Fluorine-containing oil-based drilling fluid extracting and cutting agent and preparation method thereof

An oil-based drilling fluid and cutting agent technology, applied in the chemical field, can solve the problems of insufficient temperature resistance of the cutting agent, affecting high-quality drilling, and only suitable cutting agent, etc., to achieve obvious cutting effect and use The effect of safety and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

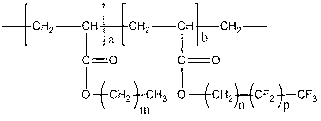

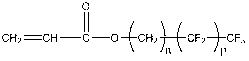

Method used

Image

Examples

Embodiment 1

[0032] Weigh 150g of octadecyl acrylate and 10g of perfluorohexyl ethyl acrylate, dissolve in 1000 mL of dimethyl sulfoxide (DMSO) solvent, stir at room temperature until completely dissolved, then add to the In a four-necked flask with a nitrogen tube and a thermometer. Then add 1 g azobisisobutyronitrile (AIBN), stir until dissolved and place at 25 o C in a constant temperature water bath, stir nitrogen gas for 30min, then add a condenser tube with anhydrous calcium chloride drying tube on the top of the flask, and raise the temperature of the system to 60 o C, reacted for 12 h to obtain a uniform viscous mixture. The viscous liquid was added to a mixture of anhydrous ether and anhydrous acetone at the same volume ratio to precipitate a solid, which was dried and pulverized to obtain 143 g of the product.

Embodiment 2

[0034] Weigh 100g of octadecyl acrylate and 1g of perfluorohexylethyl acrylate, dissolve in 1000 mL of dimethyl sulfoxide (DMSO) solvent, stir at room temperature until completely dissolved, then add to a container equipped with a stirrer, condenser, In a four-necked flask with a nitrogen tube and a thermometer. Then add 1 g azobisisobutyronitrile (AIBN), stir until dissolved and place at 25 o C in a constant temperature water bath, stir nitrogen gas for 25min, then add a condenser tube with anhydrous calcium chloride drying tube on the top of the flask, and raise the temperature of the system to 50 o C, reacted for 4 h to obtain a uniform viscous mixture. The viscous liquid was added to a mixture of anhydrous ether and anhydrous acetone in the same volume ratio to precipitate a solid, which was dried and pulverized to obtain 93 g of the product.

Embodiment 3

[0036] Weigh 300g of octadecyl acrylate and 60g of perfluorohexyl ethyl acrylate, dissolve in 1000 mL of dimethyl sulfoxide (DMSO) solvent, stir at room temperature until completely dissolved, then add to the In a four-necked flask with a nitrogen tube and a thermometer. Then add 10 g azobisisobutyronitrile (AIBN), stir until dissolved and place at 25 o C in a constant temperature water bath, stir nitrogen gas for 35 minutes, then add a condenser tube with anhydrous calcium chloride drying tube on the top of the flask, and raise the temperature of the system to 80 o C, reacted for 36 h to obtain a uniform viscous mixture. The viscous liquid was added to a mixture of anhydrous ether and anhydrous acetone at the same volume ratio to precipitate a solid, which was dried and pulverized to obtain 310 g of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com