Lifted cutting agent and preparation method and oil-based drilling fluid

A technology of shear lifting agent and hydroxyl group, applied in the field of shear lifting agent and its preparation, oil-based drilling fluid, can solve the problems of limiting the wide application of shear lifting agent, low shear lifting force of shear lifting agent, etc., and achieve dynamic carrying and static suspension ability. Strong, high cutting force, improve the effect of cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a preparation method of a cutting agent, comprising:

[0025] The styrene vinyl carboxylic acid copolymer, diamine and hydroxyl-containing fatty acid are reacted to obtain the cutting agent.

[0026] In the present invention, the reaction temperature is preferably 150-180°C, more preferably 160-170°C. In the present invention, the reaction time is preferably 6-10 hours, more preferably 8 hours.

[0027] In the present invention, the preparation method of the cutting agent is preferably:

[0028] Reacting styrene vinyl carboxylic acid copolymer with diamine; reacting the obtained reaction product with hydroxyl-containing fatty acid to obtain the cutting agent.

[0029] In the present invention, the reaction temperature of the styrene vinyl carboxylic acid copolymer and diamine is preferably 150-180°C, more preferably 160-170°C. In the present invention, the reaction time between the styrene vinyl carboxylic acid copolymer and the diamine is pref...

Embodiment 1

[0045] Copolymerize 1.0 mol of styrene acrylic acid copolymer and 1.0 mol of hexamethylenediamine at 150°C for 3 hours, then add 1.0 mol of hydroxyl-containing dodecanoic acid for 3 hours at 150°C, after natural cooling Obtain viscous cutting agent.

[0046] The styrene acrylic acid copolymer is the 303 type product provided by Shanghai Xianglan Chemical Co., Ltd.; the source of the hydroxyl-containing dodecanoic acid is the 2-hydroxydodecanoic acid product provided by Hubei Jusheng Technology Co., Ltd.

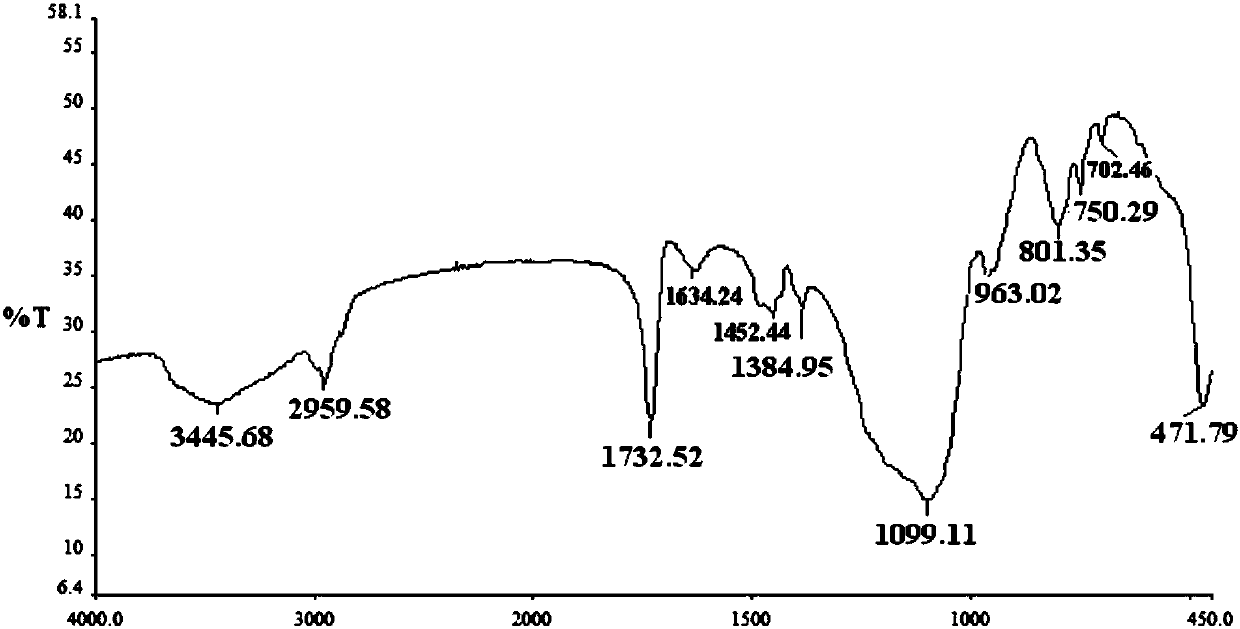

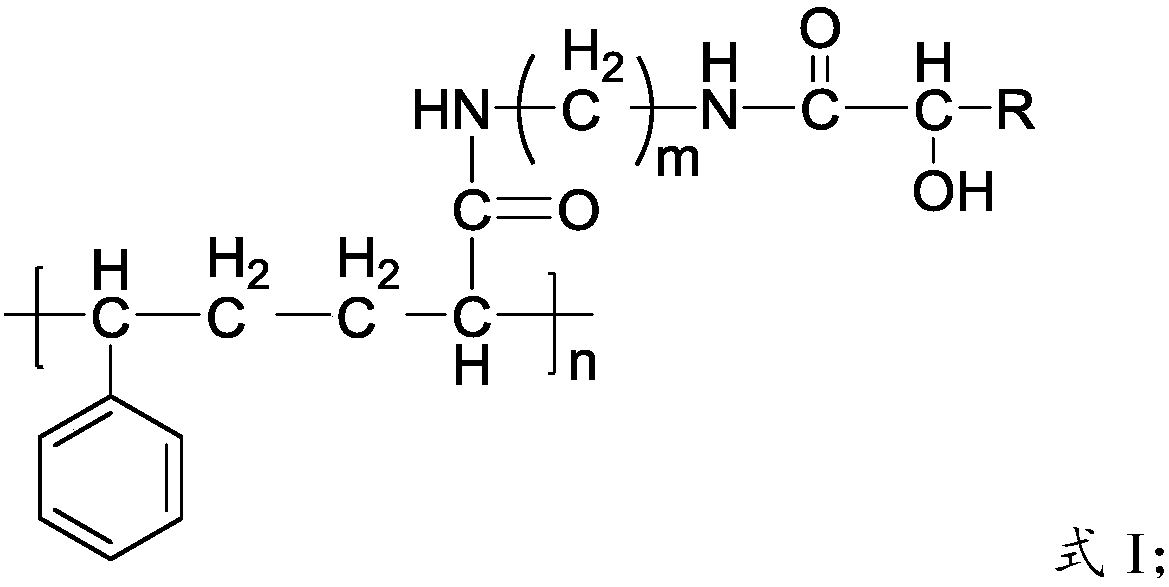

[0047] Carry out infrared spectrum detection to the cutting agent prepared in Example 1 of the present invention, and the detection result is as follows: figure 1 shown by figure 1 It can be seen that the cutting agent prepared in Example 1 of the present invention has the structure of formula 1:

[0048]

[0049] According to the method described in the above technical solution, the cutting effect of adding the cutting agent prepared in Example 1 of the present inventio...

Embodiment 2

[0061] Copolymerize 1.0 mol of styrene-itaconic acid copolymer and 1.0 mol of decanediamine at 160°C for 4 hours, then add 1.0 mol of hydroxyl-containing tetradecanoic acid, and conduct copolymerization at 160°C for 4 hours, naturally After cooling, viscous cutting agent is obtained.

[0062] The source of the styrene-itaconic acid copolymer is the product provided by the Pudong Branch of Shanghai Highland Barley Industry Co., Ltd.; the 3-hydroxy myristic acid product provided by the source of the hydroxyl-containing myristic acid Guangxi Jinle Chemical Co., Ltd. .

[0063] Infrared spectrum detection was carried out on the cutting agent prepared in Example 2 of the present invention, and the detection result showed that the cutting agent prepared in Example 1 of the present invention had the structure of formula 2:

[0064]

[0065] According to the method described in the above technical solution, the cutting effect of adding the cutting agent prepared in Example 2 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com