Aluminum alloy plate bending limit evaluation device capable of automatically adjusting gap

A technology of aluminum alloy plate and bending limit, which is applied in the direction of applying stable bending force to test the strength of materials, measuring devices, and analyzing materials. It can solve the problems of manual measurement of gap value and inability to record the bending process in real time, so as to save time and Economical cost, convenient mold change, simple card installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with the accompanying drawings.

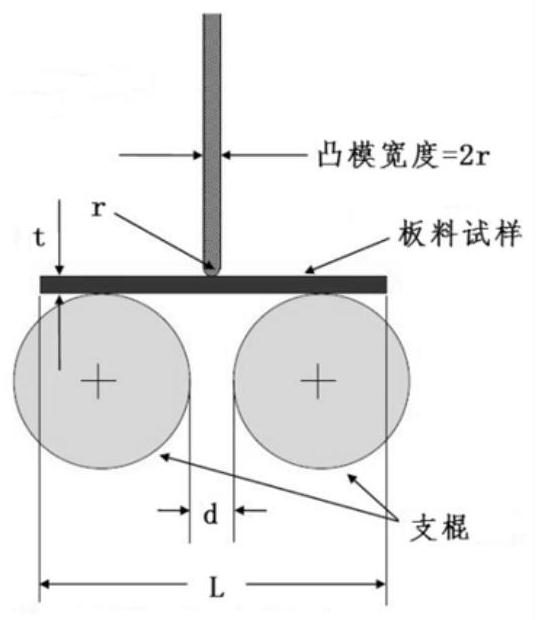

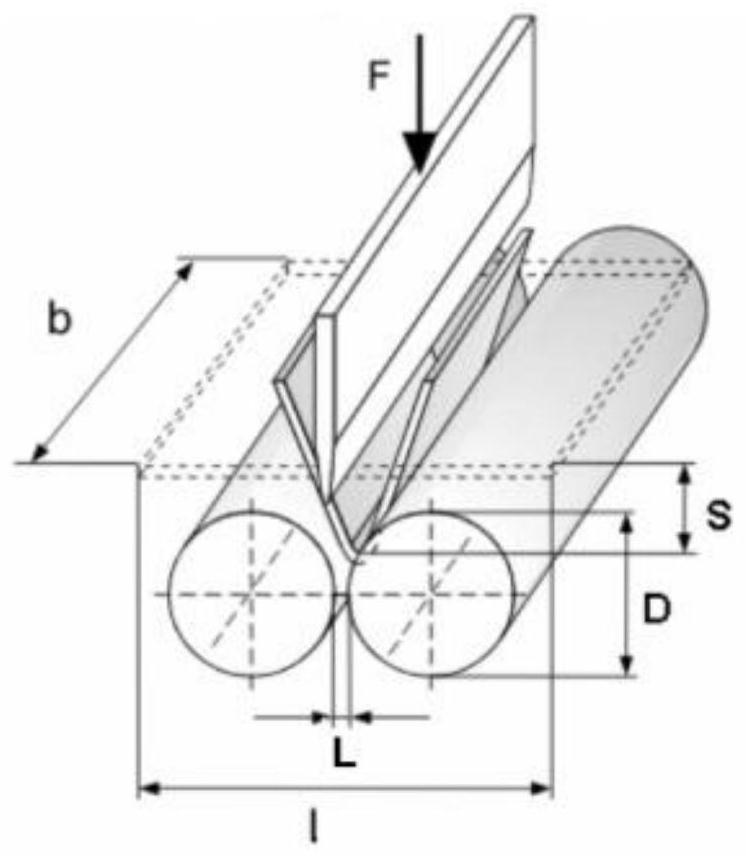

[0072] As mentioned earlier, the bending limit is an important index to study the bending properties of sheet metal. The existing bending limit evaluation device has disadvantages such as cumbersome adjustment process of the die distance, low adjustment accuracy, high requirements for the test experience of the adjustment personnel, and a low degree of automation.

[0073] Using the bending limit evaluation device described in the technical solution of the present invention can solve the above problems, so that testers can quickly and easily adjust the distance between the dies, and at the same time feed back the load and the stroke curve of the punch in real time to improve the test efficiency. The bending limit evaluation device can be applied to general and public limit bending standard tests at the same time.

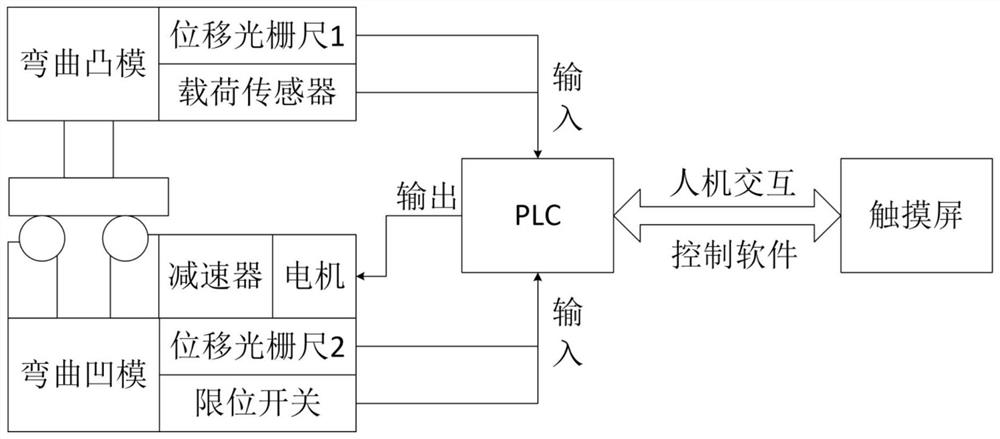

[0074] image 3 It is the overall design concept of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com