Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Easy to change mold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

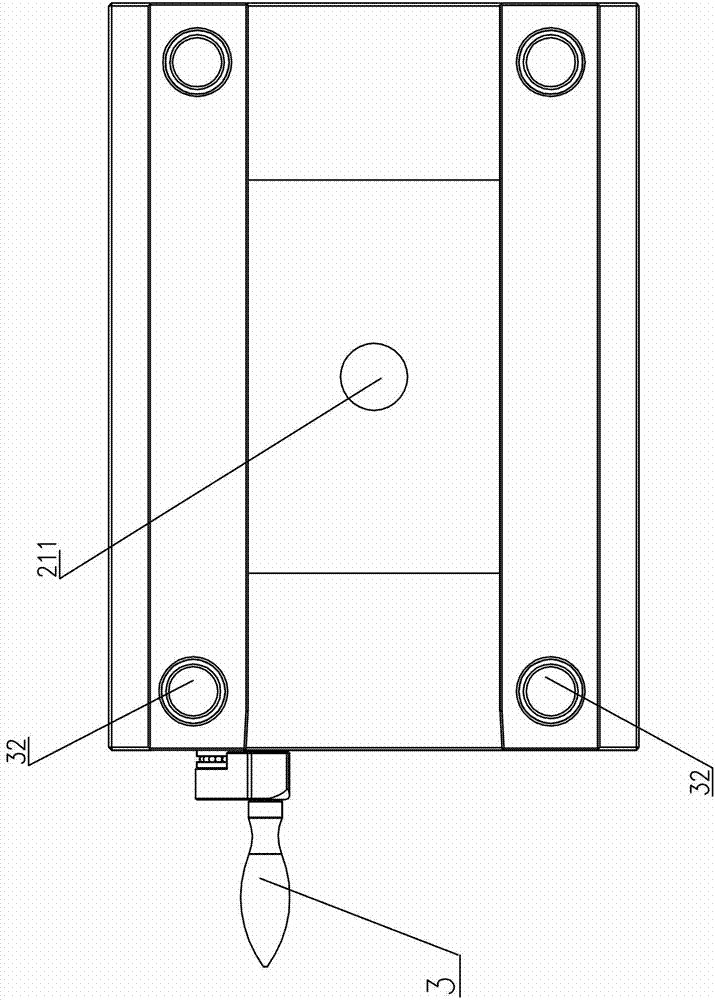

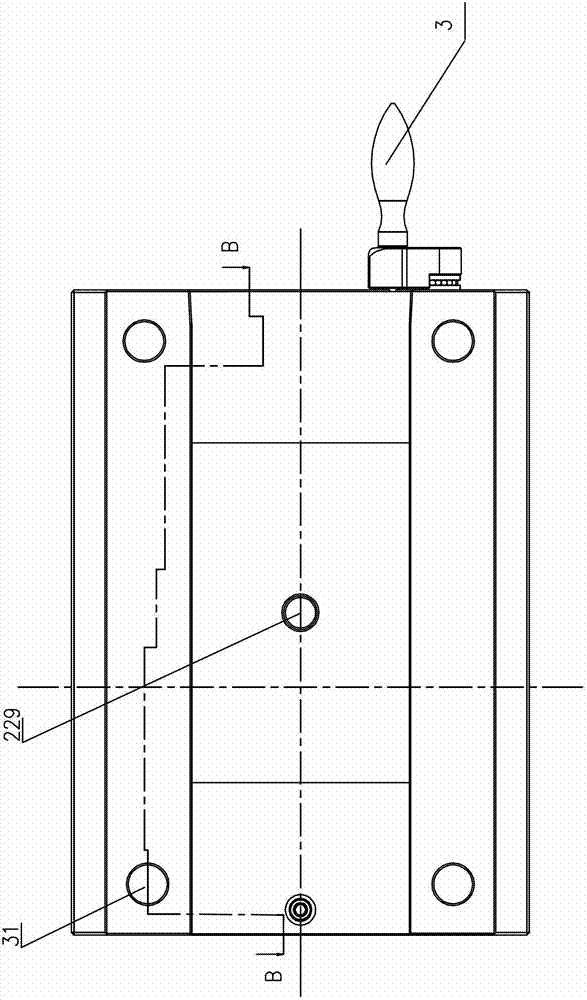

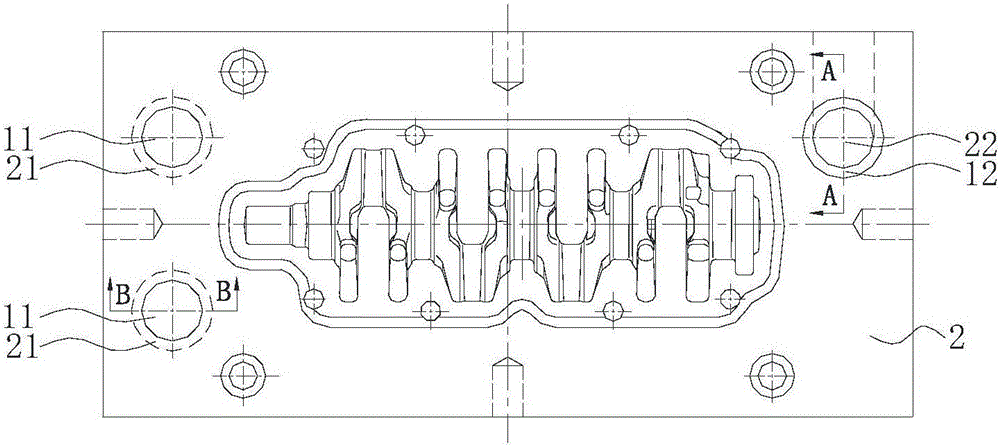

Injection mould with rapidly-replaced mould cores

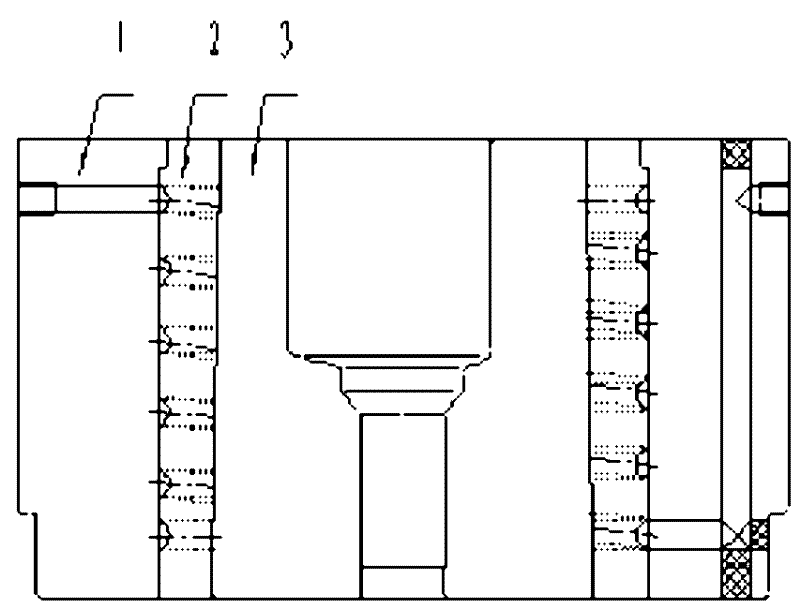

The invention discloses an injection mould with rapidly-replaced mould cores. The injection mould is composed of a movable mould and a stationary mould, wherein a main body of the movable mould is composed of a movable mould base and a movable mould core movably arranged on the movable mould base; a main body of the stationary mould is composed of a stationary mould base and a stationary mould core movably arranged on the stationary mould base; the butt joint faces of the movable mould base and the stationary mould base are respectively provided with a mould core mounting sliding chute which horizontally extends from front to back; at least the front ends of the mould core mounting sliding chutes are provided with plug-in mounting holes for mounting or dismounting the mould cores; the mould cores are provided with tracks matched with the mould core mounting sliding chutes so as to move along the mould core mounting sliding chutes; and the mould cores are inserted to or dismounted from the mould core mounting sliding chutes on the mould bases through the plug-in mounting holes, thus the mould cores are replaced. According to the invention, only one set of mould base needs to be manufactured to be matched with the mould cores of different cavities which are manufactured according to spline standards tested based on different performance indexes; the mould replacing operation is easier and more convenient than that of the prior art, so that the mould replacing time is greatly shortened; and the manufacturing cost of various test spline moulds can also be greatly reduced.

Owner:广州现代塑料有限公司

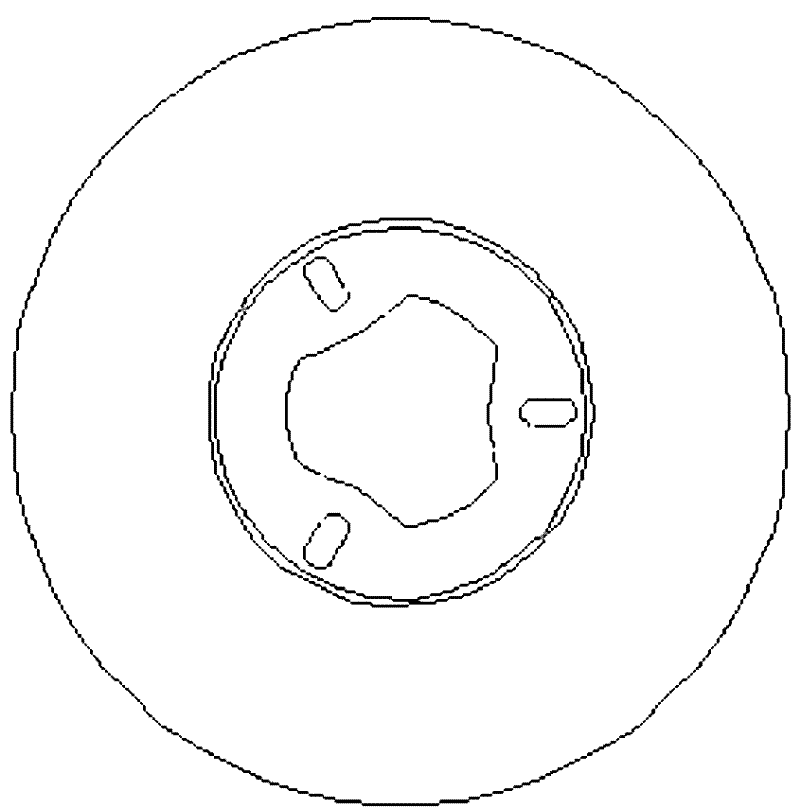

Method for processing integral concave mould of universal joint

The invention discloses a method for processing an integral concave mould of a universal joint. The method comprises the following steps: (1) processing an external mould: sawing materials, roughly turning a big circle and a middle circle of the external mould, thermally treating, finely turning and grinding before pressing, thermally pressing the big circle and the middle circle, finely turning an inner hole and grinding the inner hole; (2) processing an internal mould: sawing materials, roughly turning, thermally treating, finely turning, flatly grinding, roughly milling an inner chamber and finely milling the inner chamber; and (3) cold-pressing the processed external mould and internal mould, wherein 0.3-0.5% interference fit of the outer diameter of the internal mould is adopted between the internal and external moulds, thereby obtaining the integral concave mould of the universal joint. The invention discloses a new method for processing the integral concave mould of the universal joint. The integral concave mould of the universal joint processed according to the method is high in size precision, has convenience in assembling and exchanging and has a positive practical significance.

Owner:JIANGSU SUNWAY PRECISION FORGING

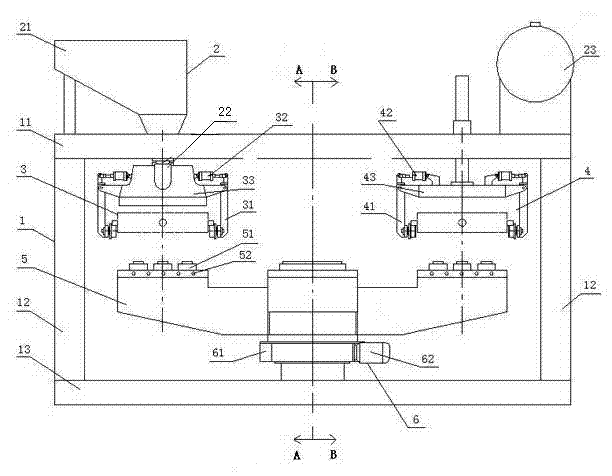

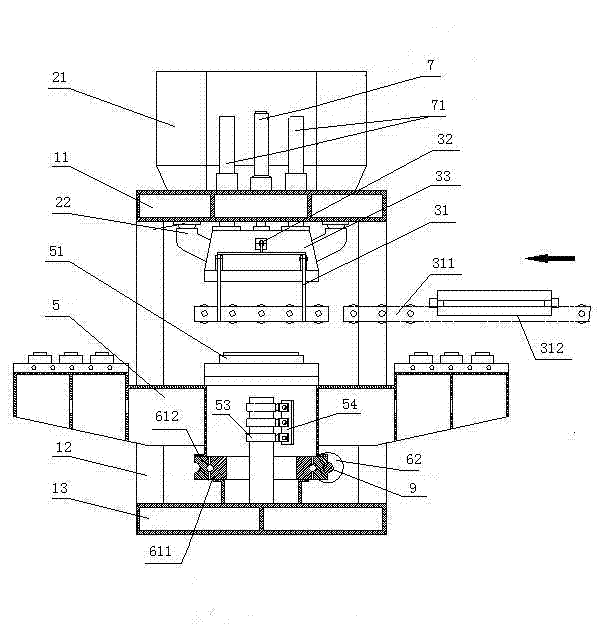

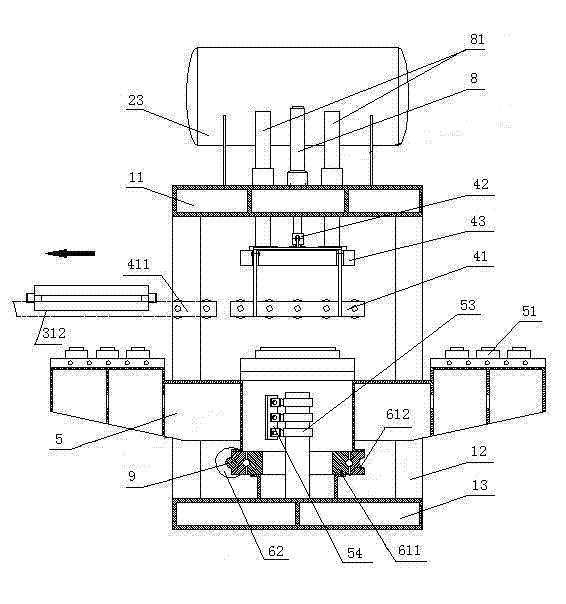

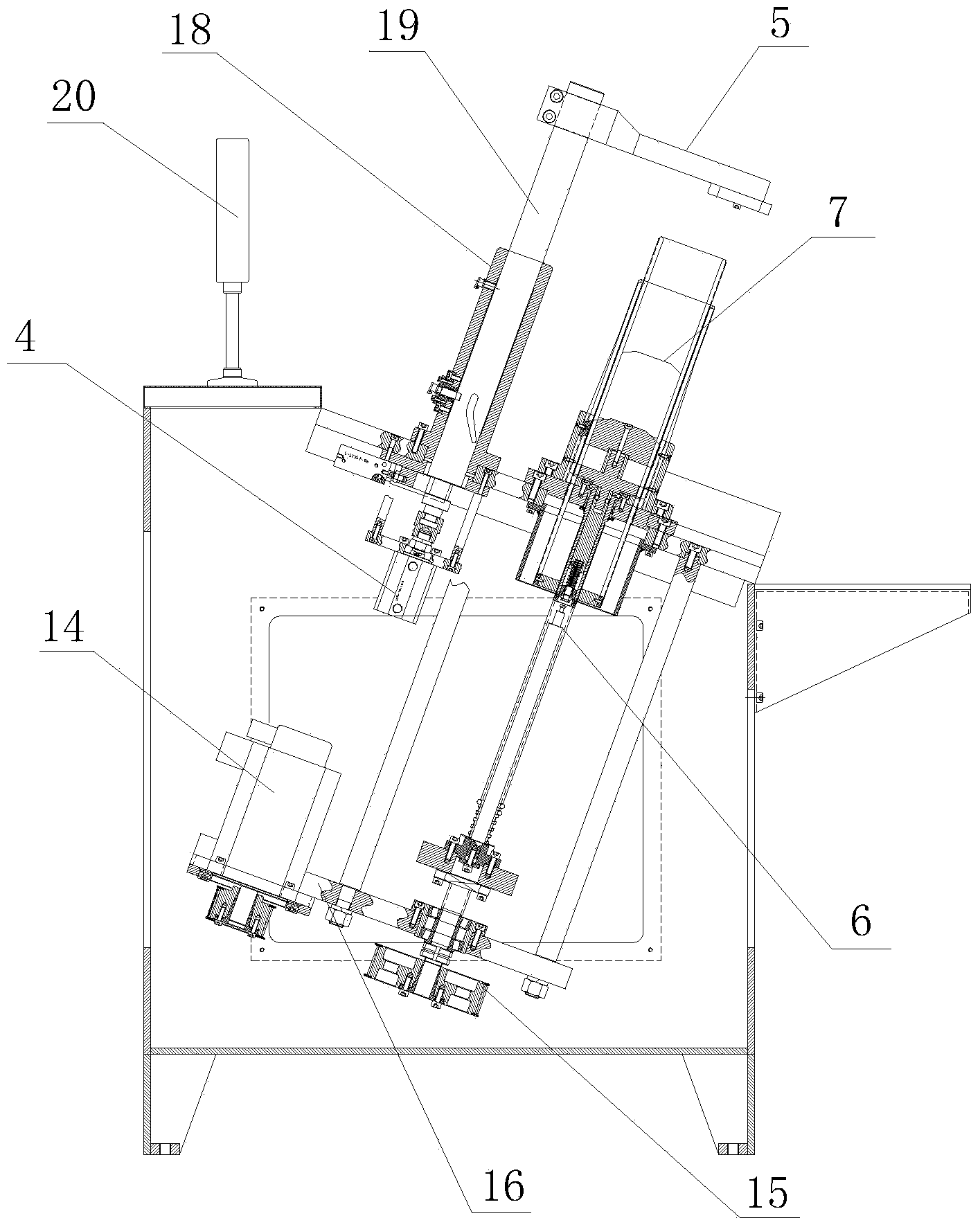

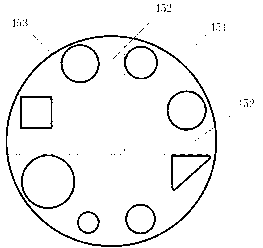

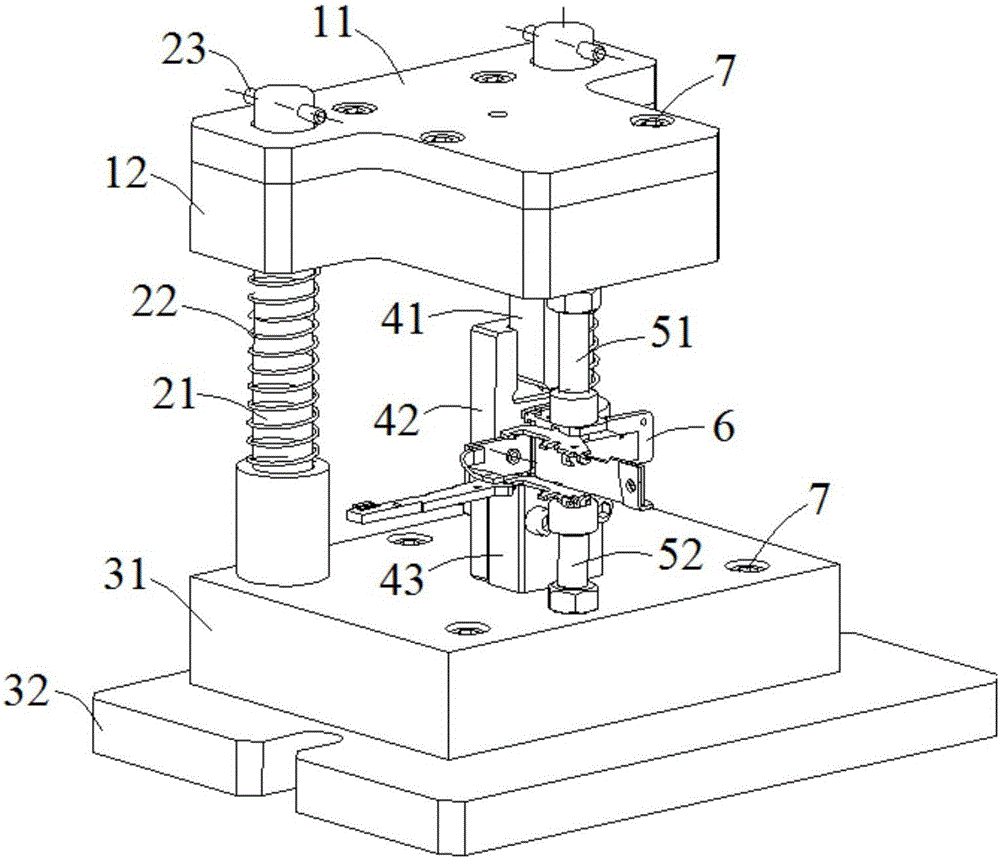

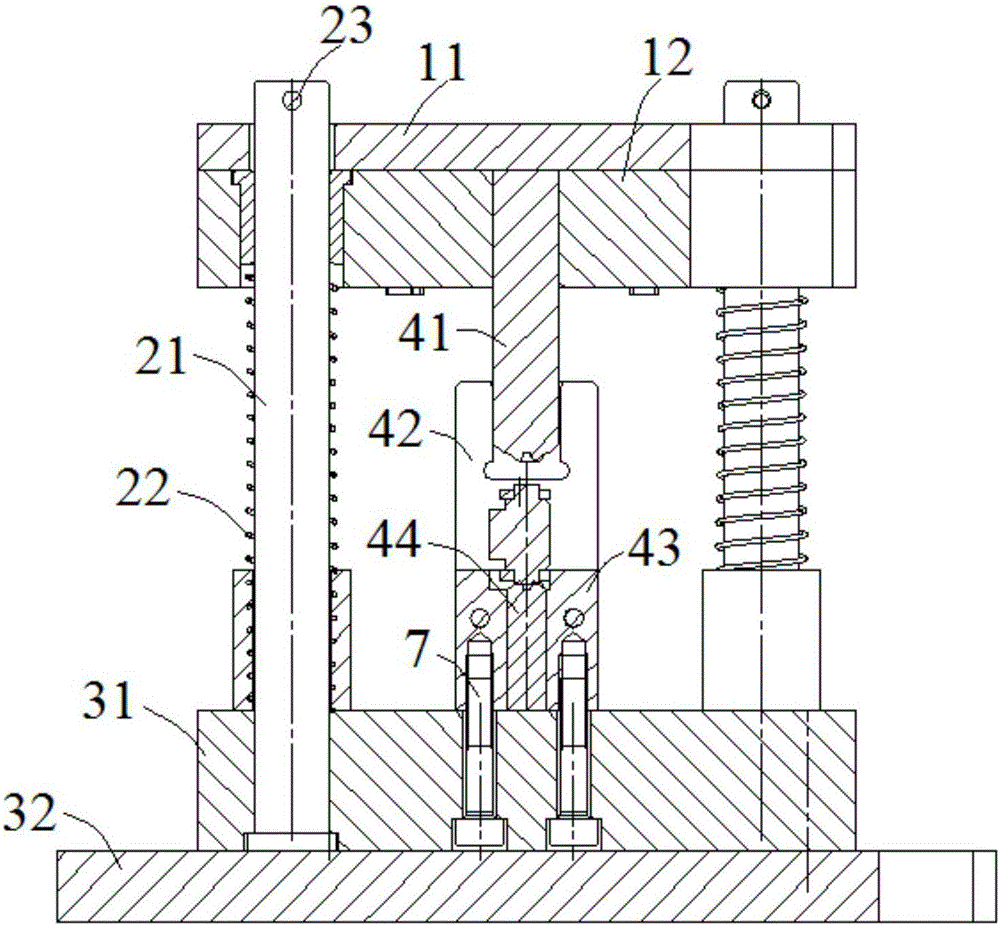

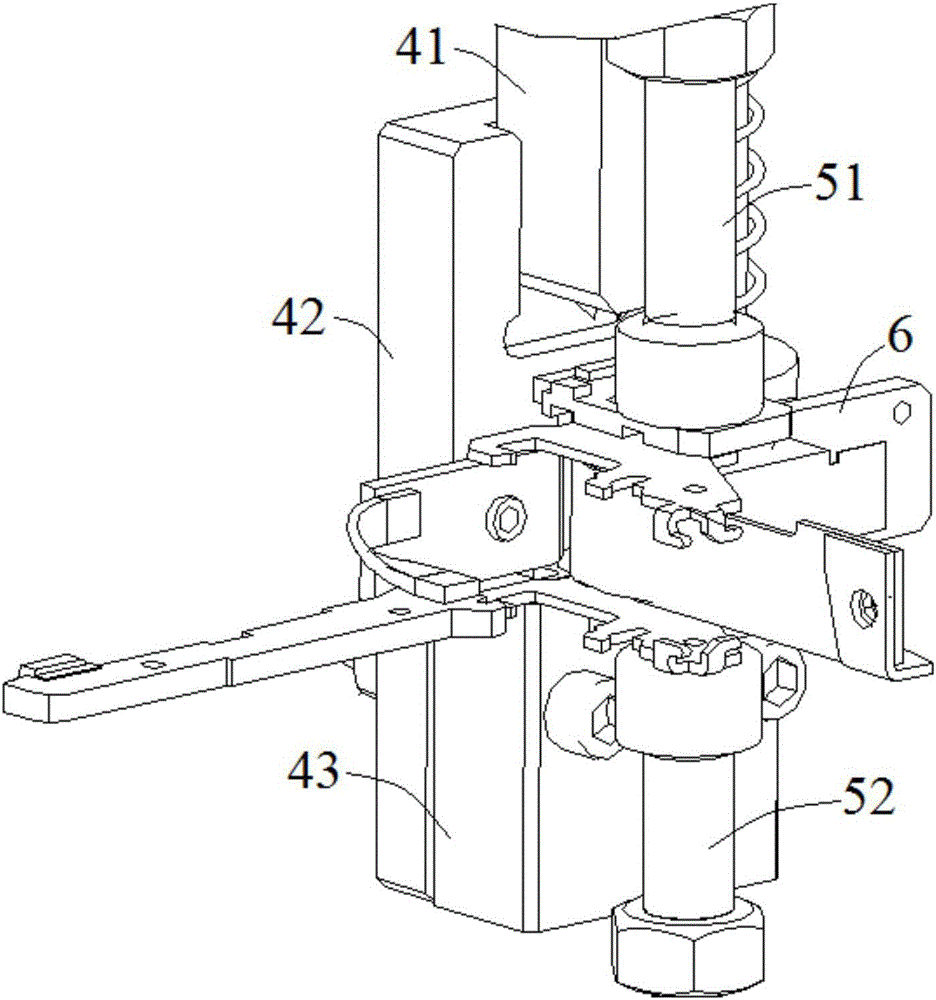

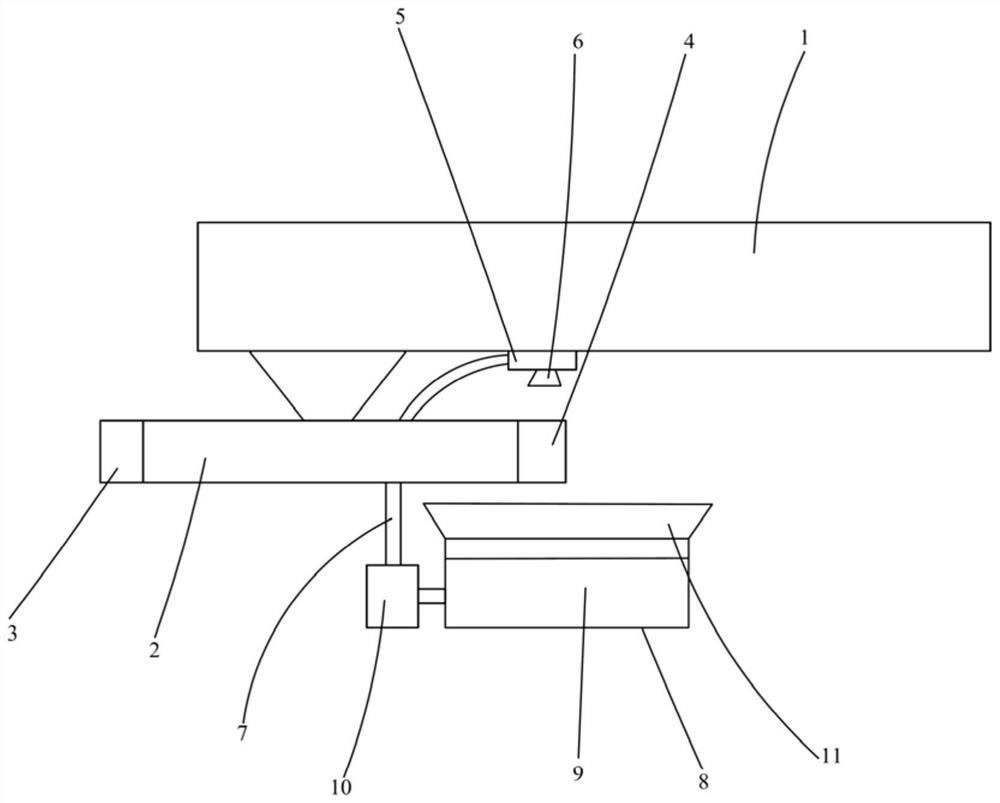

Equipment and method for improving sand lined casting efficiency

ActiveCN103203434AImprove efficiencyReasonable structural designMoulding machinesIndustrial engineeringCasting

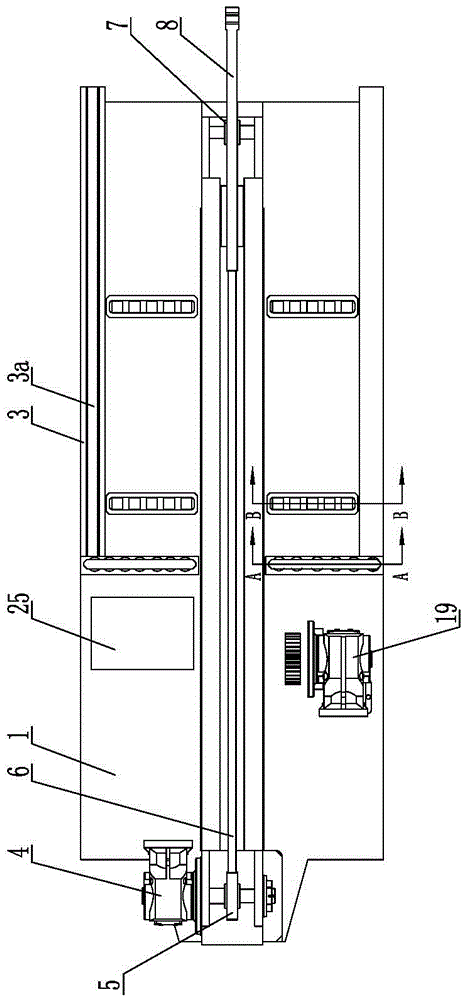

The invention relates to equipment and a method for improving sand lined casting efficiency, and belongs to the technical field of iron sand lined casting. The equipment comprises a supporting frame composed of an upper beam, a base and a vertical pillar between the upper beam and the base, a sand adding and jetting device, and a rotating mechanism arranged on the base. The equipment is characterized by further comprising a four-station working platform, a lifting type sand jetting head and a lifting type roller bed opening and closing mechanism, wherein the four-station working platform is fixed on the rotating mechanism; the lifting type sand jetting head is connected at one side of the upper beam, and the lifting type roller bed opening and closing mechanism is connected at the other side; the lifting type sand jetting head and the lifting type roller bed opening and closing mechanism are respectively arranged on left and right sides; and the four-station working platform is arranged below the lifting type sand jetting head and the lifting type roller bed opening and closing mechanism. The equipment disclosed by the invention is reasonable in structure and design, convenient to clean mold, high in sand lined casting efficiency and convenient for users to operate.

Owner:浙江省机电设计研究院有限公司

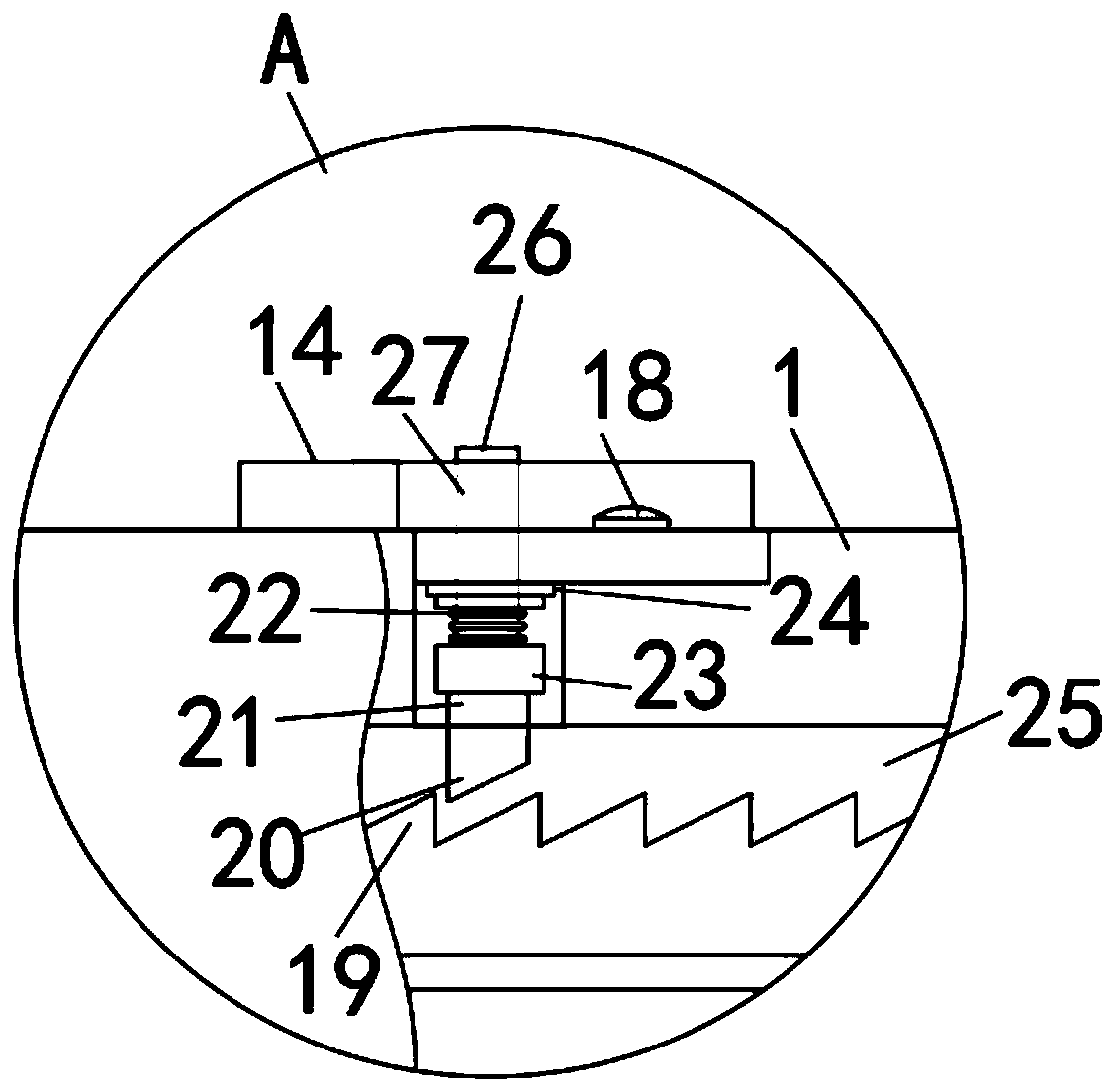

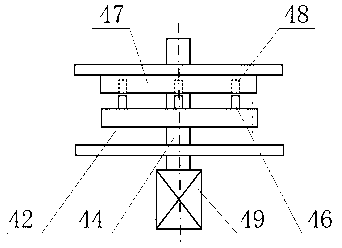

Upper die clamp-type hydraulic clamping device of bending machine

The invention relates to improvement for upper die clamping devices of bending machines, in particular to an upper die clamp-type hydraulic clamping device of a bending machine. The upper die clamp-type hydraulic clamping device of the bending machine comprises a driving sliding block and a plunger hydraulic oil cylinder. The upper die clamp-type hydraulic clamping device of the bending machine is characterized in that the plunger hydraulic oil cylinder is arranged in a mounting hole in a mounting plate of the driving sliding block, a press plate is arranged on one side, located on a cylinder body of the plunger hydraulic oil cylinder, of the mounting plate, a clamping plate is arranged on the other side, located on a piston rod of the plunger hydraulic oil cylinder, of the mounting plate through ball screws, a clamping groove is formed in the lower portion of the clamping plate, and a tensioning mechanism is arranged in the clamping groove of the clamping plate. The upper die clamp-type hydraulic clamping device of the bending machine solves the problems that the upper die clamping device of the existing bending machine is low in die change operation efficiency, the labor intensity of operation personnel is large, upper die locating accuracy is poor, and the service life of a hydraulic oil cylinder is short. The upper die clamp-type hydraulic clamping device of the bending machine is mainly used for the improvement of the upper die clamping devices of the existing bending machines.

Owner:HUANGSHI HUAXIN MACHINERY EQUIP

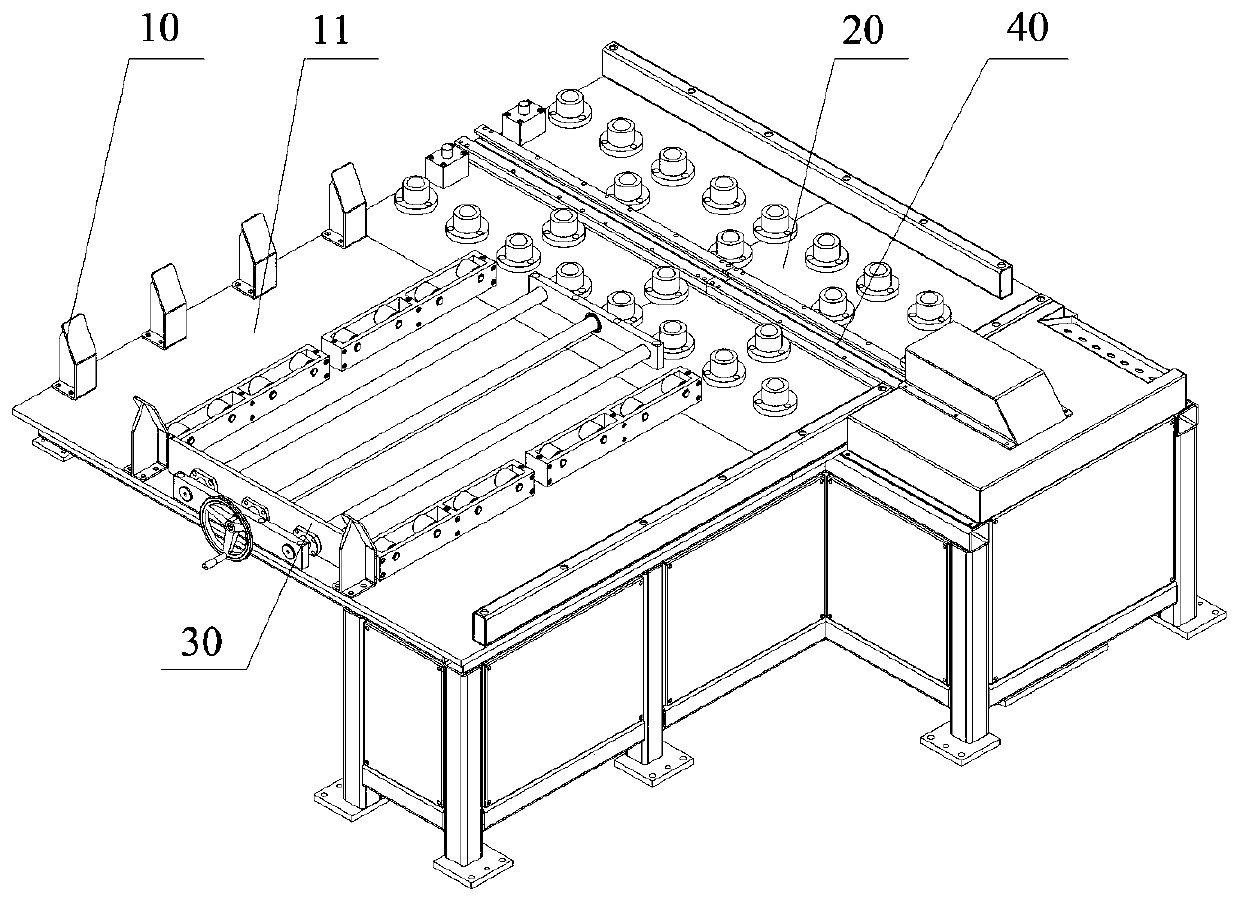

Die changing trolley of press machine and die changing method

The invention discloses a die changing trolley of a press machine in the field of press machines. The die changing trolley comprises a trolley body; the bottom of the trolley body is provided with wheels, the trolley body is provided with a driving mechanism, a pair of die carrier guide rails and a die carrier pushing-pulling mechanism, the die carrier pushing-pulling mechanism comprises a pushing-pulling motor, the output end of the pushing-pulling motor is provided with a belt pulley I, and the belt pulley I is connected with a belt pulley II in a driving way through a belt to which a sliding pothook is connected; the lower part of a die carrier is provided with double rows of die carrier rollers, the trolley body is provided with a die carrier limiting mechanism comprising a base plate, the base plate is provided with a slide wheel axle which is rotatably connected with a side wheel, and the upper end of the side wheel axle is provided with a pressing plate; and the trolley body is provided with a die carrier lifting mechanism in parallel, the die carrier lifting mechanism comprises a roller carrier controlled by a hydraulic cylinder to lift, horizontal rollers are horizontally arranged on the roller carrier, and roller shafts of the horizontal rollers are parallel to the die carrier guide rails. By using the die changing trolley, the die carrier of the press machine can be rapidly changed, the die changing time can be shortened, and the die changing efficiency can be increased.

Owner:YANGLI GRP CORP LTD

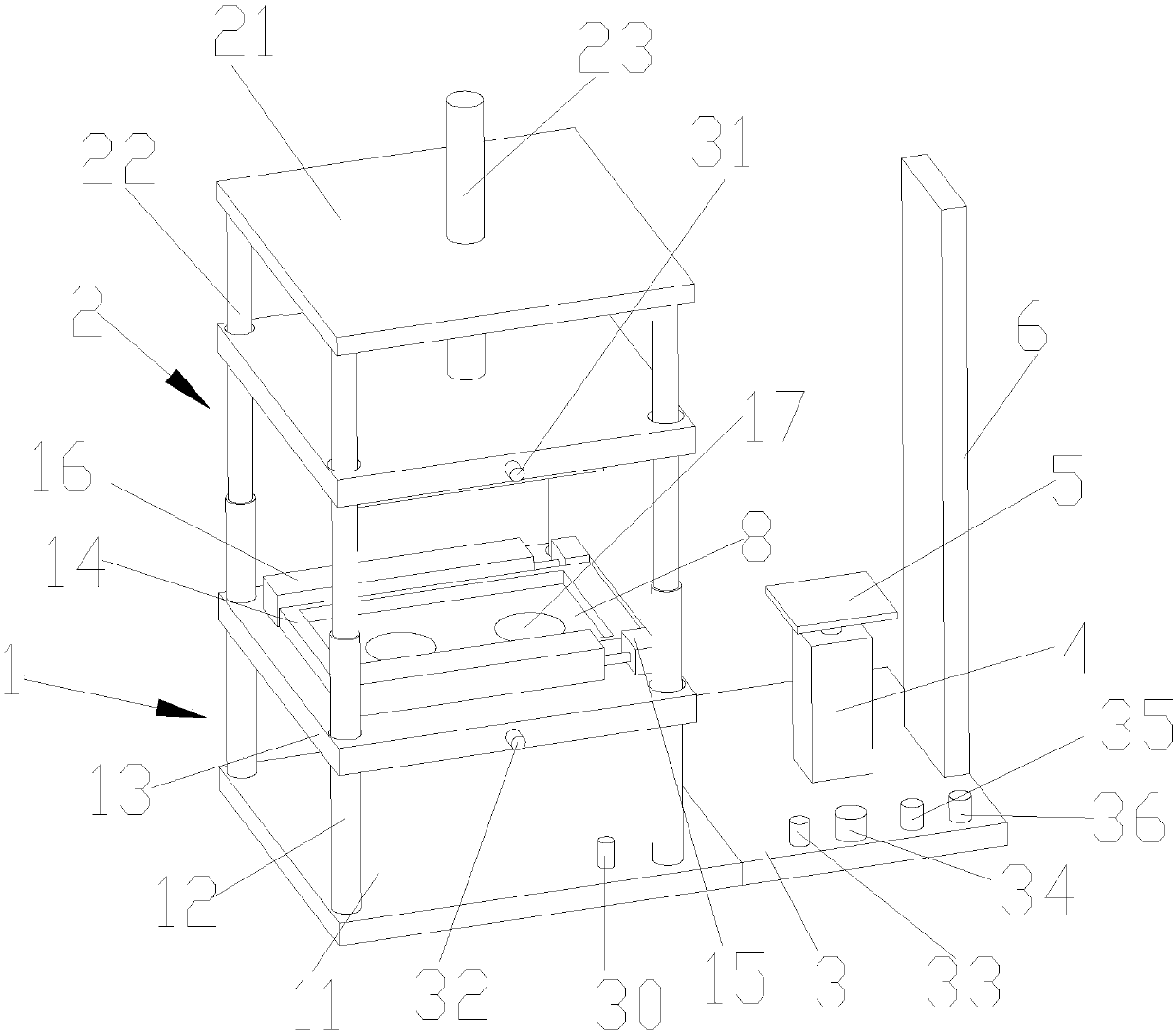

Adjusting mould for fixing to-be-assembled barrel boxes

PendingCN109094111AShorten the timeRealize assembly workPaper-makingBox making operationsEngineeringMechanical engineering

The invention relates to the technical field of processing and packaging equipment, in particular to an adjusting mould for fixing to-be-assembled barrel boxes. The adjusting mould comprises a positioning device, longitudinal adjusting devices, transverse adjusting devices, a longitudinal telescopic device, a transverse telescopic device and a limiting forming device, wherein the end portions of the longitudinal adjusting devices and the transverse adjusting devices can be movably arranged on the positioning device, the longitudinal telescopic device is arranged between the longitudinal adjusting devices in a vertical state, the transverse telescopic device is arranged between the transverse adjusting devices in a horizontal state, one end of the limiting forming device can be slidably arranged on the longitudinal adjusting devices and the transverse adjusting devices, and a material suction device is arranged at the end, far away from the positioning device, of the limiting forming device. According to the adjusting mould for fixing the to-be-assembled barrel boxes, assembly operation of different assembling packaging boxes is realized, the mould can be adjusted by screw rods leftand right and up and down, the time and the cost are saved for customers, and mould changing is more convenient and faster.

Owner:亚晟(东莞)自动化设备科技有限公司

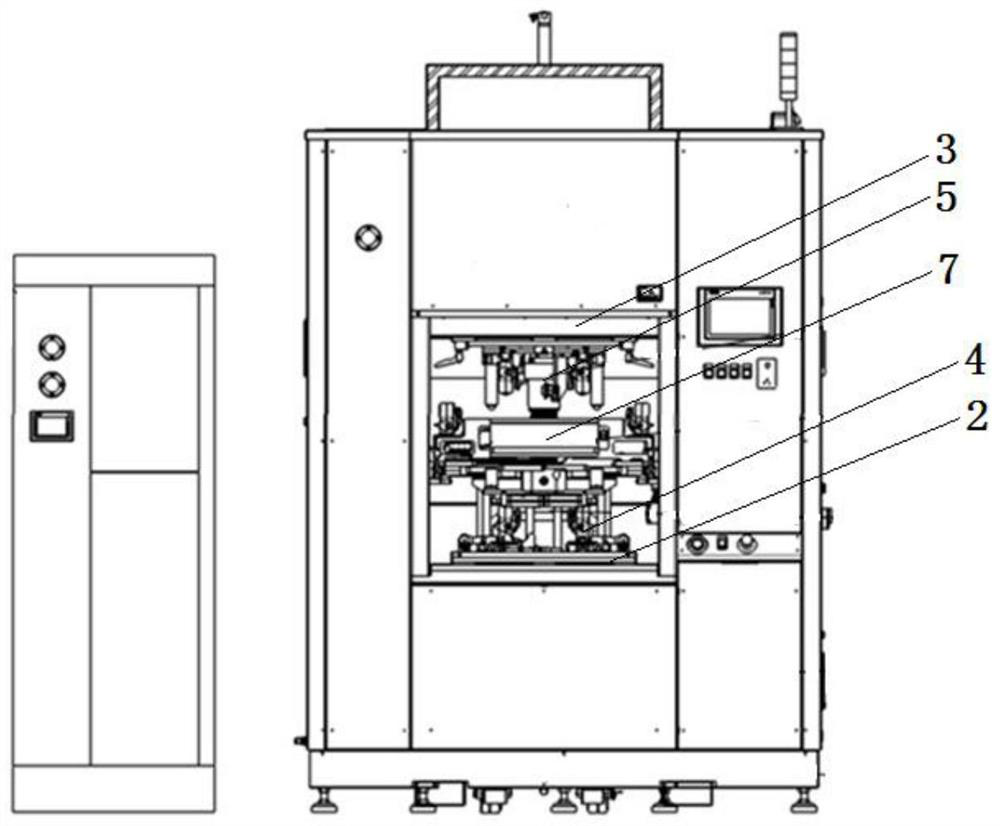

Hot-gas welding plastic welding equipment and welding method

The invention provides hot-gas welding plastic welding equipment and a welding method. The equipment comprises a base, on which a first frame, a second frame, a third frame and a fourth frame are arranged, wherein a lower slide table and an upper slide table are arranged on the first frame and the second frame, the upper end of the lower slide table is provided with an upper mold clamp, the lowerend of the upper slide table is provided with a lower mold clamp, the third frame and the fourth frame are provided with a middle slide table used to occupy or avoid space positions among the lower slide table and the upper slide table and the lower slide table, and a nitrogen heating middle mold is arranged on the middle slide table. When welding with hot gas welding plastic welding equipment, there is no such problem of poor welding quality after the hot plate is contaminated by plastic parts in hot plate welding, and there is no such problem of friction debris in the process of vibration friction welding. Heated nitrogen is used to heat the welding surface of an upper plastic part and a lower plastic part to the welding temperature for welding then, which costs less than the laser welding. And as long as it is a plastic part, the plastic part can be welded by the equipment to expand the application range of the equipment.

Owner:长春超维智能设备制造有限公司

Direct-pressing mode locking device for mechanical equipment

The invention discloses a direct-pressing mold locking device for mechanical equipment. The direct-pressing mold locking device for mechanical equipment comprises a mold locking mechanism, an air cylinder mold locking push plate and a fine adjustment push plate, wherein the two sides of the mold locking mechanism are respectively provided with a mold locking mechanism side plate, and the two sidesof the mold locking mechanism side plate are respectively connected with an air cylinder extension plate. By placing a detachable direct-pressing mold in a limiting groove of the mold locking mechanism, the detachable direct-pressing mold can be pushed through a first push air cylinder and a second push air cylinder to be touched with the fine adjustment push plate. By adjusting the position of the fine adjustment push plate through a push plate pad, the detachable direct-pressing mold can be clamped and locked by the mold locking push plate for air cylinders and the fine adjustment push plate for air cylinders, so that a mold installation is achieved. Replacing of the mold has reverse operations. By resetting the first push cylinder and the second push cylinder and pressing an electromagnetic switch, a second electromagnetic ring is electrified to attract a first electromagnetic ring to drive a limiting gear block to ascend, and the position of the fine-adjustment push plate can be adjusted at will. The direct-pressing mold locking device for mechanical equipment has the advantages of simple and convenient operation, convenient die locking and die changing, and improved work efficiency of die locking and die changing in direct pressure production.

Owner:陈忠信

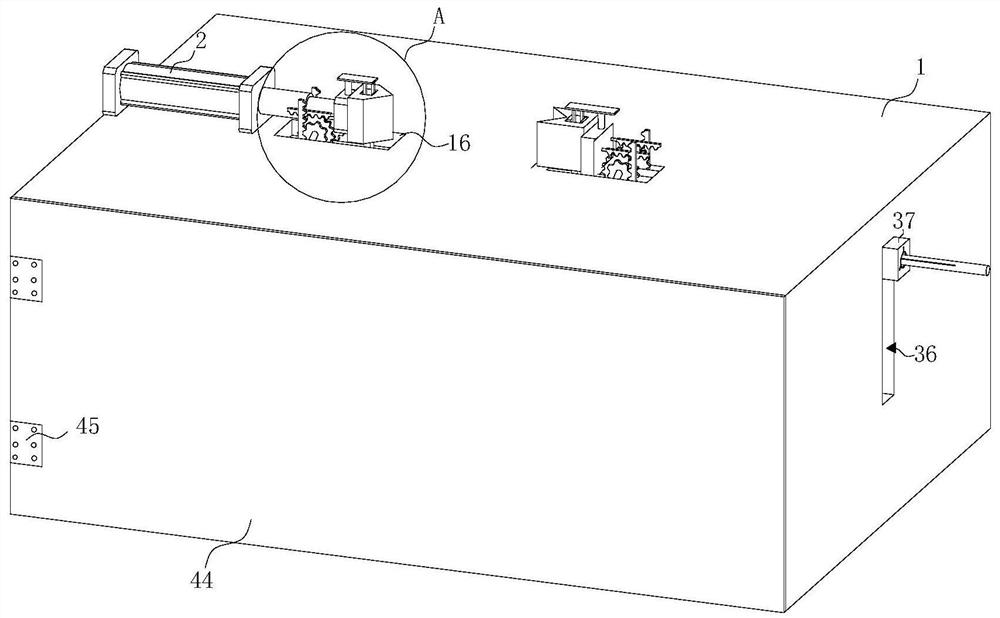

Mold frame system capable of quickly replacing mold core

The invention provides a mold frame system capable of quickly replacing a mold core, and relates to the technical field of molds. The mold frame system capable of quickly replacing the mold core solves the technical problem of low efficiency caused by the fact that the mold core can be replaced only when the mold is disassembled from an injection molding machine during wire changing production inthe prior art. The mold frame system capable of quickly replacing the mold core comprises a front mold frame, a rear mold frame, a front mold core and a rear mold core, wherein mold core mounting grooves are formed in the front mold frame and the rear mold frame, the front mold core and the rear mold core are correspondingly arranged in the mold core mounting grooves of the front mold frame and the rear mold frame, threaded holes are formed in the back surfaces, opposite to a mold clamping surface, of the front mold core and the rear mold core, bolts can correspondingly penetrate through the mold core mounting grooves of the front mold frame and the rear mold frame and can be correspondingly connected with corresponding threaded holes in a threaded way, and the front mold core, and the rear mold core and the rear mold frame can be matched with the threaded holes through bolts. According to the mold frame system capable of quickly replacing a mold core, the mold replacing efficiency isvery high and rapid line changing production is realized.

Owner:中山英诺莱比智能科技有限公司

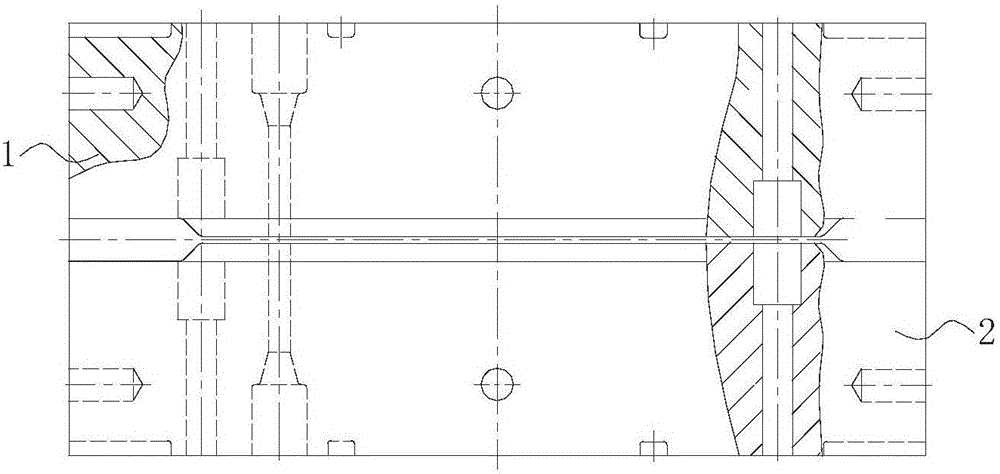

Injection mould capable of being easily de-molded

The invention discloses an injection mould capable of being easily de-molded. The injection mould is formed by a movable mould and a fixed mould, which are used as the injection mould, wherein each one of the movable mould and the fixed mould comprises a molding part, a pushing-out mechanism, a mould guide part and a pouring system; a mould cavity is arranged in the mould; the mould cavity is arranged on the mould closing face of the single injection mould, namely, the mould cavity is arranged on the mould closing face of the movable mould or the mould closing face of the fixed mould; the mould closing face of the other injection mould has no mould cavity and is a plane; the movable mould and the fixed mould are closed to form the complete injection mould cavity. According to the injection mould disclosed by the invention, the structure of only arranging the mould cavity on the single injection mould is applicable to injection of a standard test sample strip or an injection piece with the similar shape. The injection mould has the beneficial effects of being beneficial to simplification of the structure of the mould, improving the manufacturability of the mould and reducing the cost of the mould.

Owner:广州现代塑料有限公司

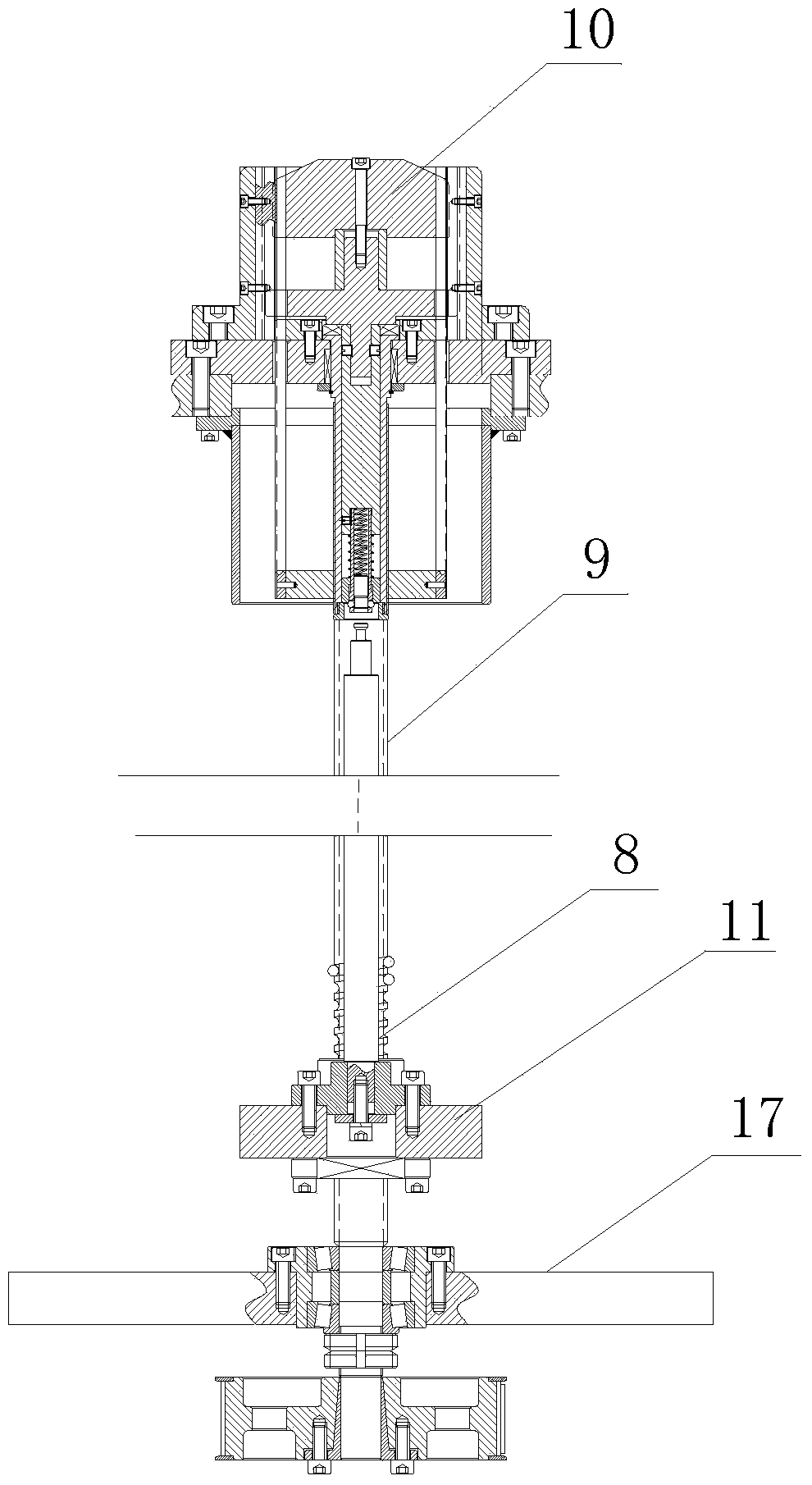

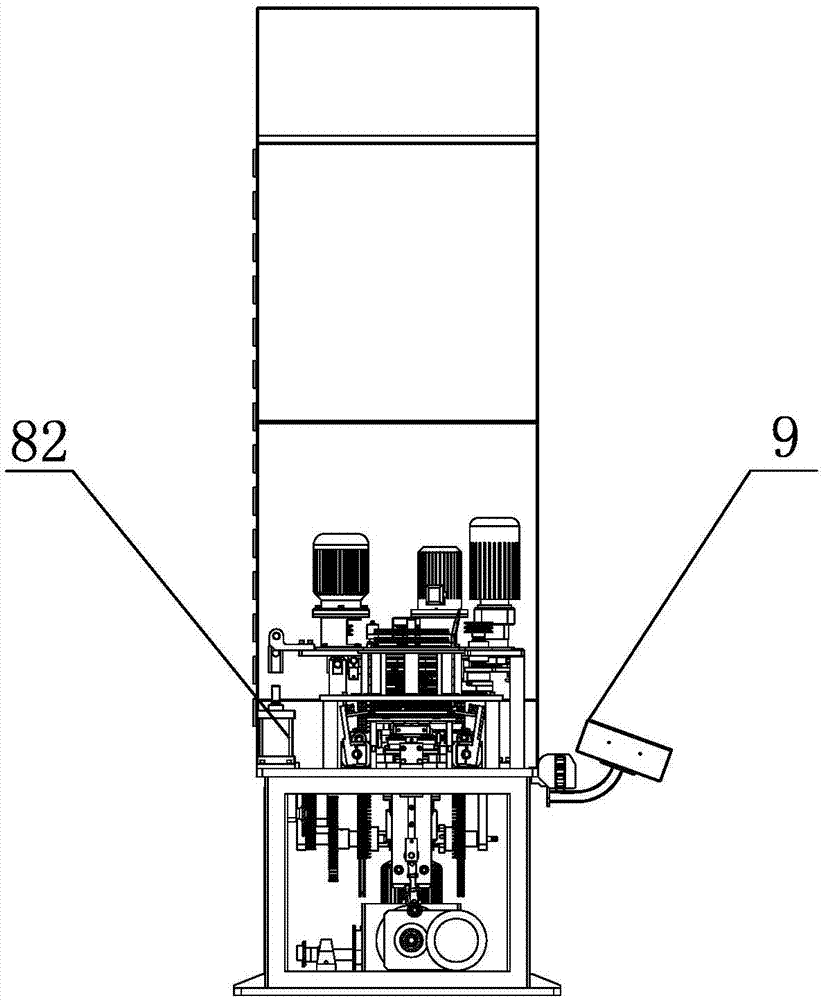

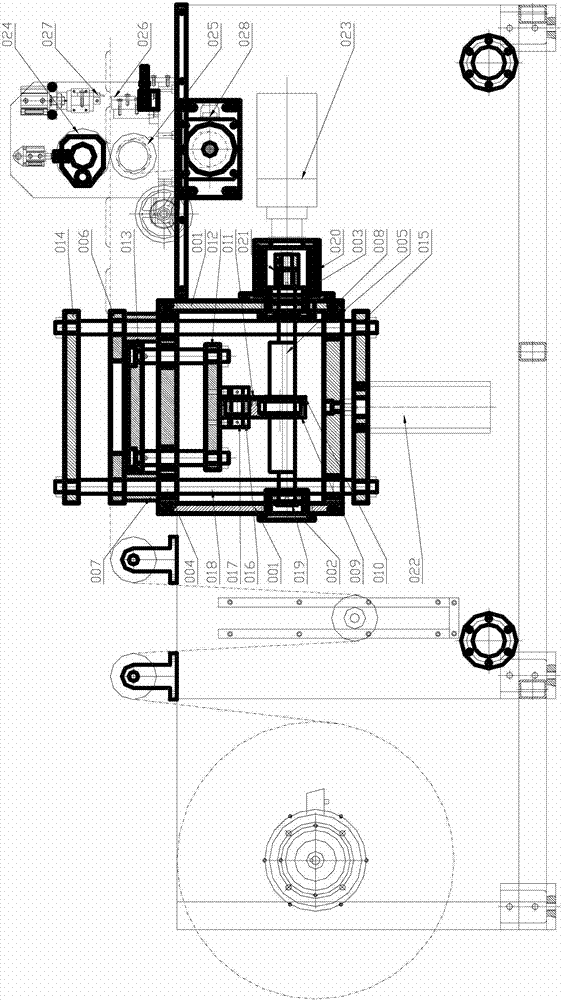

Semi-automatic coil inserting machine

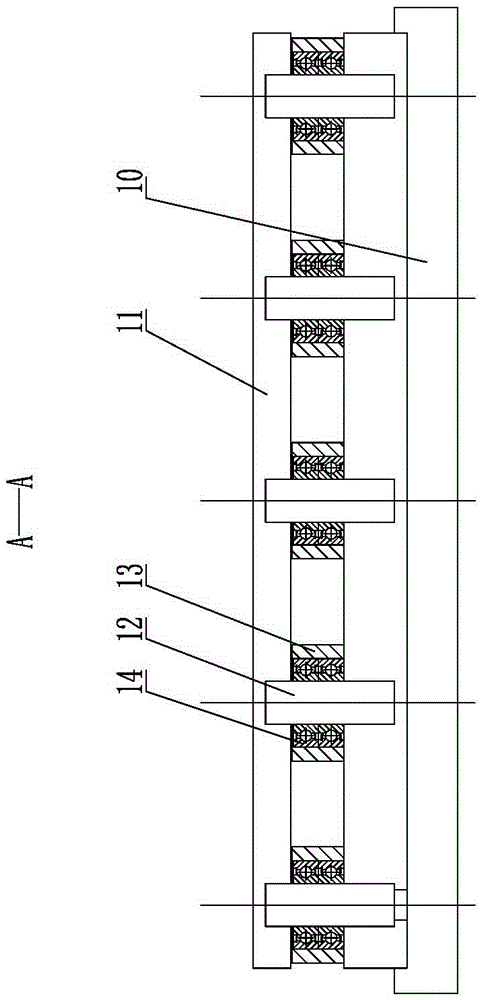

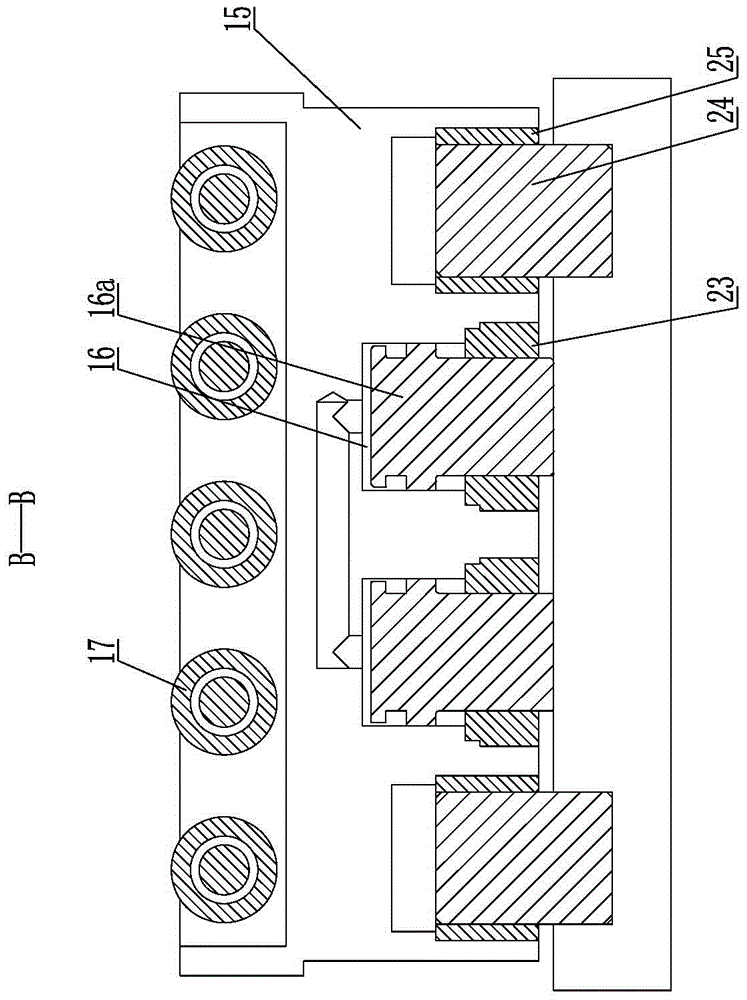

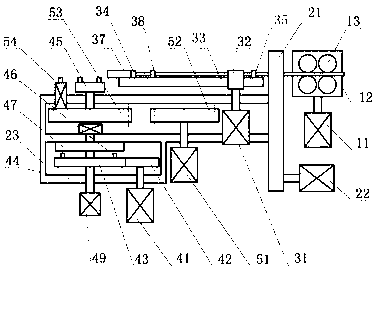

InactiveCN103683742ASmall footprintImprove work efficiencyManufacturing dynamo-electric machinesBall screwControl system

The invention discloses a semi-automatic coil inserting machine comprising a case, a press arm mechanism, a mold mechanism and a control system. The press arm mechanism comprises a press block controlled by an oil cylinder. The mold mechanism comprises a push device and a mold device. The push device comprises a ball screw, a guide pillar and a copper push head. The ball screw, the guide pillar and the copper push head are connected with one another through a screw nut. The guide pillar and the screw nut are in sliding connection. The upper end of the ball screw is connected with the copper push head. The mold device comprises a storage strip and a guide strip. According to the semi-automatic coil inserting machine, improvements are made on the basis of an original coil inserting machine, and a cam box of a paper beating mechanism is omitted, so that occupation area of a machine body is small, production cost is reduced, and debugging and maintaining are greatly facilitated; the semi-automatic coil inserting machine is simple in structure, mold change is facilitated, mechanical working efficiency can be improved, and economic benefit can be increased.

Owner:NIDE MECHANICAL EQUIP

Universal mold frame achieving convenient and rapid mold change

The invention relates to a universal formwork with convenient mold change, which comprises an upper formwork structure and a lower formwork structure connected up and down, a lower support plate, a jacking cylinder, a connecting block and a positioning plate; one side of the bottom plate is provided with a connecting The lower support plate; the lower support plate is provided with a jacking cylinder, and the upper end of the jacking cylinder is provided with a connecting block, and the material of the connecting block is an electromagnet; the lower supporting plate is located on one side of the jacking cylinder. Positioning plate. The universal mold frame with convenient mold change of the utility model has a compact structure, and can precisely position the upper mold assembly and the lower mold assembly through the upper moving plate and the lower moving plate, and can be applied to different types of molds. There is no need to replace the mold base, the production cost is low, and the processing efficiency is high, which meets the production and processing needs of the enterprise.

Owner:苏州永为客模架智造股份有限公司

One-die multi-hole carbon die with vertical die capable of being installed and replaced conveniently

InactiveCN103507145ACooperate wellReduce frictionMould separation apparatusMouldsEngineeringElectrical and Electronics engineering

Owner:太仓市日精模具有限公司

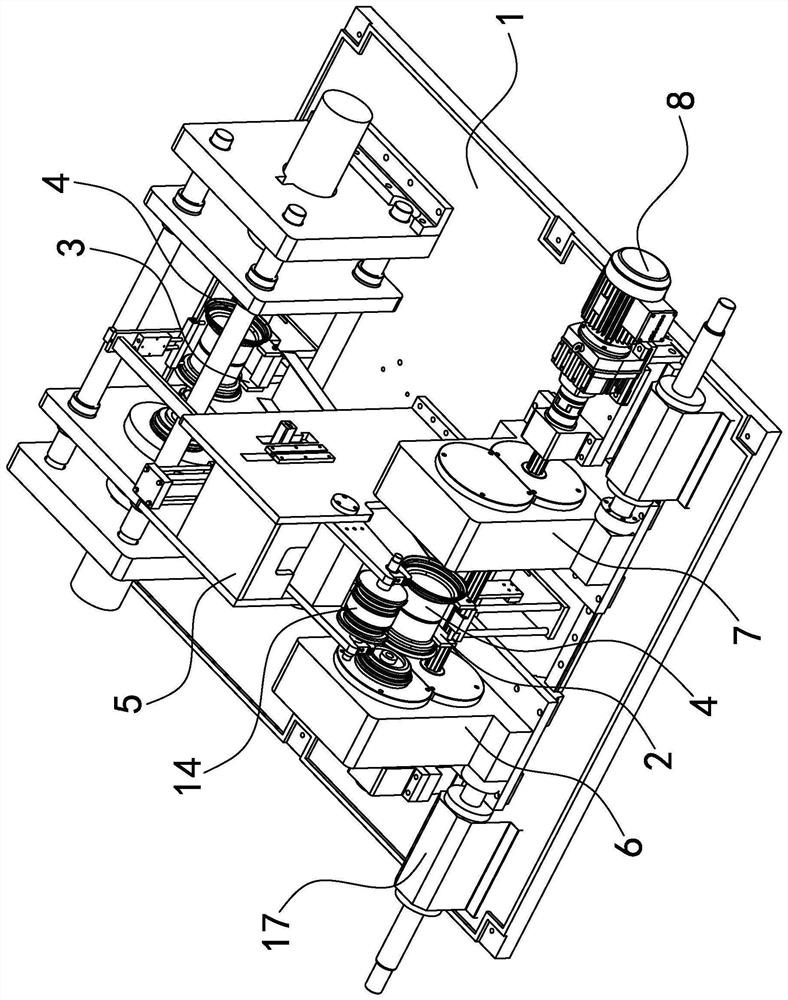

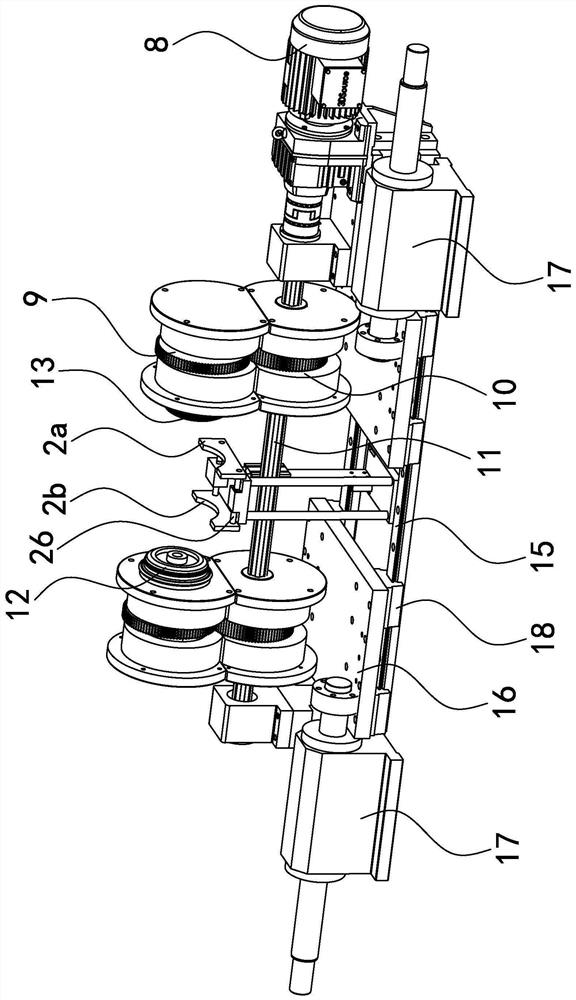

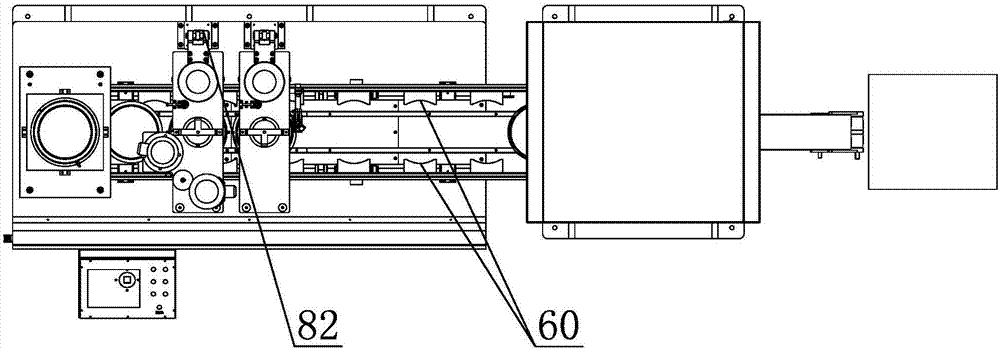

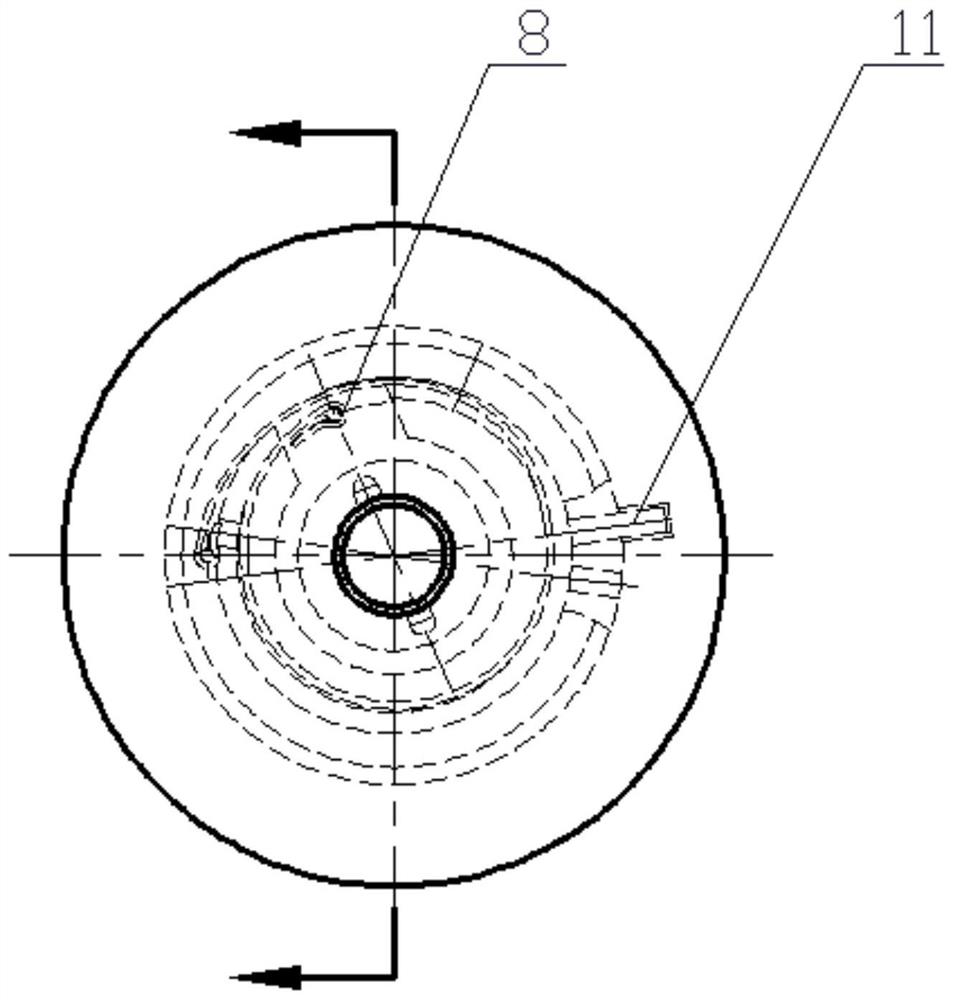

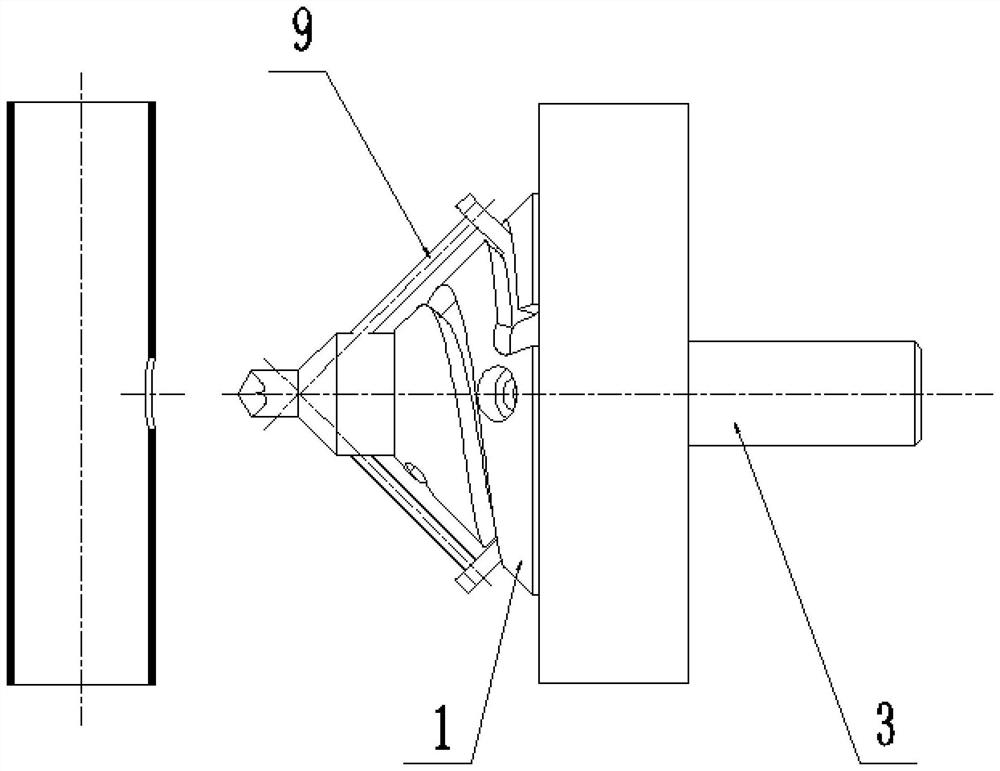

Rim spinning and shaping all-in-one machine

PendingCN112517752AHigh degree of automationIncrease productivityShaping toolsMetal-working feeding devicesMachineMachining

The invention provides a rim spinning and shaping all-in-one machine, and belongs to the technical field of rim manufacturing. The problems that existing rim machining is low in production efficiencyand low in percent of pass are solved. The rim spinning and shaping all-in-one machine comprises a base, an external rotation forming device, a cold-molding shaping device, a controller and a conveying device; the conveying device comprises a rolling ring positioning frame and a shaping positioning frame; and the rolling ring positioning frame and the shaping positioning frame are both used for supporting a rim; The controller is used for controlling the external rotation forming device to work so as to conduct external rotation forming on a to-be-machined rim on the rolling ring positioning frame, used for controlling the conveying device to work so as to automatically convey the rim which is located on the rolling ring positioning frame and subjected to external rotation forming to the shaping positioning frame, and used for controlling the cold-molding shaping device to work so as to carry out cold-molding shaping on the rim which is positioned on the shaping positioning frame and subjected to external rotation forming. The rim spinning and shaping all-in-one machine has the advantages of high automation degree and accurate finished product size.

Owner:ZHEJIANG FENGCHI MECHANICAL

End trimming device for automobile decorative strips

InactiveCN102350802AMeet the requirements for trimmingEasy to useBeltsEngineeringMechanical engineering

Owner:宁波市胜源技术转移有限公司

Automatic wire bending machine

The invention mainly discloses an automatic wire bending machine. The automatic wire bending machine comprises the following mechanisms including a feeding mechanism, a rotating mechanism, a shearing mechanism, a die-changing mechanism and a bending mechanism. The feeding mechanism is used for conveying a metal wire. The rotating mechanism can rotate by 360 degrees around the axis of the conveyed metal wire. The shearing mechanism is installed on the rotating mechanism and located at the front end of the feeding mechanism. The die-changing mechanism is installed on the rotating mechanism and located at the front end of the shearing mechanism. The bending mechanism is installed on the rotating mechanism and located at the front end of the die-changing mechanism. The automatic wire bending machine can be used for numerical control wire bending equipment, has the functions of wire conveying, wire bending and forming, and wire shearing, can achieve a one-shot wire forming function with multiple die positions switched automatically, has two wire forming modes, namely bending and push bending at the same time, and can realize a mechanical structure of a two-dimensional numerical control bending function and a three-dimensional numerical control bending function.

Owner:ZHEJIANG OMNIPOTENT SPRING MACHINE

Dual-table die-changing trolley and die-changing method thereof

The invention discloses a dual-table die-changing trolley and a die-changing method thereof. The dual-table die-changing trolley comprises a die loading table for replacing a die to be punched, a dieconveying table which is connected to the die loading table and used for placing the die to be punched, a die pushing device which is arranged on the die loading table and used for pushing the die tobe punched from the die loading table to the die conveying table, and a die conveying device which is connected to the die conveying table and used for conveying the die to be punched from the die conveying table to a punching machine. The dual-table die-changing trolley and the die-changing method thereof are simple and convenient for die-changing operation; the loading and die conveying devicesare simple to modify and have good process adaptability; the requirements for working objects and matching conditions are low, and die loading of different process cycles can be adapted; and the production line has a high degree of generality, different production lines without adjustment or slight adjustment can be adapted, and practical production is suitable.

Owner:湖南大捷智能装备有限公司

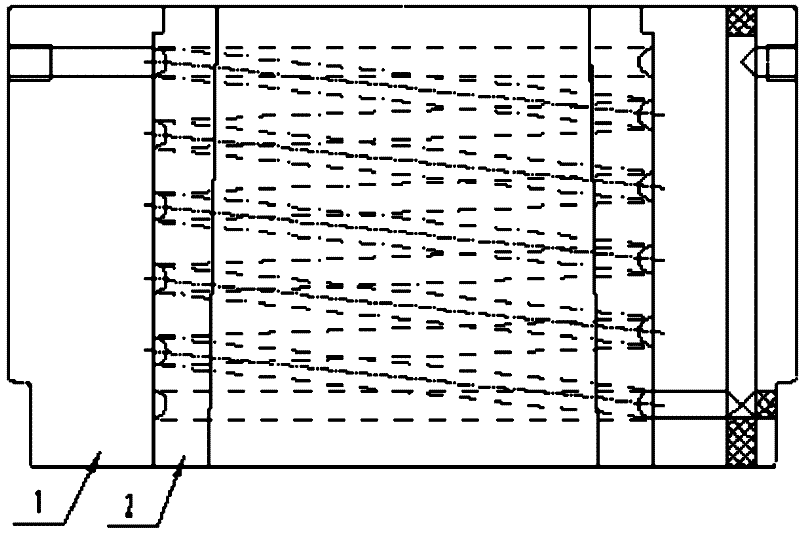

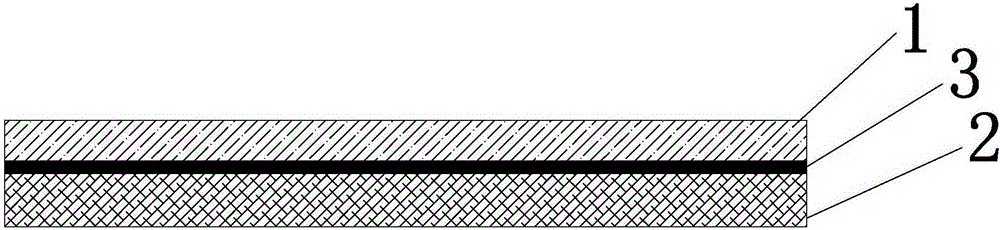

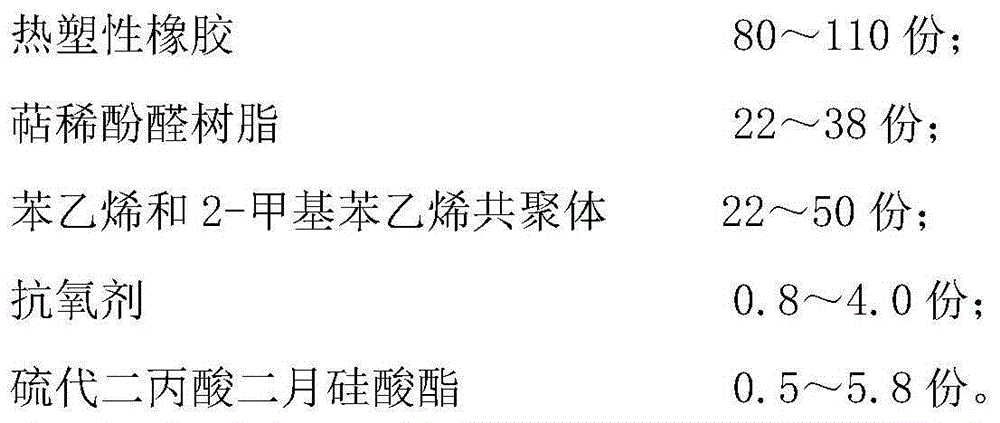

Ultrasonic composite sofa cloth

InactiveCN105196637AWith three-dimensional relief effectWith waterproof effectPattern makingLayered productsEngineeringSurface structure

The invention provides ultrasonic composite sofa cloth. Diversity of a surface structure of the sofa cloth is improved. Besides, the sofa cloth is of a multi-layer structure, durability is good, threads and thread ends do not exist, embossing uniformity is good, the problem of thread falling is avoided, and the sofa cloth comprises warp-knitted super-soft short-pile lint (1) and staple cotton bottom cloth (2) from top to bottom in sequence. A glue layer (3) used for bonding the warp-knitted super-soft short-pile lint (1) to the staple cotton bottom cloth (2) is arranged between the warp-knitted super-soft short-pile lint (1) and the staple cotton bottom cloth (2).

Owner:HAINING MINGXI TEXTILES CO LTD

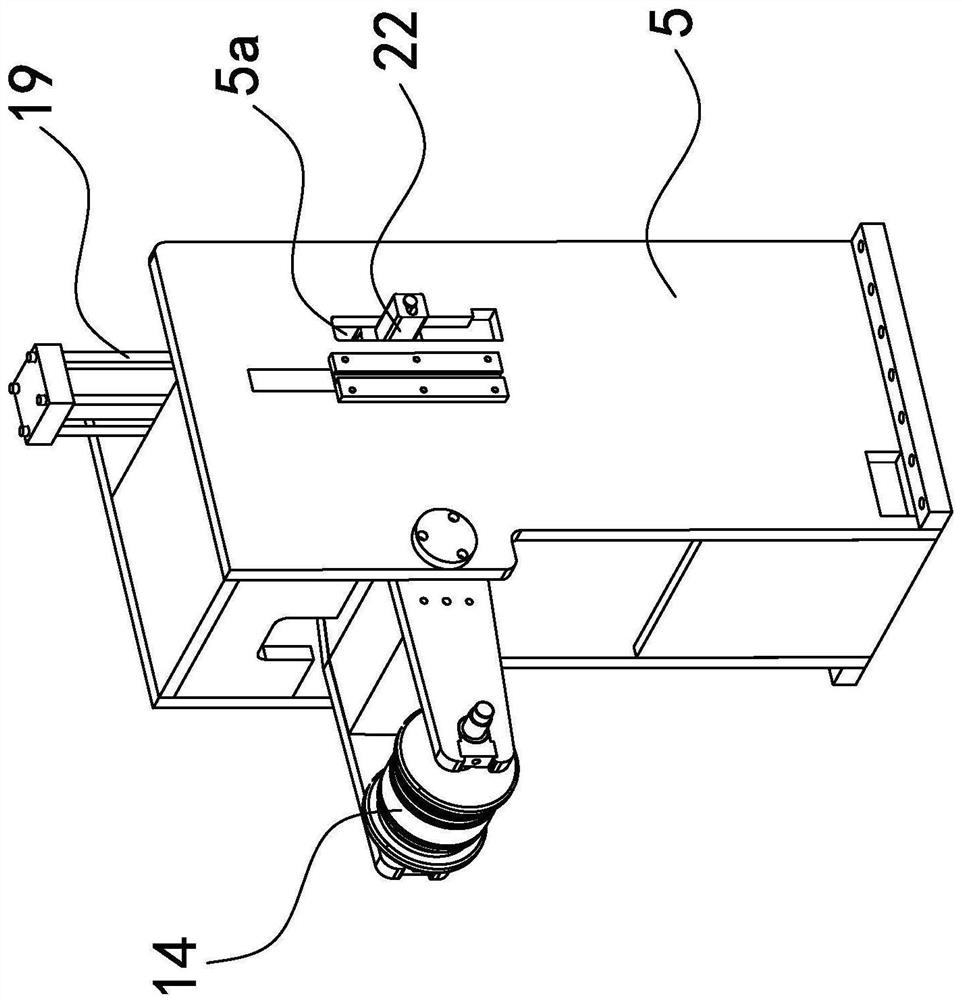

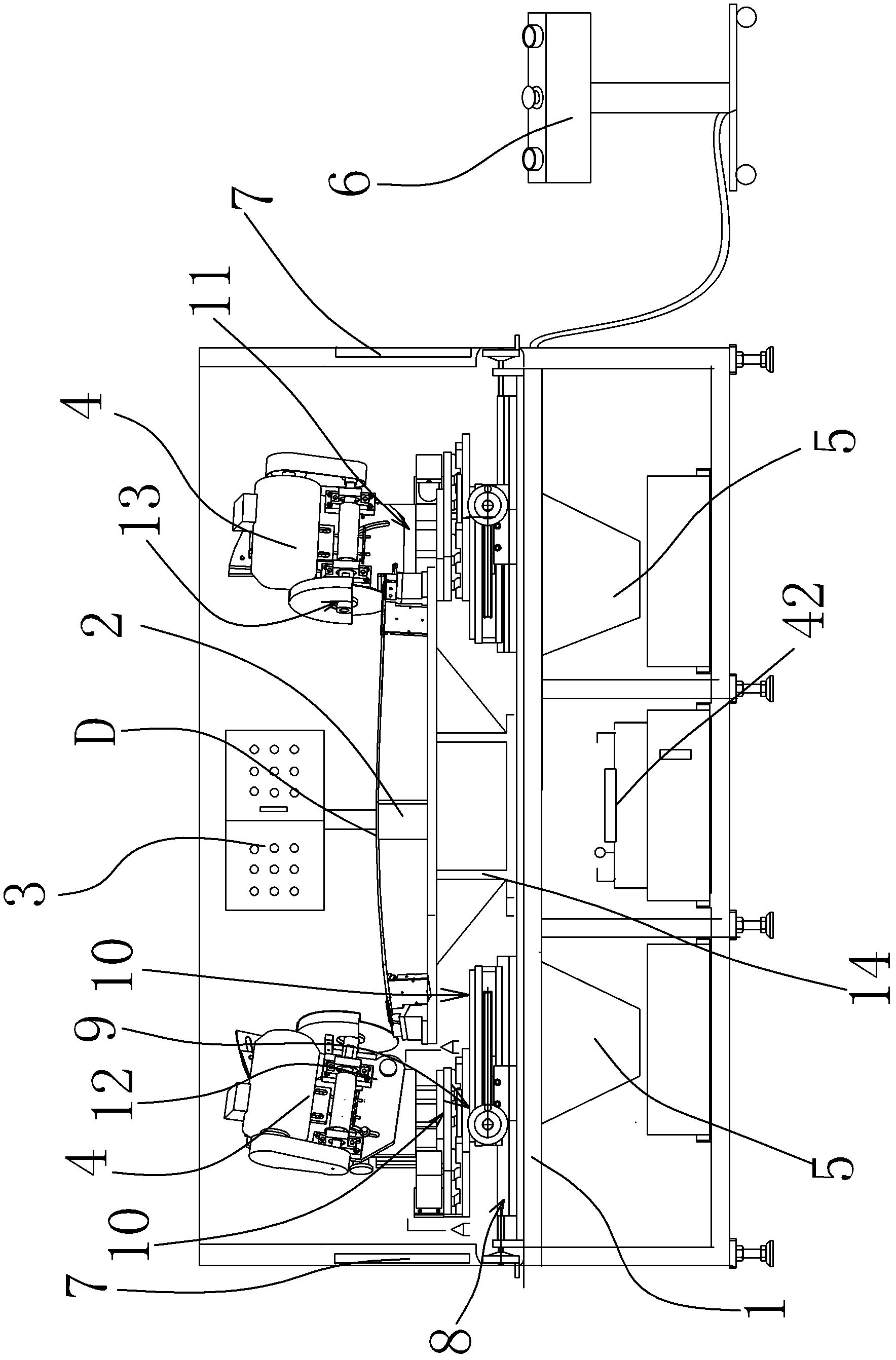

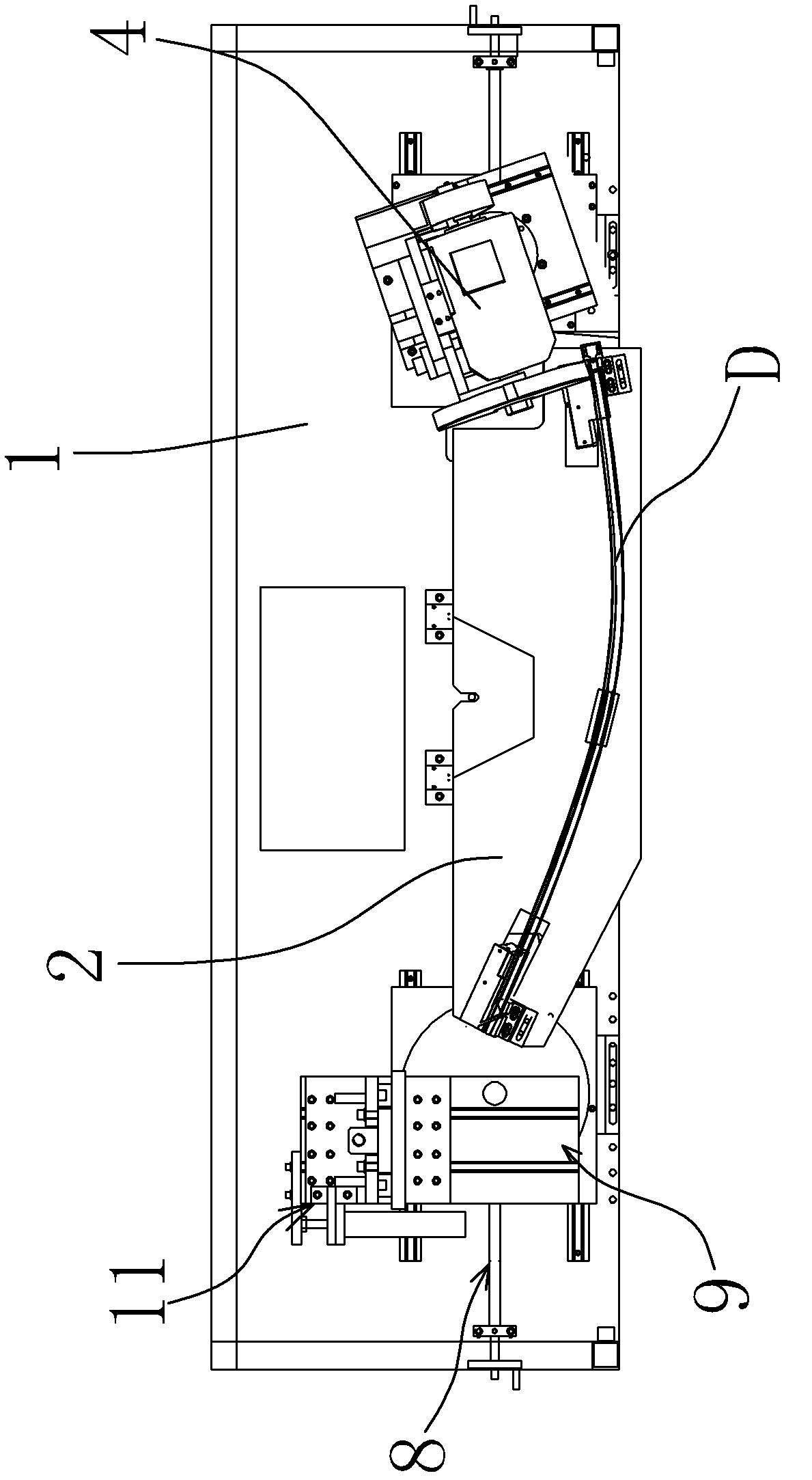

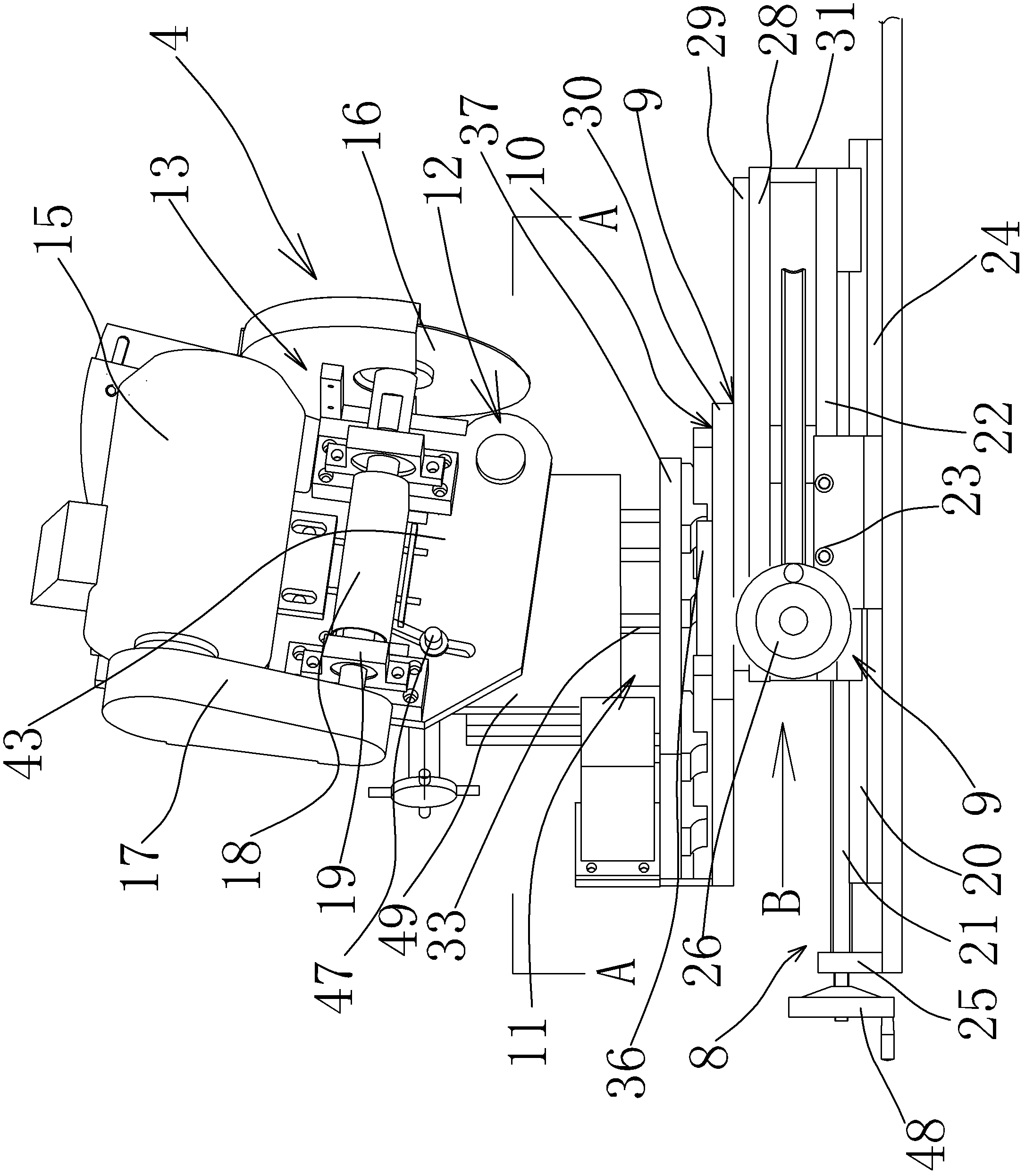

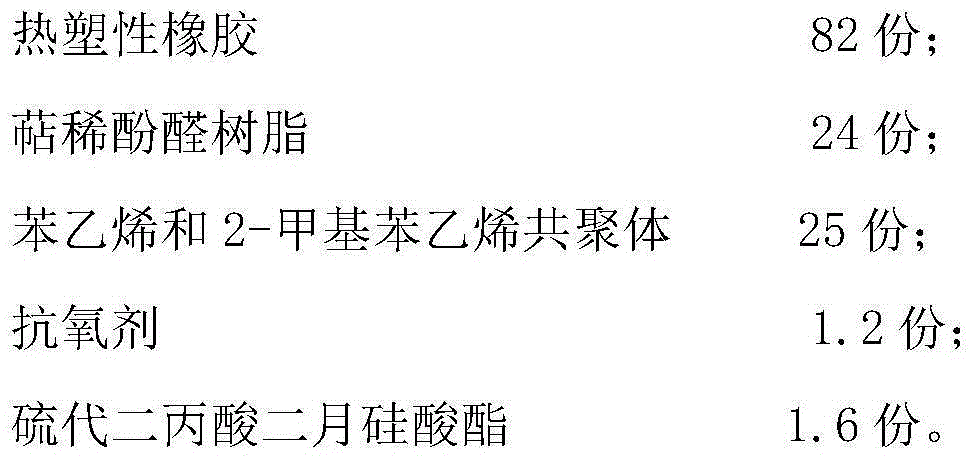

Edge-profiling, glue-injecting and oven-drying all-in-machine machine for bottom cover

ActiveCN107029948AHigh degree of automationEasy to change moldLiquid surface applicatorsCoatingsProduct typeEngineering

The invention relates to an edge-profiling, glue-injecting and oven-drying all-in-machine machine for a bottom cover. The edge-profiling, glue-injecting and oven-drying all-in-machine machine comprises an unloading mechanism, an edge-profiling mechanism, a glue-injecting mechanism, a drying oven, a lower power mechanism and an embracing-sending mechanism, wherein the lower power mechanism comprises a total power motor, a power transmission shaft, an unloading assembly, an edge-profiling assembly and a glue-injecting lifting assembly; the unloading assembly, the edge-profiling assembly and the glue-injecting lifting assembly are separately positioned below the unloading mechanism, the edge-profiling mechanism and the glue-injecting mechanism; when the unloading assembly, the edge-profiling assembly and the glue-injecting lifting assembly descend, the embracing-sending mechanism is used for performing embracing-sending on products on the unloading assembly, the edge-profiling assembly and the glue-injecting lifting assembly; when the unloading assembly, the edge-profiling assembly and the glue-injecting lifting assembly ascend, the unloading mechanism unloads products to an unloading lifting assembly; and the edge-profiling mechanism and the glue-injecting mechanism are used for processing products on an edge-profiling lifting assembly and the glue-injecting lifting assembly. The whole machine only adopts one lower power mechanism, is environmentally friendly and energy-saving; and products are various, and all product types can be replaced. The whole machine is fully automatic and intelligent, does not need guard of staff, and is high in degree of automation; and mound change and maintenance are convenient.

Owner:SUZHOU HYCAN HLDG CO LTD

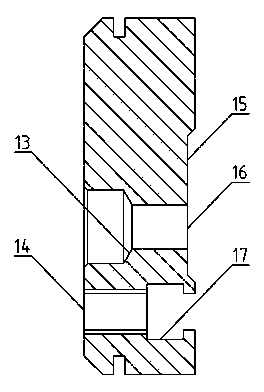

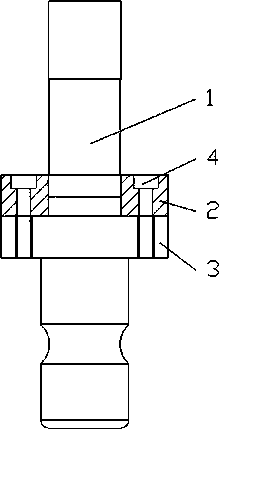

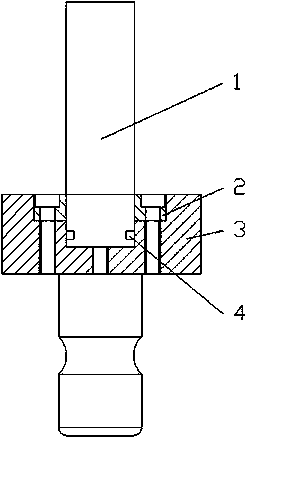

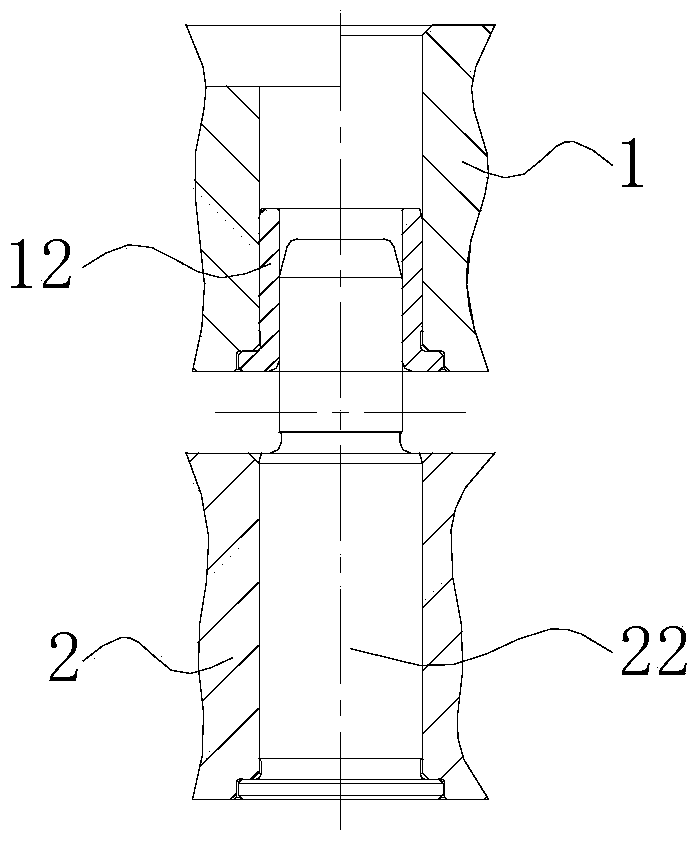

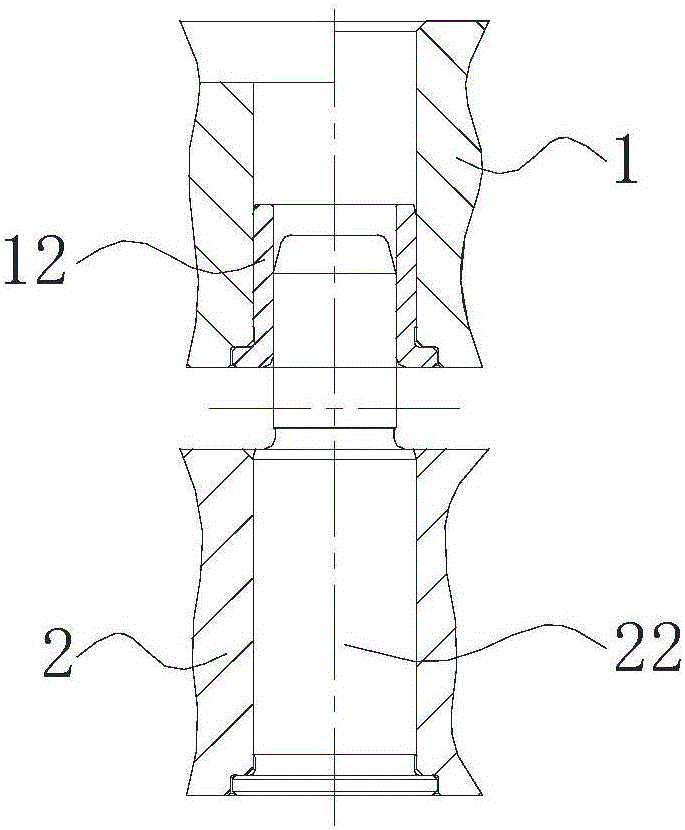

New Structure of Guide Pillar and Guide Bush for Crankshaft Forging Die

InactiveCN105081175BSolve the problem of difficult misalignment controlGuaranteed shapeShaping toolsForging/hammering/pressing machinesEngineeringSwaging

The invention discloses a novel guide post and guide sleeve structure of a crankshaft forging die, which is used for guiding the relative movement between the upper and lower dies of the forging die. Three guide posts and guide sets on the parting surface, any set of guide posts and guide sets includes a guide sleeve that is only fixedly positioned on the upper or lower die forging, and a guide sleeve that is only fixed on the lower or upper die forging and Corresponding to the guide sleeve on the die forging upper or lower die and can slide through the guide post positioned in the guide sleeve, wherein the three guide post guide sleeve set includes two guide post guide sleeves at both ends of one side of the parting surface A set of guide posts and guide sleeves on the other side of the parting surface that is only positioned at one end, and two sets of guide posts and guide sleeves, and one set of guide posts and guide sleeves are respectively placed on the guide posts and guide sleeves on the upper and lower dies for die forging. The distribution is set in reverse. The invention has a simple structure, is convenient for mold loading, mold changing, and debugging, and is convenient and quick to operate, effectively solves the problem of difficult control of forging misalignment, has high stability of forging process, and good product consistency.

Owner:重庆大江杰信锻造有限公司

Tripping device chiseling and riveting fixture and riveting method thereof

ActiveCN106710970APrecise positioningAccurate rivetingEmergency protective device manufactureEngineering

The invention discloses a tripping device chiseling and riveting fixture and a riveting method thereof, which belong to the technical field of special fixtures. The tripping device chiseling and riveting fixture an upper mold, guide columns, reset springs, a lower mold, an upper punch, a rear baffle plate, a U-shaped positioning block and a lower punch, wherein the guide columns are arranged between the upper mold and the lower mold, each reset spring is connected on the corresponding guide column, the upper punch is connected with the upper mold, the U-shaped positioning block is fixed on the lower mold, a U-shaped groove is formed in the U-shaped positioning block, a lower punch fixing hole is formed in the groove bottom of the U-shaped groove, and the lower punch penetrates out of the lower punch fixing hole; and the rear baffle plate is arranged on one side of the U-shaped positioning block, a limiting groove is formed in the side wall on one side, close to the U-shaped positioning block, of the rear baffle plate, and the upper punch moves in the vertical direction along the limiting groove. The tripping device chiseling and riveting fixture can complete the riveting of a tripping device part in one step, is reliable in riveting quality, concise in structure, low in cost, and convenient in popularization and application.

Owner:JIANGSU DAQO KFINE ELECTRIC

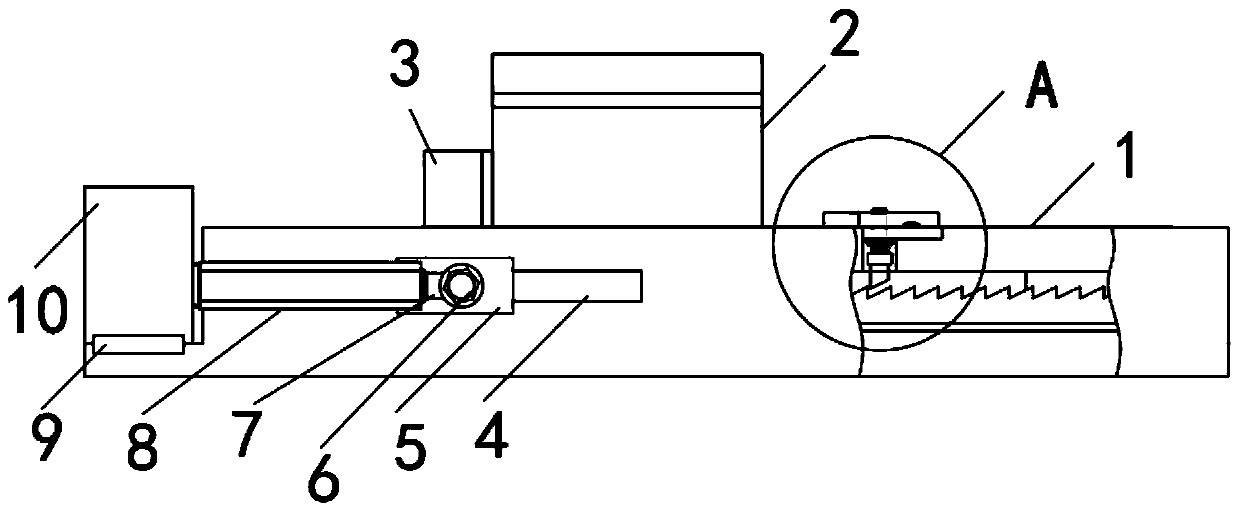

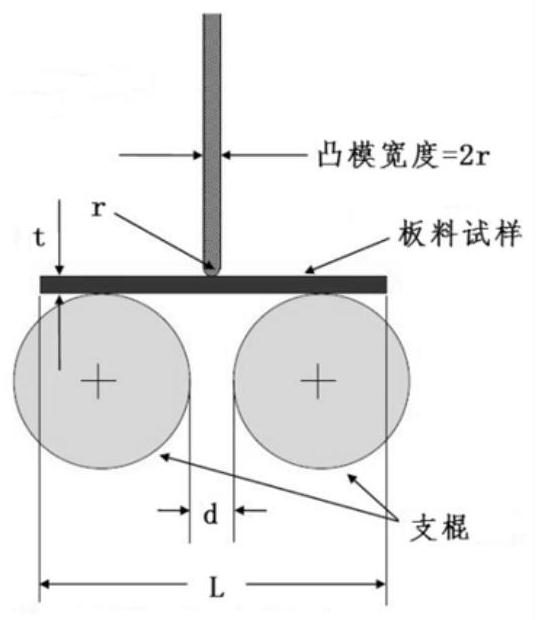

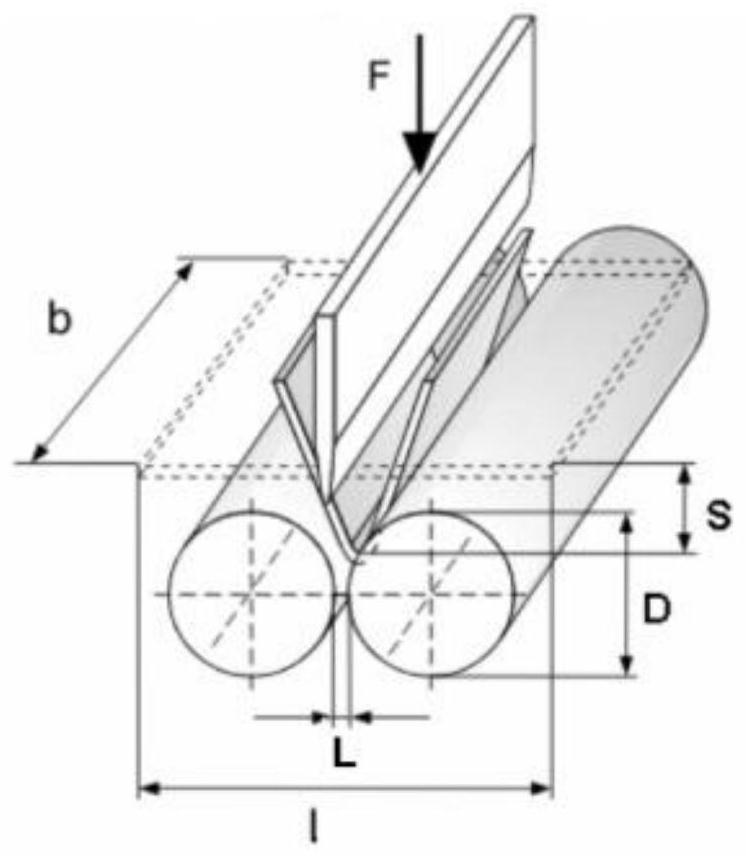

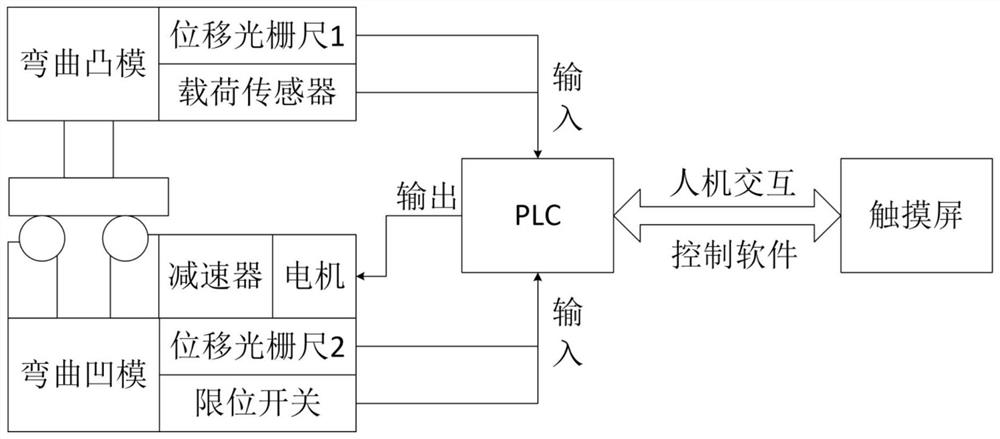

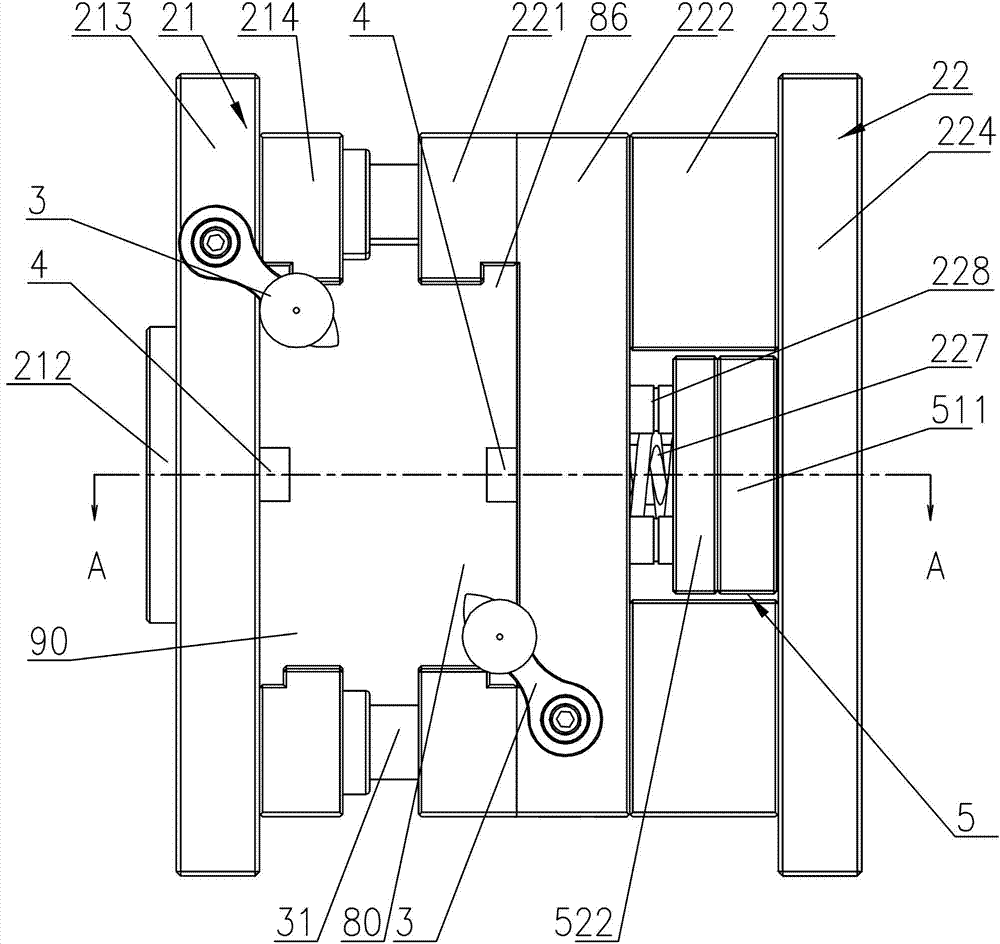

Aluminum alloy plate bending limit evaluation device capable of automatically adjusting gap

PendingCN114062157AAccurate adjustmentEasy to adjustMaterial strength using steady bending forcesGratingElectric machinery

The invention discloses an aluminum alloy plate bending limit evaluation device capable of automatically adjusting a gap and belongs to the field of testing. A screw driving assembly, a left-right-handed screw, a supporting assembly and a set of bending die are arranged on a bottom plate; a left-handed external thread section and a right-handed external thread section of the left-right-handed screw are respectively and correspondingly provided with a female die holder; the two female die holders are respectively provided with a female die supporting roller; a male die holder is arranged above the midpoint of the left-right-handed screw, and a male die is fixed below the male die holder; a first grating ruler, a load sensor and a second grating ruler are arranged; the output ends of the first grating ruler, the second grating ruler and the load sensor are correspondingly connected with the signal input end of a PLC respectively; and the signal output end of the PLC is correspondingly connected with the control end of a servo driving motor, and the signal output end of the PLC is further correspondingly connected with a touch screen, so that a man-machine interaction and control interface of the evaluation device is formed. The bending process can be dynamically monitored, and the problem that the bending process cannot be recorded in real time when a gap value is manually measured by an experimental device is solved.

Owner:BAOSHAN IRON & STEEL CO LTD

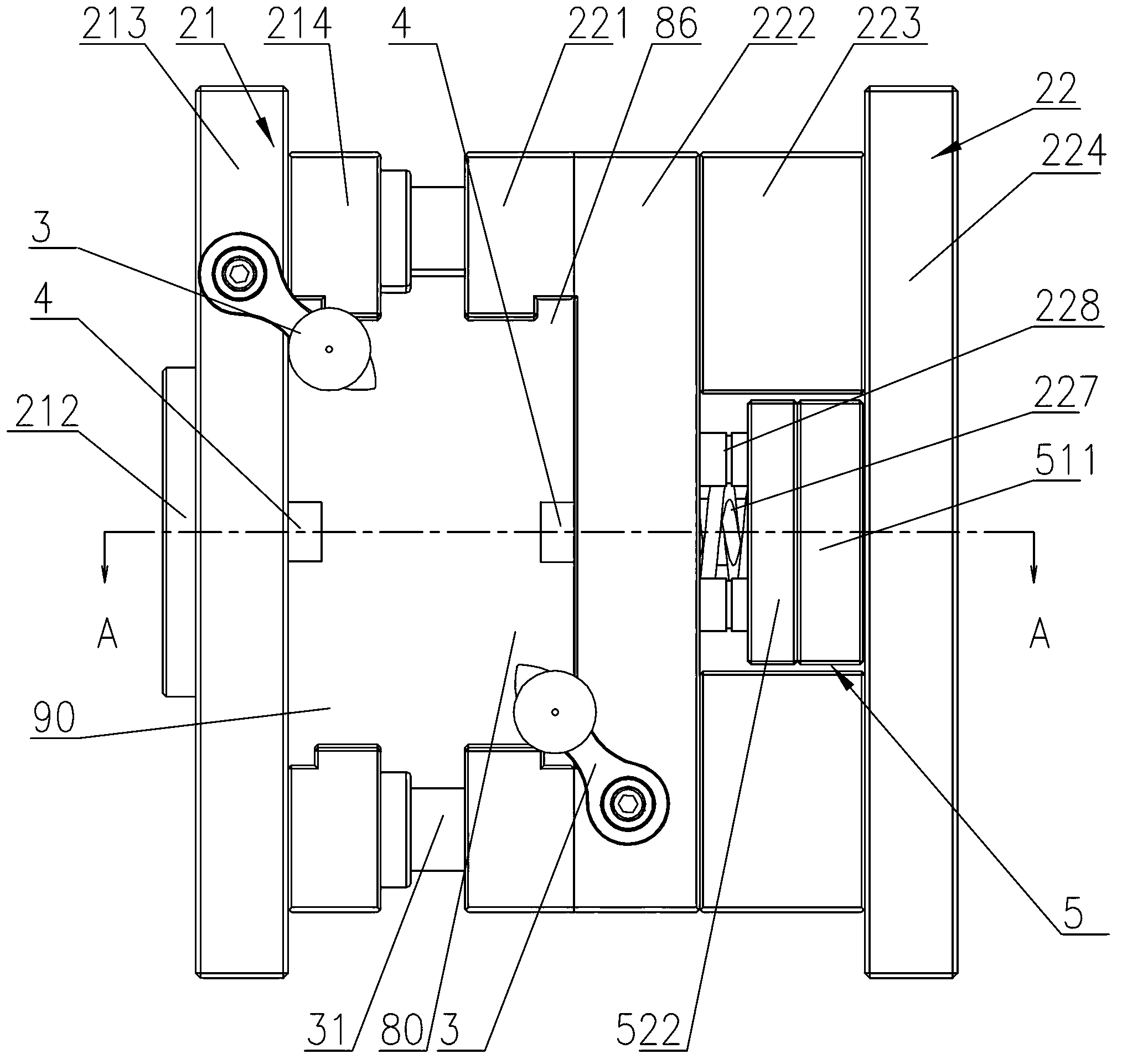

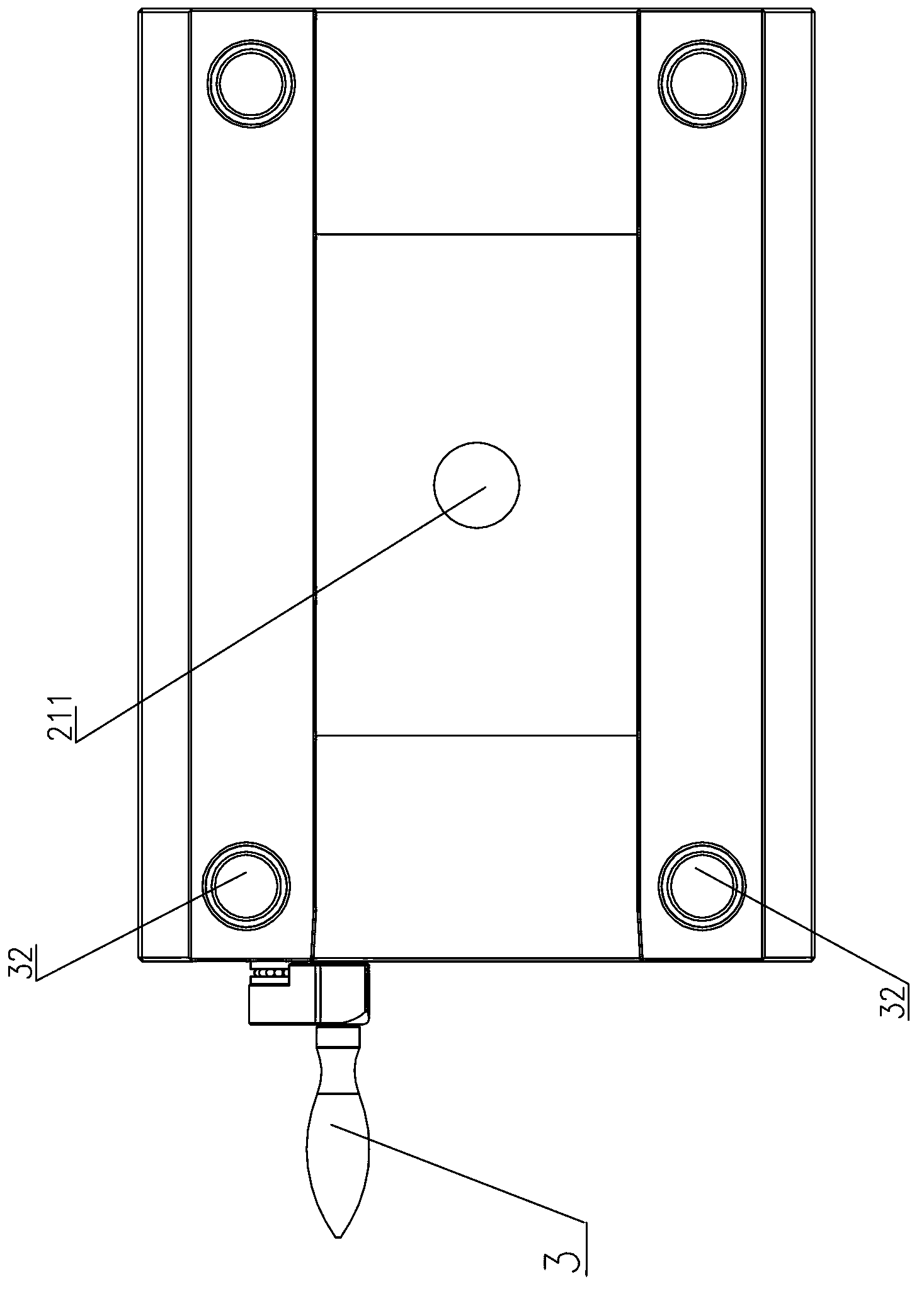

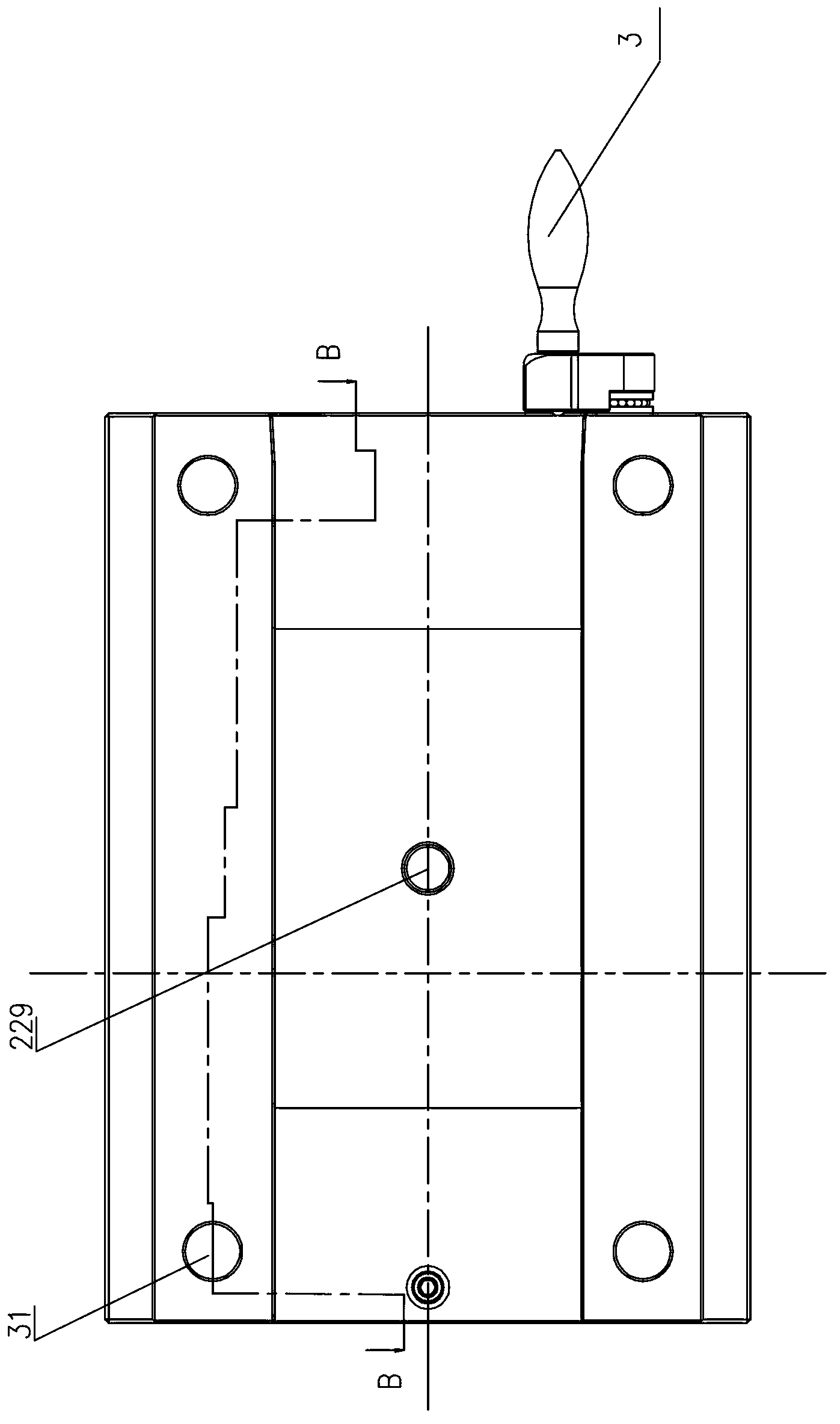

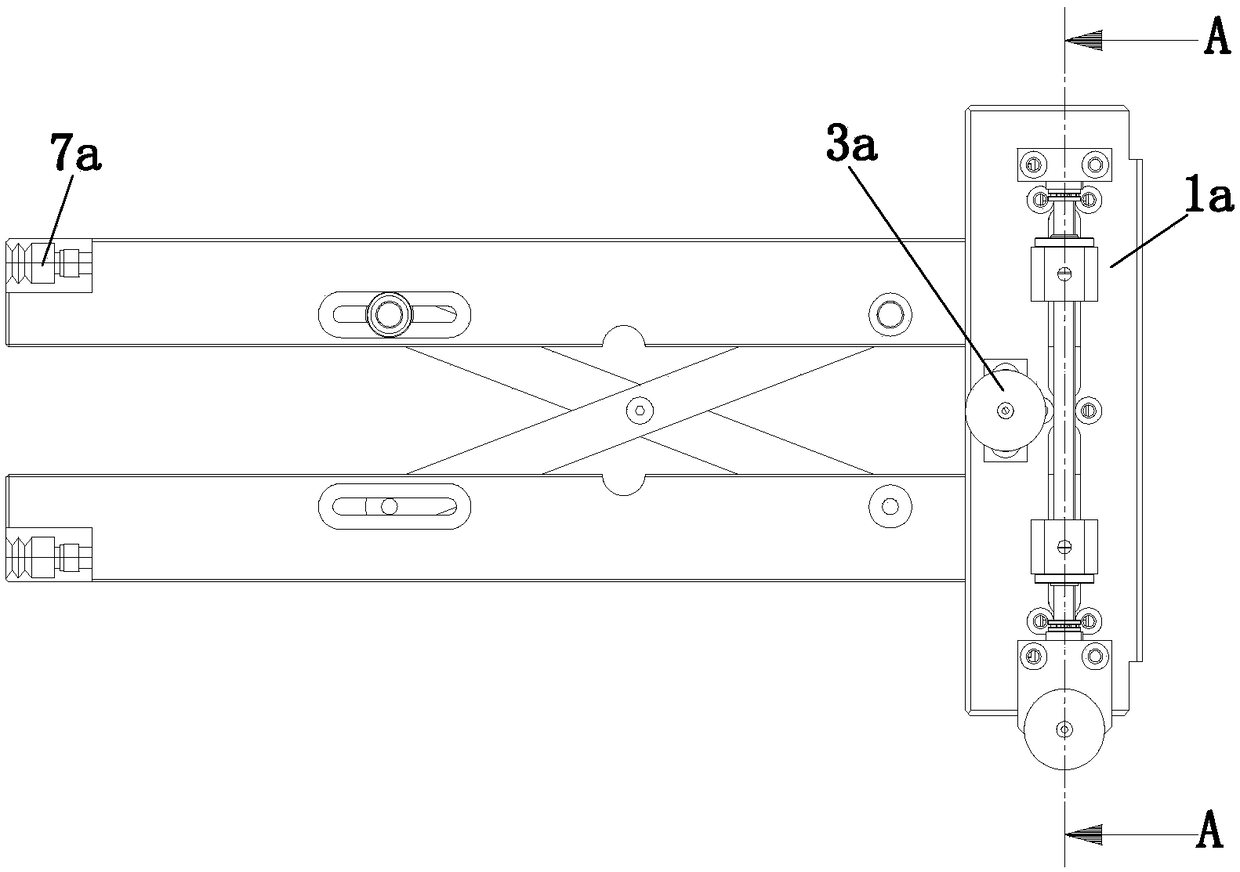

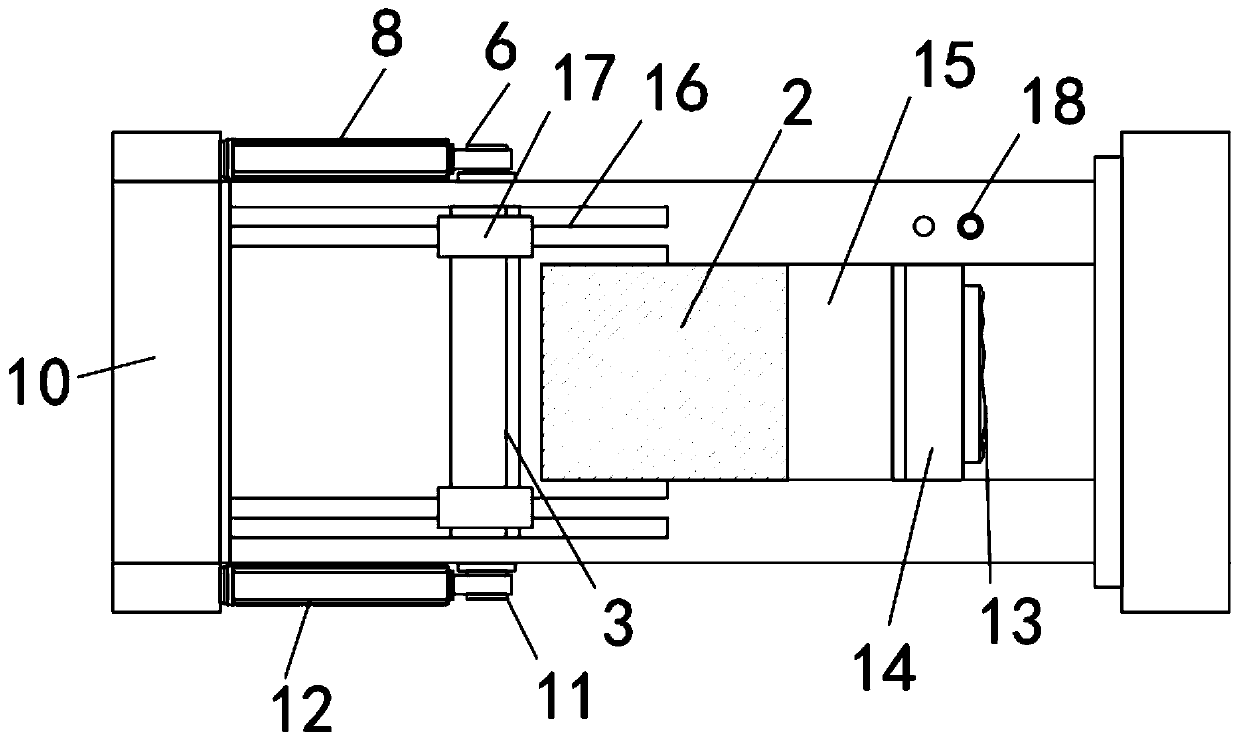

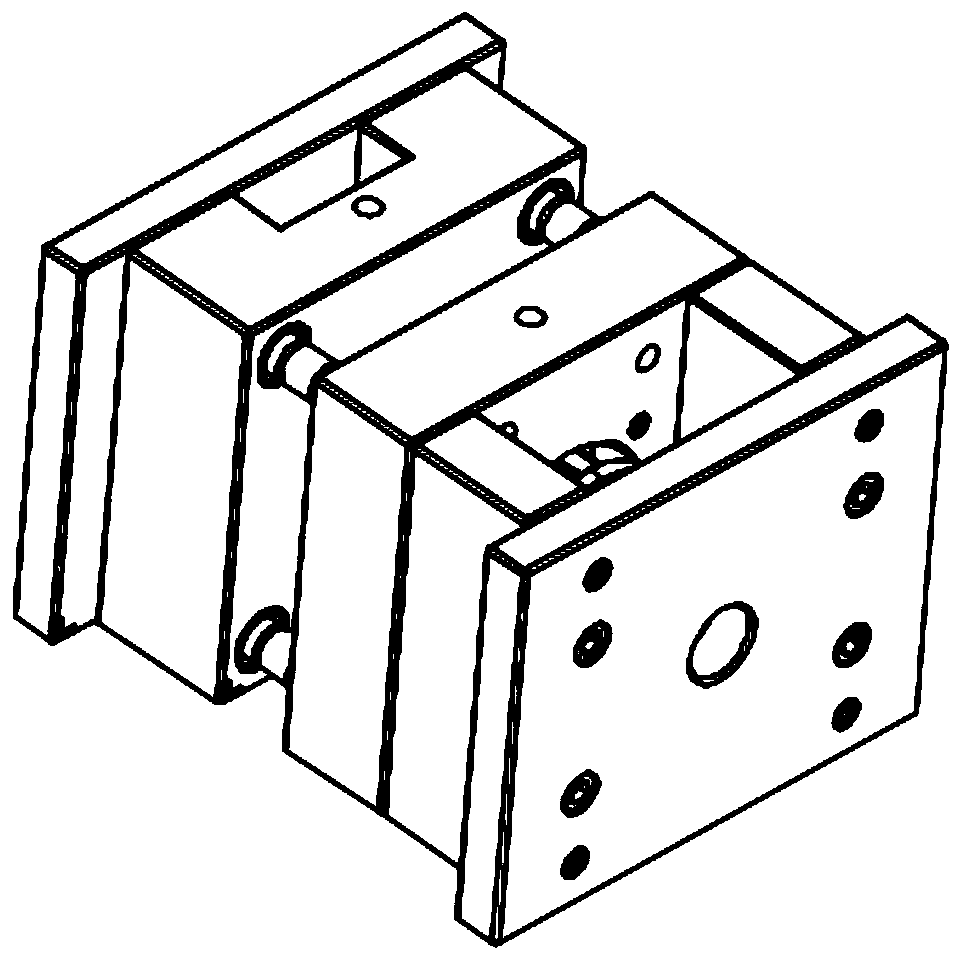

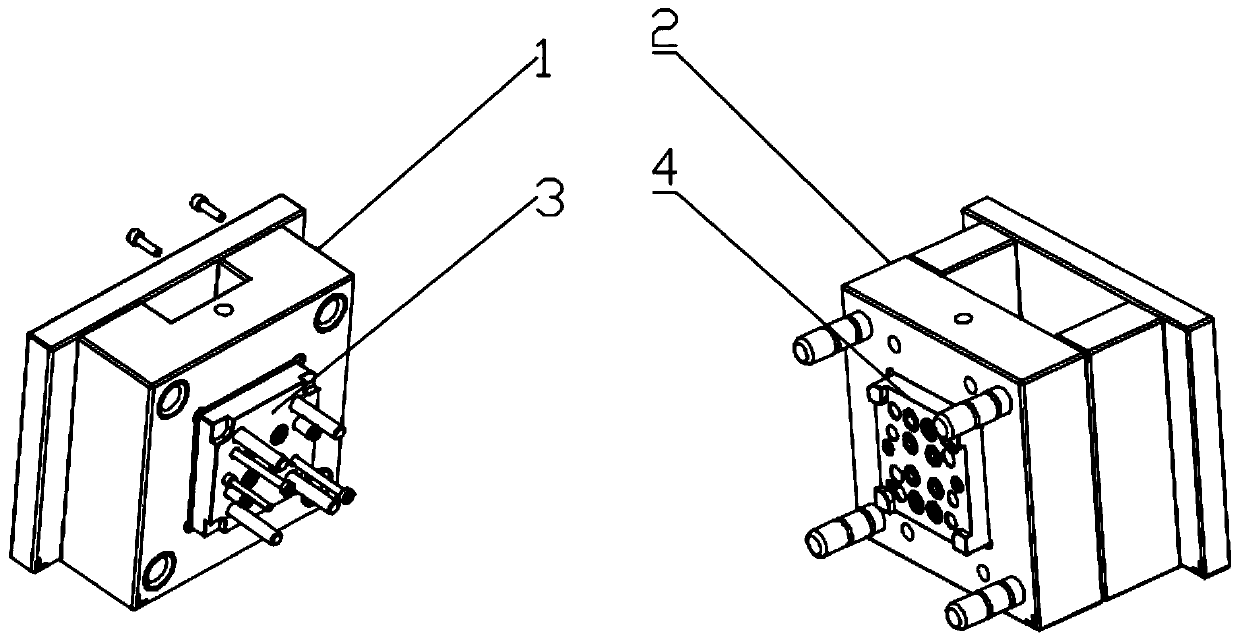

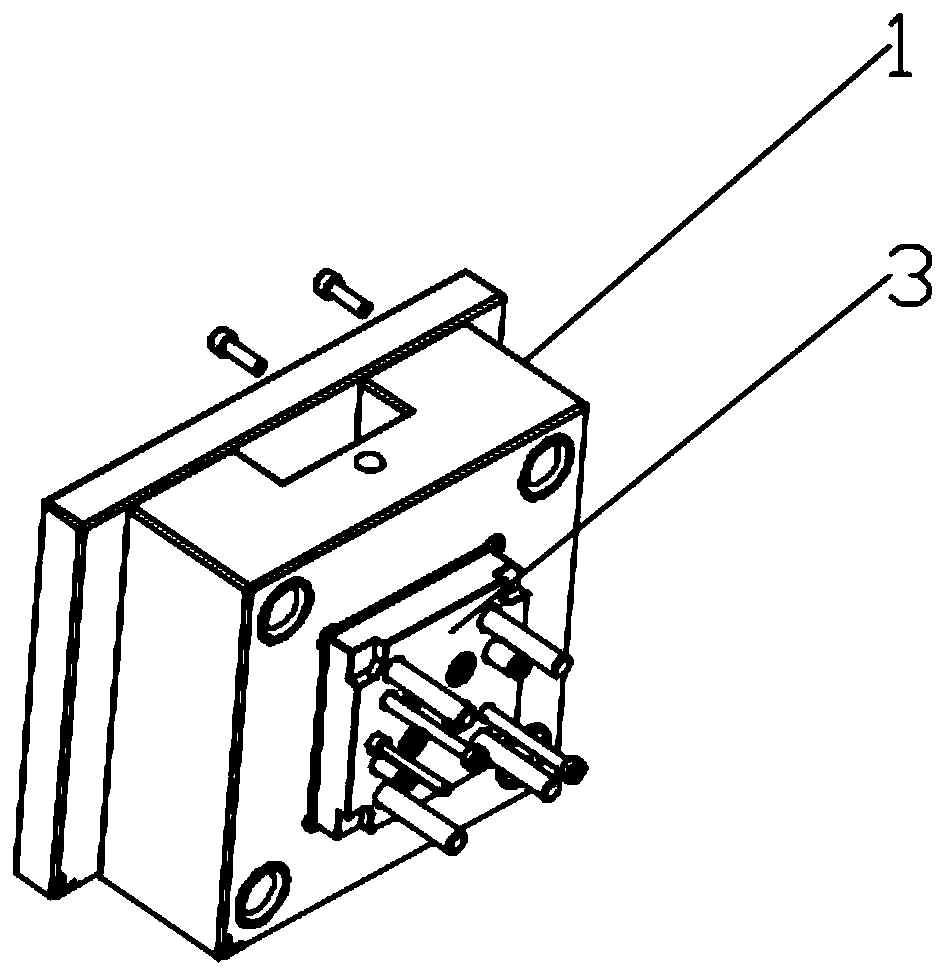

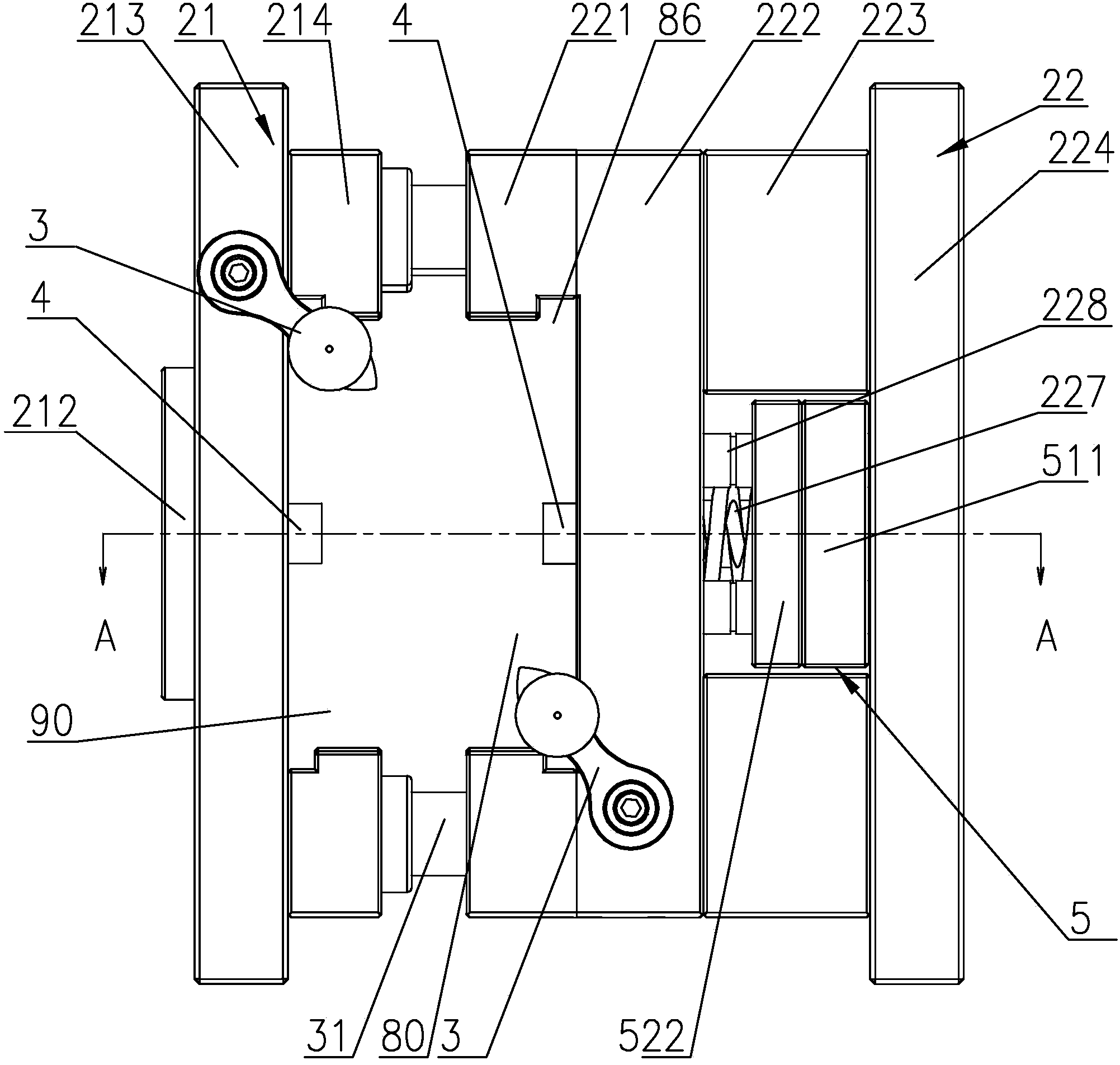

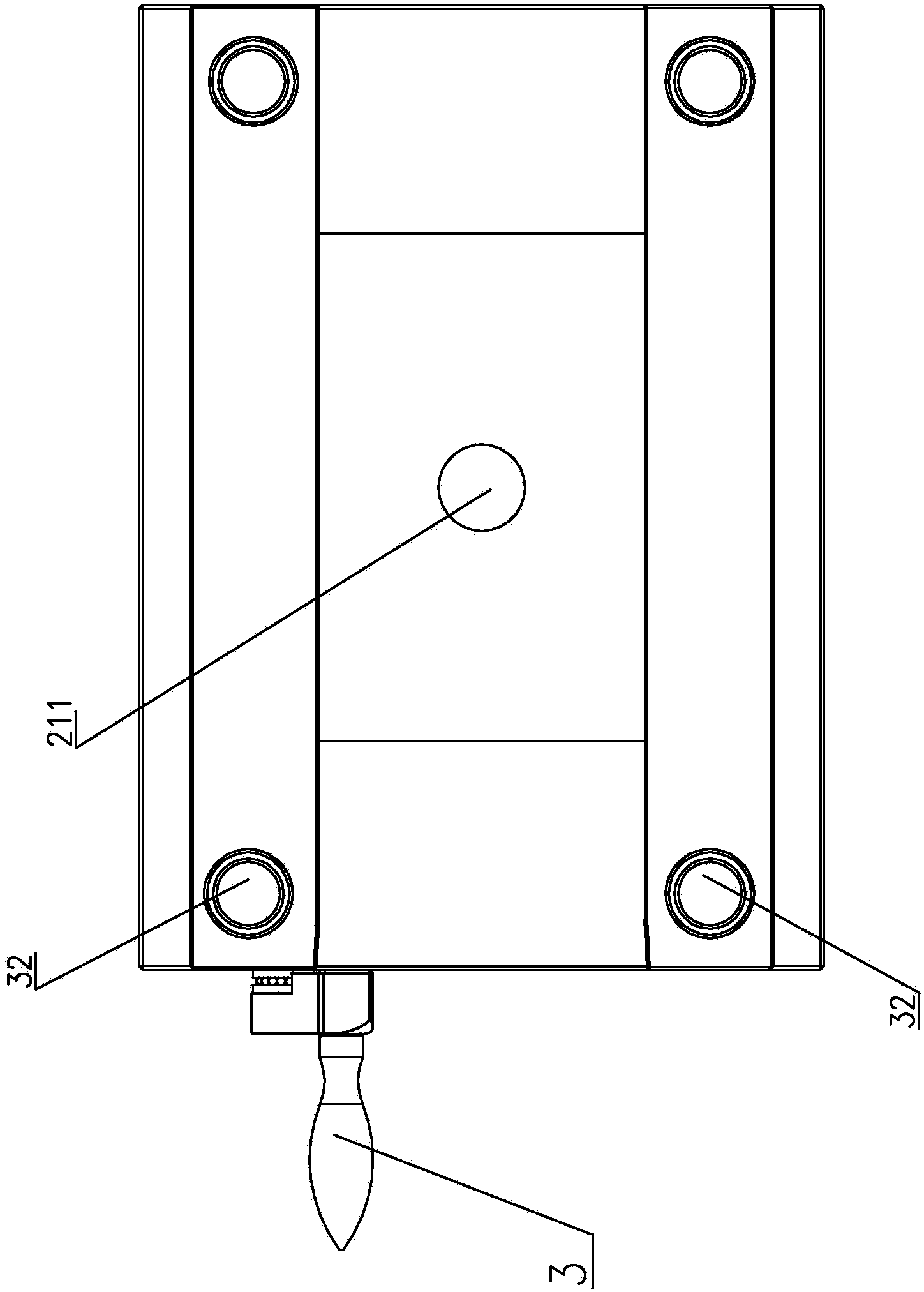

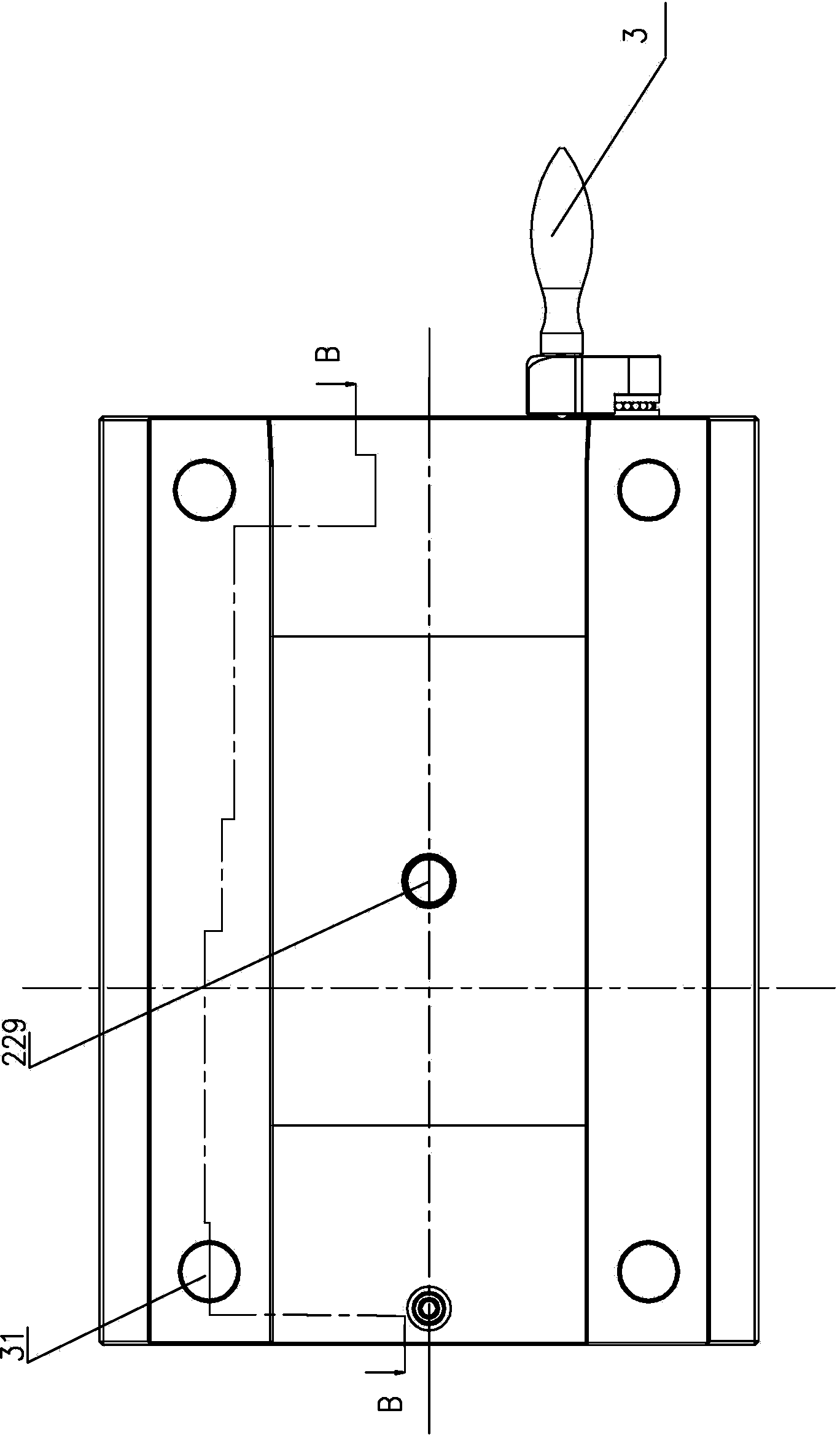

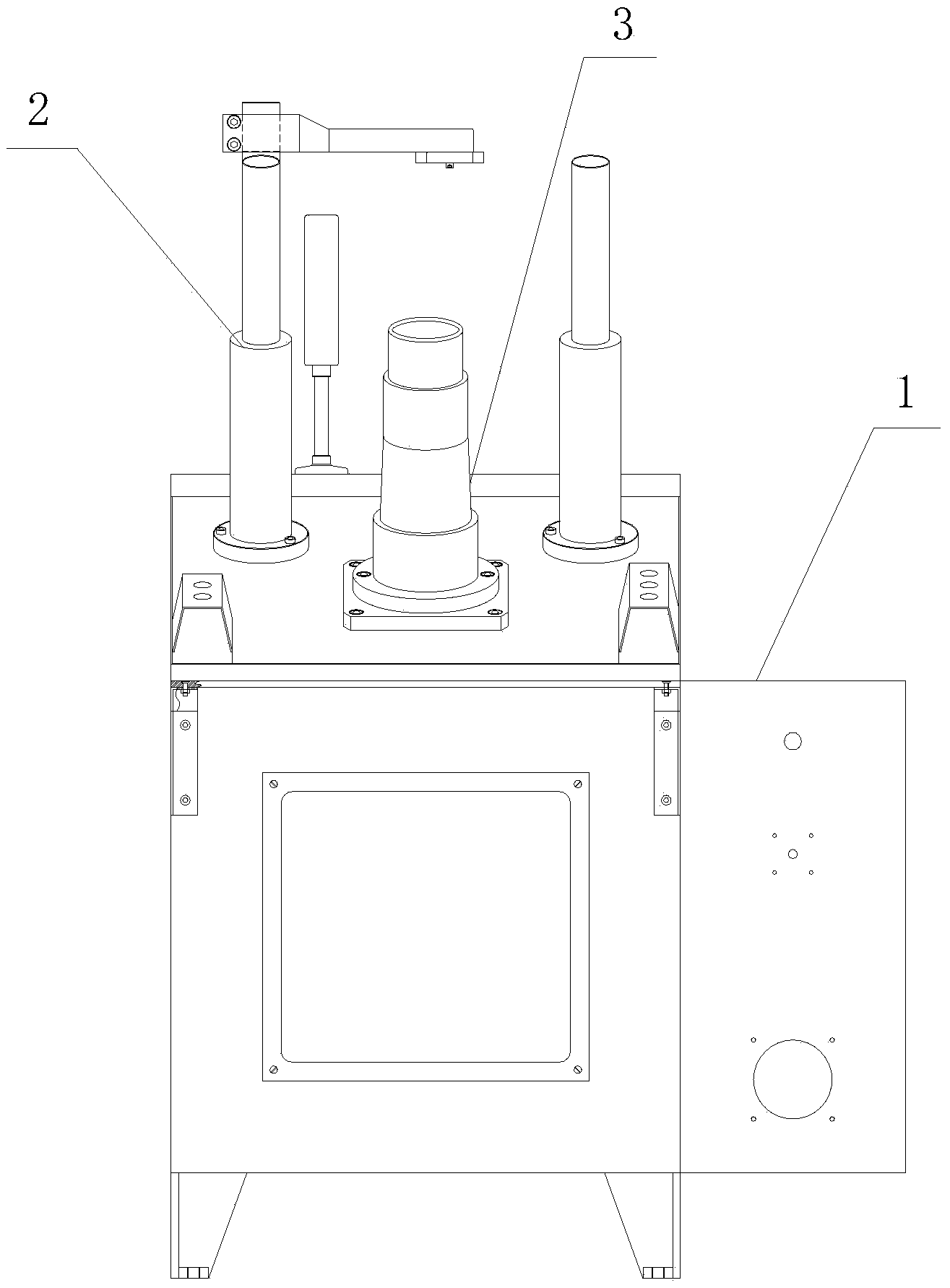

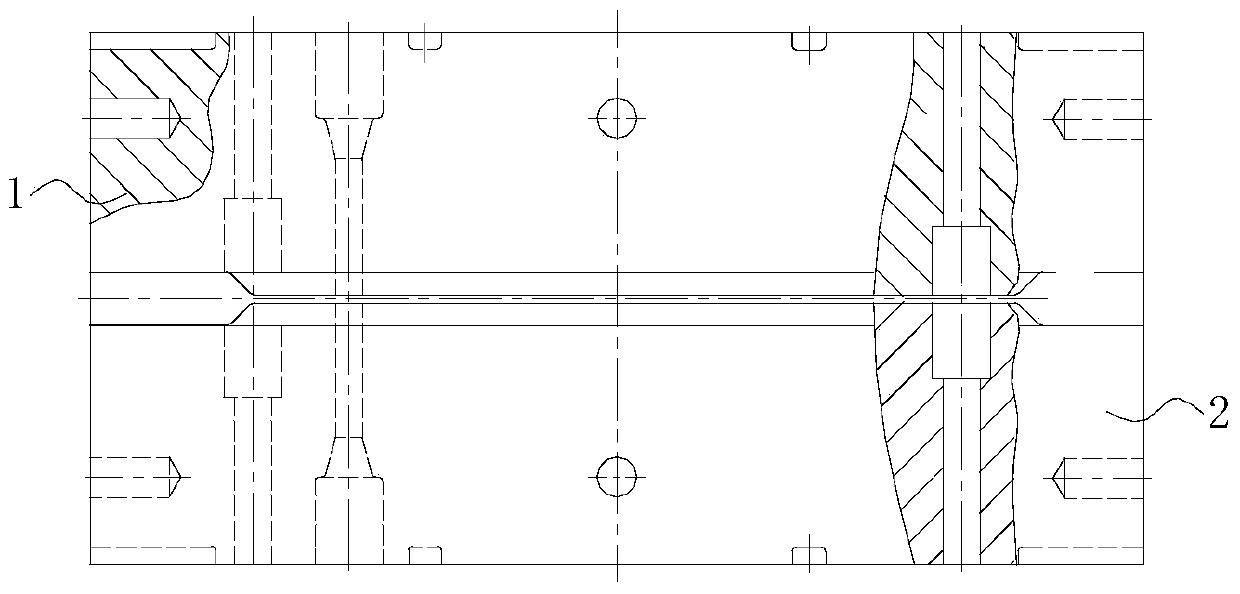

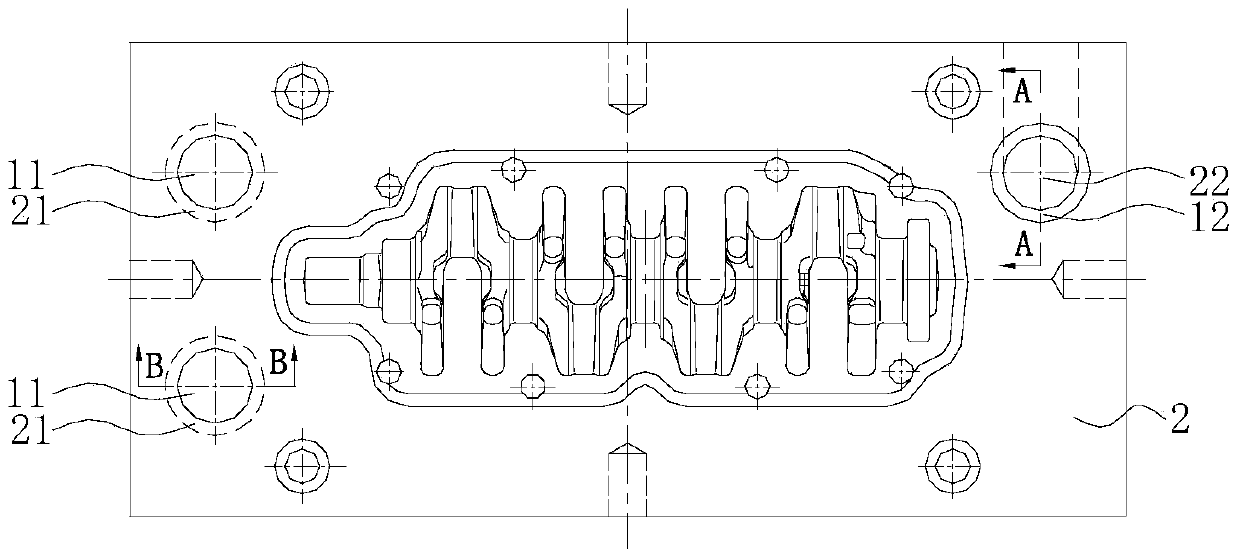

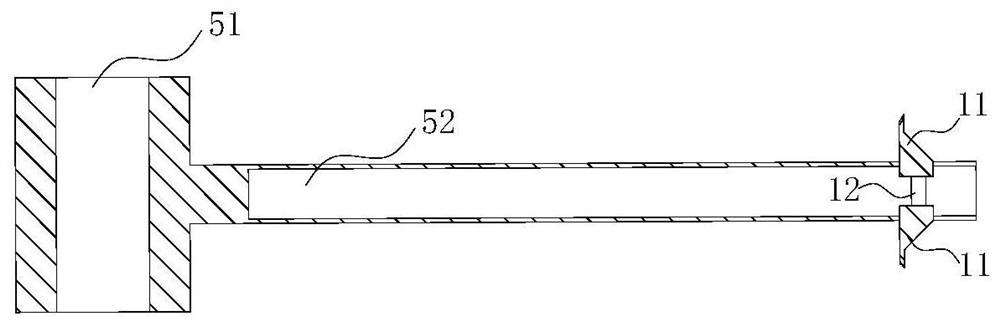

Injection mould with rapidly-replaced mould cores

The invention discloses an injection mould with rapidly-replaced mould cores. The injection mould is composed of a movable mould and a stationary mould, wherein a main body of the movable mould is composed of a movable mould base and a movable mould core movably arranged on the movable mould base; a main body of the stationary mould is composed of a stationary mould base and a stationary mould core movably arranged on the stationary mould base; the butt joint faces of the movable mould base and the stationary mould base are respectively provided with a mould core mounting sliding chute which horizontally extends from front to back; at least the front ends of the mould core mounting sliding chutes are provided with plug-in mounting holes for mounting or dismounting the mould cores; the mould cores are provided with tracks matched with the mould core mounting sliding chutes so as to move along the mould core mounting sliding chutes; and the mould cores are inserted to or dismounted from the mould core mounting sliding chutes on the mould bases through the plug-in mounting holes, thus the mould cores are replaced. According to the invention, only one set of mould base needs to be manufactured to be matched with the mould cores of different cavities which are manufactured according to spline standards tested based on different performance indexes; the mould replacing operation is easier and more convenient than that of the prior art, so that the mould replacing time is greatly shortened; and the manufacturing cost of various test spline moulds can also be greatly reduced.

Owner:GUANGZHOU MODERN PLASTIC CO LTD

Rubber extrusion equipment

Owner:ZHANG JIAGANG BAIXIONG KLIMENS MACHINERY

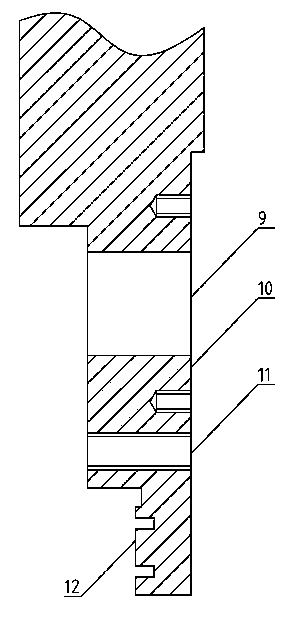

Novel guide column and guide sleeve structure of crankshaft forging die

InactiveCN105081175ASolve the problem of difficult misalignment controlGuaranteed shapeShaping toolsForging/hammering/pressing machinesEngineeringMechanical engineering

The invention discloses a novel guide column and guide sleeve structure of a crankshaft forging die. The novel guide column and guide sleeve structure is used for guiding the relative movement between an upper die forging die body and a lower die forging die body of the forging die. The novel guide column and guide sleeve structure comprises three guide column and guide sleeve sets arranged on the parting face between the upper die forging die body and the lower die forging die body. Each guide column and guide sleeve set comprises a guide sleeve only fixed to and positioned on the upper die forging die body or the lower die forging die body, and a guide column which is only fixed to and positioned on the lower die forging die body or the upper die forging die body, corresponding to the guide sleeve on the upper die forging die body or the lower die forging die body and is positioned in the guide sleeve in a slidable and penetrating manner. The three guide column and guide sleeve sets include the two guide column and guide sleeve sets at the two ends of one side of the parting face, and the guide column and guide sleeve set on the other side of the parting face, wherein only one end of the guide column and guide sleeve on the other side of the parting face is positioned. The distribution direction of the guide columns and the guide sleeves, on the upper die forging die body and the lower die forging die body, of the corresponding two guide column and guide sleeve sets is opposite to the distribution direction of the guide column and the guide sleeve, on the upper die forging die body and the lower die forging die body, of the other guide column and guide sleeve set. The novel guide column and guide sleeve structure is simple in structure, beneficial to die arrangement, die replacement and adjustment, convenient and rapid to operate and use, capable of effectively solving the problem that the forging piece offset amount is difficult to control, high in forging process stability and good in product consistency.

Owner:重庆大江杰信锻造有限公司

A kind of production method and production system of bevel gear

Owner:十堰万恒科贸发展有限公司

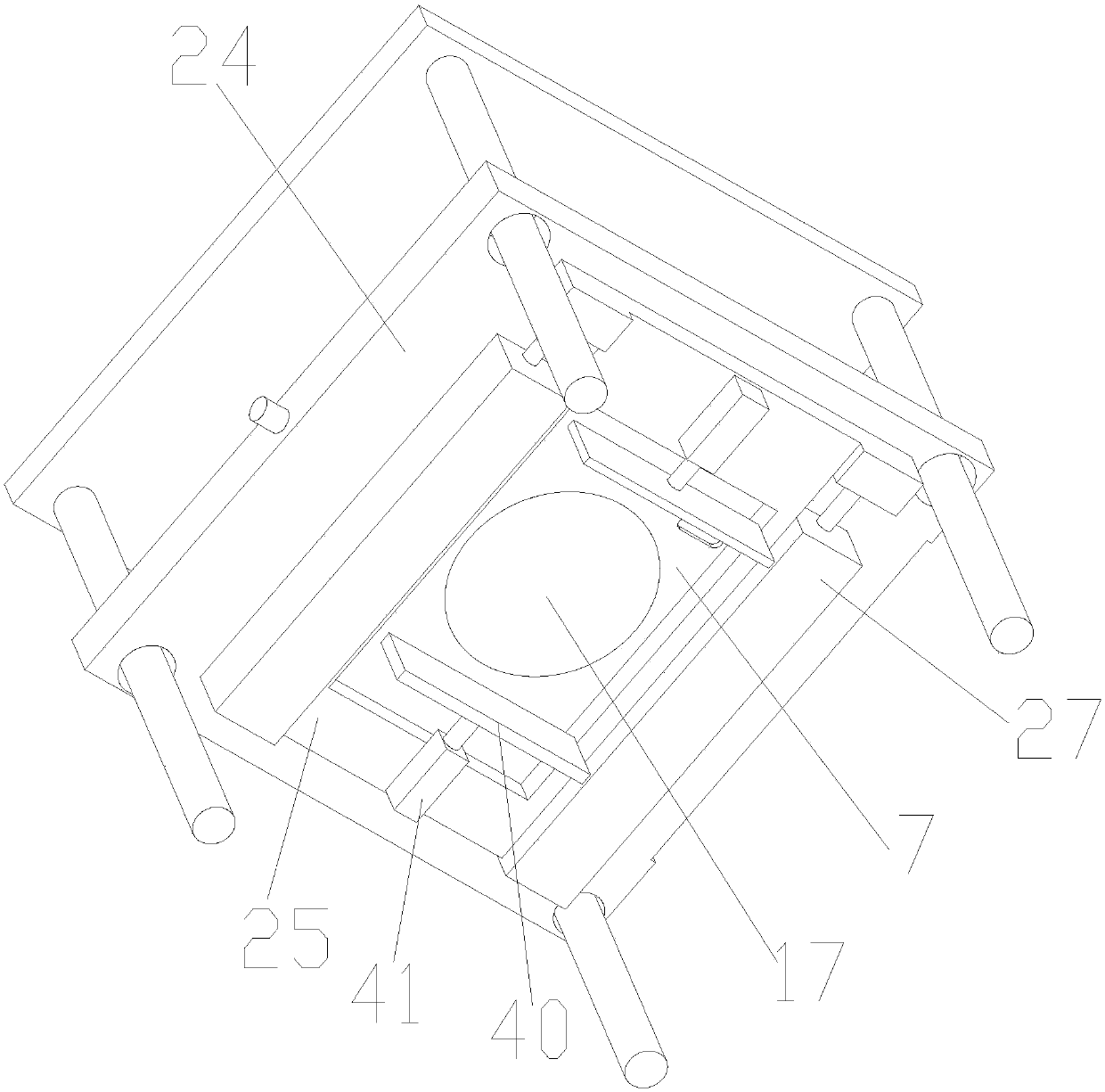

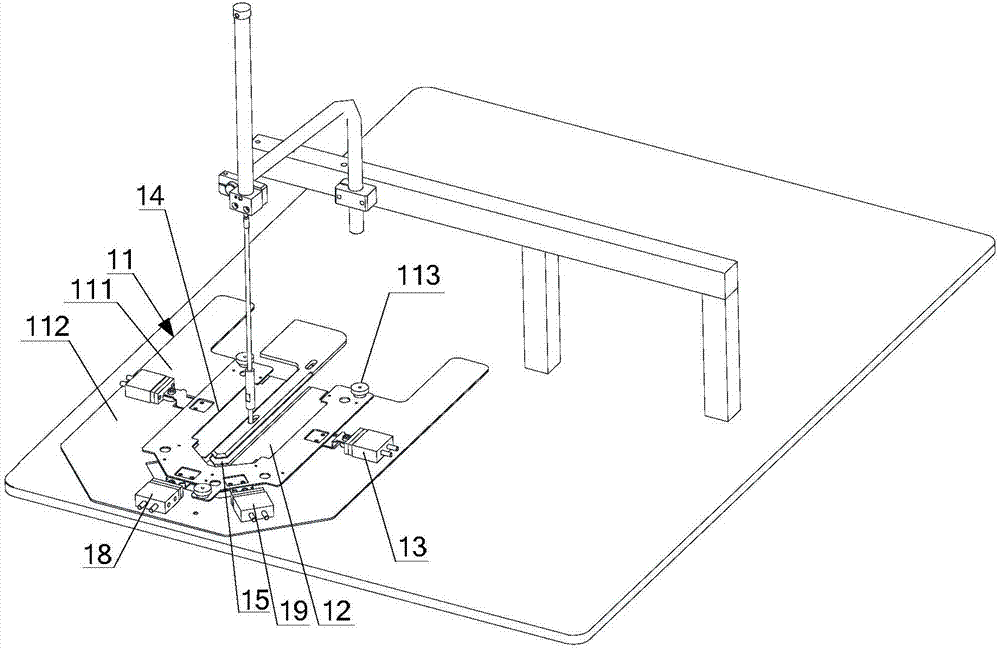

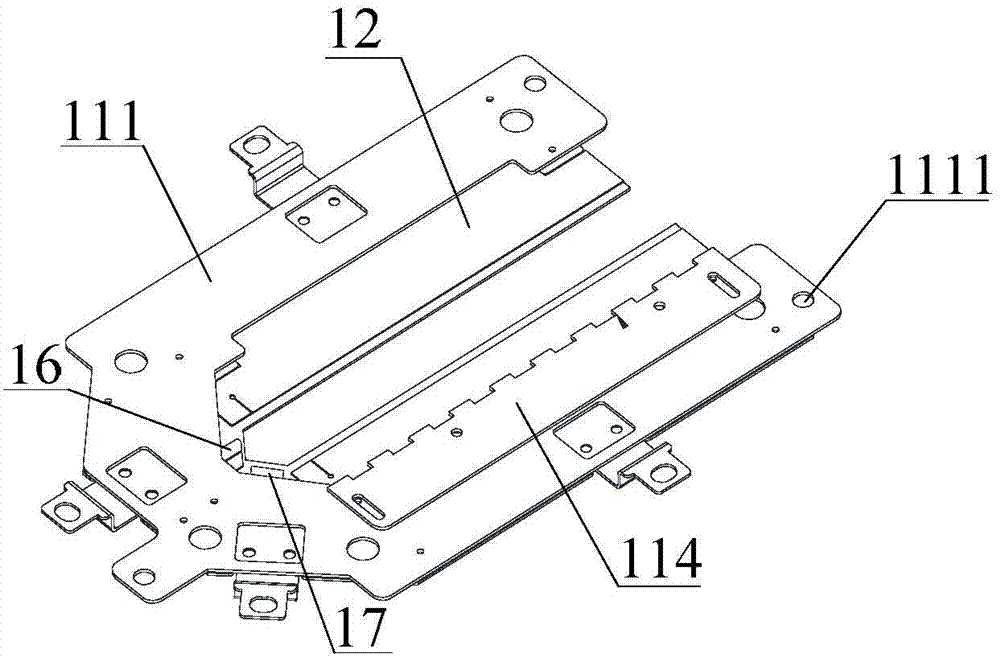

Sleeve vent folding mechanism with replaceable template

PendingCN107488945AEasy to change moldThe process of mold change is convenient and fastWork-feeding meansReciprocating motionStructural engineering

The invention provides a sleeve vent folding mechanism with a replaceable template. The sleeve vent folding mechanism comprises a template assembly, two first insertion pieces and two first transmission assemblies. The template assembly is provided with a machining groove which extends in the first direction and opened in the first end of the template assembly. The middle of the machining groove is indented downward to form a shaping groove extending in the first direction. The template assembly forms an installation space. The first insertion pieces are parallel to the first direction and oppositely arranged in the portions, on the two sides of the machining groove, of the installation space through the first transmission assemblies in a reciprocating mode in the second direction respectively. The first direction is perpendicular to the second direction. The sleeve vent folding mechanism can assist the sleeve vent folding work and has the advantages of being convenient to operate, beneficial for template replacing, strong in universality and stable in machining quality.

Owner:SHANGHAI WEISHI MACHINERY

Aluminum profile bending forming system

InactiveCN111659774AEasy to change moldAccurately distinguish typesShaping toolsEngineeringMechanical engineering

The invention discloses an aluminum profile bending forming system, and belongs to the technical fields of aluminum profile bending. The aluminum profile bending forming system comprises a worktable,a bending cylinder, and a mold-changing bending mechanism. The bending cylinder and the mold-changing bending mechanism are arranged on the worktable, the bending cylinder is located at one side of the mold-changing bending mechanism, the mold-changing bending mechanism is provided with a first mold bracket and a second mold bracket, and the first mold bracket and the second mold bracket are connected with a plurality of male molds and female molds. The replacement of the different molds can be realized through movement, when aluminum profiles need to be subjected to different types of bending, the molds are more convenient to replace, and time and effort are not wasted.

Owner:张政

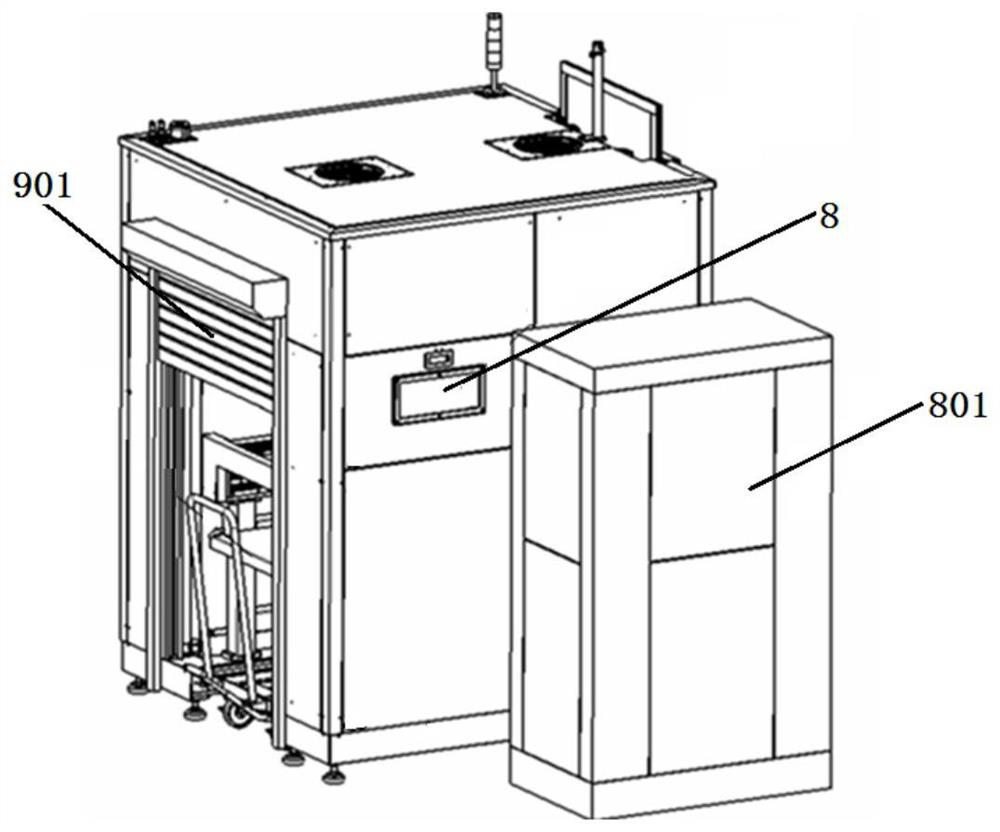

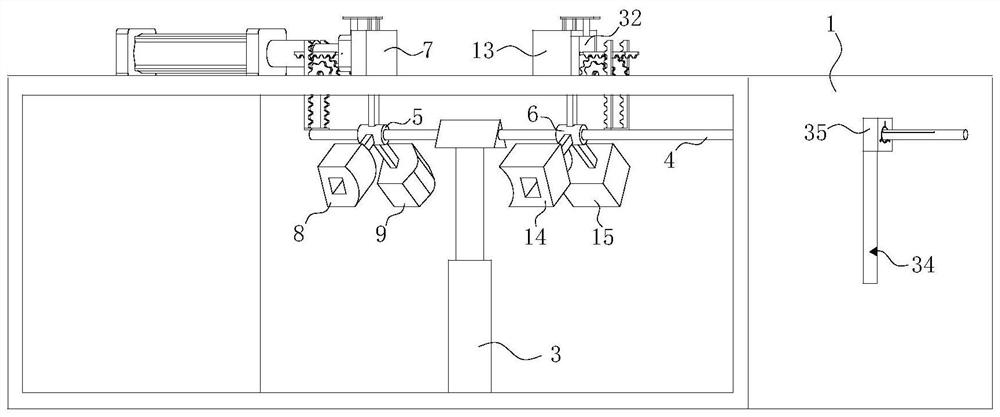

Lithium battery aluminum plastic film automatic forming machine

InactiveCN103915581BSmooth transmissionEasy to change moldSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsMolding machinePlastic film

The invention relates to a lithium battery aluminum-plastic film automatic forming machine, which includes a lithium battery aluminum-plastic film transmission device, a lithium battery aluminum-plastic film forming device and a cutting device. The lithium battery aluminum-plastic film forming device includes an upper mold device, a lower mold device, Fixing device and power device, the lower mold device slides up and down on the fixing device driven by the gas-hydraulic booster cylinder, the upper mold device includes the lower mold connecting plate, the eccentric wheel connecting plate, and the straight line connecting the two ends of the lower die connecting plate and the eccentric wheel connecting plate Bearing guide column, install an eccentric shaft on the inner side of the forming lower cover plate, install a coupling and deceleration servo motor on the outside of the forming cover plate, the coupling connects the deceleration servo motor and the eccentric shaft, and install a crankshaft on the eccentric shaft The crankshaft connecting plate is connected and drives the eccentric connecting plate of the upper mold device. The lower mold device of the present invention is driven by a deceleration servo motor, and the upper mold device is driven by the forming eccentric shaft and the crankshaft connecting plate, and the upper mold device is used for upper molding. The deceleration servo motor can be controlled by molding, and the automatic adjustment stroke can be adjusted to achieve precise control. , can be adapted to a variety of product processing.

Owner:广东赛洋科技有限公司

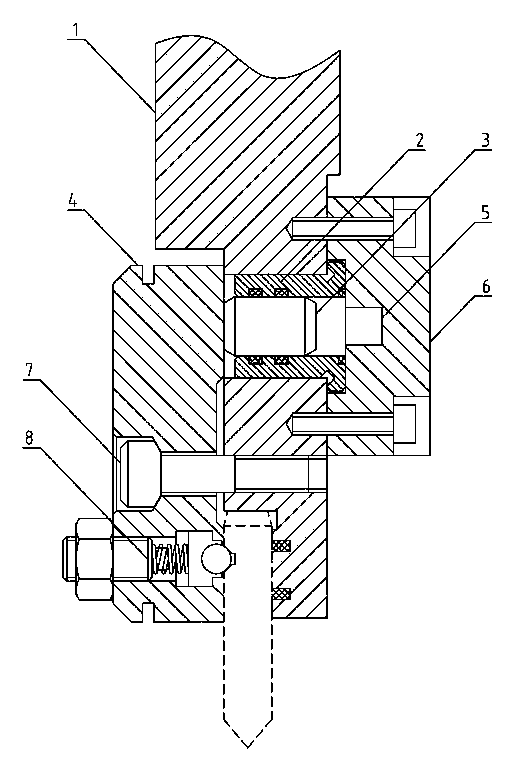

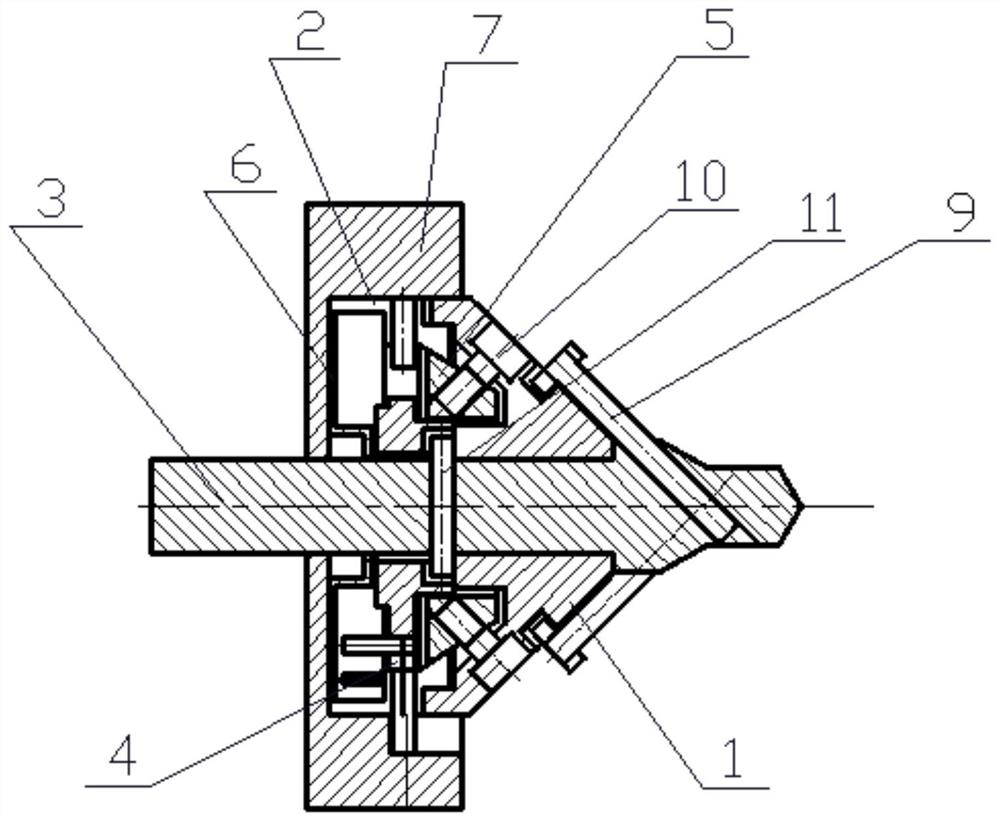

Flanging hole machining die device

The invention discloses a flanging hole machining die device. The flanging hole machining die device comprises a positioning sleeve and a hole drilling and flanging mandrel, wherein the hole drilling and flanging mandrel penetrates through the positioning sleeve; a conical spiral guide sleeve is connected to the hole drilling and flanging mandrel; a hole drilling and flanging positioning piece is connected to the conical spiral guide sleeve; two sets of flanging pins are connected to the two sides of the hole drilling and flanging positioning piece through two sets of screws respectively; a hole drilling and flanging adjusting guide sleeve is arranged in the positioning sleeve; an axial block is connected to the hole drilling and flanging adjusting guide sleeve; a hole drilling and flanging mandrel sheet is arranged on the hole drilling and flanging mandrel; a disc type spring sheet is arranged on the hole drilling and flanging mandrel; and a fixing needle is arranged on the disc type spring sheet. According to the flanging hole machining die device, a conical spiral principle is utilized, and a conical spiral groove is driven by rotation, so that a flanging hole can be machined at one time, the production efficiency is increased, the appearance is uniform, and the quality is stable.

Owner:广东恒基金属股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com