Full-digital speed change control method for wire feeding for submerged arc welding

A submerged arc welding and all-digital technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve problems affecting real-time control accuracy, unable to achieve real-time information collection, real-time information processing, etc., to achieve high control accuracy and The effect of reliability, good stability of control parameters, high adjustment accuracy and adjustment sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

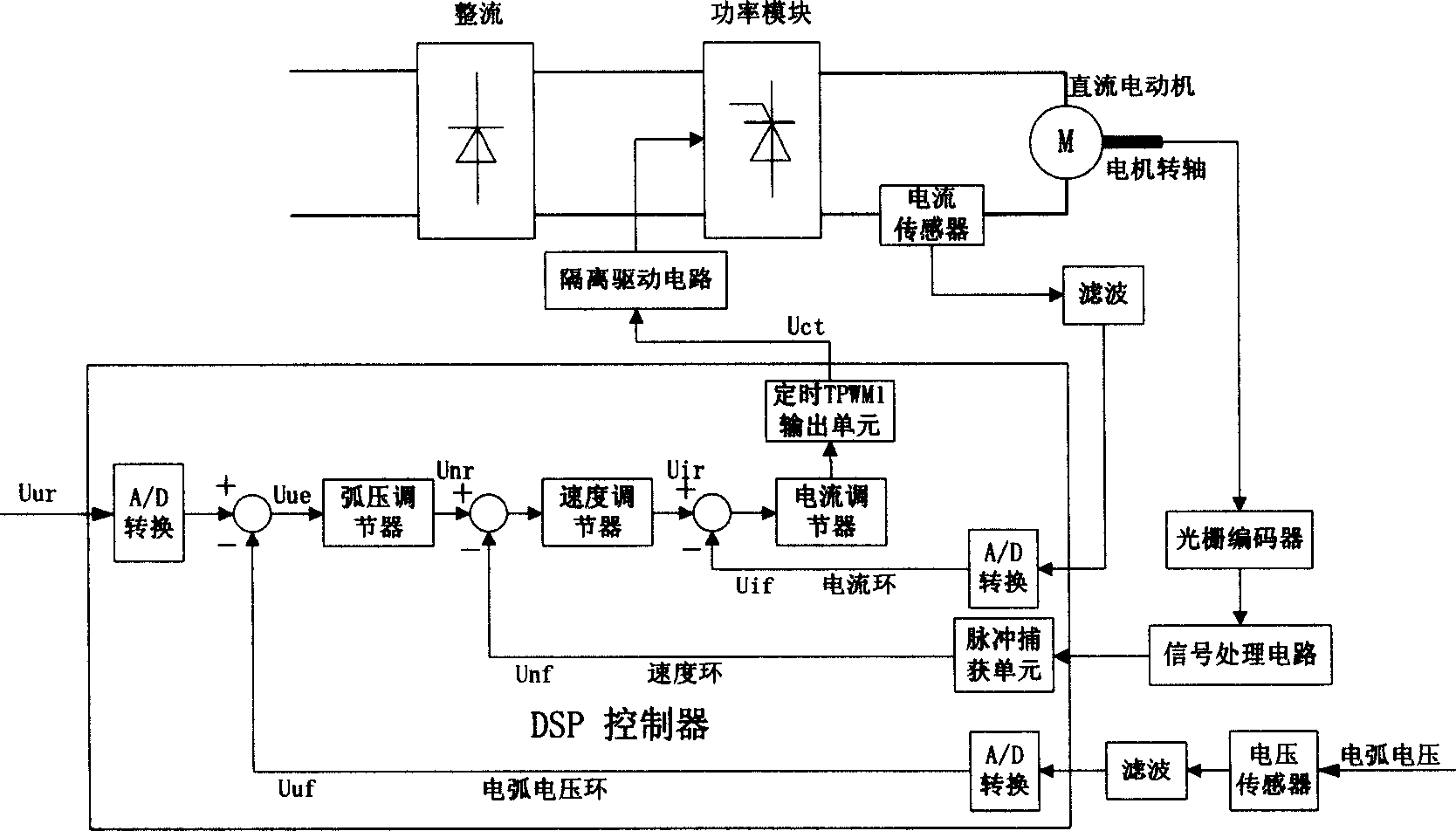

[0013] The following embodiments are provided in conjunction with the accompanying drawings and the technical solutions of the present invention:

[0014] Take φ4.0 HO8MnA welding wire low-carbon steel plate (thickness 12mm) surfacing welding as an example, the characteristic of welding power supply is constant current characteristic, the target value of welding current is 500A, and the target value of arc voltage is 32V. Among them, the arc voltage deviation value Uue, the target value of the rotational speed Unr, the target value of the armature current Uir and the control signal Uct of the power circuit are calculated by software during the welding process, the arc voltage feedback Uuf, the rotational speed feedback value Unf, the armature The current feedback value Uif is sent into the DSP through the hardware circuit, and is calculated by the DSP or converted by the DSP to obtain the corresponding digital quantity. The implementation process is as follows:

[0015] 1. Be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com