Piezoelectric ink jet printing head and its producing method

An inkjet printing head and manufacturing method technology, applied in printing and other directions, can solve the problems of uneven shrinkage of ceramic materials, limiting inkjet printing resolution, and inability to increase the density of inkjet printing heads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

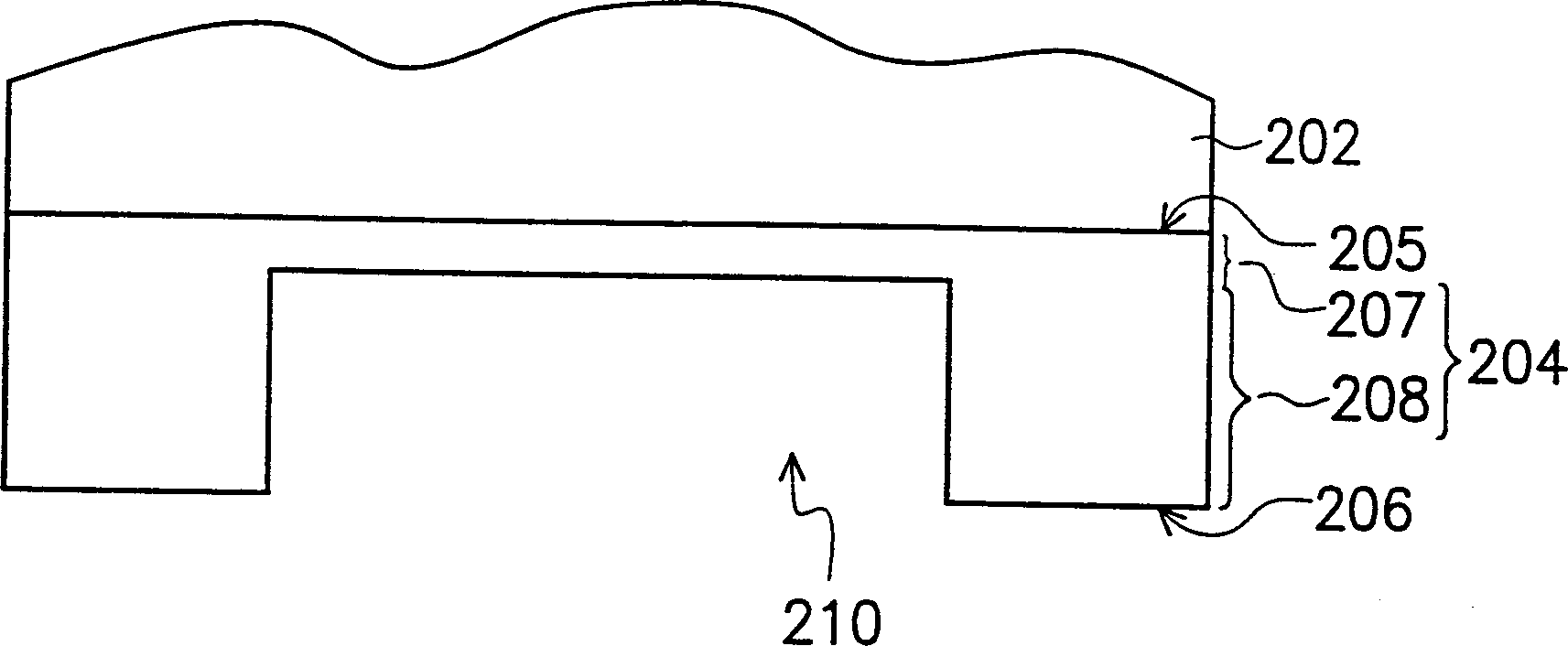

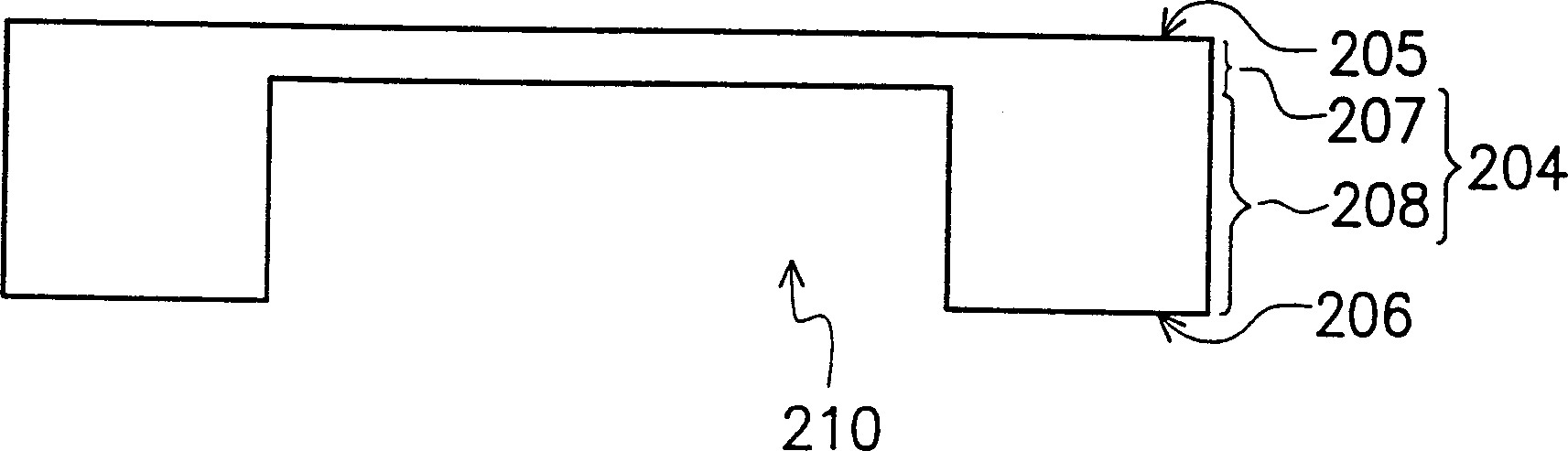

[0037] Please refer to Figure 2A-2D, is a cross-sectional flow chart of a method of manufacturing a piezoelectric inkjet print head according to an embodiment of the present invention. First, if Figure 2A As shown, a substrate 202 is provided, and its material is, for example, silicon, ceramics, metal, etc., and a metal layer 204 (metal layer) is formed on the substrate 202 by means of electroplating, and then lithography ( photolithography) and etching (etching), remove part of the metal layer 204 to form a groove 210, wherein the groove 210 is sunk in the second surface 206 of the metal layer 204, it is worth noting that the groove 210 is half-etched (half etching), so it does not completely penetrate the metal layer 204, so that the depth of the groove 210 is slightly smaller than the thickness of the metal layer 204, and the metal layer 204 is divided into a first metal layer 207 and a first metal layer 207. The second metal layer 208 . Among them, the function of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com