Turboshaft Engine Compressor Case Spraying Method and Its Protective Fixture

A technology for turboshaft engines and compressors, which can be used in coatings, devices for coating liquids on surfaces, and pre-treated surfaces, etc., and can solve problems such as easy deformation of casings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

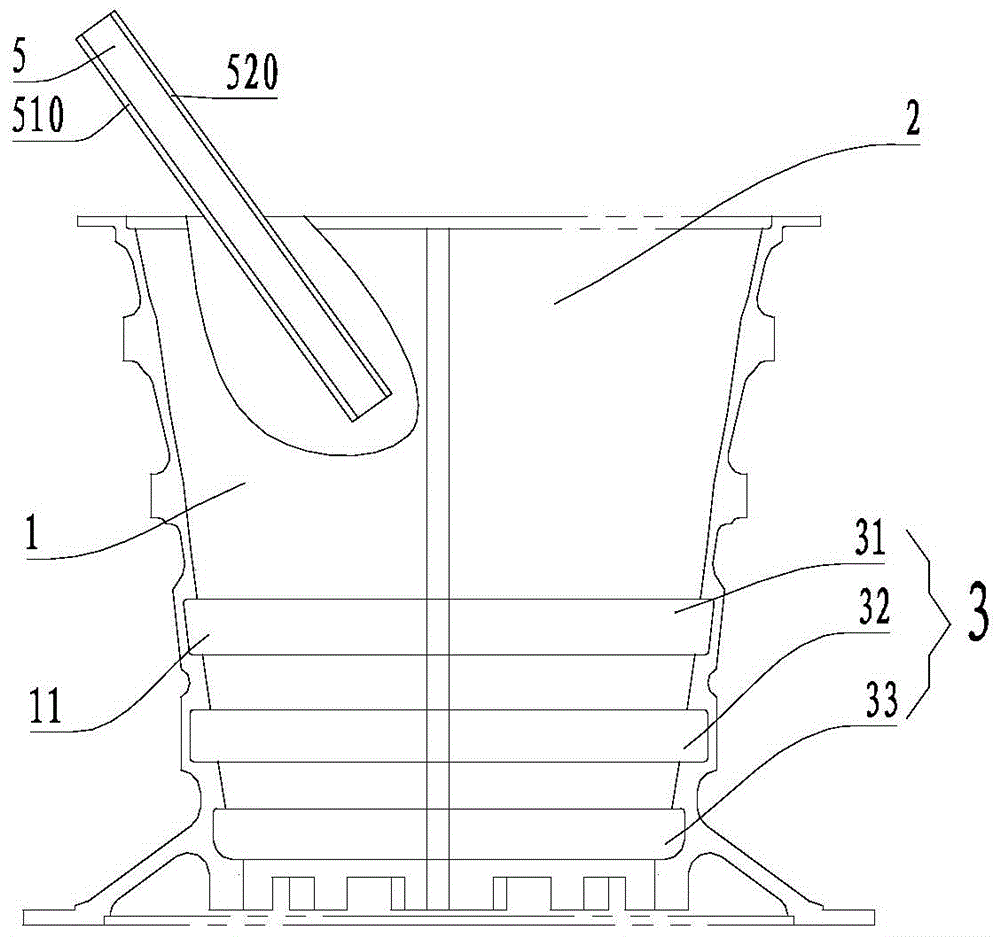

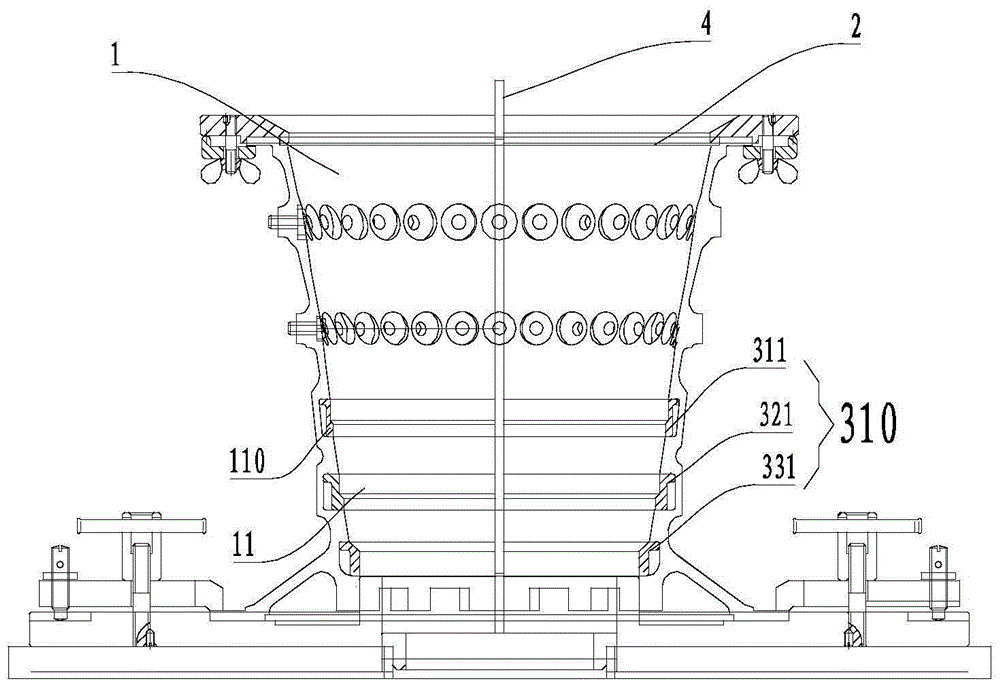

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0031] In the turboshaft engine compressor casing spraying method provided by the present invention, the first casing 1 and the second casing 2 are combined for spraying. The deformation caused by spraying after the combination of the first casing 1 and the second casing 2 will be digested inside the casing, and combined with heat treatment, shot blasting and other processes to control the deformation of the casing after spraying coating within 0.05mm.

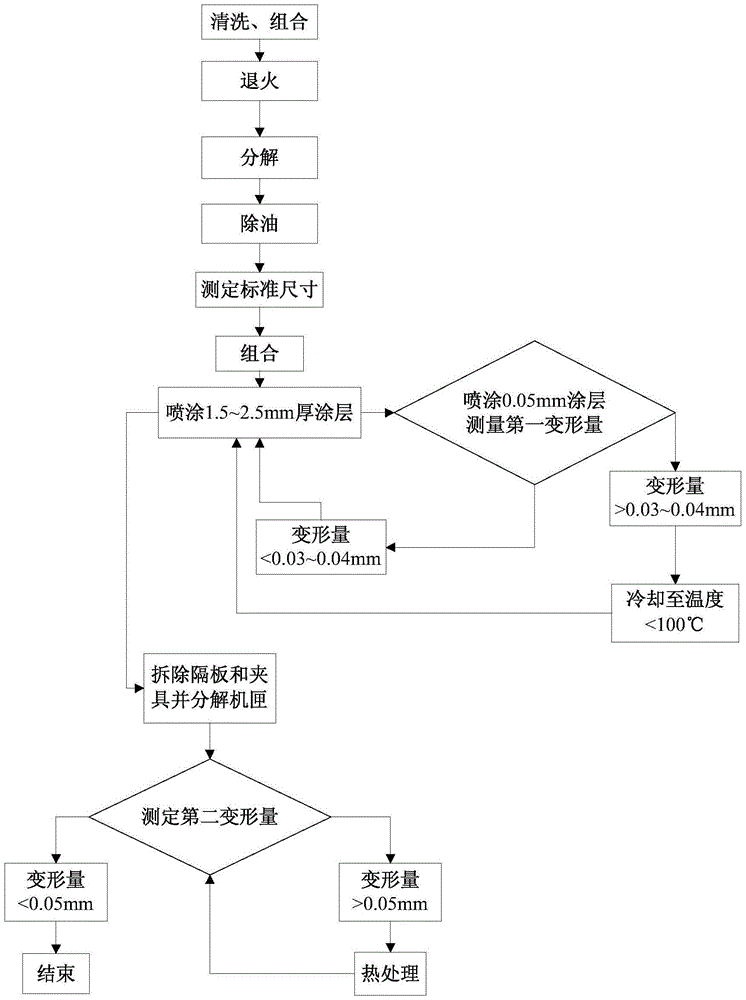

[0032] see figure 1 , the method includes the following steps:

[0033] 1) Measuring the standard size: measure the size of the first casing 1 and the second casing 2 to obtain the standard size. The first casing 1 and the second casing 2 are combined according to a conventional method. Obviously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com