High-wear-resistance automobile shaft component powder metallurgy material

A high wear resistance, powder metallurgy technology, applied in the field of powder metallurgy, can solve the problems of low elongation and section shrinkage, poor wear resistance, strength and hardness, and low material utilization rate, and achieve elongation and section shrinkage. The effect of high rate, good strength and hardness, and high material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

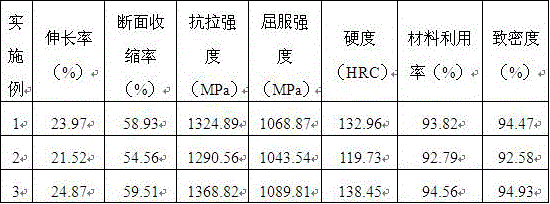

Examples

preparation example Construction

[0042] The preparation method of the high wear resistance powder metallurgy material for automobile shaft parts comprises the following steps:

[0043] S1: Iron powder, chromium powder, molybdenum powder, copper powder, nickel powder, lead oxide powder, yttrium powder, titanium carbide powder, tantalum carbide powder, tin powder, zinc oxide powder, aluminum oxide powder, graphene powder, pentaerythritol, Add stearic acid, polyvinyl chloride fiber, and basalt fiber into the mixer, and stir for 11-16min at a speed of 200-450r / min to prepare mixture A;

[0044] S2: Add ethylene glycol ether acetate, hypromellose, and ethylene distearic acid amide into a blender and stir for 13-19 min at a speed of 300-460 r / min to prepare a mixture B;

[0045] S3: The mixture A prepared in step S1, the mixture B prepared in step S2, chlorinated paraffin, glycidoxypropyltrimethoxysilane, silicon carbide, manganous sulfide, alkyd resin, inhibitor, adhesive Add additives, reinforcing agents, cuttin...

Embodiment 1

[0055] A powder metallurgy material for automobile shaft parts with high wear resistance, including the following raw materials in units of weight: 1080 parts of iron powder, 8 parts of chromium powder, 6 parts of molybdenum powder, 8 parts of copper powder, 4 parts of nickel powder, oxidation 6 parts of lead powder, 5 parts of yttrium powder, 18 parts of titanium carbide powder, 14 parts of tantalum carbide powder, 10 parts of tin powder, 5 parts of zinc oxide powder, 2 parts of manganous sulfide, 1.5 parts of alumina powder, 5 parts of graphene powder , 8 parts of ethylene glycol ether acetate, 4 parts of chlorinated paraffin, 5 parts of hypromellose, 8 parts of pentaerythritol, 4 parts of ethylene bis stearic acid amide, 6 parts of stearic acid, 5 parts of polyvinyl chloride fiber , 3 parts of basalt fiber, 2 parts of silicon nitride, 5 parts of glycidoxypropyltrimethoxysilane, 2 parts of silicon carbide, 1 part of alkyd resin, 1 part of inhibitor, 2 parts of adhesive, 1 par...

Embodiment 2

[0077]A powder metallurgy material for automobile shaft parts with high wear resistance, including the following raw materials in units of weight: 554 parts of iron powder, 8 parts of chromium powder, 6 parts of molybdenum powder, 7 parts of copper powder, 3 parts of nickel powder, oxidation 5 parts of lead powder, 4 parts of yttrium powder, 15 parts of titanium carbide powder, 12 parts of tantalum carbide powder, 8 parts of tin powder, 3 parts of zinc oxide powder, 1.6 parts of manganese sulfide, 1.2 parts of alumina powder, 3 parts of graphene powder , 6 parts of ethylene glycol ether acetate, 3 parts of chlorinated paraffin, 4 parts of hypromellose, 5 parts of pentaerythritol, 3 parts of ethylene bis stearic acid amide, 5 parts of stearic acid, 4 parts of polyvinyl chloride fiber , 2 parts of basalt fiber, 2 parts of silicon nitride, 3 parts of glycidoxypropyltrimethoxysilane, 1 part of silicon carbide, 1 part of alkyd resin, 0.8 parts of inhibitor, 1 part of adhesive, 0.7 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com