Quick change device for female die

A technology of concave molds and mold bases, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of low universality of mold bases, high cost of opening molds, cumbersome and time-consuming operations, affecting experiments, and production efficiency. The effect of facilitating multi-process stamping operations, overcoming installation gaps, and shortening die change time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

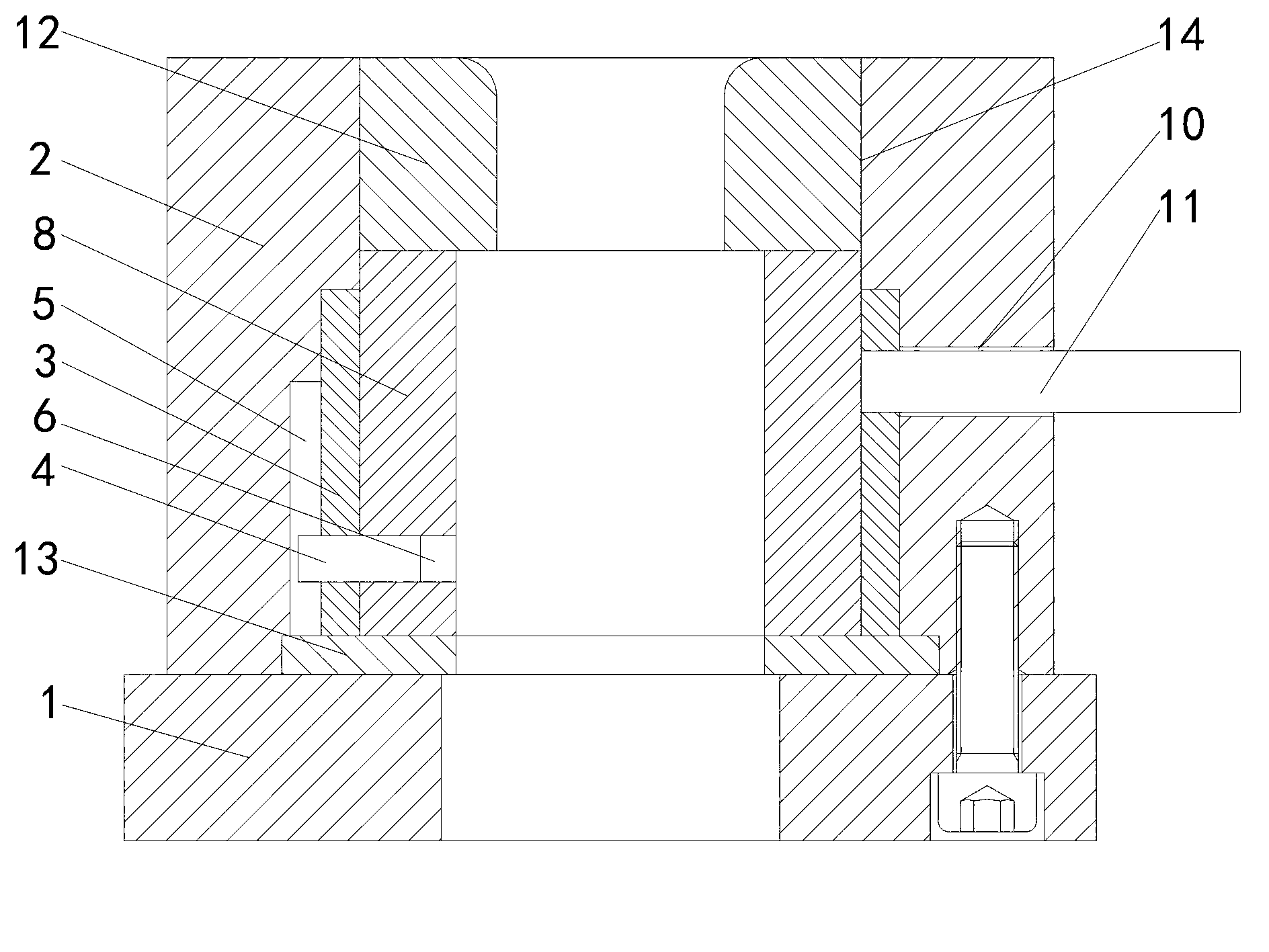

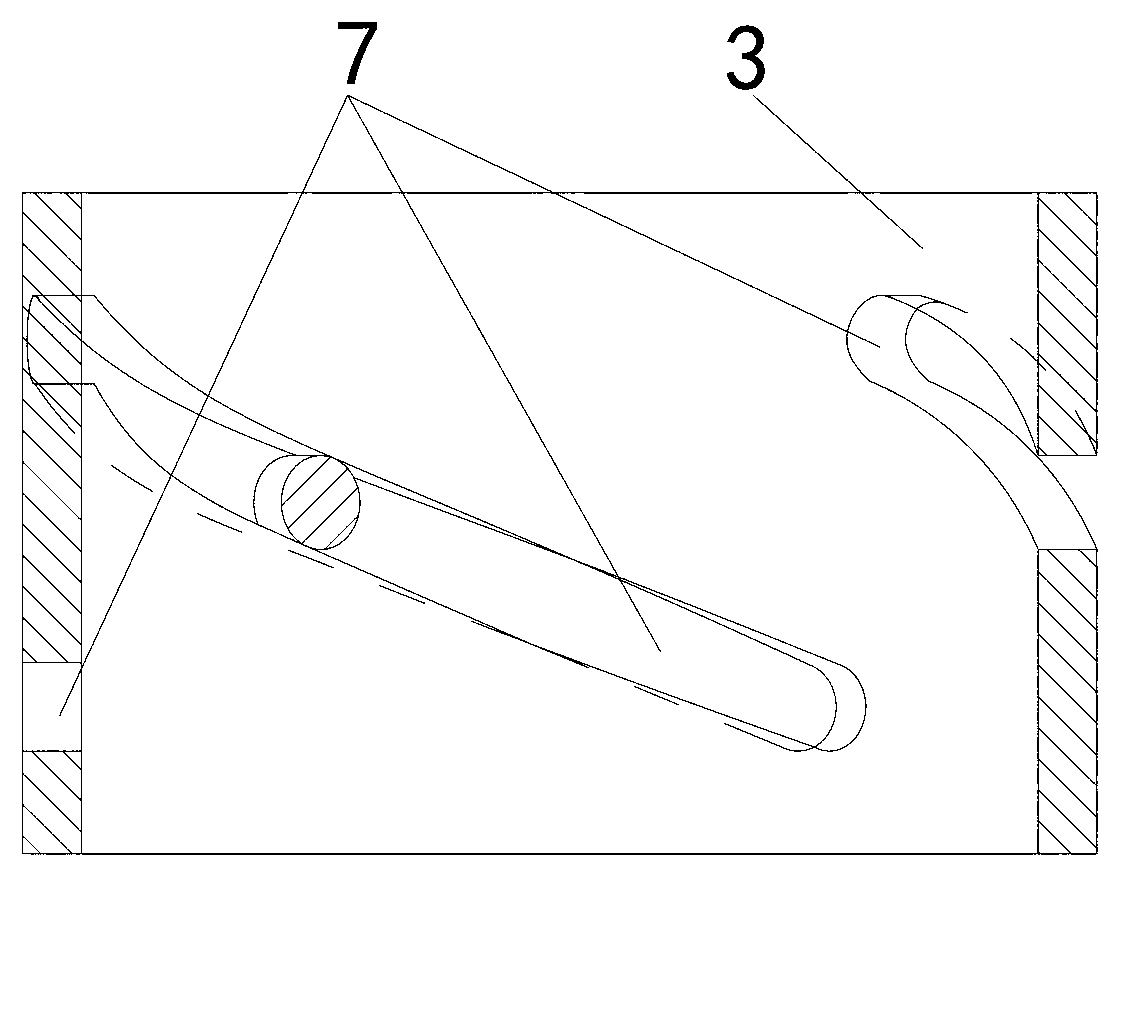

[0019] See 1 and figure 2 , the solution of this embodiment is: a die quick change device, mainly composed of a die base 1, a die holder 2, a die 12 and a die pad 8, the die holder 2 is a hollow cylindrical tube body and is fixed on the die base 1, the die 12 and the die pad 8 are arranged inside the die holder 2, the die 12 is supported by the die pad 8, and the die pad 8 There is also a spiral sleeve 3 between the inner wall of the die holder 2, and the wall of the spiral sleeve 3 is provided with a track groove 7 and a socket 9, and a pin hole 6 is provided on the wall of the die pad 8, A handle slot 10 and a sliding pin limiting groove 5 are provided on the wall of the die holder 2, and the track groove 7, the pin hole 6 and the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com