Edge-profiling, glue-injecting and oven-drying all-in-machine machine for bottom cover

An all-in-one, rounded edge technology, applied to devices that apply liquid to the surface, other household appliances, household appliances, etc., can solve the problems of low degree of automation, many power parts of the machine, not meeting energy-saving requirements, etc., to achieve the degree of automation High and easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

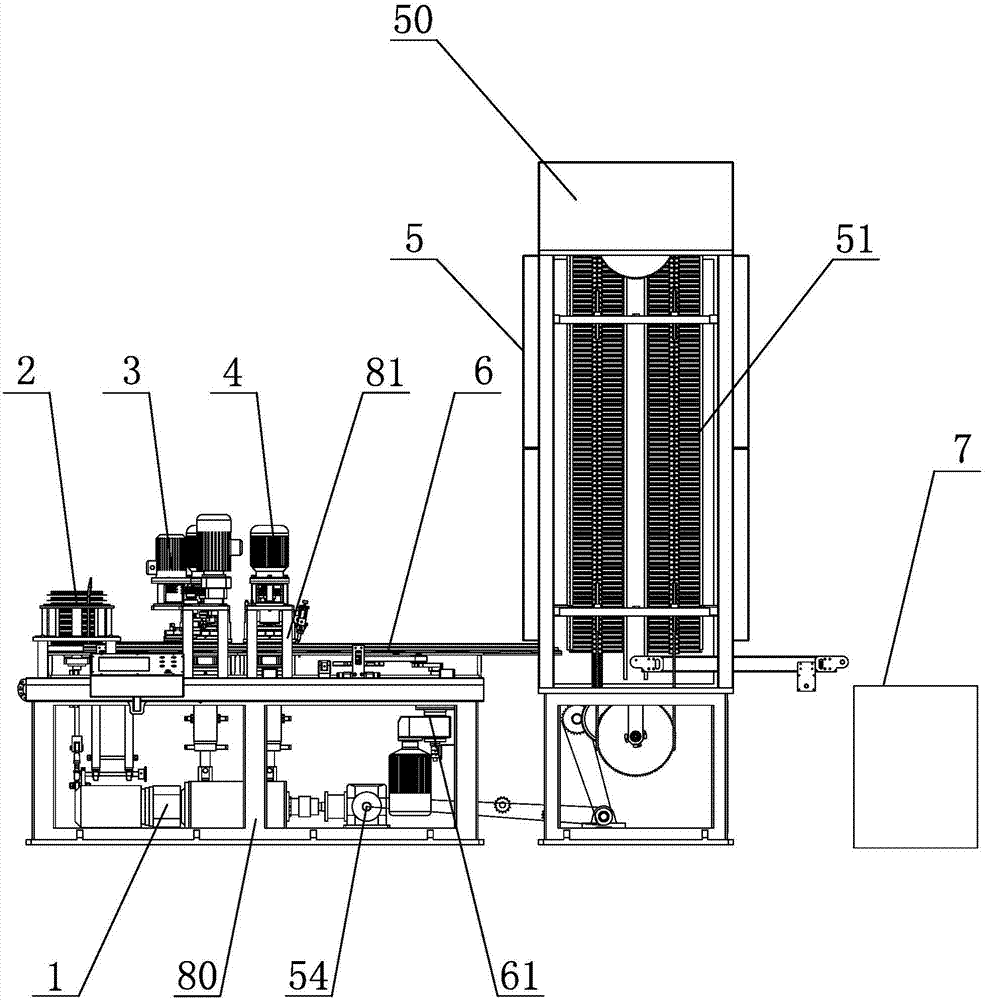

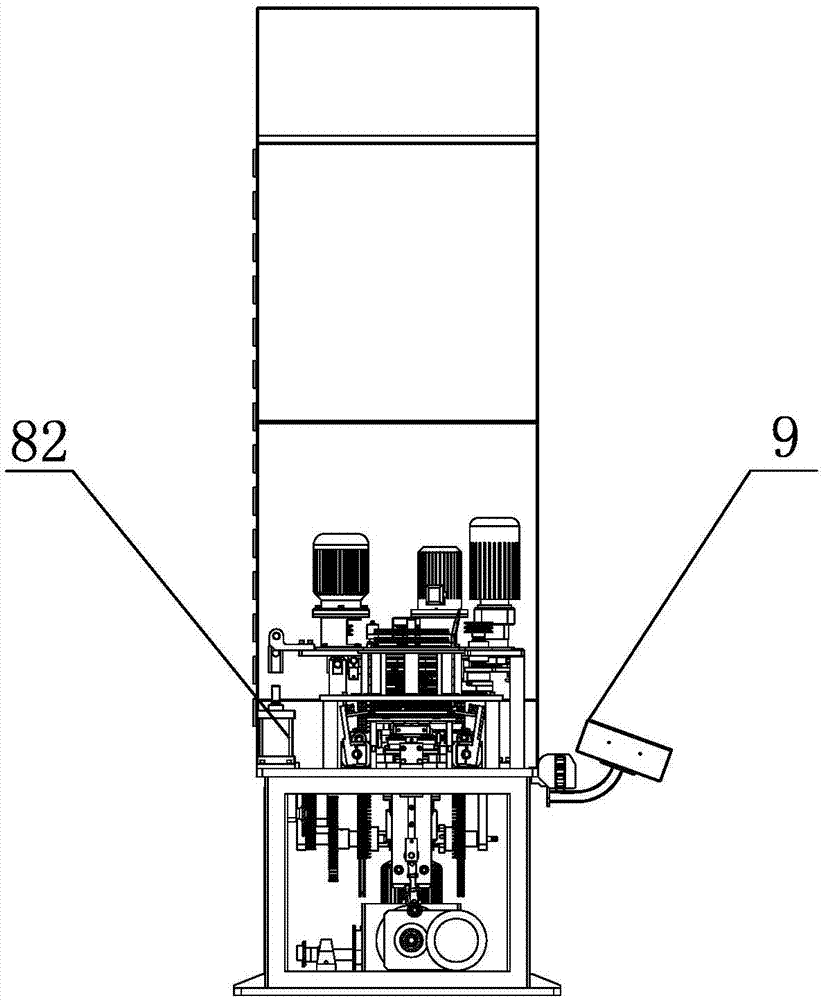

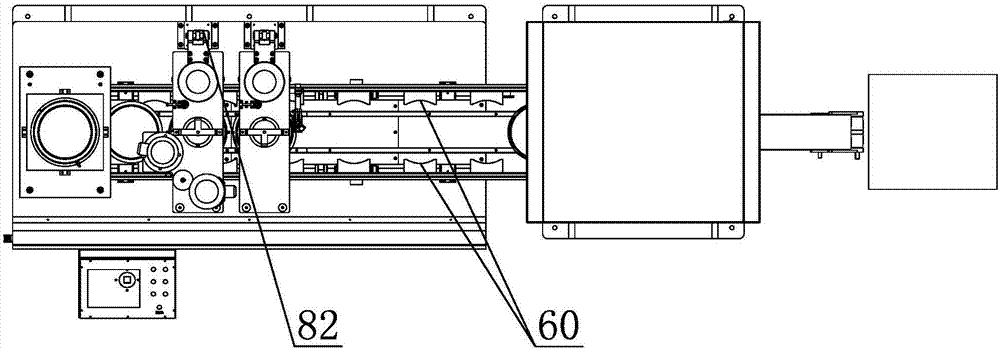

[0065] like Figure 1-3 The bottom cover round edge glue injection oven integrated machine shown in the figure includes a blanking mechanism, a round edge mechanism 3, a glue injection mechanism 4, an oven 5, a lower power mechanism 1, and a holding mechanism 6. The following details each mechanism describe:

[0066] like Figure 4 As shown: the lower power mechanism 1 includes a total power motor 10, a power transmission shaft 11 connected to the total power motor 10, a blanking lifting assembly connected to the power transmission shaft 11, a round edge lifting assembly, and a glue injection lifting assembly . In this example:

[0067] The round edge lifting component and the glue injection lifting component have the same structure, wherein the round edge lifting component is located under the round edge mechanism for the round edge process, and the glue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com