Universal mold frame achieving convenient and rapid mold change

A general-purpose formwork and convenient technology, applied in the field of general-purpose formwork, can solve the problems of not meeting the production and processing needs of enterprises, increasing the production cost of enterprises, and low efficiency of mold change, etc., to achieve compact structure, high processing efficiency and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

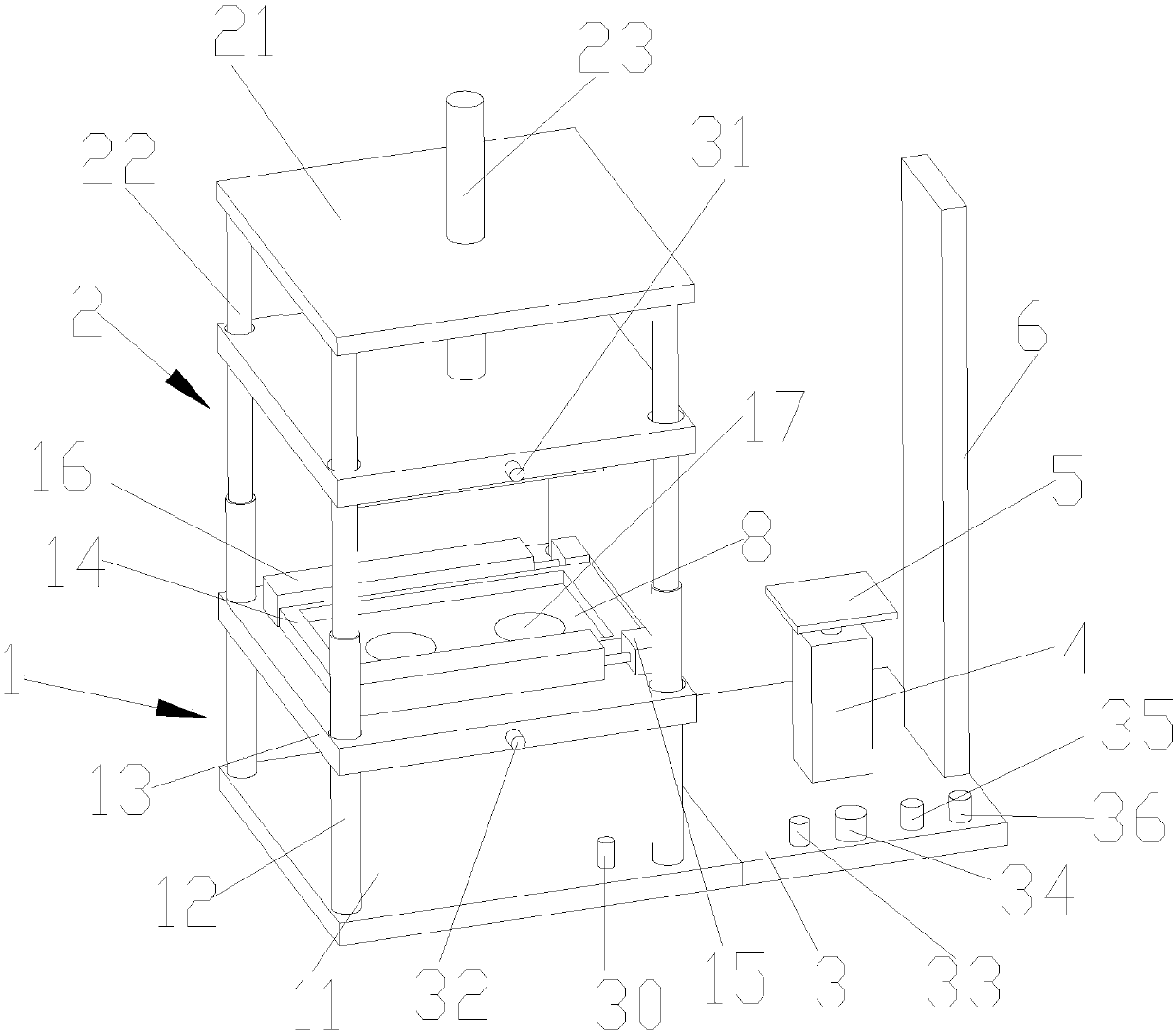

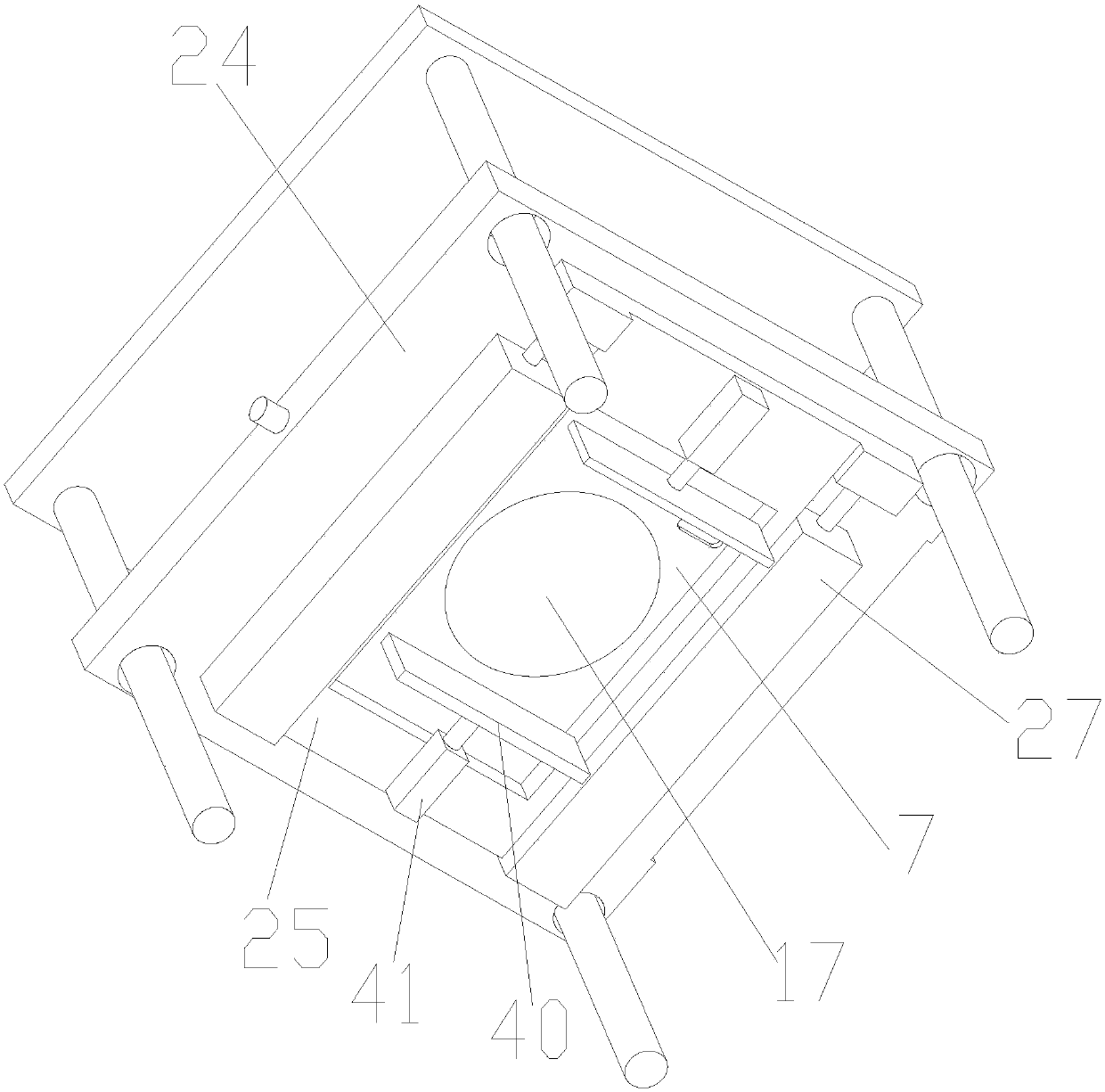

[0019] as attached Figure 1-2 The shown universal formwork of the present invention, which is convenient for mold change, includes an upper formwork structure 2 and a lower formwork structure 1 connected up and down, as well as a lower support plate 3, a jacking cylinder 4, a connecting block 5 and a positioning board6.

[0020] The lower formwork structure 1 includes a bottom plate 11, a lower guide column 12, a lower template 13, a lower moving plate 14, an electromagnet 15, a first moving cylinder 16, and an electromagnetic chuck 17; Guide post 12, the material of the above-mentioned lower guide post 12 is an electromagnet; the lower guide post 12 is fixed with a lower template 13; the lower template 13 is provided with a lower moving plate 14; the two sides of the lower moving plate 14 Link to each other with the first moving c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com