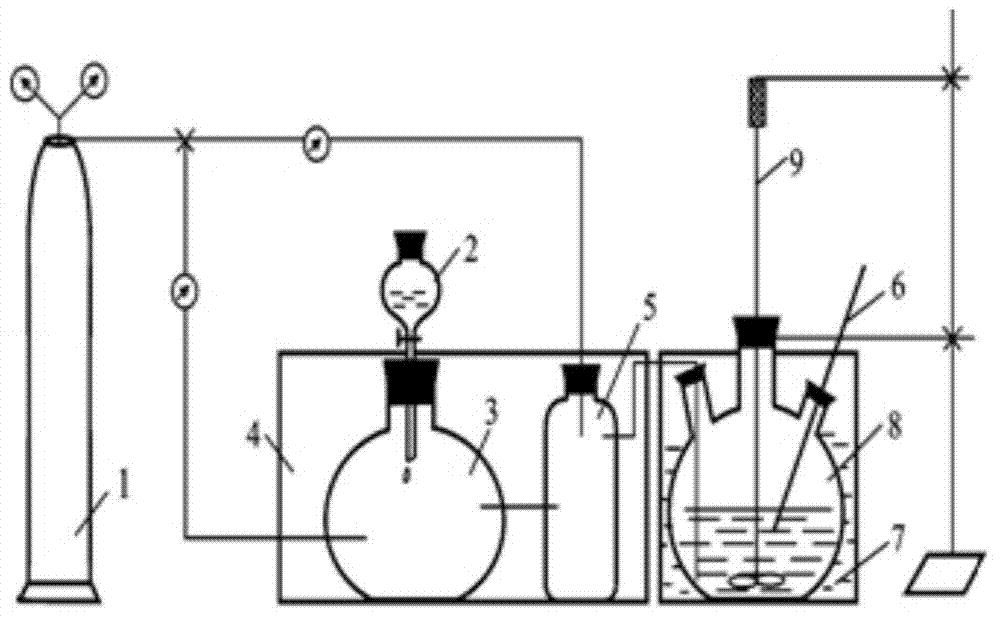

[0060] (1) First, weigh the waste engine oil and put it into the reactor, put the reactor into the electric heating constant temperature water bath, and adjust the temperature of the water bath to 40°C;

[0061] (2) Then weigh the liquid SO 3 Put the waste engine oil and liquid SO into the dropping funnel 3 The weight ratio is 89:15, in order to make the liquid SO dripped from the dropping funnel 3 into gas SO 3 , the gas generator connected to the dropping funnel is kept at 50-70°C through the thermal cycle of the jacketed water bath, so that the gas SO 3 Continuously enter the sulfonation reactor to react evenly with waste engine oil;

[0062] (3) Gas SO 3 Before entering the reactor with N 2 Mixed, N 2 As a carrier gas and diluent gas to control the sulfonation reaction rate, N 2 The flow rate is 80mL / min;

[0063] (4) Gas SO 3 After reacting with waste engine oil for 2 hours, add triethylamine to the reactor to adjust the pH to 8, then add sodium oleate and Span-8...

Embodiment 2

[0065] (1) First, weigh the waste engine oil and put it into the reactor, put the reactor into the electric heating constant temperature water bath, and adjust the temperature of the water bath to 60°C;

[0066] (2) Then weigh the liquid SO 3 Put the waste engine oil and liquid SO into the dropping funnel 3 The weight ratio is 109:15, in order to make the liquid SO dripped from the dropping funnel 3 into gas SO 3 , the gas generator connected to the dropping funnel is kept at 50-70°C through the thermal cycle of the jacketed water bath, so that the gas SO 3 Continuously enter the sulfonation reactor to react evenly with waste engine oil;

[0067] (3) Gas SO 3 Before entering the reactor with N 2 Mixed, N 2 As a carrier gas and diluent gas to control the sulfonation reaction rate, N 2 The flow rate is 90mL / min;

[0068] (4) Gas SO 3 After reacting with waste engine oil for 4 hours, add ethylenediamine to the reactor to adjust the pH to 8-9, then add sodium oleate and S...

Embodiment 3

[0070] (1) First, weigh the waste engine oil and put it into the reactor, put the reactor into the electric heating constant temperature water bath, and adjust the temperature of the water bath to 50°C;

[0071] (2) Then weigh the liquid SO 3 Put the waste engine oil and liquid SO into the dropping funnel 3 The weight ratio is 100:15, in order to make the liquid SO dripped from the dropping funnel 3 into gas SO 3 , the gas generator connected to the dropping funnel is kept at 50-70°C through the thermal cycle of the jacketed water bath, so that the gas SO 3 Continuously enter the sulfonation reactor to react evenly with waste engine oil;

[0072] (3) Gas SO 3Before entering the reactor with N 2 Mixed, N 2 As a carrier gas and diluent gas to control the sulfonation reaction rate, N 2 The flow rate is 85mL / min;

[0073] (4) Gas SO 3 After reacting with waste engine oil for 3 hours, add ethylenediamine to the reactor to adjust the pH to 8-9, then add sodium oleate and Sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com