Drilling slurry for coring of highly loose stratums as well as preparation method and application of drilling slurry

A loose, formation technology, applied in the direction of chemical instruments and methods, drilling composition, etc., can solve the problems of low harvest rate of coring, improve the harvest rate, enhance dynamic shear force and static shear force, and improve the adjustment effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

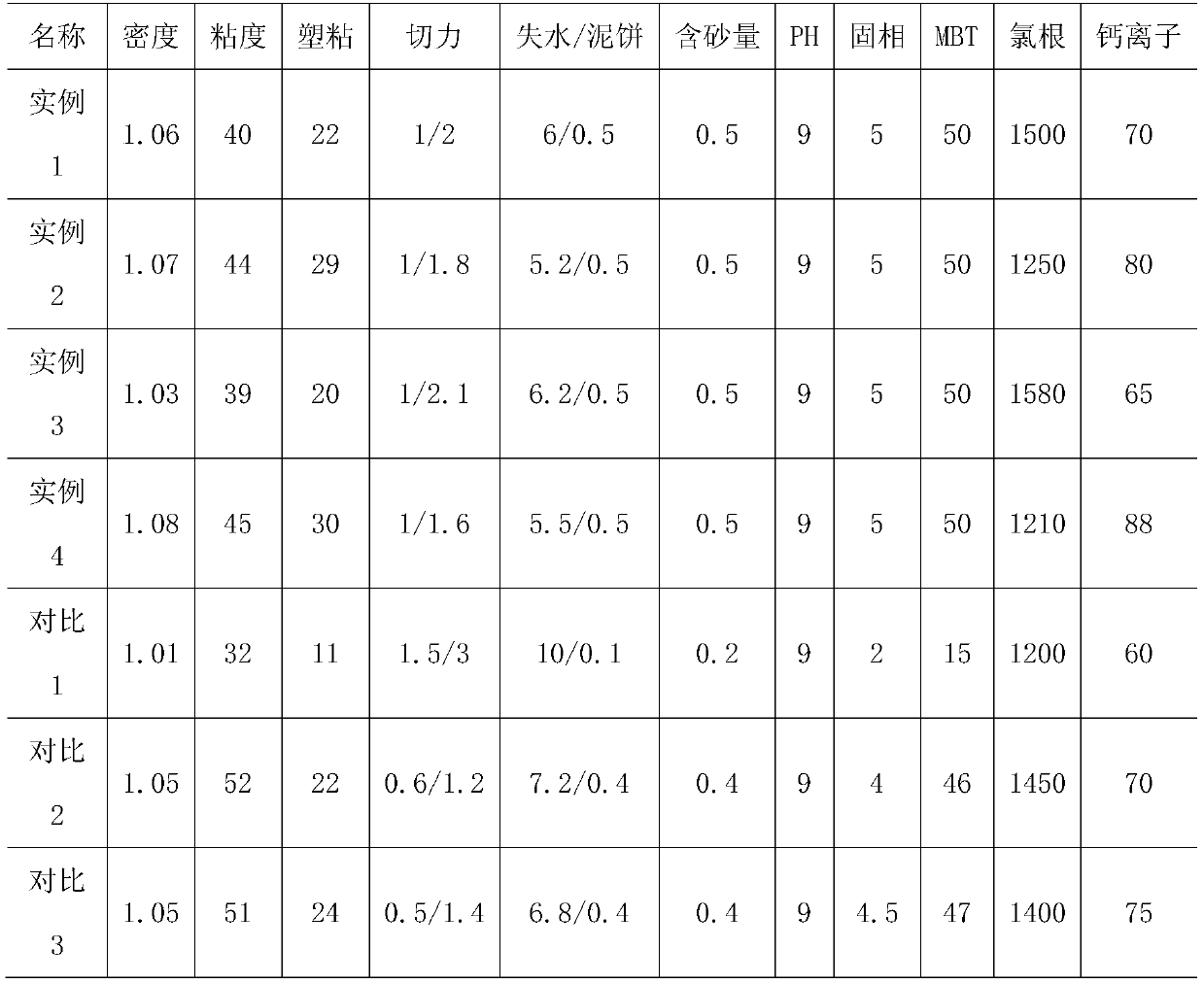

Examples

Embodiment 1

[0031] The thickness of the drilled loose overburden in this embodiment is about 63m, and the formation lithology is silty clay, loose gravel soil, etc. The upper formation is easy to absorb water and swell, causing the diameter of the hole to shrink and the hole wall to collapse. The drilling slurry is configured to meet the construction requirements of the upper formation.

[0032] The first step is to configure the slurry, the formula is: fresh water + 0.2% NaOH + 0.2% Na 2 CO 3 +10% bentonite, fully hydrated for 24 hours after preparation, and fully stirred during the hydration process to prevent precipitation; the second cloth is equipped with glue, the formula is: 0.1% NaOH + 0.1% Na 2 CO 3 +0.6% MMH (positive gel) + 0.4% JMP-1 + 0.4% K-HPAN (polyacrylonitrile-potassium salt) + 0.8% NH 4 -HPAN (polyacrylonitrile complex ammonium salt), fully hydrated.

[0033] When drilling and coring, put the slurry into the hole first, replenish the glue in time during the drilling...

Embodiment 2

[0036] The thickness of the drilled loose overburden in this embodiment is about 58m, and the formation lithology is silty clay, sand and the like. The upper formation is easy to absorb water and swell, causing the diameter of the hole to shrink and the hole wall to collapse. Shallow groundwater contaminates drilling fluid.

[0037] The drilling slurry is configured to meet the construction requirements, and the formula is: fresh water + 0.2% NaOH + 0.2% Na 2 CO 3 +10% bentonite for full hydration for 24 hours. Configure glue, the formula is: 0.2%NaOH+0.2%Na 2 CO 3 +0.6% MMH (positive gel) + 0.4% JMP-1 + 0.4% K-HPAN (polyacrylonitrile-potassium salt) + 0.8% NH 4 -HPAN (polyacrylonitrile complex ammonium salt), fully hydrated.

[0038] When drilling and coring, put the slurry into the hole first, replenish the glue in time during the drilling and coring process, and gradually add glue to the hole until the glue is used up, so as to improve the stability of the drilling sl...

Embodiment 3

[0041] This embodiment is based on embodiment 1, and the difference with embodiment 1 is:

[0042] The first step is to configure the slurry, the formula is: fresh water + 0.1% NaOH + 0.1% Na 2 CO 3 +5% bentonite, fully hydrated for 24 hours after preparation, and fully stirred during the hydration process to prevent precipitation; the second cloth is equipped with glue, the formula is: 0.1% NaOH+0.1% Na 2 CO 3 +0.5% MMH (positive gel) + 0.3% JMP-1 + 0.3% K-HPAN (polyacrylonitrile-potassium salt) + 0.5% NH 4 -HPAN (polyacrylonitrile complex ammonium salt), fully hydrated.

[0043]After the final hole, the harvest rate of coring is counted, and the harvest rate can reach 81%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com