Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Improve machining precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Off-line feed rate scheduling for reduction of machining time and enhancement of machining accuracy in CNC machining

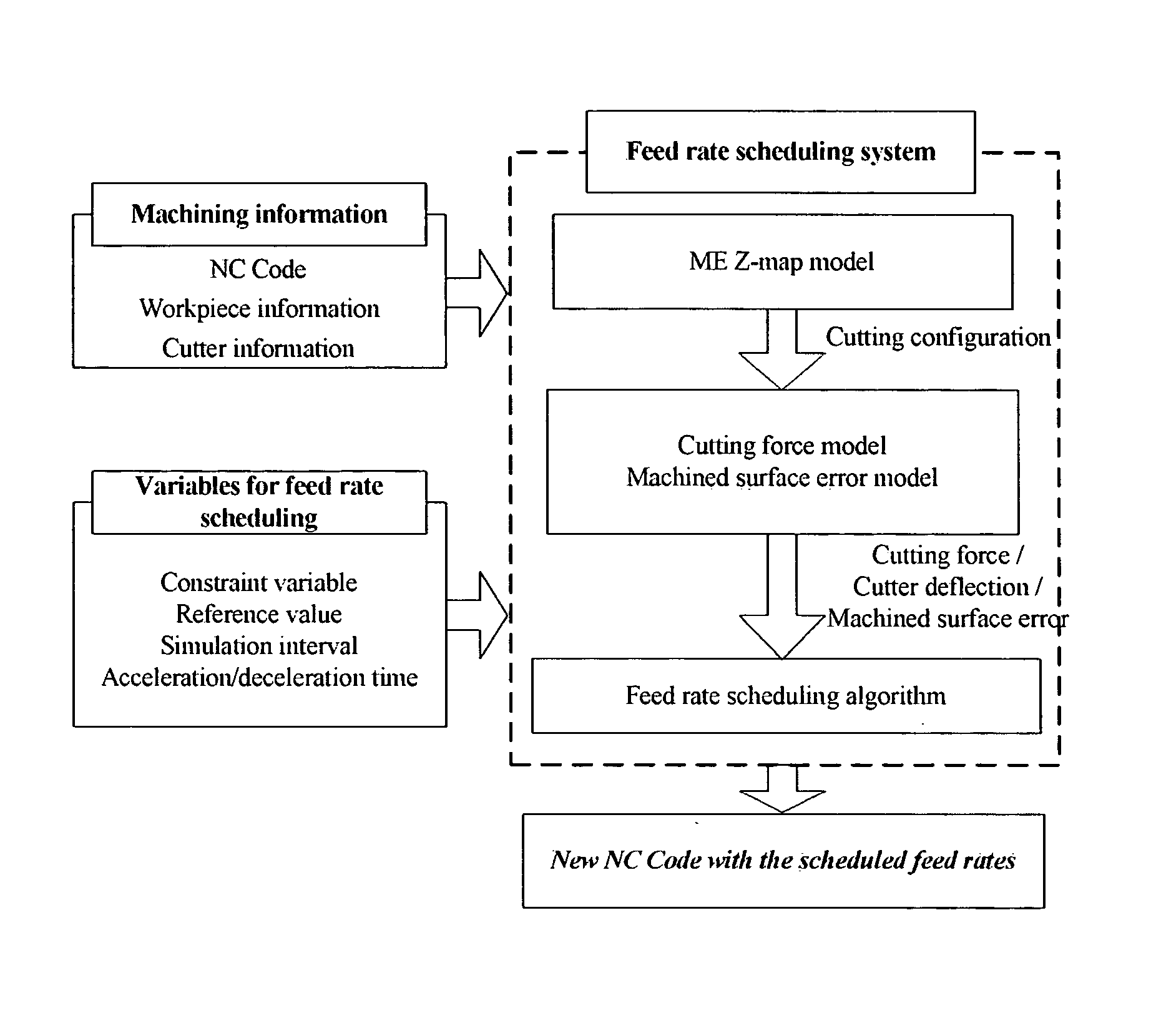

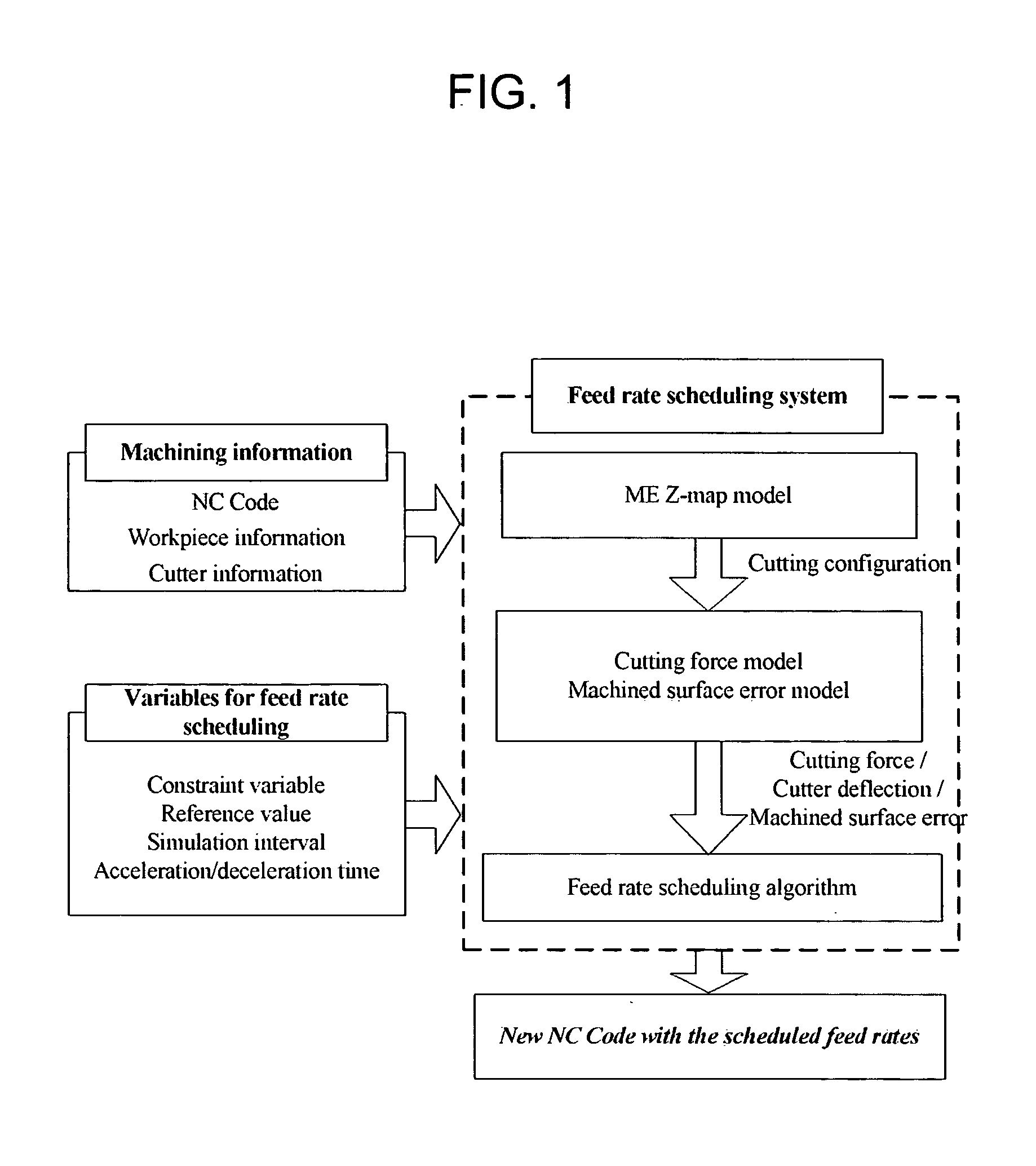

InactiveUS20050113963A1Improve machining precisionIncrease productivityComputation using non-denominational number representationNumerical controlMachined surfaceSpecific rotation

An off-line feed rate scheduling method of a CNC machining process includes selecting a constraint variable and inputting a reference value related to the constraint variable; estimating a cutting configuration where a maximum constraint variable value (CVV) occurs through ME Z-map modeling; receiving the estimated cutting configuration and estimating a specific rotation angle (φs) where the maximum constraint variable value occurs through constraint variable modeling; calculating a feed rate that satisfies the reference value of the constraint variable at the estimated specific rotation angle; and applying the calculated feed rate to the NC code. Cutting force or machined surface error may be selected as a constraint variable depending on machining conditions.

Owner:POSTECH ACAD IND FOUND

High-precision LED circuit board forming process without process edge

ActiveCN106900139AReduced Dimensional TolerancesImprove machining precisionPrinted circuit manufactureLED circuitElectrical and Electronics engineering

The present invention provides a high-precision LED circuit board forming process without a process edge. The process comprises the steps: performing routing design aiming at the shape of the product of a LED circuit board, designing an auxiliary process edge at the shape edge of each LED circuit board in a PNL board, and arranging location holes and optical points on the auxiliary process edge; according to the routing design, employing the location holes on the auxiliary process edge for location, performing rough routing processing of each LED circuit board, and performing routing of the PNL board to a SET board keeping the auxiliary process; and employing the optical points on the auxiliary process edge for location, employing a CCD optical routing machine to complete the fine routing of the LED circuit board, and removing the auxiliary process edge of each LED circuit board in the SET board.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

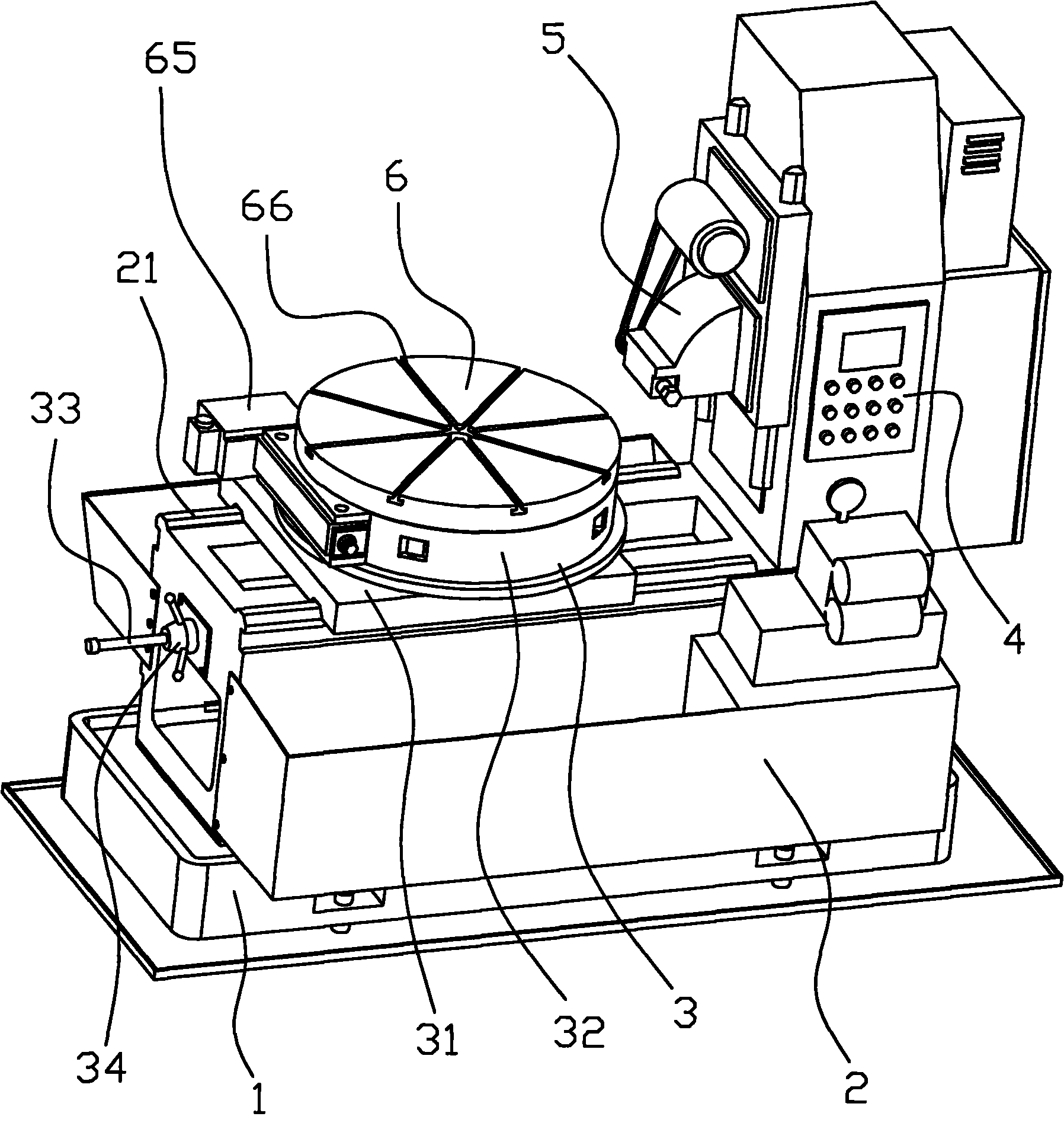

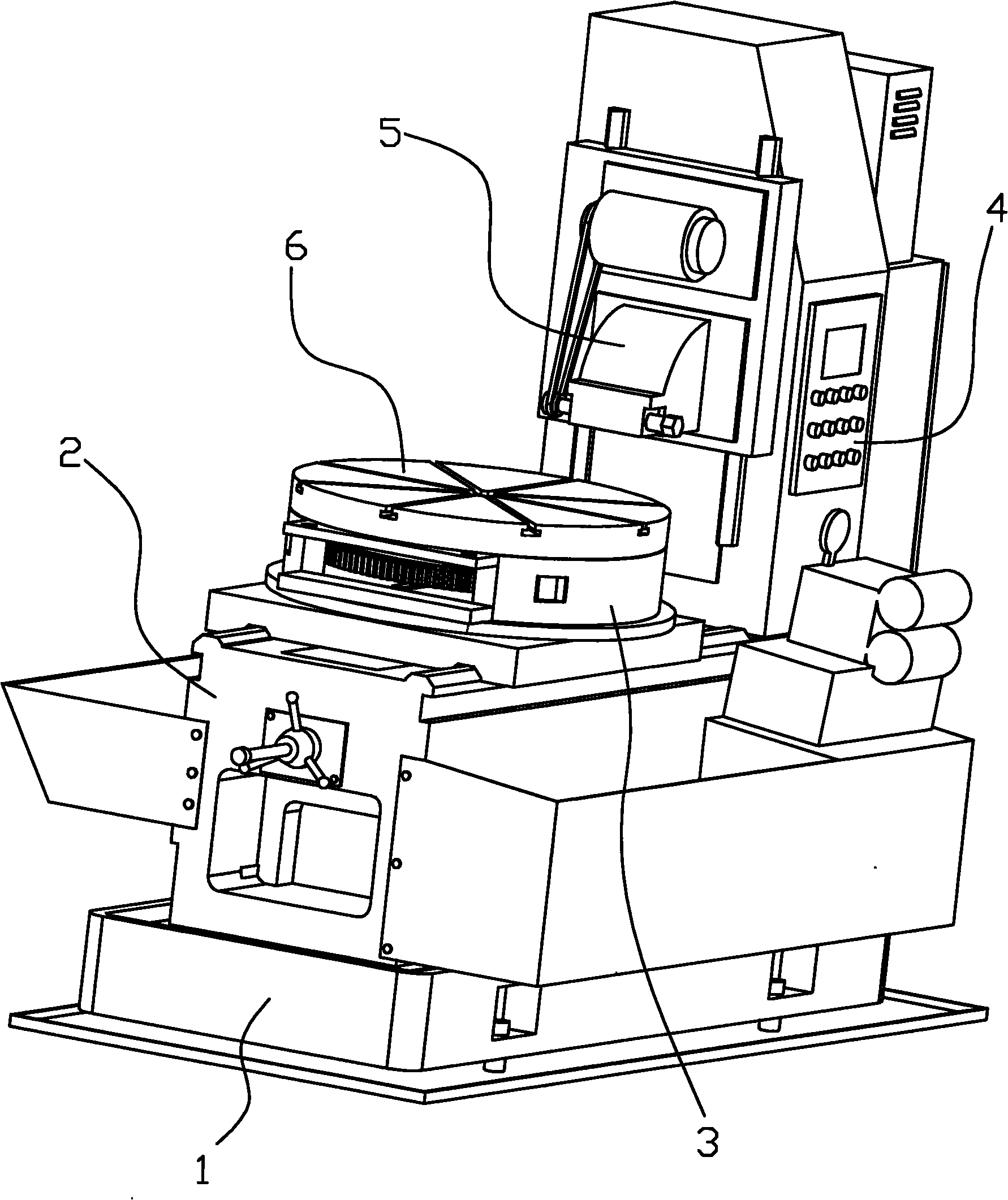

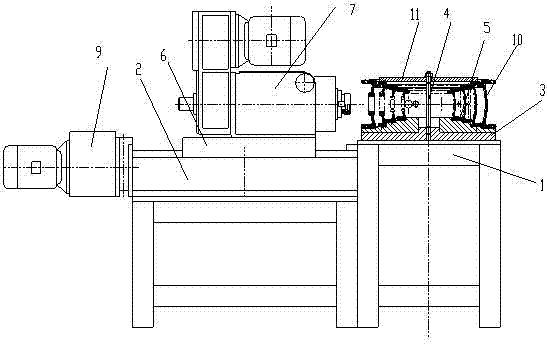

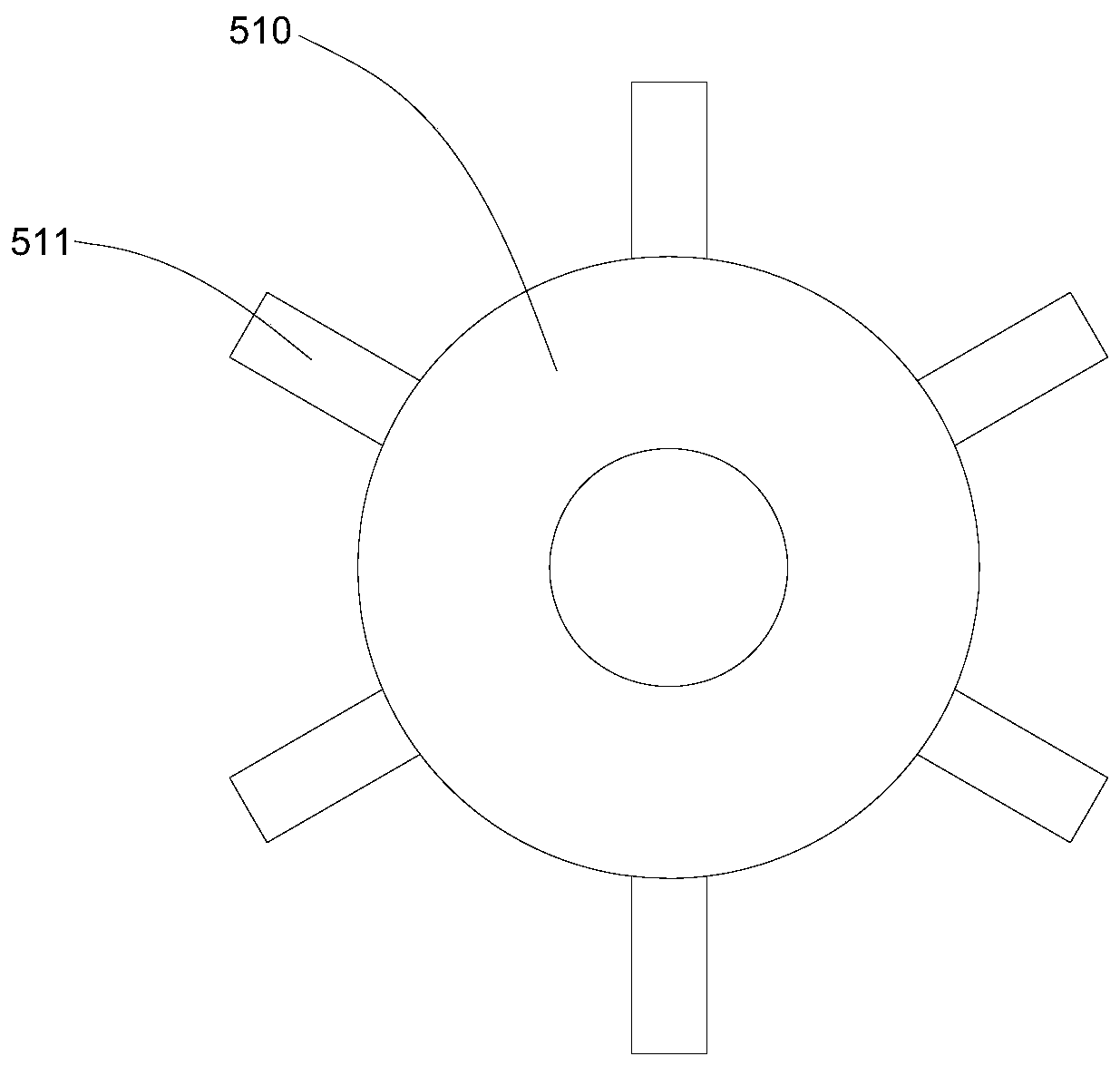

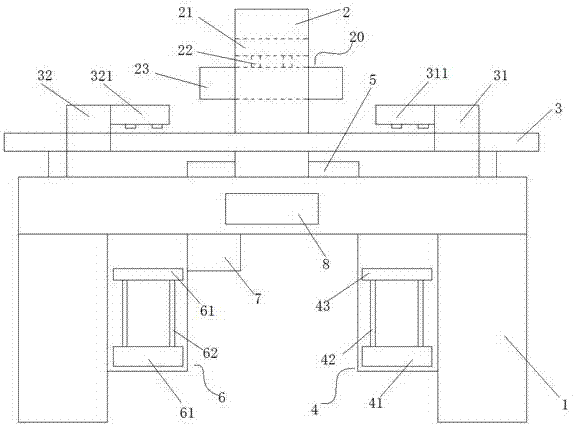

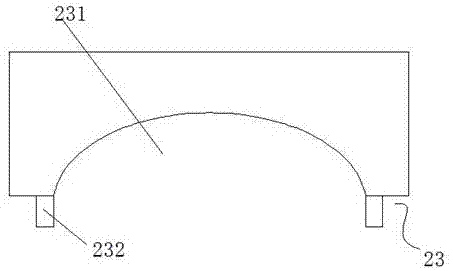

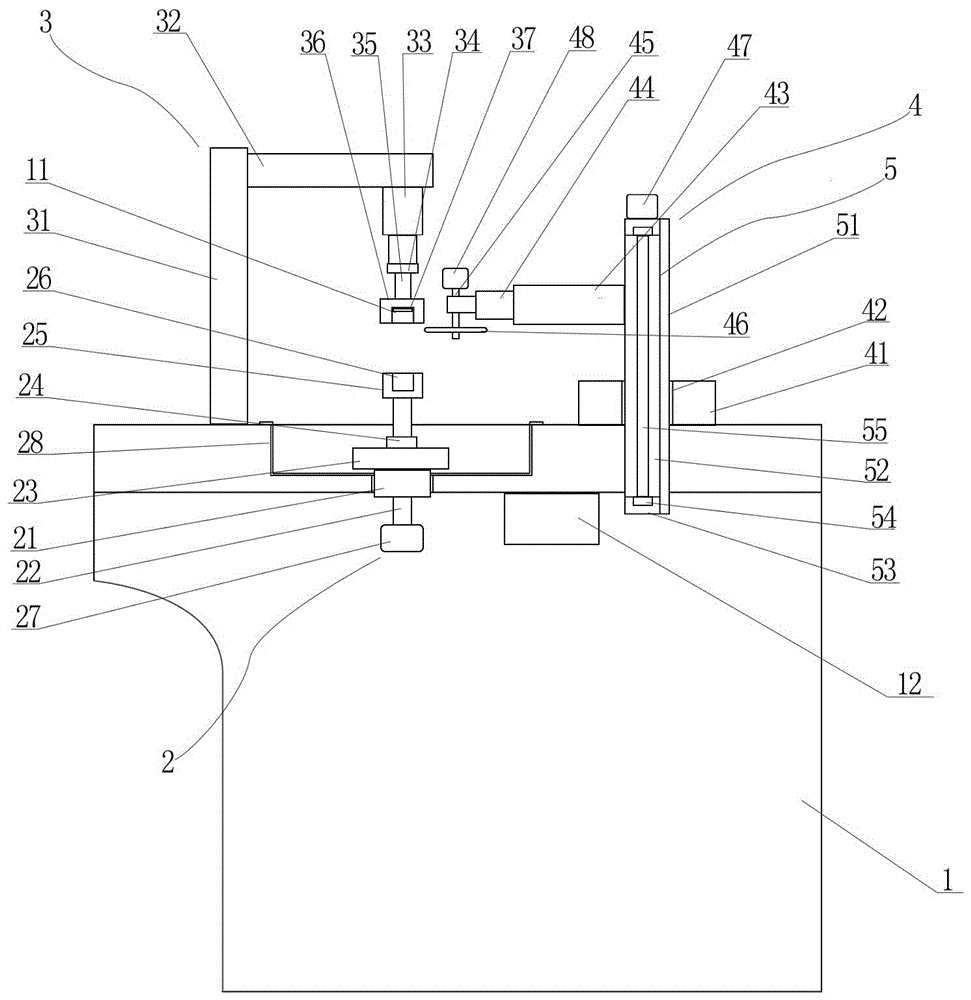

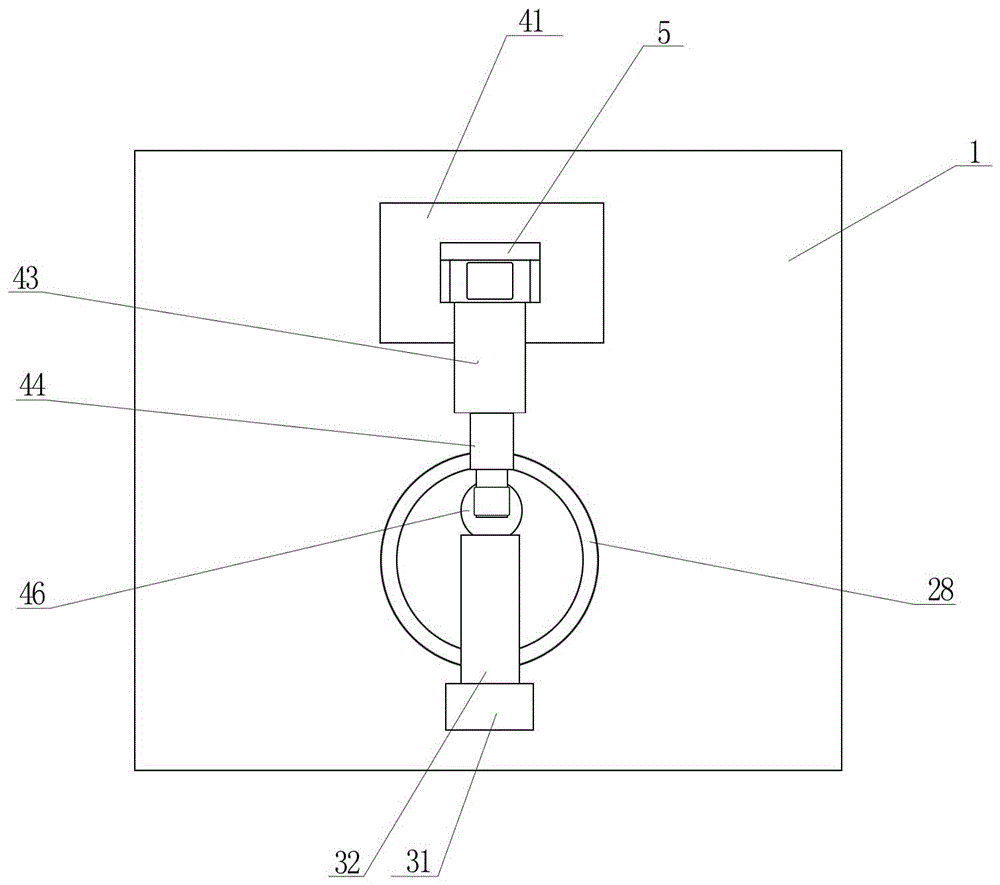

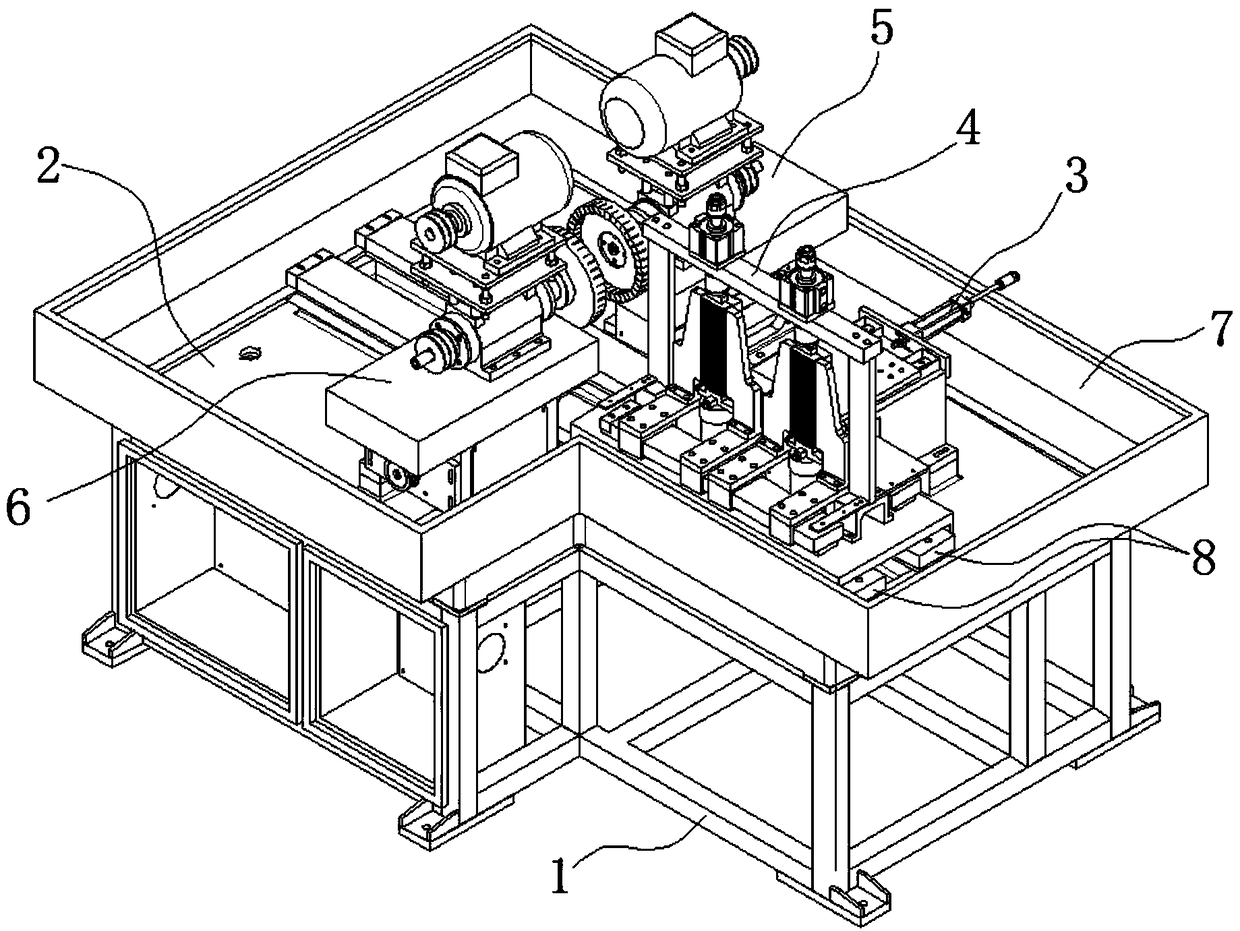

Indexing slotter

InactiveCN101774040AEasy to installAccurate control center distanceLarge fixed membersMilling equipment detailsReciprocating motionEngineering

The invention discloses an indexing slotter, which comprises a slotter body (2), a milling device (5), a sliding work platform (3) and a control device (4), wherein, the slotter body (2) is arranged in a slotter base (1), the milling device (5) is fixed on the slotter body (2) that is provided with a guide rail (21), the sliding work platform (3) is arranged on the guide rail (21) and can reciprocate along the guide rail (21), and the control device (4) is used for controlling the milling device (5) and the sliding work platform (3) to work coordinately. The indexing slotter is characterized in that the sliding work platform (3) is provided with a rotary table (6) for fixing a work piece to be processed, the rotary table (6) is provided with a structure for fixing the work piece when the work piece is processed by the milling device (5), and the rotary table (6) is horizontally-rotatably linked with an output shaft of a rotary motor which is fixed on the sliding work platform (3) by a transmission device. Compared with the prior art, the indexing slotter has the advantages of easy installation of the work piece, more accurate control of center distance and high processing accuracy.

Owner:胡建军

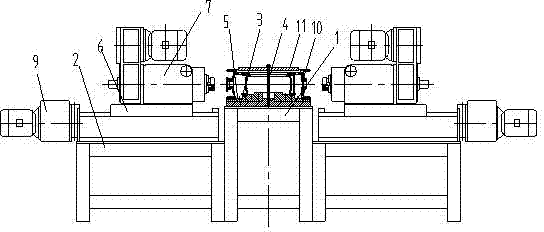

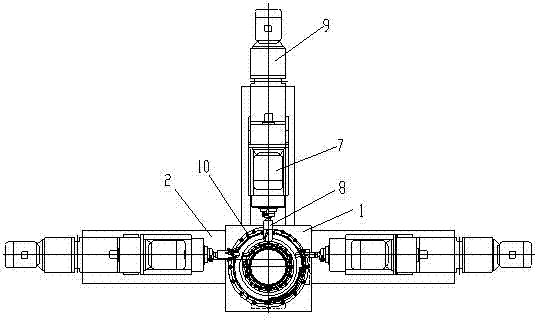

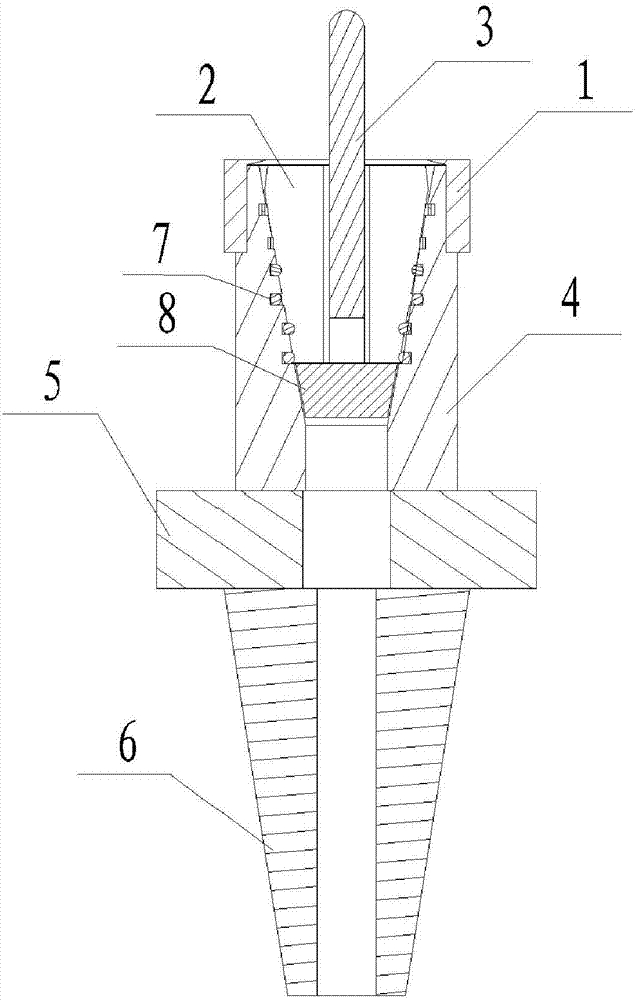

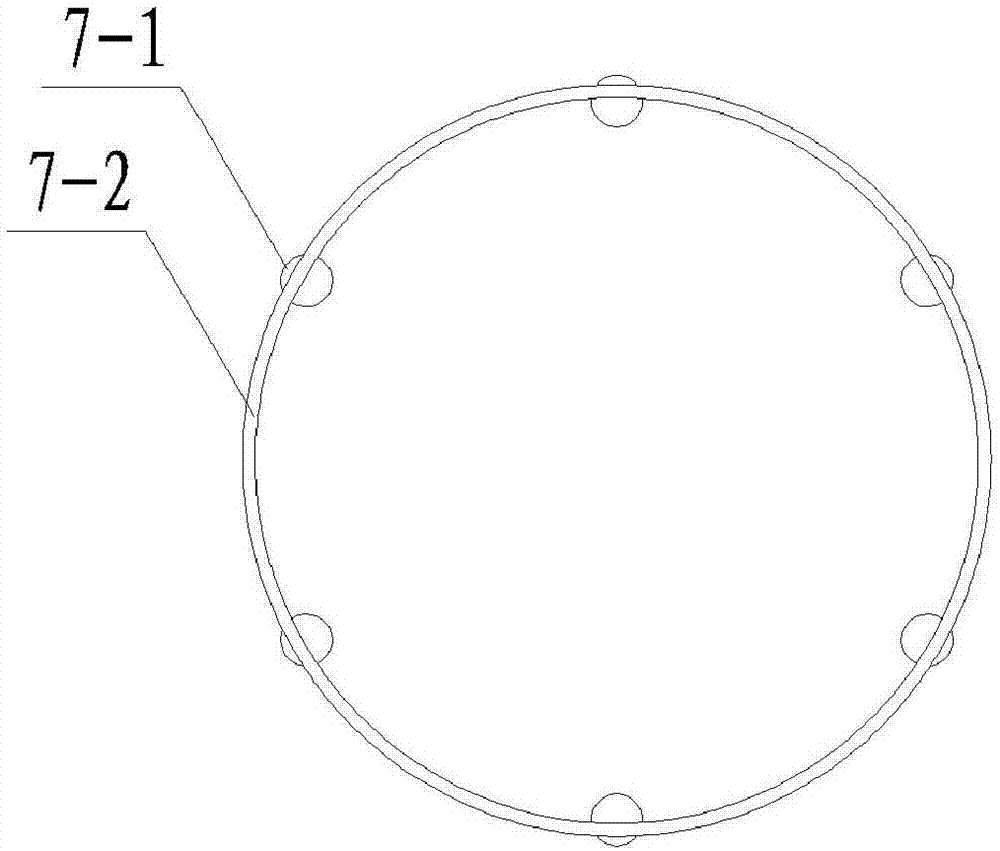

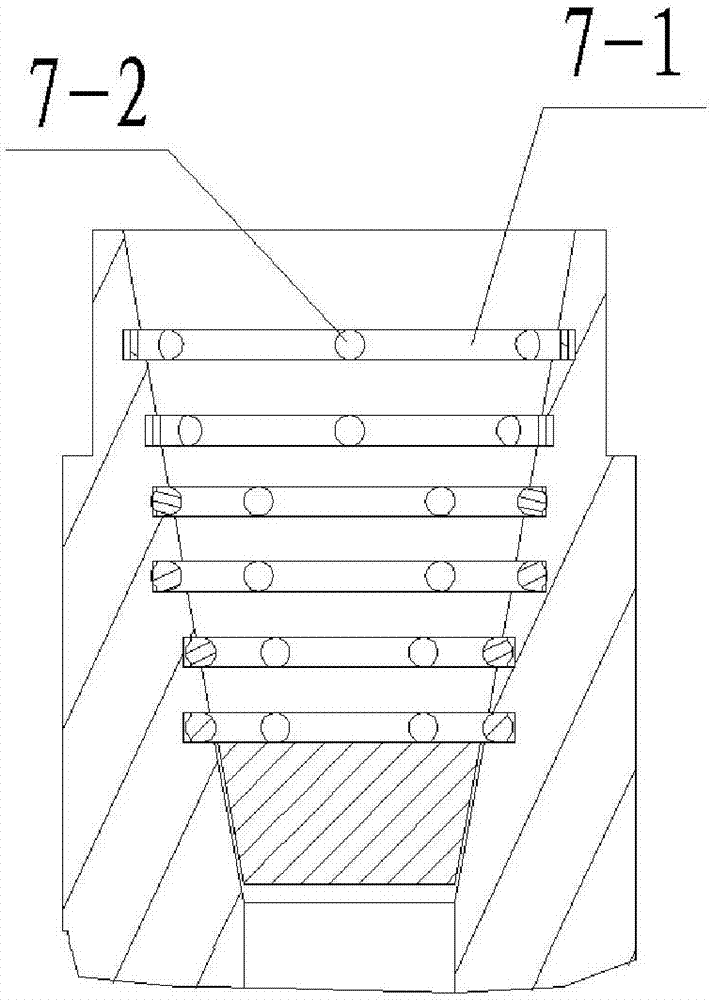

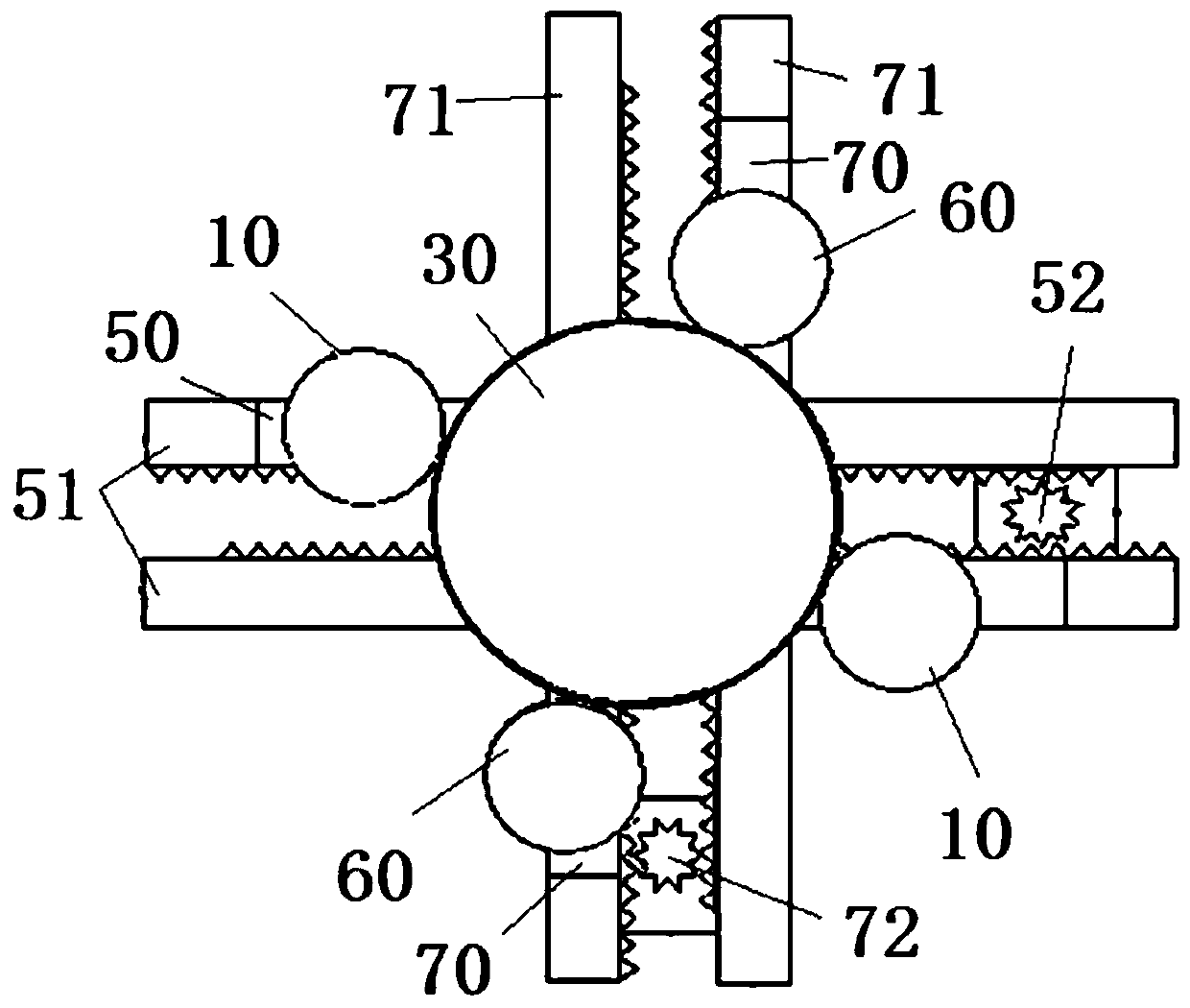

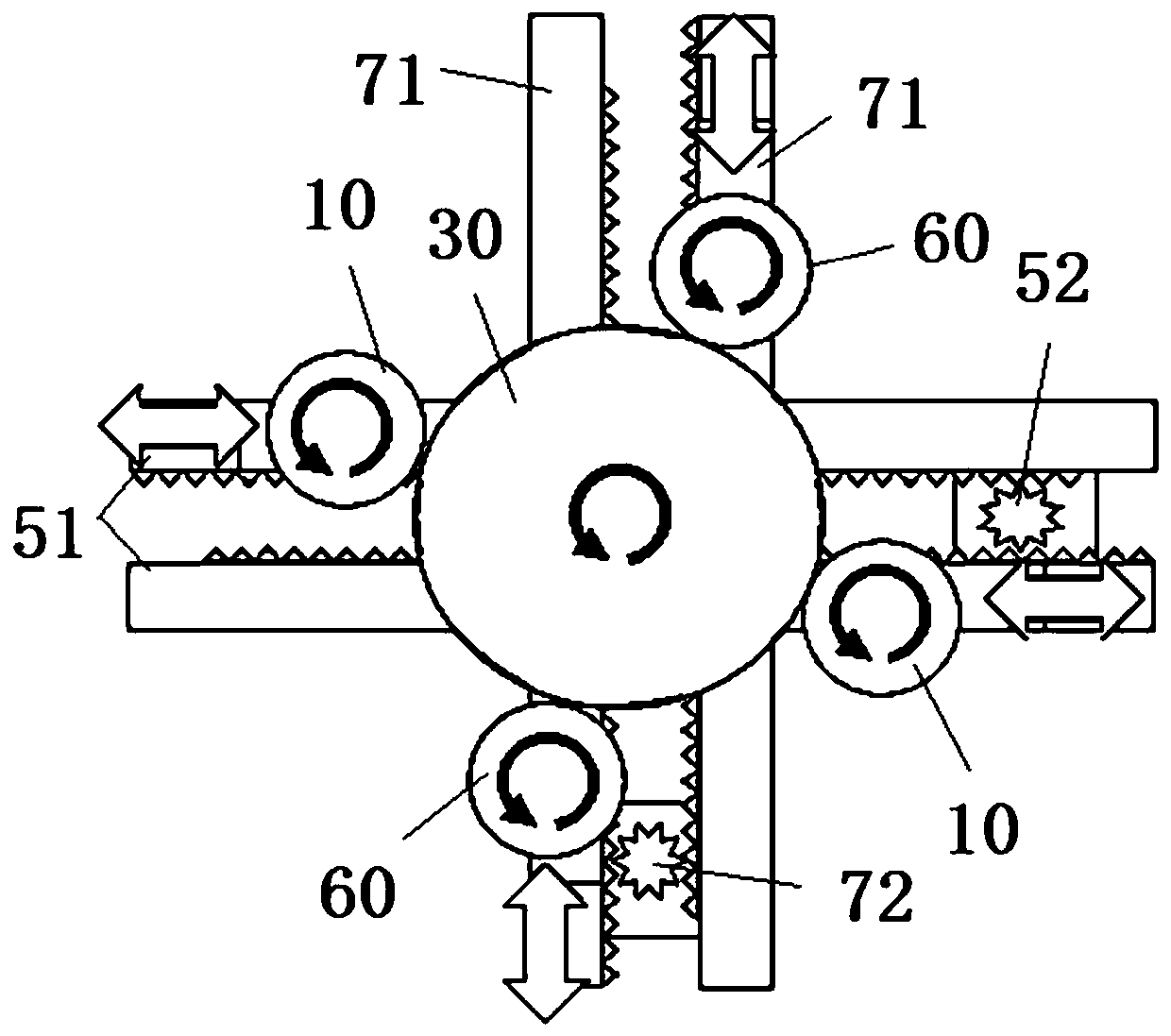

SMF20-50 multi-station drill boring machine

InactiveCN102773712AImprove interchangeabilityReduce clampingOther manufacturing equipments/toolsPositioning apparatusMachining timeMachine tool

The invention discloses an SMF20-50 multi-station drill boring machine, comprising a pagoda disc seat and bases. The bases are all distributed on the left side, the right side, and the middle of the plane around the pagoda disc seat. The pagoda disc seat is provided with a pagoda disc. The pagoda disc comprises a locating shaft arranged in the center of the pagoda disc. At least four layers of step clamping surfaces are arranged by using the locating shaft as a center. Each base is moveably provided with a sliding table. The sliding table is provided with a power head. The power head is provided with a drill head. The direction of the drill head points to the pagoda disc. Through the SMF20-50 multi-station drill boring machine disclosed by the invention, three holes can be drilled while one-time clamping positioning is carried out, and the machining precision is guaranteed by the self precision of a machine tool without repeated clamping and repeated adjusting, so that the clamping and adjusting time is greatly shortened. The three holes are simultaneously machined so as to largely shorten the machining time. The SMF20-50 multi-station drill boring machine disclosed by the invention has the advantages of high precision, short process flow, and small cumulative error, lightened labor intensity and improved machining efficiency; in addition, the assembly interchangeability of parts is very good.

Owner:常州华东人防设备有限公司

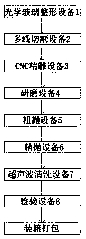

Surface preparation process for high-precision, ultrathin and ultrahigh-flatness optical lens

InactiveCN108081036AImprove performanceImprove practicalityStone-like material working toolsMegasonic cleaningEngineering

The invention discloses a surface preparation process for a high-precision, ultrathin and ultrahigh-flatness optical lens and relates to the technical field of optical lens processing. Devices adoptedin the surface preparation process include the optical glass shaping device, the multi-line cutting device, the CNC fine carving device, the grinding device, the rough polishing device, the fine polishing device, the ultrasonic cleaning device and the detection device which constitute a production assembly line. Processing precision and flatness can be improved greatly, the overall performance ofthe optical lens is improved, and the practicability of the optical lens is improved.

Owner:蒙锐(上海)光电科技有限公司

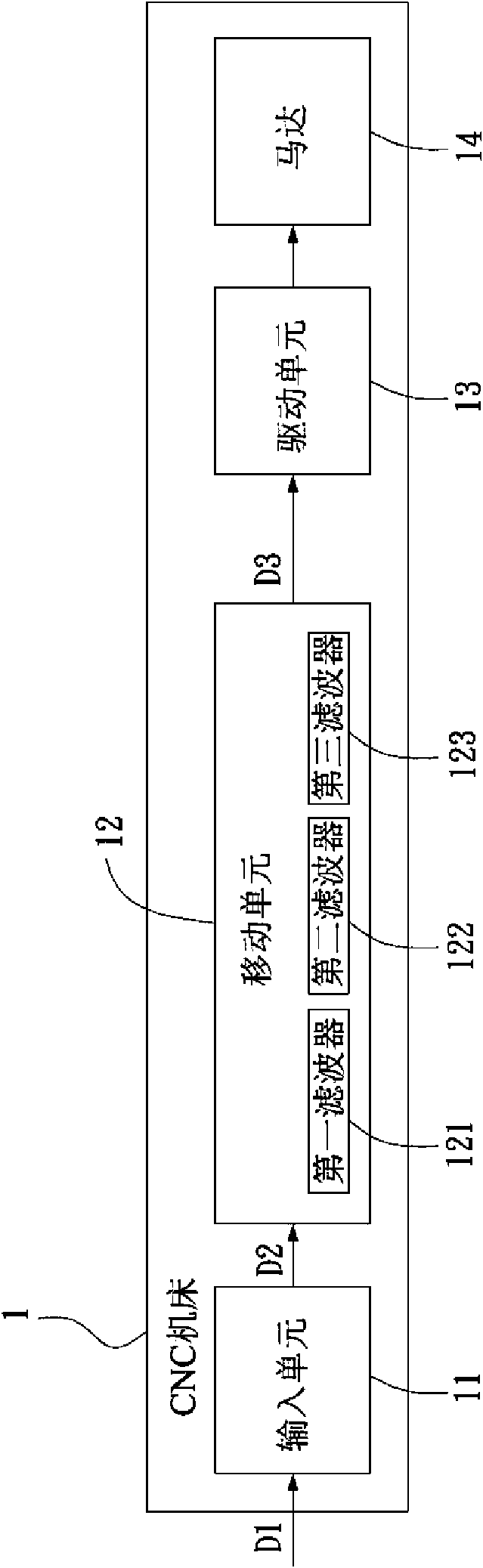

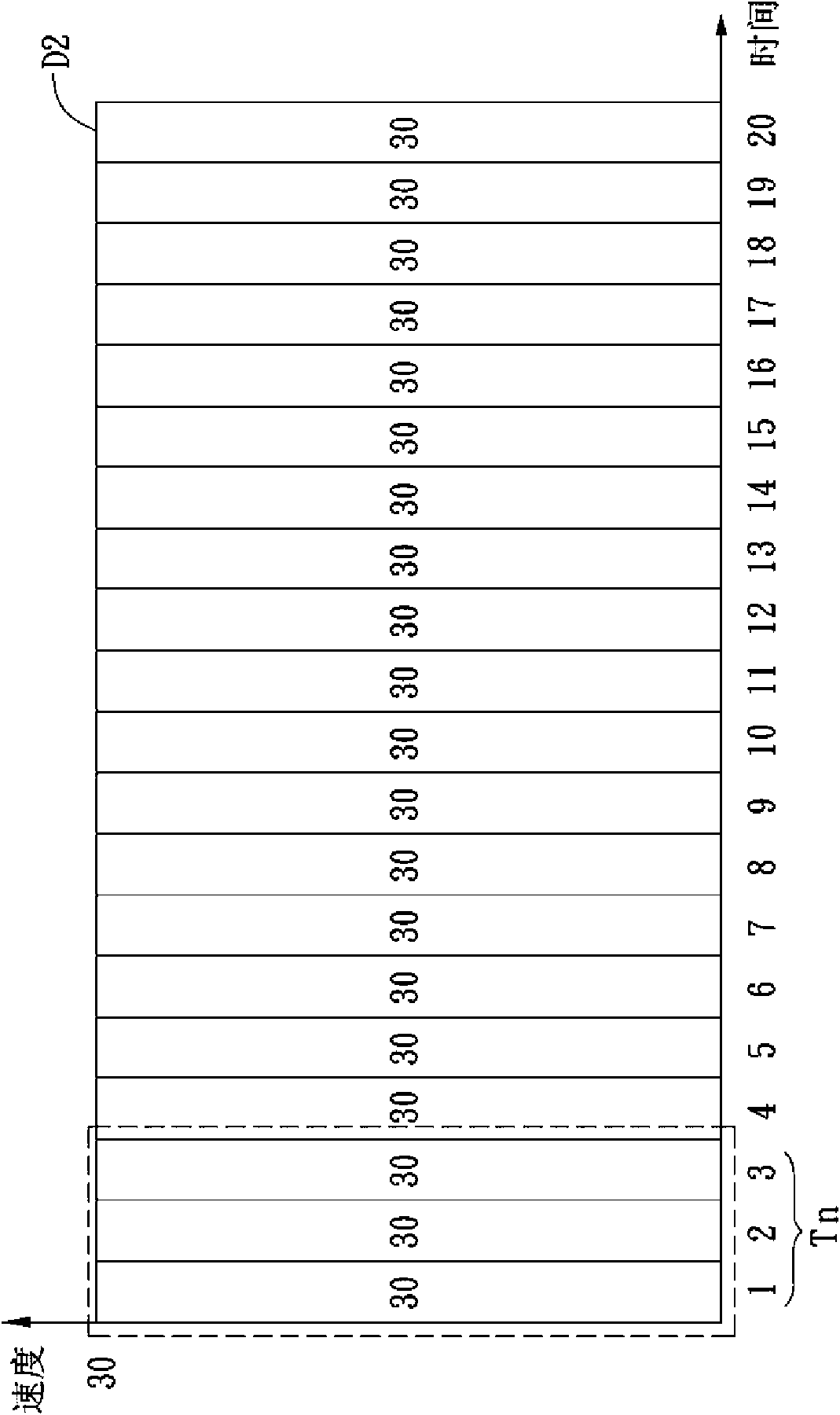

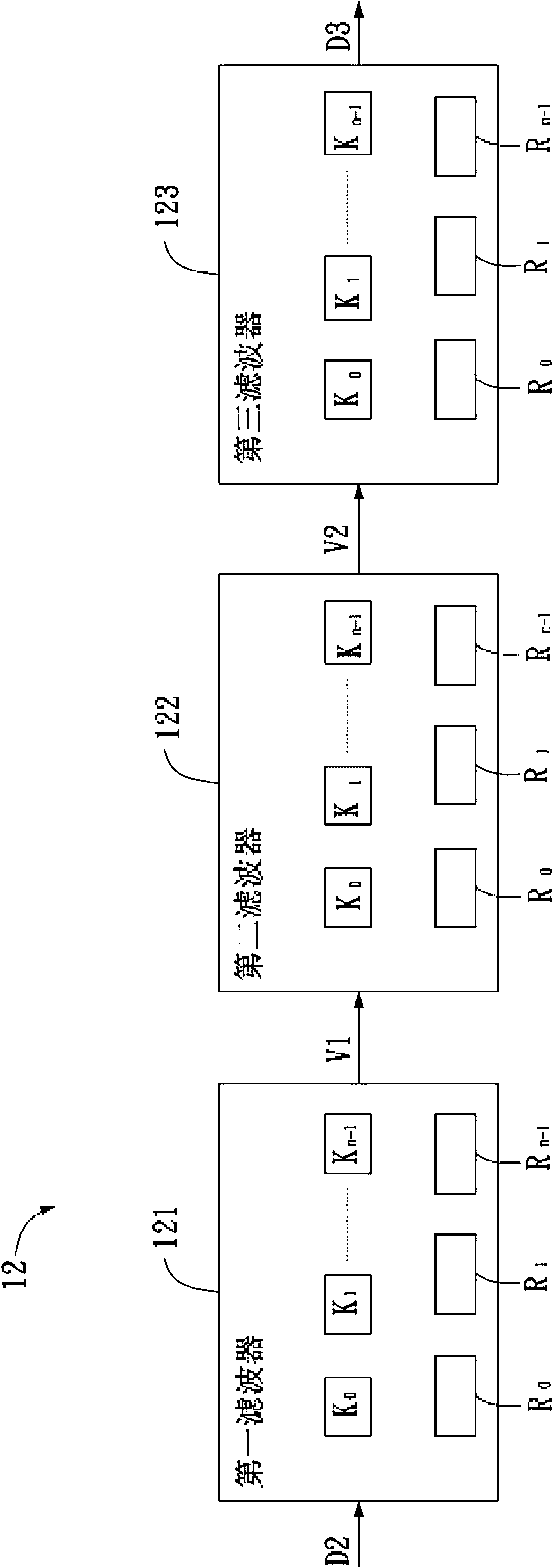

Acceleration and deceleration control device and acceleration and deceleration control method

InactiveCN101609326AThe jerk curve is smoothImprove machining precisionNumerical controlTransducing UnitComputer science

The invention provides an acceleration and deceleration device which is used for controlling the acceleration and deceleration of a CNC lathe. The device comprises an interpolation arithmetic unit, a movable unit and a drive conversion unit. The interpolation arithmetic unit is used for processing a speed command by interpolation arithmetic and outputting a pulse speed. The movable unit comprises an arithmetic filter which comprises a plurality of buffers, and each buffer stores a weight value; the movable unit works out an acceleration and deceleration pulse by utilizing a first functional according to the pulse speed and the weight values of the buffers. The drive conversion unit is used for converting the acceleration and deceleration pulse into a drive signal so as to drive a motor. The invention can improve the processing precision and the product quality. The invention also provides an acceleration and deceleration method.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

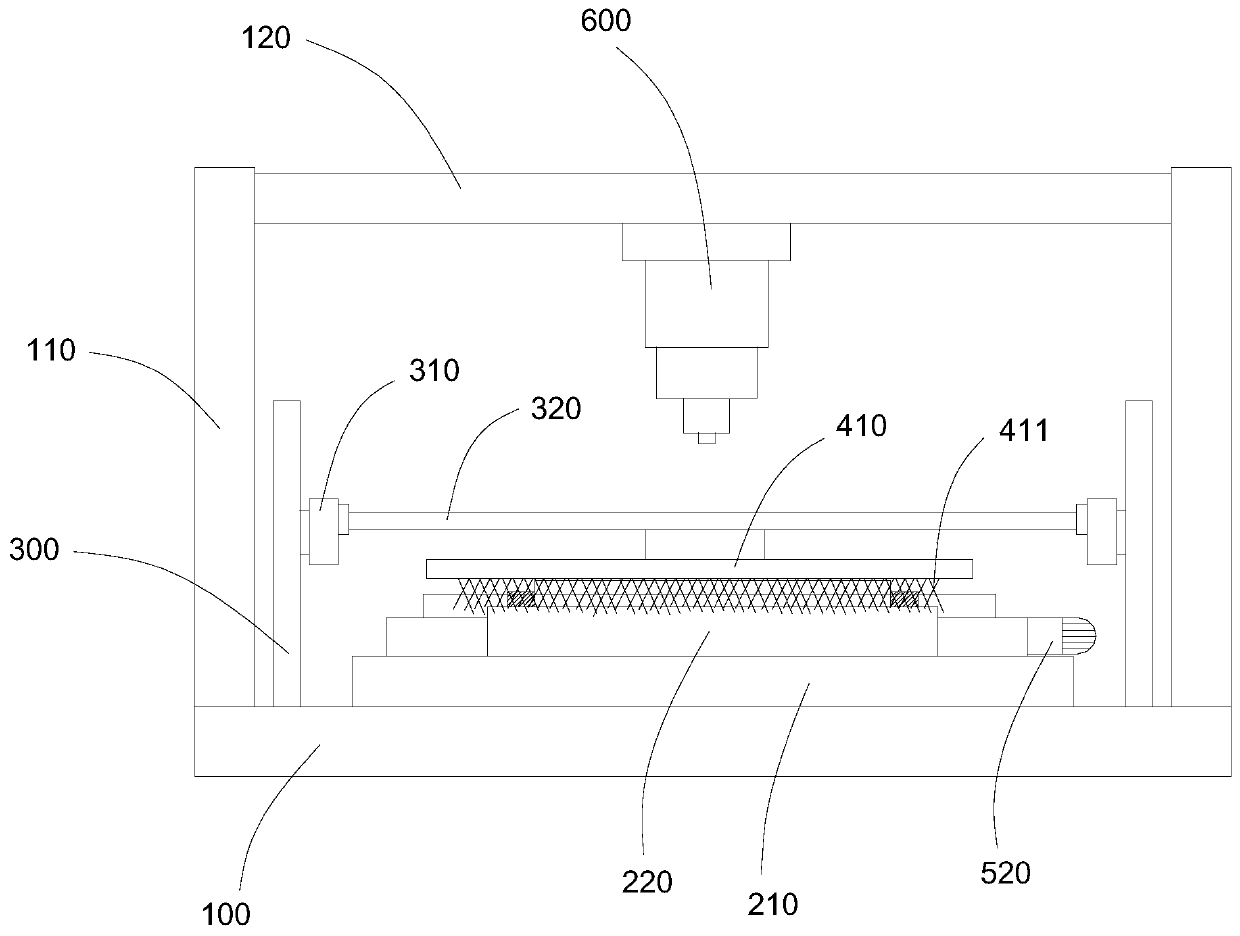

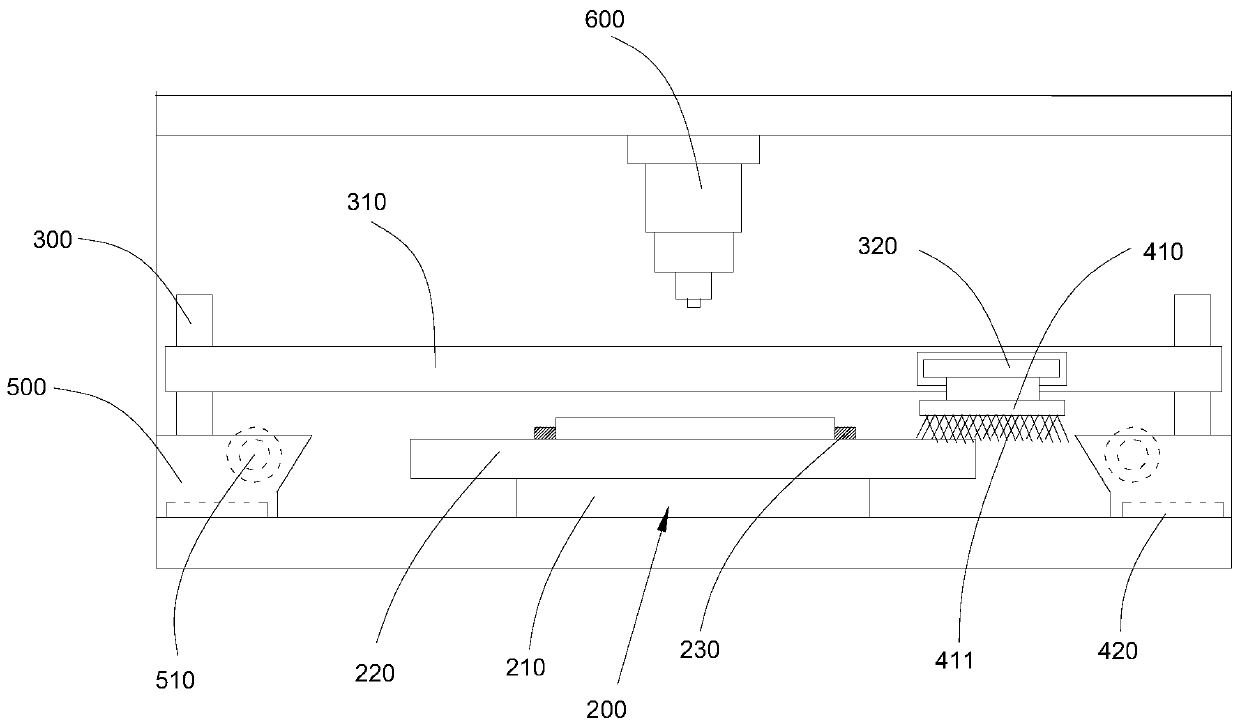

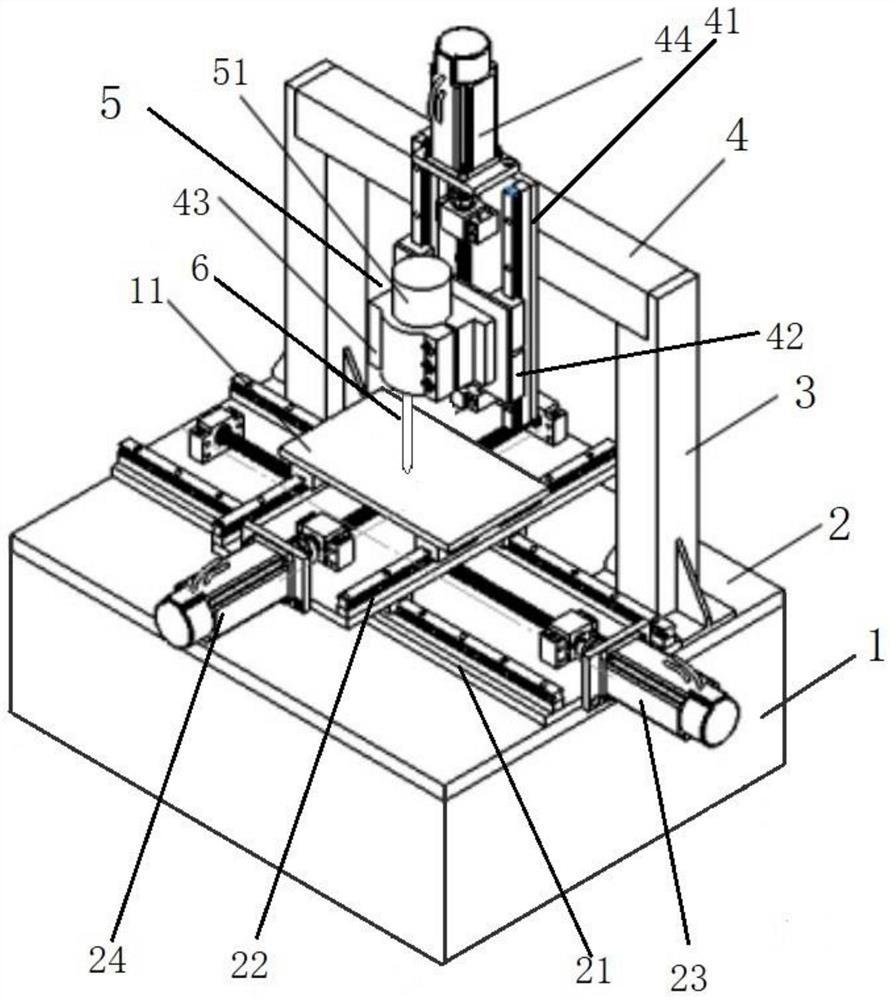

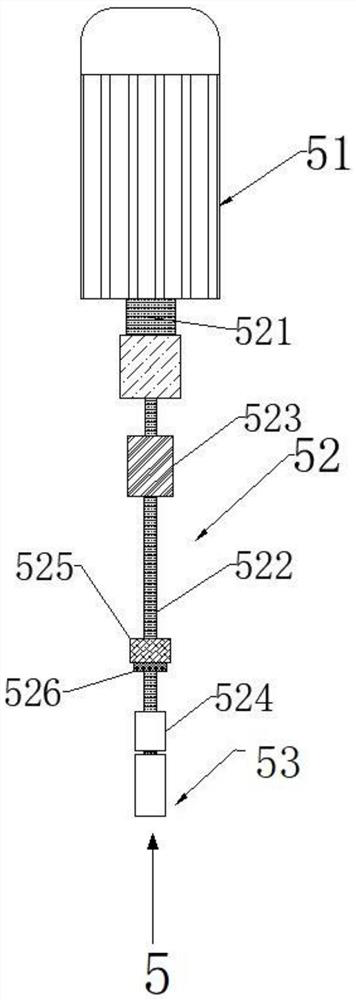

Ultra-precision horizontal micro-EDM machine tool

InactiveCN110935965ASimple structureEasy to cleanElectrical-based auxillary apparatusBristleElectric machinery

The invention provides an ultra-precision horizontal micro-EDM machine tool, which comprises a base and a workbench arranged on the base, and is characterized in that both sides of the workbench are provided with two supports, the two supports on the same side are provided with a first rodless cylinder therebetween, the two first rodless cylinders are located at the same height, a second rodless cylinder is erected between sliding blocks of the two opposite first rodless cylinders, a sliding block of the second rodless cylinder faces the workbench, the sliding block of the second rodless cylinder is provided with a first electromagnet plate, and the bottom surface of the first electromagnet plate is provided with bristles; and two ends of the workbench are further provided with scrap collecting boxes, each scrap collecting box is located between the two supports at the same end, the scrap collecting box is internally provided with a rotating roller, and the rotating roller is driven bya motor. The micro-EDM machine tool is simple in structure and capable of effectively cleaning a machined machine tool, common scraps or magnetized scraps are cleaned up, the accuracy of the placingposition of a workpiece is guaranteed, and thus the machining precision is improved.

Owner:邱爱鑫

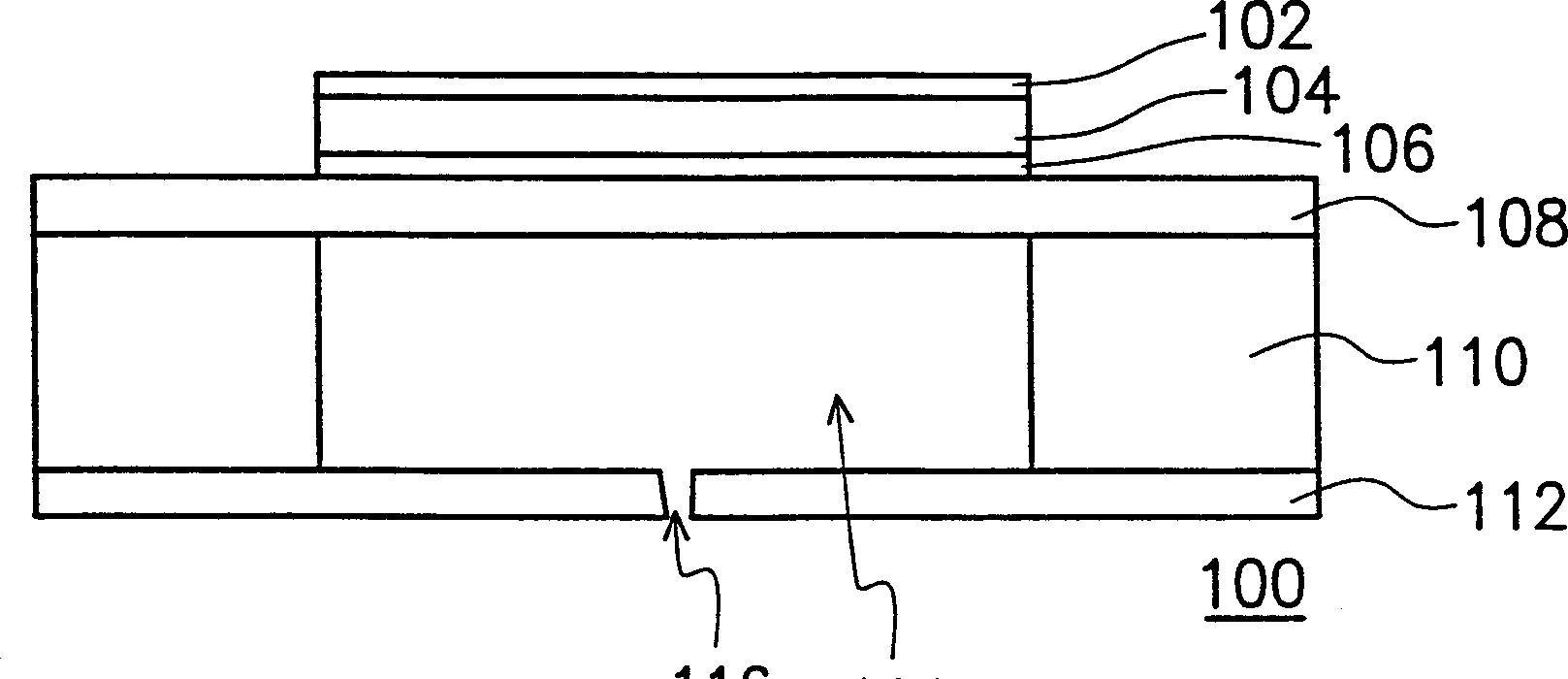

Piezoelectric ink jet printing head and its producing method

The piezoelectric ink jet printing head has one notched metal layer to replace normal ceramic vibrating layer and ink cavity layer to avoid the stress destruction caused by high temperature sintering. The producing electroplating and micro-etching process includes forming one notched metal layer on a substrate, removing the substrate, forming the lower electrode layer and one figured piezoelectric layer, forming the upper electrode layer, adhering one jet hole sheet to the second surface of the metal layer to constitute one ink cavity together with the notch.

Owner:NANODYNAMICS INC

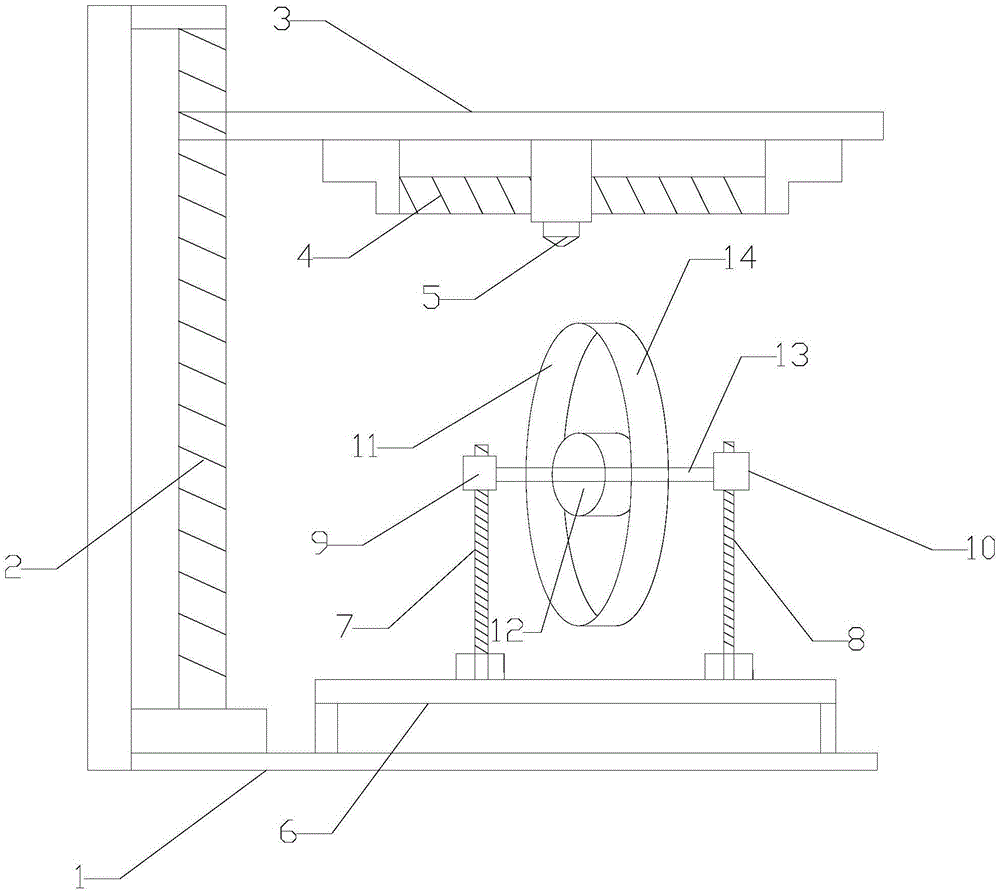

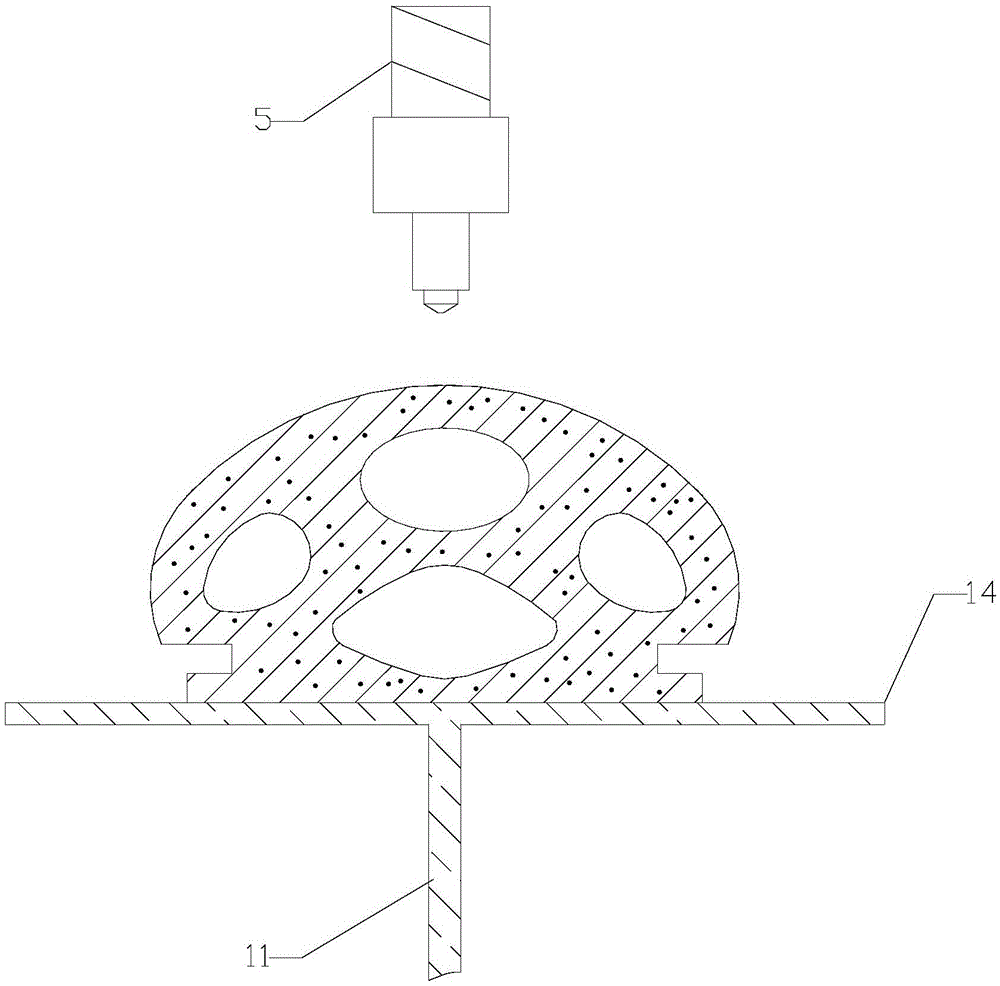

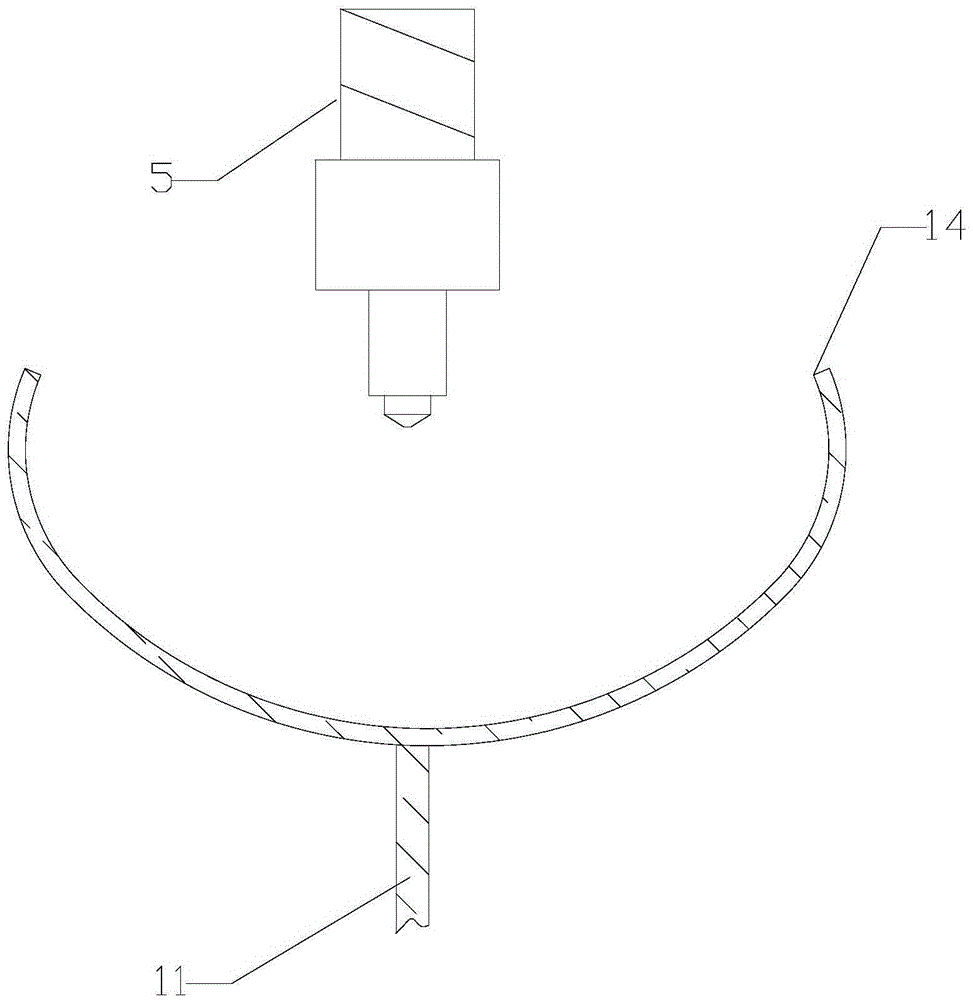

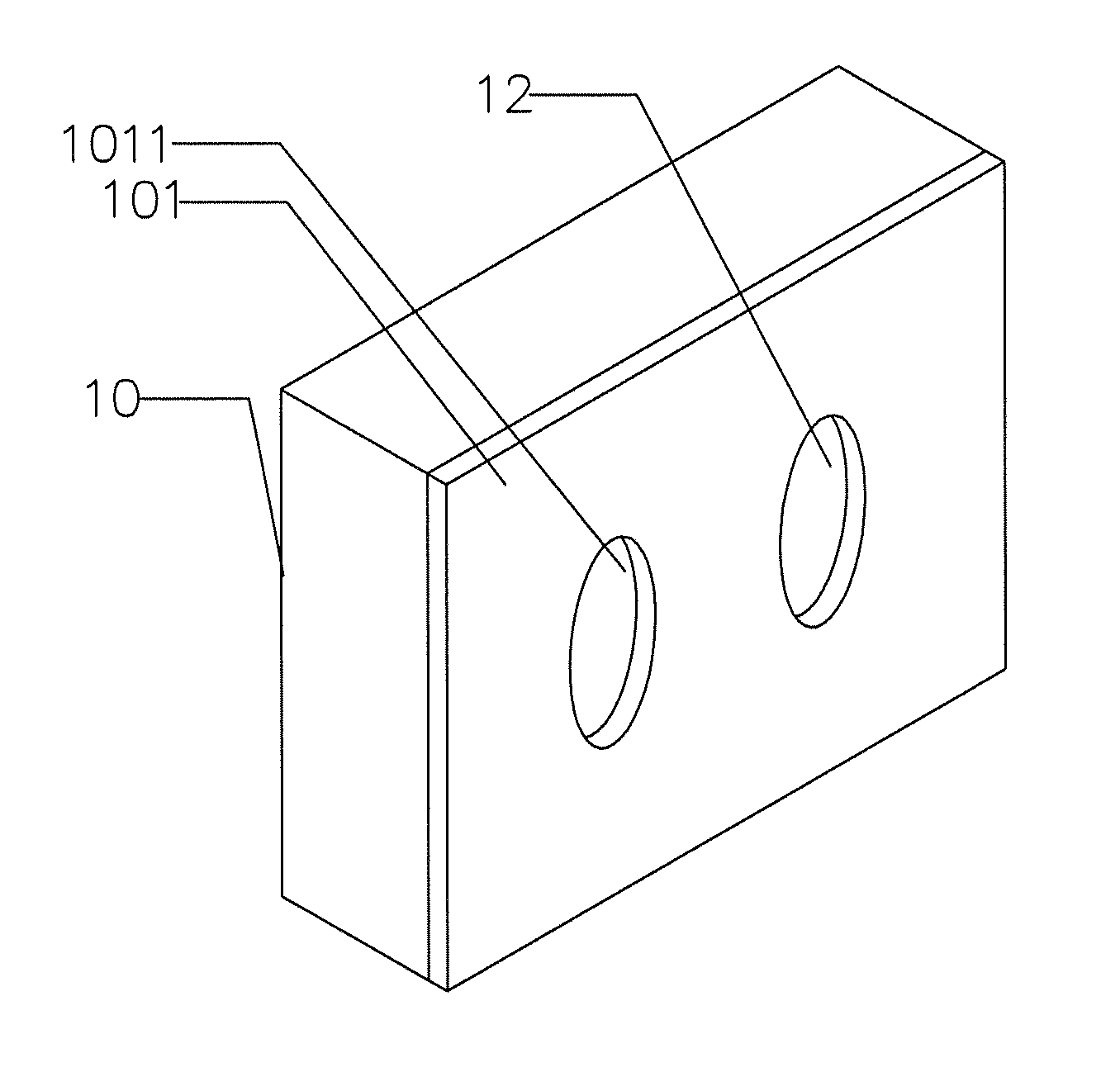

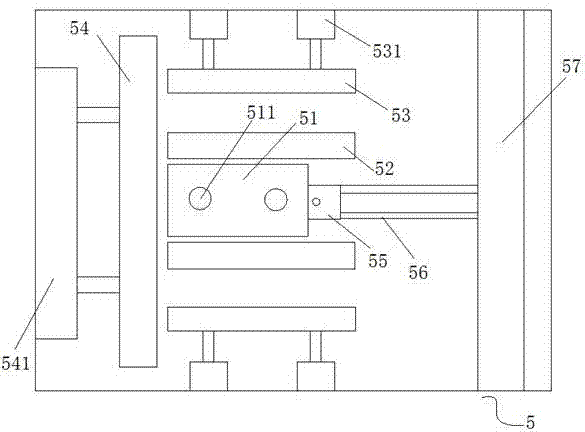

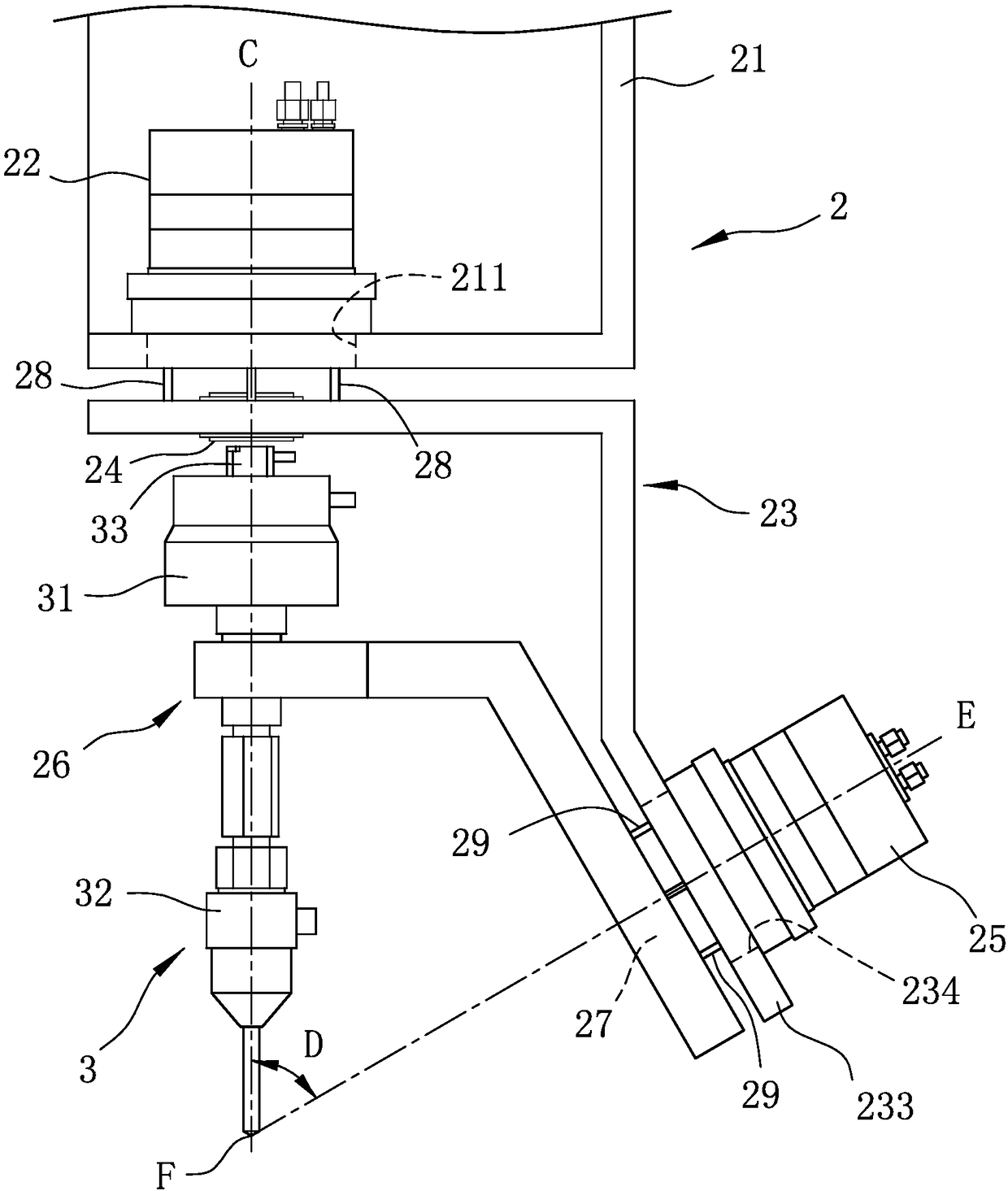

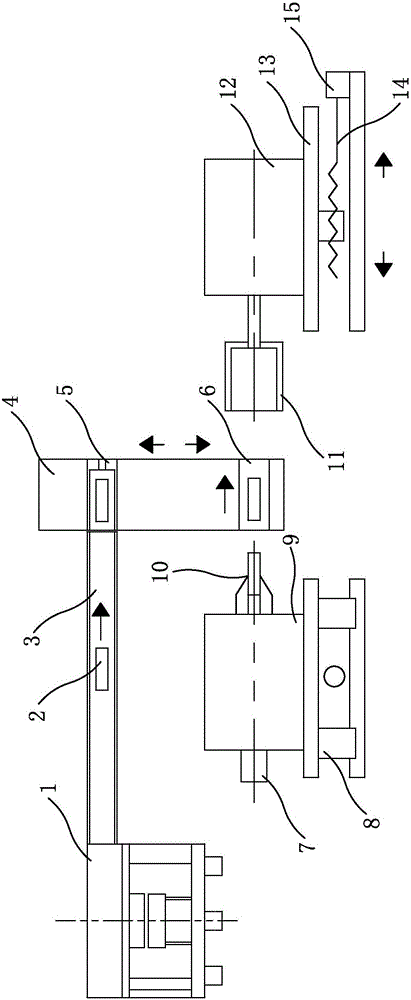

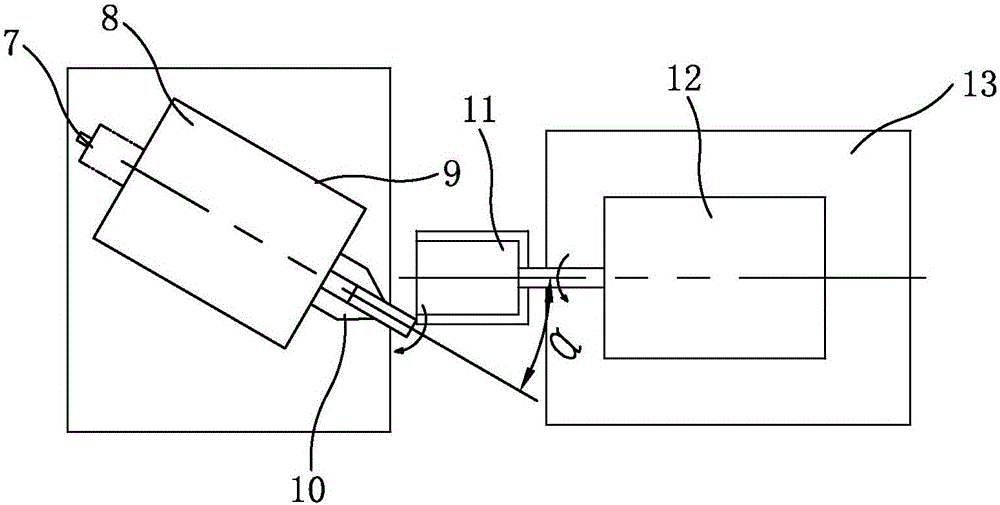

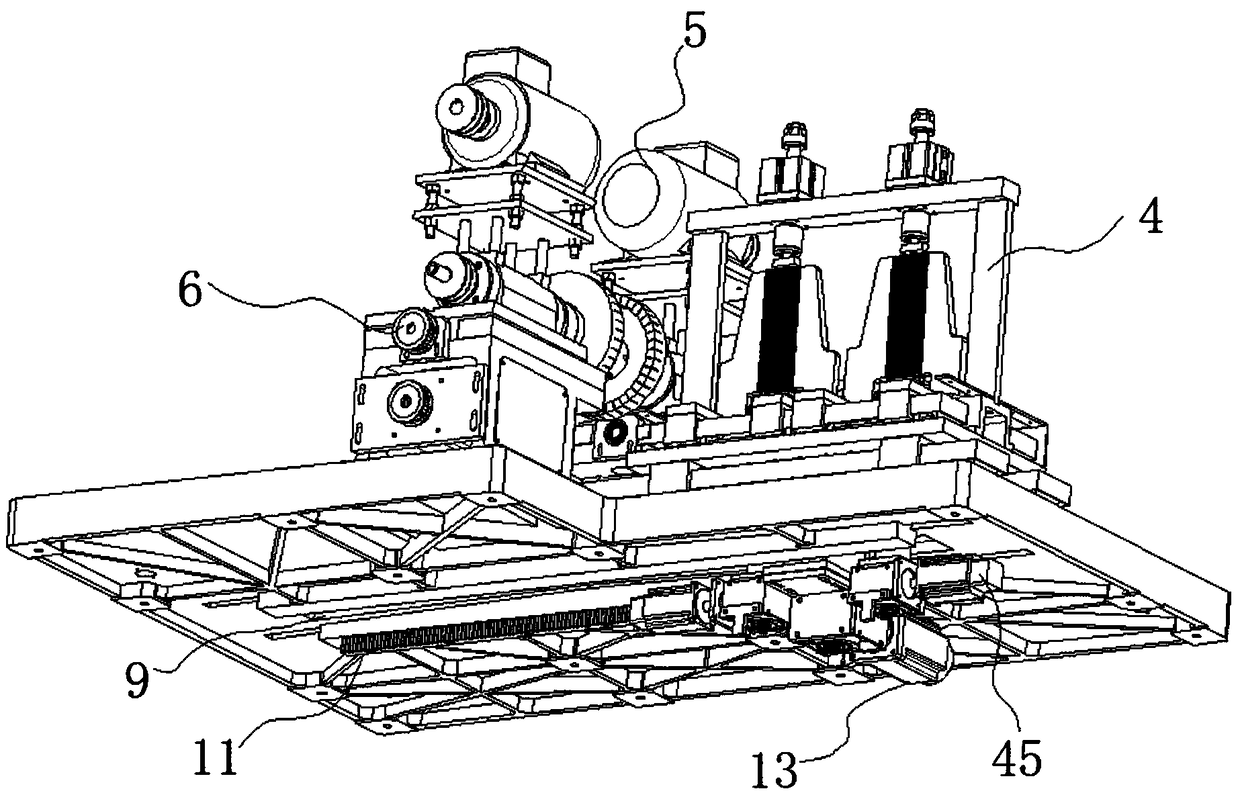

3D printing machine for manufacturing hollow rubber tires

ActiveCN105584053AEasy to shapeImprove machining precisionAdditive manufacturing apparatusHorizontal axisEngineering

The invention relates to a 3D printing machine for manufacturing hollow rubber tires, and belongs to the field of 3D printing technologies. A movable platform (3) is arranged in the printing machine, a horizontal X-direction screw (4) is arranged below the movable platform (3), and a spraying nozzle (5) is arranged on the horizontal X-direction screw (4) and can move on the horizontal X-direction screw (4); a rotation driving device (12) is further arranged on the printing machine, a rotating body (11) capable of rotating around the horizontal axis is arranged on the rotation driving device (12), and a side ring (14) is arranged on the outer side of the rotating body (11); and the spraying nozzle (5) is used for printing the hollow tires on the side ring (14). The 3D printing machine for manufacturing the hollow rubber tires has the beneficial effects of being good in product molding, high in machining accuracy and high in manufacturing speed.

Owner:JIANGSU RISINGSUN TIRE

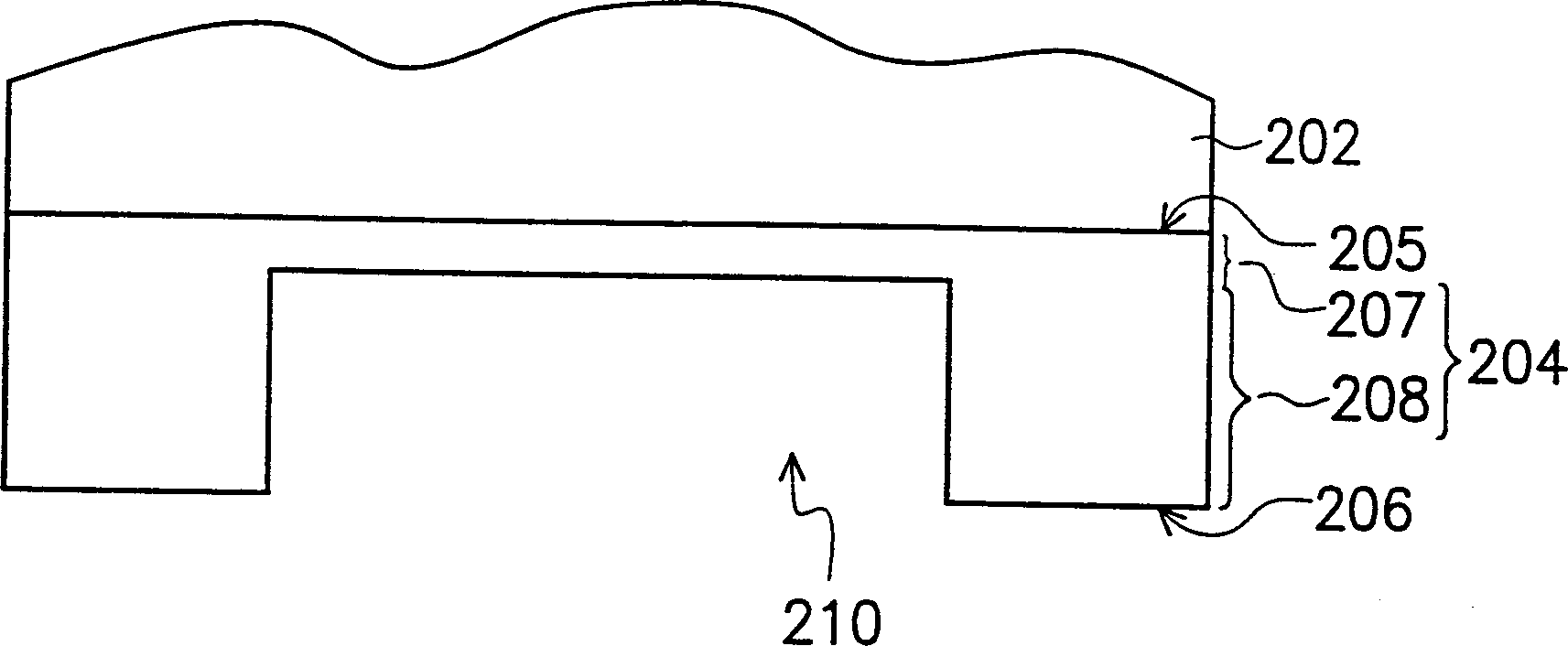

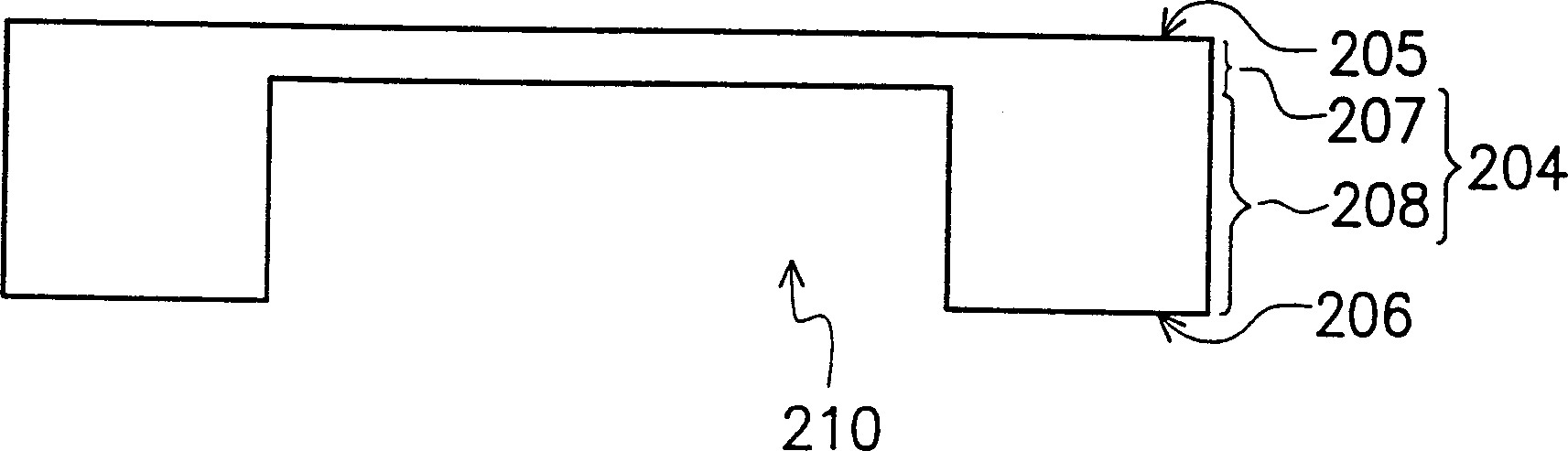

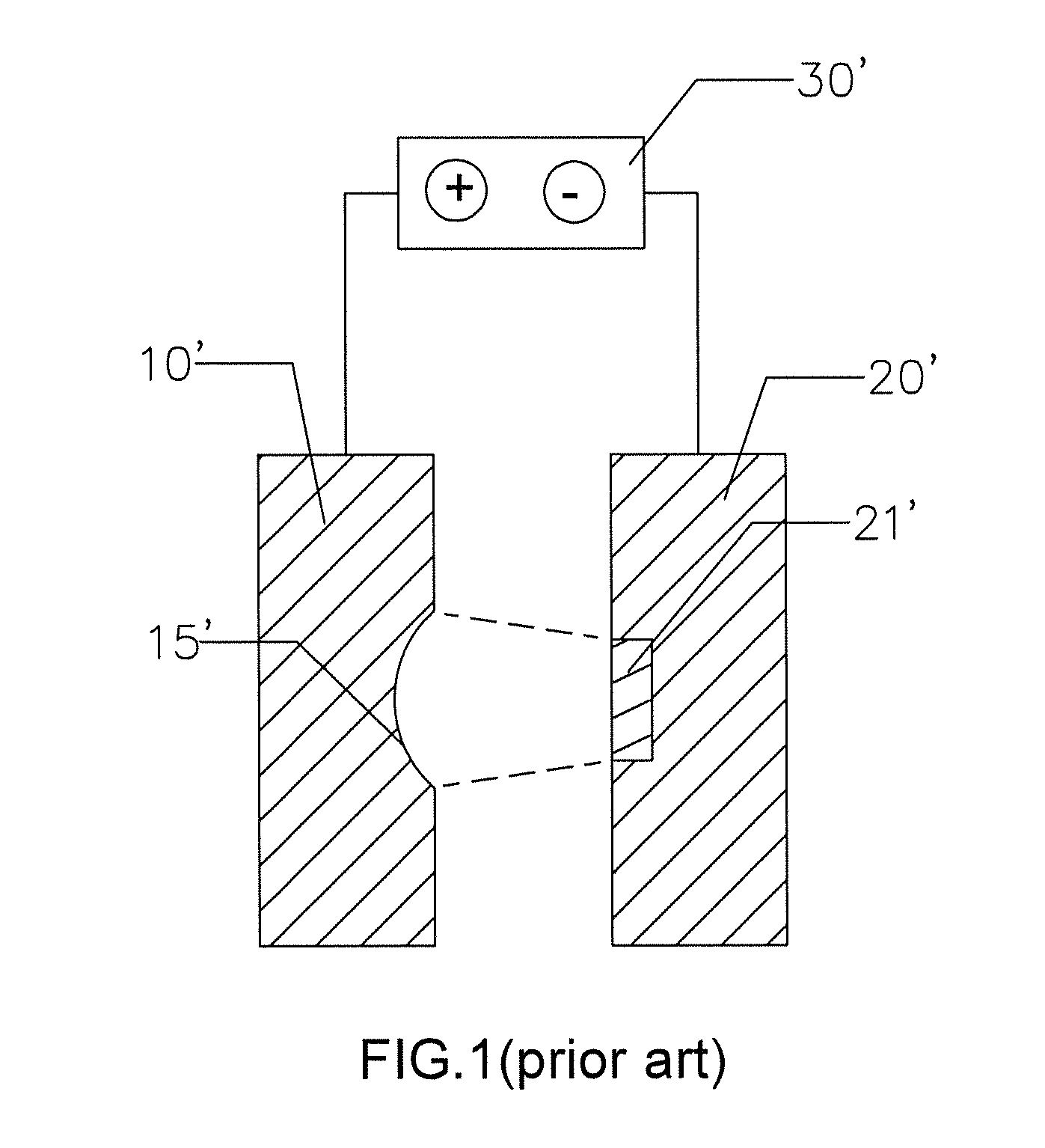

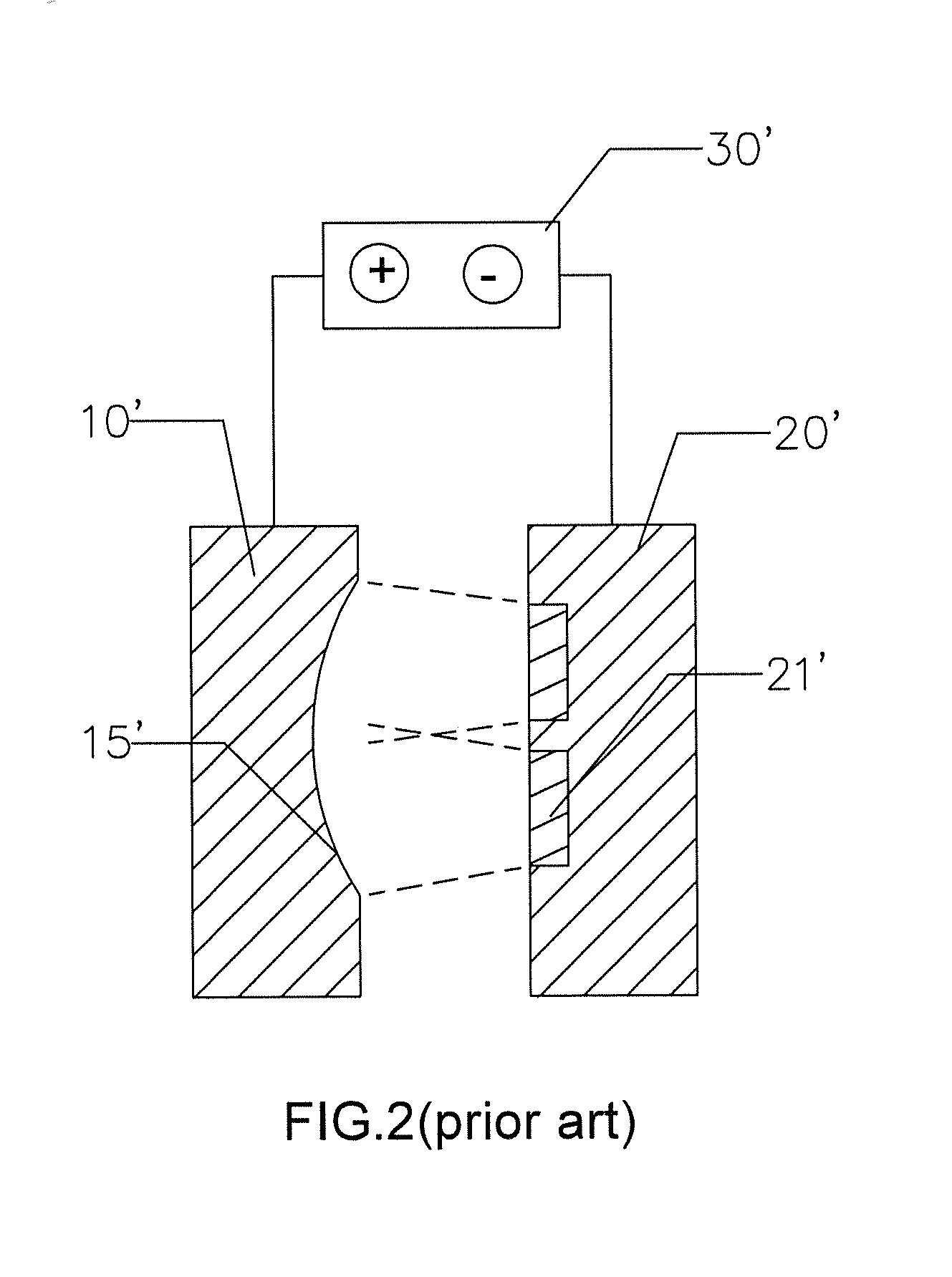

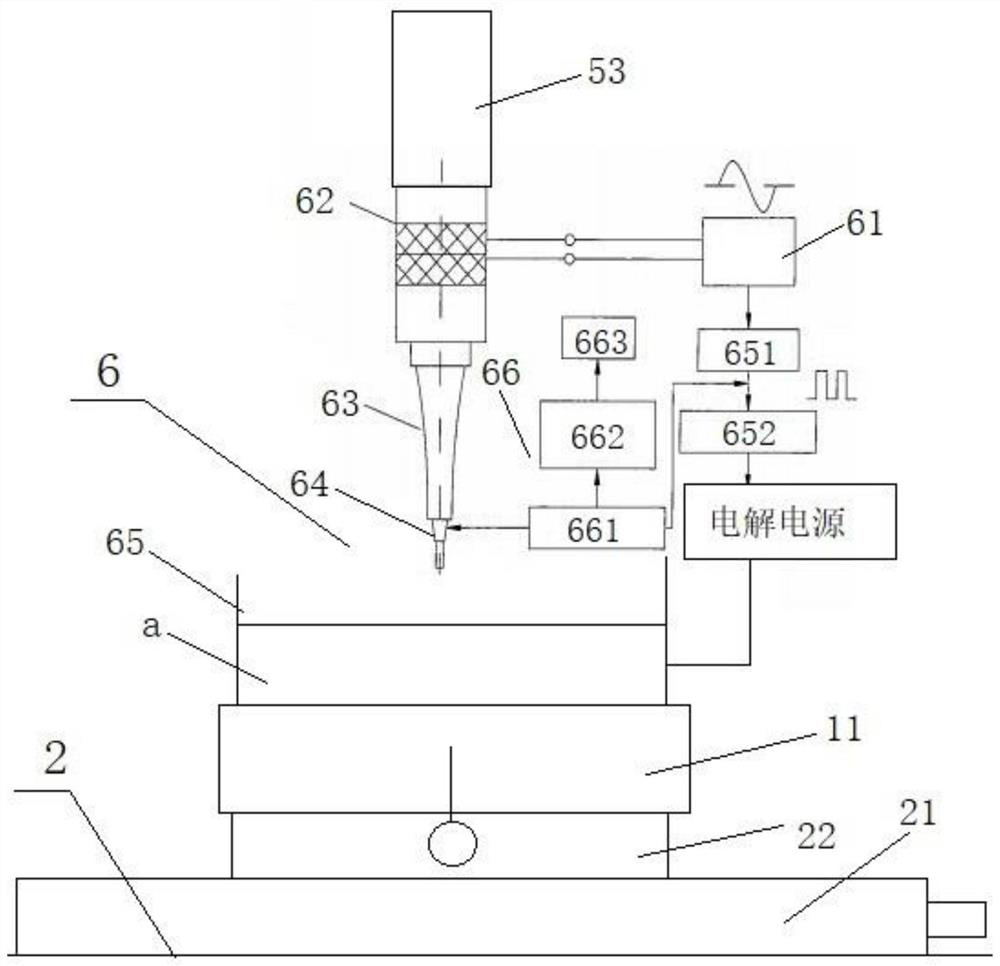

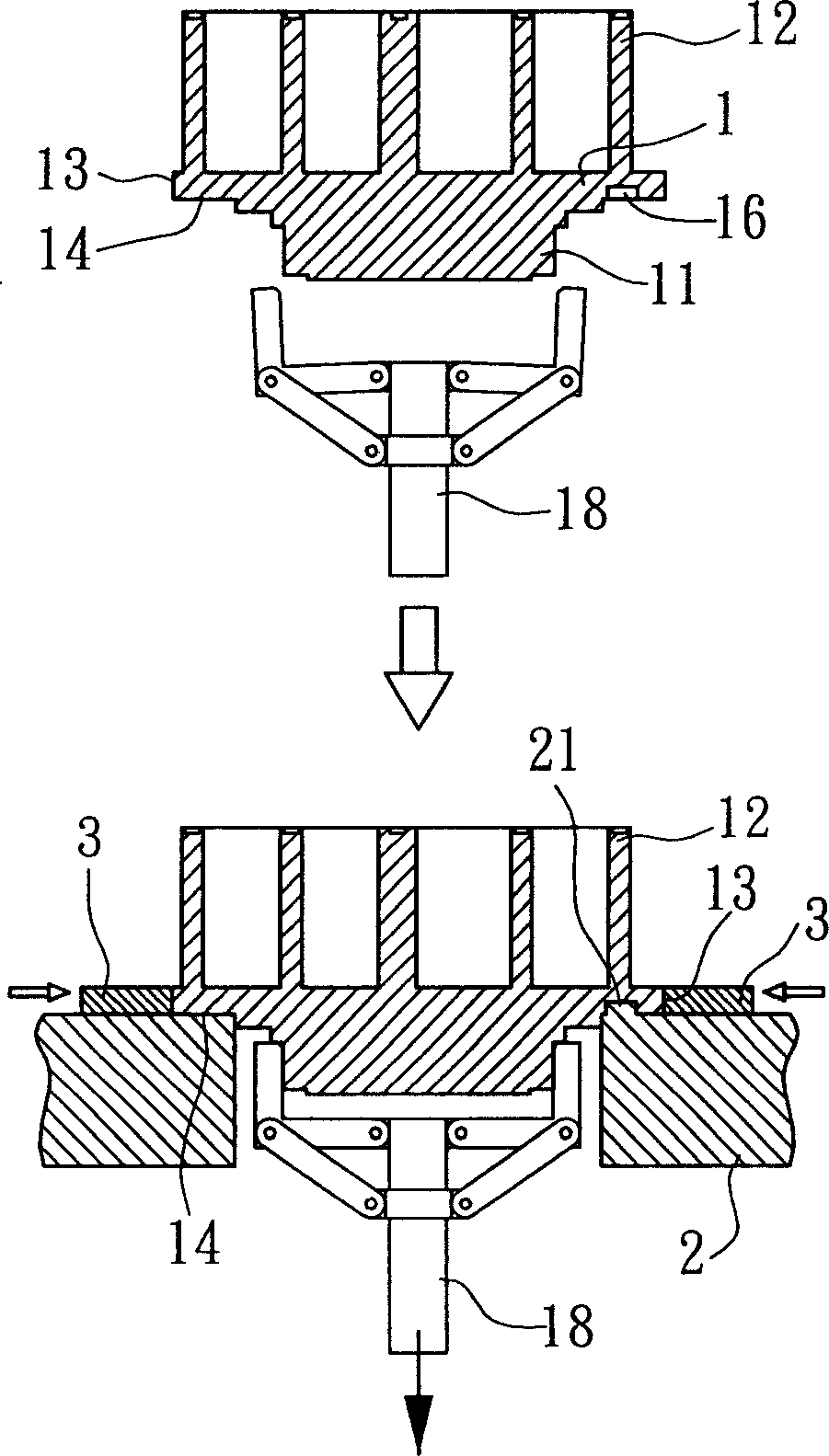

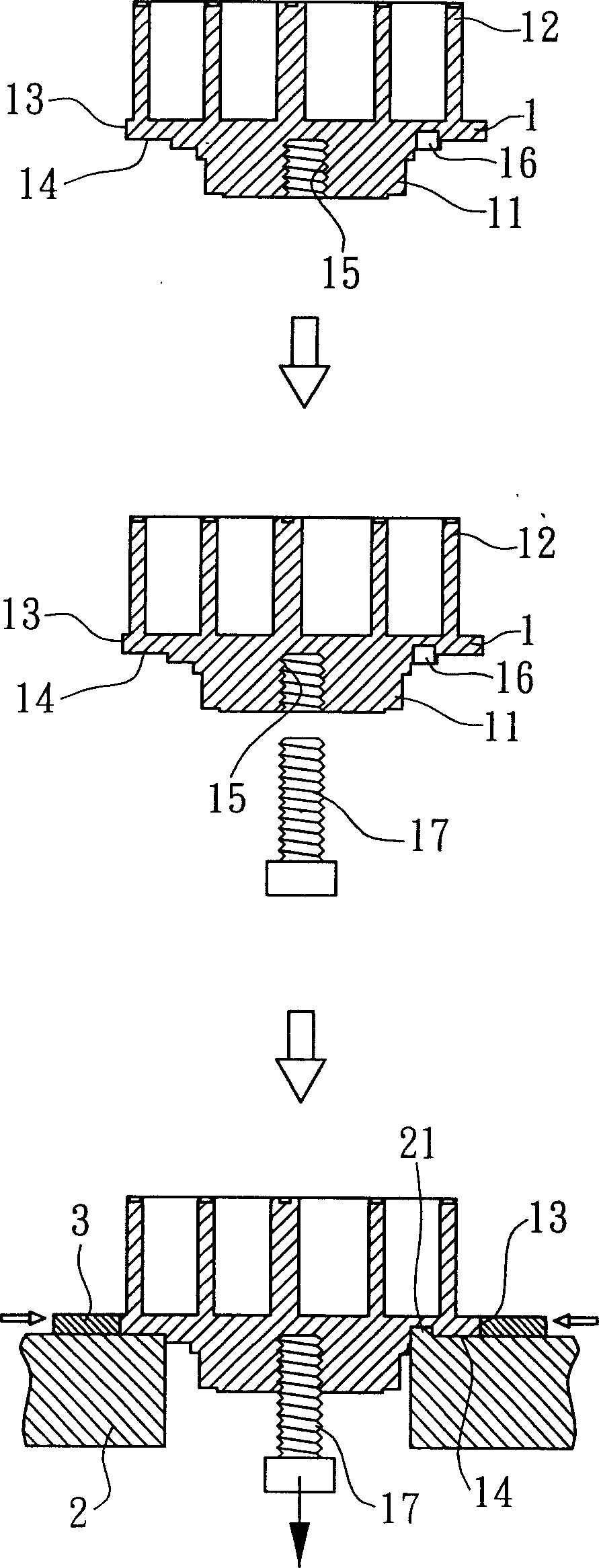

Electrolytic machining method and semifinished workpiece by the electrolytic machining method

InactiveUS20120171507A1Improve machining precisionReduce decreaseElectrolysis componentsElectrochemical machining apparatusElectrolysisIncrease size

The present invention relates to an electrolytic machining method. For increasing size precision of electrolytic machining method, a metallic mask layer is formed on the surface of a workpiece whose material has high conductivity or volume electrochemical equivalent, whereby the metallic mask layer can be used as a sacrificial layer of electrolytic machining and simultaneously protects the non-machining region of the workpiece so as to reduce lateral machining of the workpiece Consequently, the size precision of electrolytic machining is enhanced. In addition, the feasibility of electrolytically machining a miniature interval between two machined structures is increased as well. In addition, the present invention provides a semifinished electrolytic workpiece, comprising a workpiece and a metallic mask layer formed on the surface of the workpiece. The conductivity or volume electrochemical equivalent of the metallic mask layer is smaller than that of the workpiece.

Owner:METAL INDS RES & DEV CENT

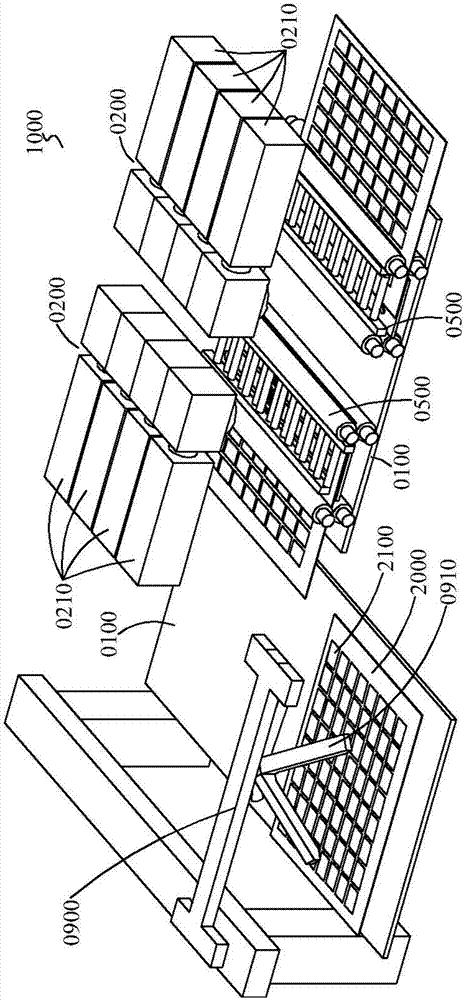

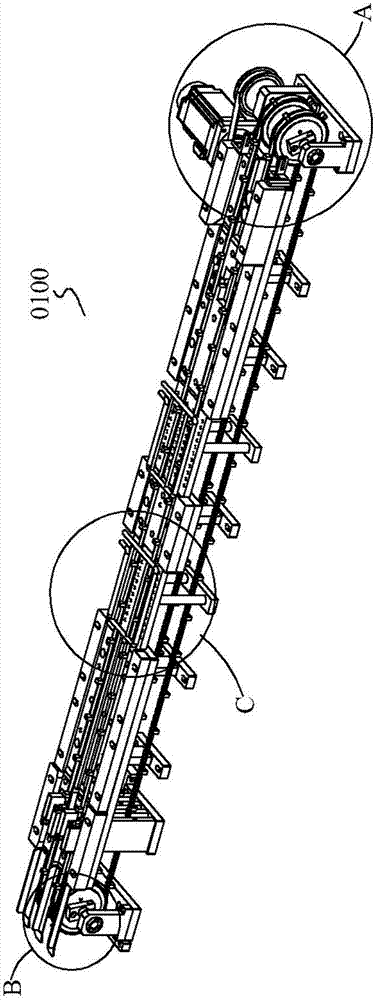

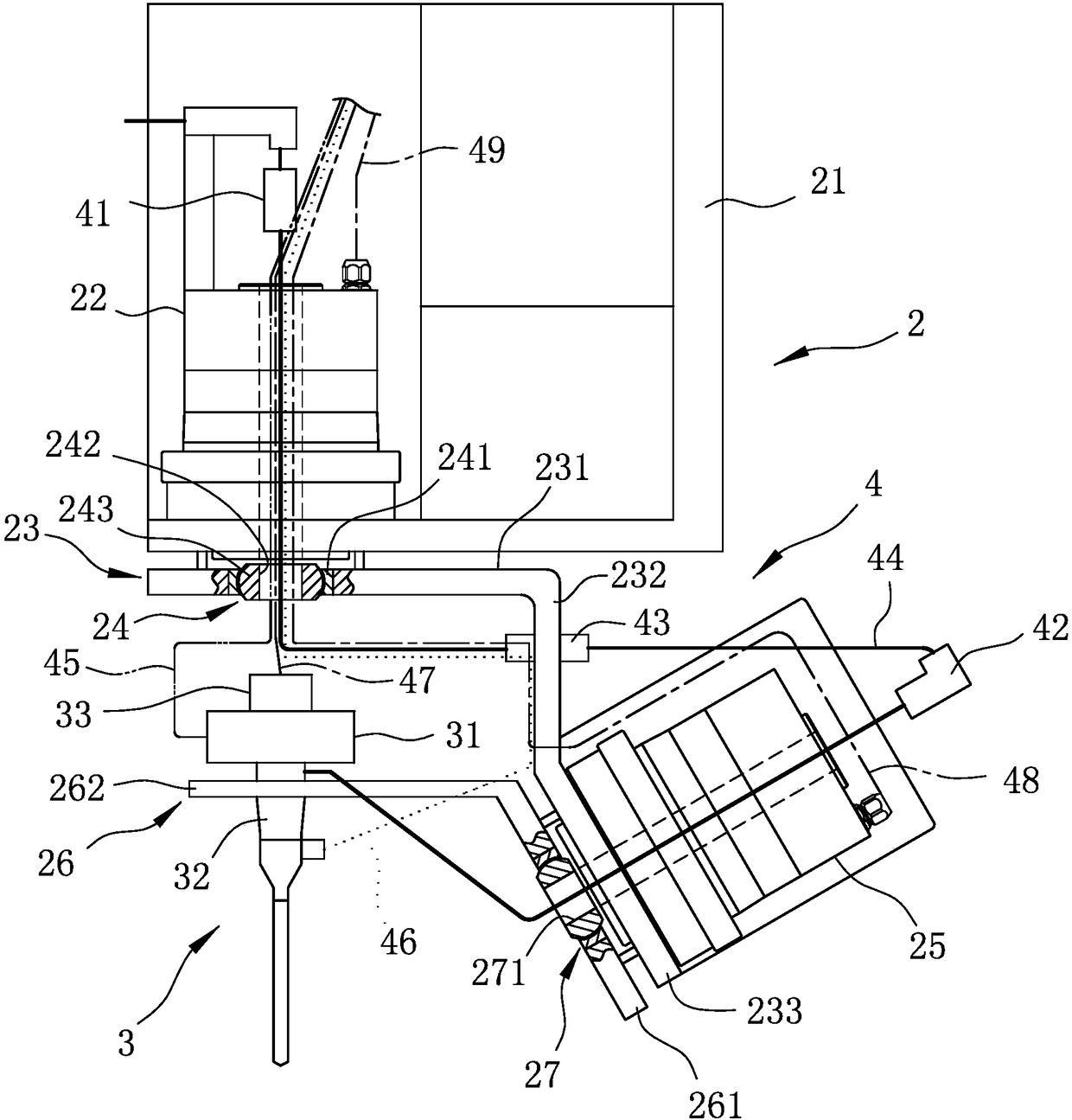

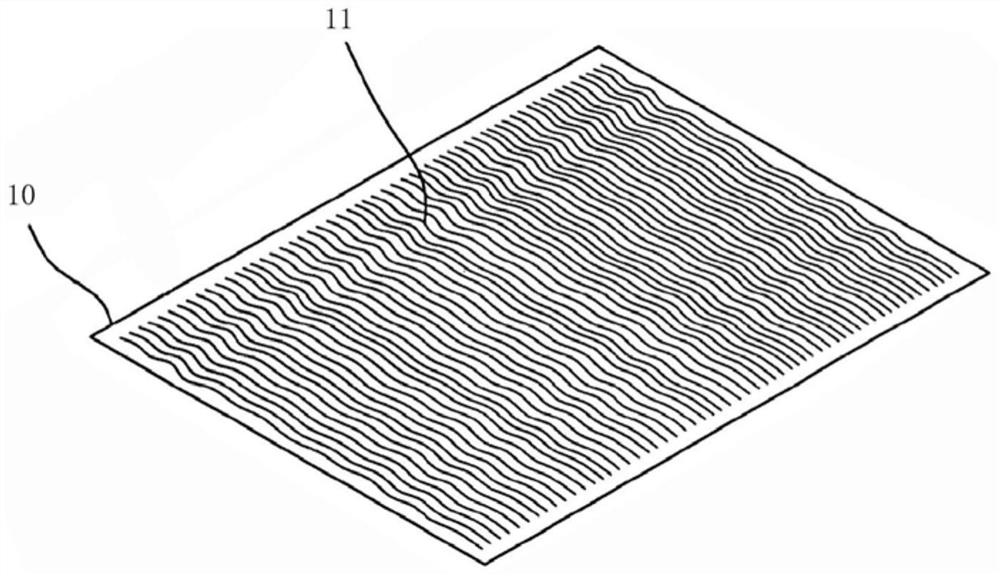

Multi-axis laser slot milling machine

PendingCN107511589ASmall area of actionImprove processing efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMulti axis

A multi-axis laser slot milling machine comprises a conveying mechanism and at least one milling mechanism. The conveying mechanism comprises a moving portion and multiple base plate clamps arranged on the moving portion. The base plate clamps are used for clamping base plates in a one-to-one correspondence manner. The base plate clamps move along with the moving portions and pass through the milling station. Each base plate is provided with multiple card bases at least arranged in array in a first direction. The first direction and the movement direction of the base plate are not parallel. When multiple milling mechanisms are arranged, the milling mechanisms are distributed in the movement direction of the base plates. The milling mechanisms comprise multiple laser devices. The multiple laser devices are arranged on the milling station and distributed in array in the first direction. The laser devices are used for emitting laser beams and milling burying slots on the surface of the corresponding card bases. The multi-axis laser slot milling machine is high in machining efficiency and good in precision and has the multi-axis machining capacity.

Owner:深圳华创兆业科技股份有限公司

Efficient precision machining process for showing stand

InactiveCN112775623AIncrease flexibilityImprove processing efficiencyShow shelvesShow hangersUltrasonic vibrationMachining process

An efficient precision machining process for a showing stand comprises the following steps that (1) correction is conducted, specifically, a showing stand blank is measured through a height gauge, and the showing stand blank which does not meet the requirement is corrected through a tool; (2) a reference surface is milled, specifically, the reference surface of the showing stand blank is milled by adopting precision machining equipment, the precision machining equipment comprises a rack, a bottom plate, gantry stand columns, a gantry cross beam, a main shaft mechanism and an ultrasonic vibration machining mechanism; (3) a vertical machining center is used for machining; (4) drilling is conducted; (5) correction is conducted; and (6) surface treatment is conducted, specifically, the surface of the corrected showing stand blank is sprayed, and the showing stand is obtained. The efficient precision machining process for the showing stand is reasonable in process setting, simple, controllable, high in flexibility and machining efficiency, high in machining precision, capable of being used for large-scale production, good in economical efficiency and wide in application prospect.

Owner:TAICANG U UP DISPLAY FIXTURES CO LTD

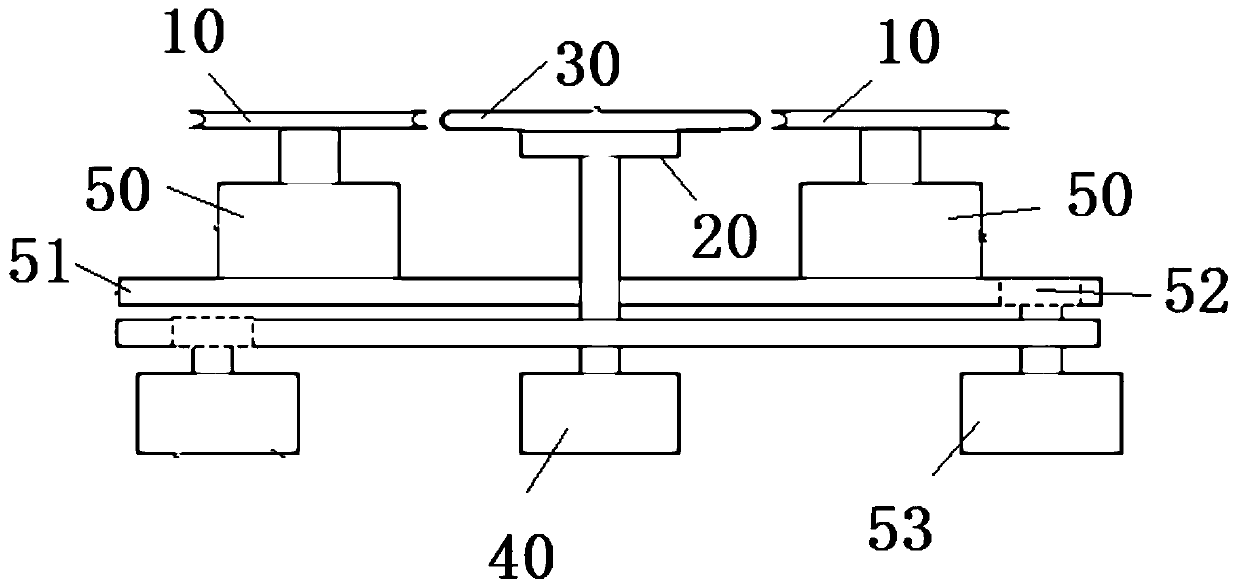

Plastic semi-finished product automatic edge folding and forming equipment

PendingCN107443798AImplement stacking and imputationAutomate operationBox making operationsPaper-makingStructural engineeringMachine

The invention provides plastic semi-finished product automatic edge folding and forming equipment. The equipment comprises a machine frame, a positioning frame is arranged in the middle of the upper part of the rack, and the equipment is characterized in that a positioning guide rod is symmetrically arranged above the horizontal plane of the machine frame, two ends of the guide rod are symmetrically provided with a first translating mechanism and a second translating mechanism; a feeding mechanism is arranged below one side of the machine frame, a discharging mechanism is arranged below the other side of the machine frame, the middle area of the horizontal plane of the machine frame is provided with a processing part, the positioning frame is provided with an auxiliary positioning device facing with the processing part; the first translating mechanism is connected with a first vacuum suction head, the second translating mechanism is connected with a second vacuum suction head. The invention can realize high uniformity and edge folding and forming of the plastic shell of the semi-finished products, and has the advantages of high processing precision, repeatability of 99.9% and more and high edge folding efficiency, and reduces production cost, and realizes automatic operation and product collection.

Owner:游启康

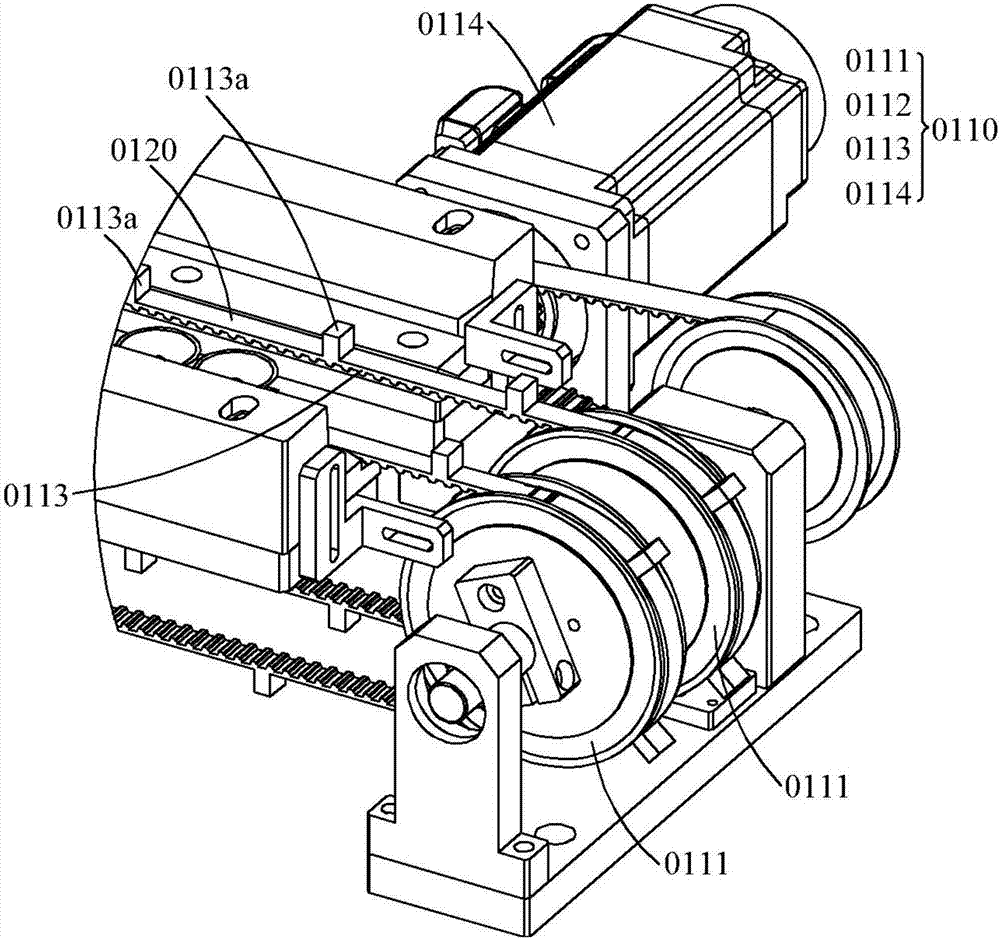

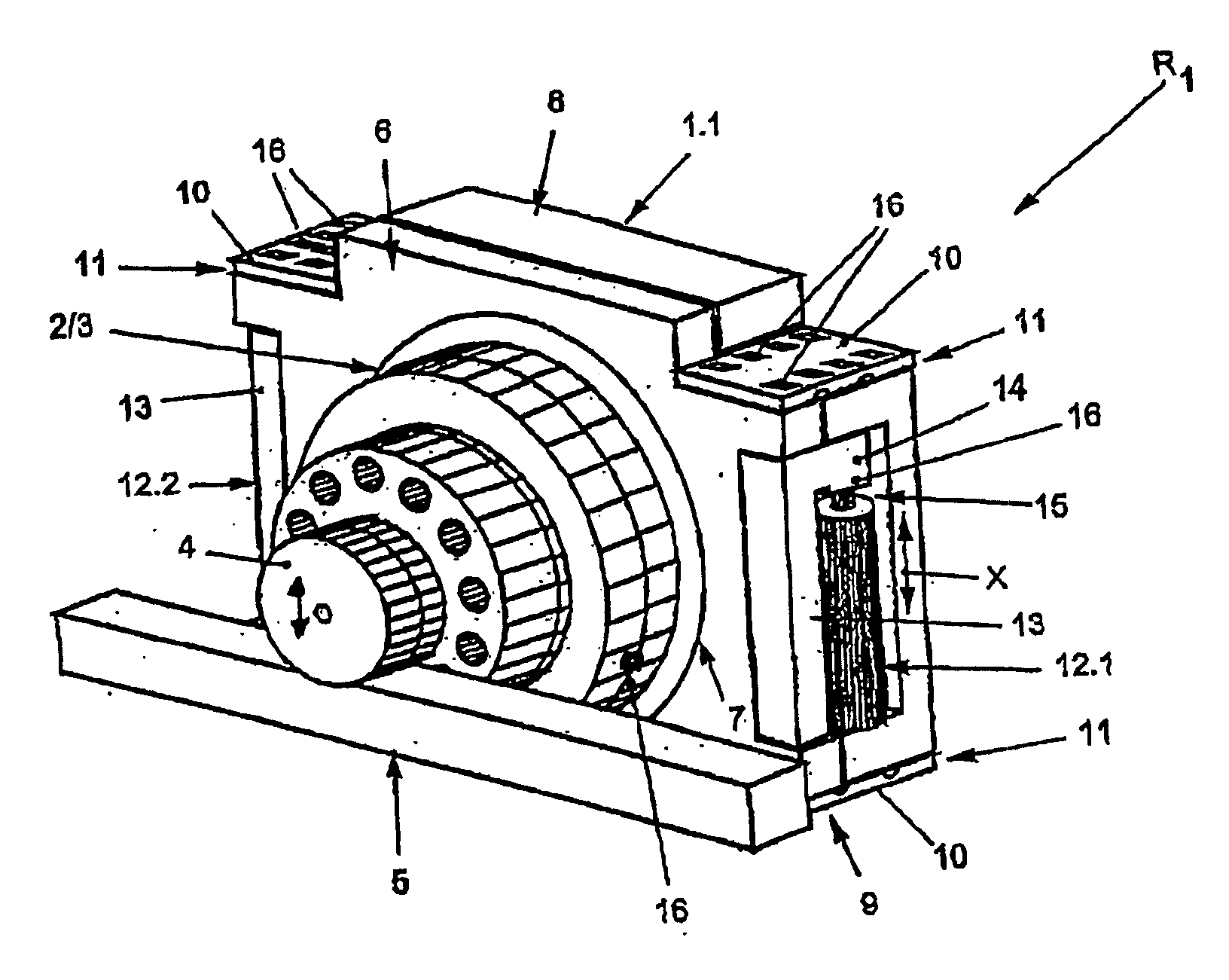

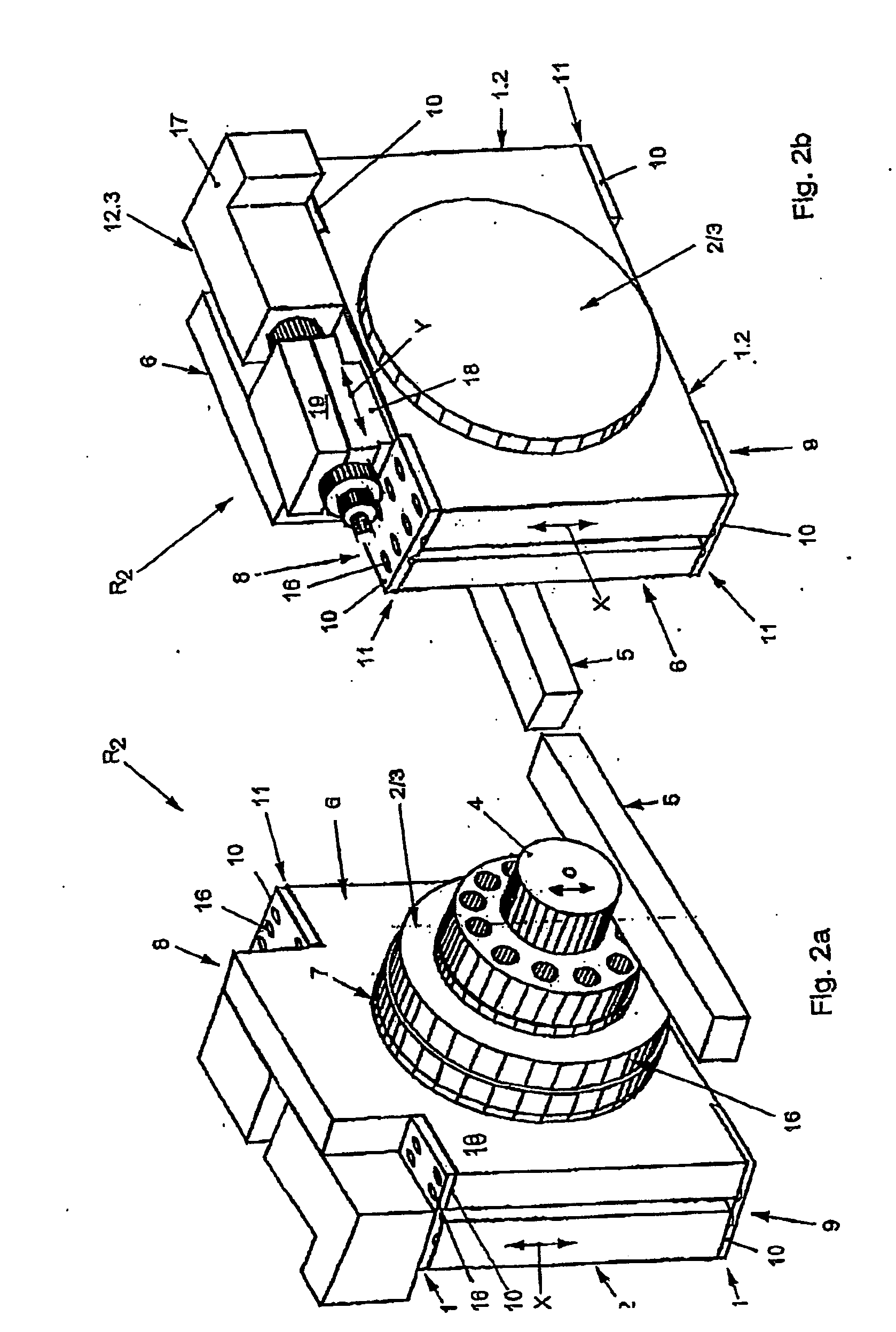

Linear drive, in particular a rack and pinion drive

InactiveUS20090320630A1Improve machining precisionNarrow designPortable liftingFeeding apparatusLinear driveRack and pinion

The invention relates to a linear drive, in particular a rack and pinion drive, comprising at least one motor element (2) which is mounted on or in a retaining element (1.1, 1.2). The motor element (2) drives, directly or indirectly, a pinion (4), optionally, via an integrated drive (3), said pinion co-operating with a linear guide (5). According to the invention, the retaining element (1.1, 1.2) can be displaced by at least one actuator (12.1 to 12.3) in relation to a receiving element (6).

Owner:WITTENSTEIN GROUP

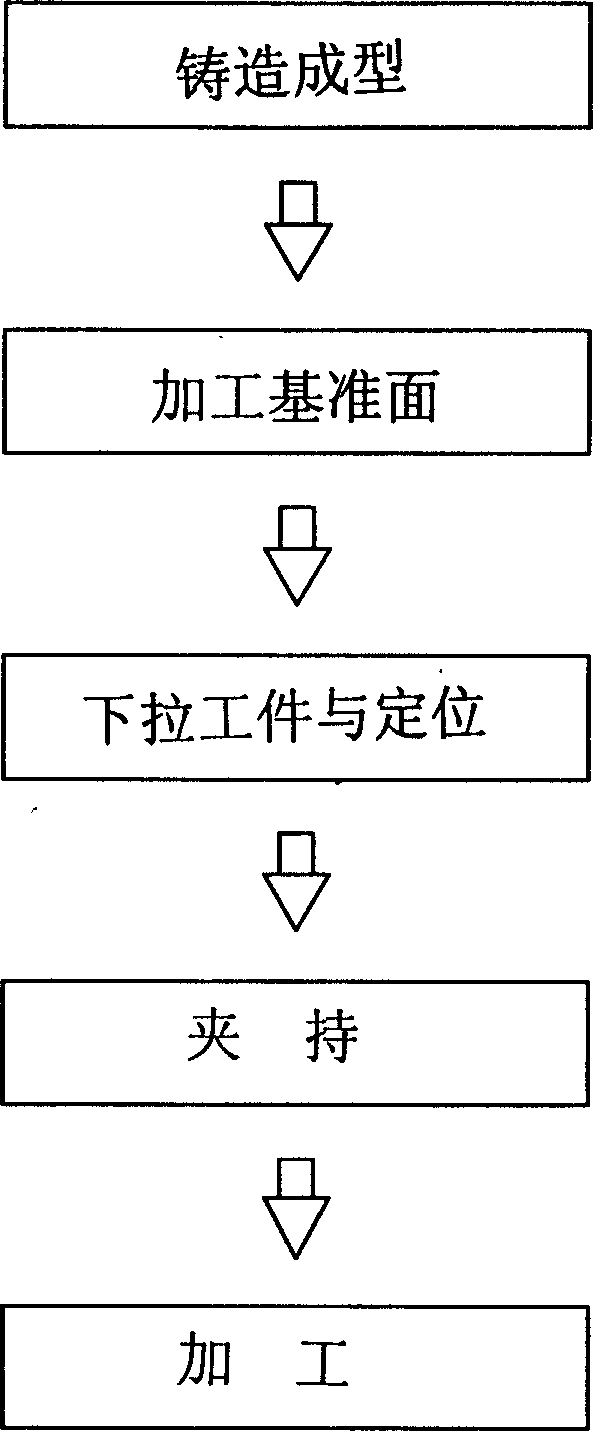

Turbination processing method of compressor

InactiveCN1601107AHigh strengthImprove machining precisionRotary piston pumpsRotary piston liquid enginesCircular discEdge surface

The invention relates to a scroll processing method of compressor. It includes the following steps: casting forming : the scroll is formed by compression casting type to make the scroll have a disc, each the both side of the disc has a seating body and a scroll piece. Processing base level: each of the outer edge surface of the disc and the surface connected to the seating body is processed to vertical base level and horizontal base level, as well as the outer edge surface of the seating body is processed. Pulling down work piece and fixing position: the seating body is clamped by tool and pulled down to make the horizontal base level hug closely to stable tool platform to fix the position, the scroll piece is convex out of the stable tool. Centre gripping: the clamp device is clamped to the vertical base level to make the scroll be fixed with steady centre gripping. Processing: after the scroll is fixed with steady centre gripping, the scroll can be processed by processing implement to make sure that each of the processing surfaces can be parallel to the vertical base level or horizontal base level. The invention can ensure each of the processing surfaces is parallel to the vertical base level or horizontal base level, realize the improvement of the effect of the processing precision, improve the intensity of the scroll.

Owner:宁波汇峰聚威科技股份有限公司

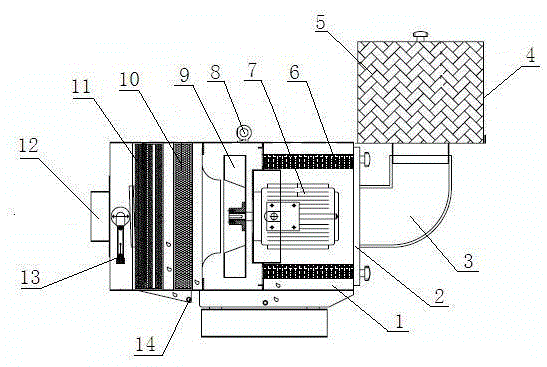

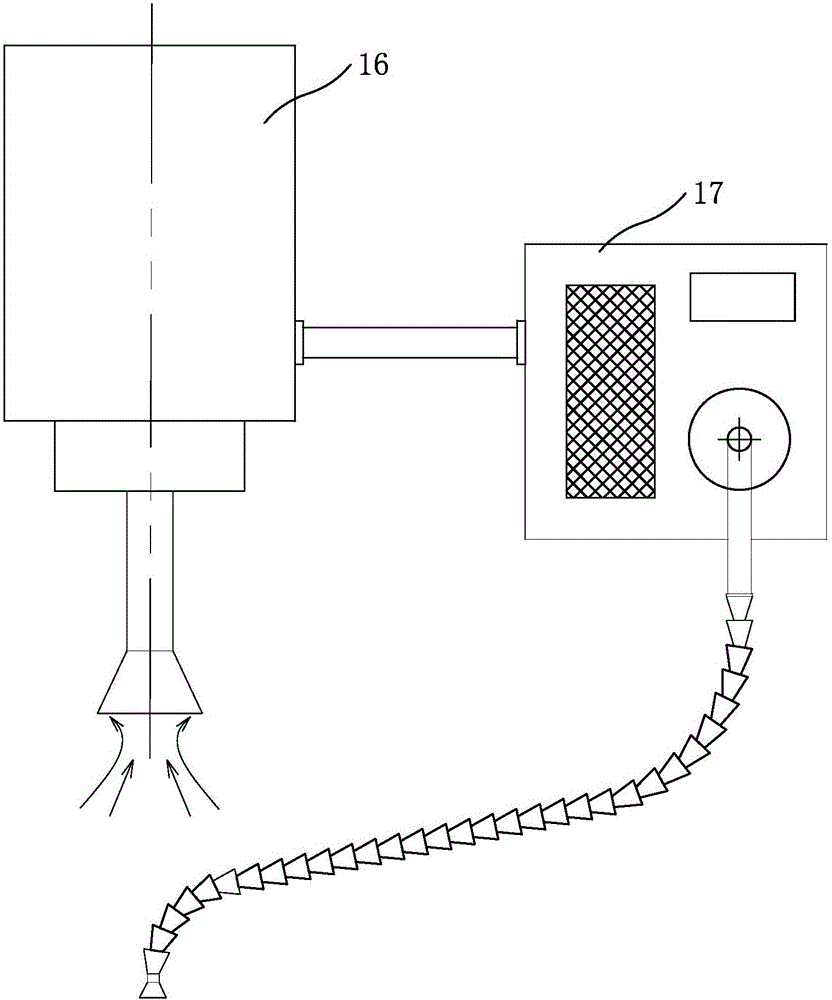

Environment-friendly and energy-saving equipment with purification device and purification method

InactiveCN105413370AImprove machining precisionSave resourcesCombination devicesOccupational injuryImpeller

The invention provides environment-friendly and energy-saving equipment with a purification device and a purification method. Almost electromechanical equipment, which is used at present, is not provided with a purification device of an oil mist separation system; particles with the size of 0.3 microns to 3.5 microns in oil mist in the electromechanical equipment are harmful to the health of human bodies when being inhaled by people; and the oil mist is deposited in a working region and accidents including occupational injuries and the like are easy to cause. The environment-friendly and energy-saving equipment comprises a base (1), wherein a groove is formed in the base; a motor (7) is mounted at the middle part in the groove; two tertiary filtering devices (6) are arranged on the side faces of the motor respectively; the front end of the motor is connected with a centrifugal impeller (9) through a connection shaft; a secondary filtering device (10) is arranged at the front end of the centrifugal impeller; a primary filtering device (11) is arranged at the front end of the secondary filtering device; and an oil mist suction inlet (2) is mounted on the front end face of the base. The environment-friendly and energy-saving equipment with the purification device is provided by the invention.

Owner:哈尔滨宇光环保节能科技发展有限公司

Thin-wall appearance part machining process

InactiveCN111037229AGuaranteed aesthetic requirementsGuaranteed accuracyAircraft componentsSurface finishMilling cutter

The invention discloses a thin-wall appearance part machining process which comprises a step of roughing a mounting surface: roughly machining a raw material by adopting a disc milling cutter, roughlydigging a cavity surface of the raw material by adopting a rough milling cutter, removing residual materials at corners, and preliminarily forming a mounting surface of a workpiece; a step of performing appearance surface finish machining: conducting finish machining on a surface opposite to the mounting surface to the designated size to form an appearance surface by using the disc milling cutter, a ball cutter and a forming cutter; a step of grinding the appearance surface: grinding an appearance surface and polishing the appearance surface; a step of performing fine machining on the mounting surface: reversely clamping and fixing a semi-finished product through a suction cup clamp and repeatedly performing roughing and finish machining on the mounting surface; and a step of performing powder spraying processing: carrying out powder spraying treatment on the appearance surface. By means of the mode, an appearance part is subjected to material removing machining, finish machining is conducted after multiple times of roughing, the workpiece precision is guaranteed, the multi-curved-surface precision machining of a thin-wall part of the appearance part can be effectively conducted,meanwhile, the requirement of the appearance part for the attractive appearance can be met, and the machining precision and quality can be improved.

Owner:SUZHOU LIANJIA PRECISION MACHINERY

Cutter handle with shock absorption function

PendingCN107972185AWith damping functionSimple structureStone-like material working toolsVibration amplitudeMilling cutter

The invention relates to a cutter handle with a shock absorption function. The cutter handle with the shock absorption function comprises a handle body, a damping block and a clamping head, wherein aninner hole is formed in the handle body and used for holding the damping block and the clamping head. The damping block is arranged at the bottom of the inner hole. The clamping head is arranged on the upper portion of the damping block. Four to six circles of grooves are formed in the surface of the inner hole. Shock absorption devices are arranged in the grooves and surround the periphery of the clamping head. The cutter handle with the shock absorption function is simple in structure, and convenient to use. When stone is machined, shaking or vibration of the surface of the stone is reduced. The damping block and the shock absorption devices convert kinetic energy into potential energy, the vibration amplitude of the milling cutter clamping head is relieved, vibration of a milling cutter is further relieved, and the surface coating of the milling cutter is protected. The machining accuracy of the surface of the stone is improved, and the service life of the coated cutter can also beprolonged.

Owner:SHENYANG JIANZHU UNIVERSITY

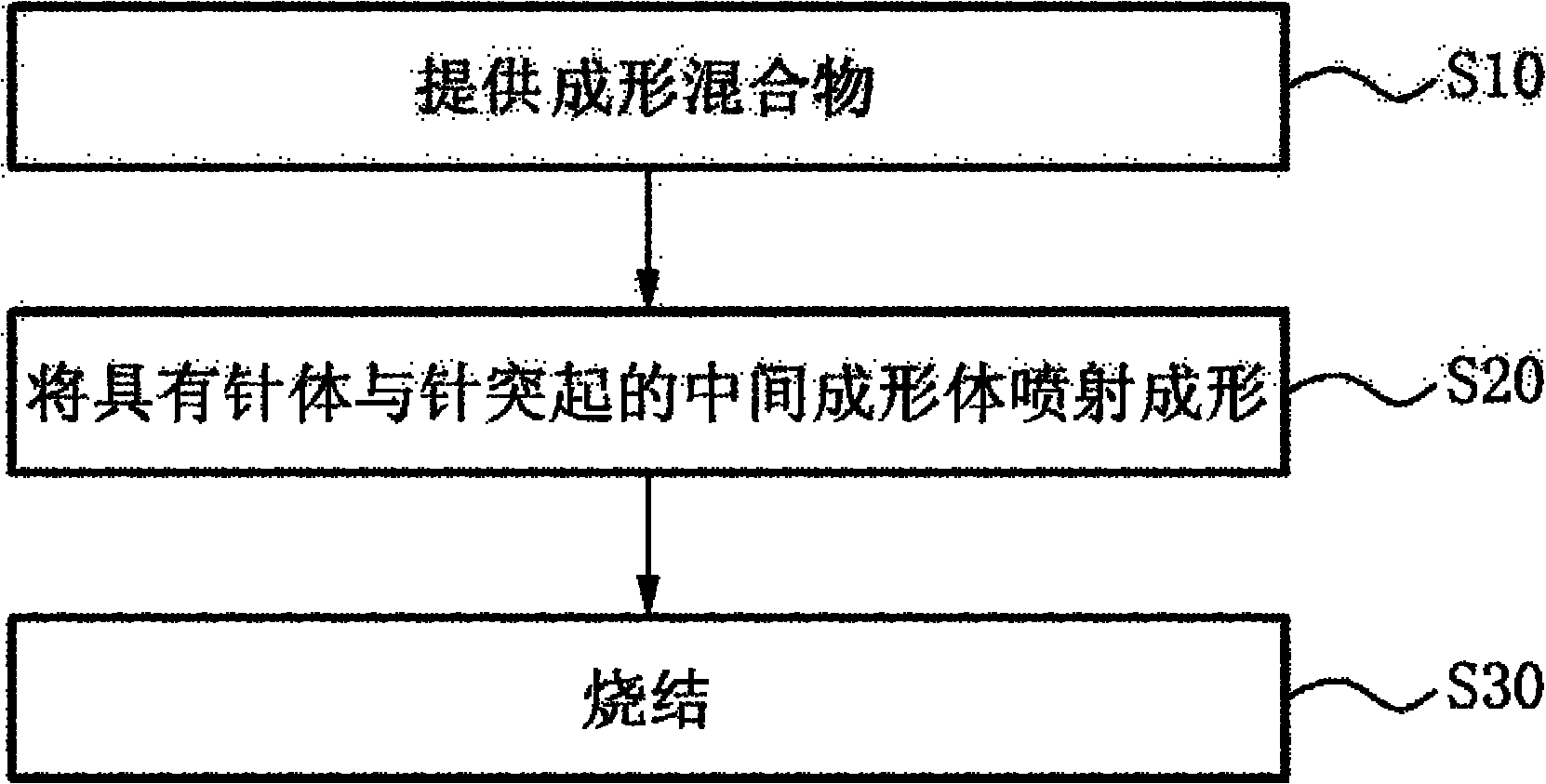

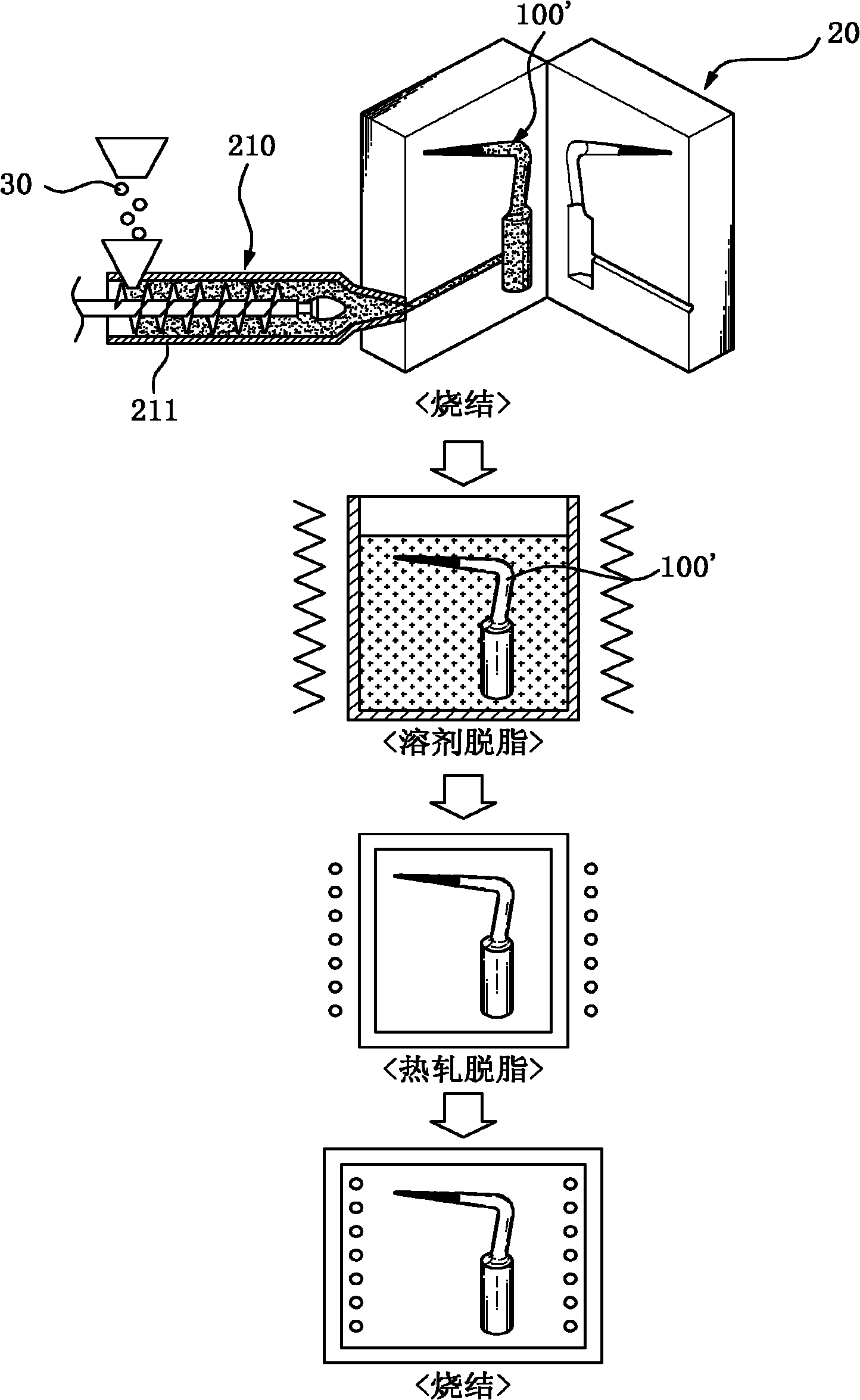

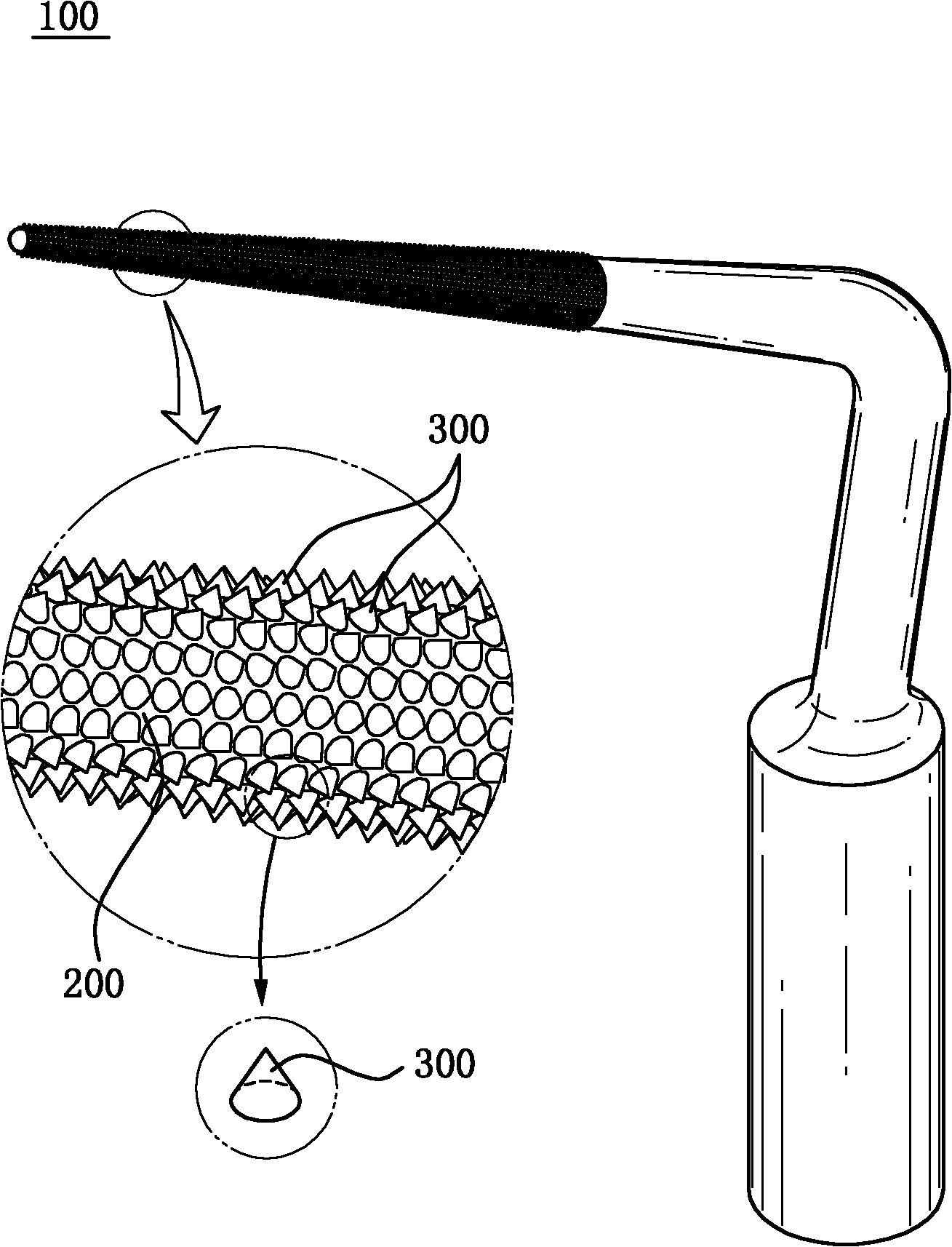

Ultrasonic wave syringe needle for dental department and medical treatment and manufacture method thereof

ActiveCN102018582AReduce manufacturing costSimplify Manufacturing EngineeringSurgeryDentistrySyringe needleBiomedical engineering

The invention provides an ultrasonic wave syringe needle for a dental department and medical treatment and a manufacture method thereof, wherein the durability and reliability of the ultrasonic wave syringe needle can be improved, and the ultrasonic wave syringe needle is easy to manufacture. The manufacture method of the ultrasonic wave syringe needle for the dental department and the medical treatment comprises the following steps: ejecting shaped mixture comprising powder to manufacture a middle shaping body, wherein the middle shaping body comprises a syringe body and a plurality of syringe bulges, and the syringe bulges are integrated on the surface of the syringe body and form a bulge; and sintering the middle shaping body.

Owner:赛搭泰克公司 +1

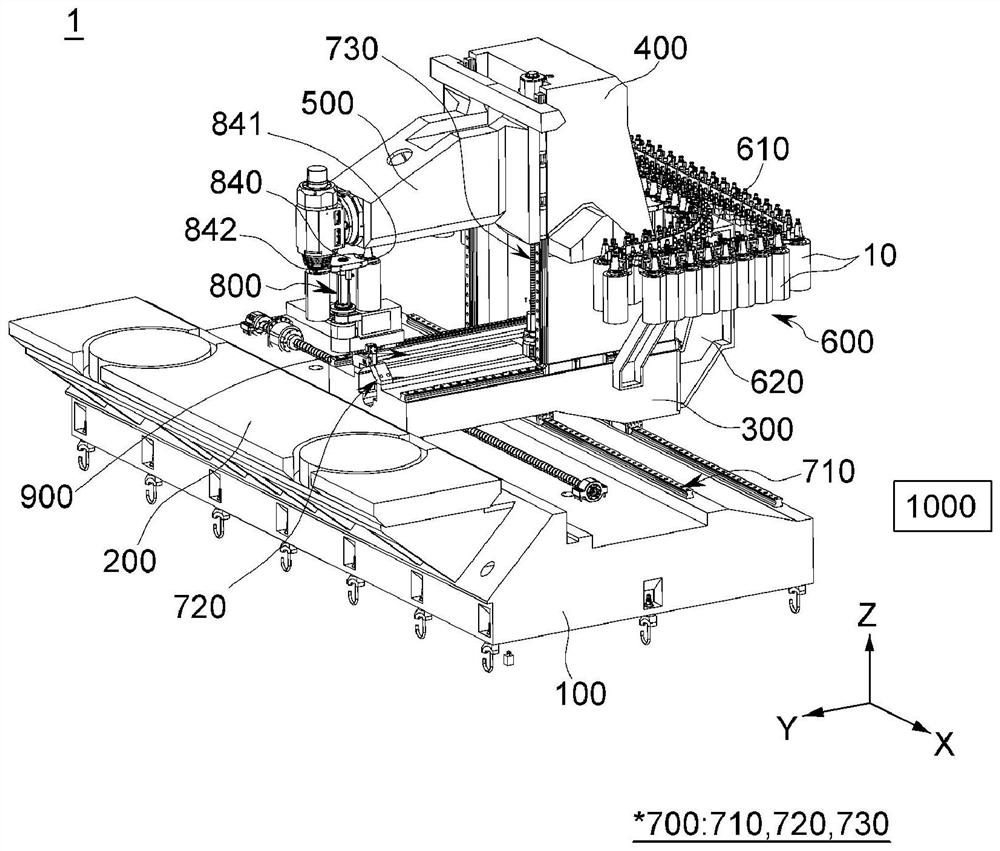

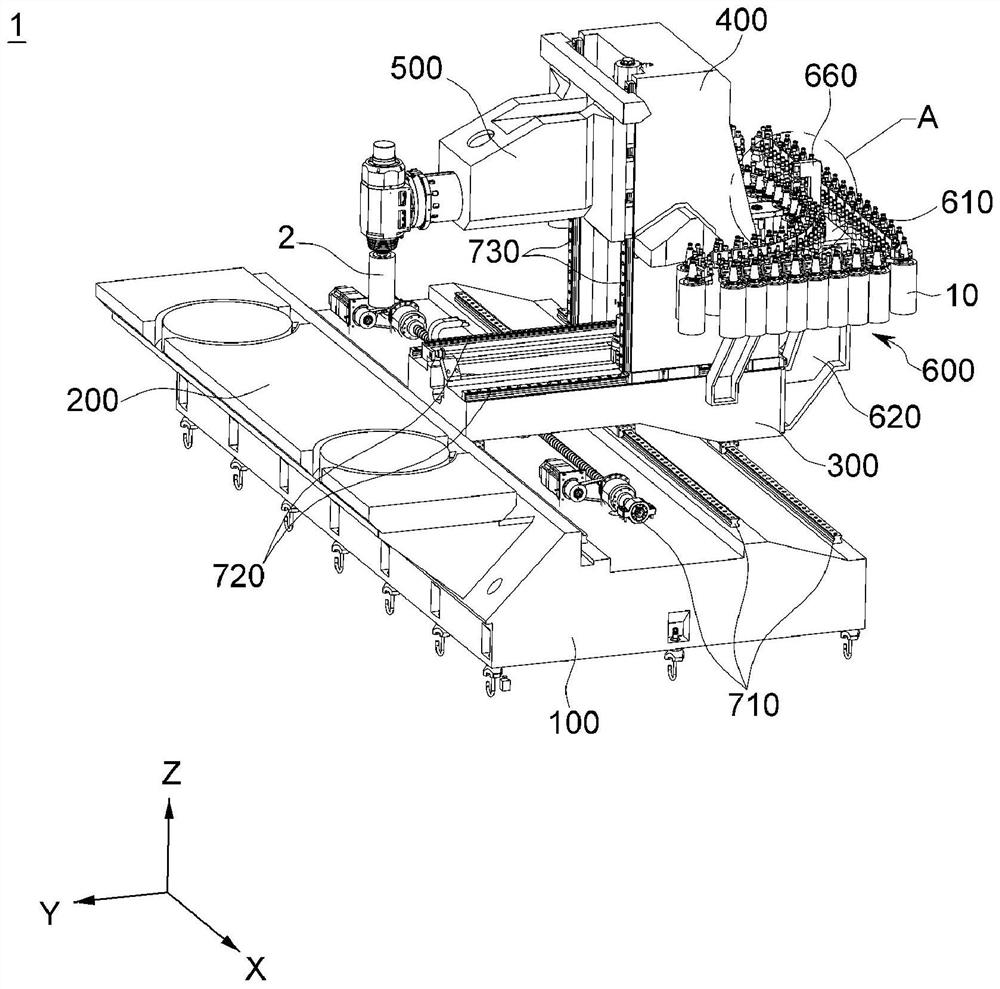

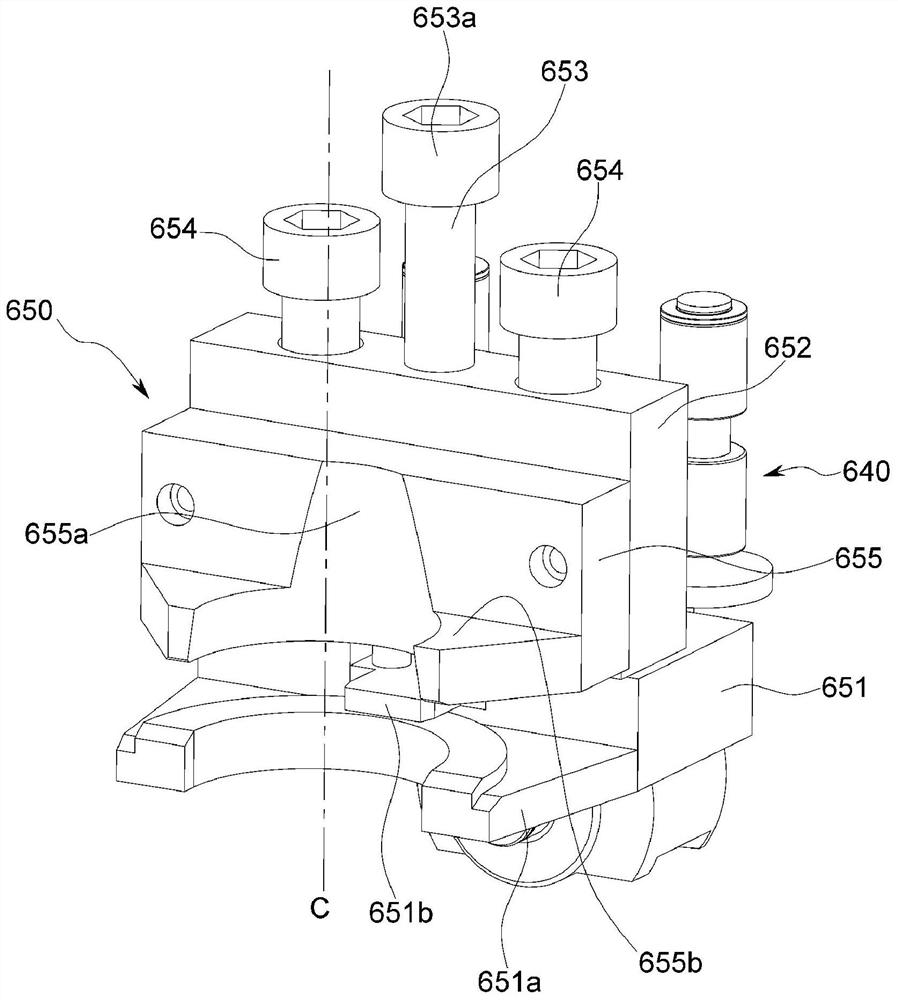

Tool magazine of machine tool

ActiveCN113412175AReduce replacement timeIncrease production capacityLarge fixed membersPositioning apparatusMachine toolMachining

Owner:DN SOLUTIONS CO LTD

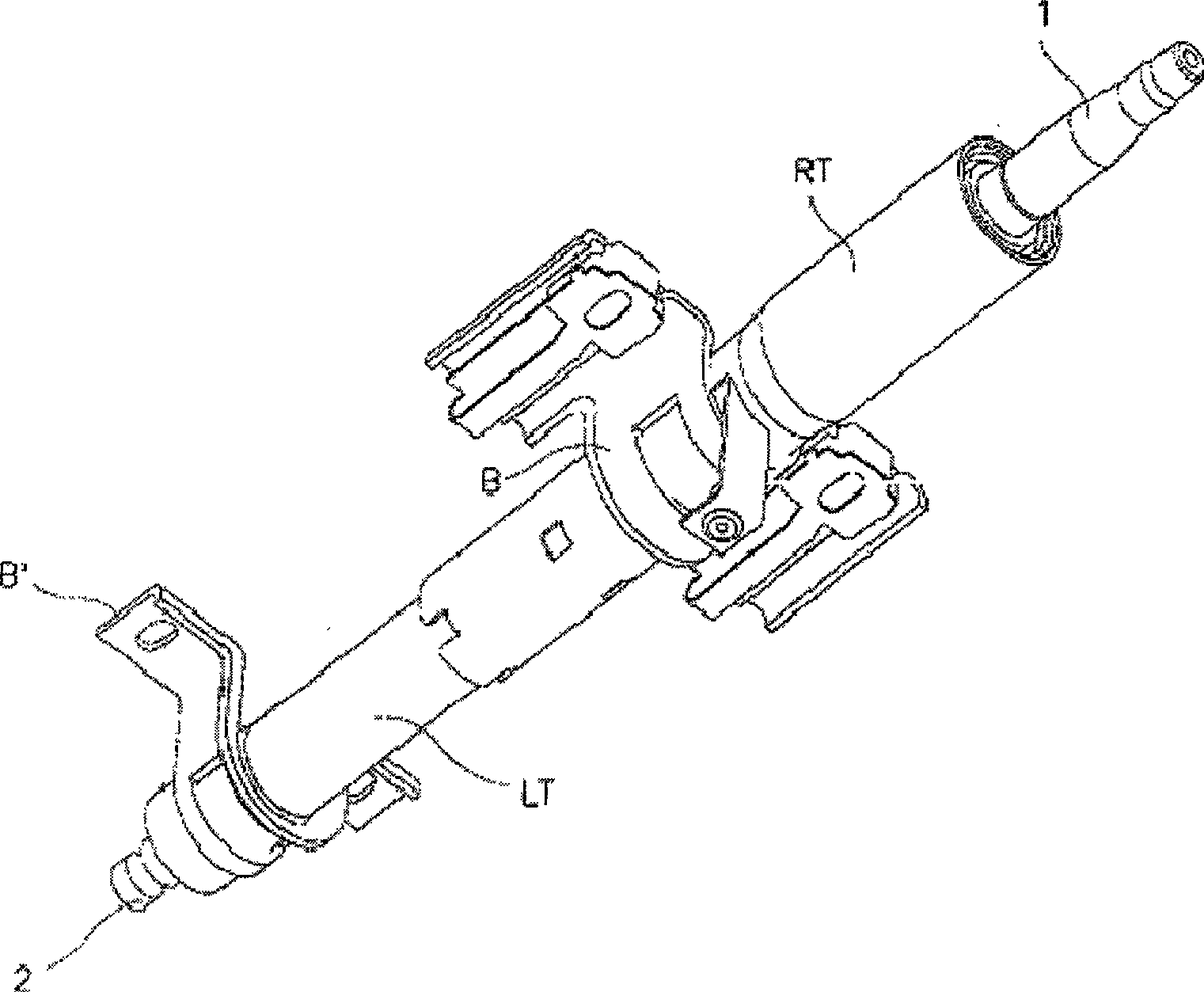

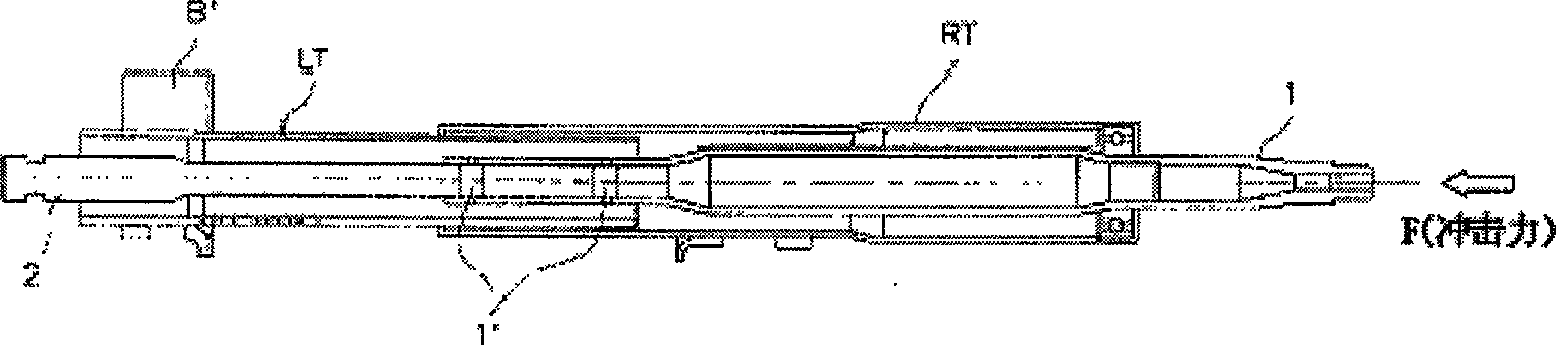

Processing method of upper shaft used for steering apparatus

ActiveCN101497103AReduce thicknessImprove machining precisionSteering columnsEngine componentsVolumetric Mass DensityControl theory

The invention relates to a method for processing an upper end shaft of a steering device capable of improving the processing density, saving cost of materials and improving the processing speed. The processing method comprises processing a cylindrical tube (30a) into first to second deformative shafts sequentially to obtain the upper end shaft finally. The method for processing the upper end shaft reduces thickness of a hollow tube and prolongs a length sequentially, and an inner key slot is formed by inserting a spindle having key slot, thereby improving the processing precision, saving materials, and improving the processing speed.

Owner:KOWOO

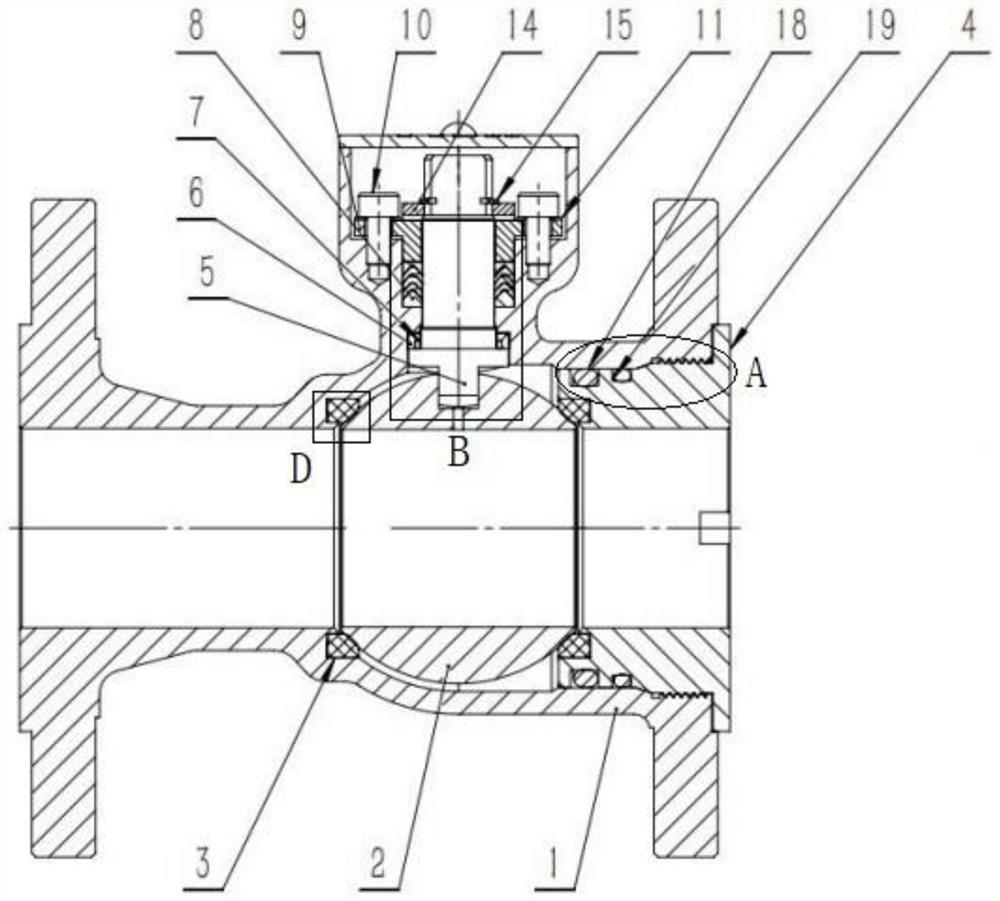

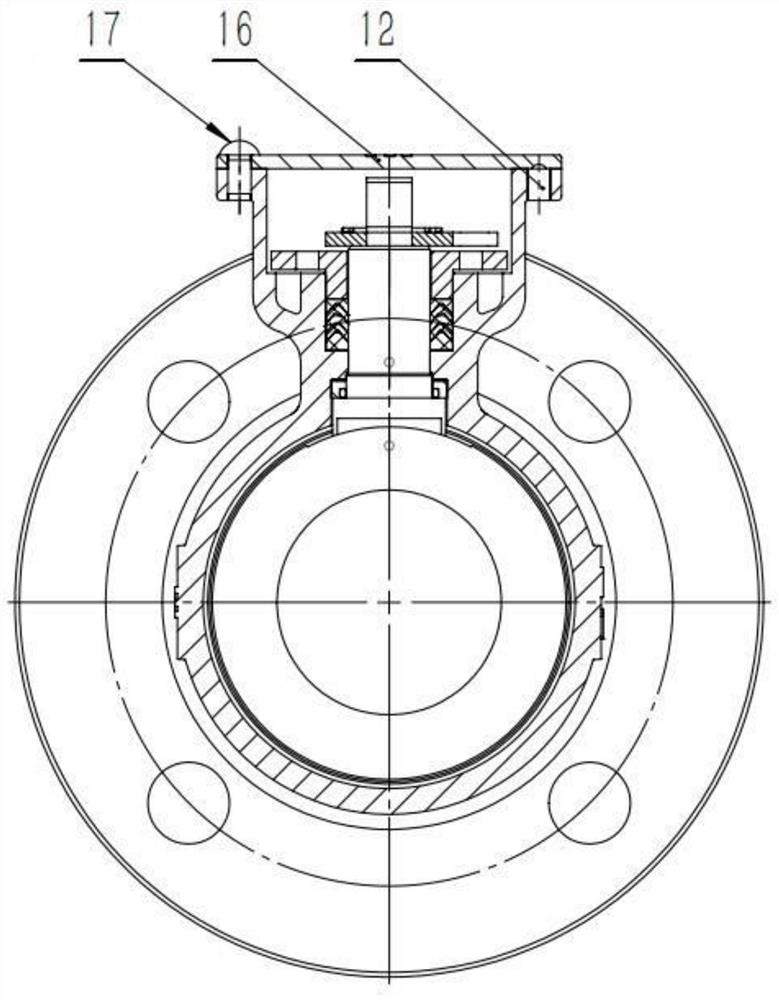

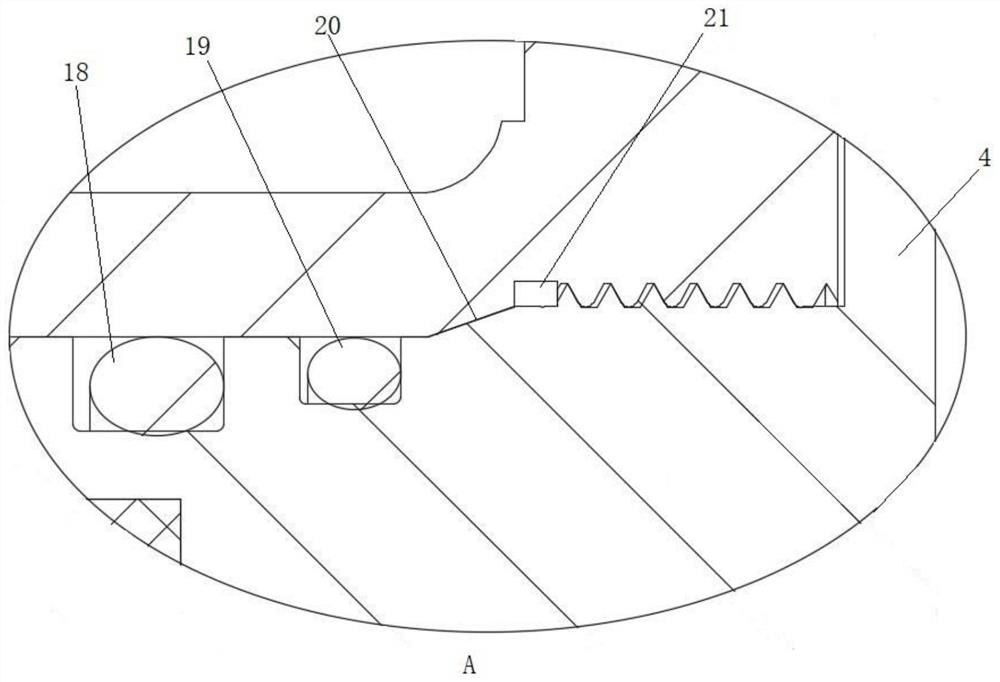

Dustproof low-torque one-piece type gas ball valve

PendingCN111927974AImprove mechanical propertiesImprove machining precisionSpindle sealingsPlug valvesEngineeringVALVE PORT

The invention belongs to the technical field of valves, and includes a dustproof low-torque one-piece type gas ball valve. A medium flowing-in channel, a valve ball and a medium flowing-out channel are coaxially and sequentially arranged inside an integrated valve body; the valve ball is arranged on a valve seat; the contact surface of the spherical surface of the valve ball with the valve seat issealed; the upper part of the valve ball is connected with the bottom end of a valve rod; a spanner is connected at the top end of the valve rod; a bonnet is mounted at one end, close to the medium flowing-out channel, inside the valve body; a sealing structure between the bonnet and the valve body comprises a first O-ring, a conical sealing surface and a PTFE sealing pad which are arranged sequentially in the medium flowing direction; a sealing structure between the valve rod and the valve body comprises a tooth-shaped labyrinth combined sealing structure and a V-shaped packing sealing structure; and a dustproof cover located above the valve rod is arranged on the valve body. The gas ball valve is good in sealing performance, good in fireproof performance and long in service life.

Owner:LIANGGANG VALVE GRP

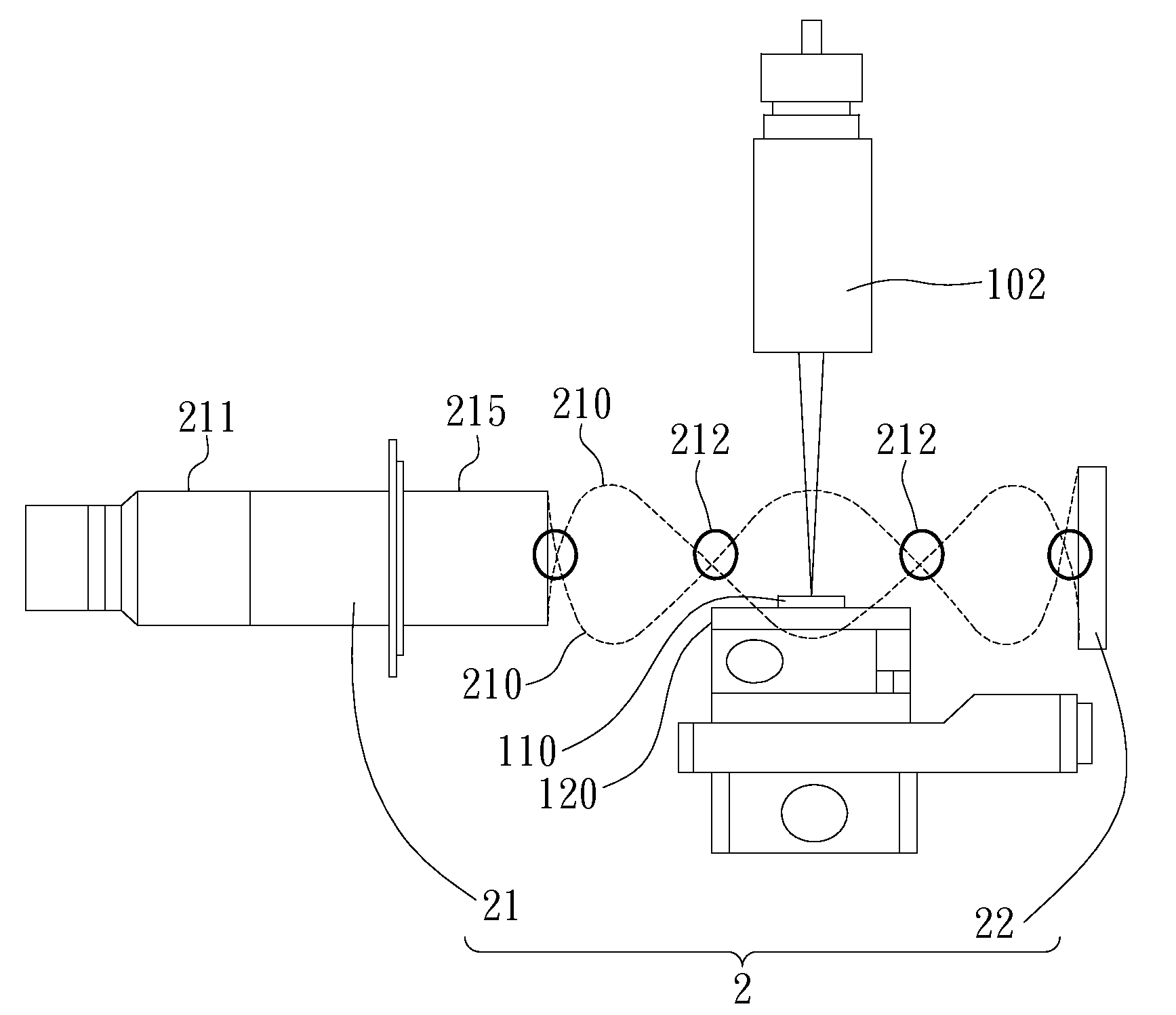

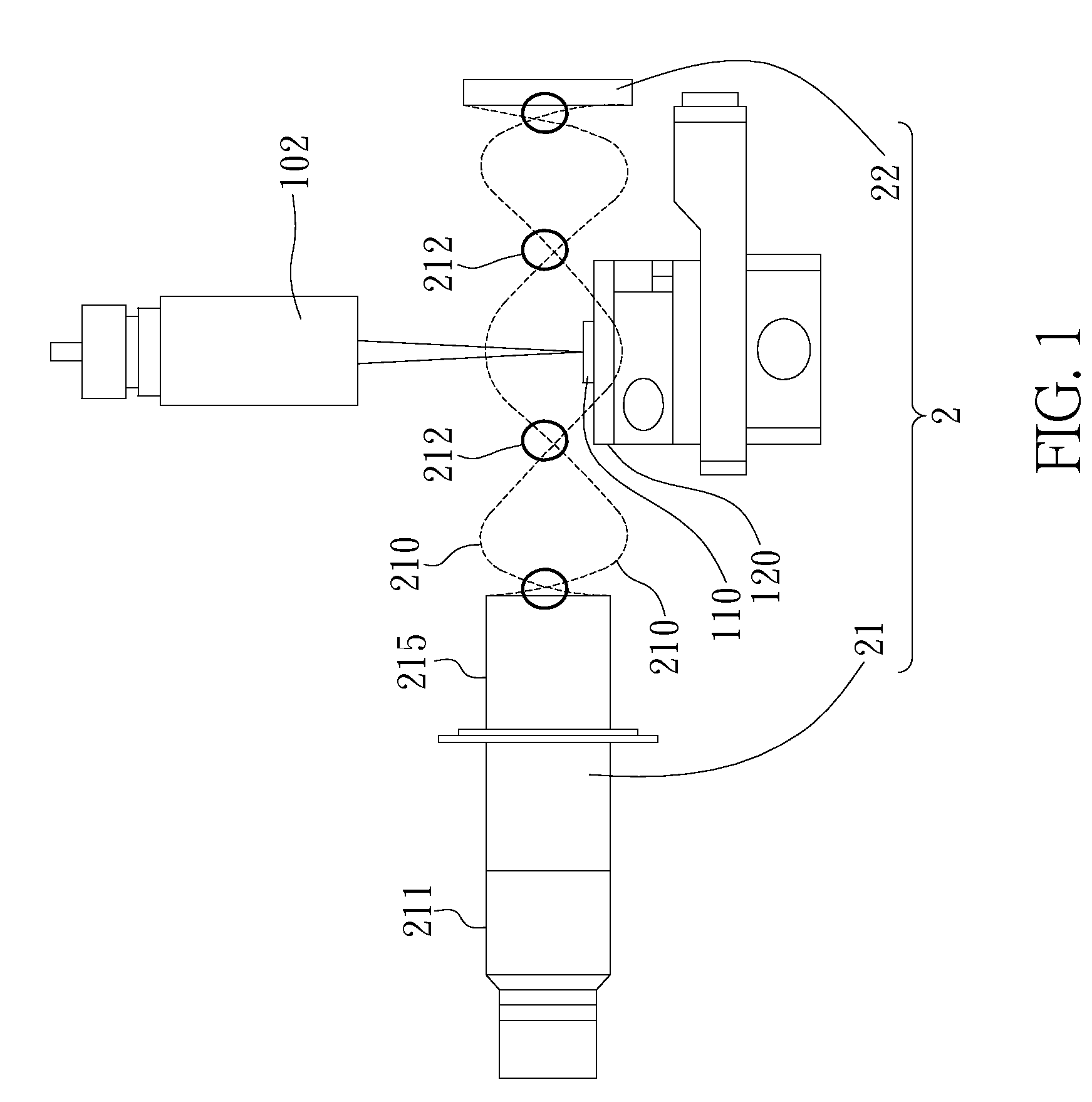

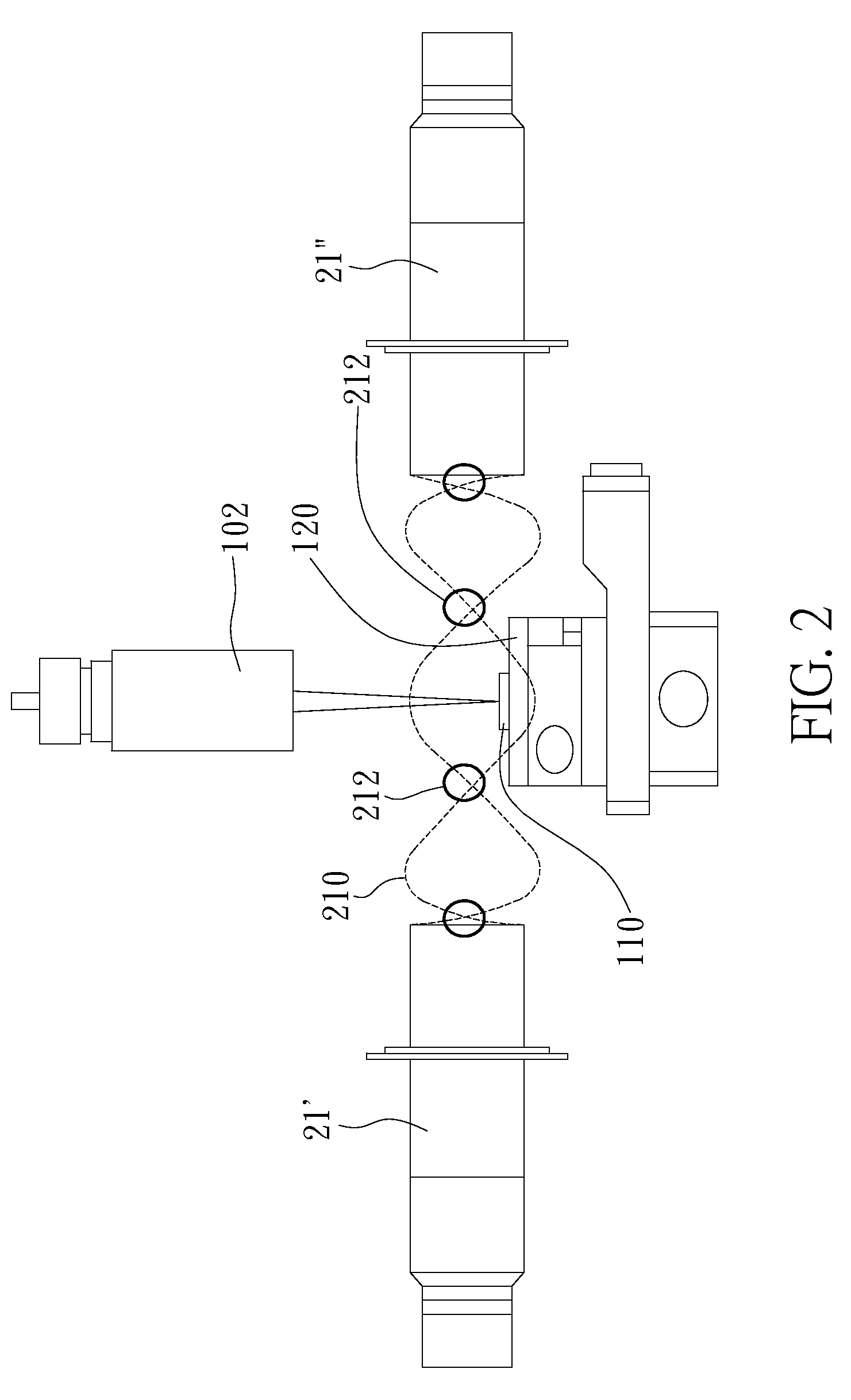

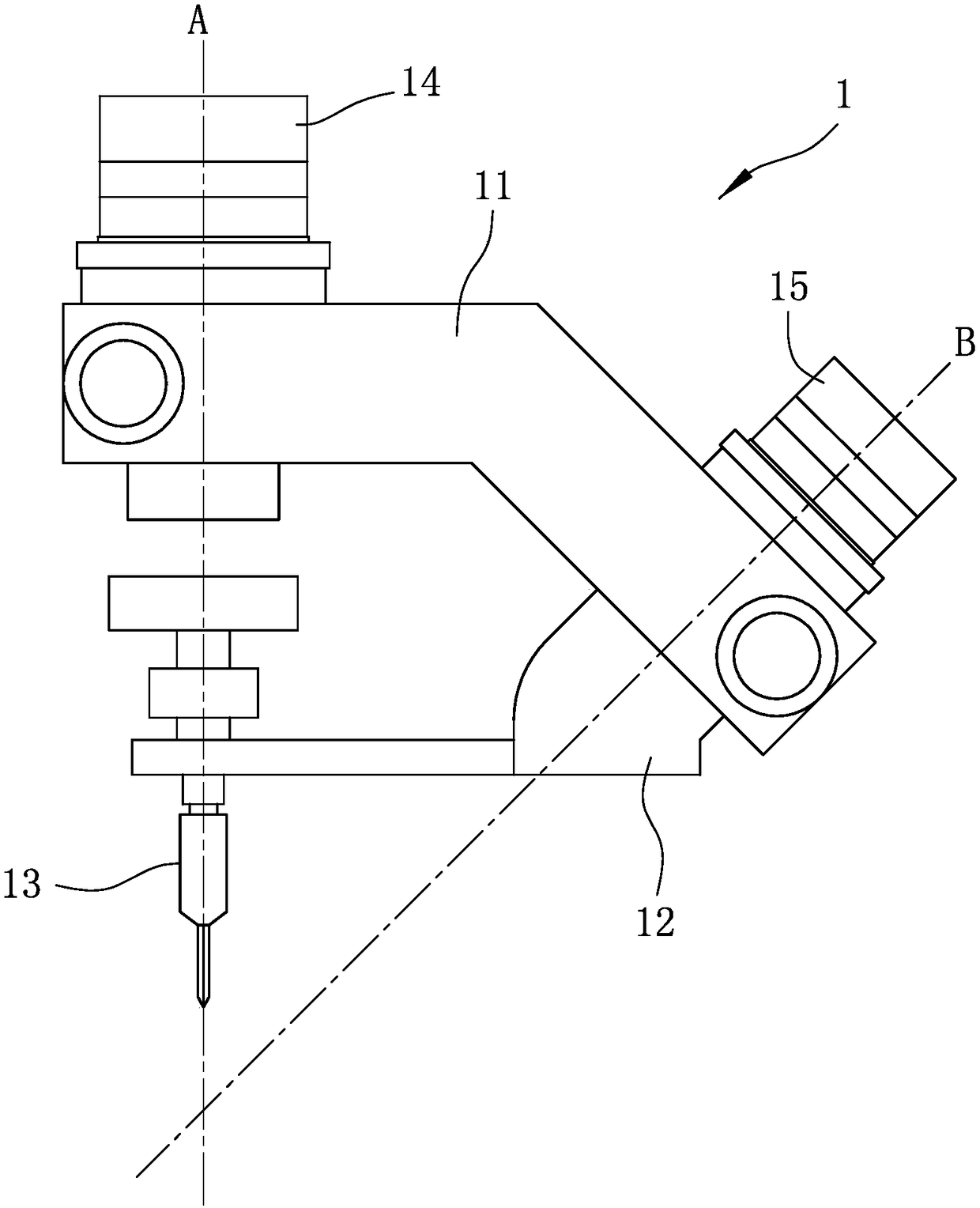

Method for removing micro-debris and device of the same

InactiveUS20090303840A1Improve machining precisionEasy to operateFouling preventionSonic/ultrasonic/infrasonic transmissionEngineeringAcoustic wave

The present invention provides a method for removing micro-debris generated in a laser machining process operated on machined object and device of the same. The machined object is placed on a movable machining platform within a machining range and machined at a particular machining location. By disposing an acoustic wave generator and a reflector part, or by disposing a plurality of acoustic wave generators, at least two standing waves extending across the machining range and two standing wave nodes are generated. The micro-debris generated from the laser machining process is moved away by the standing waves to concentrate at the standing wave nodes, and subsequently removed from the standing wave nodes.

Owner:IND TECH RES INST

Water cutter cutting apparatus

InactiveCN109108838AReal-time monitoring of tilt angleImprove machining precisionAbrasive feedersAbrasive machine appurtenancesPneumatic valveEngineering

The invention relates to a water cutter cutting apparatus, which comprises a bearing seat unit and an output unit, wherein the bearing seat unit comprises a base, a first motor arranged on the base, afirst rotation seat connected to the first motor, a second motor arranged on the first rotation seat, and a second rotation seat connected to the second motor, and the output unit comprises a pneumatic valve, a cutting head communicated to the pneumatic valve, a controller for controlling the first motor and the second motor, and an inertial measurement assembly capable of sensing the inclinationangle of the cutting head. According to the present invention, the inertial measurement assembly can real-timely sense the attitude and the positioning signal and feeds back to the controller to makethe controller control the first motor and the second motor, such that the cutting head can maintain the target angle or real-timely compensate the angle so as to improve the processing precision.

Owner:GONGIN PRECISION IND

Polishing device

ActiveCN110605629AReduce vibrationImprove machining precisionEdge grinding machinesGrinding drivesEngineeringMechanical engineering

The invention provides a polishing device. The polishing device comprises a bearing mechanism and a first polishing mechanism, wherein the bearing mechanism is used for bearing a wafer; the first polishing mechanism comprises at least one set of rotating first polishing wheels, a first polishing groove extending in the circumferential direction is formed in each first polishing wheel, each set offirst polishing wheels comprises the two first polishing wheels, the two first polishing wheels in each set are symmetrically arranged with respect to the wafer, and the axes of the two first polishing wheels share the same surface with the axis of the wafer; and the two first polishing wheels in each set can be close to or away from the wafer so as to make the inner side wall of each first polishing grooves be propped against or away from the wafer. According to the polishing device, the wafer is polished through the first polishing grooves in the two symmetrically-arranged first polishing wheels, the wafer can be kept stable and balanced in the polishing process, the vibration of the wafer is reduced, the precision degree of wafer processing is improved, the polishing efficiency is accelerated, and the polishing quality of the wafer is improved.

Owner:XIAN ESWIN MATERIAL TECH CO LTD +1

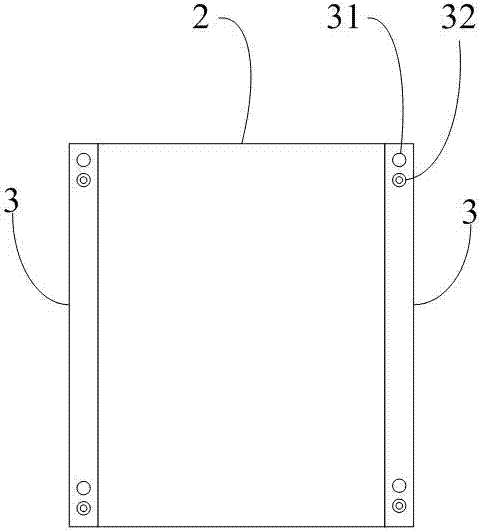

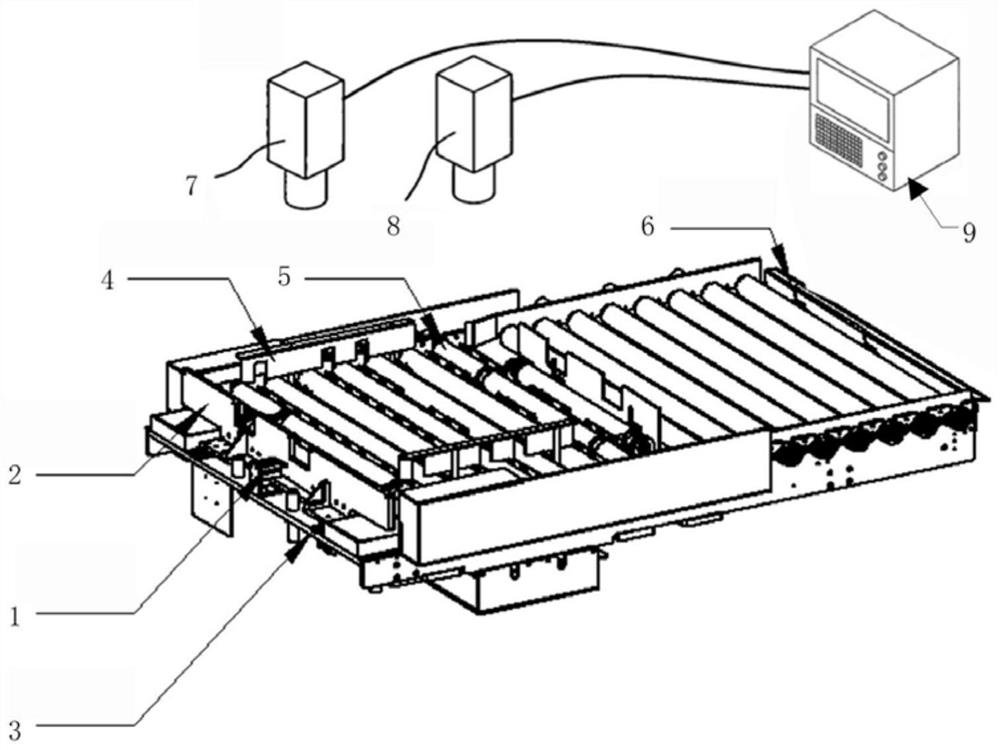

Conveying and locating mechanism of PCB collection machine and board collection and discharge method

InactiveCN111792377AImprove stabilityImprove machining precisionCharge manipulationConveyor partsStructural engineeringMechanical engineering

The invention provides a conveying and locating mechanism of a PCB collection machine and a board collection and discharge method. The conveying and locating mechanism of the PCB collection machine comprises a plate push cylinder (1), a plate push cylinder baffle (2), a plate push guide rail mechanism (3), a plate slapping mechanism (4), conveying rollers (5) and a conveying supporting plate (6).The conveying supporting plate (6) is arranged at the tail end of the conveying rollers (5). The plate push cylinder baffle (2) is arranged on the side face of the plate slapping mechanism (4). The conveying and locating mechanism efficiency reduces the conditions of PCB falling and improves the processing quality of PCBs.

Owner:上海名起机械制造有限公司

Oil mist separation device used for mechanical and electrical equipment and separation method

InactiveCN108236824AImprove machining precisionPurify the working environmentCombination devicesMaintainance and safety accessoriesImpellerMicrometer

The invention relates to an oil mist separation device used for mechanical and electrical equipment and a separation method. Most of currently used mechanical and electrical devices do not have an oilmist separation system purifying device, oil mist in the mechanical and electrical equipment is inhaled into the human body at the particles of 0.3-3.5 micrometers and causes harm to the health, anddeposition of the oil mist in the working area easily causes occupational injury and other accidents. The oil mist separation device comprises a base (1), wherein a groove is formed in the base (1), an electric motor (7) is arranged in the middle position in the groove, two tertiary filtering devices (6) are respectively arranged on the side faces of the electric motor, the front end of the electric motor is connected with a centrifugal impeller (9) by a connecting shaft, a secondary filtering device (10) is arranged at the front end of the centrifugal impeller, a primary filtering device (11)is arranged at the front end of the secondary filtering device, and an oil mist suction port (12) is arranged at the front end face of the base. The invention discloses the oil mist separation deviceused for mechanical and electrical equipment and the separation method.

Owner:哈尔滨获强商贸有限公司

Automatic glass column side surface grooving device

ActiveCN105817973AAvoid damageReduce work intensityGrinding carriagesGrinding drivesBiochemical engineeringInductor

The invention discloses an automatic glass column side surface grooving device. The device comprises a frame; a rotating module is arranged on the frame; a fixing module and a grinding module are respectively arranged on two sides of the rotating module; the fixing module includes a support rod arranged on the frame; a transverse plate is horizontally arranged on one side of the support rod; an extension column is vertically arranged at the lower part of the transverse plate; a second bearing is arranged at the bottom of the extension column; the bottom of the second bearing is connected with a rotating rod; the rotating rod is coaxially provided with a first connecting disc; a first concave hole is formed in the bottom center of the first connecting disc; an inductor is arranged on the top surface of the first concave hole, and is a disc-shaped structure; and a controller is arranged in the frame, and is connected with the inductor and the extension column. The device has such advantages as simple structure, convenience for use and capability of satisfying grinding of grooves with different types.

Owner:SUZHOU SUTENG ELECTRONICS TECH

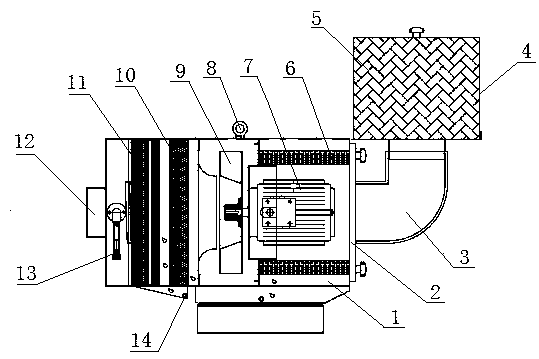

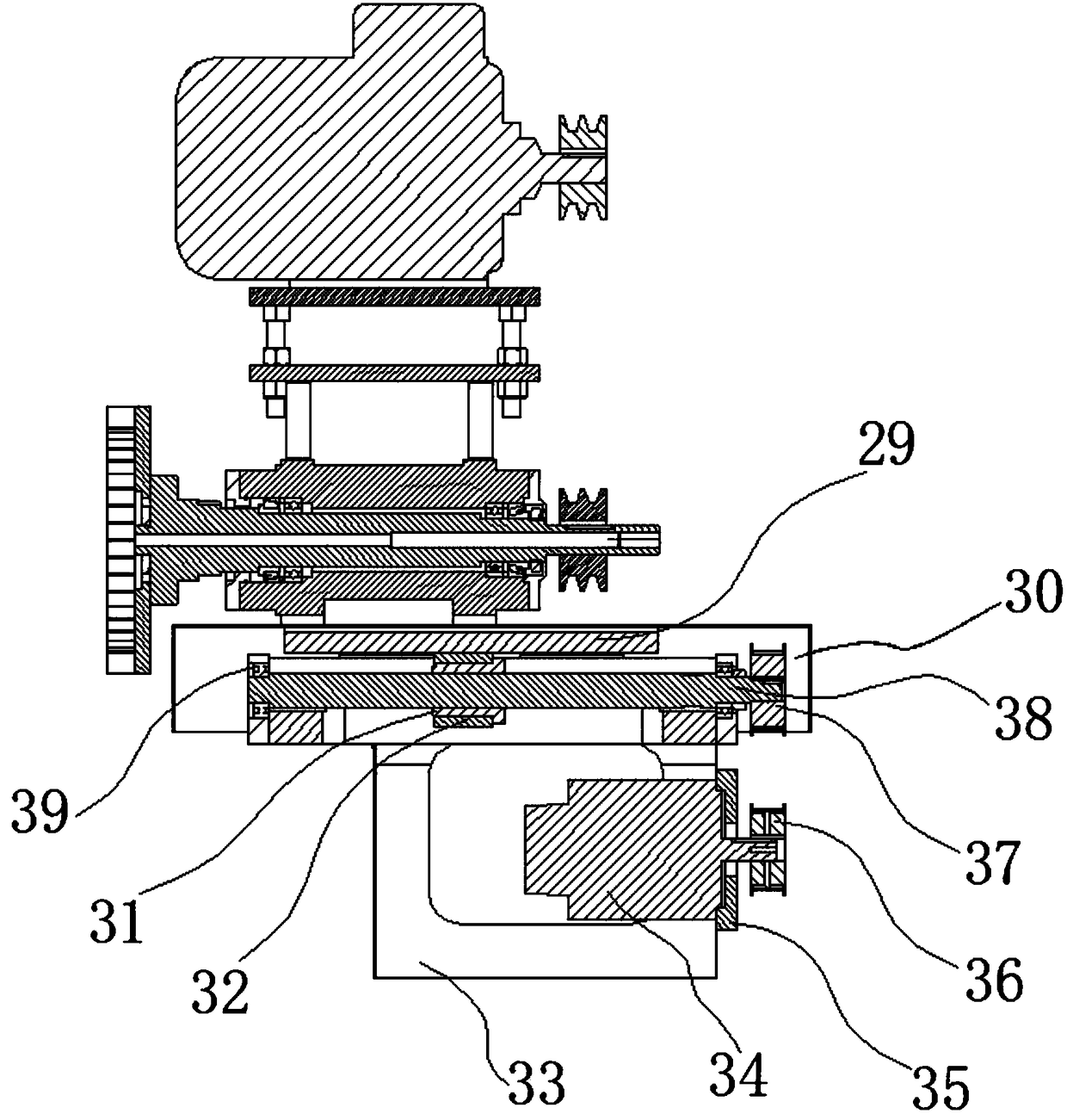

A ceramic ferrule pc spherical surface processing machine

InactiveCN103612179BReasonable structural designHigh degree of automationEdge grinding machinesRevolution surface grinding machinesEngineeringMachine

The invention relates to a PC spherical surface processing machine for ceramic ferrule, the main point of which is that the workpiece is loaded and unloaded in the air pipe through compressed air after being automatically sorted by a vibrating hopper and a discrimination system; after the grinding of the workpiece is completed, the loading and unloading module moves downward to drive the discharge channel Before reaching the workpiece chuck, the compressed air blows out the workpiece through the blowing head. This structure uses the pneumatic principle that the compressed air pushes the workpiece to move in the air pipe, so as to realize the storage, loading and unloading and blowing of the workpiece in the air pipe; thus effectively improving the PC spherical surface processing. Machine automation. The workpiece is finished to be an optical fiber ceramic ferrule. The present invention solves the problem of automatically processing the spherical surface of the small cylinder end, the inner hole of the small cylinder end surface and the chamfering of the inner hole of the small cylinder end surface of the optical fiber ceramic ferrule by the above technical means. The structure design is reasonable, the degree of automation is high, the processing precision and work efficiency are high, and the processing method is feasible; it is suitable for the processing of the small cylindrical end of the optical fiber ceramic ferrule and the improvement of similar products.

Owner:NINGBO NINGCHUANG AUTOMATION DEVICE

Machine tool for glass edge grinding and chamfering

InactiveCN108214179AFully automatedEasy to useEdge grinding machinesGrinding carriagesEngineeringMachine tool

The invention discloses a machine tool for glass edge grinding and chamfering. The machine tool comprises a lathe bed, a rack table board, a feeding and positioning mechanism, a movable frame mechanism, a first grinding sliding table mechanism and a second grinding sliding table mechanism. The rack table board is fixedly mounted on the lathe bed, a stroke hole is formed in the rack table board, and two sets of movable frame sliding rails are fixedly mounted on the two sides of the stroke hole. The movable frame sliding rails are fixedly connected with the movable frame mechanism. The feeding and positioning mechanism is mounted on the rack table board. The first grinding sliding table mechanism and the second grinding sliding table mechanism are mounted at the positions, located on the twosides of the rear half sections of the movable frame sliding rails, of the rack table board correspondingly. A movable frame transmission mechanism is mounted at the bottom of the rack table board. The machine tool for glass edge grinding and chamfering is high in machining precision and high in machining rate; machined products are diversified; and it is important that the machine tool is convenient to use, the procedures are concentrated, automation of glass edge grinding and chamfering is achieved, and the labor intensity is reduced.

Owner:ZHEJIANG PUJIANG HUATONG MECHANICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com