Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

143results about How to "Reduce die change time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

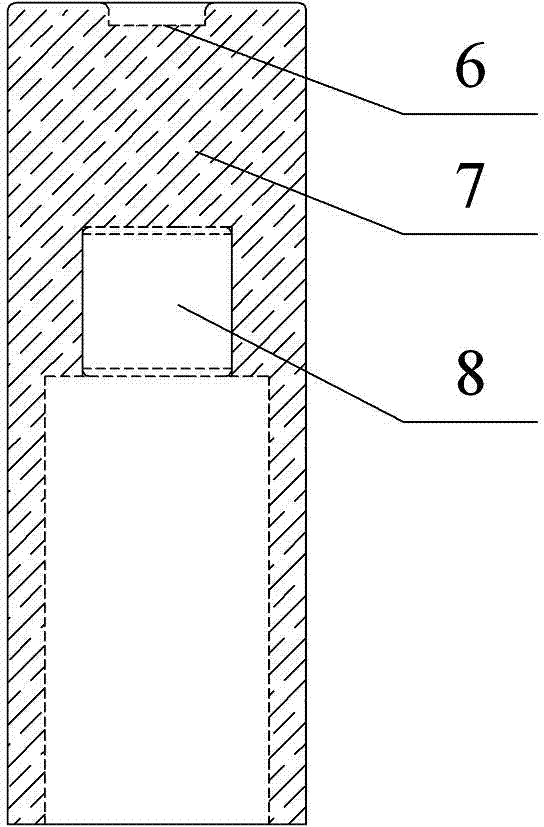

Injection mould with rapidly-replaced mould cores

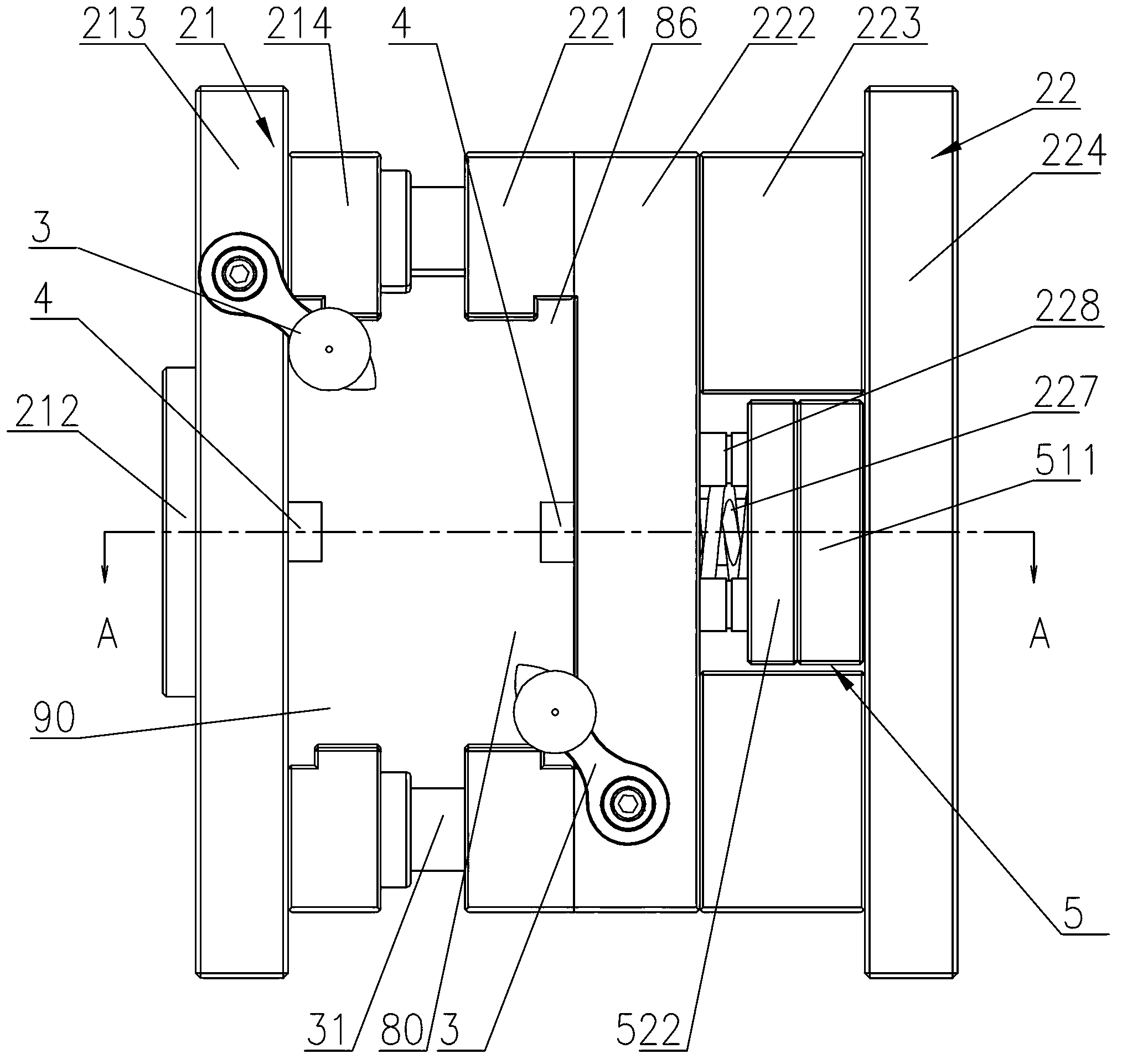

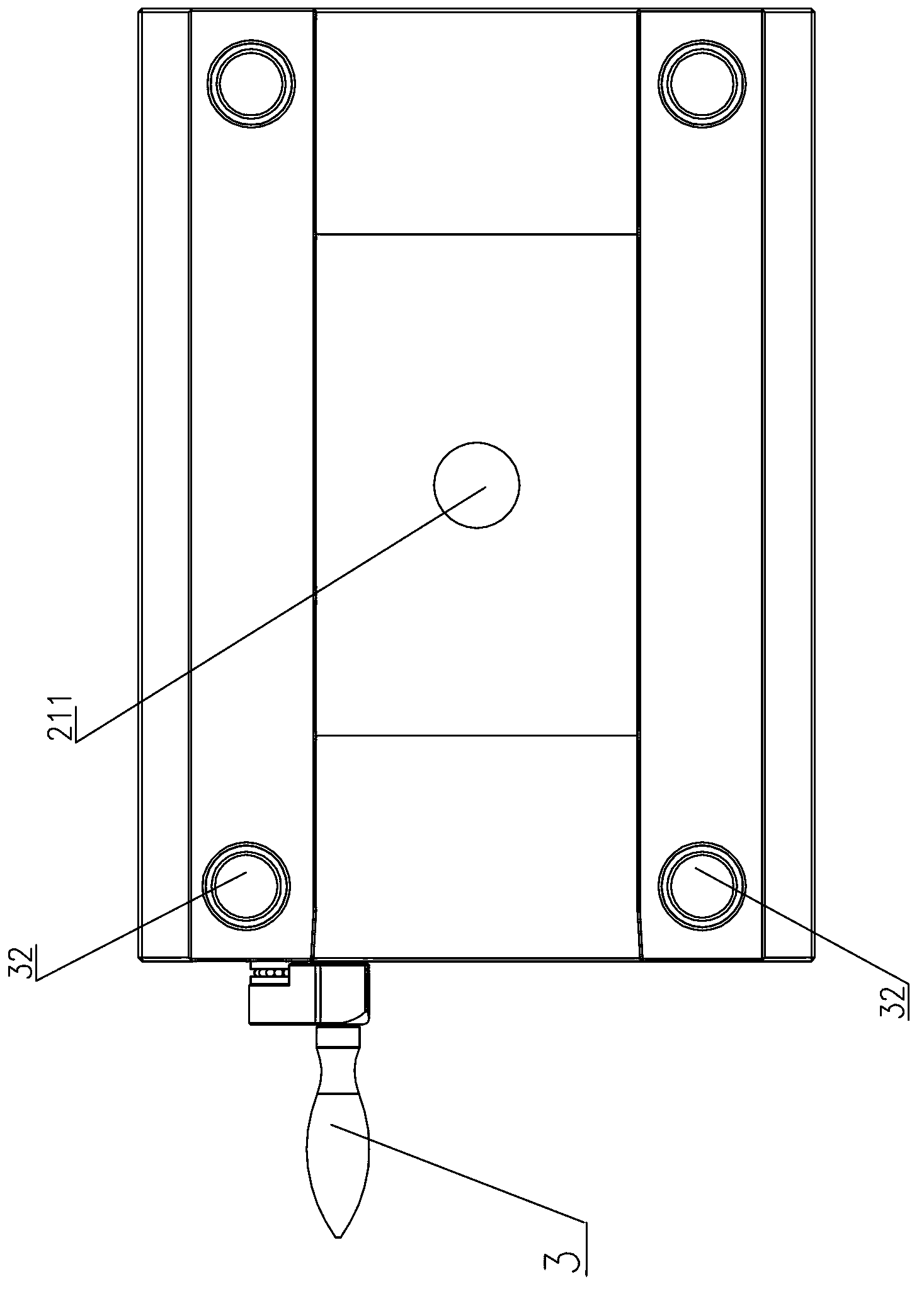

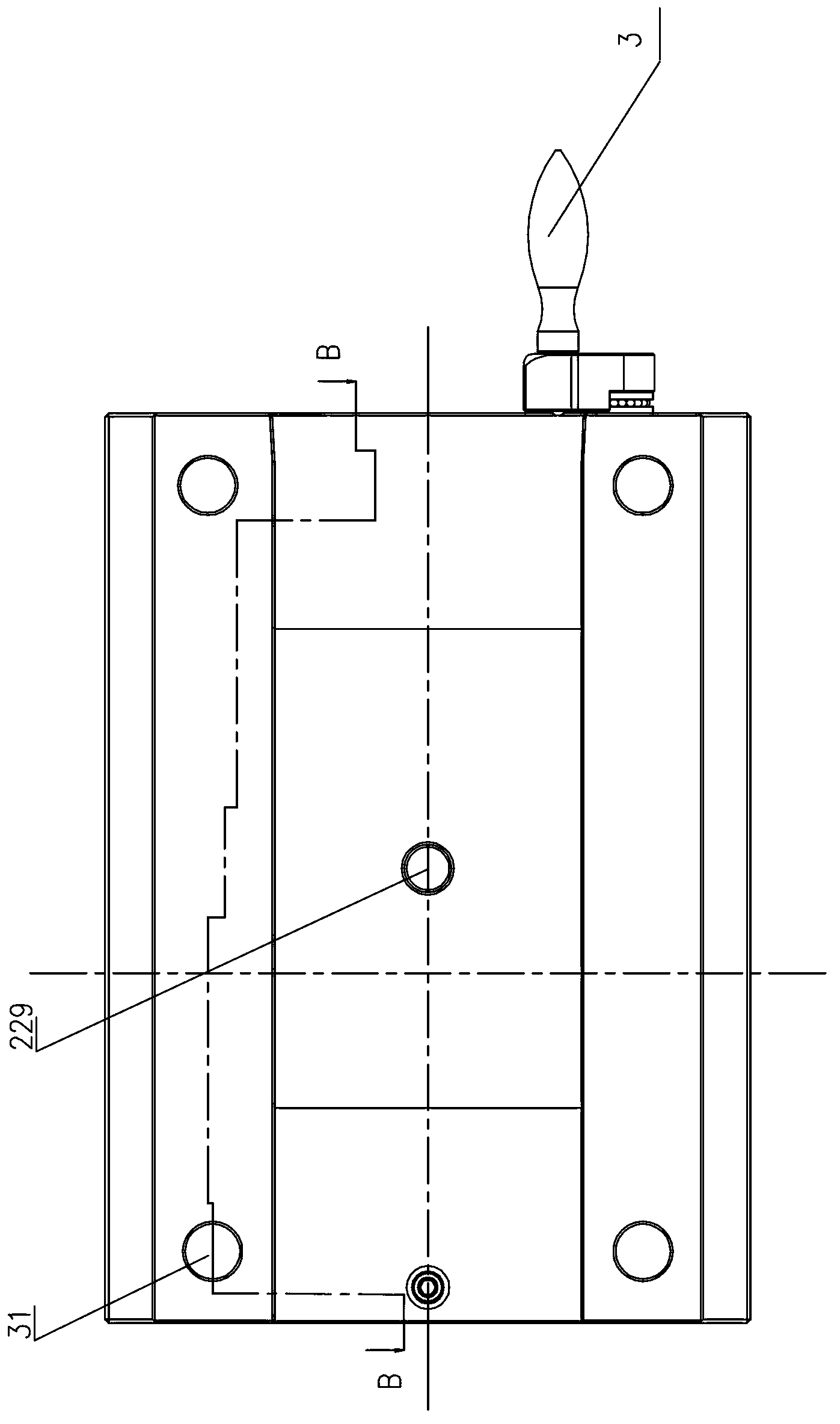

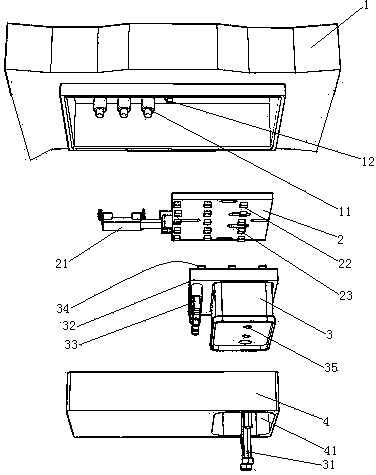

The invention discloses an injection mould with rapidly-replaced mould cores. The injection mould is composed of a movable mould and a stationary mould, wherein a main body of the movable mould is composed of a movable mould base and a movable mould core movably arranged on the movable mould base; a main body of the stationary mould is composed of a stationary mould base and a stationary mould core movably arranged on the stationary mould base; the butt joint faces of the movable mould base and the stationary mould base are respectively provided with a mould core mounting sliding chute which horizontally extends from front to back; at least the front ends of the mould core mounting sliding chutes are provided with plug-in mounting holes for mounting or dismounting the mould cores; the mould cores are provided with tracks matched with the mould core mounting sliding chutes so as to move along the mould core mounting sliding chutes; and the mould cores are inserted to or dismounted from the mould core mounting sliding chutes on the mould bases through the plug-in mounting holes, thus the mould cores are replaced. According to the invention, only one set of mould base needs to be manufactured to be matched with the mould cores of different cavities which are manufactured according to spline standards tested based on different performance indexes; the mould replacing operation is easier and more convenient than that of the prior art, so that the mould replacing time is greatly shortened; and the manufacturing cost of various test spline moulds can also be greatly reduced.

Owner:广州现代塑料有限公司

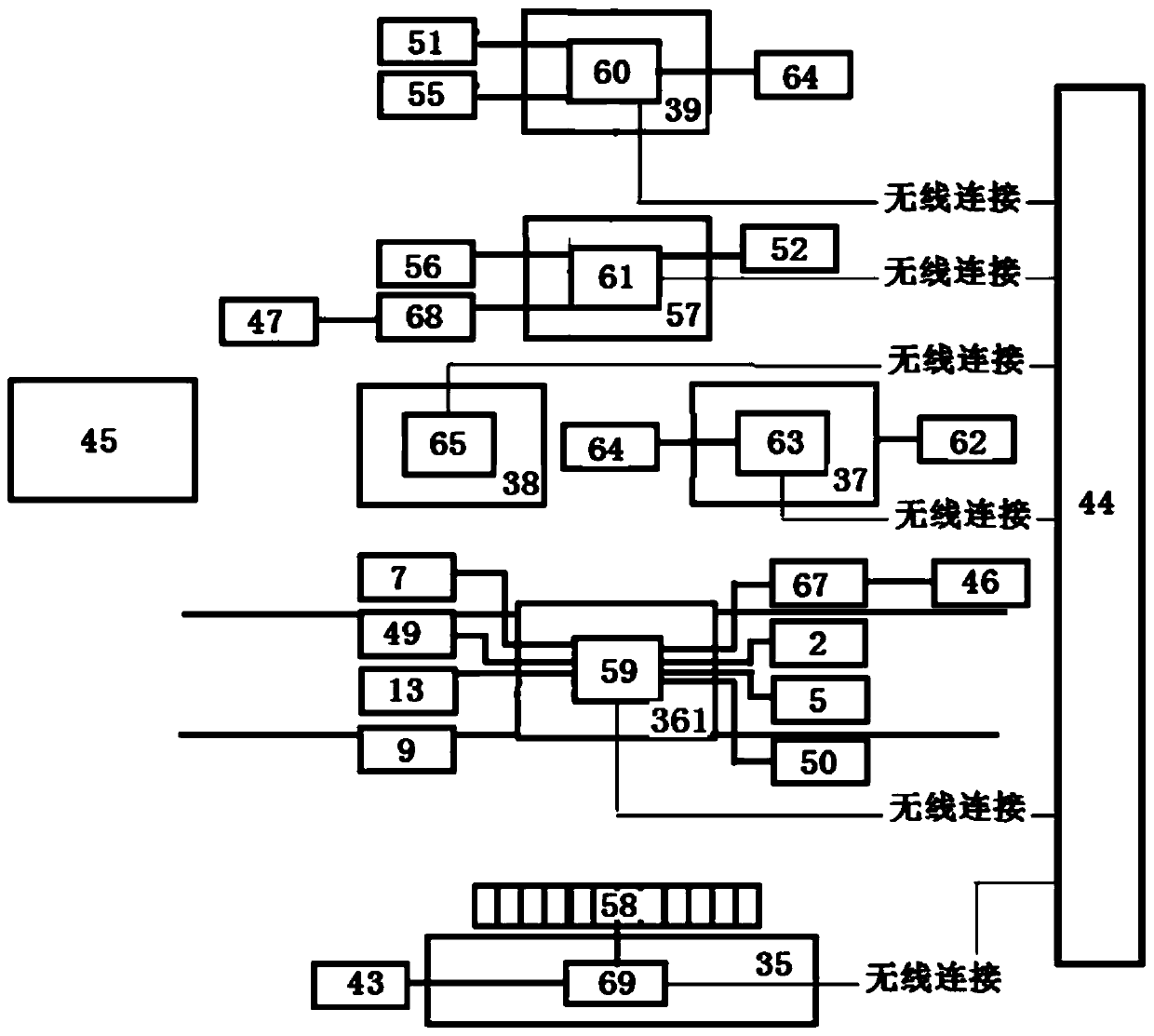

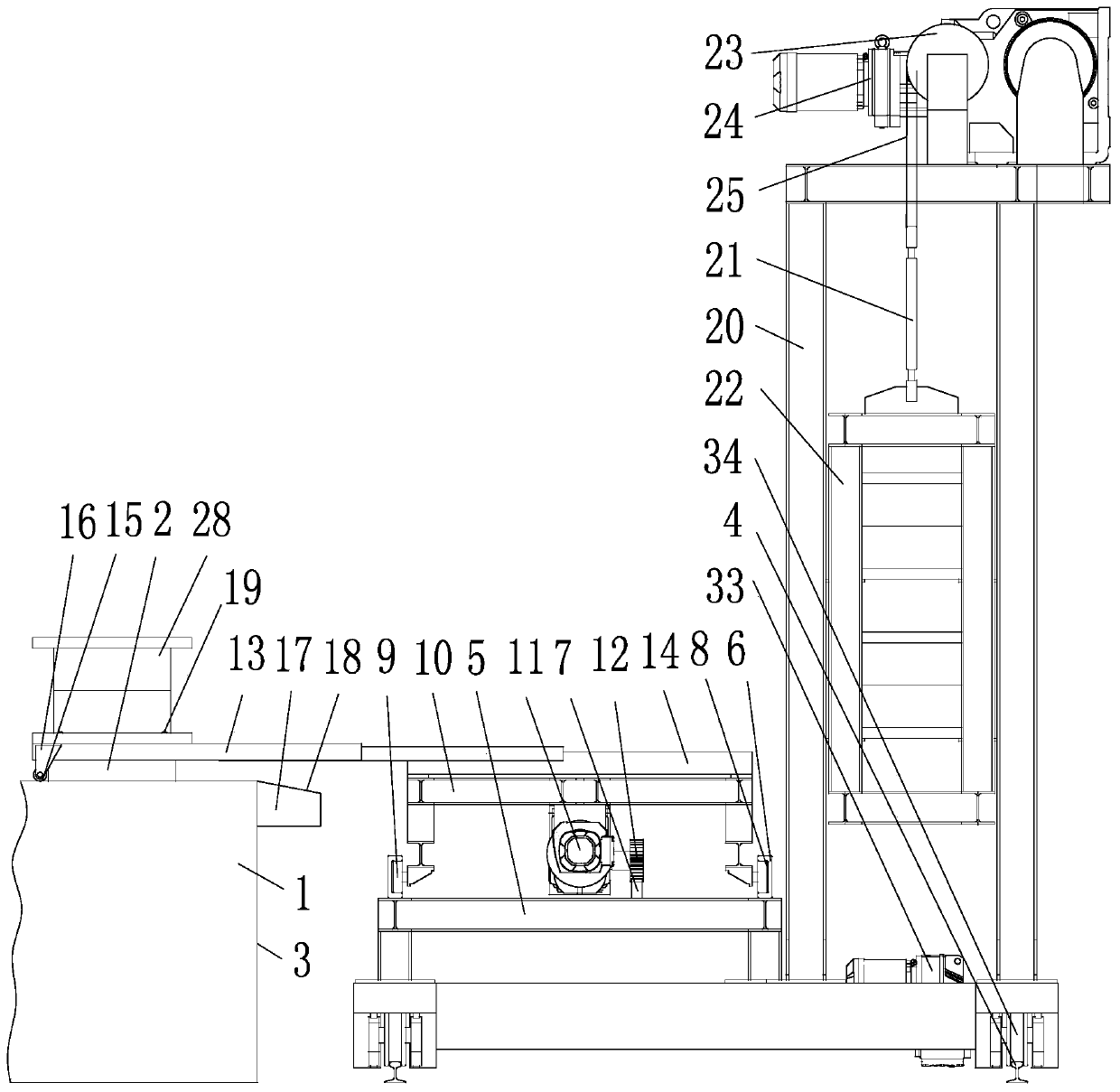

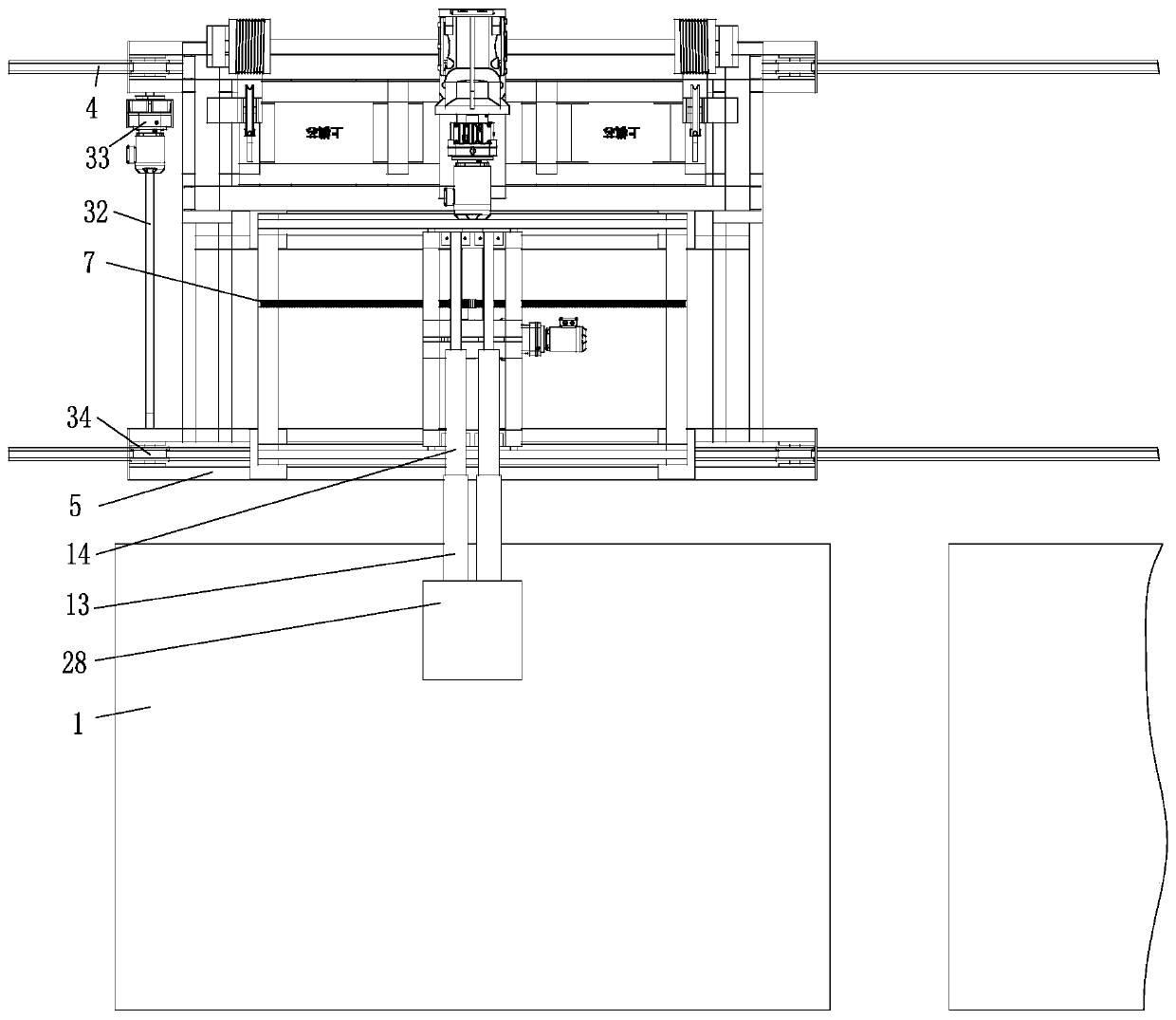

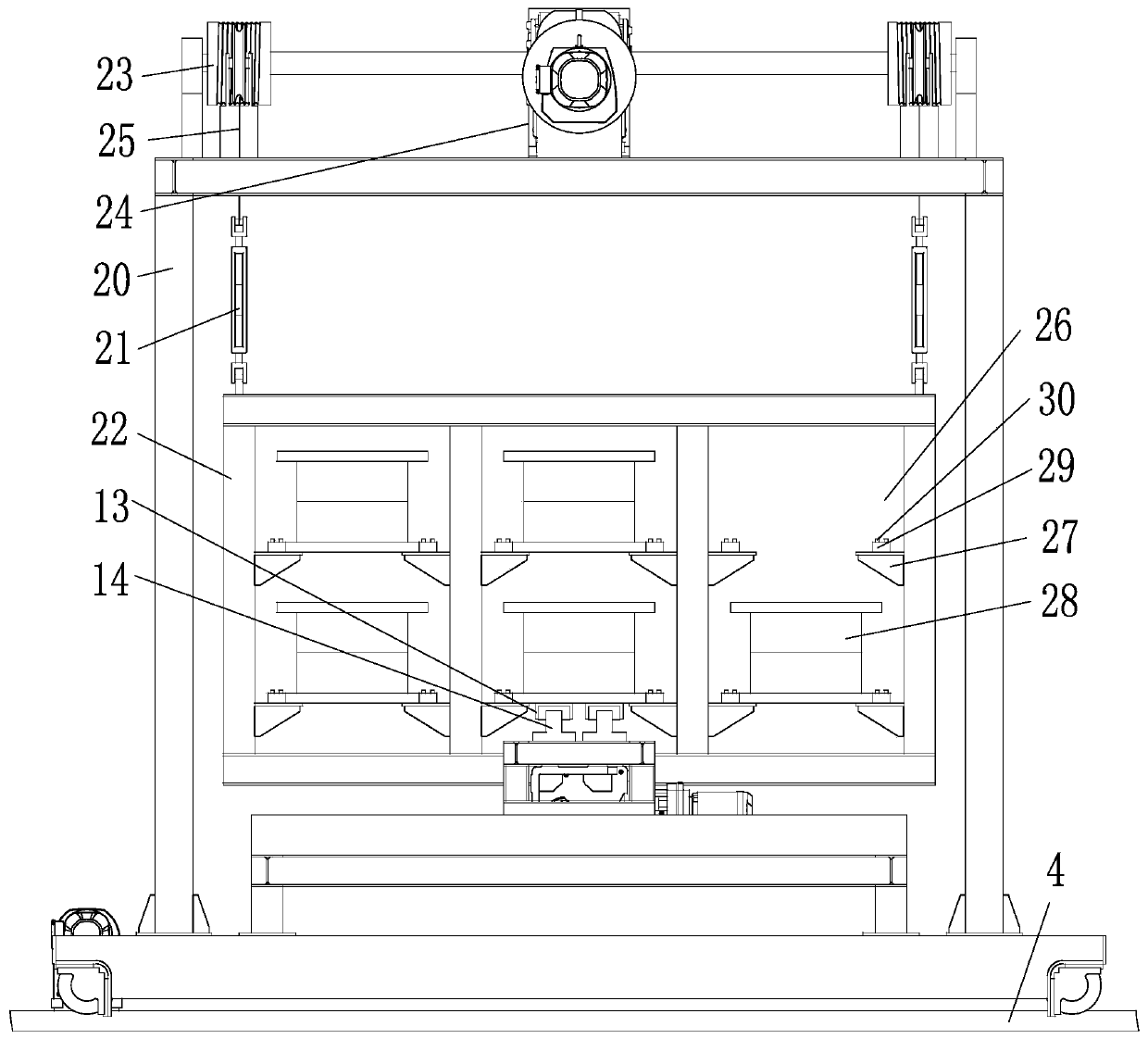

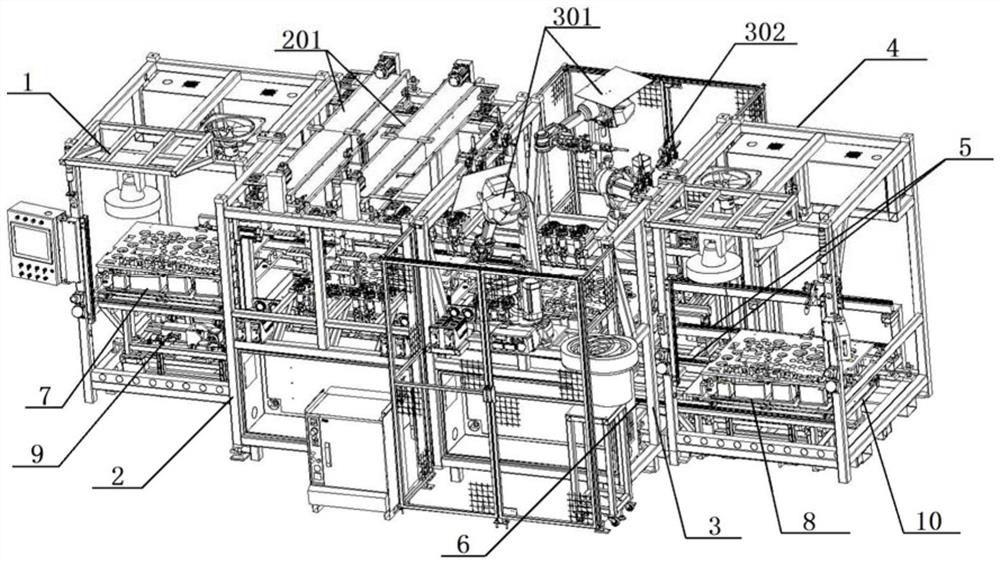

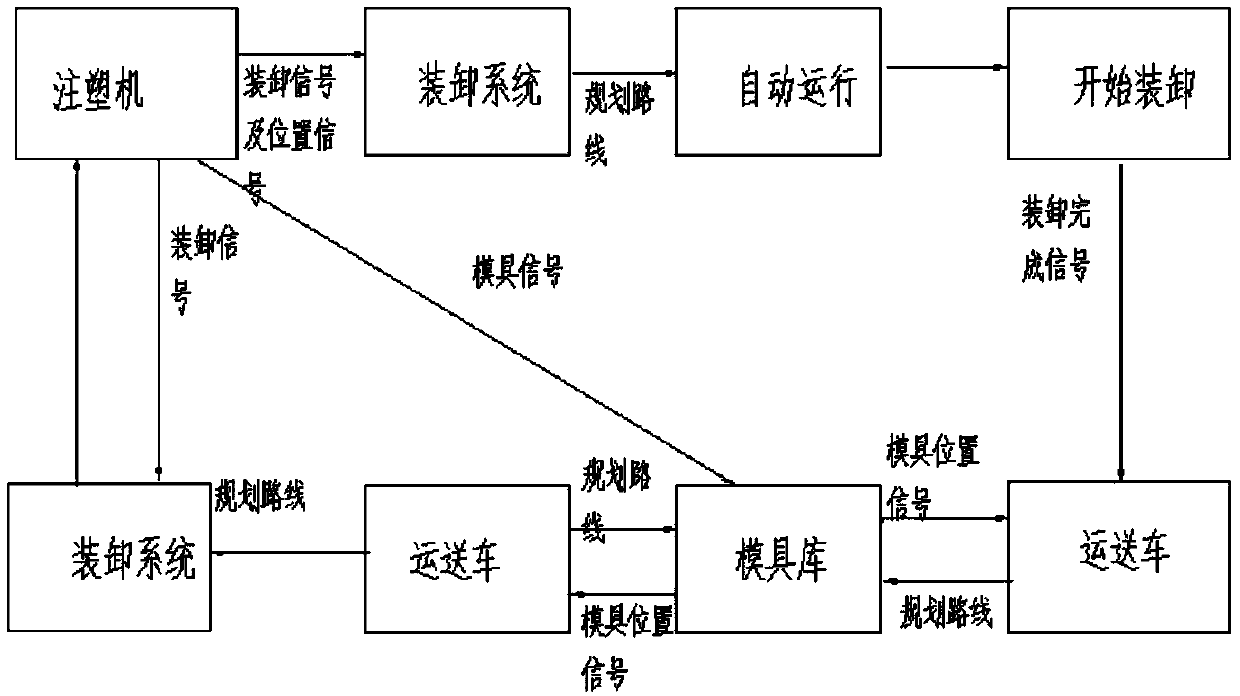

Automatic die carrying die change system and method in unmanned state

The invention discloses an automatic die carrying die change system in an unmanned state. The system comprises a die library, a die carrying vehicle, a preheating station, a transition platform, an injection molding machine and a control system. The system is characterized by further comprising an automatic charging station, a first charging module, a second charging module, RFID electronic tags,an RFID card reader, a wireless communication module, a two-dimensional code, a two-dimensional code recognizer, a walking positioning code reader, a unit position sensor, a first wireless communication module and a second wireless communication module. Due to the adoption of the structure, the automatic die change process only lasts for 3 min, the die change time is remarkably shortened, the production efficiency is improved, the labor cost is greatly reduced, and the system has the beneficial effects that the automation degree is high, the production efficiency is high, the labor cost is low, the occupied space is small, the use rate of the injection molding machine is high, and lifting is stable.

Owner:QINGDAO LICI ELECTRIC

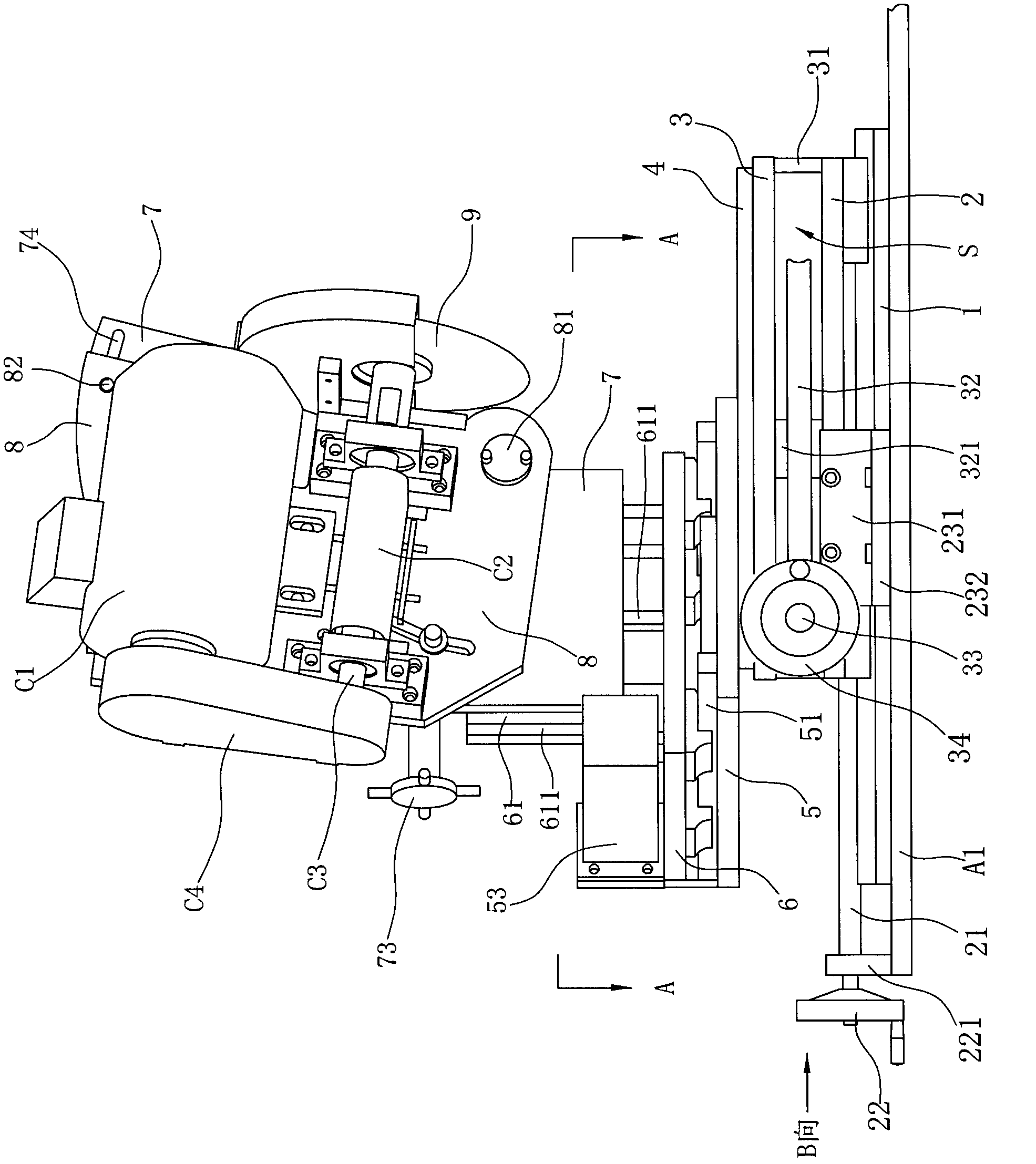

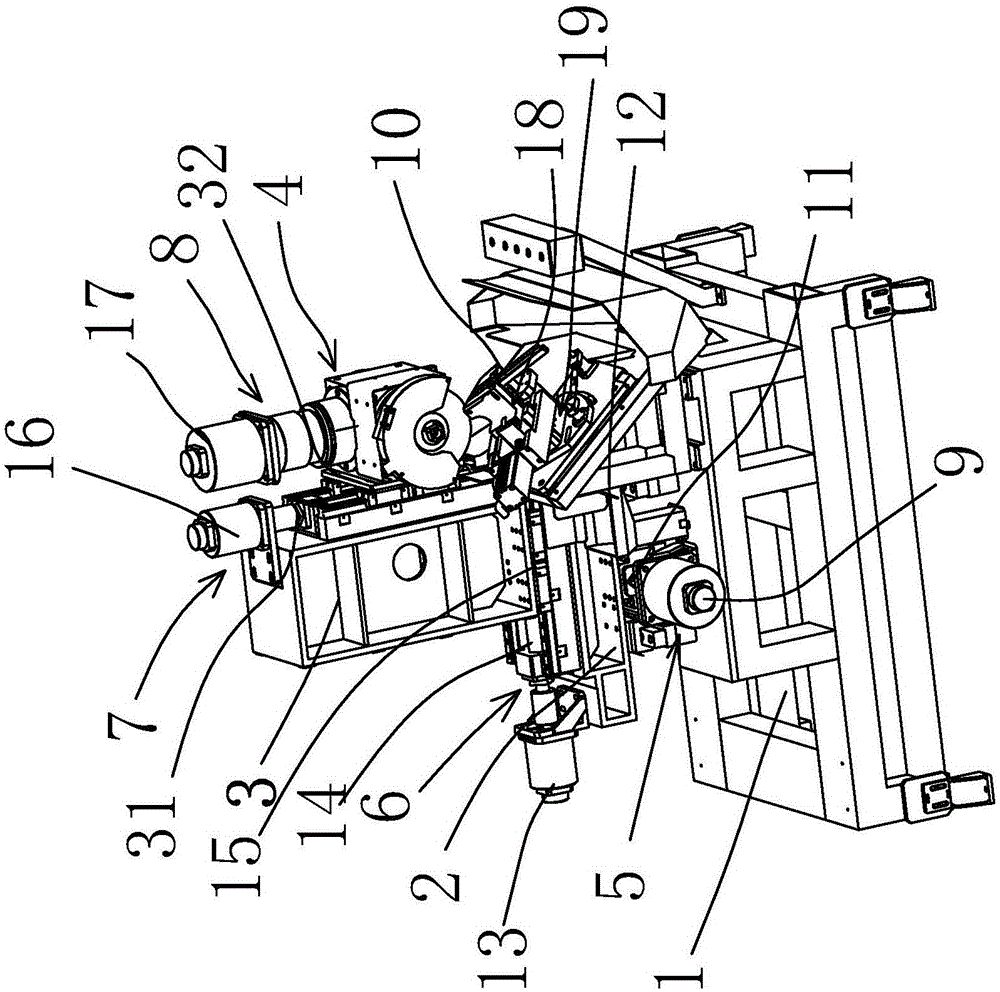

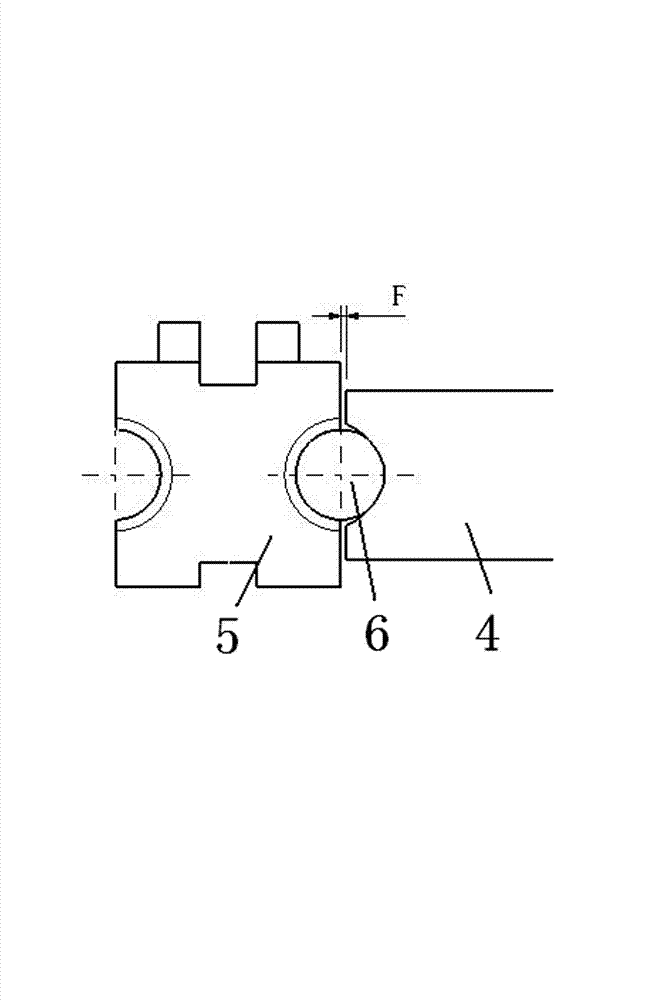

Saw cutting machine for machining decorative strips

ActiveCN102303161ASimultaneous sawingGuaranteed length accuracyMetal sawing devicesThree-dimensional spaceEngineering

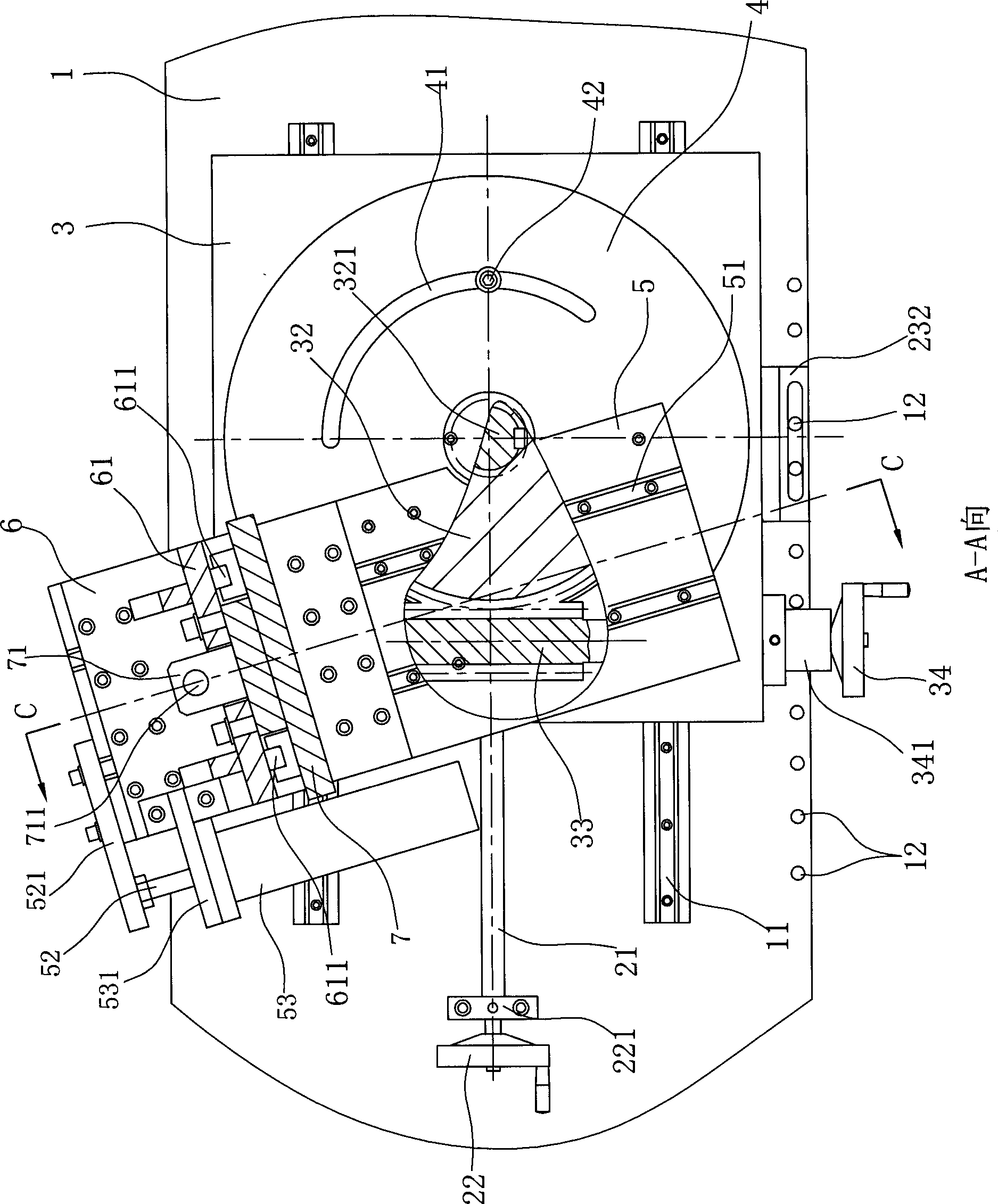

The invention relates to a saw cutting machine for machining decorative strips. The saw cutting machine comprises a machine frame, saw cutting machine heads and a clamp device, and is characterized in that the two saw cutting machine heads are arranged on two sides of the machine frame; the clamp device is arranged between the two saw cutting machine heads; each saw cutting machine head is arranged on a driving device capable of regulating a three-dimensional cutting angle of saw bit space of the saw cutting machine head; and the driving device is fixedly arranged on the machine frame. In thesaw cutting machine, the saw cutting machine heads are arranged on two sides of the decorative strips, so that two ends of the decorative strips are sawed simultaneously, and the work efficiency is improved; in the process of machining the decorative strips, the two ends of the decorative strips can be sawed only by being clamped once, so the error of machining length due to back-and-forth movement of the decorative strips is avoided, and the accuracy of the machining length of the decorative strips is ensured; and the two saw cutting machine heads can regulate three-dimensional space by the driving device, so that saw bits can regulate the cutting angle flexibly according to the decorative strips with different end part structures, and the time of die change and regulation is shortened.

Owner:NINGBO MINTH AUTOMOTIVE PARTS RES&DEV CO LTD

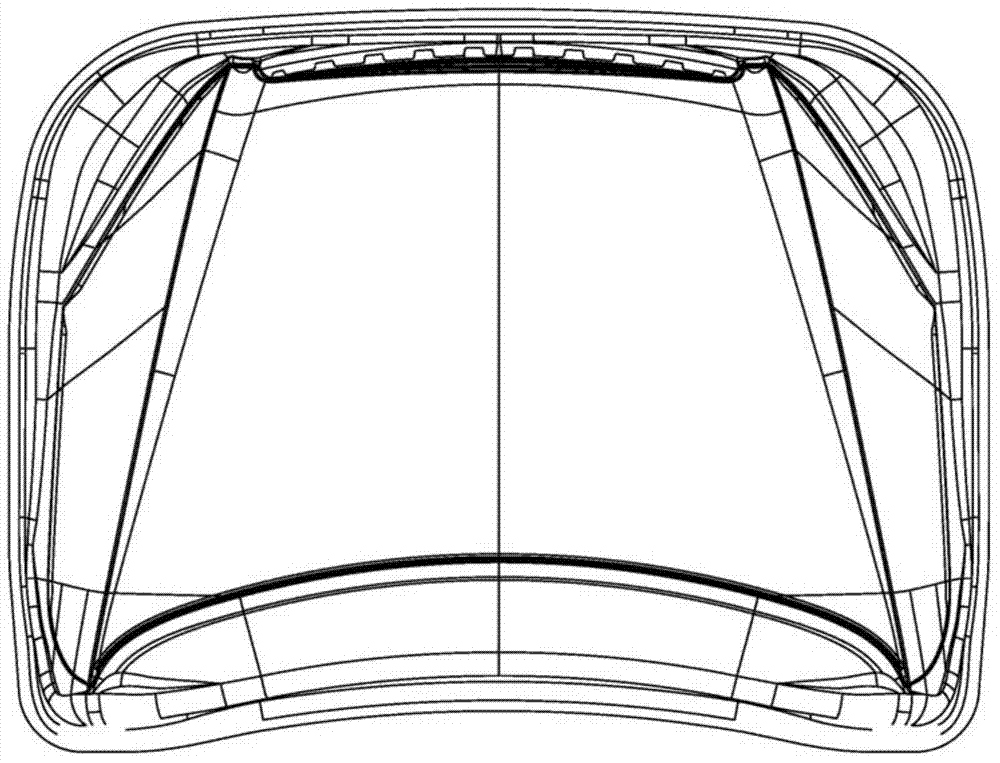

Automobile top cover die

The invention relates to equipment for automobile production, in particular to an automobile top cover die which comprises an upper die seat and a skylight puncher. A movable pushing plate and a switching cylinder driving the movable pushing plate to move in the horizontal direction are further arranged on the upper die seat, the skylight puncher is connected under the upper die seat in a lifting mode, the movable pushing plate is located between the upper die seat and the skylight puncher, a first jacking convex block is arranged on the lower surface of the movable pushing plate, and a second jacking convex block matched with the first jacking convex block is arranged on the upper end face of the skylight puncher. The automobile top cover die can meet production requirements of top covers with skylights and top covers without skylights, and solves the problem that two sets of dies are needed for top covers with skylights and top covers without skylights of the same automobile type.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

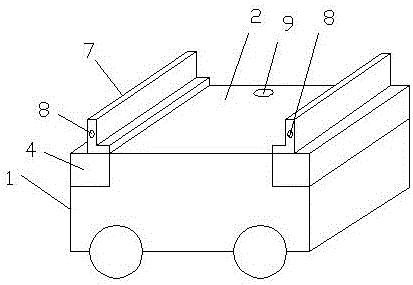

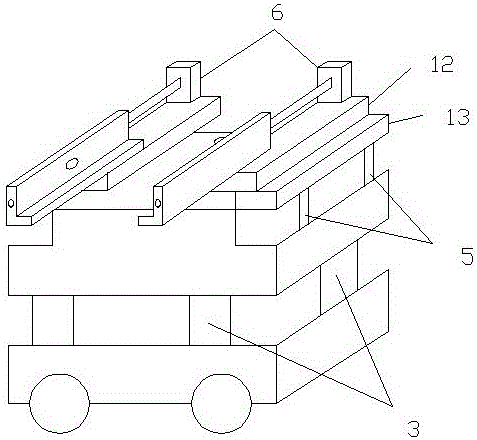

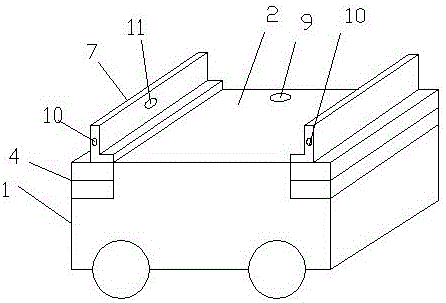

Quick mold change trolley and mold change method thereof

InactiveCN106426666AFriction between the bottom surface of the mold and the table and trolleySmooth mold change processShaping toolsElectrical controlEngineering

The invention discloses a quick mold change trolley and a mold change method thereof. The quick mold change trolley comprises a trolley body; the trolley body includes a bearing surface and a chassis; the trolley body is provided with an electric control system for controlling the mold change process; mounting bases are arranged at two ends of the trolley body; lifting mechanisms are connected between the mounting bases and the trolley body; mold shifting arms are arranged on the mounting bases; horizontal translation mechanisms are connected between the mold shifting arms and the mounting bases; the cross sections of the mold shifting arms are L-shaped; and shoulder steps matched with the mold shifting arms are respectively arranged on two sides of a mold. Compared with the prior art, the quick mold change trolley has the following beneficial effects: the mold is firstly hoisted through the lifting mechanisms; then, the mold is shifted onto the trolley through the translation mechanisms; and in the whole process, no friction is generated among the bottom surface of the mold, a worktable and the trolley, the mold change process is stable, the mold change time is saved, and the mold change efficiency is improved.

Owner:JIANGSU ZHISHI TECH CO LTD

Multi-axis sawing machine with sawing paths and sawing angles adjustable

The invention belongs to the technical field of automobile part machining equipment, and provides a multi-axis sawing machine with adjusting sawing paths and sawing angles adjustable. The multi-axis sawing machine comprises a main rack which is provided with a main motion frame, an upper motion frame and a sawing mechanism; the main motion frame is provided with a first driving mechanism, the upper motion frame is provided with a second driving mechanism, a third driving mechanism is arranged between the upper motion frame and the sawing mechanism, and the sawing mechanism is provided with a fourth driving mechanism; the main rack is further provided with a product fixing mechanism opposite to the sawing mechanism, and the lower end of the product fixing mechanism is provided with an angle adjusting assembly. The multi-axis sawing machine has the advantages that spatial three-dimensional adjusting can be achieved through a servo motor, so that a saw blade can flexibly adjust the cutting angle according to automobile parts of different end structures; in addition, the whole saw blade is adjustable in rotating speed and controllable in path; meanwhile, the lower end of the product fixing mechanism is provided with the angle adjusting assembly, therefore, multiple automobile part products can share one machine, and the utilization rate of the sawing machine is improved.

Owner:重庆敏特汽车零部件有限公司

Drawing and flanging two-purpose die

The invention belongs to the technical field of cold punching dies of pressure manufacturing process equipment, and particularly relates to a drawing and flanging two-purpose die, which comprises a convex die and a concave die, wherein the convex die and the concave die are arranged in a mutual opening and closing way, at least one of the convex die and the concave die is driven by a driving unit to do reciprocating movement so as to realize the opening and closing action, a concave cavity of the concave die is in a step shape, the large end of the concave die faces downwards, and the edge of the convex die is provided with a detachable embedding block. When the embedding block is arranged on the convex die, the size of the convex die corresponds to the size of the large end of the concave die; when the embedding block is detached, the size of the convex die corresponds to the size of the small end of the concave die. The drawing and flanging two-purpose die has the advantages that the drawing and flanging two-purpose die can be simultaneously used for the drawing process and the flanging process, the effect of one die with two purposes is realized, the trial cost is reduced, the cost investment of a trial die is reduced, and the casting pollution is reduced; meanwhile, the switching is convenient, the die replacement time is shortened, and the production efficiency is improved.

Owner:CHERY AUTOMOBILE CO LTD

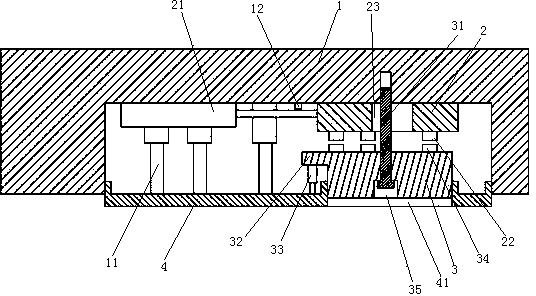

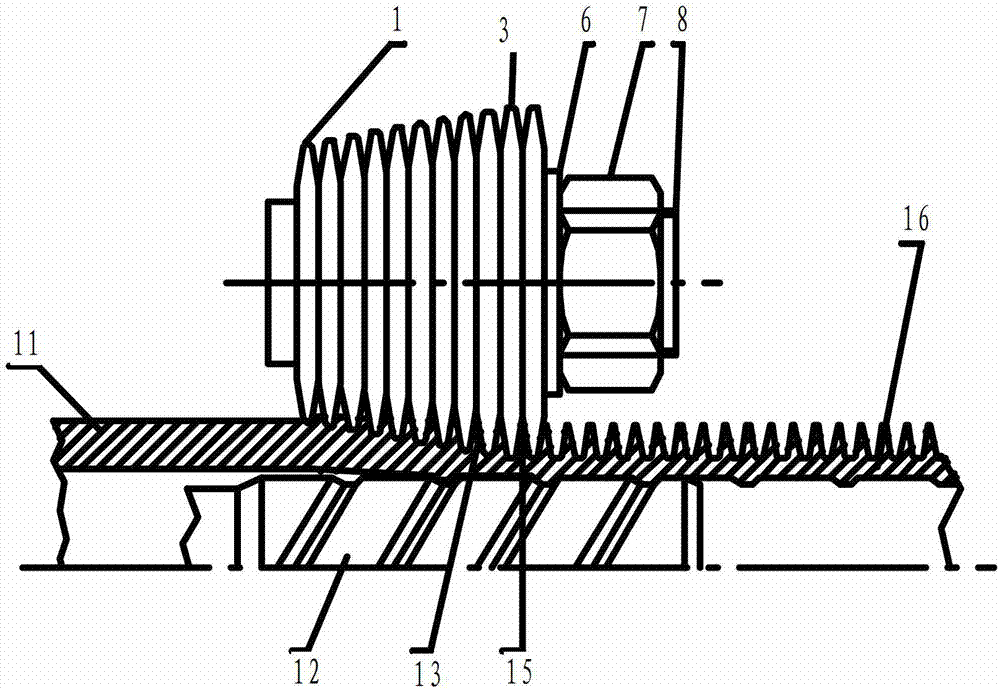

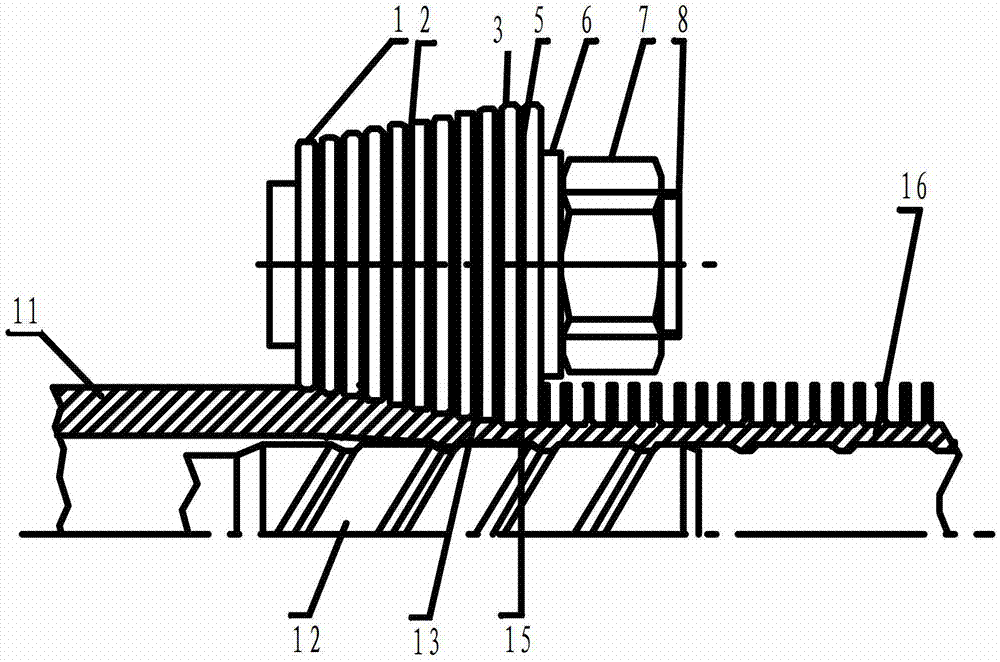

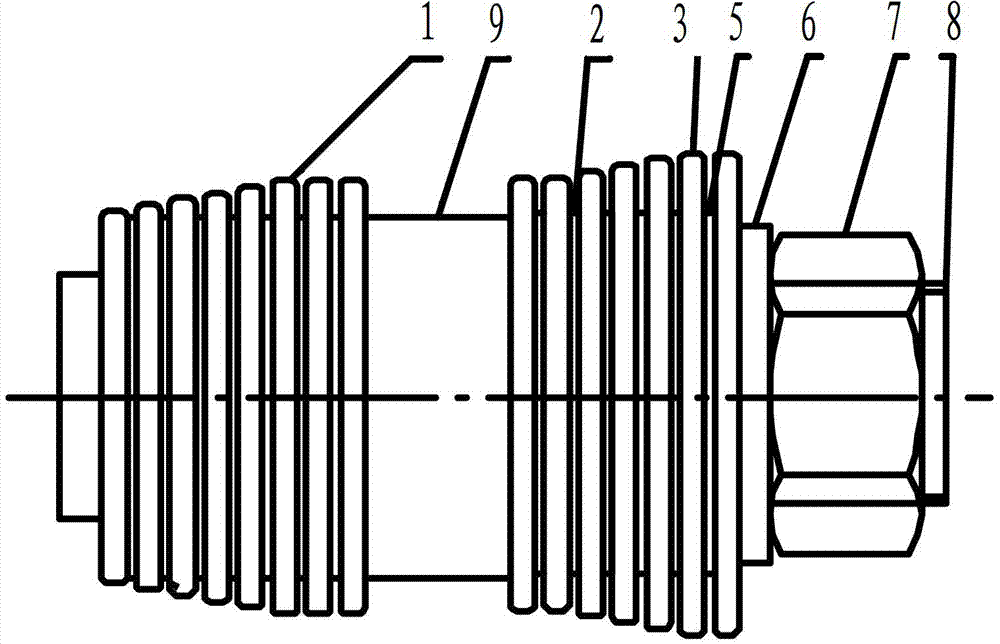

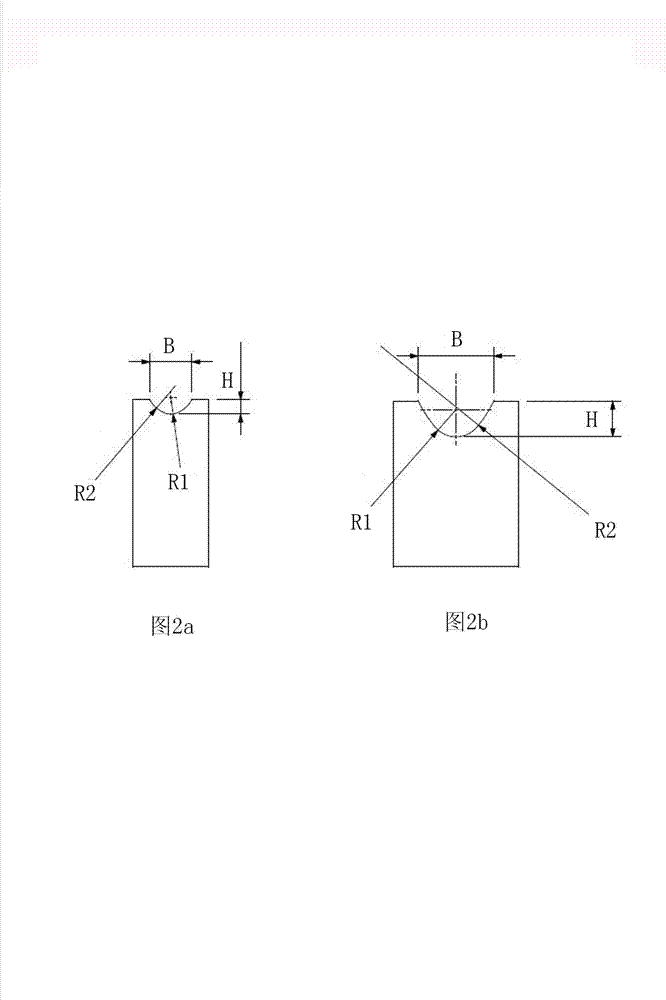

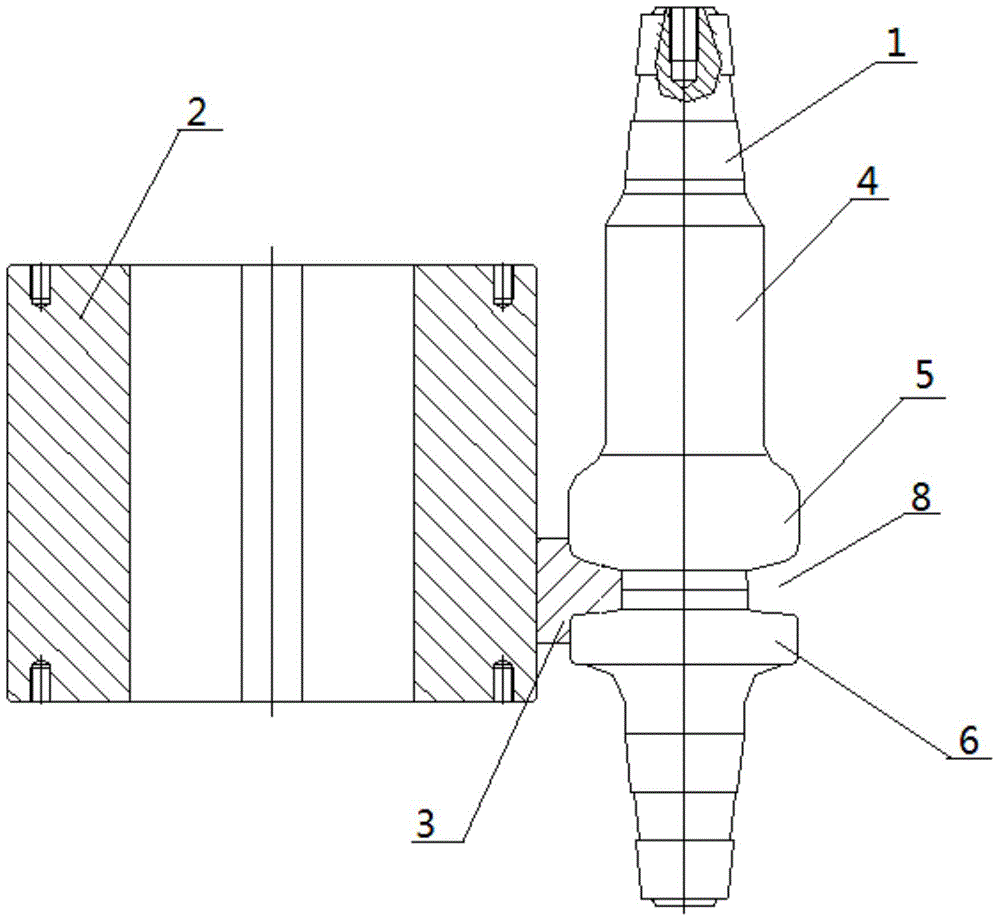

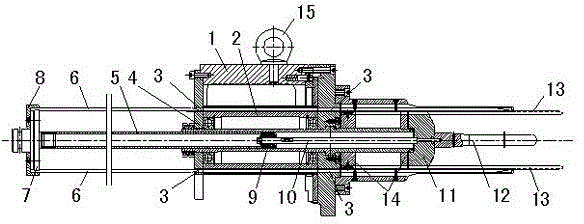

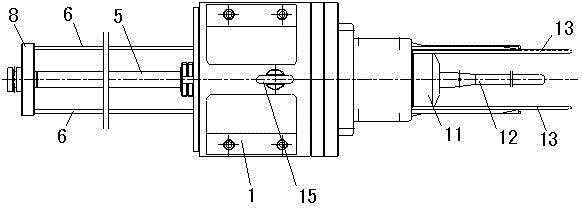

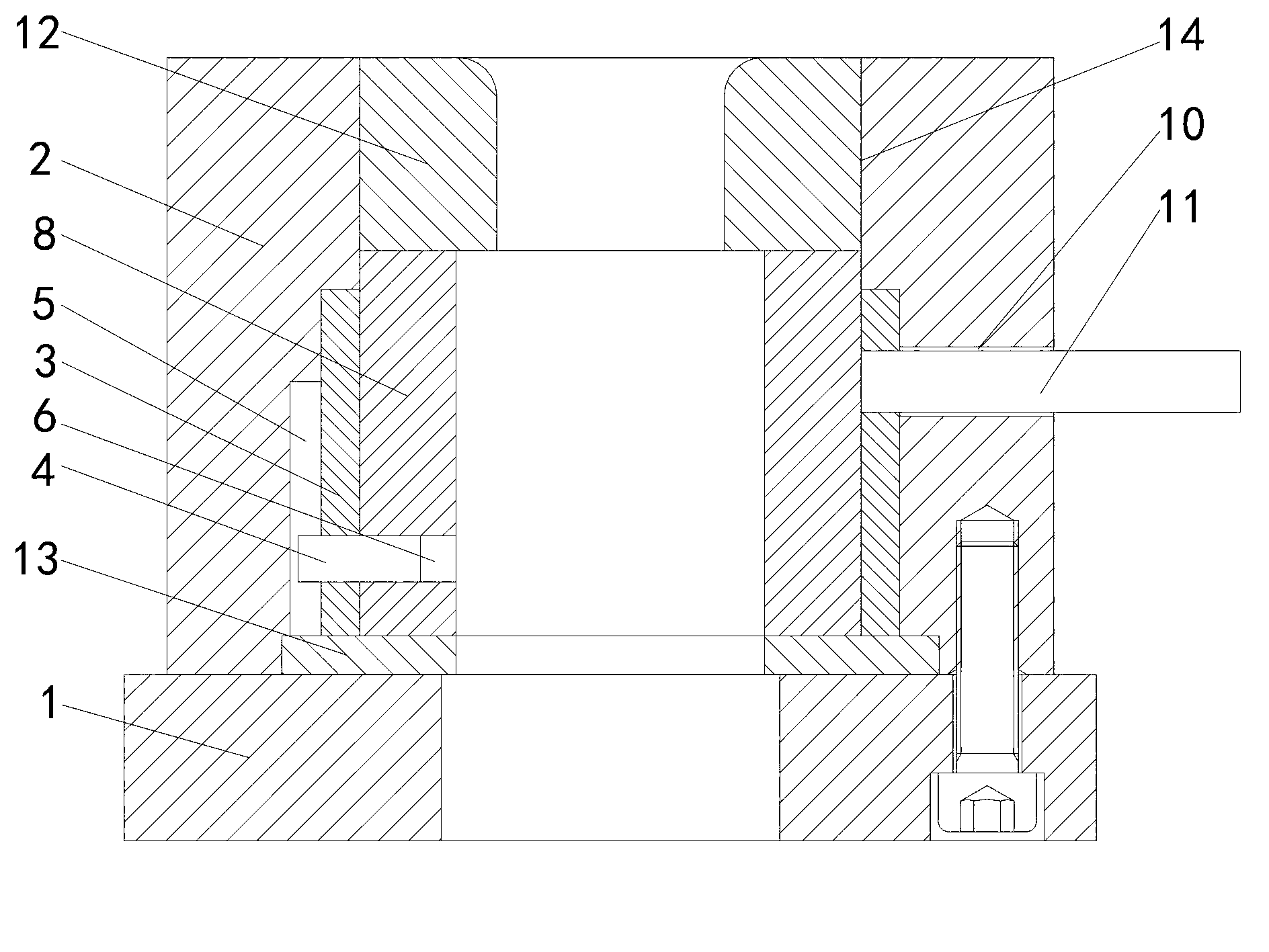

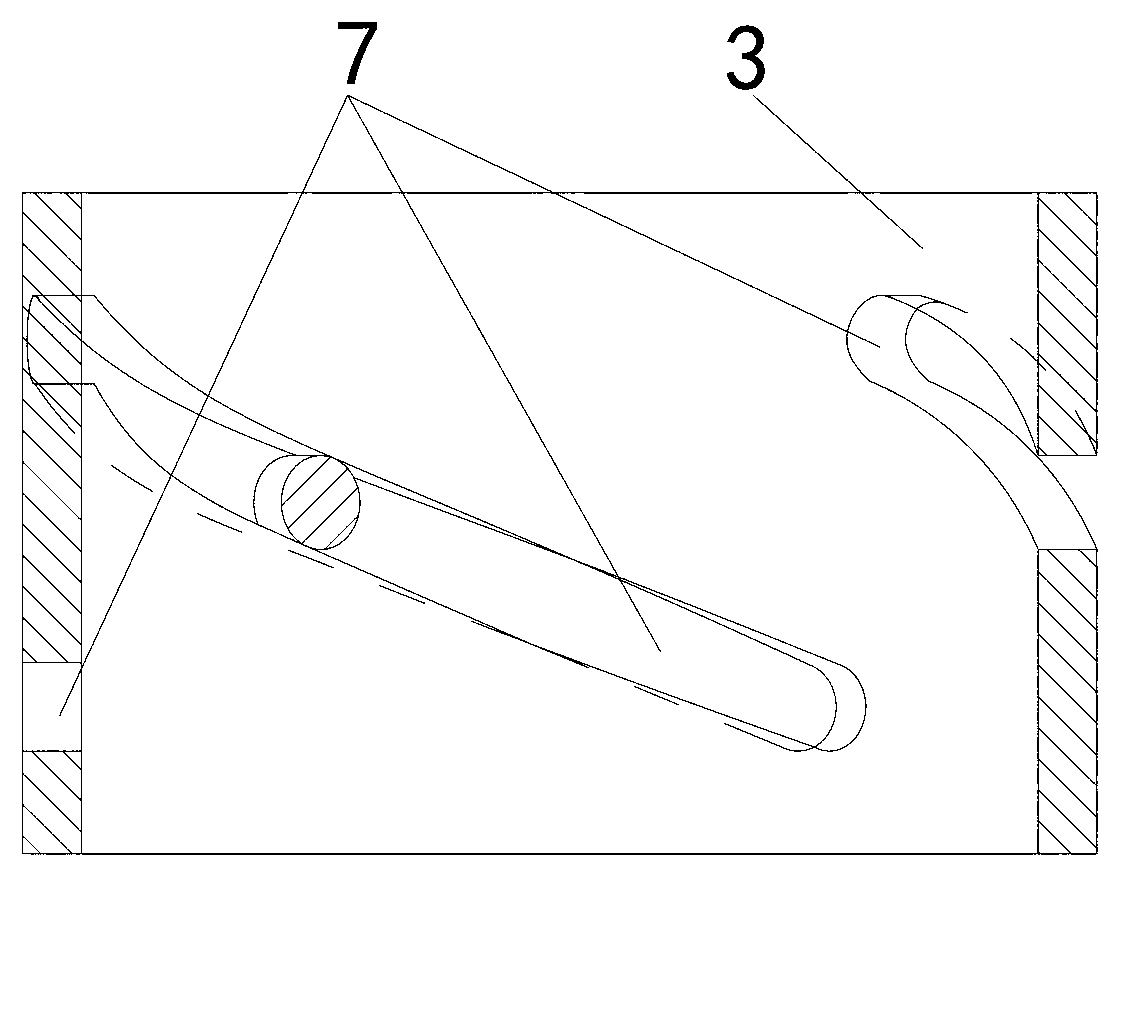

Combined cutting tool for processing finned tube

ActiveCN103191979AReduce thicknessConvenient ArrangementShaping toolsHeat exchange apparatusEngineeringFin height

The invention discloses a combined cutting tool for processing a finned tube. The combined cutting tool comprises a spindle (8), a transition blade (1), a design-finalized blade (3), a transition gasket (2) clamped in the middle of the transition blade, a design-finalized gasket (5) clamped in the design-finalized blade, a positioning gasket (4) clamped between the transition blade and the design-finalized blade, a gasket (6) and a nut (7), wherein the transition blade (1) and the design-finalized blade (3) are fixedly sleeved on the spindle (8), and the gasket (6) and the nut (7) are used for locking and fixing the blades. The combined cutting tool is characterized in that the transition blade (1) is kept to be invariant, the thickness of the design-finalized blade (3) is larger than that of the transition blade (1), the thickness of a fin is reduced through combining different cutting tools and gaskets, and accordingly the purpose of reducing the weight per unit length of the fin is achieved. The combined cutting tool for processing the finned tube has the advantages that the fin thickness is reduced, the weight per unit length of the fin reduced, and the cost is saved; the fin height and the fin shape before the fin design is finalized are ensured; the stability in the processing process is high; the die replacement time is reduced, and the work efficiency is improved; the gaskets can be used repeatedly; a cutting tool combining and arranging mode is simple, the cutting tool cost is low, and the blade using time is long.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

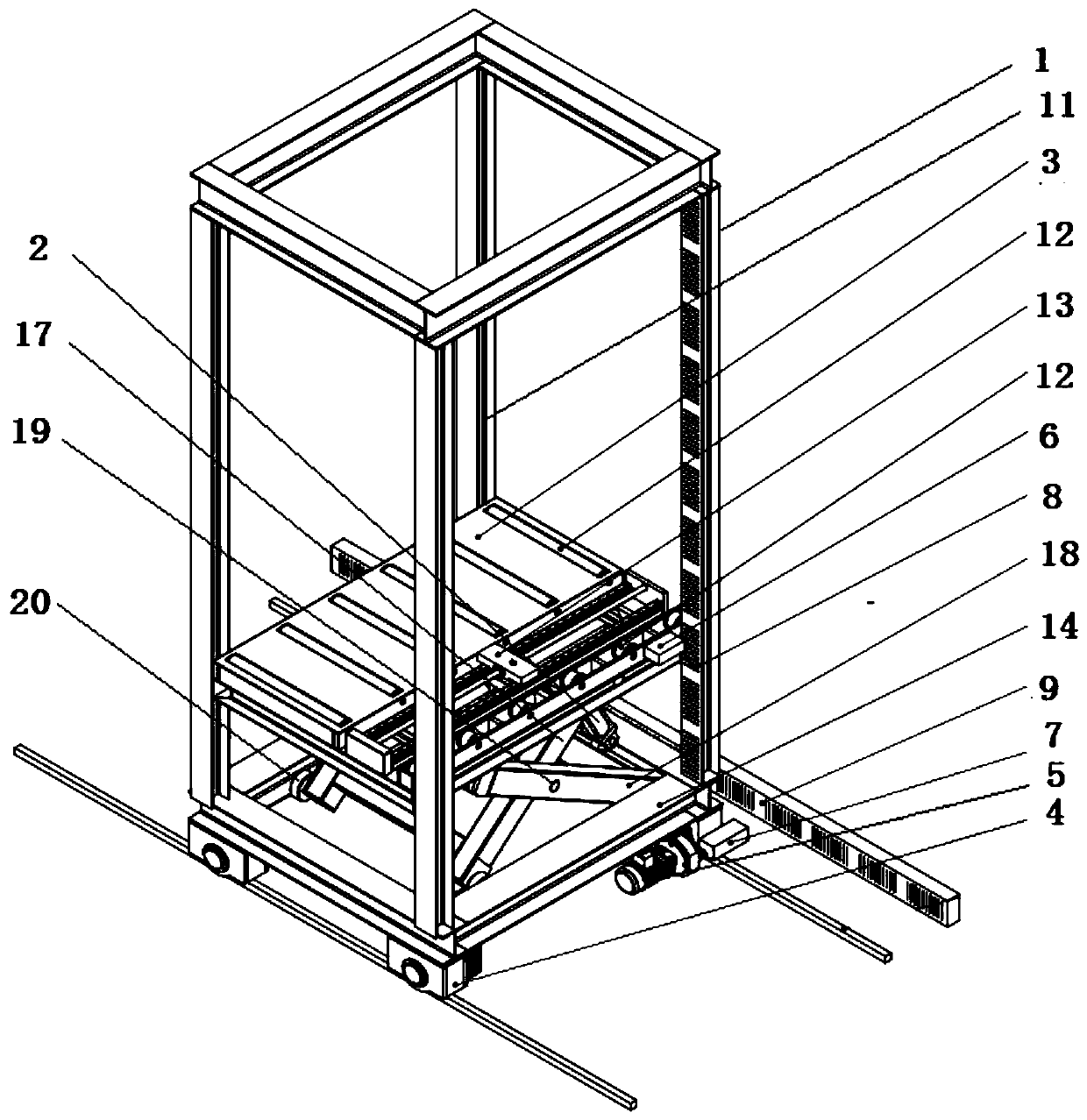

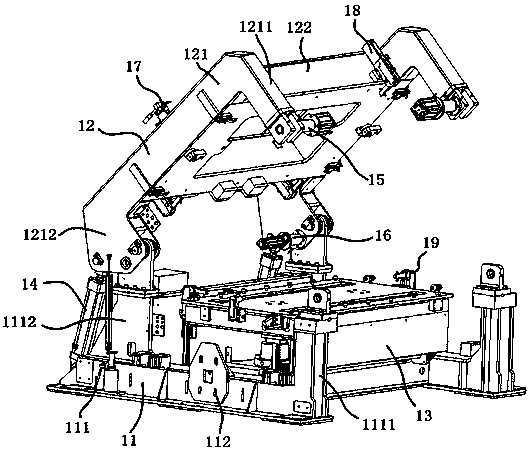

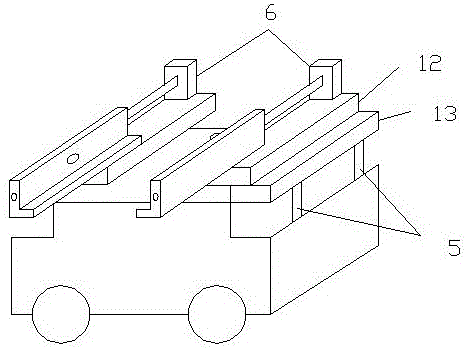

Multidimensional lifting type die changing trolley and die changing method thereof

ActiveCN106552870AFriction between the bottom surface of the mold and the table and trolleySmooth mold change processShaping toolsElectrical controlEngineering

The invention discloses a multidimensional lifting type die changing trolley and a die changing method thereof. The multidimensional lifting type die changing trolley comprises a trolley body. The trolley body comprises a bearing face and a bottom frame. An electrical control system used for controlling the die changing process is configured on the trolley body. The bearing face and the bottom frame are connected through first lifting mechanisms. Installation seats are arranged at the two ends of the trolley body. Second lifting mechanisms are connected between the installation seats and the trolley body. Each installation seat is arranged in a split manner and comprises an upper part and a lower part, wherein a first horizontal moving mechanism is connected between the upper part and the lower part, a die moving arm is arranged on the upper part, and a second horizontal moving mechanism is connected between the die moving arm and the upper part. Compared with the prior art, the multidirectional lifting type die changing trolley and the die changing method thereof have the beneficial effects that a die is lifted through the lifting mechanisms, then the horizontal moving mechanisms move the die to the trolley, no friction happens between the bottom face of the die and a worktable and the trolley in the whole process, the die changing process is stable, in addition, the die changing time is saved, and the die changing efficiency is improved.

Owner:JIANGSU ZHISHI TECH CO LTD

Pipe fitting flattening and flaring tool

ActiveCN107790551AInsufficient weld strengthQuick changeShaping toolsMetal working apparatusGratingPipe fitting

The invention discloses a pipe fitting flattening and flaring tool. Flattening weld inspection and pipe end flaring of pipe fittings can be realized by a spotting force at the same time, and accordingly, working efficiency is improved; a rapid die changing structure is arranged in the tool, and dies can be replaced rapidly and accurately, so that working efficiency is improved remarkably, and diechanging time is reduced; a grating ruler is arranged in the pipe fitting flattening and flaring tool, and central positions of weld joints can be detected accurately.

Owner:ZHEJIANG MOTORBACS TECH

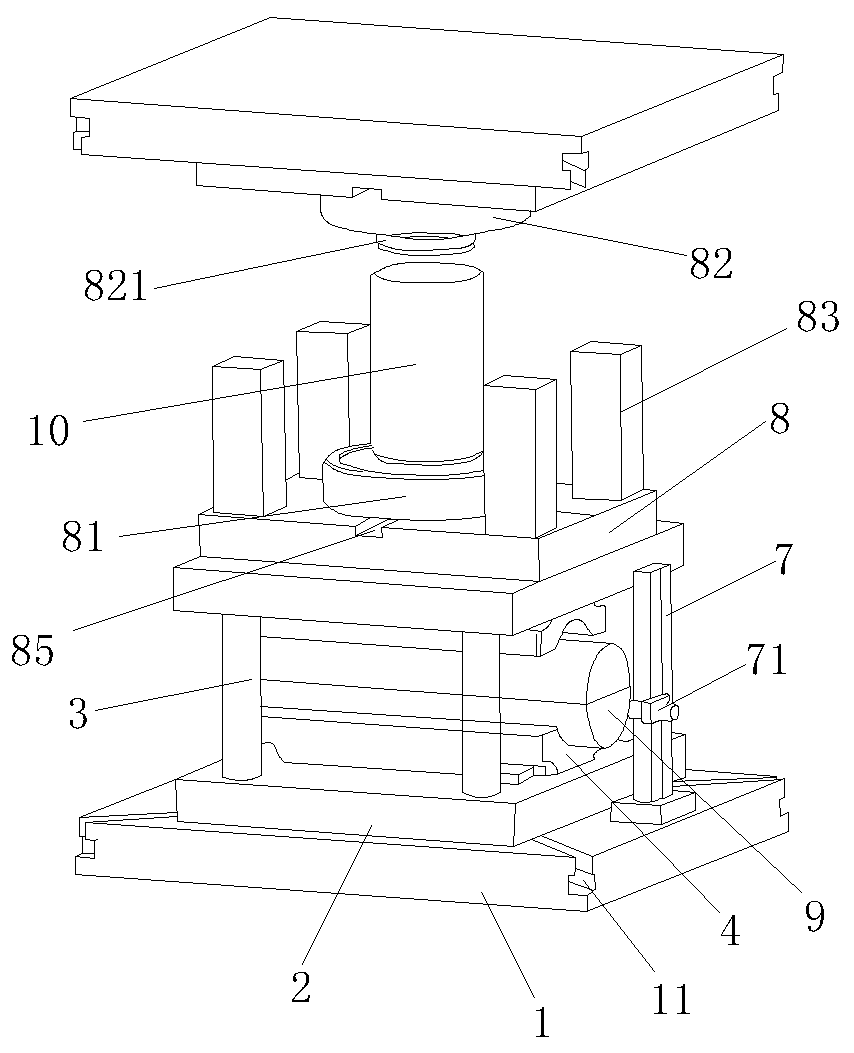

Electric permanent magnetic chuck capable of realizing quick die exchange

The invention discloses an electric permanent magnetic chuck capable of realizing quick die exchange. The electric permanent magnetic chuck comprises a fixed die plate and a movable die plate, wherein a positioning hole and a positioning ring are arranged in the middle of the fixed die plate; the movable die plate is provided with a positioning pin; die holes are formed in the fixed die plate and the movable die plate, and proximity switches, temperature sensors and magnetic sensors are arranged in the die holes; magnetic assemblies and cover plates are arranged in the die holes, and lead slots are formed in the cover plates; proximity switch indicator lamps, hazard warning lamps and aerial linker joints are arranged on side surfaces of the fixed die plate and the movable die plate; the proximity switches, the temperature sensors, the magnetic sensors, magnetic induction loops, the proximity switch indicator lamps and the hazard warning lamps are connected with the aerial linker joints through power lines respectively; the aerial linker joints are connected with a controller through the power lines; and the controller is connected with a manual control box and an external power line through the power lines. The product has good magnetic absorption, die screw installation is avoided, the machining cost is reduced, the die exchange time is shortened, and the production efficiency is improved.

Owner:佛山市顺德区盛锵节能设备有限公司

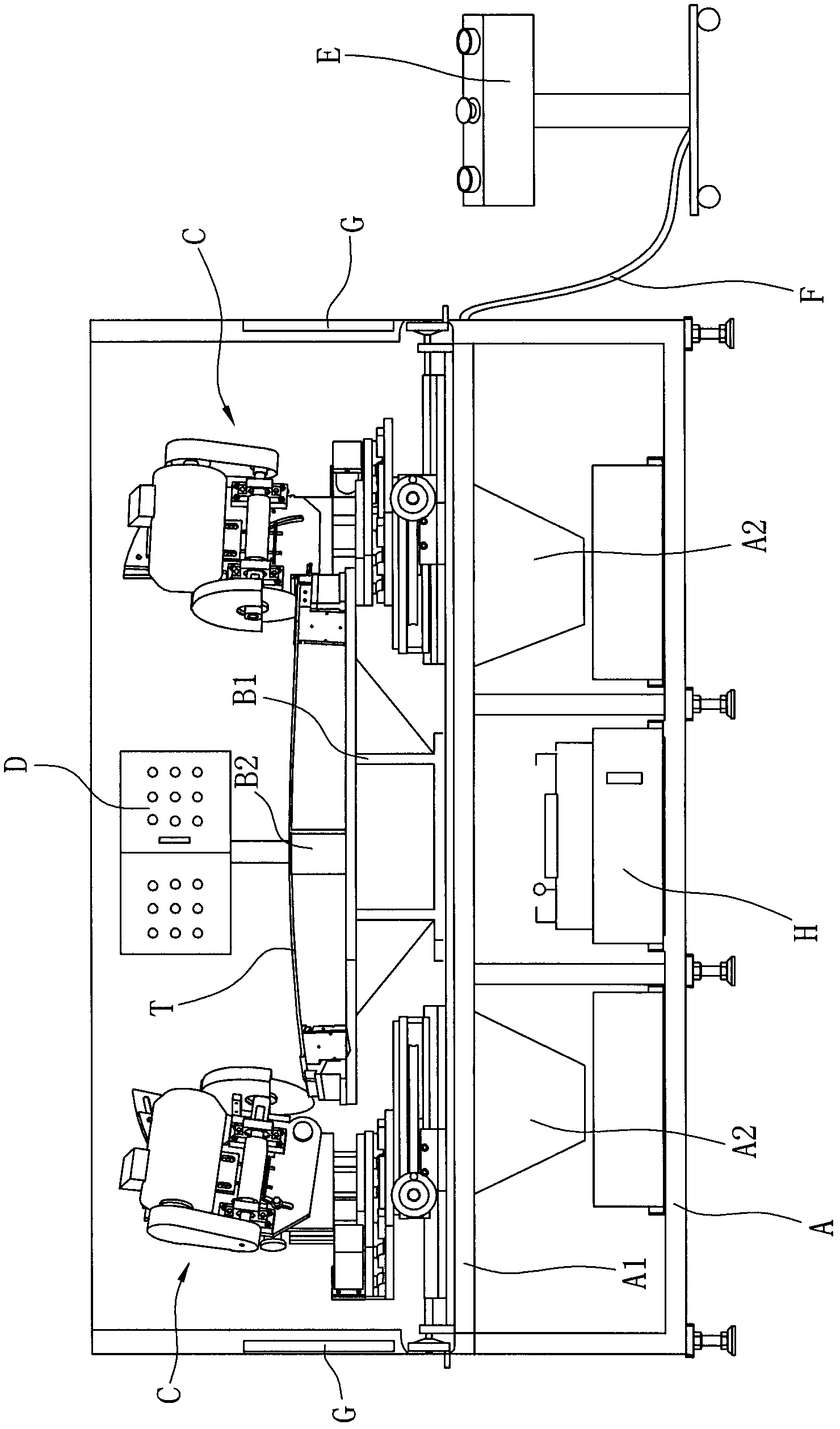

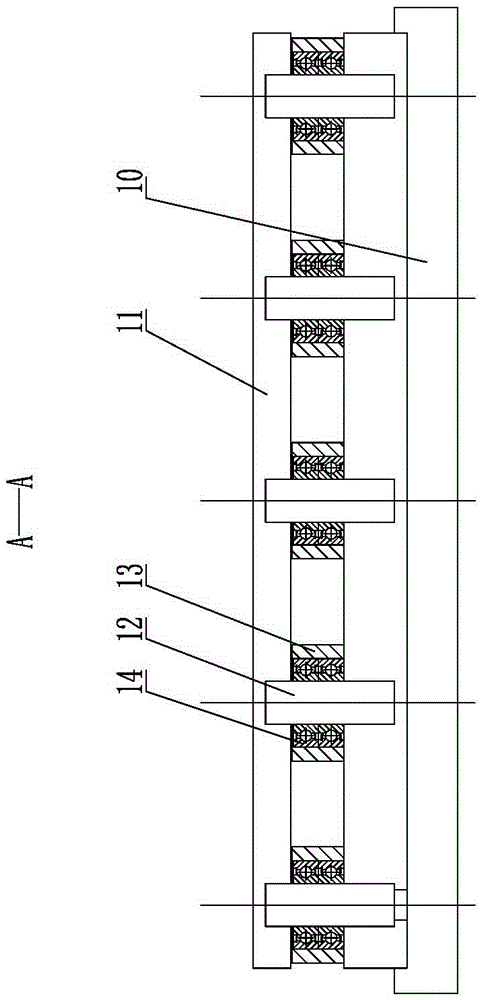

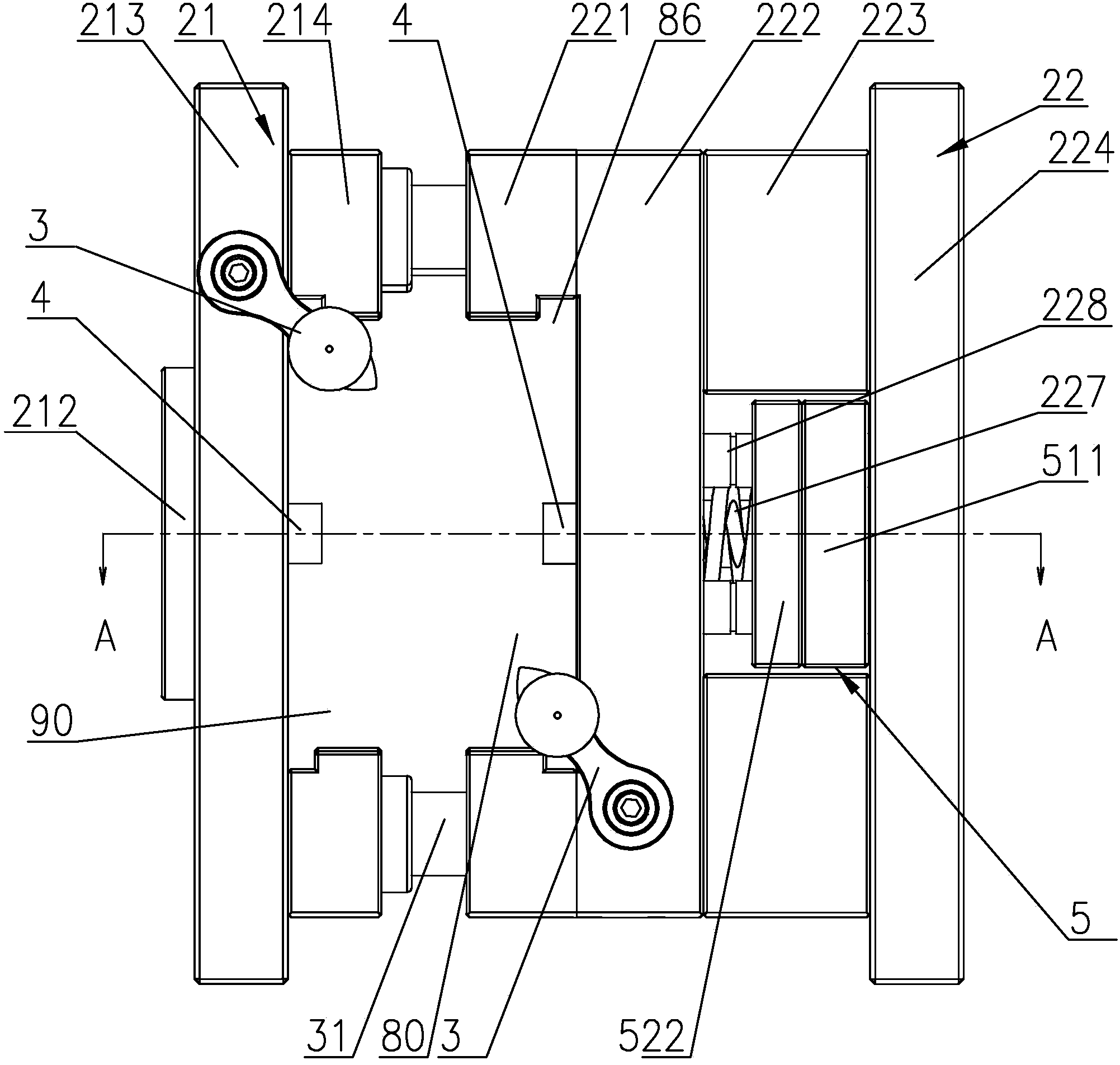

Quick die changing mechanism and die changing method

The invention relates to a quick die changing mechanism comprising a plurality of stamping apparatuses, a die changing trolley, a die taking and placing device and a die storage frame. Working tablesof the stamping apparatuses are provided with die lifting devices, the die changing trolley is provided with a walking device and a plurality of walking rails arranged in parallel, the die taking andplacing device is installed on the die changing trolley, and the die storage frame is located on the rear side of a die translocation device and provided with a die transposition device; and the stamping apparatuses are located on the front side of the die changing trolley and are arranged side by side in the length direction of the walking rails. The quick die changing mechanism is transposed among the multiple stamping apparatuses through the die changing trolley, dies in the die storage frame and dies mounted on the working tables of the stamping apparatuses are transposed through the die taking and placing device, the die changing time is shortened to be within 5 minutes, time wasted by die changing is short, the labor intensity is small, and the quick die changing mechanism is suitable for meeting the demand for high-efficiency product conversion of an automated production line with the multiple stamping apparatuses.

Owner:机械科学研究院浙江分院有限公司

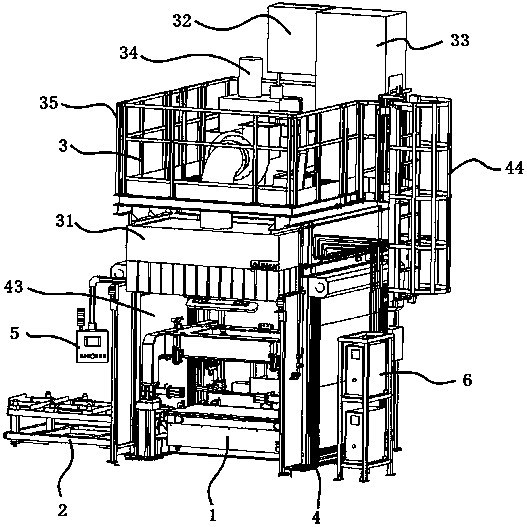

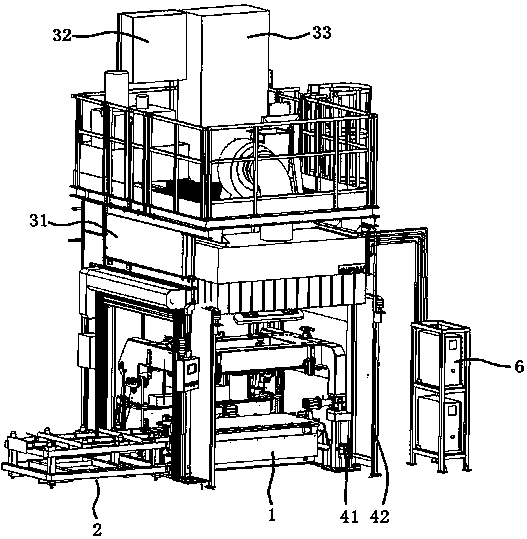

Forming device for automotive carpet hot-pressing foaming

The invention discloses a forming device for automotive carpet hot-pressing foaming. The forming device for automotive carpet hot-pressing foaming comprises a die frame body, a die replacement trolleyand a top platform. The die frame body is provided with a fixed lower frame, an overturn upper frame, an overturn air cylinder and a lifting platform. The die replacement trolley is located beside the fixed lower frame. The top platform is located above the die frame body. The top platform is provided with an exhaust system, a pneumatic control system and a hydraulic system. The forming device for automotive carpet hot-pressing foaming has the beneficial effects that because of the optimization on the butt joint between the die replacement trolley and the die frame body, it is realized that the die replacement trolley can carry out quick and accurate positioning when die replacement is carried out, and therefore, the time for die replacement is shortened, and the production efficiency isimproved.

Owner:上海古汉汽车饰件模具有限公司

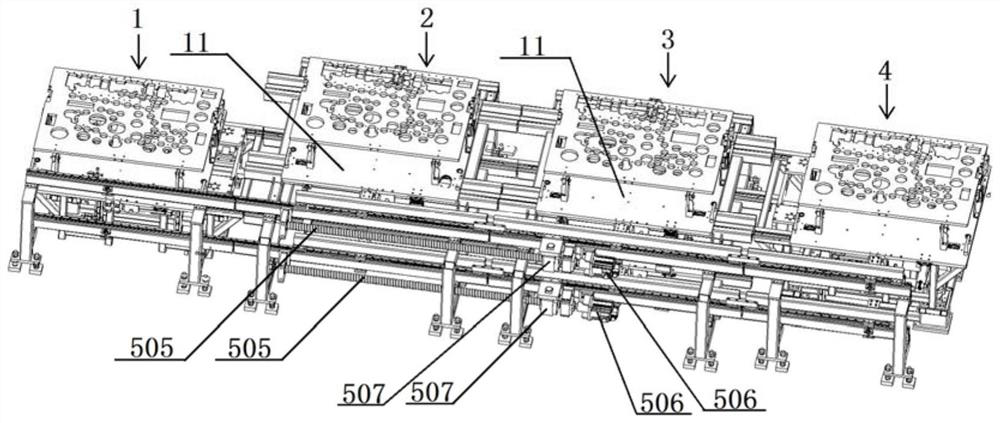

Flexible welding production line for automobile door trim panel

PendingCN112339277ARealize flexible collinear productionFlexible welding realizedDomestic articlesManufacturing lineIndustrial engineering

The invention relates to a flexible welding production line for an automobile door trim panel. The flexible welding production line comprises a workpiece placing station frame, two sets of flexible welding station frames, a workpiece taking station frame, an upper-layer tool conveying rail, a lower-layer tool return rail and two sets of transfer guide rails, wherein the workpiece placing station frame serves as a workpiece placing station, a first forming die lifting mechanism is arranged on the workpiece placing station frame, one set of transfer guide rails are installed on the first formingdie lifting mechanism in the horizontal direction, and the first forming die lifting mechanism is used for transferring a forming die located on the lower-layer tool return rail to the upper-layer tool conveying rail; and a second forming die lifting mechanism is arranged on the workpiece taking station frame, the other set of transfer guide rails are installed on the second forming die lifting mechanism in the horizontal direction, and the second forming die lifting mechanism is used for transferring the forming die located on the upper-layer tool conveying rail to the lower-layer tool return rail. The flexible welding production line has the advantages of being suitable for various small-batch automobile door trim panel projects and capable of realizing flexible collinear production ofvarious products.

Owner:CHANGCHUN FAWAY ADIENT AUTOMOTIVE SYST CO LTD

Die changing trolley of press machine and die changing method

The invention discloses a die changing trolley of a press machine in the field of press machines. The die changing trolley comprises a trolley body; the bottom of the trolley body is provided with wheels, the trolley body is provided with a driving mechanism, a pair of die carrier guide rails and a die carrier pushing-pulling mechanism, the die carrier pushing-pulling mechanism comprises a pushing-pulling motor, the output end of the pushing-pulling motor is provided with a belt pulley I, and the belt pulley I is connected with a belt pulley II in a driving way through a belt to which a sliding pothook is connected; the lower part of a die carrier is provided with double rows of die carrier rollers, the trolley body is provided with a die carrier limiting mechanism comprising a base plate, the base plate is provided with a slide wheel axle which is rotatably connected with a side wheel, and the upper end of the side wheel axle is provided with a pressing plate; and the trolley body is provided with a die carrier lifting mechanism in parallel, the die carrier lifting mechanism comprises a roller carrier controlled by a hydraulic cylinder to lift, horizontal rollers are horizontally arranged on the roller carrier, and roller shafts of the horizontal rollers are parallel to the die carrier guide rails. By using the die changing trolley, the die carrier of the press machine can be rapidly changed, the die changing time can be shortened, and the die changing efficiency can be increased.

Owner:YANGLI GRP CORP LTD

Multi-directional numerical control linkage precision forming process of transmission planetary carrier

ActiveCN109433985ALow costGuaranteed positioning accuracyForging/hammering/pressing machinesNumerical controlHigh volume manufacturing

The invention discloses a multi-directional numerical control linkage precision forming process of a transmission planetary carrier. The process is characterized in that a heated metal bar is formed through numerical control linkage of an upper punch, a front punch, a rear punch, a left punch and a right punch in five directions, and a precise forging of the transmission planetary carrier with thecomplicated shape is prepared in a single station and through one-time heating and multi-directional forming; and the front punch, the rear punch, the left punch and the right punch in a die are arranged in four side square holes in a female die, and are not separated all the time in the forming process. The forging forming planet carrier forge piece is small in machining allowance, the production efficiency is greatly improved, the cost can be reduced to a great extent, and a certain foundation can be laid for mass production of the current part.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

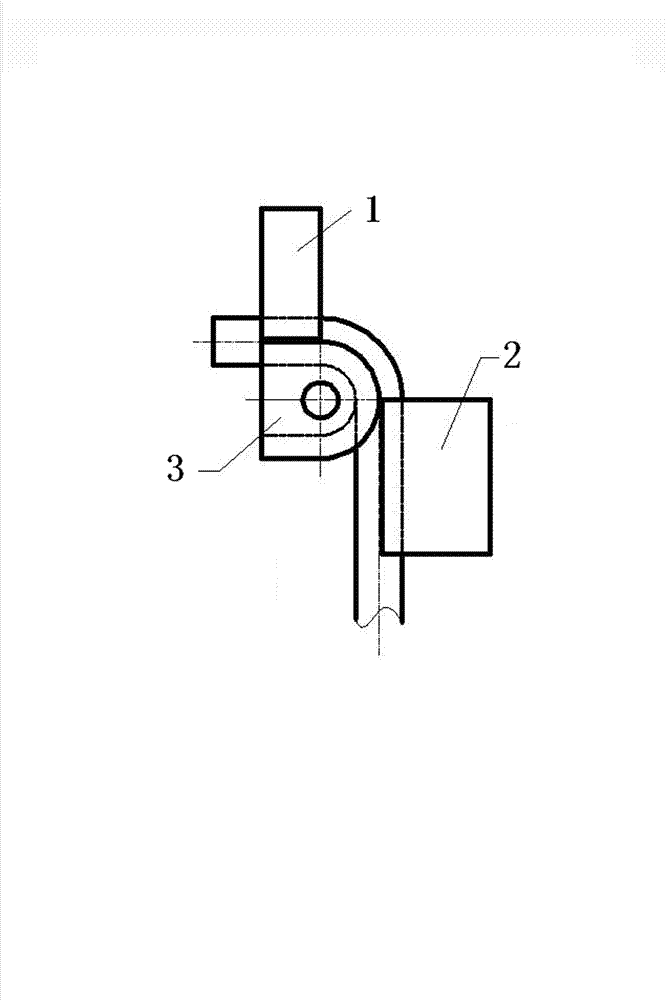

Multi-purpose pipe bending mould

The invention discloses a multi-purpose pipe bending mould which comprises a fixed mould and a movable mould. The multi-purpose pipe bending mould is characterized in that a special-shaped processing groove is formed on the movable mould and is formed by connecting two arc surfaces of different radii, the middle portion of the special-shaped processing groove is a first arc surface, two ends of the first arc surface are respectively connected with a second arc surface, the first arc surface and the second arc surface are smoothly connected, and a semi-circular processing groove is formed on the fixed mould. By improving processing grooves of the movable mould and a guide plate, the multi-purpose pipe bending mould can meet the requirement of bending pipes of different diameters. The multi-purpose pipe bending mould has the advantages of being capable of reducing mould manufacturing quantity greatly, reducing mould costs, shortening mould changing time, improving production efficiency, and integrating the management optimization and the design standard of the mould.

Owner:上海汽车空调配件股份有限公司

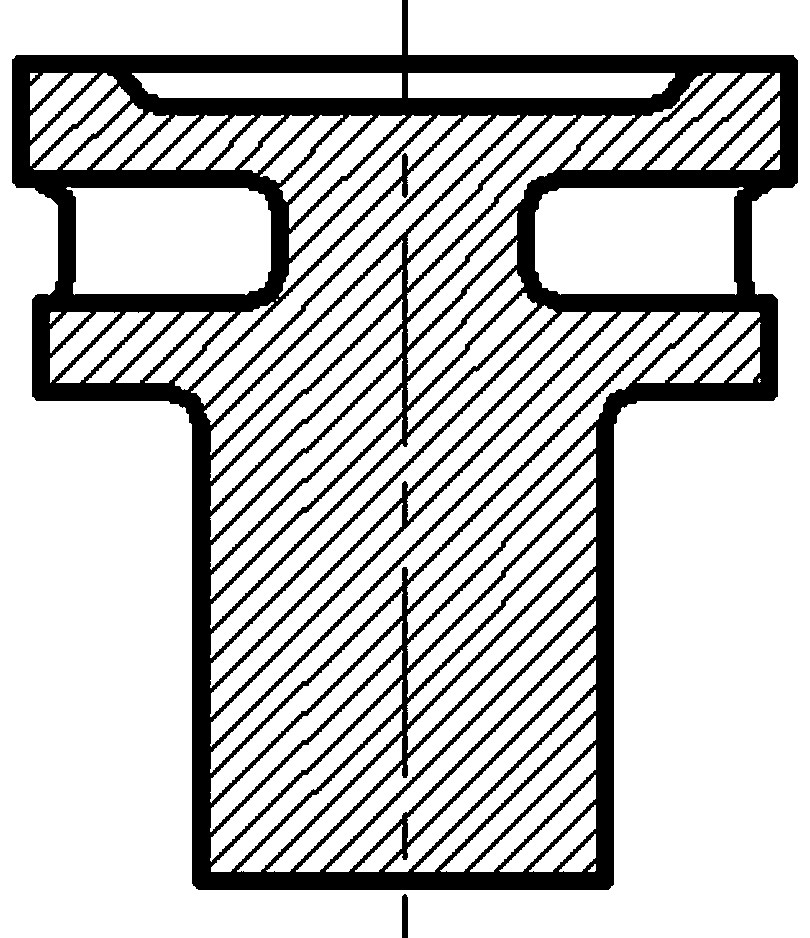

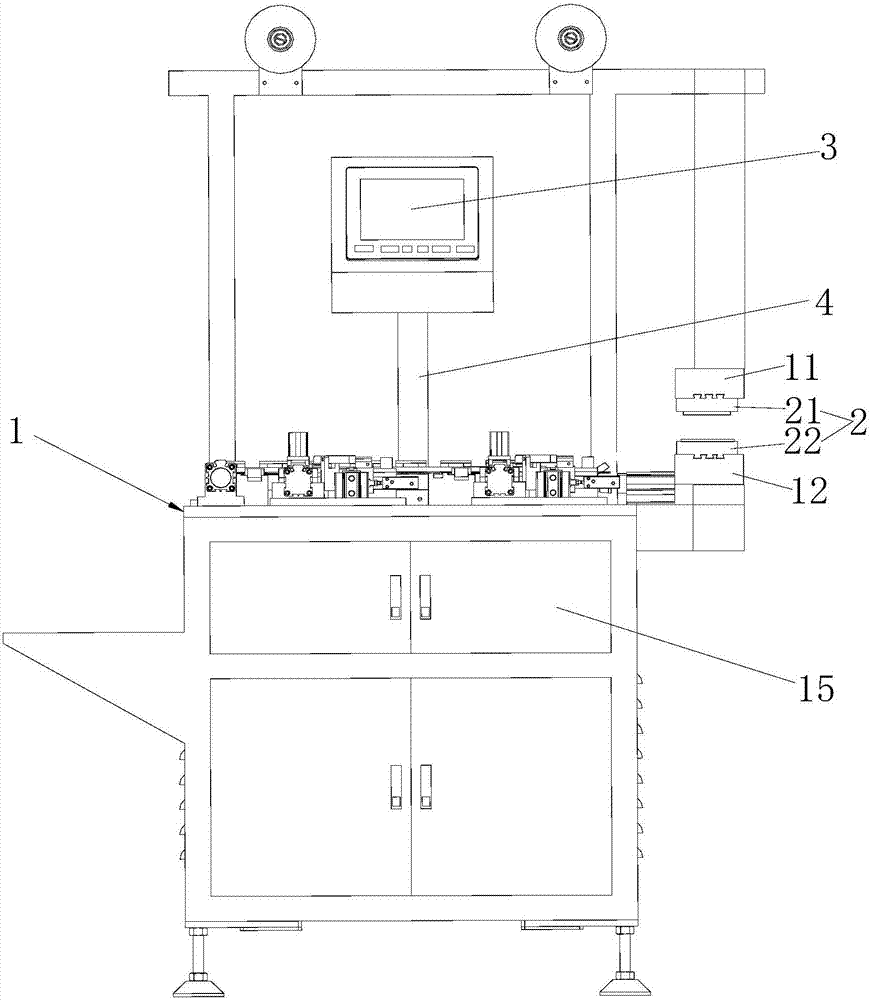

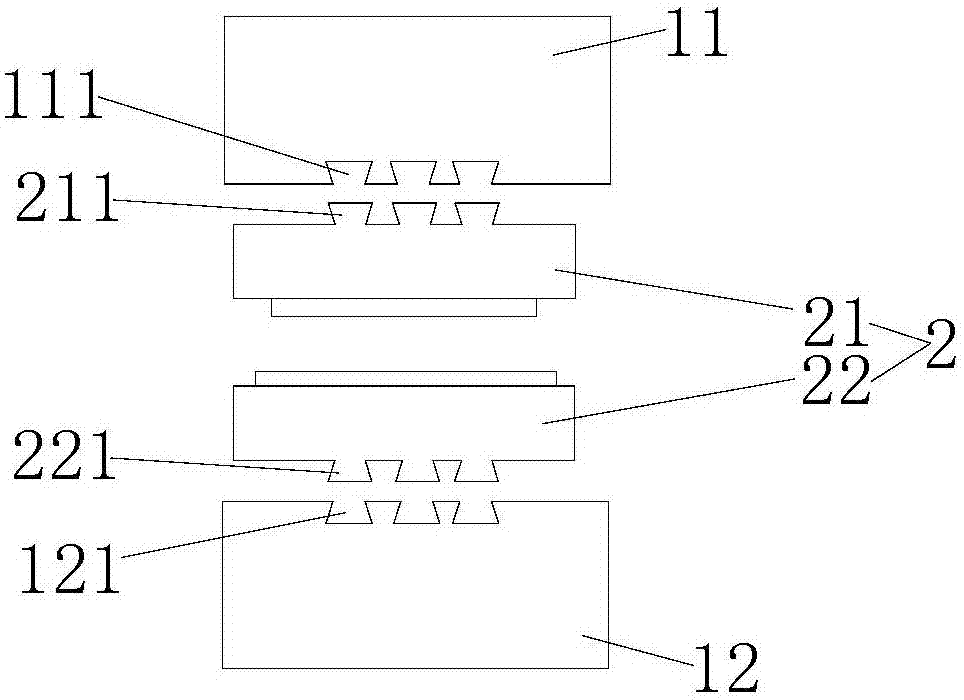

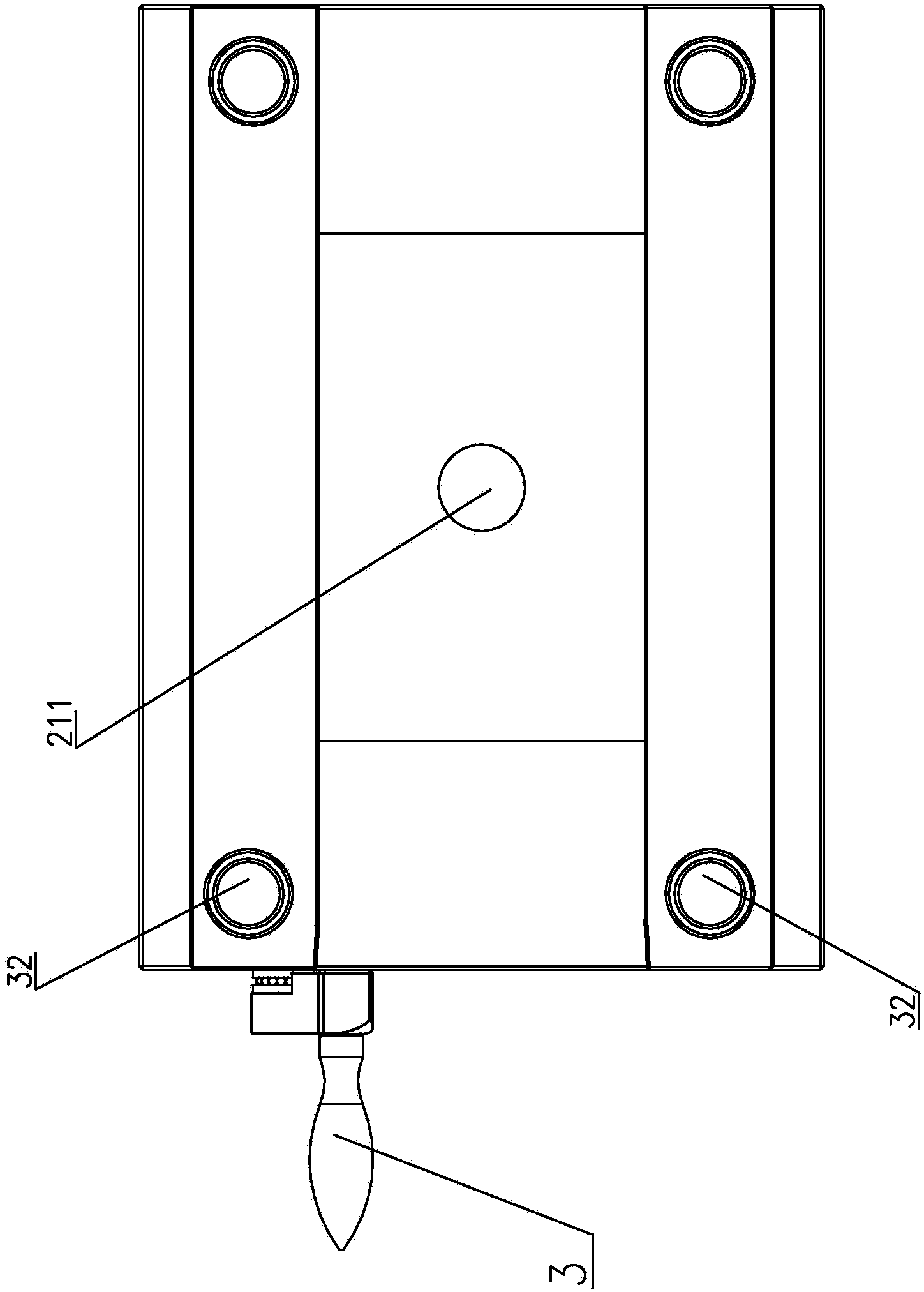

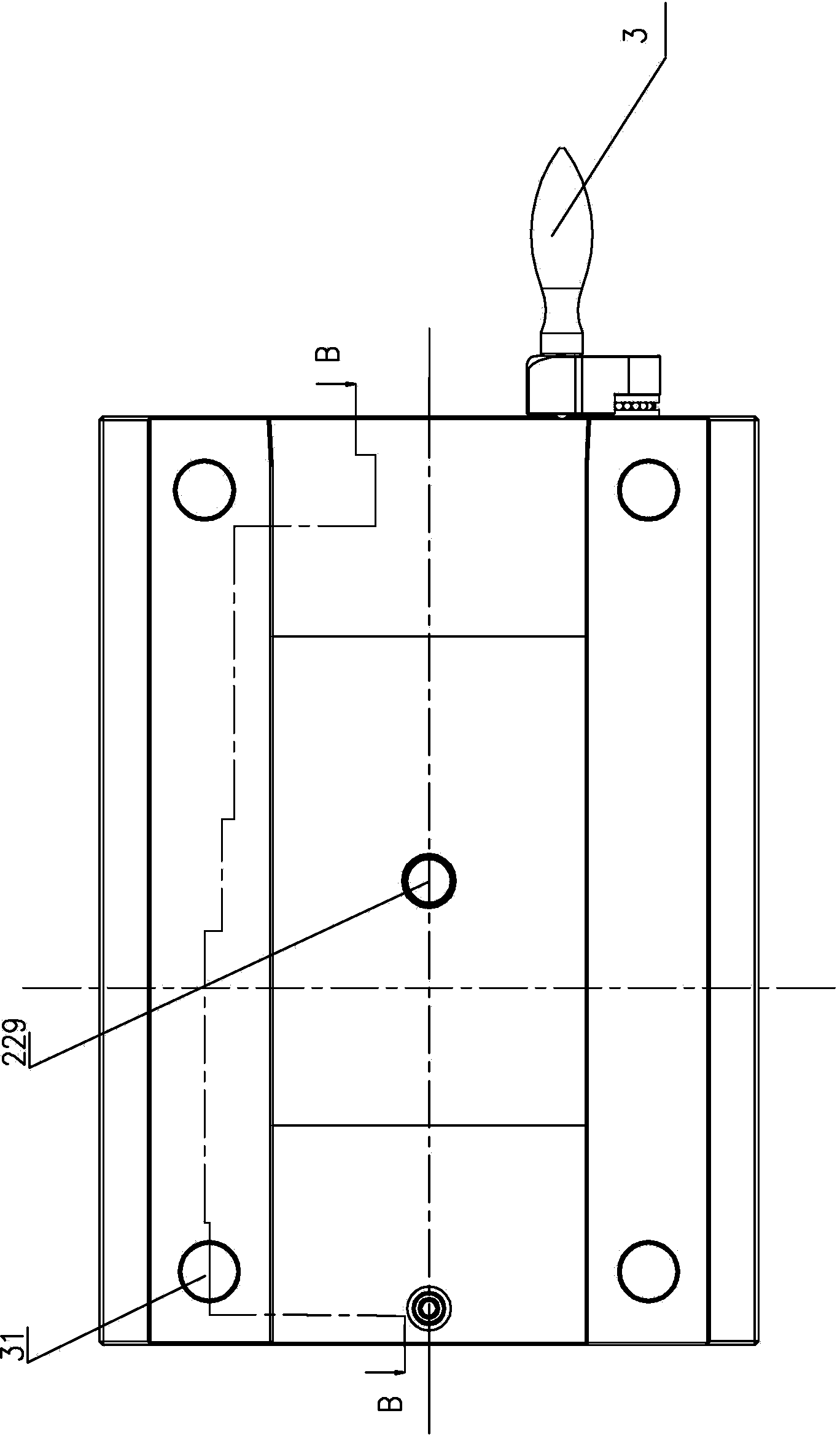

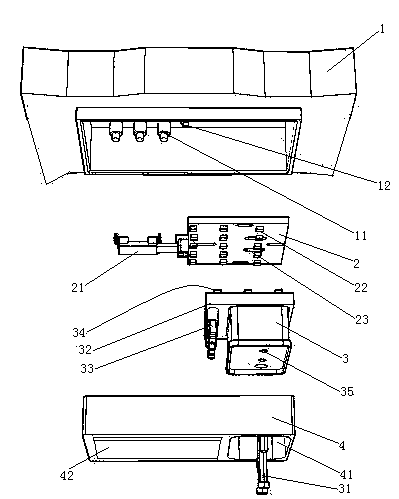

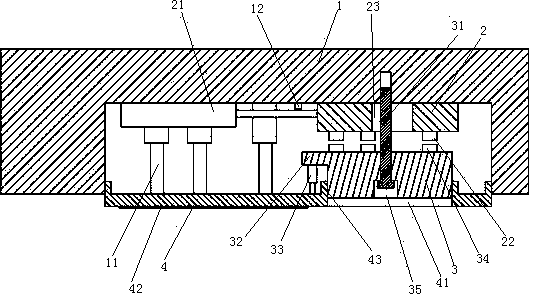

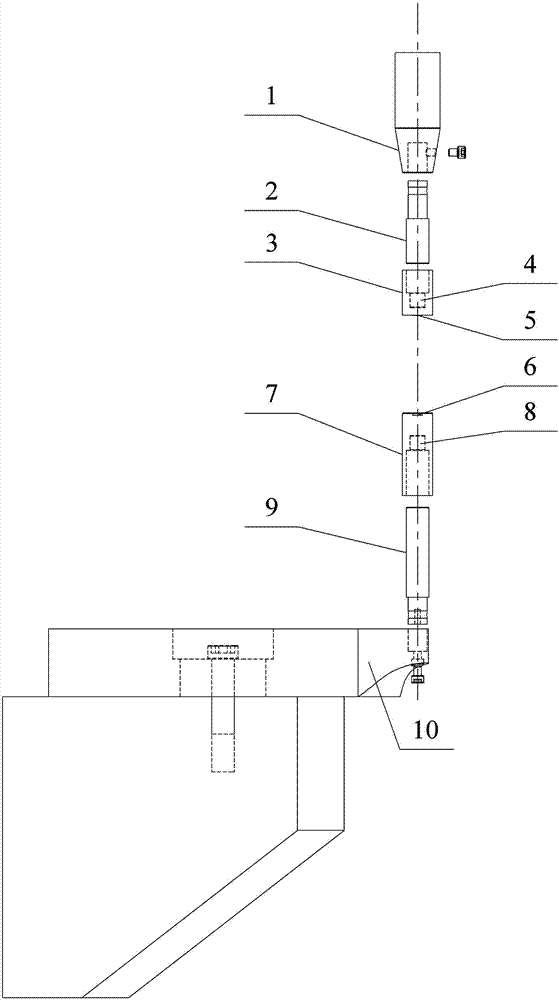

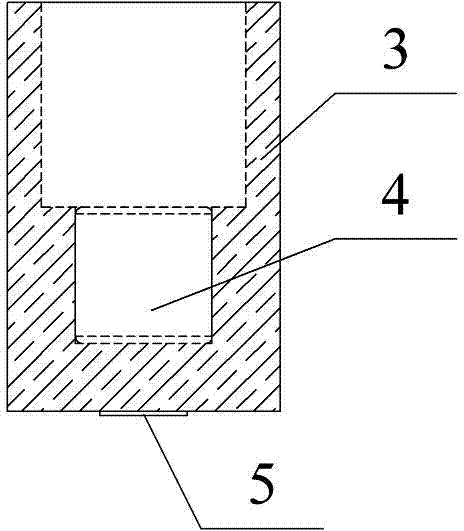

Automatic insertion device for motor groove wedge segments

InactiveCN107070111AFor quick replacementEasy to operateManufacturing dynamo-electric machinesEngineeringManipulator

The invention is applicable to the technical field of motor production equipment, and provides an automatic insertion device for motor slot wedges, including a frame, a cutting mold, a cutting mold including an upper mold and a lower mold, and the frame is also provided with a lower base body and an upper base. The upper end of the lower base body is provided with three lower fixing grooves, the lower end of the lower mold is provided with three lower fixing ribs that can be inserted into the lower fixing grooves, the lower end of the upper base body is provided with three upper fixing grooves, and the upper end of the upper mold is provided with three The upper fixing ribs that can be inserted into the upper fixing groove, the cross-sections of the lower fixing groove, the lower fixing ribs, the upper fixing groove and the upper fixing ribs are all in the shape of a dovetail, and the upper seat body is threaded with an upper locking piece, and the lower seat body is threaded The lower locking piece is connected, the winding part is connected with the frame, and the manipulator for inserting the slot wedge into the motor rotor after winding is connected with the frame. The invention provides an automatic insertion device for motor slot wedges, which can save mold changing time and is beneficial to improve production efficiency.

Owner:SHENZHEN LUTRON MECHANICAL & ELECTRICAL EQUIP CO LTD

Mold replacing trolley for automatic assembly for automobile production

InactiveCN107900226AAvoid damageImprove work efficiencyShaping toolsEngineeringMechanical engineering

The invention provides a mold replacing trolley for an automatic assembly for automobile production. The mold replacing trolley comprises a moving track and a base; the base is arranged on the movingtrack through moving rollers at the lower end; a support is arranged on the base; a lifting platform is arranged on the support; a telescopic air cylinder is arranged at the back end of the lifting platform; a mold gripping clamping jaw is arranged on the telescopic air cylinder; a temporary storage platform is arranged at the upper part of the support; and universal wheels are arranged on the upper end surfaces of the base, the lifting platform and the temporary storage platform. The lifting platform on the support is used as a lifting and lowering passage for molds, the mold gripping clamping jaw is driven by the telescopic air cylinder to lift and lower the molds, the dismounted molds are placed on the temporary storage platform in advance, mold lifting work is performed, and then the dismounted molds are placed after mold lifting, so that the working efficiency is improved, and the mold replacing time is shortened; and the molds are fixed through a fixing and adsorbing block, so that damage to the molds due to the fact that the molds fall off from the mold replacing trolley is avoided.

Owner:芜湖戎征达伺服驱动技术有限公司

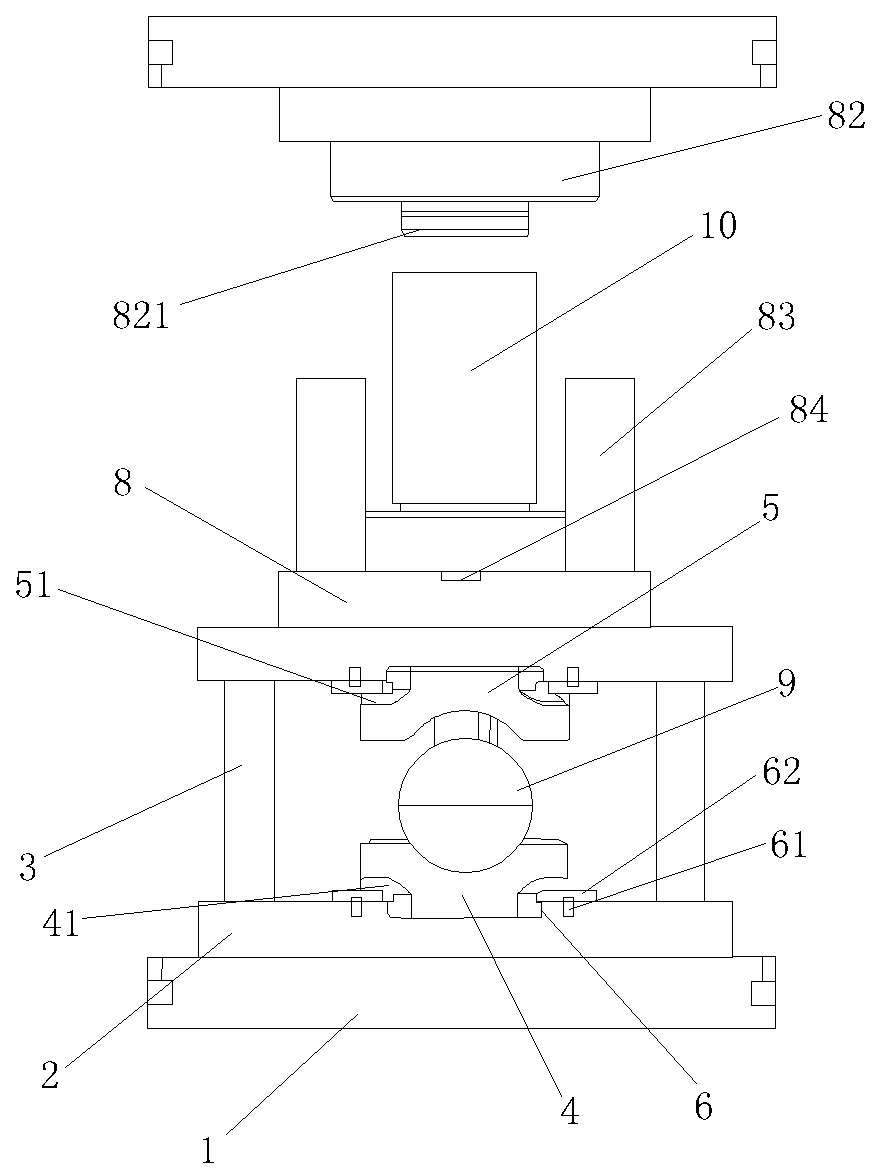

Locking mechanism and bending die quick clamping system including locking mechanism

PendingCN111167949AClamp evenlyEliminate incomplete clamping of moldsShaping toolsShaping safety devicesClassical mechanicsEngineering

The invention discloses a locking mechanism and a bending die quick clamping system including the locking mechanism. The locking mechanism comprises a mounting base and one set or more sets of clamping execution assemblies, the one set or more sets of clamping execution assemblies arranged in the longitudinal direction are provided on the one transverse side or two transverse sides of the mountingbase, a mold is clamped between the clamping execution assemblies and the mounting base, and the clamping execution assemblies are close to or away from the mounting base in a plane perpendicular tothe longitudinal direction; and the adjacent clamping execution assemblies are arranged next to each other. The locking mechanism and the bending die quick clamping system including the locking mechanism can completely eliminate the situation that the mold cannot be completely clamped when the clamping position slightly changes due to mold machining errors or mold abrasion and other reasons (potential safety hazards can occur), it is guaranteed that any segment of the mold at the any mounting position on the mounting base is uniformly and consistently clamped, and the clamping force is not degraded.

Owner:王勇

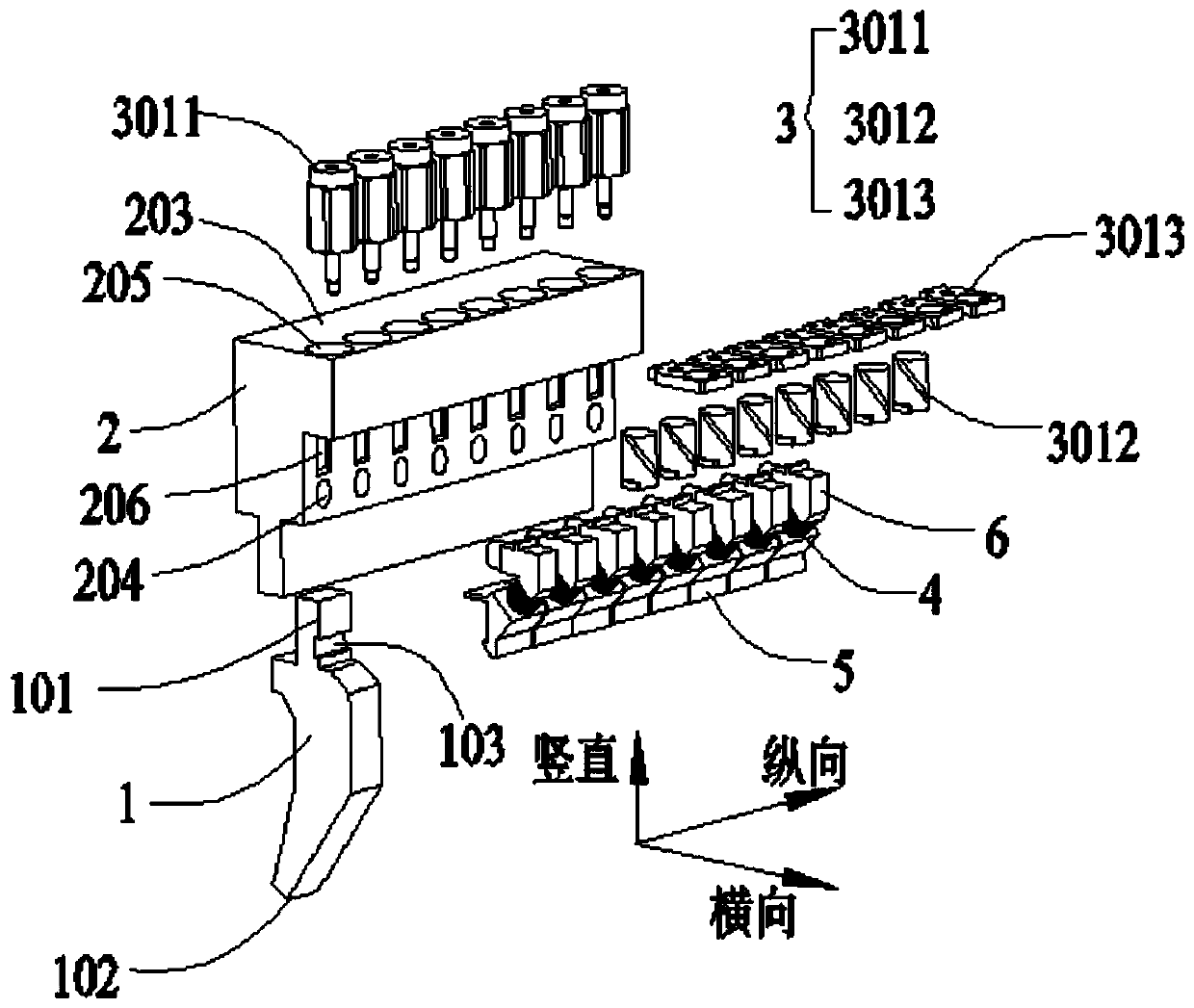

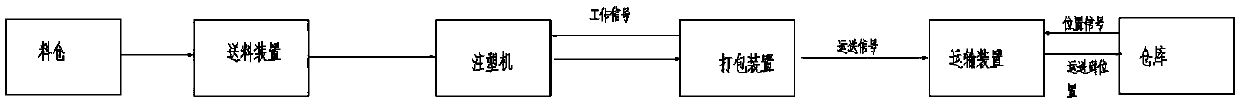

Intelligently-controlled injection molding machine production machine group

InactiveCN109624208AIncrease productivityImprove replacement efficiencyIntelligent controlSignal acquisition

The invention relates to an intelligently-controlled injection molding machine production machine group. The production machine group is mainly composed of a material bin, feeding devices, injection molding machines, packaging devices, conveying devices and a warehouse; each packaging device is mainly composed of a packaging machine and a counting system, and when products are produced through theinjection molding machines and counted through the counting systems and the number reaches the counting number, the packaging machines conduct packaging; and after packaging is finished, conveying signals are sent to the conveying devices, and the products are conveyed to the specified positions of the warehouse. According to the intelligently-controlled injection molding machine production machine group, through a control system comprising a signal collector, a sensor, a central processing unit and the like, automatic production and intelligent control of the injection molding machine groupare achieved, the production efficiency is improved, and the labor cost is reduced.

Owner:TEDERIC MACHINERY

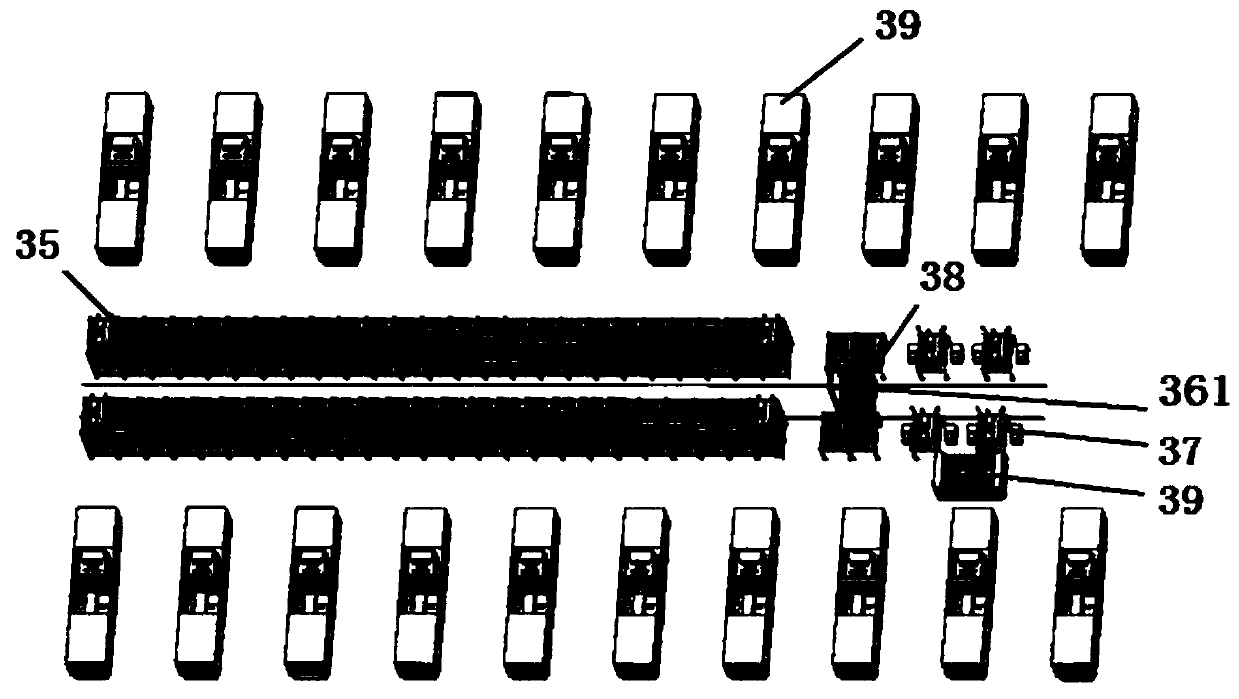

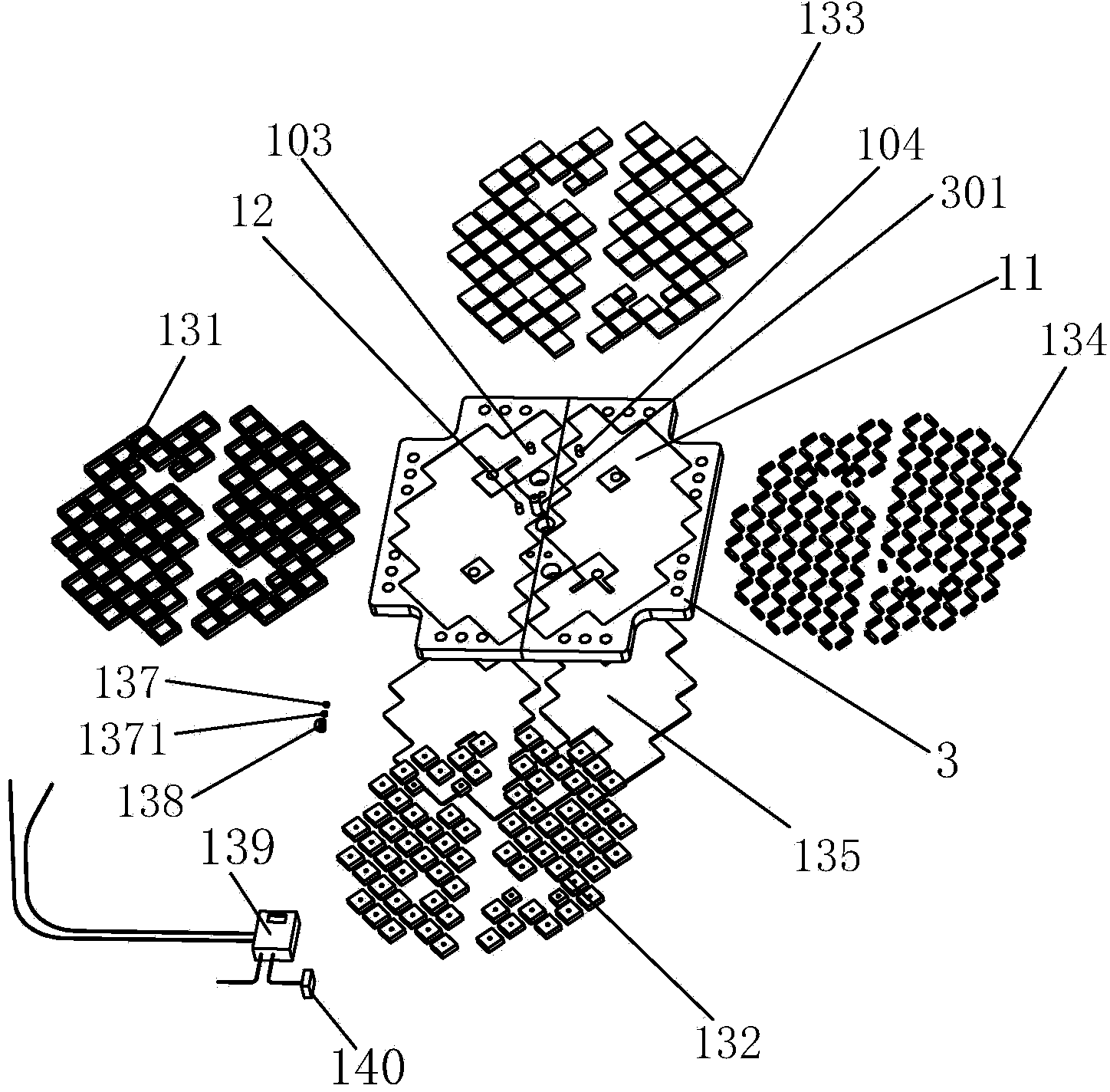

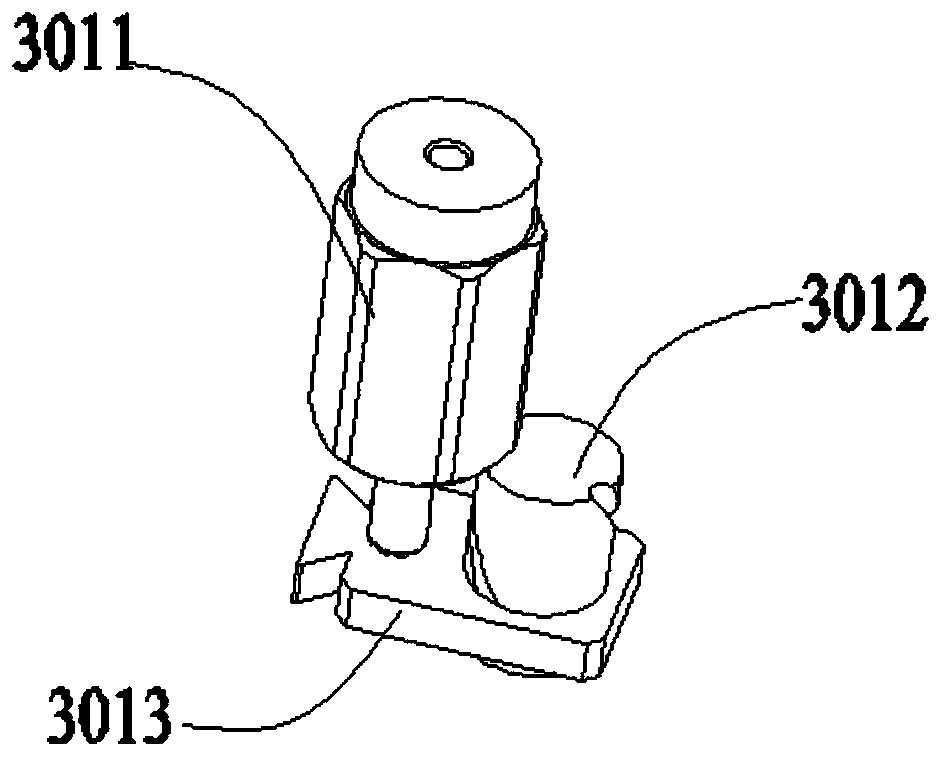

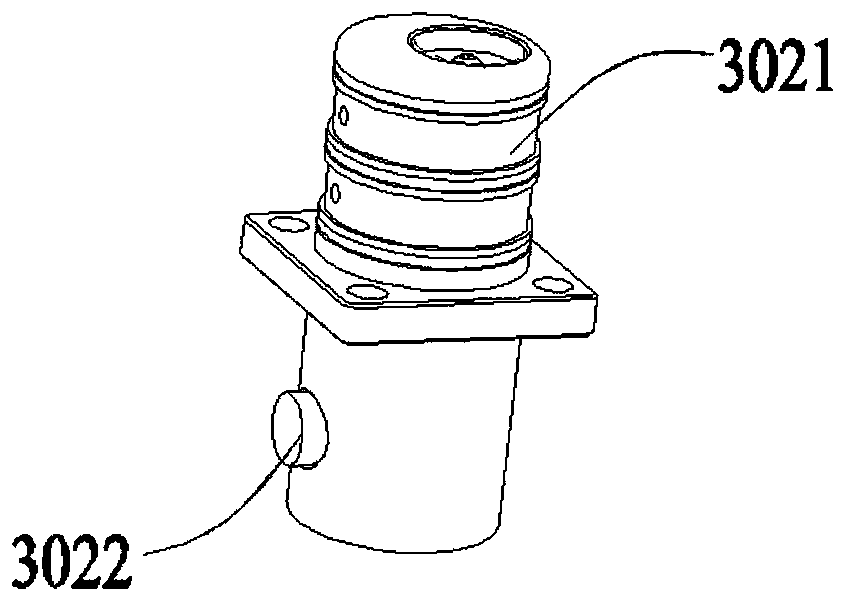

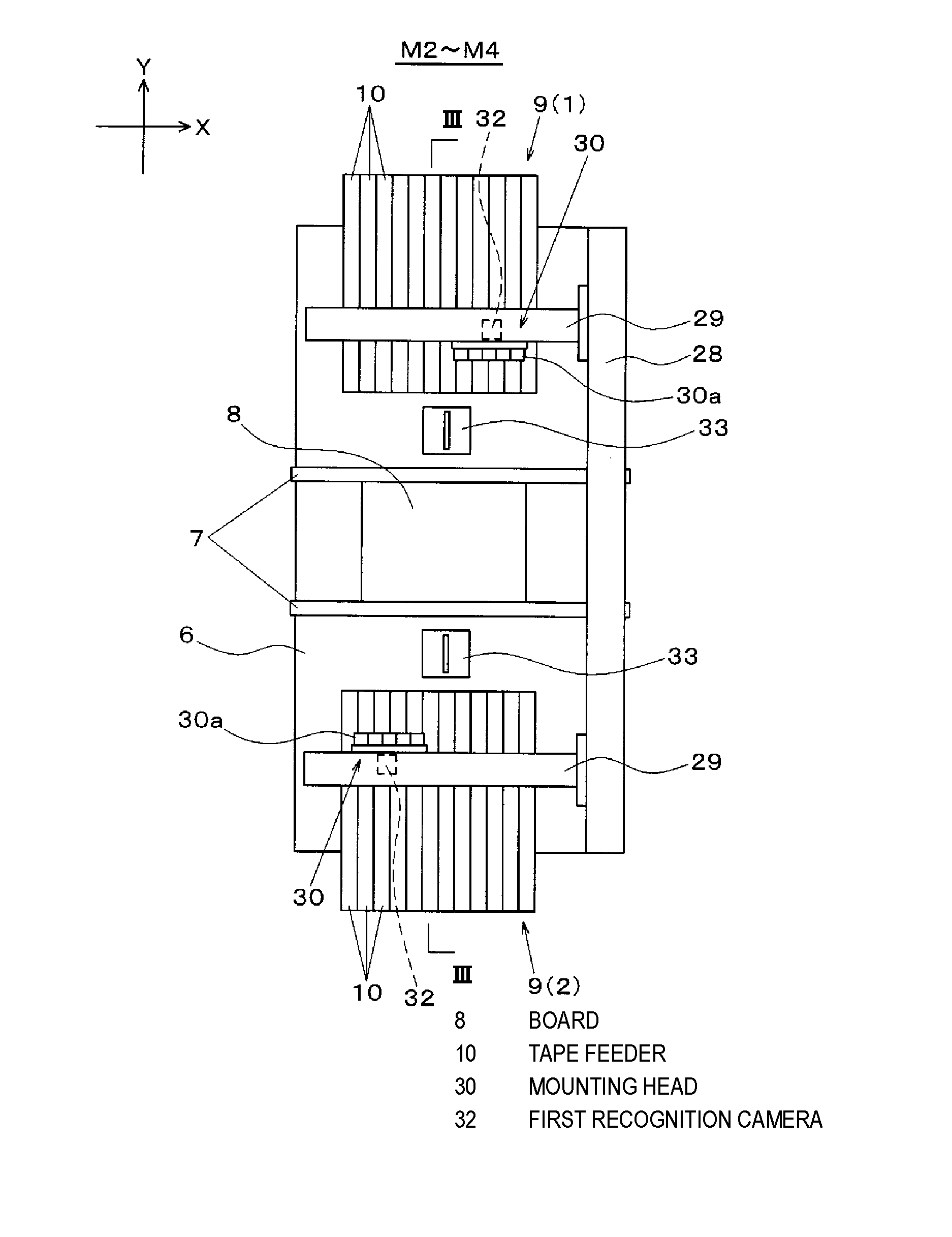

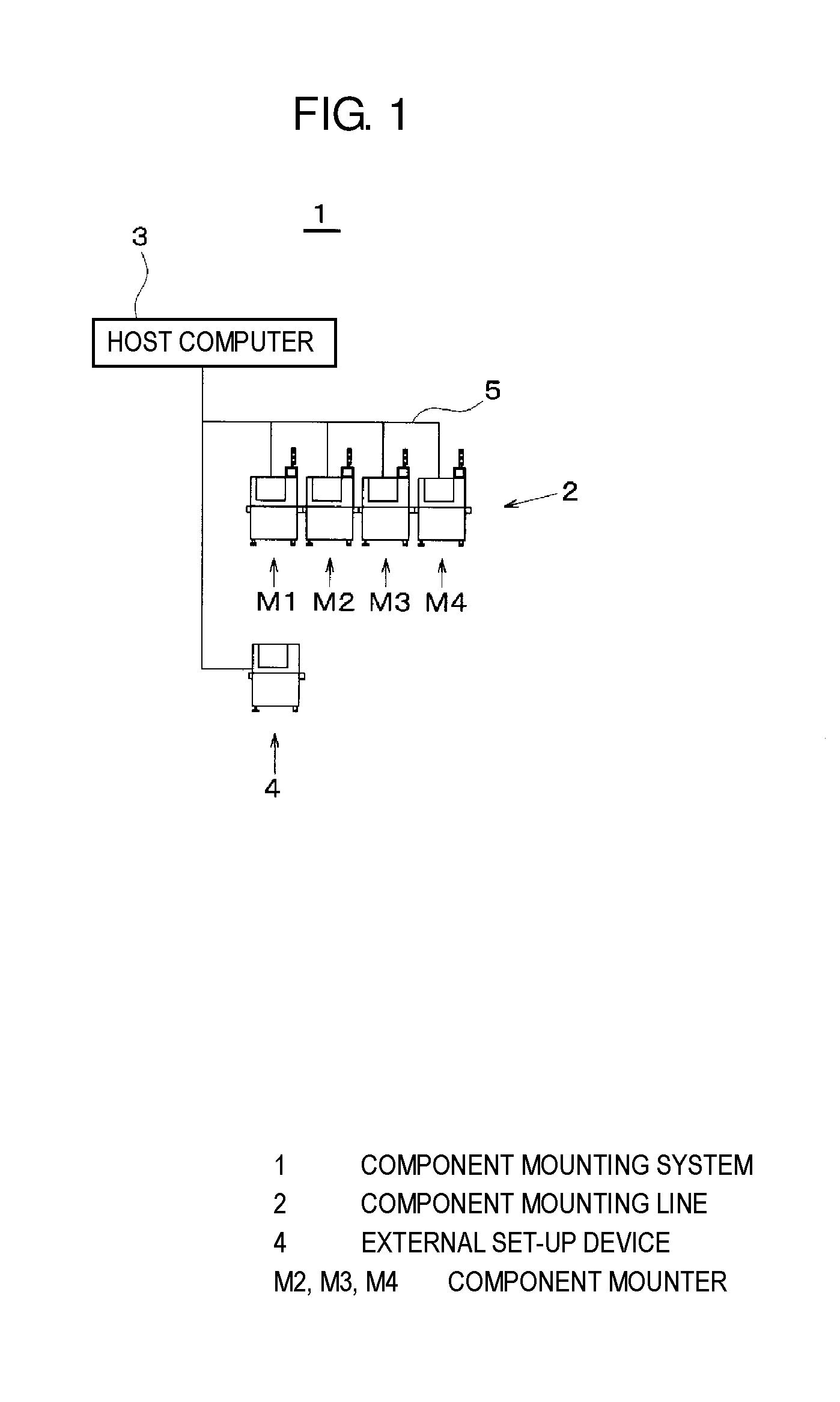

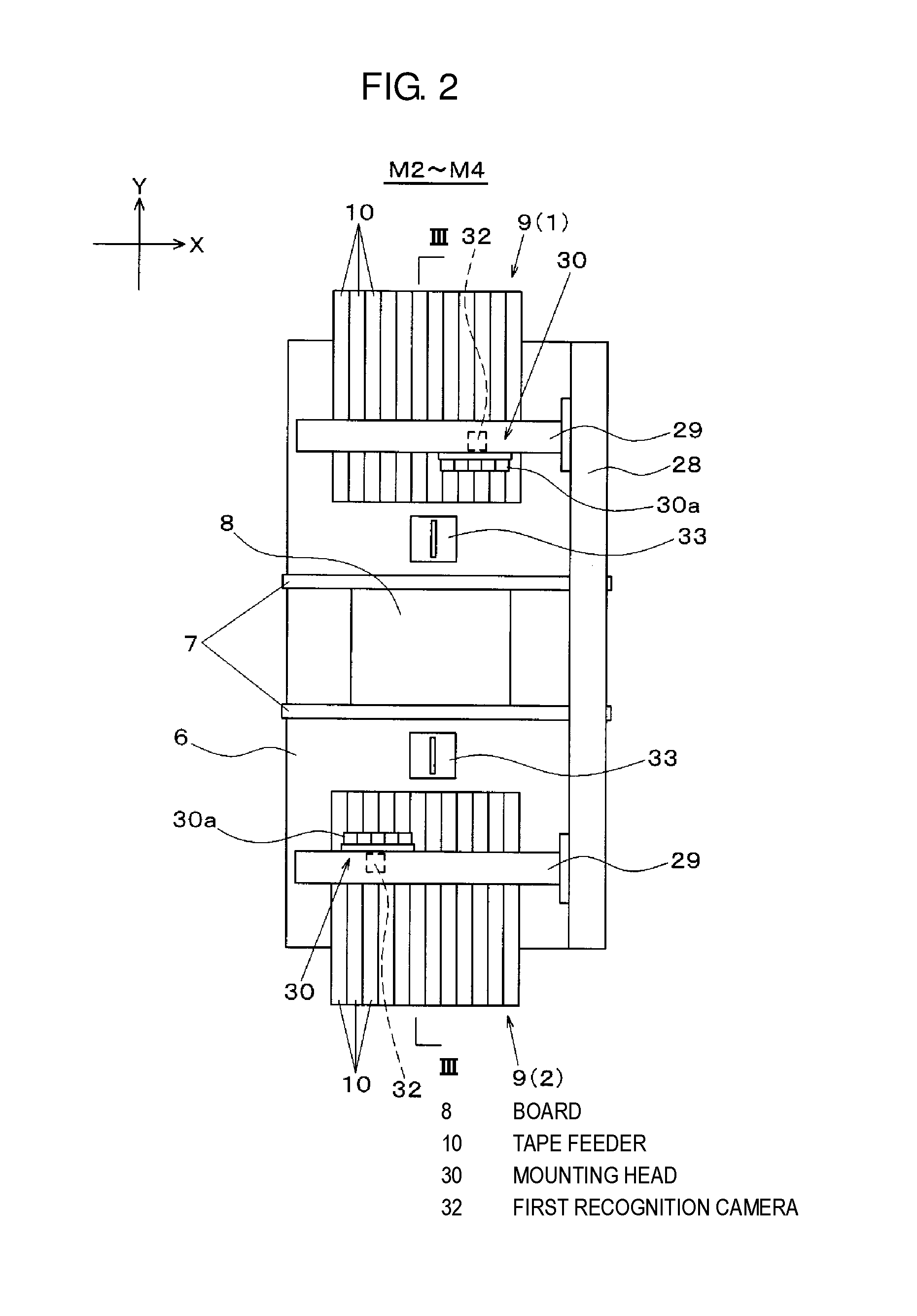

Component mounting system and component mounting method in component mounting system

ActiveUS20160366797A1Reduce die change timeAccurately determineElectrical componentsElectrical and Electronics engineeringEngineering

An external set-up device calculates a shift amount of a supply position of a component which is supplied by a tape feeder that is disposed on the carriage. The storage stores supply position shifting data in which the shift amount of the component supply position is related to a feeder address and a feeder ID. The component mounter compares the feeder ID of the tape feeder with the feeder ID included in the component supply position shifting data which is read from the storage, and, in a case in which the feeder IDs do not match, calculates the shift amount of the component supply position of the corresponding tape feeder and updates the supply position shifting data. The component mounter mounts the components onto a board based on the updated component supply position shifting data.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Die structure for producing race for large mine car wheel

ActiveCN104942198AReduce usageRealize ring rollingForging/hammering/pressing machinesEngineeringThermal treatment

The invention discloses a die structure for producing a rack for a large mine car wheel. The die structure comprises a core roller and a main die. A forge piece is arranged between the core roller and the main die, the middle of the core roller is a cylindrical section of a cylinder structure, an upper shoulder portion and a lower shoulder portion are arranged on the cylindrical section, and a groove is formed between the upper shoulder portion and the lower shoulder portion. The upper end face of the upper shoulder portion inclines downwards, the lower end face of the upper shoulder portion inclines upwards, the upper end face of the lower shoulder portion inclines downwards, and the side face of the lower shoulder portion inclines outwards from top to bottom. The side face of the main die is a vertical face. A holding roller device is further arranged, and a boss is arranged on the top of a holding roller. The die structure is used for machining the race forge piece for the large mine car wheel, consumption of materials is reduced, preparation is made for subsequent thermal treatment, and the quality and performance of products are guaranteed; two-station ring rolling is achieved, secondary remelting is avoided, and energy is saved.

Owner:WUXI LONGDI PRECISED FORGINGS

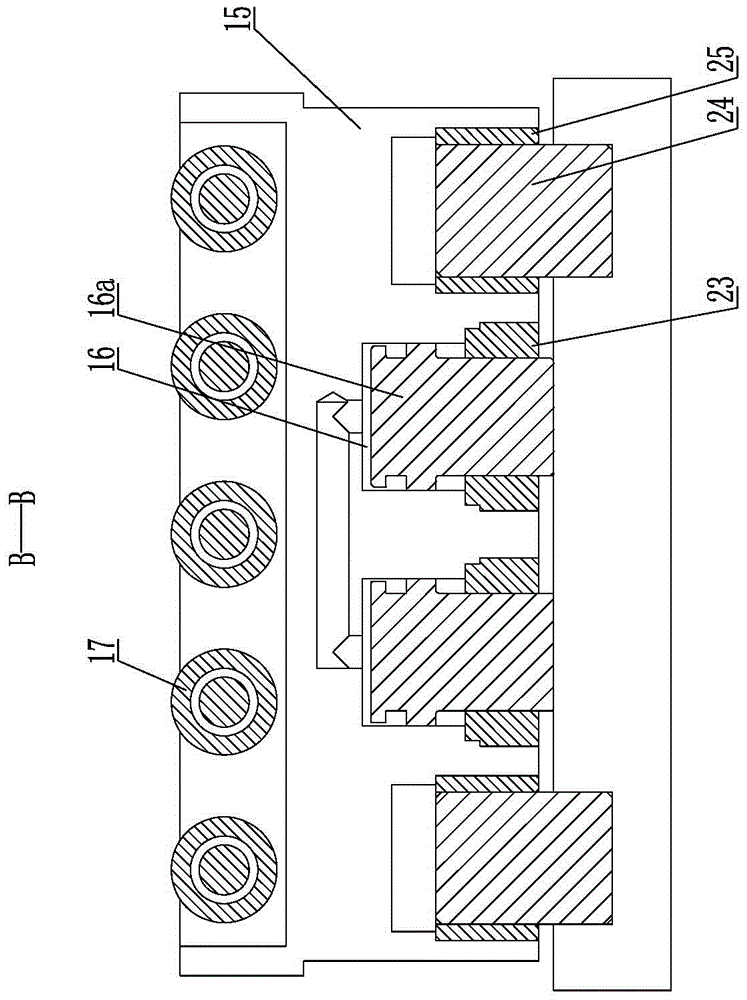

Lifting type die changing trolley and die changing method thereof

ActiveCN106475473ASmooth mold change processReduce die change timeShaping toolsMetal working apparatusElectrical controlEngineering

The invention discloses a lifting type die changing trolley and a die changing method thereof. The lifting type die changing trolley comprises a trolley body, the trolley body comprises a bearing face and a bottom frame; an electrical control system used for controlling the die changing process is arranged on the trolley body, the bearing face is connected with the bottom frame through a first lifting mechanism, mounting bases are arranged at the two ends of the trolley body, second lifting mechanisms are connected between the mounting bases and the trolley body, die moving arms are arranged on the mounting bases, horizontal moving mechanisms are connected between the die moving arms and the mounting bases, the cross sections of the die moving arms are in L shapes, and shoulder steps matched with the die moving arms are arranged on the two sides of a die; compared with the prior art, the trolley has the beneficial effects that the die is lifted up through the lifting mechanisms, and is moved to the trolley through the horizontal moving mechanisms, in the whole process, no friction exists between the bottom face of the die and a work table and exists between the bottom face of the die and the trolley, the die changing process is stable, the die changing time is shortened, and the die changing efficiency is improved.

Owner:JIANGSU ZHISHI TECH CO LTD

Quick hoisting type mold changing trolley and mold changing method thereof

ActiveCN106391881ASmooth mold change processReduce die change timeShaping toolsBearing surfaceElectrical control

The invention discloses a quick hoisting type mold changing trolley and a mold changing method thereof. The quick hoisting type mold changing trolley comprises a trolley body, wherein the trolley body comprises a bearing surface and an underbed; the trolley body is provided with an electrical control system for controlling a mold changing process; mounting seats are arranged at two ends of the trolley body; a lifting mechanism is connected between each mounting seat and the trolley body; each mounting seat is arranged in a separate manner, and comprises an upper part and a lower part; a first horizontal translation mechanism is connected between each upper part and the corresponding lower part; each upper part is provided with a mold shifting arm; and a second horizontal translation mechanism is connected between each mold shifting arm and the corresponding upper part. Compared with the prior art, the quick hoisting type mold changing trolley has the beneficial effects that a mold is lifted up through the lifting mechanisms at first, and then moves to the trolley through the translation mechanisms, in a whole process, the bottom surface of the mold does not rub a working table and the trolley, the mold changing process is stable, mold changing time is saved, and mold changing efficiency is improved.

Owner:JIANGSU ZHISHI TECH CO LTD

Injection mould capable of being easily de-molded

The invention discloses an injection mould capable of being easily de-molded. The injection mould is formed by a movable mould and a fixed mould, which are used as the injection mould, wherein each one of the movable mould and the fixed mould comprises a molding part, a pushing-out mechanism, a mould guide part and a pouring system; a mould cavity is arranged in the mould; the mould cavity is arranged on the mould closing face of the single injection mould, namely, the mould cavity is arranged on the mould closing face of the movable mould or the mould closing face of the fixed mould; the mould closing face of the other injection mould has no mould cavity and is a plane; the movable mould and the fixed mould are closed to form the complete injection mould cavity. According to the injection mould disclosed by the invention, the structure of only arranging the mould cavity on the single injection mould is applicable to injection of a standard test sample strip or an injection piece with the similar shape. The injection mould has the beneficial effects of being beneficial to simplification of the structure of the mould, improving the manufacturability of the mould and reducing the cost of the mould.

Owner:广州现代塑料有限公司

Bridge vehicle top cover die

The invention relates to vehicle production equipment, in particular to a bridge vehicle top cover die comprising an upper die seat, a skylight punch and a pressure plate. The upper die seat is provided with a movable push plate and a switching cylinder driving the movable push plate to move horizontally; the skylight punch is connected onto the upper die seat in a lifting manner, the movable push plate is located between the upper die seat and the skylight punch, the lower surface of the movable push plate is provided with a first ejecting projection, the upper end face of the skylight punch is provided with a second ejecting projection matching with the first ejecting projection, the skylight punch is provided with a first air spring extending vertically, the first air spring is connected to the pressure plate, the lower surface of the pressure plate is provided with a rubber layer, and the skylight punch penetrates the pressure plate. The bridge vehicle top cover die is capable of meeting the requirements of producing top covers with skylight and without skylight, and the defects that the top covers with skylight and without skylight of vehicles in the same specification is produced through two sets of dies is solved.

Owner:泰州英格伟精密机械有限公司

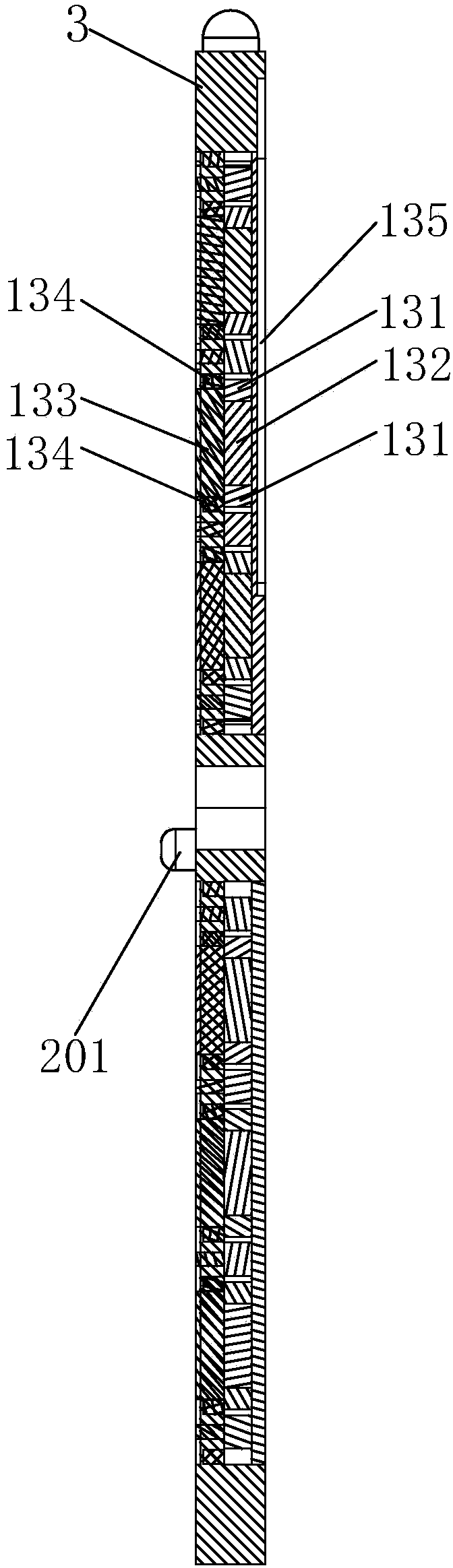

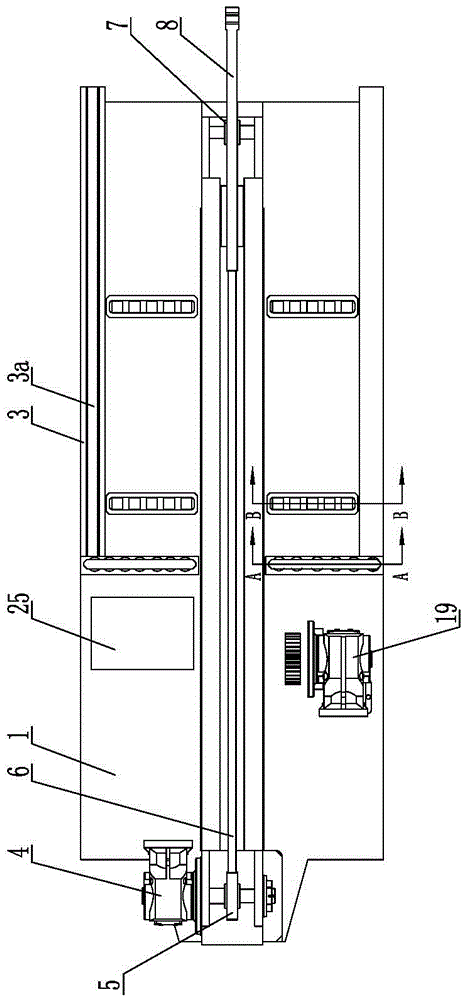

Coil inserting die for coil inserting machine

InactiveCN104467317AEasy to replaceReduce die change timeManufacturing dynamo-electric machinesModular designEngineering

The invention discloses a coil inserting die for a coil inserting machine. The coil inserting die for the coil inserting machine comprises a tank, a push rod sleeve and a pull rod; a dabber is arranged in the center of the tank; a material warehouse is arranged on the dabber in the mode of being capable of rotating around the dabber; the material warehouse is arranged in an internal cavity of the tank; the dabber is hollow; one end of the push rod sleeve is inserted into the dabber and connected with one end of the pull rod through a push rod sleeve nut; the other end of the pull rod is connected with a copper push head; a coil distribution needle is arranged on the outer end face of the copper push head; the other end of the push rod sleeve is provided with a push rod base; multiple paper pushing rods are horizontally arranged along the external circumference of the push rod base; through holes corresponding to the paper push rods are formed in the tank with the dabber as the center, so that the paper push rods pass through the corresponding through holes and bring out and insert insulation paper in the material warehouse into a winding groove of a motor stator. By the adoption of the modular design, replacement is convenient, the die replacement time is shortened, and the use efficiency of equipment is improved.

Owner:NIDE MECHANICAL EQUIP

Quick installation method of riveting-pressing die

InactiveCN104772397AEasy to install and replace moldsReduce die change timeShaping toolsTool steelMagnet

The invention relates to a quick installation method of a riveting-pressing die; the structure of the traditional riveting-pressing die is changed and the original integrated structure of the riveting-pressing die is divided into a die fixed punch and a sleeve, wherein the sleeve is arranged on the periphery of the die fixed punch in a sleeving manner and is provided with a die working face, and the riveting-pressing die does not need to be fixed through screws. A quick installation device of the riveting-pressing die comprises an upper die fixed base of a riveting press, an upper die fixed punch, an upper die sleeve, an upper die magnet, an upper die working face, a lower die working face, a lower die sleeve, a lower die magnet, a lower die fixed punch and a lower die fixed base of the riveting press; during use, the upper die sleeve and the lower die sleeve are arranged in the fixed punches respectively through magnetic force in a sleeving manner, and accordingly quick replacement and installation of an upper die and a lower die achieved. The quick installation device of the riveting-pressing die has the advantages of replacing the traditional die structure with the sleeve structure, having a small size, saving massive tool steel and being simple in structure, convenient to manufacture, easy to maintain and fast and convenient to operate.

Owner:上海惠亚电子有限公司

Quick change device for female die

InactiveCN103008457AReduce die change timeOvercoming installation gapsShaping toolsCushionEngineering

The invention discloses a quick change device for a female die. The quick change device mainly comprises a die holder, a female die fixing seat, the female die and a female die cushion, wherein a spiral sleeve is further arranged between the female die cushion and the inner wall of the female die fixing seat, a track groove and an insertion hole are formed in the cylinder wall of the spiral sleeve, a pin hole is formed in the wall of the female die cushion, a handle slot and a sliding pin position-limiting groove are formed in the wall of the female die fixing seat, the track groove, the pin hole and the sliding pin position-limiting groove are connected through a sliding pin, and a handle penetrates the handle slot and is arranged into the insertion hole. The quick change device disclosed by the invention has the beneficial effects that the female die cushion can directly eject the female die out of the female die fixing seat by rotating the spiral sleeve through the handle, so that the die change time is greatly shortened; and simultaneously, the die change action does not involve the position relation between the female die fixing seat and other blanking parts, so as to overcome a larger mounting gap required for the common quick change structure, realize the same precise positioning with the fixed female die, eliminate the need of re-aligning the positions of an upper die and a lower die after die change and greatly facilitate multi-step stamping operation.

Owner:FUJIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com