Six-claw drilling fluid coating agent and preparation method thereof

A coating agent and drilling fluid technology, applied in the field of six-claw drilling fluid coating agent and its preparation, can solve the problems of poor coating performance, poor temperature resistance and poor stability of the coating agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

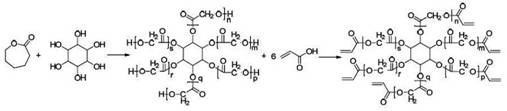

Method used

Image

Examples

Embodiment 1

[0056] In this example, the six-claw prepolymer and the six-claw drilling fluid coating agent were prepared by the following method

[0057] Six claw prepolymer preparation:

[0058] (1) Rotate ε-caprolactone at 50°C and pressure -0.08MPa for 1 hour, and set aside; add 180 parts of cyclohexanehexanol, 685 parts of ε-caprolactone, and cyclohexanehexa The molar ratio of alcohol to ε-caprolactone is 1:6, 3.46 parts of dibutyltin, after 20 minutes of nitrogen gas, it is sealed, and the temperature is raised to 210°C through the electric heating temperature control system, and the reaction is 5h, and the hexaclaw-shaped hydroxyl-terminated polycaprolactone is obtained. ester.

[0059] (2) Add 100 parts of hexapod-shaped hydroxyl-terminated polycaprolactone, 50 parts of acrylic acid, 67.5 parts of toluene, and 0.01 part of p-hydroxyanisole into a reaction kettle with stirring, condensing reflux and a thermometer, and feed oxygen into it. Raise the temperature by an electric heatin...

Embodiment 2

[0064] In this example, the six-claw prepolymer and the six-claw drilling fluid coating agent were prepared by the following method

[0065] Six claw prepolymer preparation:

[0066] (1) Rotate ε-caprolactone at 50°C and pressure -0.1MPa for 1 hour, and set aside; add 180 parts of cyclohexanol, 753 parts of ε-caprolactone, and cyclohexa The molar ratio of alcohol to ε-caprolactone is 1:6.6, 5.6 parts of dibutyltin dilaurate, after 20 minutes of nitrogen gas, it is sealed, and the temperature is raised to 210°C through an electric heating temperature control system, and the reaction is 5 hours to obtain a six-claw-shaped terminal hydroxyl group Polycaprolactone.

[0067] (2) Add 100 parts of hexapod-shaped hydroxyl-terminated polycaprolactone, 60 parts of acrylic acid, 88 parts of toluene, and 0.02 parts of p-hydroxyanisole into a reaction kettle with stirring, condensing reflux and a thermometer, and feed in oxygen. Raise the temperature by an electric heating temperature co...

Embodiment 3

[0072] In this example, the six-claw prepolymer and the six-claw drilling fluid coating agent were prepared by the following method

[0073] Six claw prepolymer preparation:

[0074] The preparation process of the six-claw prepolymer is completely consistent with that of Example 1.

[0075] Preparation of six-claw drilling fluid coating agent:

[0076] The preparation of the six-claw drilling fluid coating agent consists of the following raw materials in parts by weight: 30 parts of acrylamide, 6 parts of six-claw prepolymer, N - 120 parts of vinylpyrrolidone, 150 parts of 2-acrylamide-2-methylpropanesulfonic acid, 1788 polyvinyl alcohol (1788 means that the degree of polymerization of polyvinyl alcohol is 1700, and the degree of alcoholysis is 88) 20 parts, chlorine 8 parts of 2-hydroxy-3-(trimethylamino)propyl polyethylene oxide cellulose ether, 41 parts of potassium hydroxide, 580 parts of water, 3 parts of azobisisobutyronitrile, tert-butyl hydroperoxide 1.5 parts, sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com