Combined cutting tool for processing finned tube

A technology of finned tubes and cutters, which is applied in the field of improvement of cutter combinations, can solve the problems of high weight per unit length of finned tubes, high cutter cost, and low fin height, etc., and achieve thinner fin thickness, lower cutter cost, The effect of reducing mold change time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

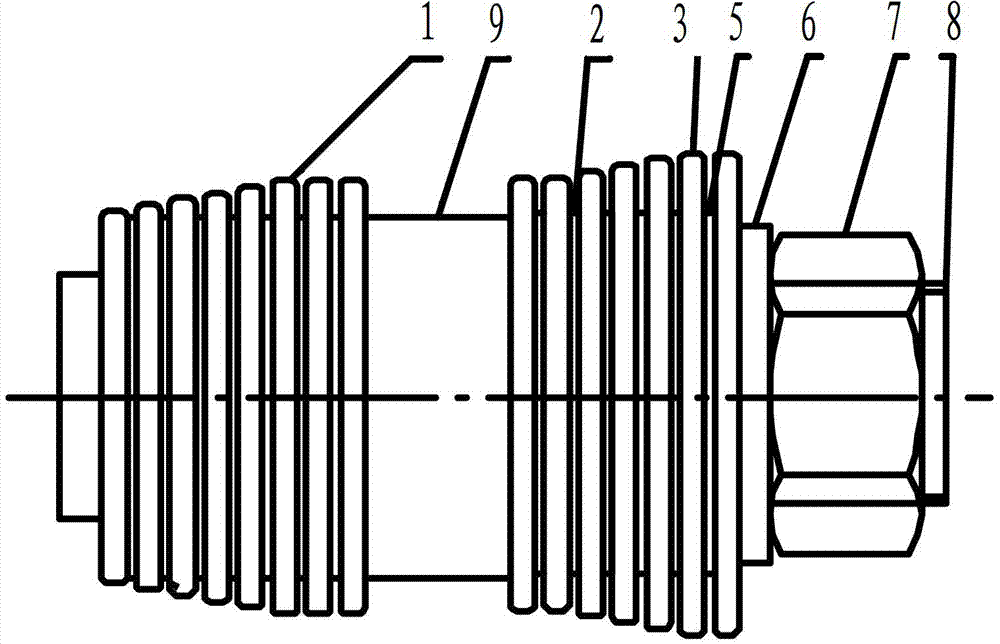

[0036] Embodiment one, such as Figure 4 As shown, according to the present embodiment, the tool for processing finned tubes and its combination include a main shaft 8, a transition blade 1 fixedly sleeved on the main shaft 8 from left to right, a transition spacer 2 clamped in the middle of the transition blade, and a row of Positioning washer 4 at the position behind transitional blade 1, shaped blade 3, shaped washer 5, washer 6 and nut 7 for locking and fixing the blade.

[0037]In this embodiment, a combination of unsharpened blades plus gaskets and unsharpened blades of different thicknesses plus gaskets of different thicknesses is used. The thickness of the transition blade 1 is 0.4 mm. There are 9 transition blades from left to right. The diameters are 65.4mm, 65.6mm, 65.8mm, 66mm, 66.2mm, 66.4mm, 66.6mm, 66.8mm, 67mm. In the middle of the transition blade 1 are 8 transition gaskets 2 with a thickness of 0.25 mm and an outer diameter of 64 mm. The combination of the ...

Embodiment 2

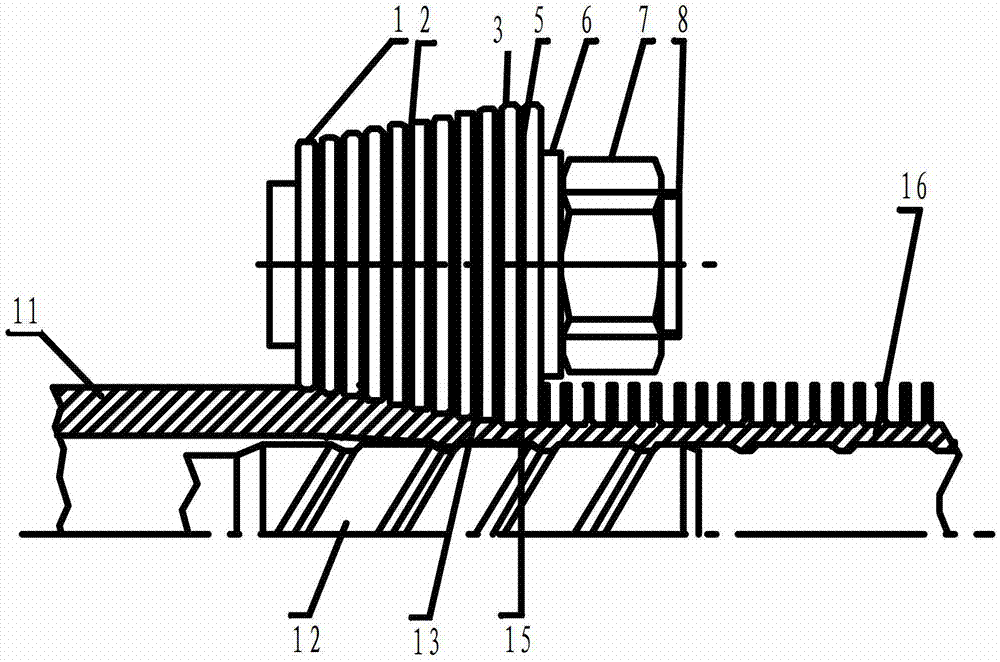

[0038] Embodiment two, this embodiment adopts prior art such as figure 2 Shown: the combination of prior art using transition blade 1 and transition spacer 2. The thickness of the transition blade 1 is 0.45mm, and the outer diameter from left to right is 65.4mm, 65.6mm, 65.8mm, 66mm, 66.2mm, 66.4mm, 66.6mm, 66.8mm, 67mm, a total of 9 pieces, and the thickness of the shaping blade 3 is 0.45mm mm, with an outer diameter of 67.1mm, a total of 2 pieces; a transition gasket 2 with a thickness of 0.1mm and an outer diameter of 64mm, a total of 9 pieces, and a shaped gasket 5 with a thickness of 0.1mm and an outer diameter of 64mm, a total of 1 piece. In this embodiment, the maximum height of the shaped fins 15 processed during the processing test is 0.7mm, and the thickness of the fins is 0.12mm. Wings, poor surface, rotten wings, excessive vibration and other unstable phenomena. After this embodiment, the technology of the present invention is adopted such as image 3 As shown,...

Embodiment 3

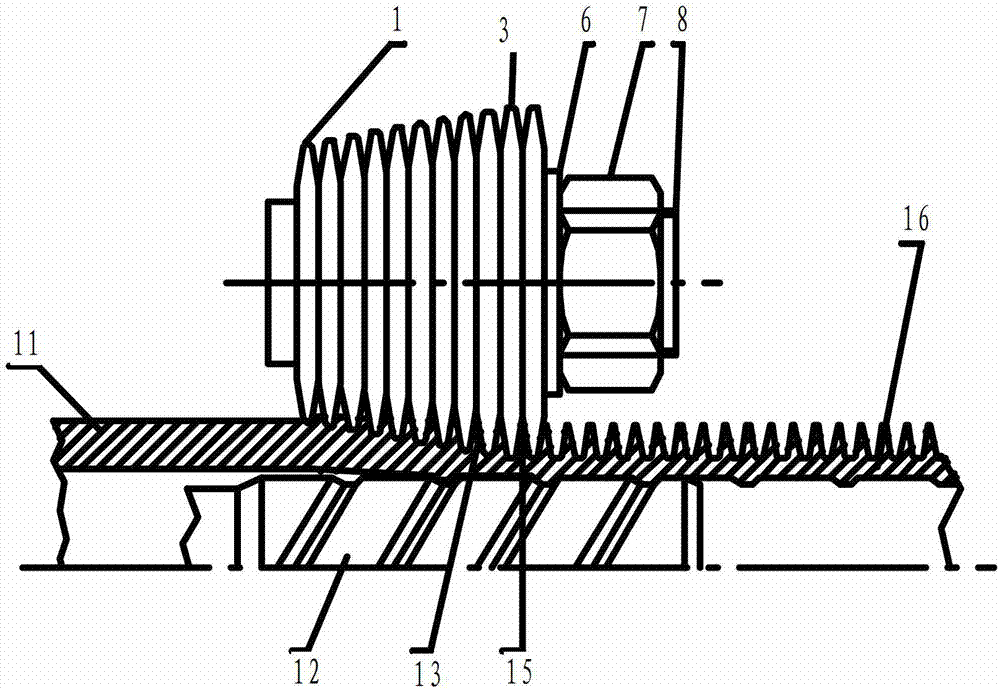

[0040] Embodiment three, this embodiment adopts prior art such as figure 1 Shown: Combination of prior art with transition sharpened insert 1 . The thickness of the transition blade 1 is 0.9mm, and the cutting angle α is 13°. The outer diameters from left to right are 65.4mm, 65.6mm, 65.8mm, 66mm, 66.2mm, 66.4mm, 66.6mm, 66.8mm, 67mm, shaped blades 3 The thickness is 0.9mm, the cutting edge angle α is 13°, and the outer diameter is 67.1mm, a total of 2 pieces; the maximum height of the shaped fin 15 processed in the process of the processing test in this embodiment is 1.5mm, after the test processing section 16 The length is 100000m, and when the average processing section 16 length is 400m, phenomena such as cracking or deformation appear in the shaping blade 3 . Adopt technology of the present invention such as after embodiment Figure 5 As shown, combinations of sharpened blades of different thicknesses are used. The thickness of the transition blade 1 is 0.9mm, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com