Electric permanent magnetic chuck capable of realizing quick die exchange

An electro-permanent magnetic chuck, fast technology, applied in the field of mold fixing plate, can solve the problems of replacing, adjusting, and repairing molds, increasing the time of mold opening and tapping, and increasing personnel costs due to splitting, so as to reduce the time of mold change, No resin filling, good magnetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

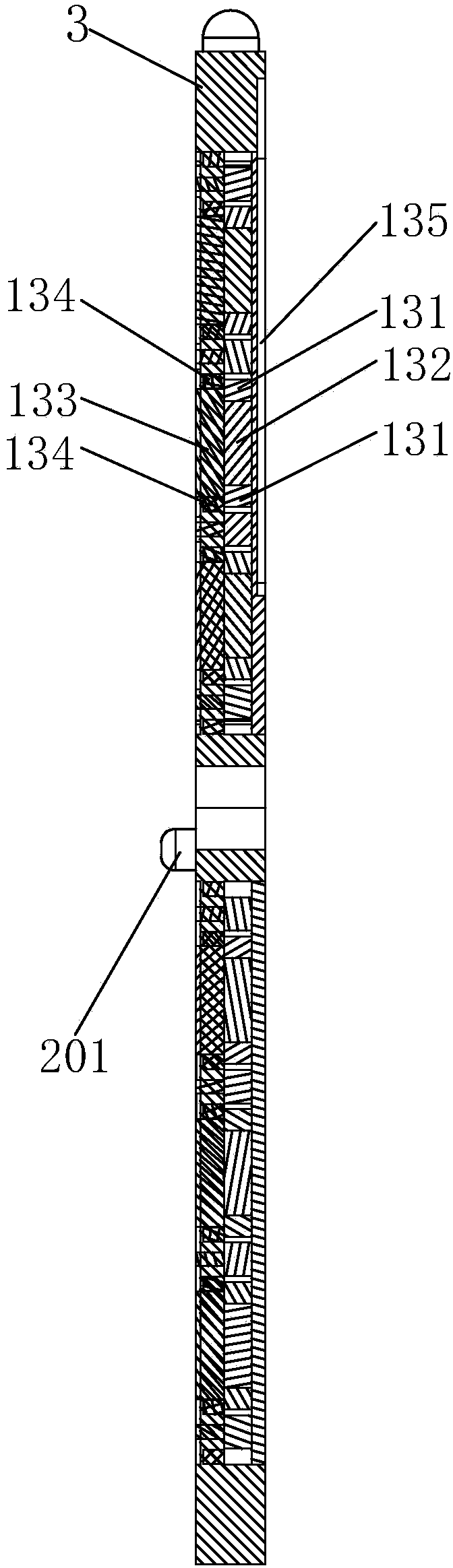

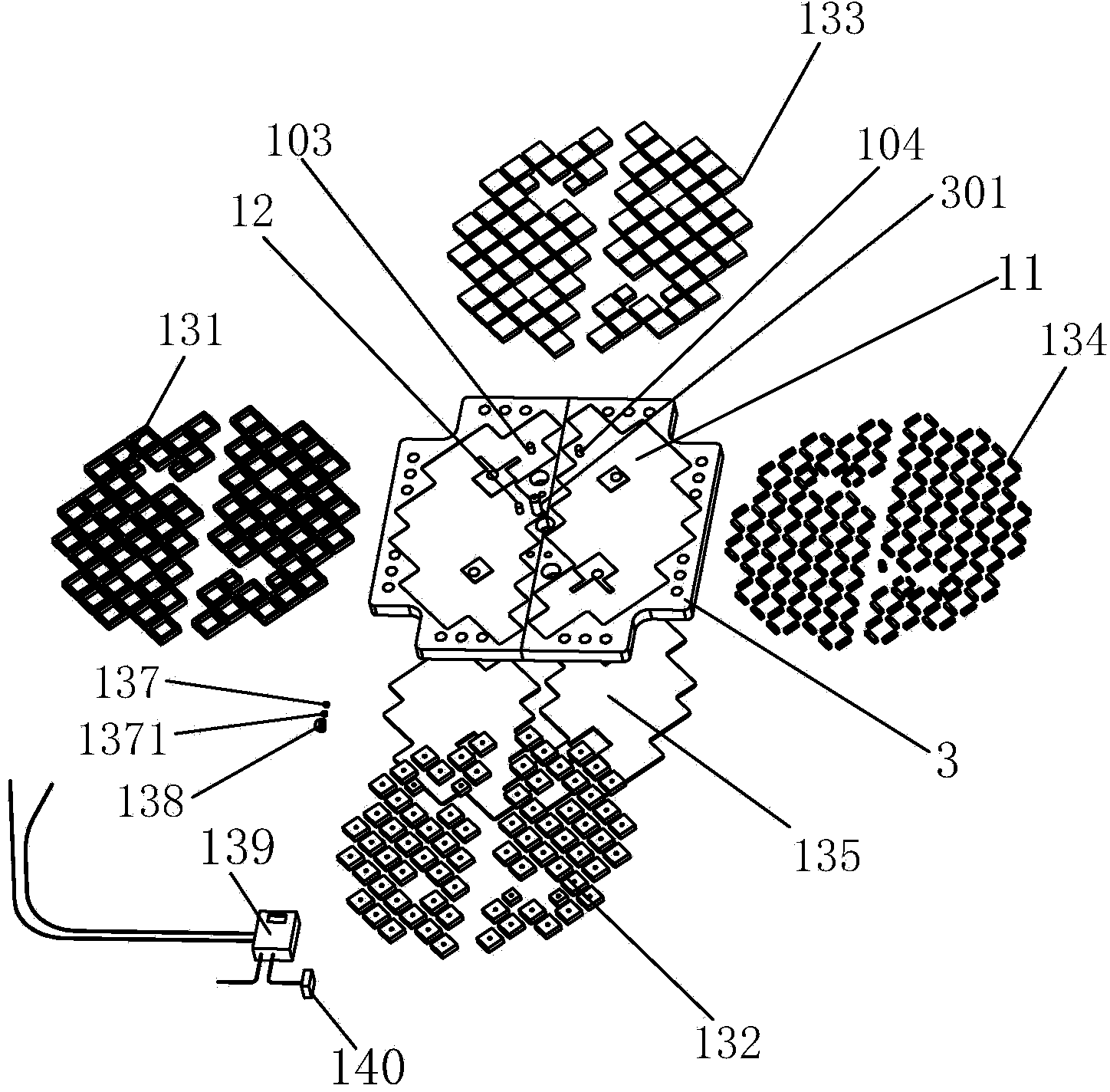

[0017] Such as figure 1 - Figure 6 Shown: the electro-permanent magnetic sucker for rapid mold change, including a fixed template 1 and a movable template 2, characterized in that: a positioning hole 101 is provided in the middle of the fixed template 1, and a positioning ring 102 is installed in the positioning hole 101; The middle part of the reverse side of the movable template 2 is provided with a positioning pin 201; the reverse side of the fixed template 1 and the movable template 2 are provided with a mold pit 11, and a proximity switch 12, a temperature sensor 103 and a magnetic sensor are arranged in the mold pit 11 ; The bottom of the mold pit 11 is pasted with some three-dimensional square steel blocks 133, and magnetically sucks NdFeB magnet strips 134 between every two three-dimensional square steel blocks 133; Neodymium nickel cobalt magnet 132, the neodymium nickel cobalt magnet 132 is tightly covered with a magnetic induction coil 131, the magnetic induction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com