Multi-directional numerical control linkage precision forming process of transmission planetary carrier

A technology of precision forming and planet carrier, applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of low production efficiency and high processing cost, and achieve easy installation and replacement, reduce mold cost, shorten The effect of die change time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

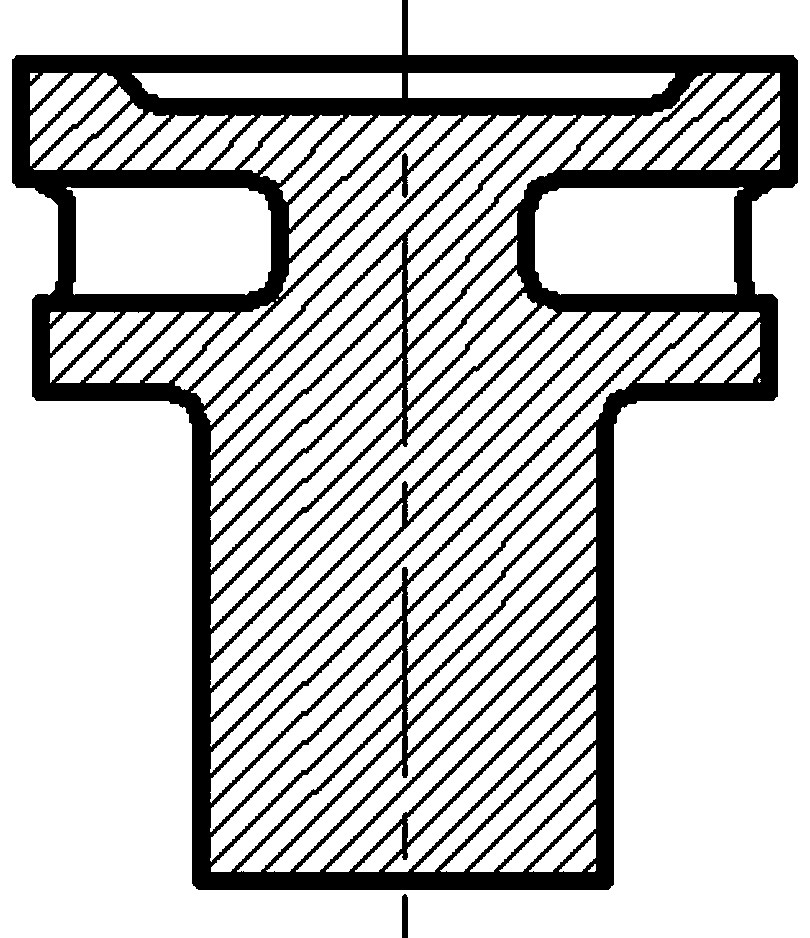

[0021] Such as figure 1 , 5 , 6, and 7, the multi-directional numerical control linkage forming process of a transmission planet carrier according to the present invention is through the upper punch 1, the front punch 4, the rear punch 8, the left punch 7, the right punch 35 The heated metal bar is formed by CNC linkage in two directions, realizing single station, one-time heating, multi-directional forming precision forgings of transmission planetary carrier with complex shape; front punch 4, rear punch 8, left punch 7 in the mold , The right punch 3 is placed in the four side square holes in the die 6, and it will not be disengaged during the forming process; to ensure its positioning accuracy, the die 6 adopts a split structure, which is easy to install and replace. It only needs to replace the more severely worn modules, which can not only reduce the mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com