Upper die clamp-type hydraulic clamping device of bending machine

A hydraulic clamping and die clamping technology, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of short service life of hydraulic cylinders, high labor intensity of operators, and poor positioning accuracy of upper dies, etc. High mold positioning accuracy, compact structure, and high mold clamping positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

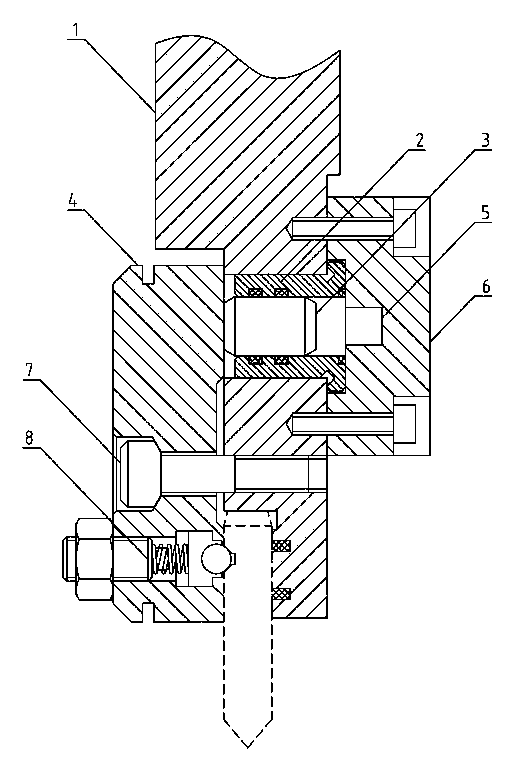

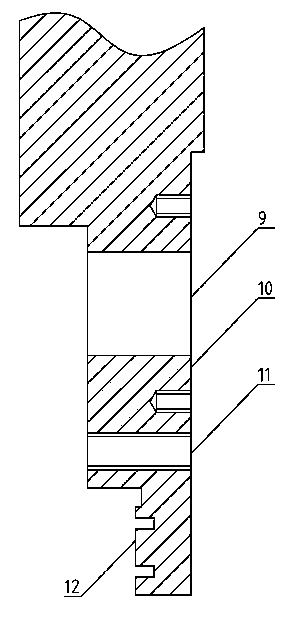

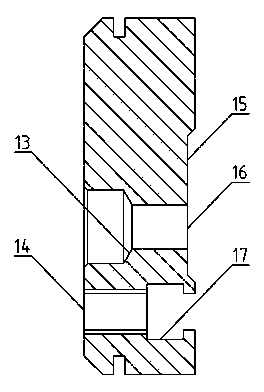

[0016] Embodiment: (see for details figure 1 ) A clamp-type hydraulic clamping device for a bending machine, which is provided with a driving slider 1 and a plunger hydraulic cylinder 2, and the lower end of the driving slider 1 is provided with a mounting plate 10 (see figure 2 ), the mounting plate 10 is respectively provided with mounting holes 9, connecting screw holes 11 and clamping positions 12; especially: the plunger hydraulic cylinder 2 is installed in the mounting holes 9 on the mounting plate 10 of the drive slider 1, and the mounting plate 10 is located on one side of the cylinder body of the plunger hydraulic cylinder 2, and a pressure plate 6 is installed, and the mounting plate 10 is located on the other side of the piston rod 3 of the plunger hydraulic cylinder 2, and a clamping plate 4 is installed with a ball screw 7, and the clamping plate 4 There is a card slot 17 below (see image 3 ), a tensioning mechanism 8 is installed in the card slot 17 of the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com