Pipe jacking thixotropic slurry and preparation method thereof

A technology of thixotropic mud and pipe jacking, which is applied in chemical instruments and methods, agriculture, organic fertilizers, etc. It can solve the problems of unreasonable mixing ratio of thixotropic mud, high construction cost, poor drag reduction effect, etc., and achieve outstanding lubricity and rebound effect, increase pipe jacking speed, and reduce frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

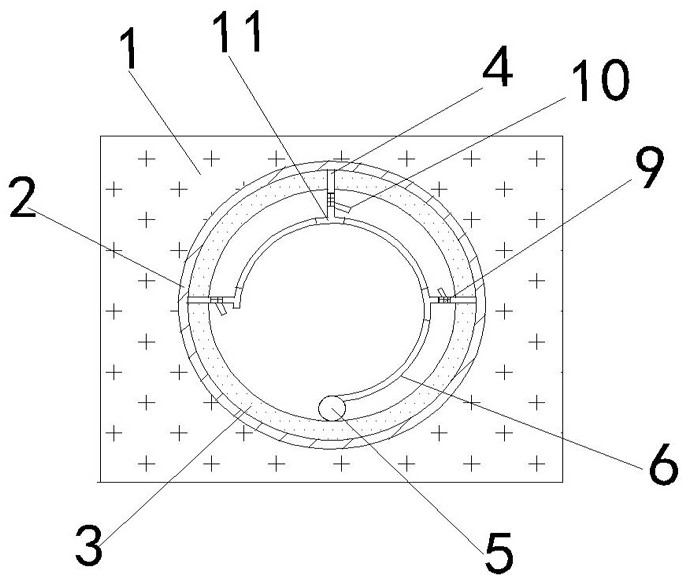

Image

Examples

Embodiment 1

[0052] A pipe jacking thixotropic mud, made of the following components by weight ratio: 7% sodium bentonite, 0.2% sodium carbonate, 0.1% polymer coagulant, MMH positive gel and / or xanthan gum 0.5% %, pregelatinized starch 1%, modified graphite and / or glass pellets 1%, water 90.2%.

[0053] According to the proportion of the above-mentioned pipe jacking thixotropic mud, the preparation is as follows.

[0054] S1. Divide the water into four parts, the first part 86.3% is added to the mixing tank, the second part 0.6% is used to dissolve the alkaline inorganic treatment agent, the third part 0.3% is used to dissolve the flocculant, and the fourth part 3% is used to prepare Mixed slurry of viscosifier and fluid loss control agent.

[0055] S2. Slowly add sodium bentonite into the mixing tank, then add the first part of water in S1 into the mixing tank, and stir evenly.

[0056] S3. Use the second part of water in S1 to melt the alkaline inorganic treatment agent to obtain a sod...

Embodiment 2

[0061] A kind of pipe jacking thixotropic mud, made of the following components by weight: 8% sodium bentonite, 0.3% sodium carbonate, 0.2% polymer coagulant, MMH positive gel and / or xanthan gum 0.6 %, pregelatinized starch 1.5%, modified graphite and / or glass pellets 2%, water 87.4%.

[0062] According to the proportion of the above-mentioned pipe jacking thixotropic mud, the preparation is as follows.

[0063] S1. Divide the water into four parts, the first part 82.3% is added to the mixing tank, the second part 0.9% is used to dissolve the alkaline inorganic treatment agent, the third part 0.6% is used to dissolve the flocculant, and the fourth part 3.6% is used to prepare Mixed slurry of viscosifier and fluid loss control agent.

[0064] S2. Slowly add sodium bentonite into the mixing tank, then add the first part of water in S1 into the mixing tank, and stir evenly.

[0065] S3. Use the second part of water in S1 to melt the alkaline inorganic treatment agent to obtain ...

Embodiment 3

[0070] A kind of pipe jacking thixotropic mud, is made of the following components by weight: 9.3% sodium bentonite, 0.42% sodium carbonate, 0.24% polymer coagulant, MMH positive gel and / or xanthan gum 0.61 %, pregelatinized starch 2%, modified graphite and / or glass pellets 3%, water 84.8%.

[0071] According to the proportion of the above-mentioned pipe jacking thixotropic mud, the preparation is as follows.

[0072] S1. Divide the water into four parts, the first part 79.4% is added to the mixing tank, the second part 1.2% is used to dissolve the alkaline inorganic treatment agent, the third part 0.6% is used to dissolve the flocculant, and the fourth part 3.6% is used to prepare Mixed slurry of viscosifier and fluid loss control agent.

[0073] S2. Slowly add sodium bentonite into the mixing tank, then add the first part of water in S1 into the mixing tank, and stir evenly.

[0074]S3. Use the second part of water in S1 to melt the alkaline inorganic treatment agent to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com