Method for processing integral concave mould of universal joint

A processing method and universal joint technology, applied in the field of mold processing, can solve the problems of large internal stress, shortening the service life of the mold, long mold processing cycle, etc., and achieve the simple and easy processing method, convenient mold loading and mold replacement , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

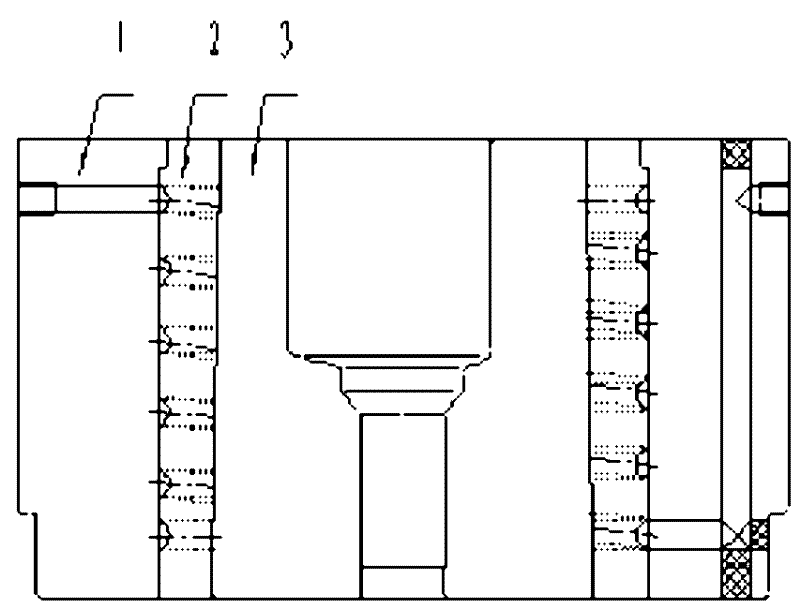

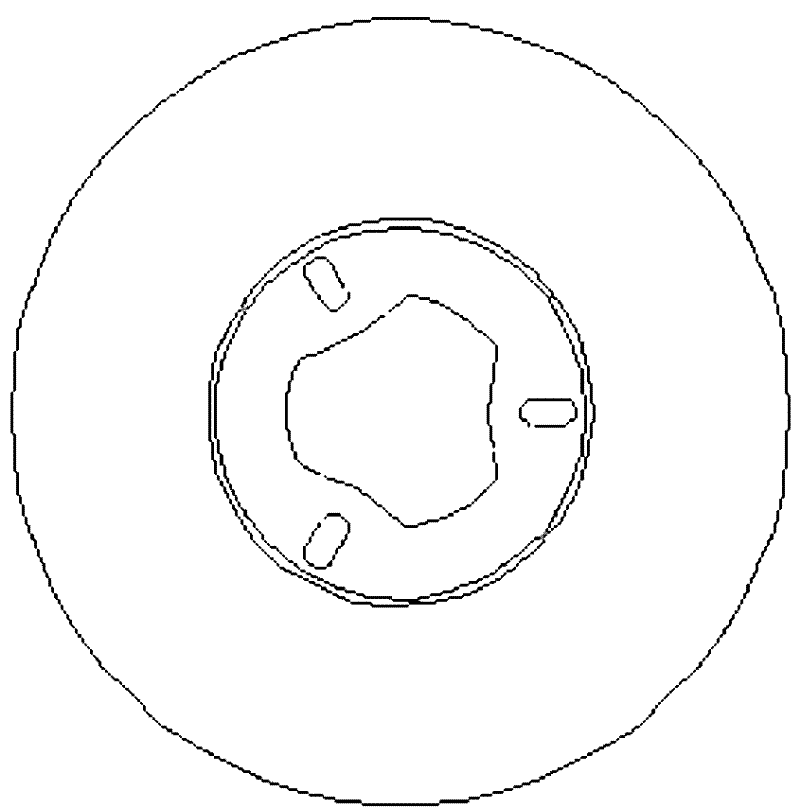

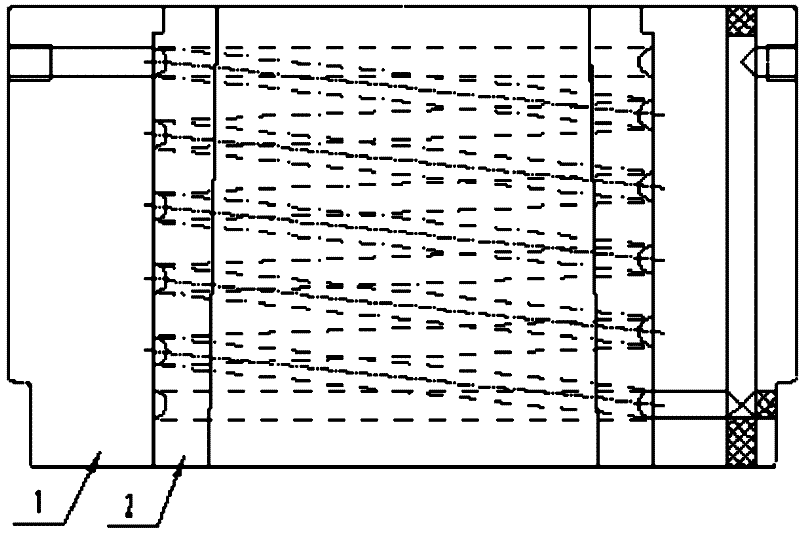

[0034] see Figure 1~5 As shown, taking the processing process of the reverse extrusion die of the GI8738 three-column grooved shell as an example, the processing method is:

[0035] (1) Processing of the outer mold:

[0036] 1) Saw material: For the saw material of large circle 1 and middle circle 2, choose die steel of φ290 and φ285mm, the material grade is H13, and the height is 170mm;

[0037] 2) Rough turning; the diameter of the outer circle of the large circle and the middle circle is φ180mm, and the height is 162mm;

[0038] 3) Heat treatment: Put the big circle into a vacuum furnace and heat it to 550°C, keep it warm for 40 minutes, continue to heat it to 850°C and keep it warm for 60 minutes, continue to heat it to 1060°C and keep it warm for 75 minutes, take the big circle out of the heating chamber, put it Cool in the oil pool for 10 to 12 minutes, then temper, and temper three times in the well tempering furnace; heat to 620°C for 120 to 180 minutes each time, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com