Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

238results about How to "Promote cleaner production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

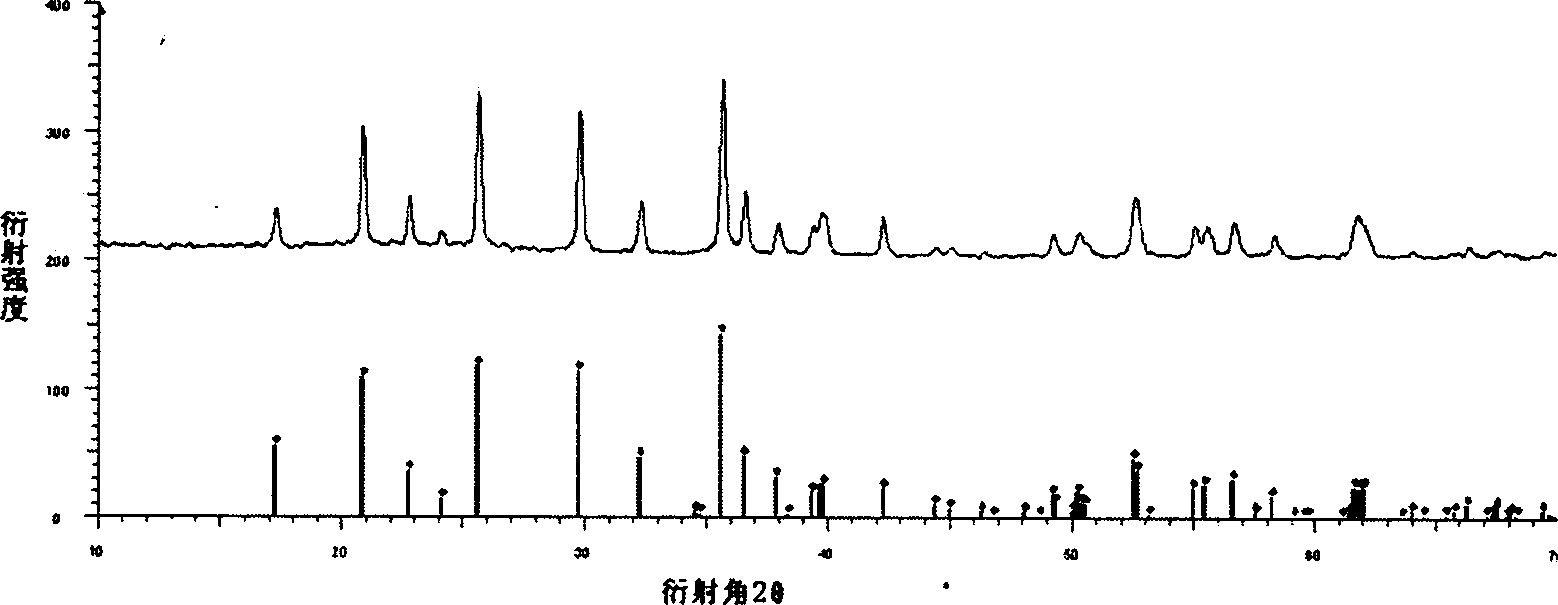

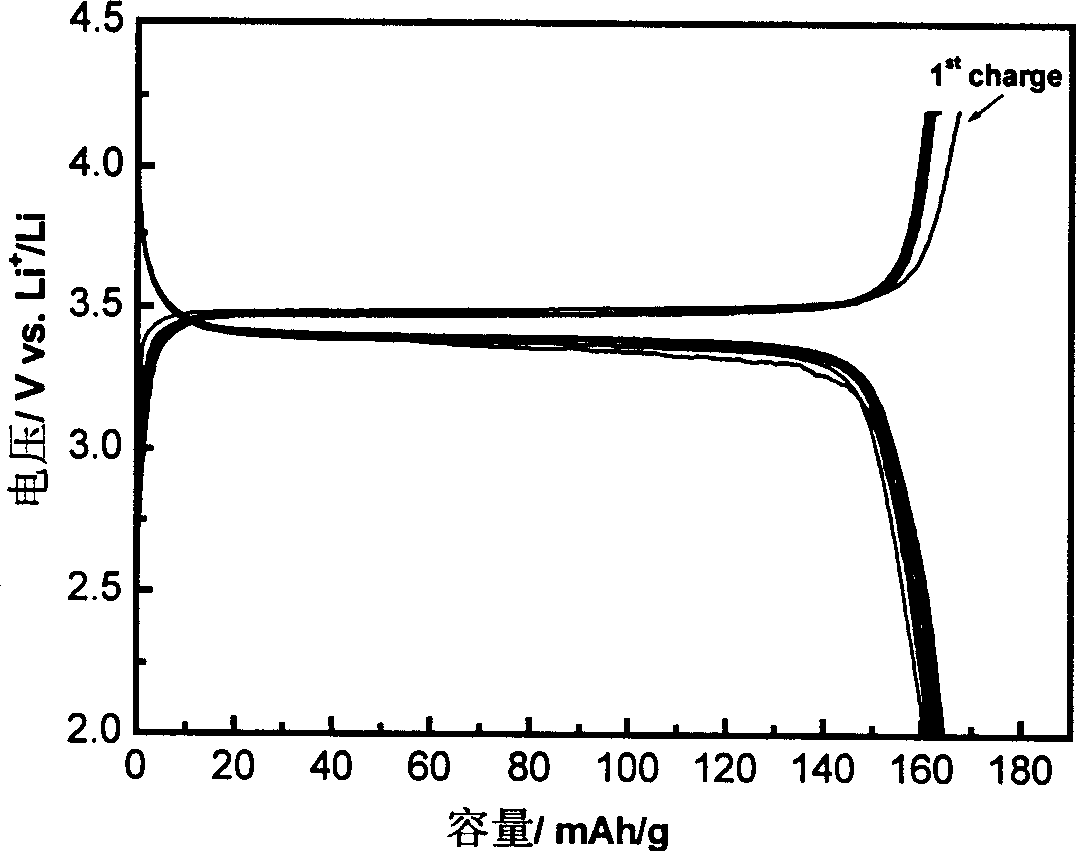

Method for preparing lithiumion cell positive material Iron-lithium phosphate

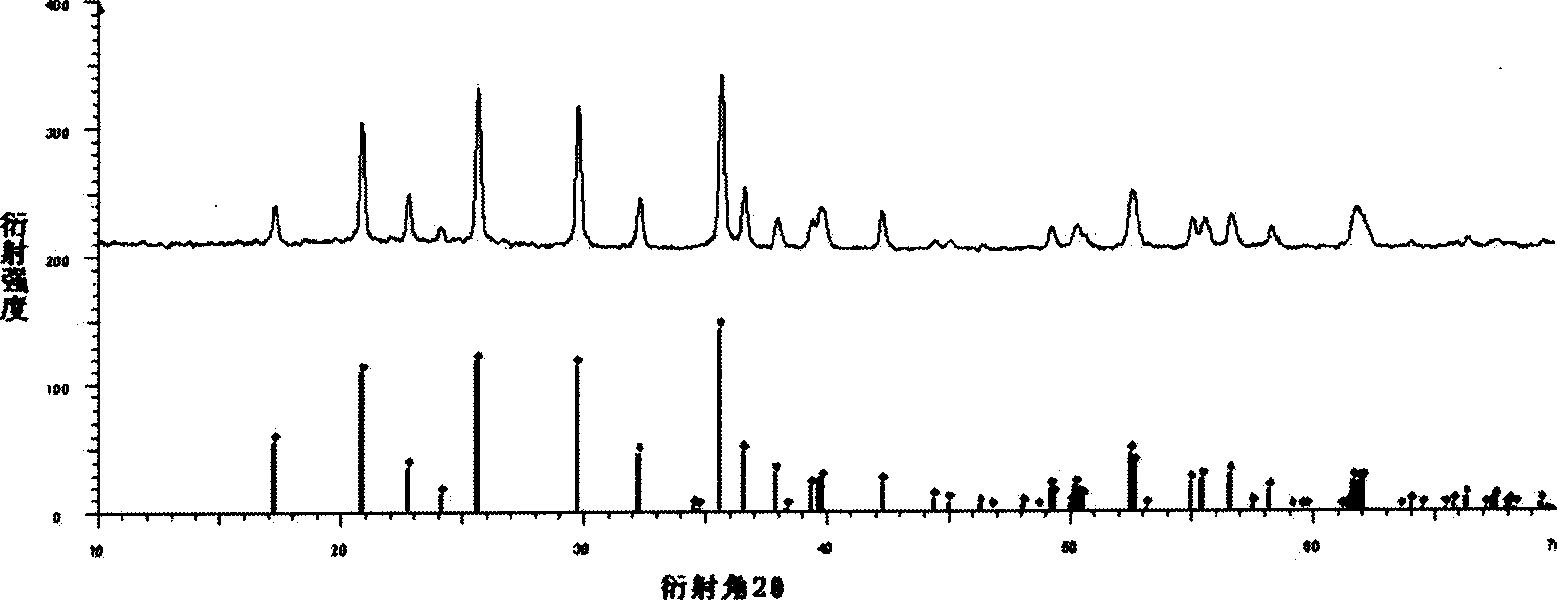

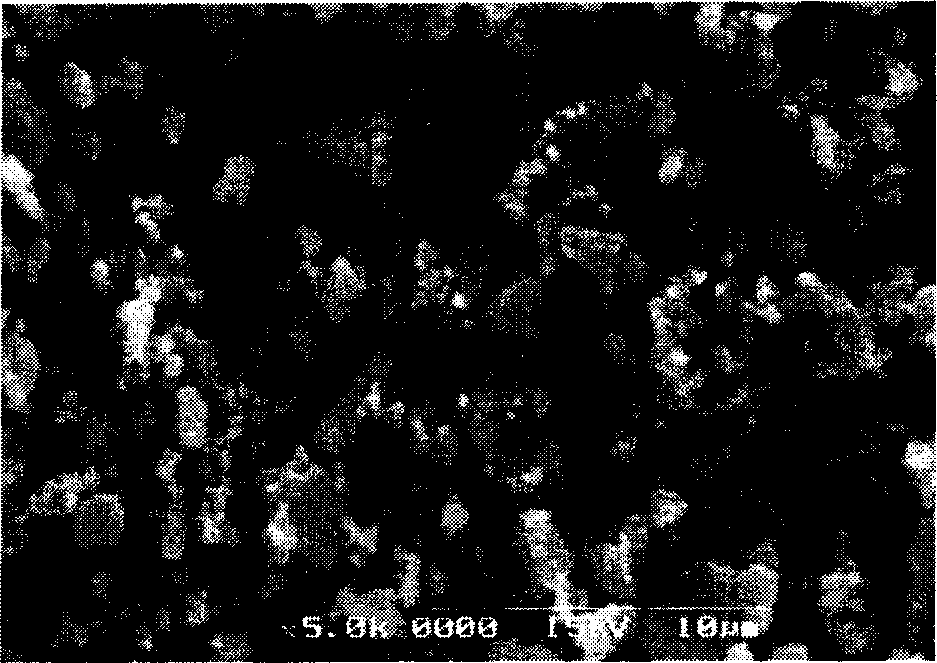

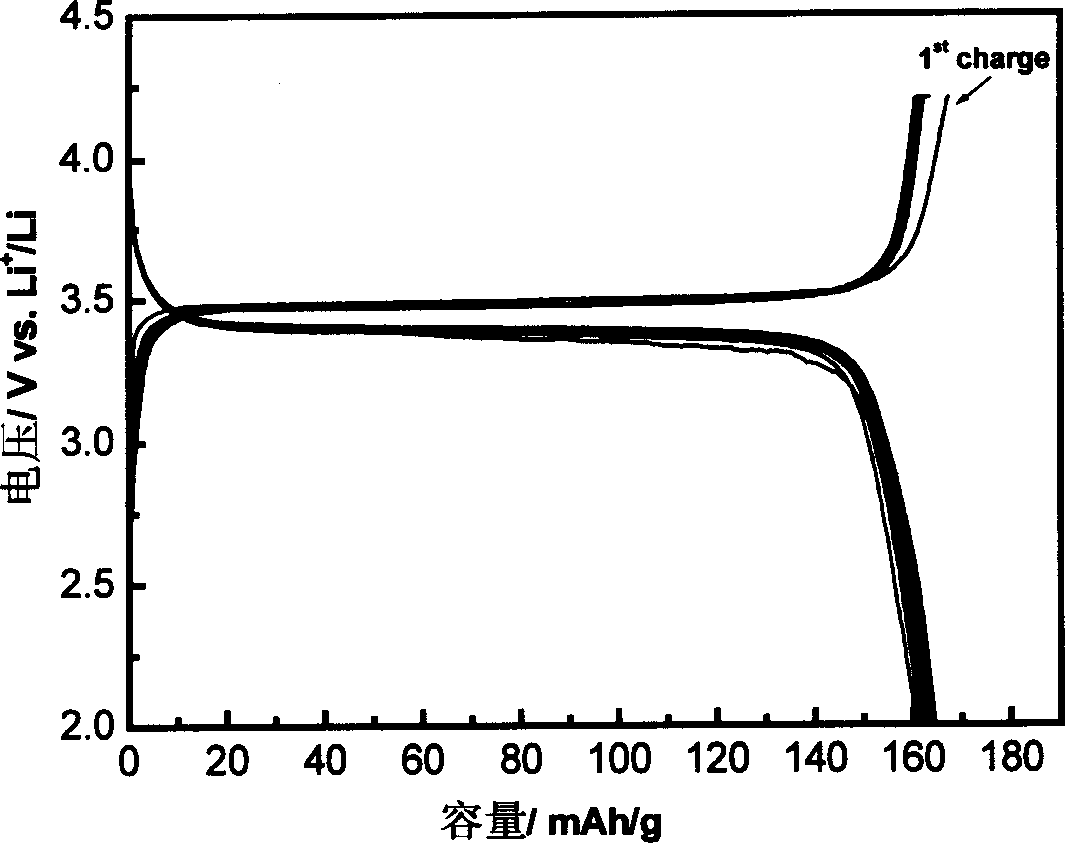

ActiveCN1581537AAvoid synthetic stepsSolve the problem of impurityElectrode manufacturing processesLithium compoundsPhosphateNitrogen gas

Mechanical solid phase method for synthesizing lithium ferric phosphate includes following steps: mixing iron powder, ferric phosphate, lithium phosphate, doping elements of phosphate, conducting agent or predecessor of conducting agent according to proportion evenly; placing the mixed admixture into ball milling container with inert gases being filled and ball milling for 18-36 hours; then putting the produced result from ball milling into high-temperature furnace with inert gases such as nitrogen gas and argon gas being filled; heating up in 10-30 deg.C / minute heating rate, baking at constant temperature 450-750 deg.C for 10-60 minutes; then cooling at 10-30 deg.C / minutes cooling rate, cooling the admixture to room temperature so as to obtain powder of lithium ferric phosphate or powder of doped powder of lithium ferric phosphate. Advantages are: feasible, no pollution, high specific capacity and good cycle performance.

Owner:SHANGHAI SINOPOLY JIAHUA BATTERY TECH

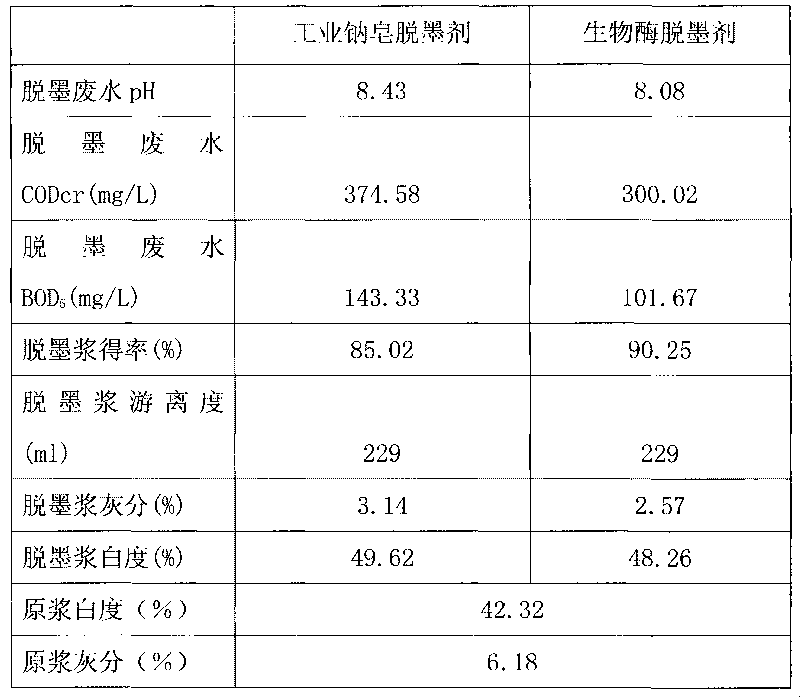

Process for de-inking waste newspaper by biologic enzyme

InactiveCN101718050AReduce usageImprove water filtration performancePaper recyclingWaste paper working-upHigh concentrationPrinting ink

The invention provides a process for de-inking waste newspaper by a biologic enzyme, which relates to the process of the pulping of waste paper. The process is characterized by comprising the following technological procedures of: (1) preparing a de-inking agent: adding one or several of alkali lipase, amylase and xylanase into cellulase to prepare a composite enzyme and then adding 0.05-0.15 kilogram of surfactant into the composite enzyme with the weight to form the de-inking agent, wherein the composite enzyme comprises the following components in proportion: 2000-10000U of cellulase, 10000-100000U of alkali lipase, 1000-5000U of xylanase and 8000-15000U of amylase; (2) pulping by using a high-concentration pulper: adding 40-60 DEG C water into the high-concentration pulper, counting by 100 kilograms of absolutely dry paper, putting 10-150 grams of de-inking agent and 0.2-0.4 kilogram of sodium metassilicate nonahydrate into waste newspaper and journal paper and stopping after starting the pulper for 10-30 minutes; and (3) carrying out the procedures of floatation and printing ink separation to obtain the de-inked pulp. The invention has the advantages that sodium hydroxide and hydrogen peroxide are not used, and the production cost and the wastewater pollution are lowered.

Owner:FUJIAN JIAFENG BIOCHEM

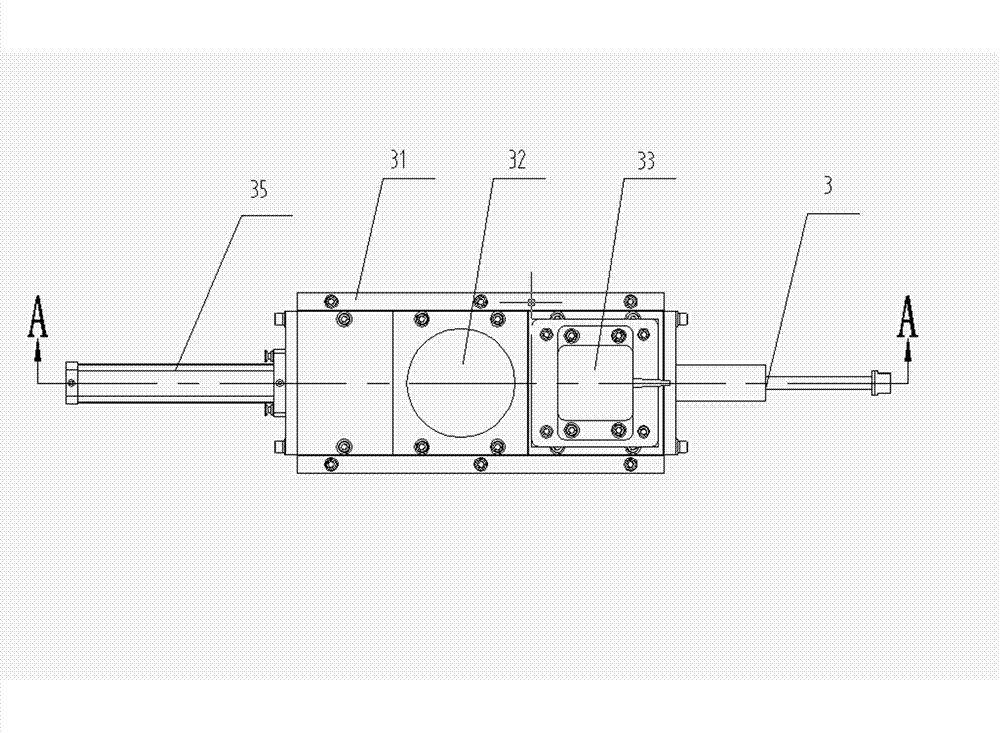

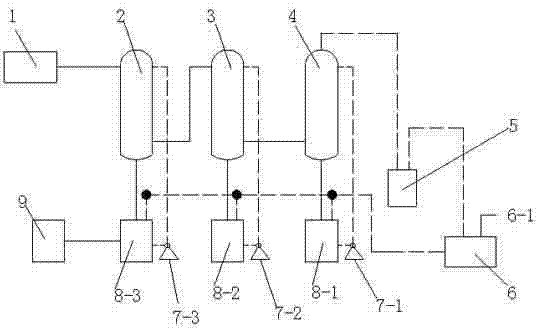

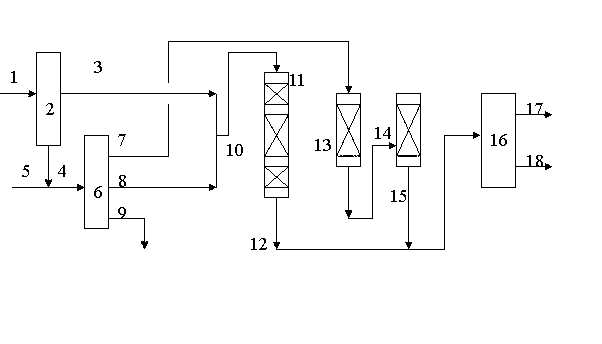

Technological method and device for semi-coke production wastewater resource utilization

ActiveCN104445815AImprove biodegradabilityImprove economic competitivenessOrganic chemistryOrganic compound preparationResource utilizationCoking wastewater

The invention discloses a technological method and device for semi-coke production wastewater resource utilization. The technological method comprises three steps, namely deep oil-water separation, high-efficiency complexing extraction dephenolization and ammonia stilling, to be specific, firstly, separating and recycling a part of coal tar from wastewater when the wastewater passes through an oil partitioning tank, recycling coal tar in a precision filter and an oil-water separator in sequence after discharged water passes through a coarse filter; feeding the oil-removed semi-coke wastewater and an extraction agent into an extraction tower for extraction and dephenolization, feeding the extract phase and a sodium hydroxide solution into a reverse extraction tower for countercurrent contact reverse extraction, feeding an obtained sodium phenolate solution into an acidification kettle, and adding sulfuric acid for acidification to obtain crude phenol; feeding dephenolized wastewater discharged from the bottom of the extraction tower into a wastewater heater, feeding into an ammonia cyanogen separator to be mixed with hot air from an air heater to remove ammonia after being heated by fume from the air heater, and feeding an ammonia-containing mixed gas discharged from the top of the ammonia-cyanogen separator into an ammonia water cooler for cooling to obtain ammonia water. By adopting the method and the device, precious resources such as coal tar, phenol and ammonia can be recycled from the semi-coke production wastewater resource, and the biodegradability of the semi-coke wastewater is improved.

Owner:陕西华祥能源科技集团有限公司

Tail gas desulfuration adopting zinc oxide method in smelting industry

ActiveCN102755826AReduce in quantityReduce wear and tearDispersed particle separationLiquid wasteDecomposition

The invention belongs to the technical filed of environmental protection, and particularly relates to tail gas desulfuration adopting a zinc oxide method in smelting industry. The tail gas desulfuration adopting a zinc oxide method in smelting industry comprises the following steps of: preparing a serous fluid-increasing smelting tail gas pressure-absorbing procedure-oxygenation procedure-plate frame pressure filtration procedure-acid decomposition procedure; the quantity of absorbing towers can be determined according to the temperature of tail gas to be processed and sulfur dioxide content, and a primary-level absorbing tower is used when the sulfur dioxide content of the tail gas is in the range of 0-6000 mg / Nm3; and a secondary-level absorbing tower is used when the sulfur dioxide content of the tail gas is in the range of 6000-12000 mg / Nm3, and a third-level absorbing tower is used when the sulfur dioxide content of the tail gas is in the range of 12000-24000 mg / Nm3. The air oxidation is realized in the absorbing tower, ZnSO3.5H2O which is easy to crystallize is oxidized to be ZnSO4, the quantity of the crystals is greatly reduced, the phenomena of sedimentation and choking are greatly relieved, and the abrasion to the circulating pump and a pipeline is relieved; and the waste acid generated by a smelting industry is utilized, part of waste fluid or waste acid is reused, and the clean production and work is promoted.

Owner:江苏恒丰伟业科技工程有限公司

Method for reclaiming and reusing iron-making dust in blast furnace

InactiveCN1632136AFavorable nodulationHelps eliminate nodulesBlast furnace detailsIron powderBlast furnace smelting

A method for recycling blast furnace ironmaking dust. The bag dust, gravity ash and other iron-containing dust recovered in the blast furnace smelting process are evenly mixed with coal powder, and sprayed into the hearth from the tuyere of the blast furnace. It is required that there is no accumulation in the hearth before injection. , no nodules in the furnace throat, and its process parameters: spray bag dust, the injection amount is 6-10Kg / t iron, hot air temperature> 1000 ℃, blast furnace zinc load <0.15Kg / t iron; spray gravity ash, injection amount is 6Kg / t iron ~ 15Kg / t iron, hot air temperature > 1050°C; spray other iron-containing dust, injection amount < 8Kg / t iron, dust particle size < 0.5mm, hot air temperature > 1050°C; the present invention has the functions of increasing iron, Saving coke, benefiting silicon reduction in molten iron, promoting smooth operation of blast furnace and strengthening smelting, benefiting safe coal injection, reducing nodulation in blast furnace, protecting the environment, and clean production, etc.

Owner:INST OF METALLURGICAL TECH DONGBEI UNIV SHENYANG

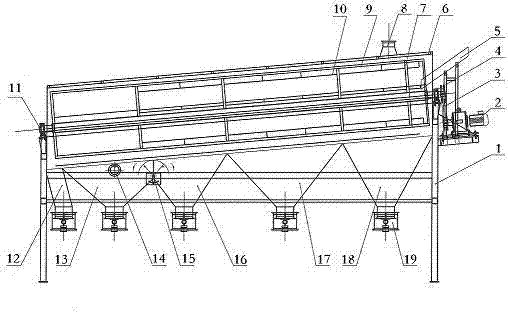

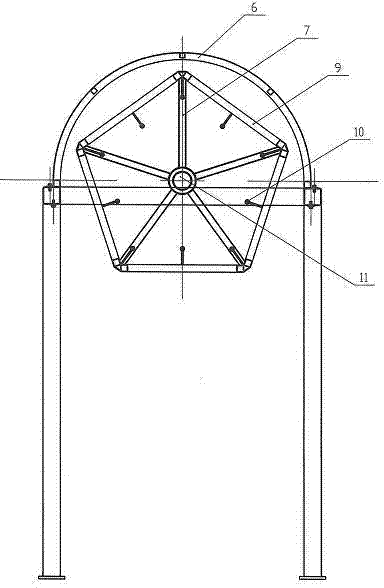

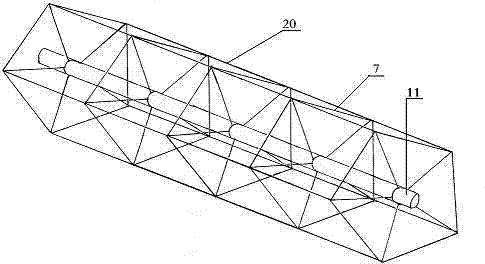

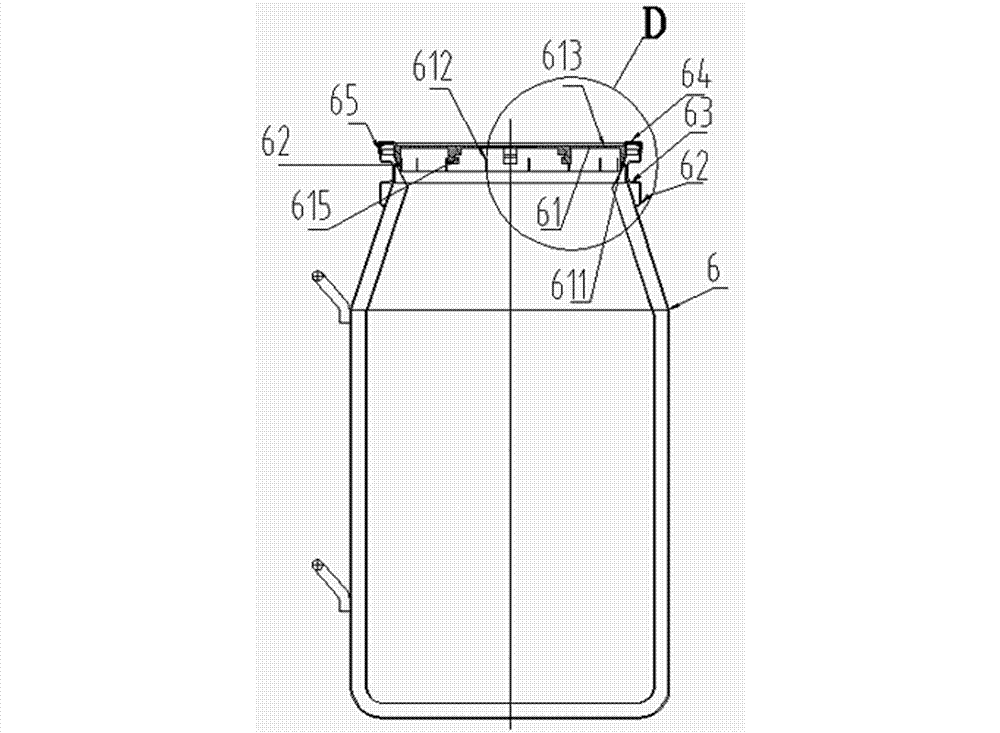

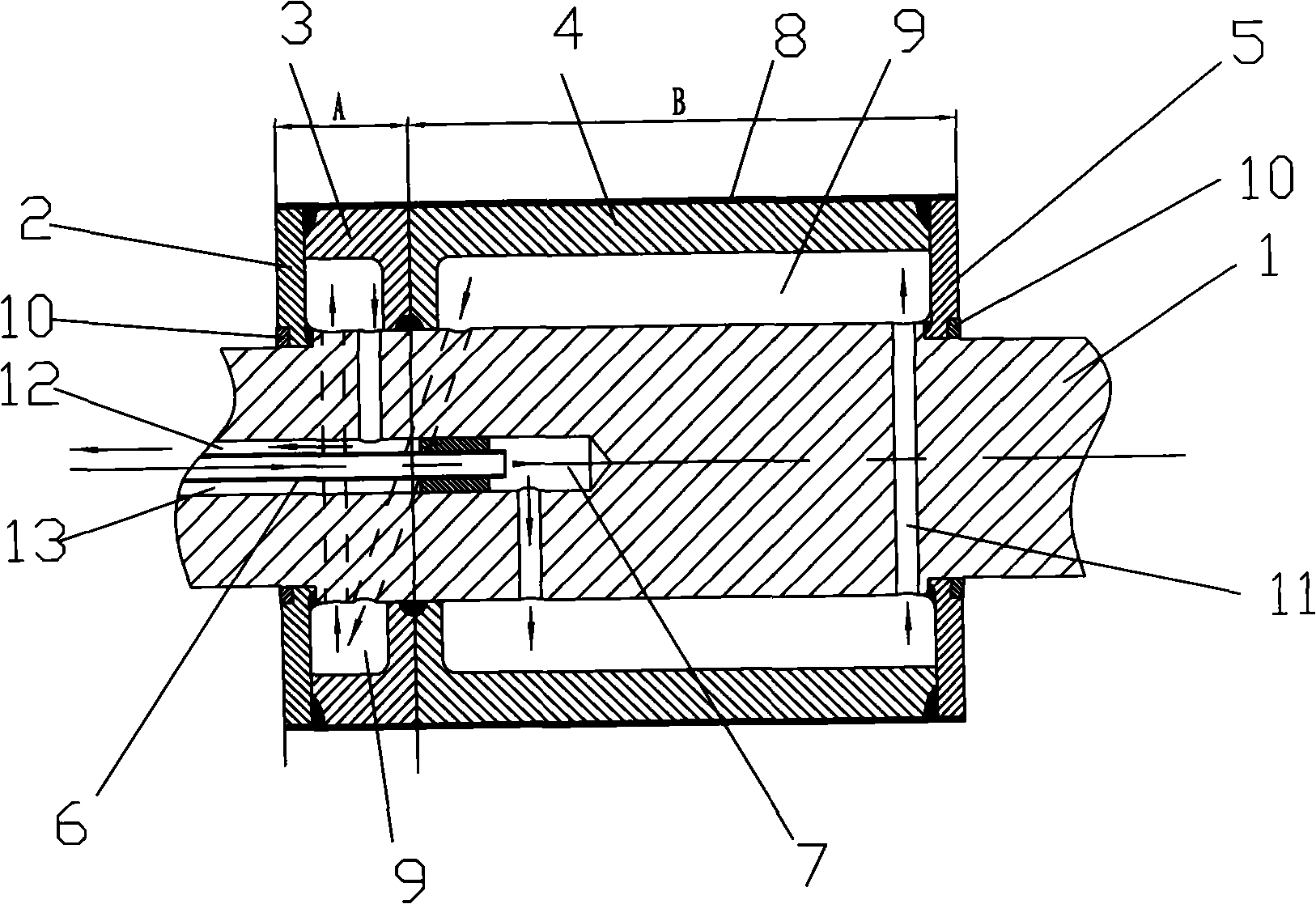

Closed five-face screen roller tobacco stalk separator

ActiveCN102342581AKeep for a long timeHigh yieldSievingTobacco treatmentPulp and paper industryEnergy conservation

The invention provides a closed five-face screen roller tobacco stalk separator. The closed five-face screen roller tobacco stalk separator comprises a frame, a housing, a screen roller, a feeding device, a discharging device, a long stalk ratio adjusting mechanism and a power mechanism, wherein the screen roll is fixed on a screen roller frame by a multi-section screen mesh plate and forms a five-face cylinder body; a screen roller shaft is arranged on a longitudinal central line of the screen roller; two ends of the shaft are rotationally mounted on the frame and have inclined angles of 4-6degrees with the horizontal plane; and a material storage bin corresponding to the multi-section screen mesh plate and consisting of a long stalk bin, a thick and short stalk bin, a thin and short stalk bin, a powder and toothpick stalk bin and a stalk turning bin is arranged at the lower part of the housing. The re-dried tobacco stalks are separated into preset groups of products with preset specifications by using a single machine at one time; the closed five-face screen roller tobacco stalk separator provided by the invention has the advantages of long tobacco stalk screening and time, uneasiness for unplugging screen hole, stable quality, obvious energy conservation, no vibration or friction in transmission and low noise; the yield of long stalk products is increased; the long stalk ratio is properly adjusted; and the maintenance cost and labor are effectively reduced. The tobacco stalks are screened within a relative sealed container with negative pressure to realize clean production.

Owner:QILIN REDRYING FACTORY YUNNAN TOBACCO REDRYING +1

Packaging machine capable of being applied to sampling industry

ActiveCN102730212ASimple structureEasy to controlClosure with auxillary devicesCans/barrels/drumsControl systemProcess engineering

The invention discloses a packaging machine capable of being applied to the sampling industry. The packaging machine comprises a machine frame, wherein a sample inlet mechanism, an automatic cover pressing device, a sample discharge mechanism, a conveying mechanism and a control system are mounted on the machine frame; a plurality of sealable charge buckets are arranged on the conveying mechanism; the motion trails of the charge buckets on the conveying mechanism are connected in series with the sample inlet mechanism, the automatic cover pressing device and the sample discharge mechanism in sequence; and the bucket covers of the charge buckets are pressed to the tops of the charge buckets through the automatic cover pressing device, and mineral samples in the charge buckets are packaged in a sealed way. The packaging machine has the advantages of simple structure, easiness in control process, high running reliability, low fault rate, good sealing property and the like.

Owner:长沙通发高新技术开发有限公司

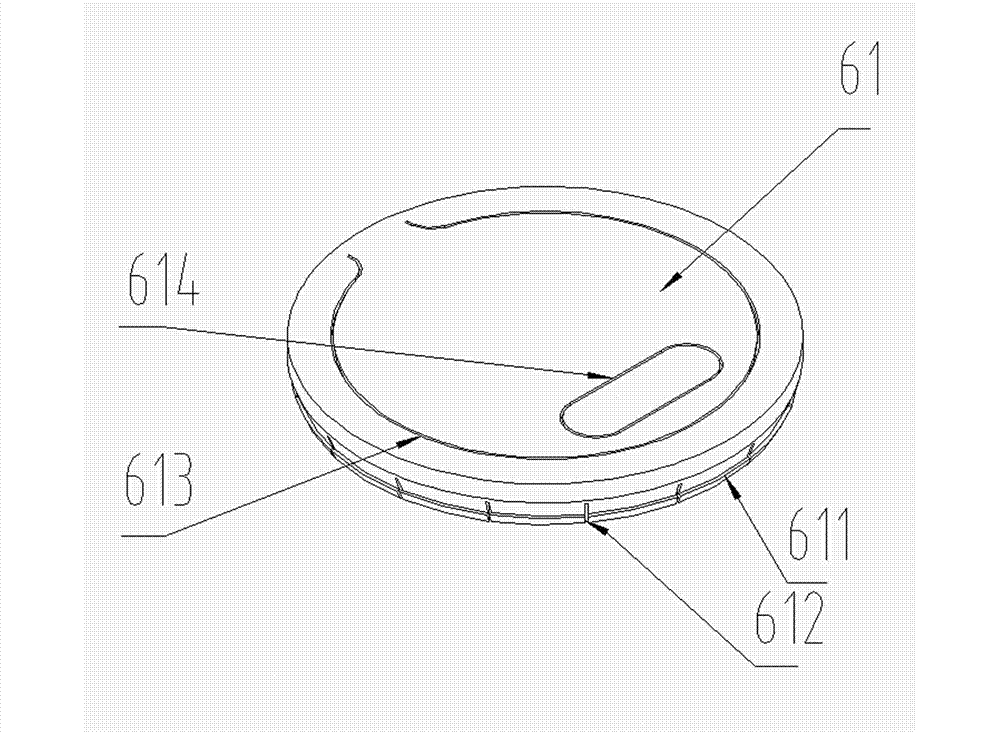

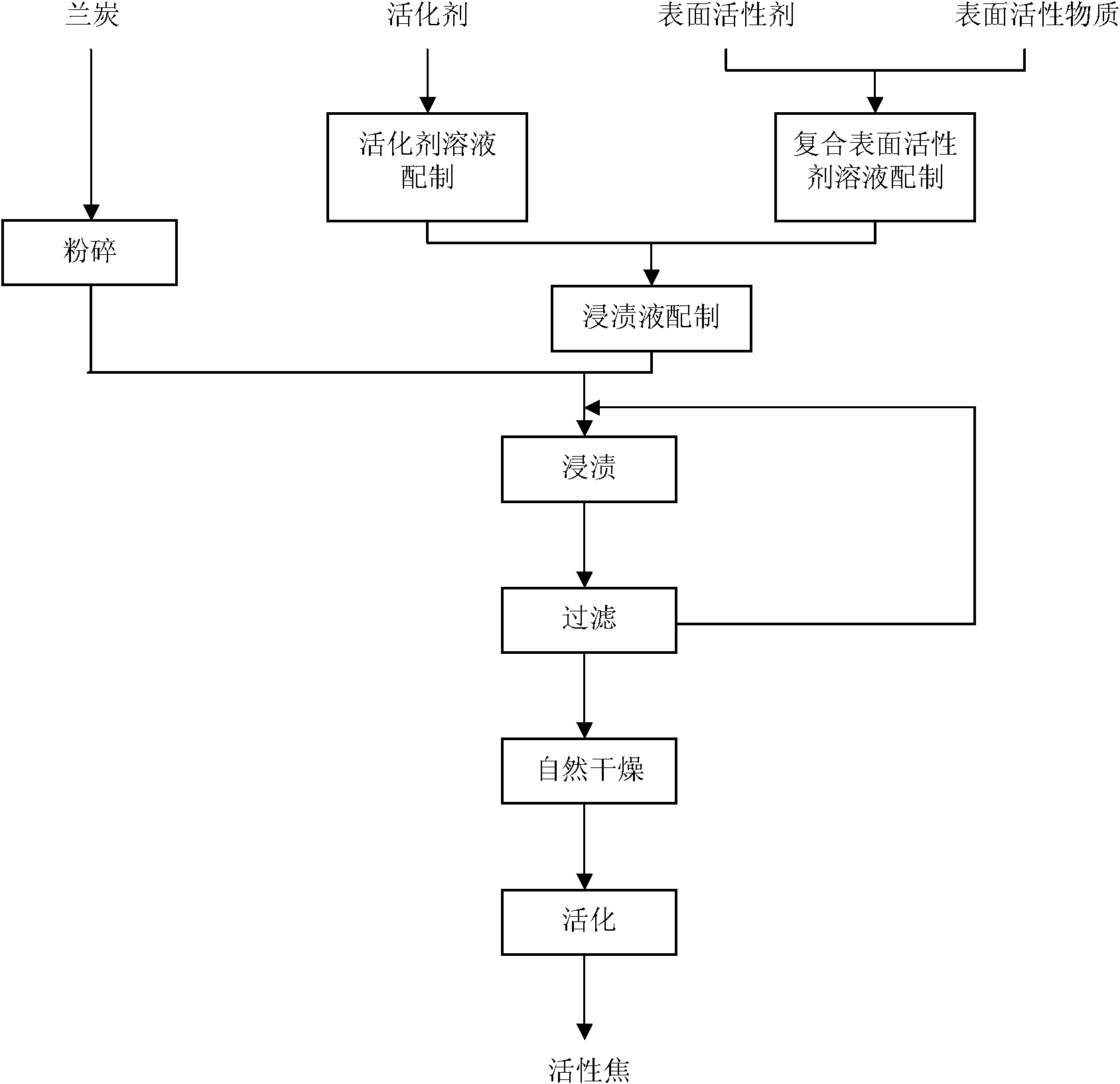

Activated coke for absorbing dioxin in flue gas and preparation method thereof

ActiveCN102728322ASolve spontaneous combustionAvoid disposition problemsOther chemical processesDispersed particle separationSorbentFlue gas

The present invention relates to an activated coke for absorbing persistent organic pollutant like dioxin in flue gas and a preparation method thereof by using coal quality semi coke as a raw material. The preparation method is as follows: crushing the coal quality semi coke; impregnating the coal quality semi coke with an impregnating solution containing metal hydroxide or alkali metal carbonate activator and compound surfactant, and naturally drying; and finally activating the impregnated and dried semi coke at 800-950 DEG C to prepare the activated coke for absorbing dioxin in flue gas. The activated coke has characteristics of developed porous structure, low manufacturing cost and good adsorption effect, etc.

Owner:BAOSHAN IRON & STEEL CO LTD +1

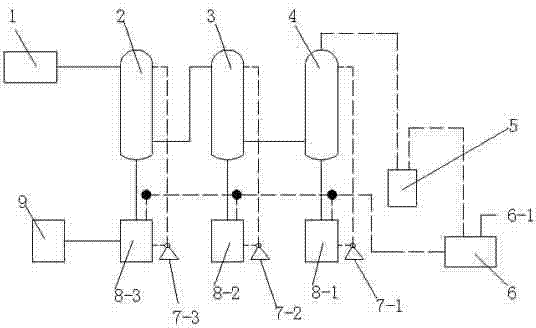

Hydrogen chloride gas circulating recovery system

InactiveCN102302890AHigh recovery rateQuality improvementChlorine/hydrogen-chlorideDispersed particle separationSulfanilamideProcess engineering

The invention relates to a hydrogen chloride gas circulating recovery system, which is characterized in that: a main body comprises a hydrogen chloride tail gas tank, a first-stage falling film tower, a second-stage falling film tower and a third-stage packing tower which are parallelly arranged, and a vacuum buffer tank which participates in forming a circulating system, wherein a gas outlet of the vacuum buffer tank is connected with a gas inlet of a water ring vacuum unit; a discharge hole of the water ring vacuum unit is connected to feeding holes of a circulating tank 1, a circulating tank 2 and a circulating tank 3 respectively; and a discharge hole on the left side of the circulating tank 3 is connected with a circulating finished product tank. Hydrogen chloride tail gas generated in the process of producing industrial sulfanilamide is subjected to circulating absorption through the structure, and the obtained hydrochloric acid can be recycled, so that the resource utilization rate is fully improved, pollution-free production is promoted, production cost is reduced, and the zero emission index of hydrogen chloride gas is met.

Owner:SUZHOU WUGAN PHARMA

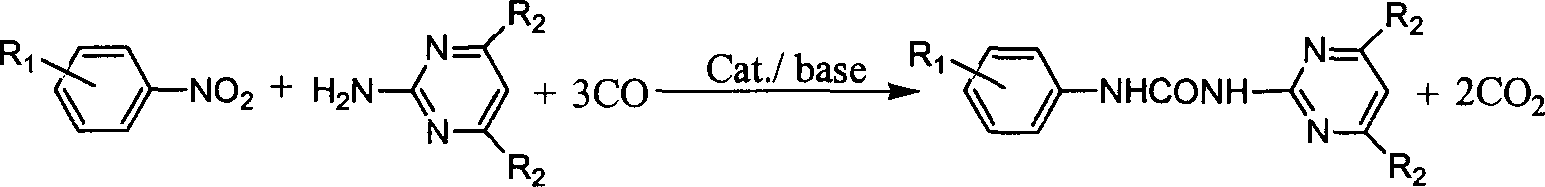

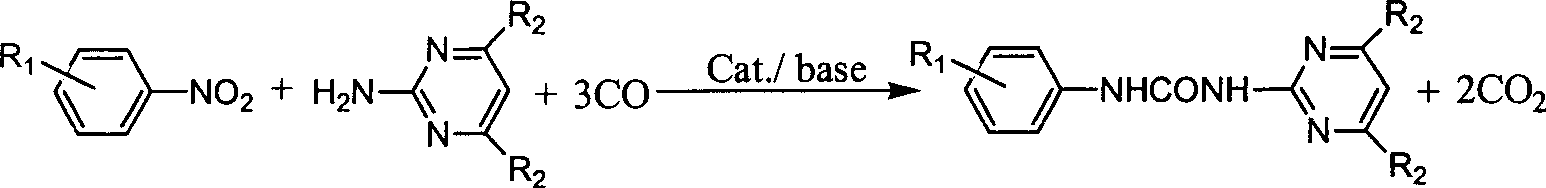

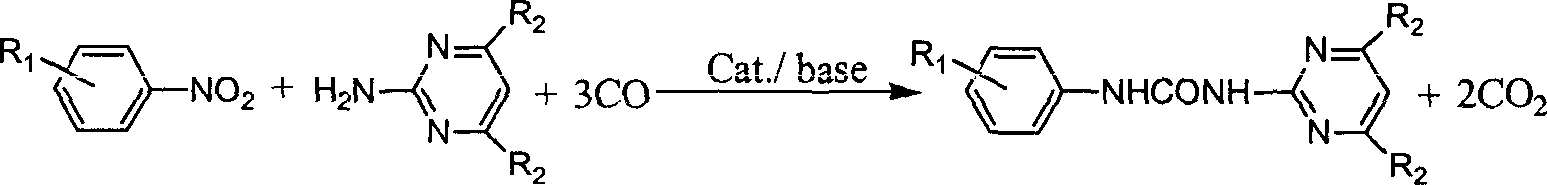

N-phenyl-N'-pyrimidinyl-substituted urea derivative synthesizing method

The method for synthesizing N-phenyl-N'-pyrimidyl substituted urea derivative is characterized by that in the presence of CO it uses substituted aminopyrimidine derivative and substituted nitrobenzene compound as raw material, uses selenium dioxide as catalyst, and uses organic alkali of triethylamine as catalyst promotor and makes them implement reaction in organic solvent in a slosed high-pressure still. The substituent R1 on the nitrobenzene can be one or several kinds of electron-donating and / or electron-attacting groups or be hydrogen atoms, and the substitutent R2 on the aminopyrimidine derivative can be one or several kinds of inert groups or hydrogen atoms. The mole dose of selenium dioxide is 0.1-20% of substrate, its reaction time is 2-20 hr., reaction temp. is 50-200 deg.C, and CD reaction pressure is 1-10.0 MPa (gauge pressure).

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

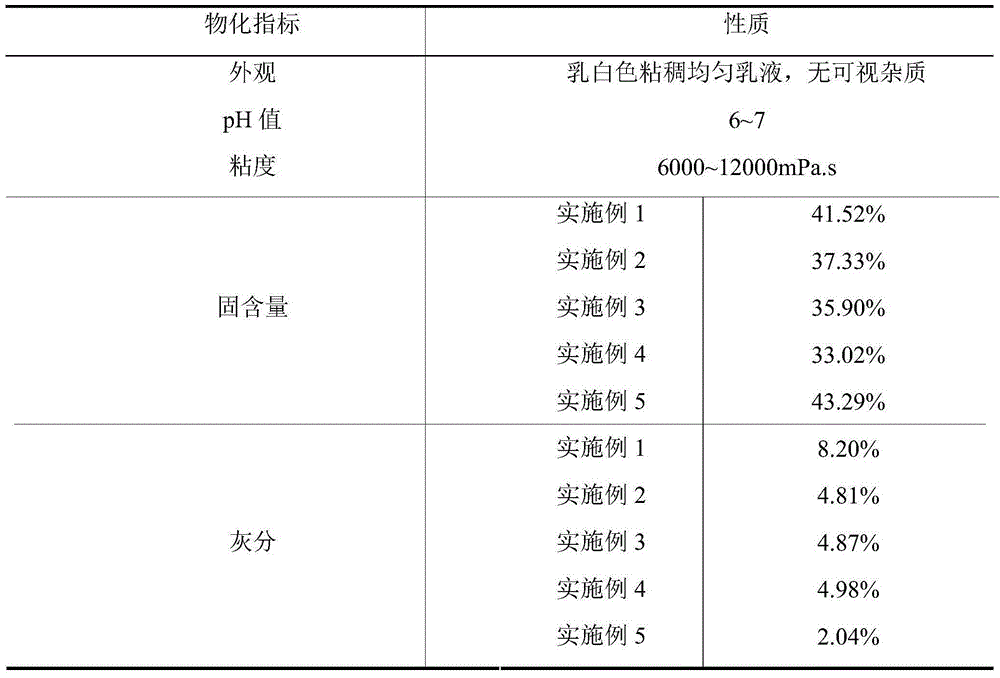

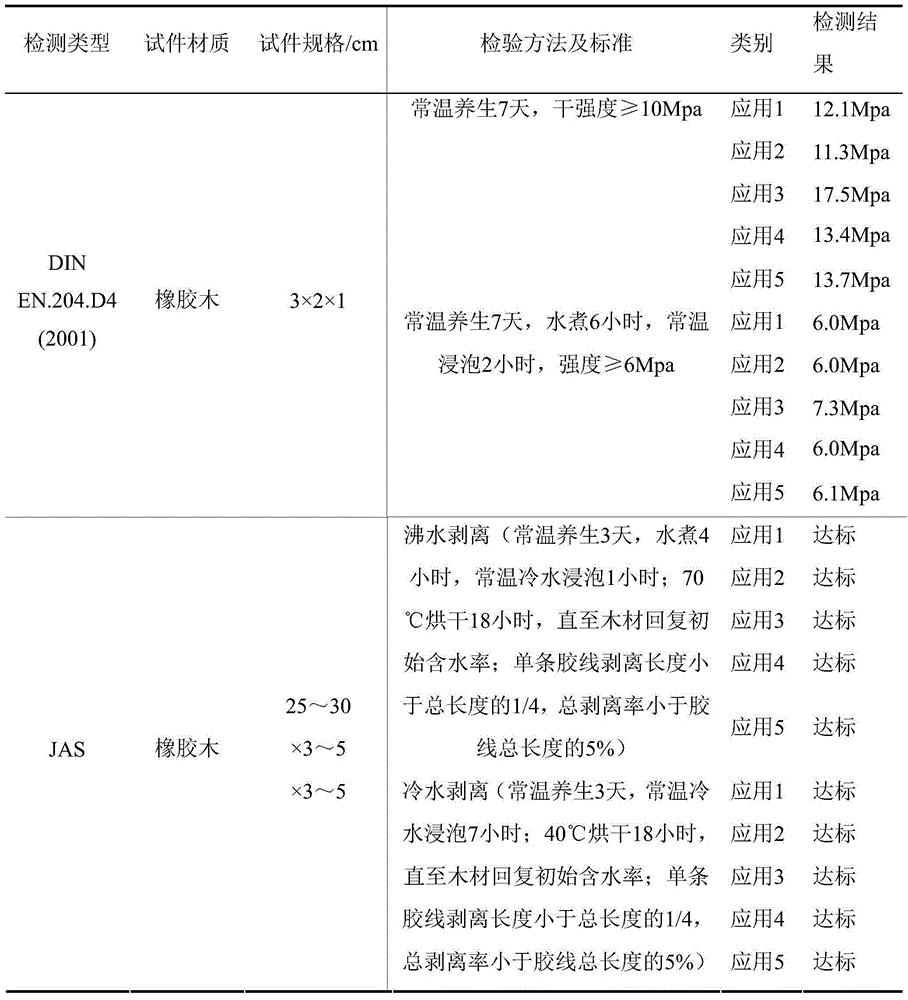

Water-based environment-friendly plate splicing adhesive and preparation method thereof

ActiveCN104479596APromote cleaner productionEasy to useMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesWater basedAdhesive

The invention relates to a water-based environment-friendly plate splicing adhesive and a preparation method thereof, belonging to the technical field of adhesives. The water-based environment-friendly plate splicing adhesive comprises the following raw materials in parts by mass: 0.1-1 part of polyvinyl alcohol, 0.5-10 parts of polyvinyl acetate emulsion, 0.5-10 parts of polyvinyl acetate-ethylene emulsion, 0.5-2 parts of calcium carbonate powder, 0.01-0.1 part of nano oxide, 0.001-0.02 part of carboxymethyl cellulose, 0.1-1 part of styrene-butadiene latex, 0.01-0.1 part of defoaming agent, 0.01-0.08 part of preservative, 6-12 parts of water and 1.34-3.46 parts of crosslinking agent. The polyvinyl acetate emulsion and polyvinyl acetate-ethylene emulsion are used as the base, and the prepared main agent is free of formaldehyde, and thus, is a water-based environment-friendly adhesive. All the monomers and components belong to low-toxicity environment-friendly chemicals which are beneficial to clean production.

Owner:康菲胶粘剂技术(广东)有限公司

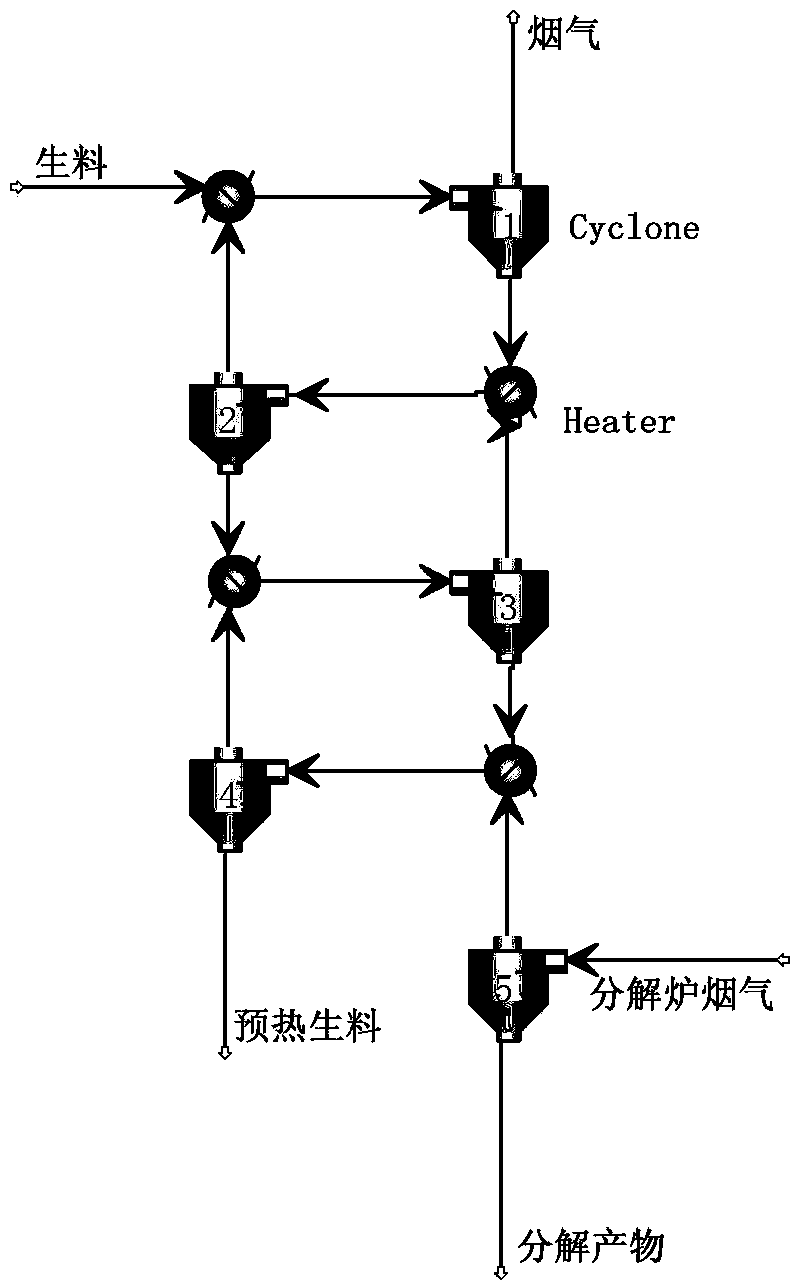

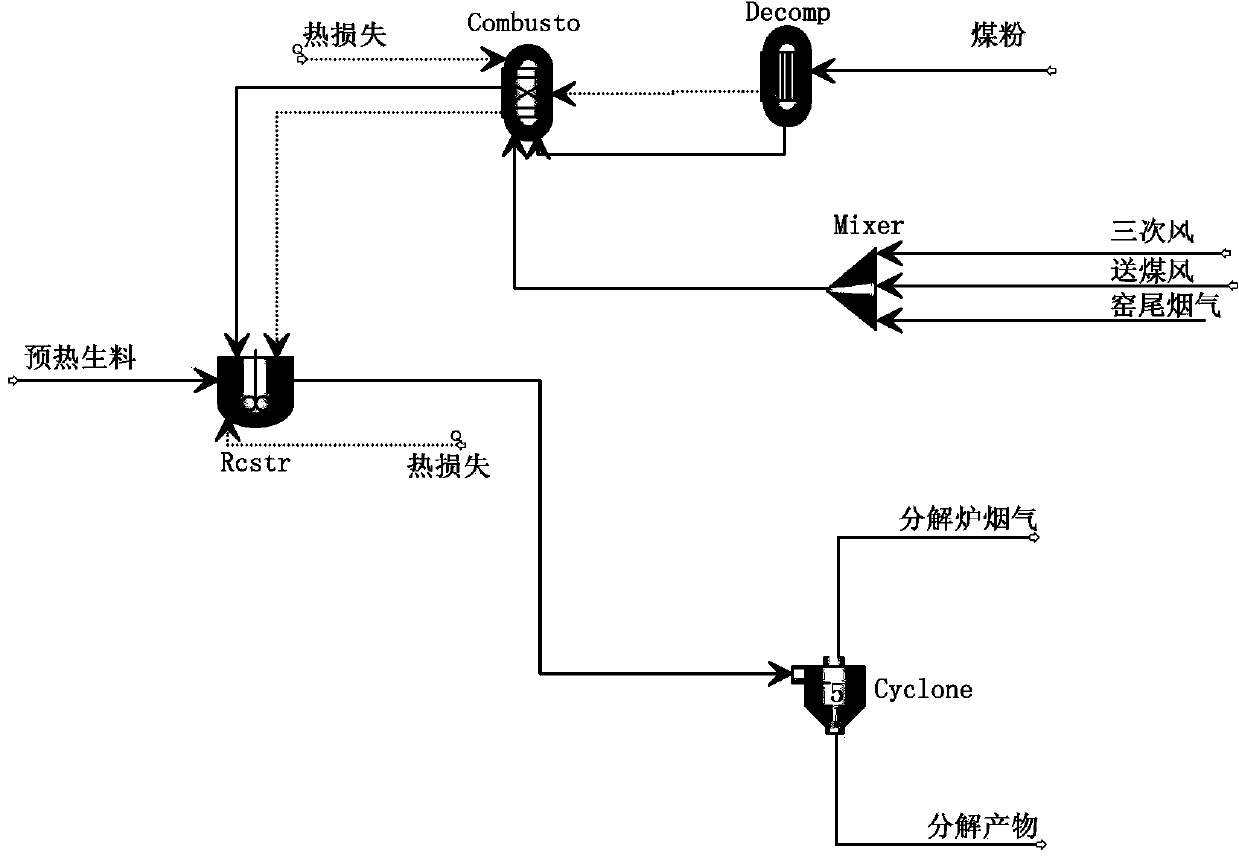

Method for modeling and optimizing cleaner production of cement clinker sintering process

ActiveCN103400196ASimplify the simulation calculation processHelpful for analysisForecastingMaterial balanceHeat conservation

The invention relates to a method for modeling and optimizing cleaner production of a cement clinker sintering process. The method comprises the steps of establishing a cement clinker sintering process model in Aspen Plus software according to a material balance relationship and the heat conservation principle of various working procedures in the cement clinker sintering process; setting and inputting data of the cement clinker sintering process, and operating the model until a simulation result meets an error requirement; selecting corresponding energy saving and emission reduction technologies according to actual production requirements, optimizing the cement clinker sintering process model, and optimizing a clinker sintering method. According to the invention, the steady-state model of the cement clinker sintering process is established based on fundamental principles of substance conservation, energy conservation and macroscopic reaction dynamics, thereby being conducive to describing influences imposed on the process by changes of process parameters and adoption of energy saving and emission reduction technologies.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

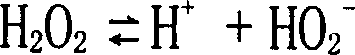

Stabilizer for use in hydrogen peroxide degumming and bleaching of flax and its preparation method and application

InactiveCN1970851ABreaks down evenly and effectivelyAvoid severe injuryBleaching apparatusFibre treatment to obtain bast fibreOxygenSurface-active agents

The invention relates to a stabilizer for hydrogen peroxide bleaching of linen rove and the textile and the new technology of degumming and bleaching for green environment protection. The stabilizer comprises 5-15% of diethylene triamine pentaacetate methylene phosphonic acids, 2-8% of sepiolite, 2-10% of montmorillonite, 1-6% of iron oxide, 1-5% of magnesium oxide, 1-8% of alumina oxide, 2-12% of gluconate, 6-20% of boric acid, 1-6% of sodium silicate, 1-8% of non-ionic surface active agent and distilled water. The stabilizer in the invention possesses merits of absorbed and chelated types and does not have their shortcomings so as to achieve the requirement with high temperature resistance, alkali-resistant and high whiteness. During the using process, after absorbed and chelated stabilizers are mixed, they are assisted by certain non-ionic surface active agent, polysaccharide cellulose protective agent and little water glass; the component of mixed stabilizers and the consumption of hydrogen peroxide are adjusted so as to achieve the required whiteness for the flax with different quality in single oxygen bleaching.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Double side coated solvent-free polyurethane laminating adhesive as well as preparation method, coating process and application thereof

InactiveCN106753172AGood adaptability to protectionWill not affect healthLiquid surface applicatorsLamination ancillary operationsEpoxyVegetable oil

The invention discloses a double side coated solvent-free polyurethane laminating adhesive, which comprises a component A and a component B, wherein the component B is prepared from one or a mixture of any two or above of polylol a of which the carbon chain length is C12 or below, polylol b with at least two degrees of functionality and above, vegetable oil modified polylol c, epoxy resin, acrylic resin and silicane resin, and a curing speed regulator d; besides being prepared from these ingredients, the component A is also prepared from a polyurethane prepolymer generated by the reaction of aromatic and / or aliphatic and / or alicyclic diisocyanate. The invention also discloses a preparation method, a coating process and application of the double side coated solvent-free polyurethane laminating adhesive. The problem that an existing solvent-free laminating adhesive needs to be previously mixed before being coated is solved.

Owner:康达新材料(集团)股份有限公司

Method for preparing lithiumion cell positive material iron-lithium phosphate

ActiveCN1255888CAvoid synthetic stepsSolve the problem of impurityElectrode manufacturing processesLithium compoundsIron powderLithium iron phosphate

Mechanical solid phase method for synthesizing lithium ferric phosphate includes following steps: mixing iron powder, ferric phosphate, lithium phosphate, doping elements of phosphate, conducting agent or predecessor of conducting agent according to proportion evenly; placing the mixed admixture into ball milling container with inert gases being filled and ball milling for 18-36 hours; then putting the produced result from ball milling into high-temperature furnace with inert gases such as nitrogen gas and argon gas being filled; heating up in 10-30 deg.C / minute heating rate, baking at constant temperature 450-750 deg.C for 10-60 minutes; then cooling at 10-30 deg.C / minutes cooling rate, cooling the admixture to room temperature so as to obtain powder of lithium ferric phosphate or powder of doped powder of lithium ferric phosphate. Advantages are: feasible, no pollution, high specific capacity and good cycle performance.

Owner:SHANGHAI SINOPOLY JIAHUA BATTERY TECH

Method for producing clean fuel oil from ethylene tar

ActiveCN103102974AIncrease profitBroaden sources of raw materialsTreatment with hydrotreatment processesTarFuel oil

The invention discloses a method for producing clean fuel oil from ethylene tar. The method consists of: fractionating ethylene tar into light fraction and heavy fraction, mixing the heavy fraction with a conventional coking raw material, conducting delayed coking to obtain coker gasoline and coker diesel oil, performing hydrofining on the coker gasoline, mixing the coker diesel oil with the ethylene tar light fraction, subjecting the mixture to hydrotreating, and leaving the reaction effluent and the coker gasoline hydrofining product together to undergo separation by a fractionating tower, thus obtaining clean gasoline and diesel oil products. Directed at the characteristics of high content of aromatic hydrocarbon, colloid, carbon residue and asphaltene in ethylene tar, the method provided in the invention fractionates the ethylene tar into light fraction and heavy fraction, and adopts different processing processes according to the composition characteristics of each fraction, thus not only enhancing the utilization rate of ethylene tar, increasing the yield of light fuel oil, but also improving the product quality of light fuel oil, and enabling the equipment to run smoothly for a long period.

Owner:CHINA PETROLEUM & CHEM CORP +1

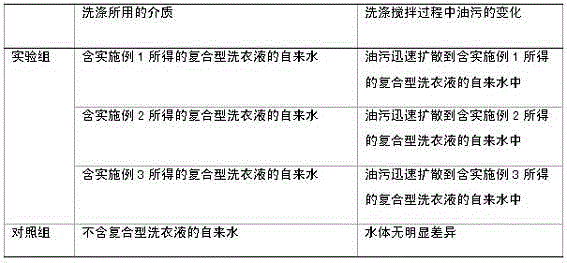

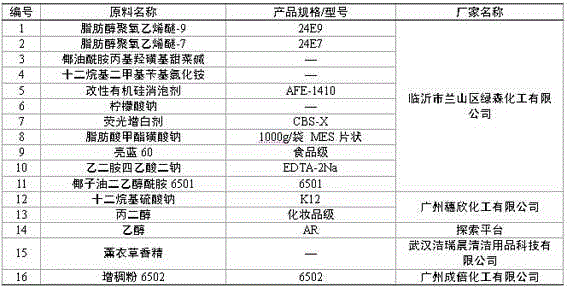

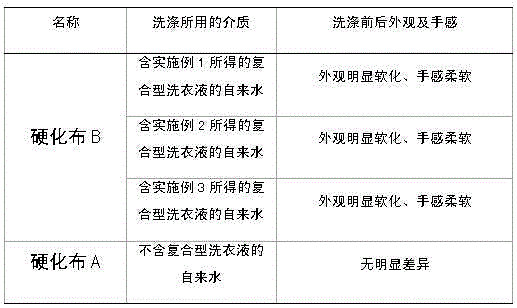

Compound liquid laundry detergent and preparation method thereof

InactiveCN104818147AStrong degreasing abilityGood degreasing effectOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsDioxyethylene EtherFatty alcohol

The invention discloses a compound liquid laundry detergent and a preparation method thereof. The compound liquid laundry detergent comprises, by mass, 10 to 15% of fatty alcohol polyoxyethylene ether-9, 5% of fatty alcohol polyoxyethylene ether-7, 4 to 6% of sodium fatty acid methyl ester sulfonate, 4 to 6% of sodium dodecyl sulfate, 6 to 8% of cocamidopropyl hydroxysulfobetaine, 3 to 4% of dodecyl dimethyl benzyl ammonium chloride, 10% of propylene glycol, 2% of ethanol, 0.25% of a modified organosilicon antifoaming agent AFE-1410, 2% of an auxiliary agent, 0.03% of a fluorescent brighting agent CBS-X, 0.03% of essence, 0.01% of pigment and 1 to 3% of a thickening agent, with the balance being deionized water. Through mutual penetration and synergism of the raw materials, the compound liquid laundry detergent has the characteristics of better detergency, stability, low foam, softness, no harm to a water body, easy degradation, etc. The raw materials used for preparation of the compound liquid laundry detergent are easily available and environment-friendly; and the preparation method is simple and easily practicable.

Owner:SHANGHAI INST OF TECH

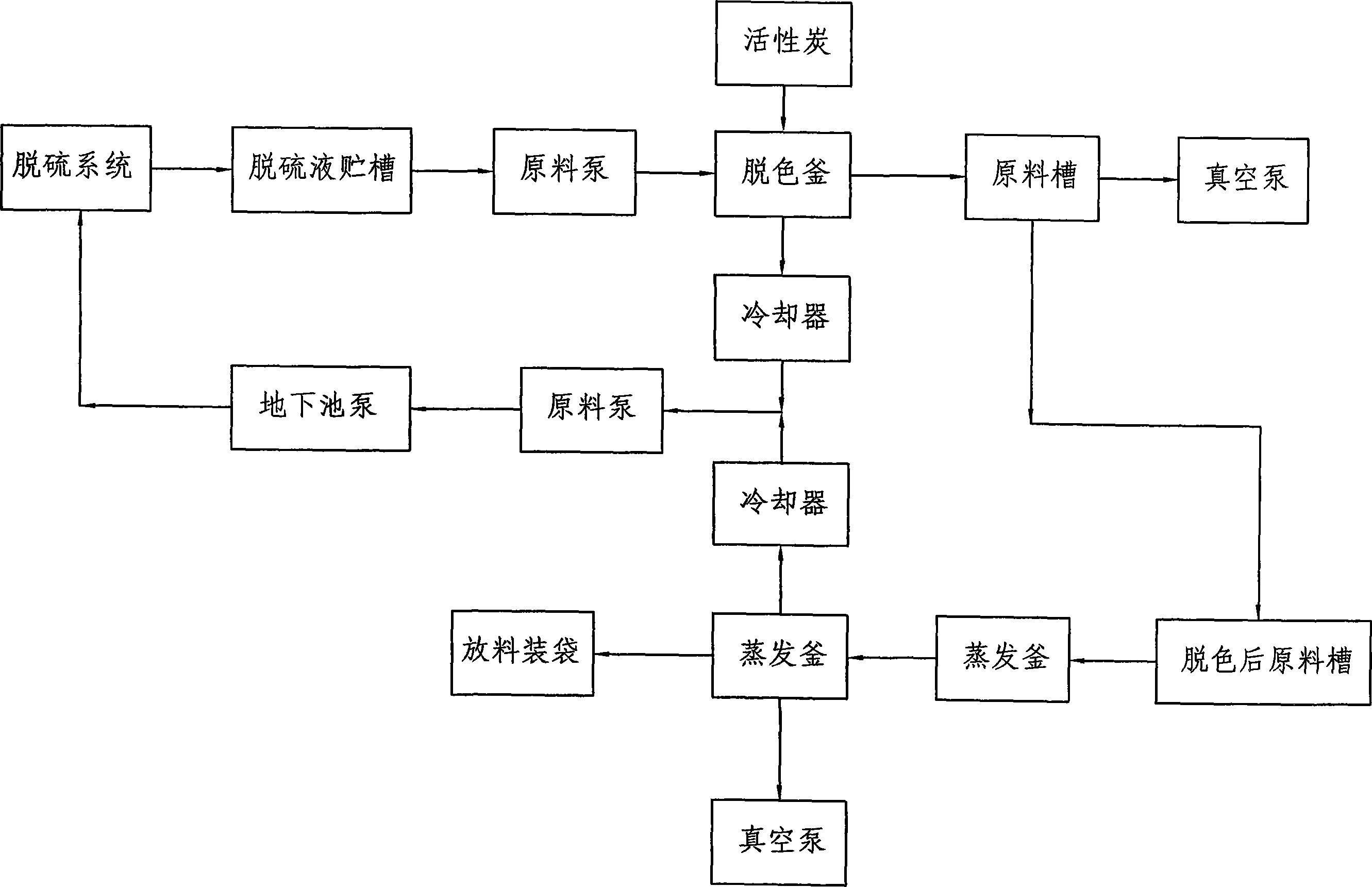

Process of extracting side salt from desulfurized liquid

InactiveCN101067096AReduce secondary salt concentrationImprove desulfurization efficiencyGas purification by liquid washingAmmoniaChemistry

The process of extracting side salt from the desulfurized liquid belongs to the field of coal gas purifying technology. The desulfurized liquid is treated through depositing, decolorizing and evaporating to cool so as to obtain the mixture containing (NH4)2S2O3 and NH4CNS as two side produced salts in the content over 90 %. The evaporated ammonia-containing condensated water is returned to the desulfurized liquid for lowering its side salt concentration. The process can obtain side salts with high value without increasing water consumption, raise desulfurizing efficiency and realize the circular use of desulfurized liquid.

Owner:SHANDONG IRON & STEEL CO LTD

Aluminum electrolysis dangerous solid waste comprehensive treatment method and resource utilization

InactiveCN107626712ASimple processShort production processWaste processingSolid waste disposalResource utilizationSilicon alloy

The invention provides an aluminum electrolysis dangerous solid waste comprehensive treatment method and resource utilization. According to the aluminum electrolysis dangerous solid waste comprehensive treatment method, other solid waste, except for waste anodes and waste aluminum dust, of aluminum electrolysis can be recycled, treatment processing is carried out through multiple procedures of primary election impurity removal, magnetic separation iron removal, flotation carbon removal, smelting reduction and the like, all aluminum electrolysis solid waste is effectively treated, renewable resources are all comprehensively utilized, and finally aluminum-silicon alloy products, electrolyte products for aluminum electrolysis, fuel powdered carbon products and the like are produced; and solidwaste treatment of the aluminum electrolysis industry is achieved, valuable resources containing aluminum, silicon, fluorine and the like are recycled and reutilized, and the good aims of protectingthe environment, saving resources and creating benefits are achieved.

Owner:陕西泰鑫有色金属综合利用有限公司

Continuous production method and device for pure cotton dyed non-woven fabric

ActiveCN107893285AEnergy savingReduce manual labor intensitySucessive textile treatmentsLiquid/gas/vapor removalWoven fabricContinuous production

The invention relates to a continuous production method and device for a pure cotton dyed non-woven fabric. The method comprises the following steps: opening raw cotton, carding, carrying out cross lapping, pre-wetting and compacting, drafting, carrying out positive and negative spunlace, efficiently squeezing, padding with scouring and bleaching liquor, steaming and carrying out reaction, efficiently rinsing, drying with a roller, carrying out multilayer loose drying, storing cloth, rolling up bleached cloth, padding with a staining solution, carrying out steaming fixation, efficiently washing, drying with a roller, carrying out the multilayer loose drying and packaging the finished product. The method provided by the invention has the advantages that energy is saved, labor intensity of workers is reduced, production time is shortened, production environment is improved, product quality is improved, sewage drainage and pollution of waste gas on the environment are reduced, and bleached products and dyed products of different technologies can be obtained on the same equipment according to factory product requirements, utilization of land, plants and equipment is improved, investment for factories is reduced, and energy conservation and emission reduction, clean production as well as intelligent factory construction which are advocated at present can be facilitated.

Owner:无锡市艾克斯染整设备有限公司

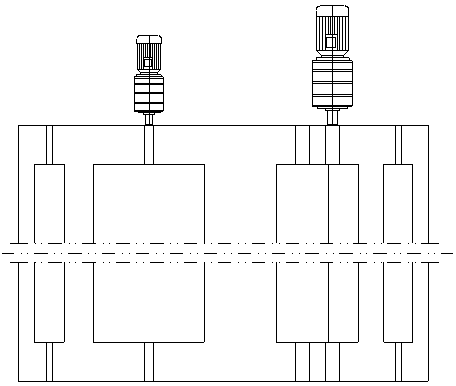

Technique for producing regenerative rubber by using kneading machinery chemical method and interrelated device thereof

InactiveCN101259739APrevents carbonization or scorchingThe equipment is easy to operatePlastic recyclingEngineeringRubber material

The invention relates to a technique for producing regenerated rubber by utilizing a milling mechanical and chemical method, wherein wasted sulfured rubber is firstly prepared into rubber powder; the rubber material is cast into a milling machine banburying room after being blended with chemical additives; a four-wing synchronous rotor of the milling machine is used for doing work on the rubber material, thereby the rubber material is heated and desulfurized; the rubber material is cooled and prepared into the finished product of the regenerated rubber by compressing and refining. The rotor comprises a rotor shaft and a left end sheet and a right end sheet on the shaft; a dextrorotatory screw wing body and a levorotary screw wing body are arranged on the rotor shaft between the left and the right end sheets; the two wing body are distributed uniformly and intersected along the circumference of the rotor shaft with an interval of 90 degrees; the cooling equipment is a spiral conveyor, wherein one end of a machine barrel is an inlet, and the other end is an outlet; a spiral mandrel connected with a power device is arranged in the machine barrel; a spiral lamina is welded on the mandrel; revolving joints are connected on two ends of the mandrel; the machine barrel is a jacketed structure; an inner cavity of a jacket and an inner bore of the mandrel are communicated with a watering and cooling device through the revolving joints and a rubber tube. The technique has the advantages of a safety and reliability, non pollution, energy saving, and low production cost.

Owner:DALIAN GENERAL RUBBER MACHINERY

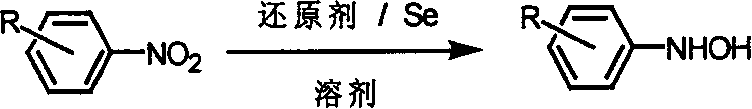

Catalytic synthesis of phenylhydroxylamine compound

During the catalytic synthesis of phenylhydroxylamine compound, substituted nitrobenzene derivative as main material is reacted inside water or organic in the presence of reductant and selenium as catalyst. The substituting radical R in nitrobenzene derivative may be one or several kinds one electron donoring and / or electron accepting substituting radicals or hydrogen atom. The reductaant may be proton donoring reductant, and the catalyst has molar consumption in 0.1-20 % of substrate. The reacting substrate has molar ratio to the solvent of 1 to 1-100, and the solvent is one or several kinds polar or nonpolar solvent. The reaction time is 0.25-20 hr and the reaction temperature is 10-100 deg.c. The present invention has simple operation, easy-to-obtain material, less reaction steps and high yield.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of organic silicon defoamer with high stability

InactiveCN106215466AImprove stabilityImprove durabilityFoam dispersion/preventionChemical industryEmulsion

The invention relates to a defoaming and foam inhibiting product for chemical industry, in particular to a preparation method of an organic silicon defoamer with high stability. The organic silicon defoamer is prepared from an organic silicon composition A, polyether-modified polysiloxane B, an emulsifier C, a coupling agent D, a thickener E and water, wherein the coupling agent D is selected from vinyl trimethoxy silane and vinyltriethoxysilane. The preparation method comprises the steps that the organic silicon composition A, polyether-modified polysiloxane B and the emulsifier C are mixed, and then heating stirring is conducted; the temperature keeps invariable, 30%-60% of water and 70%-90% of the thickener E are added while stirring is conducted, and the pH is regulated; the emulsion passes through a colloid mill, the coupling agent D is added, and stirring is conducted; dilution is conducted with the remaining thickener E and the remaining water, and the defoamer is obtained. According to the defoamer emusion product, the emulsion stability is significantly improved, so that the defoamer achieves the good stability under the extreme conditions such as strong acid and strong alkali, the durability of the defoamer is improved, and meanwhile the defoamer is not prone to be separated out.

Owner:合肥普庆新材料科技有限公司

Pulp preparing method for increasing bagasse oxygen-alkali cooking effect

InactiveCN102587178AIncreased cooking fine pulp yieldHigh whitenessPulp bleachingRaw material pretreatmentKappa numberWater consumption

The invention discloses a pulp preparing method for increasing bagasse oxygen-alkali cooking effect, comprising the steps of replacing clear water with bleaching effluents of Eop section and P section of bagasse oxygen-alkali pulp, reusing in wet stockpiling process of bagasse, carrying out oxygen-alkali cooking on the bagasse, washing, selecting, screening and bleaching to finally obtain the pulp. Compared with the yield of pulp obtained through the oxygen-alkali cooking of the bagasse subjected to wet stockpiling and sprayed by using the clear water and the yield of pulp obtained through oxygen-alkali cooking of the bagasse not subjected to wet stockpiling, the pulp obtained by utilizing the method has the advantages that the yield is respectively increased by 1-3 percentage points and 2-6 percentage points and the whiteness of unbleached pulp is increased by 1-3% ISO and the viscosity is increased by 40-110mL / g under the circumstance that pulp kappa numbers are close; the pollution load of middle-stage effluents can be decreased by 20-40%; and the water consumption per ton of pulp is decreased by 5-18m<3>.

Owner:KUNMING UNIV OF SCI & TECH

Environment-friendly type deinking agent for mixing waste paper

InactiveCN101381534ALow freezing pointGood deinking effectChemical paints/ink removersDeinkingPhenyl Ethers

The invention relates to a deinking agent, in particular to an environment-friendly mixed waste paper deinking agent. The prior waste paper deinking agent can only deink one class of waste paper in general. The invention provides the environment-friendly mixed waste paper deinking agent with wider application range, which is characterized in that the weight percentage of every component is: 5 to 10 percent of polyoxyethylene nonyl phenyl ether, 25 to 30 percent of fatty alcohol polyoxyethylene ether sodium sulfide, 5 to 10 percent of fatty alcohol polyoxyethylene ether, 10 to 20 percent of sulfonic acid, 4 to 10 percent of ethanol and the balance being water. Compared with the prior deinking agent, the deinking agent of the invention has the advantages of wide application range, good deinking effect and the like, and is few in components and simple in method.

Owner:HANGZHOU KAIBO CHEM IND

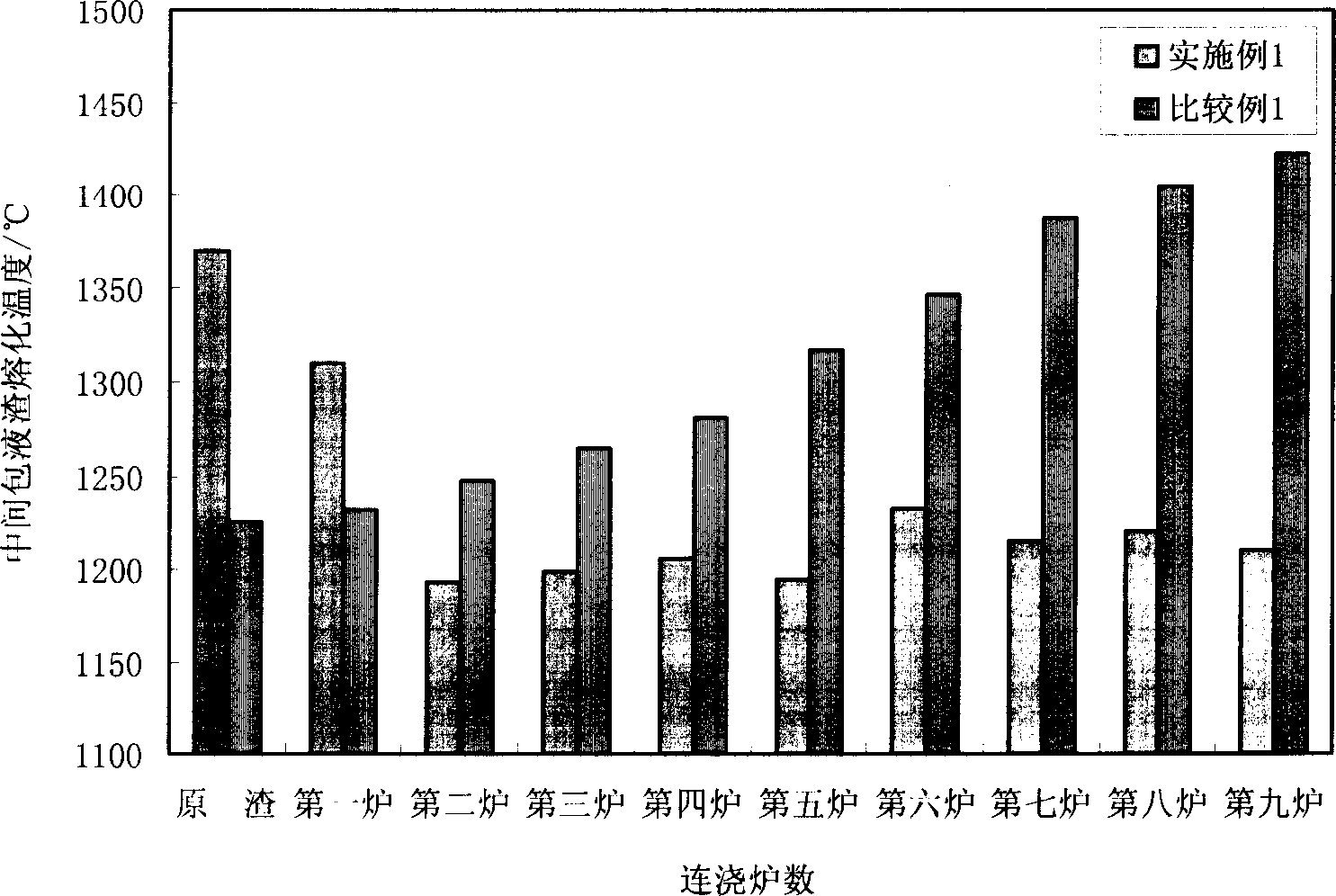

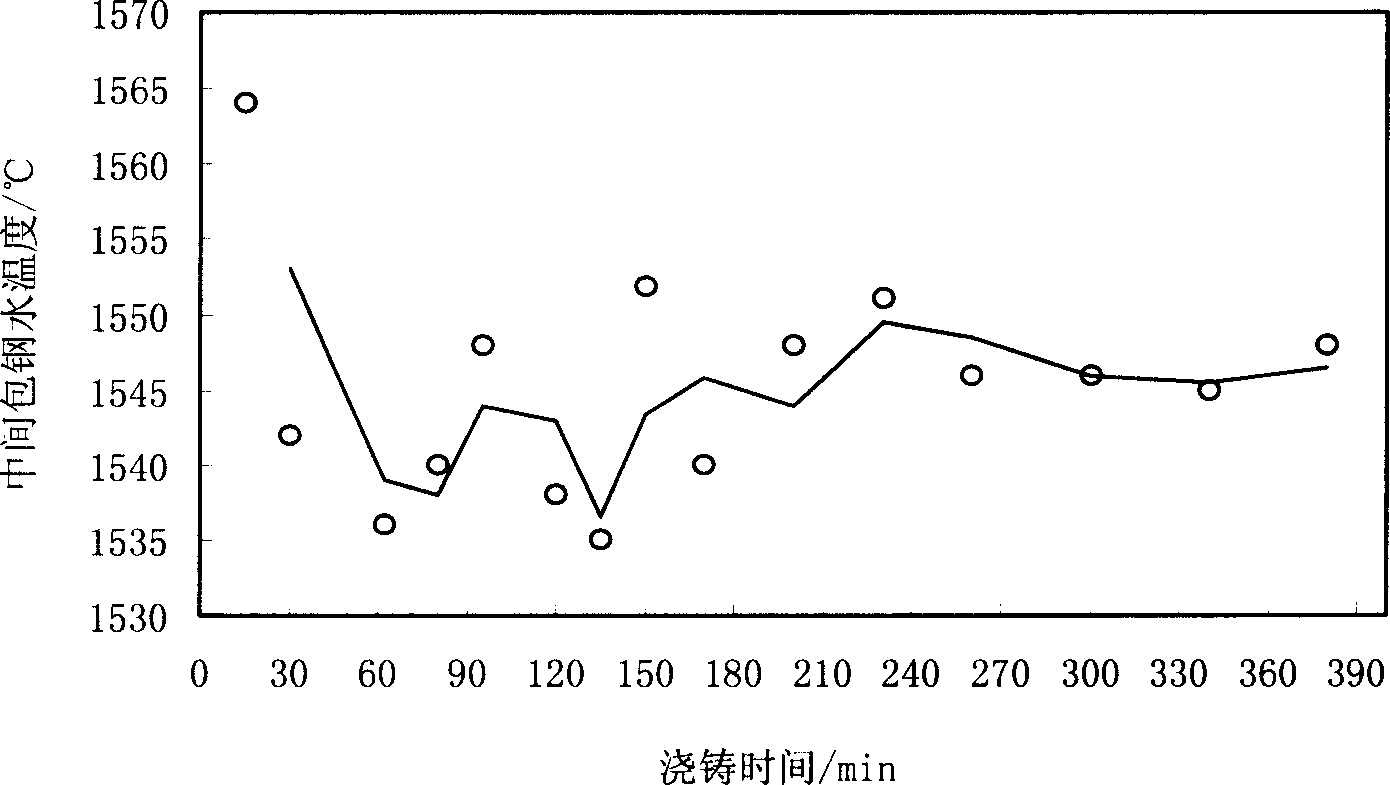

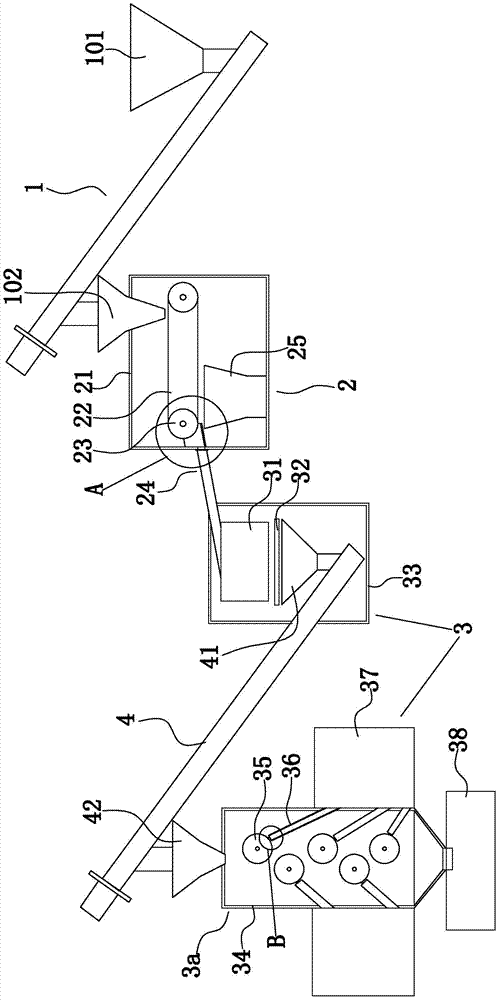

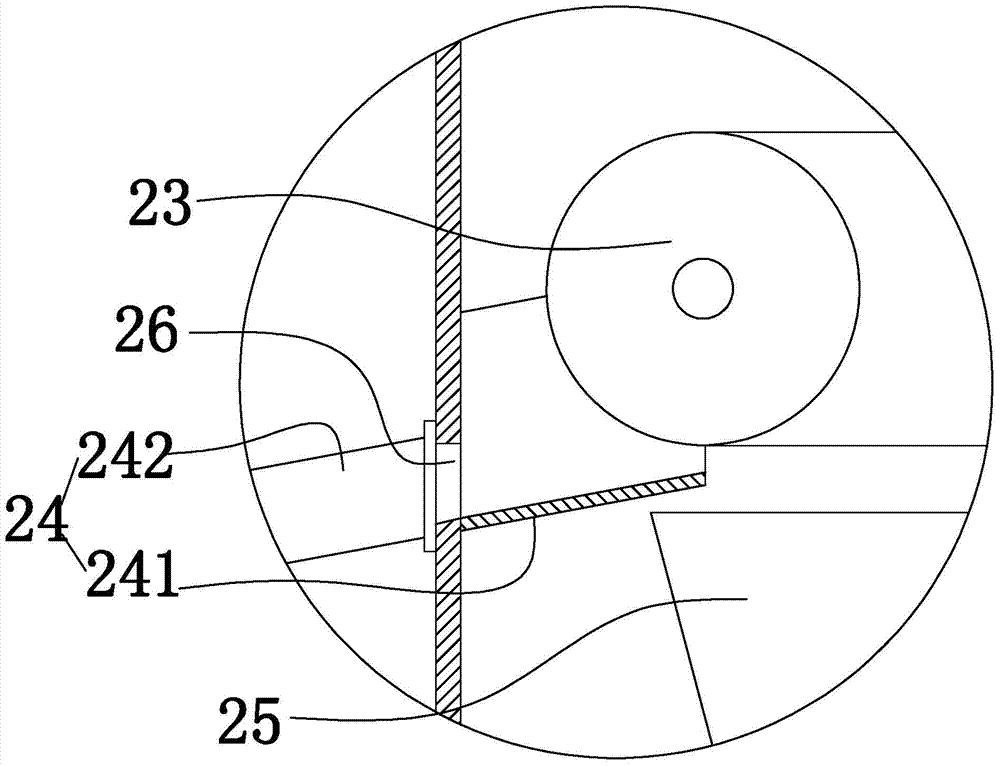

Molten steel covering agent and its preparation method

InactiveCN1911558AFacilitate package unpacking operationEliminates the danger of deterioration of steelProcess efficiency improvementFoaming agentAdhesive

The present invention is molten steel covering agent and its preparation process. The molten steel covering agent consists of Na2O 1-8 wt%, F- 0-7 wt%, Al2O3 3-40 wt%, CaO 5-40 wt%, Fe2O3 0-2 wt%, foaming agent 0.5-10 wt%, adhesive 1-20 wt% except MgO and SiO2, where the weight ratio (CaO+MgO) / SiO2 is 2-10. The molten steel covering agent is porous grains of grain size 0.1-15 mm. Its preparation process includes the following steps: mixing foaming agent, adhesive and water in a stirring vessel to prepare liquid; mixing the liquid and other components through mechanical stirring to form slurry; forming, drying, crushing and sieving. The molten steel covering agent is used in covering molten steel in ladle and possesses the metallurgical functions of maintaining heat, absorbing impurity, avoiding carburization of molten steel, etc.

Owner:LIAONING TIANHE TECH

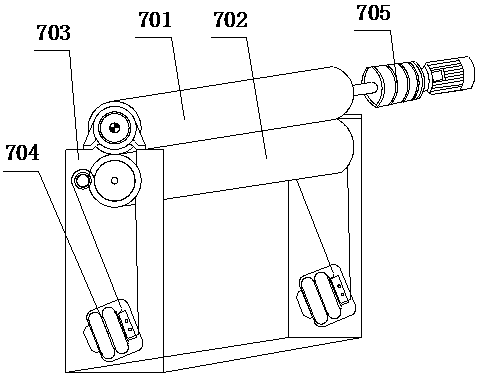

Lead powder recovery equipment

The invention discloses lead powder recovery equipment. The lead powder recovery equipment is used for removing iron impurity in lead powder recycled by an environmental-friendly dust remover effectively, so that iron impurity quality of the recycled lead powder is consistent with standards. The lead powder recovery equipment comprises an iron impurity primary filtration device and an iron impurity refined filtration device; the iron impurity primary filtration device comprises a belt transmission mechanism and a lead powder feeding device; one of the two belt wheels of the belt transmission mechanism is a magnetic belt wheel; the iron impurity refined filtration device comprises a dust raising type fine filter, a pulverizer, and a vibrating screen; the lead powder feeding device is extended along a feeding direction of the belt transmission mechanism, one end of the lead powder feeding device is extended right below the magnetic belt wheel, and the other end is extended toward a direction far from the belt transmission mechanism, and is arranged above a feed inlet of the pulverizer; the dust raising type fine filter comprises a sealed dust raising chamber and a plurality of magnetic rolls which are arranged in the sealed dust raising chamber from the upper part to the lower part successively; the top surface of the dust raising chamber is provided with a feed inlet, and the bottom surface of the dust raising chamber is provided with a feed outlet.

Owner:CHAOWEI POWER CO LTD

Method for synthesizing crotonic acid by using byproduct of croton aldehyde

InactiveCN101003473AIncrease valuePromote cleaner productionPhysical/chemical process catalystsOrganic compound preparationPhosphomolybdic acidCrotonaldehyde

This invention relates to a method for synthesizing crotonic acid from crotonaldehyde byproduct. The method comprises: distilling 20-40% crotonaldehyde byproduct by controlling the boiling point of the distillate on the top of the column at 25-65 deg.C to remove light components and obtain 45-60% crotonaldehyde in the solution in distillation kettle, adopting the solution in distillation kettle as the raw material, acetone, acetic acid, benzene or toluene as the solvent, phosphomolybdic acid as the main catalyst, and V2O5 as the cocatalyst, and reacting at 30-100 deg.C and 0.3-0.9 MPa in the presence of O2, separating the catalyst, distilling to remove the solvent, and recrystallizing with deionized water for twice to obtain crotonic acid with a purity higher than 99%. Phosphomolybdic acid can be supported by such carriers as active carbon, SiO2, gamma-Al2O3 or molecular sieve. Therefore, the catalyst can be separated from the reaction solution by filtration, and dried in air at 120 deg.C for recycling. The method has such advantages as simple process and high crotonic acid yield.

Owner:SINOPEC YANGZI PETROCHEM

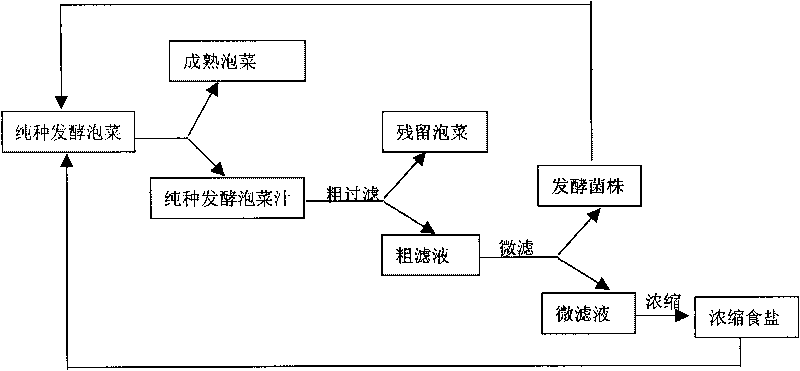

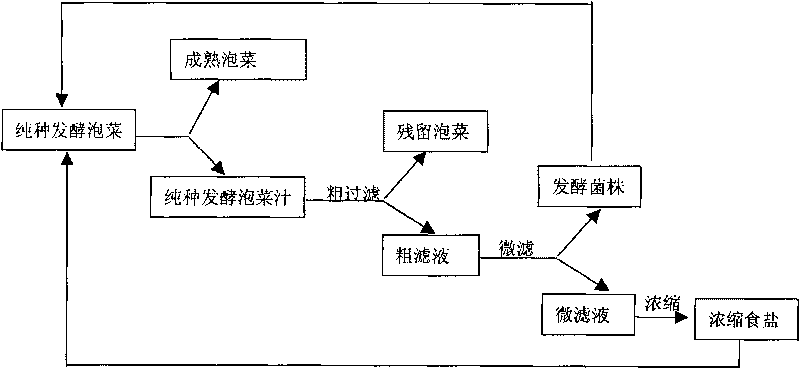

Method for recycling pure-breed fermented pickle juice

InactiveCN101703203APromote cleaner productionReduce manufacturing costFood preparationCeramic membraneFermentation

The invention relates to a method for recycling pure-breed fermented pickle juice, belonging to the fields of processing pure-breed fermented pickle and recycling pickle juice. The cleaning production of the pure-breed fermented pickle is bound up with the treatment of the pickle juice. According to the method, vegetable residues are removed by the coarse filtration of the pure-breed fermented pickle juice, the coarse filtrate is micro-filtrated by an inorganic ceramic membrane to collect fermentation strains, and the filtrate is heated up and concentrated to collect salts, the fermentation strains and the salts are reused for the pure-breed fermentation production of pickles, thus realizing the recycle of the pickle juice and the cleaning production of the pure-breed fermented pickle, and saving the production cost.

Owner:NANJING UNIV OF TECH

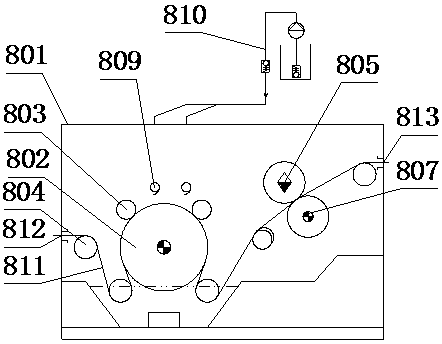

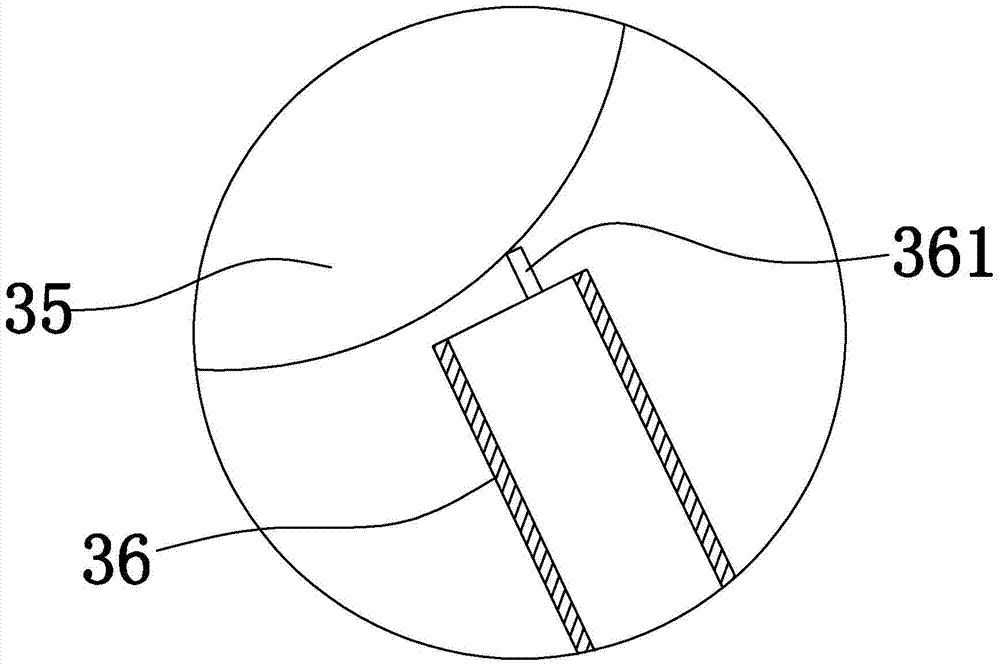

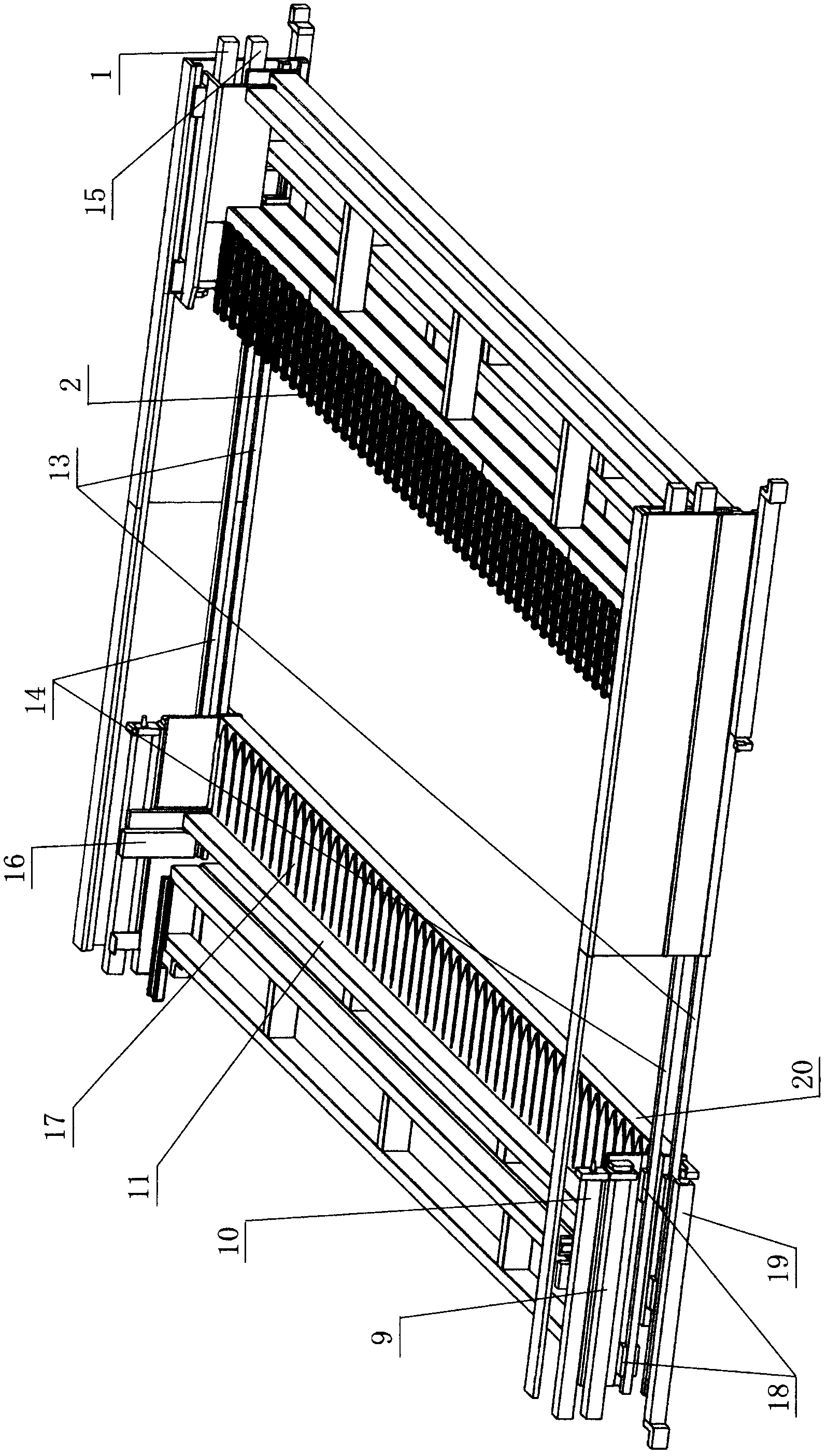

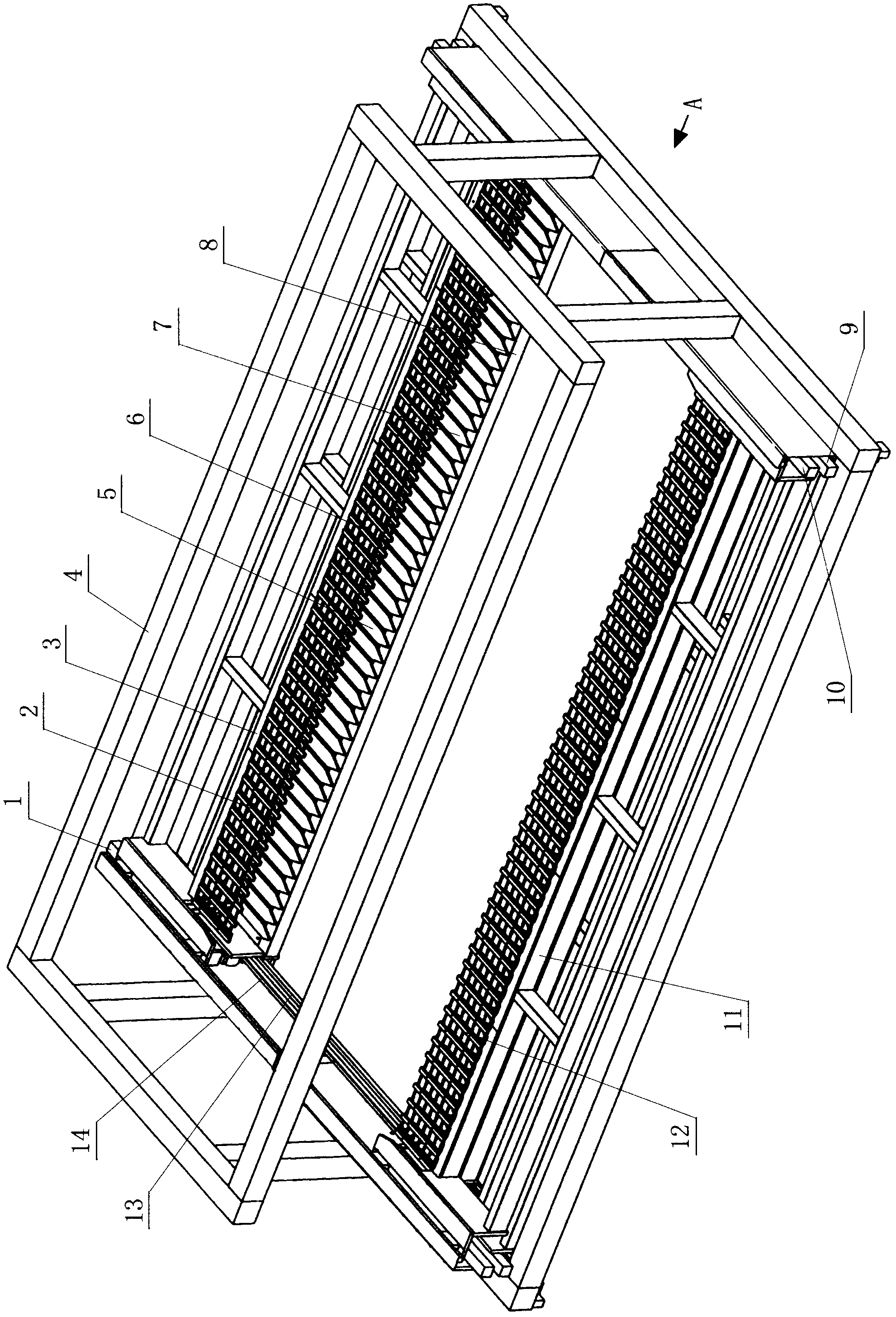

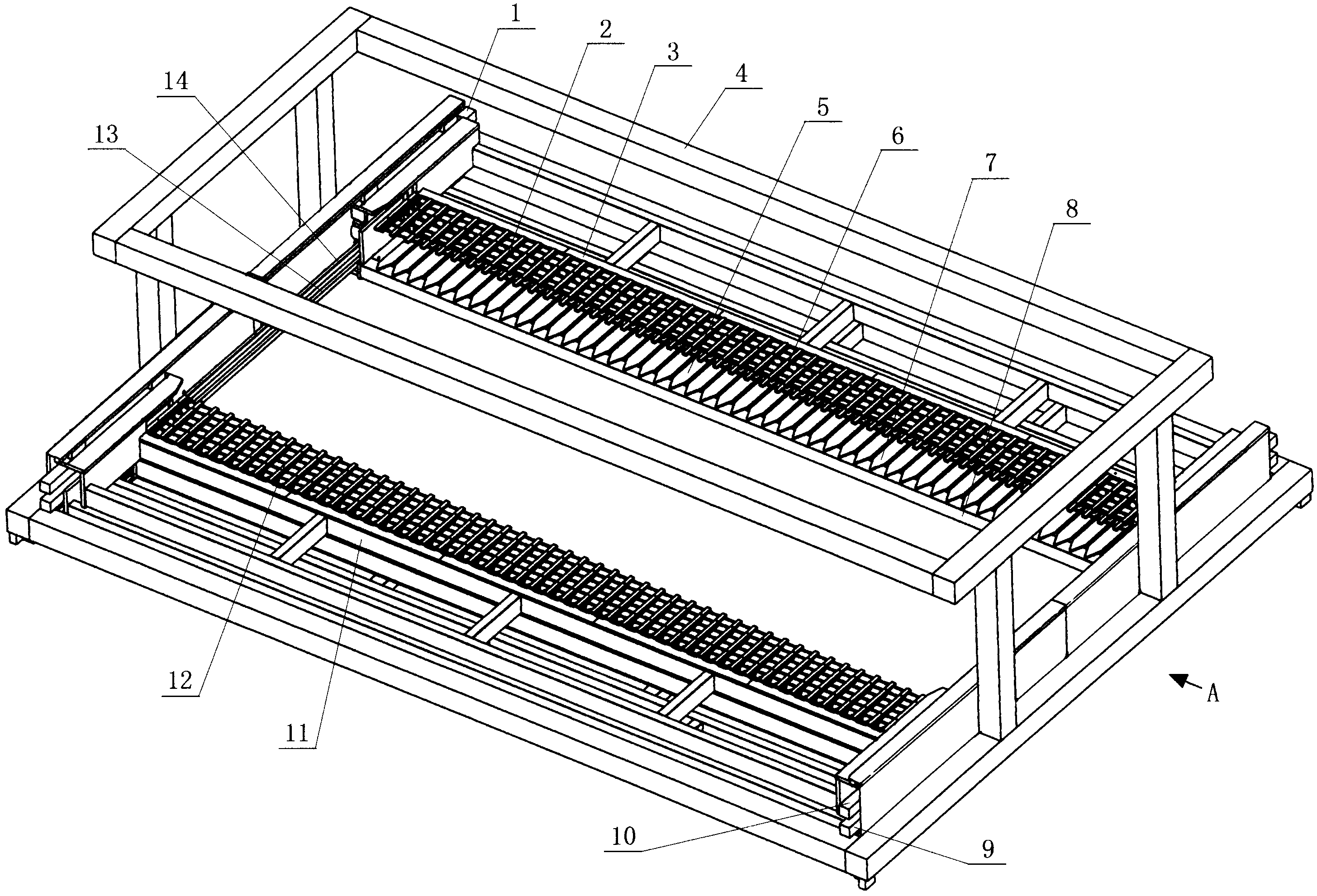

Three-layer device for tank exit, liquid brushing and storing and tank entry of manganese or zinc electrolytic cathode plate

InactiveCN102534691APrecise positioningPromote cleaner productionPhotography auxillary processesElectrolysis componentsManganeseEngineering

The invention discloses a three-layer device for the tank exit, the liquid brushing and storing and the tank entry of a manganese or zinc electrolyzing cathode plate. The three-layer device comprises a framework, a liquid brushing device, a locating device and a liquid storage device, wherein the liquid brushing device comprises a left liquid brushing actuator, a right liquid brushing actuator, a left hair brush and a right hair brush, the locating device comprises a left bracket, a right bracket, a left locating fork, a right locating fork, a left actuator, a right actuator, a left lifting actuator, a right lifting actuator, a track, a left horizontal slide block and a right horizontal slide block, the liquid storage device comprises a left liquid collecting actuator, a right liquid collecting actuator, a left liquid collecting tank, a right liquid collecting tank and liquid collecting tank tracks; the liquid collecting tank tracks are arranged at the front side and the rear side of the internal bottom of the framework; the left liquid collecting tank and the right liquid collecting tank are respectively located at the left side and the right side in the framework; the left liquid collecting tank and the right liquid collecting tank can move on the liquid collecting tank tracks; the left liquid collecting actuator and the right liquid collecting actuator are respectively arranged at internal bottoms at the left side and the right side of the framework; and the left liquid collecting tank and the right liquid collecting tank are respectively connected with the piston rods of the left liquid collecting actuator and the right liquid collecting actuator.

Owner:盐城银科环保工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com