Water cutter cutting apparatus

A technology of waterjet cutting device and cutting head, which is applied in the direction of abrasive material feeding device, used abrasive processing device, abrasive material, etc. It can solve the problem of reducing the accuracy of finished products and the flatness of the processing plane. The verticality of the two planes does not meet the tolerance standard. , Deviating from the preset angle and other problems, to achieve the effect of improving the processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

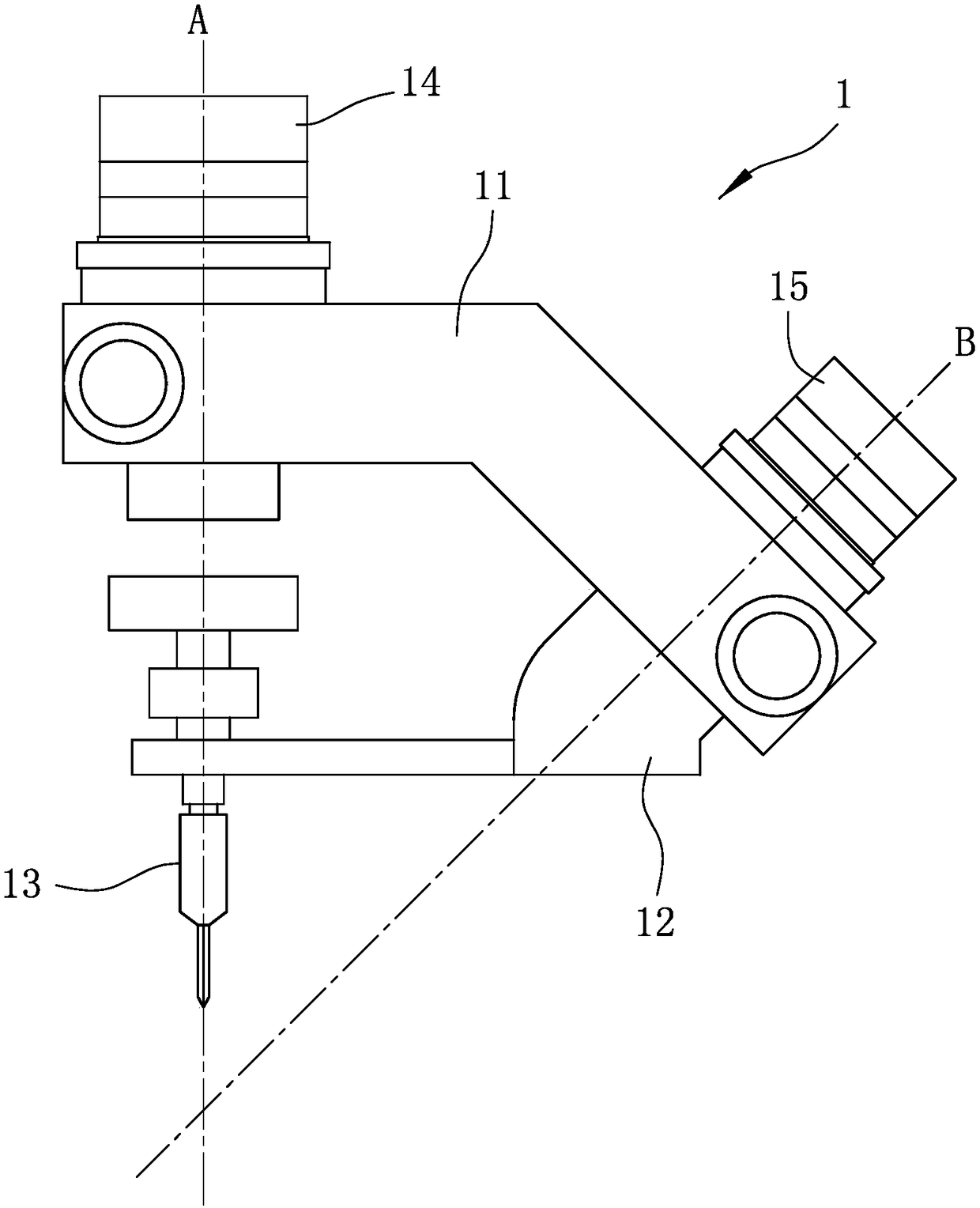

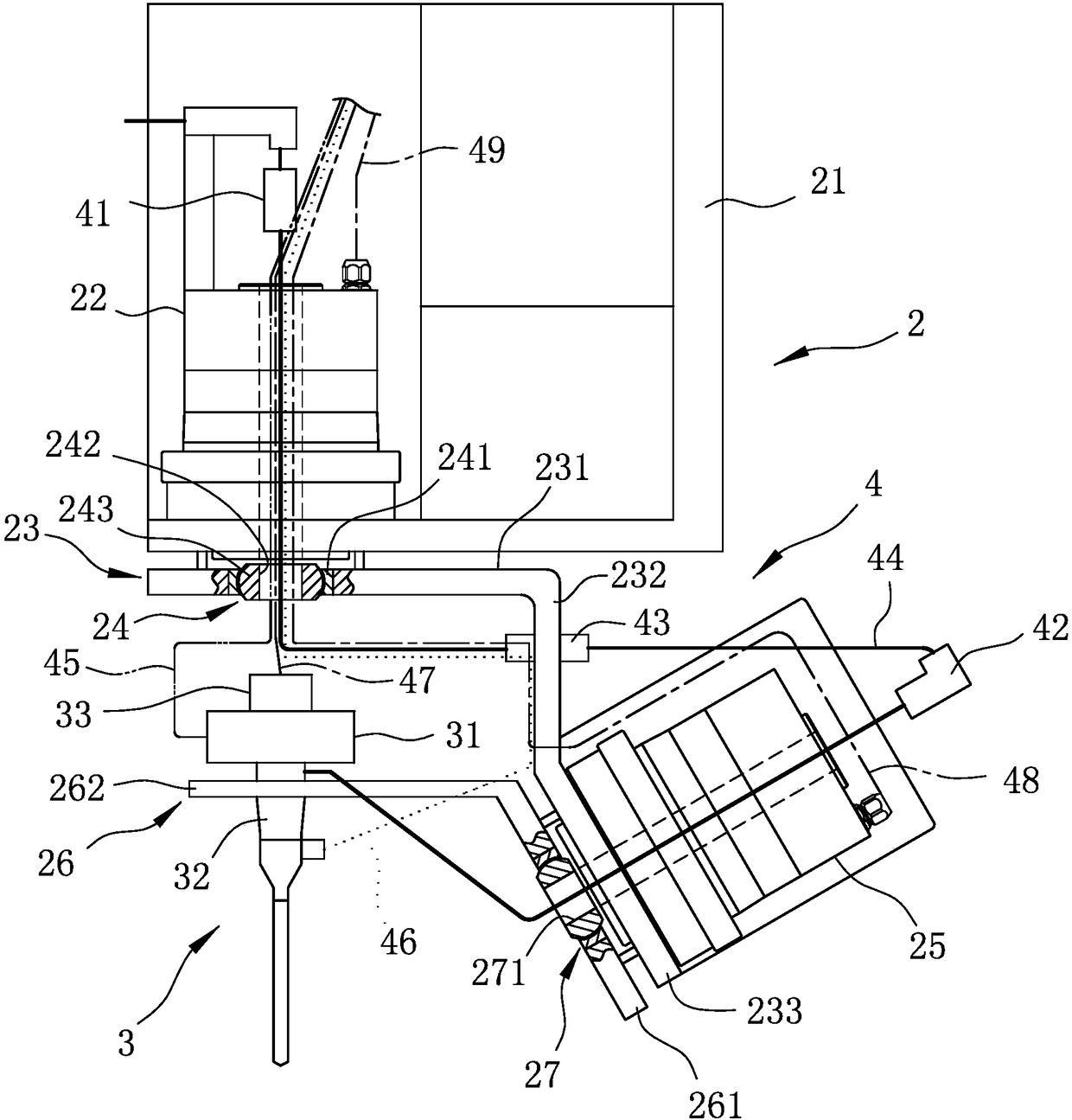

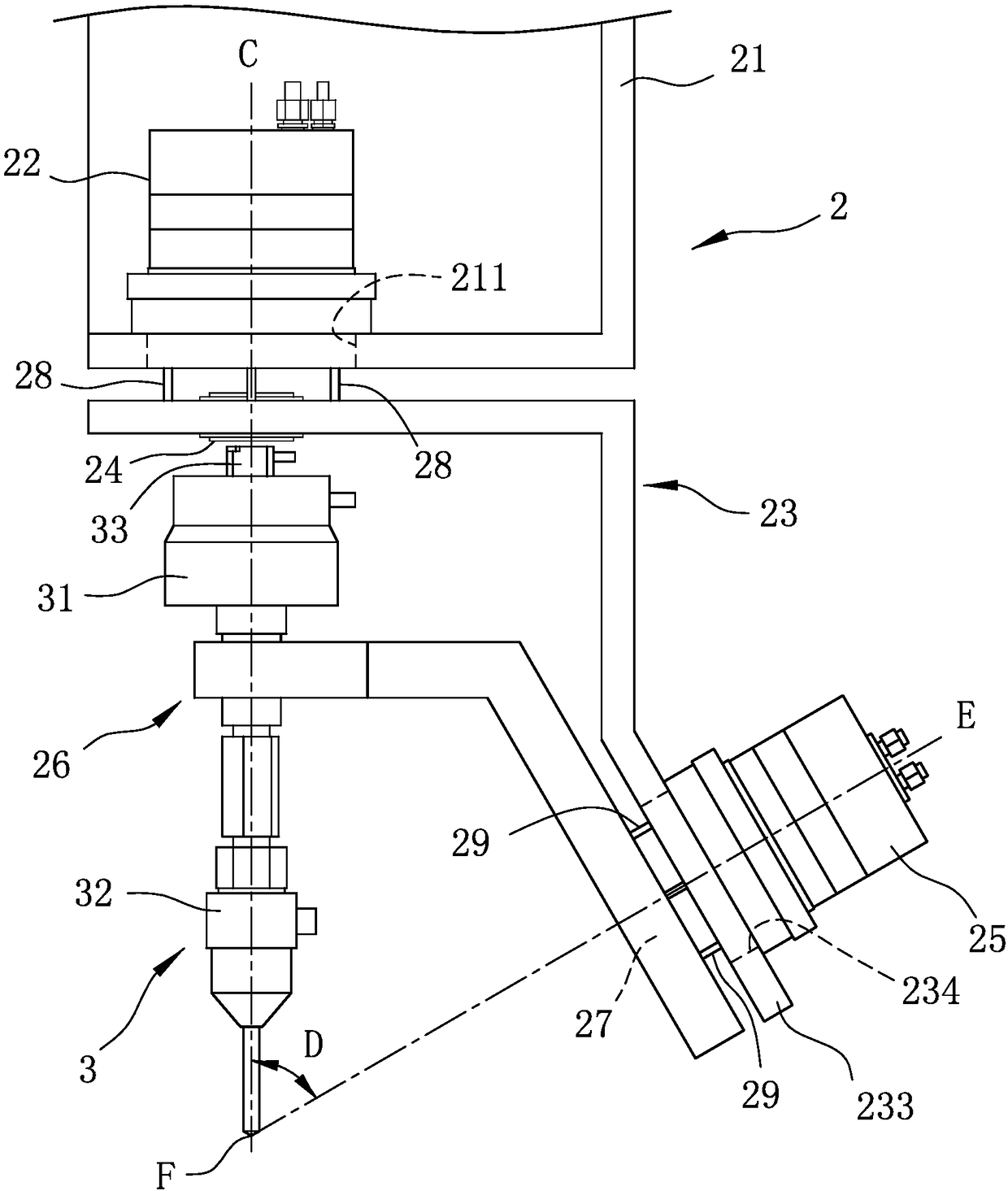

[0022] refer to figure 2 and image 3 , an embodiment of the waterjet cutting device of the present invention, comprising a seat unit 2, an output unit 3 arranged on the seat unit 2, and a pipeline unit 4 connecting the seat unit 2 and the output unit 3 (not shown in image 3 middle).

[0023] The seat unit 2 includes a base 21 for connecting other devices (not shown in the figure), a first motor 22 erected on the base 21, and a first motor 22 connected to the first motor 22 so as to be driven by the first motor. The first rotating base 23 driven by the motor 22, a first ball and socket bearing 24 embedded in the first rotating base 23, a second motor 25 arranged on the first rotating base 23, and a second motor 25 connected to the first rotating base 23 Two motors 25 , a second rotating base 26 that can be rotated by the second motor 25 , and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com