Turbination processing method of compressor

A processing method and compressor technology, which are applied to mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of defective products, deflection of the scroll 83, deflection of the disc 81, etc., and improve the machining precision. degree, the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

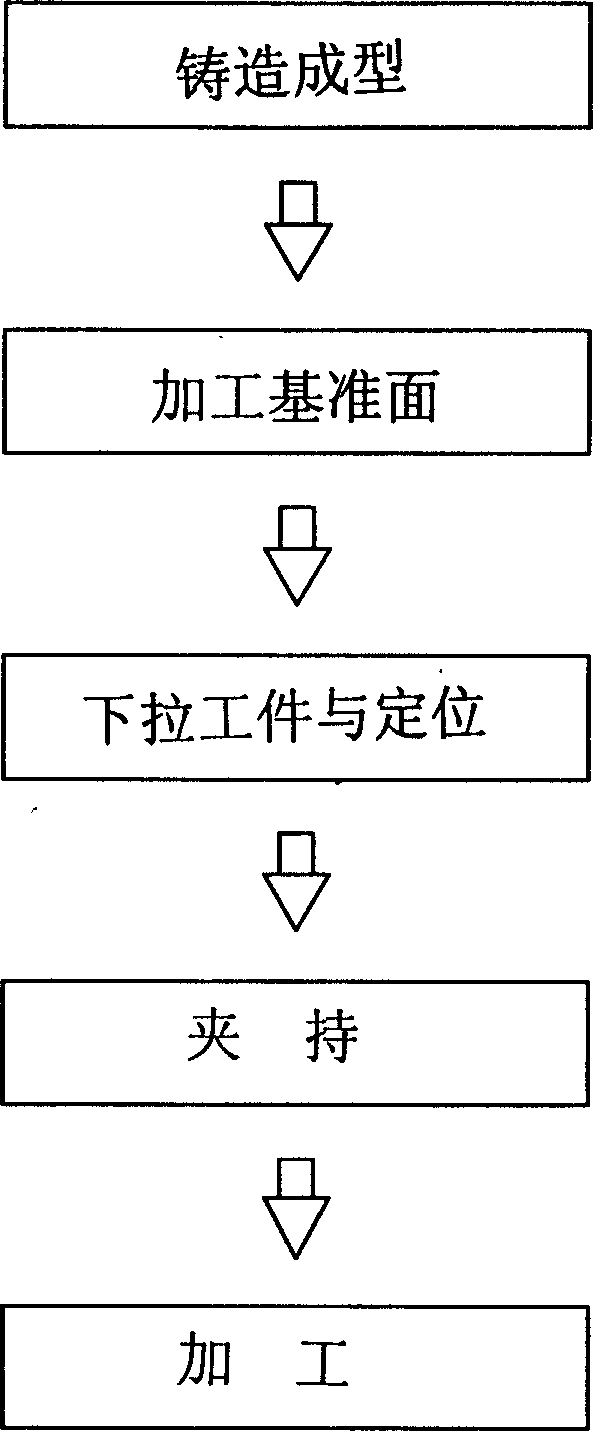

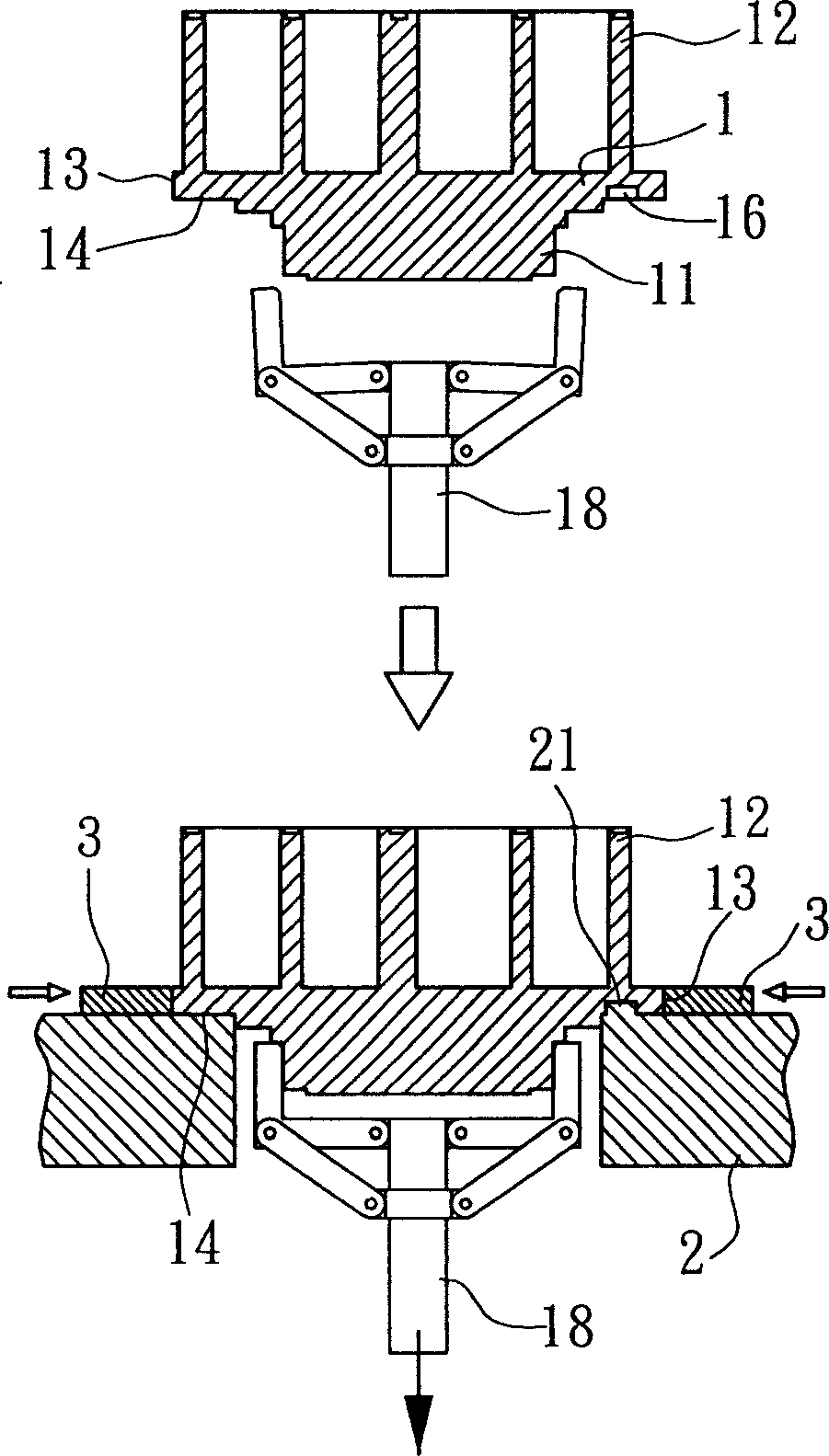

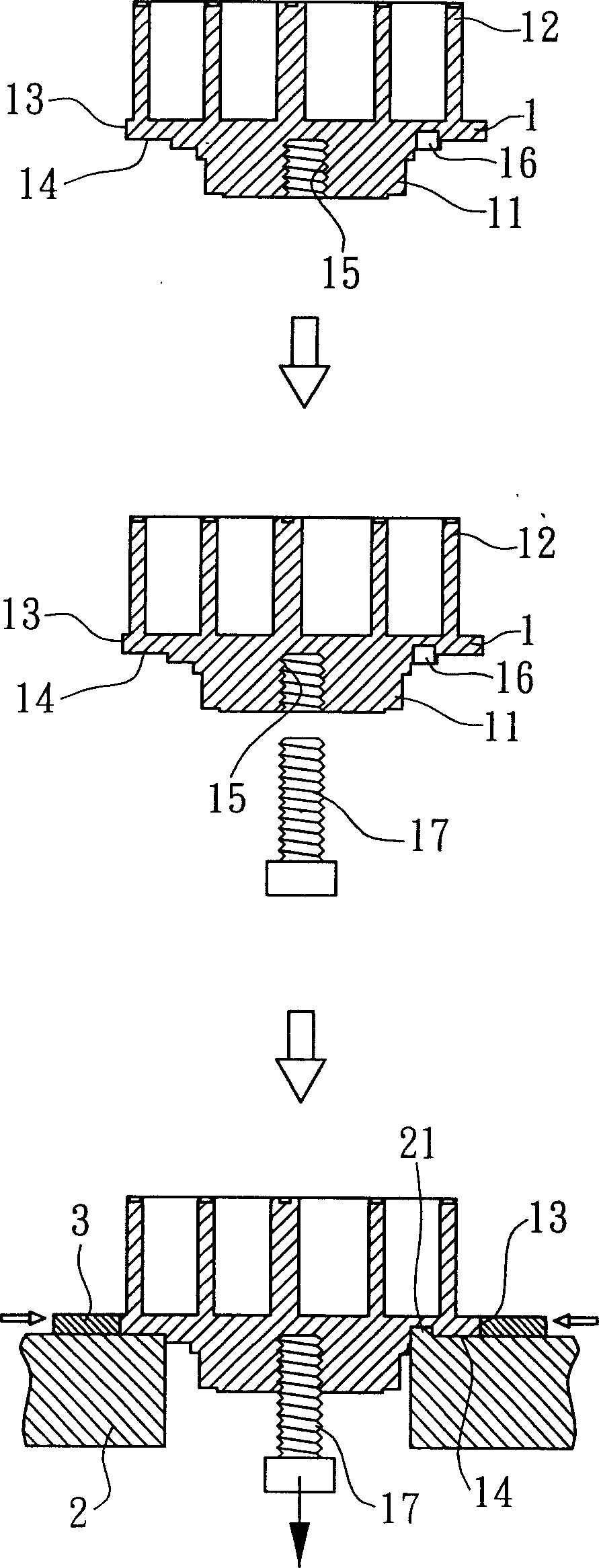

[0021] see Figure 1 to Figure 3 , the scroll processing method of the compressor of the present embodiment, comprises the following steps: casting molding:

[0022] The scroll is cast by die-casting, which is to slowly inject the molten aluminum alloy with high silicon content into the mold cavity of the steel mold through the injection hydraulic cylinder, and when the molten aluminum alloy fills the mold cavity and begins to cool and shrink, the injection oil pressure Pressurize the cylinder to inject the molten aluminum alloy into the mold cavity under high pressure, so that the pressure in the mold can reach at least 1100-1200kg / cm 2 , and then naturally cooled to make it crystallize naturally, and 3 to 5 seconds before the crystallization is complete, the injection hydraulic cylinder is pressurized again, so that the scroll casting reaches the highest density and has higher strength.

[0023] The scroll casting has a disk 1, and the two sides of the disk 1 have a base 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com