Drilling fluid and composite additive

A composite additive and drilling fluid technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as the decrease of dynamic-plastic ratio, the decrease of static shear force, and the destruction of the structure and characteristics of positively charged drilling fluid, and achieve Avoid the effect of large water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

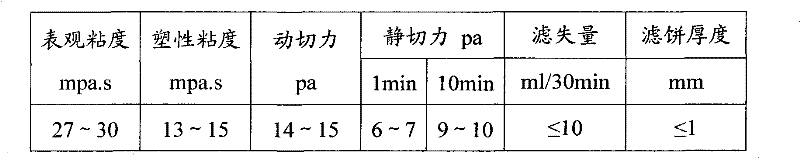

[0038] Drilling Fluid Example 1: Add 30 kilograms of bentonite and 20 kilograms of positive gel mud compound additives per cubic meter of water. The obtained drilling fluid performance parameters are as follows:

[0039]

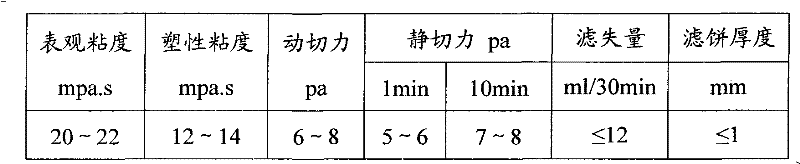

[0040] Drilling Fluid Example 2: Add 40 kg of bentonite and 10 kg of positive gel mud compound additive for every cubic meter of water. The obtained drilling fluid performance parameters are as follows:

[0041]

[0042] The drilling fluid of the invention can be applied to horizontal directional drilling, can obtain relatively large dynamic shear force, static shear force, rheological properties, sand-carrying capacity, wall protection capacity, and is environmentally friendly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com