Lathing method of skirt bases of thin-walled high-strength steel rocket hull

A technology of high-strength steel and rocket shell, applied in metal processing equipment, metal processing mechanical parts, turning equipment, etc., can solve the problems of high shell strength, large deformation, cutting deformation, etc., and achieve the effect of high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

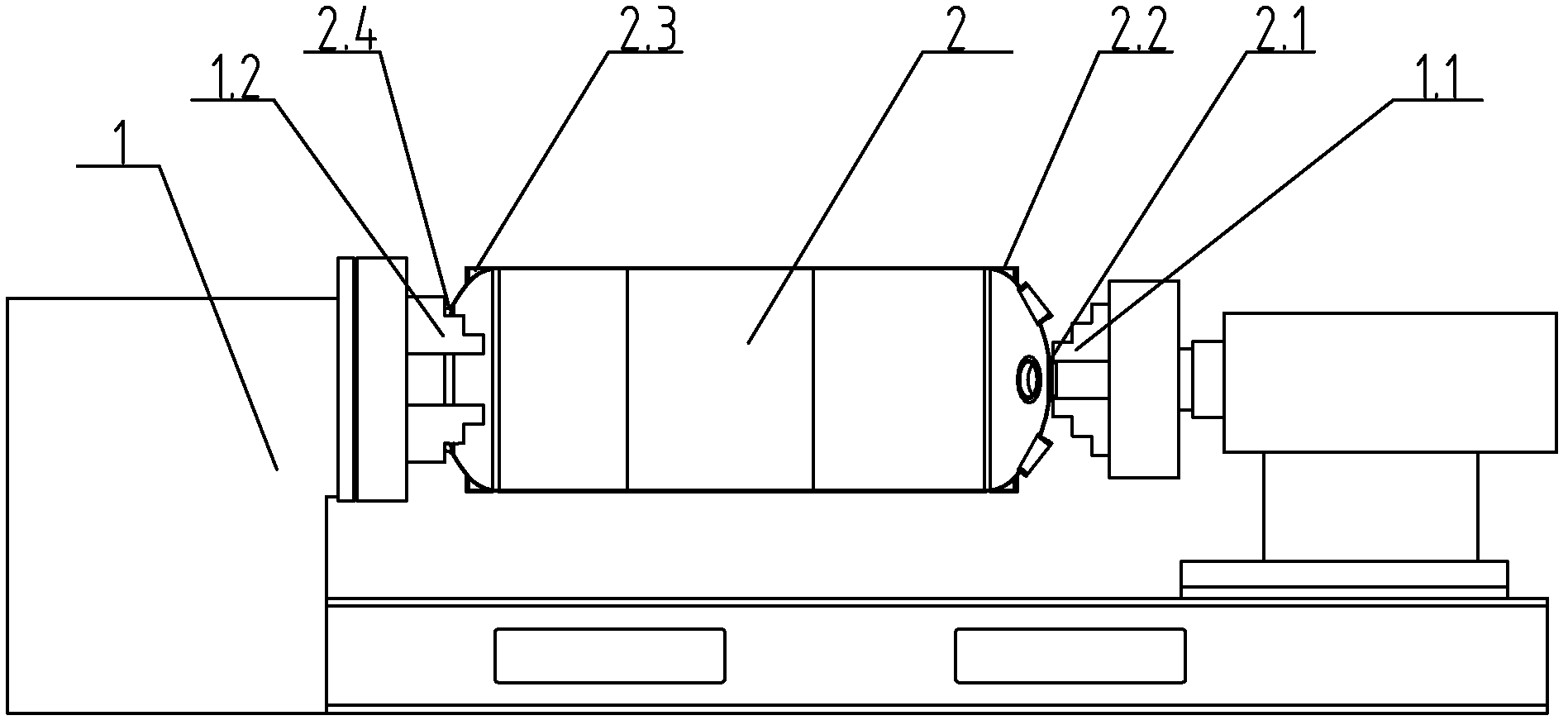

[0024] For an ultra-high-strength steel rocket combustion chamber shell with a size parameter of Φ600mm×3500mm and a wall thickness of 3mm on an aircraft, the process control process of the skirt reference is as follows:

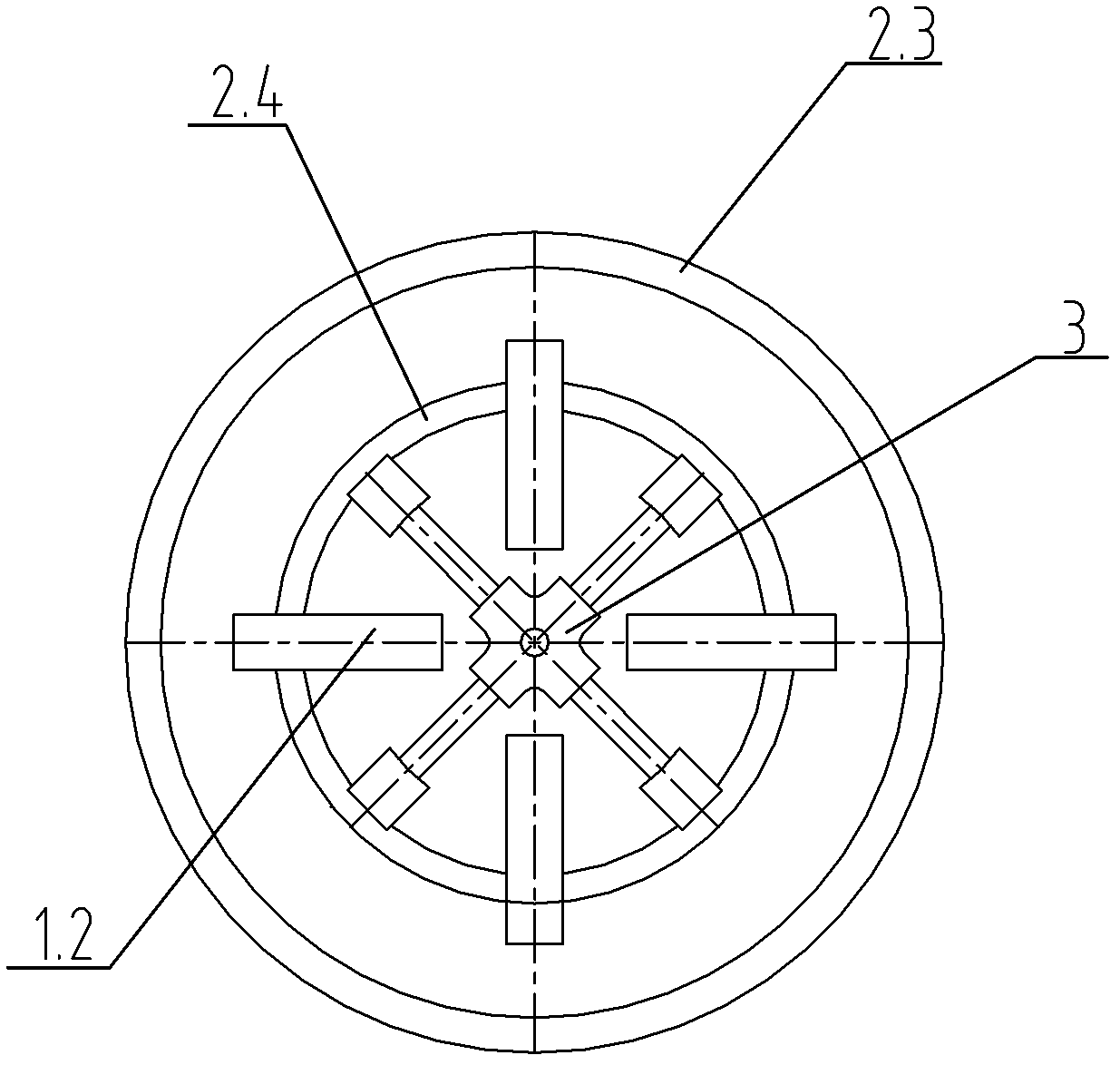

[0025] 1) Shell clamping and alignment position identification and measurement: Taking a point on the outer circle of the front skirt 2.2 of the rocket combustion chamber shell 2 as a reference, divide the outer circle of the front skirt 2.2 and the front joint 2.1 into four equal parts , the outer circle of the rear skirt 2.3 and the rear joint 2.4 are equally divided into eight equal parts, and a linear mark with a length of 10mm is made at each equal part; the four diameters at the eighth equal parts of the outer circle of the rear skirt 2.3 are measured and marked as Record;

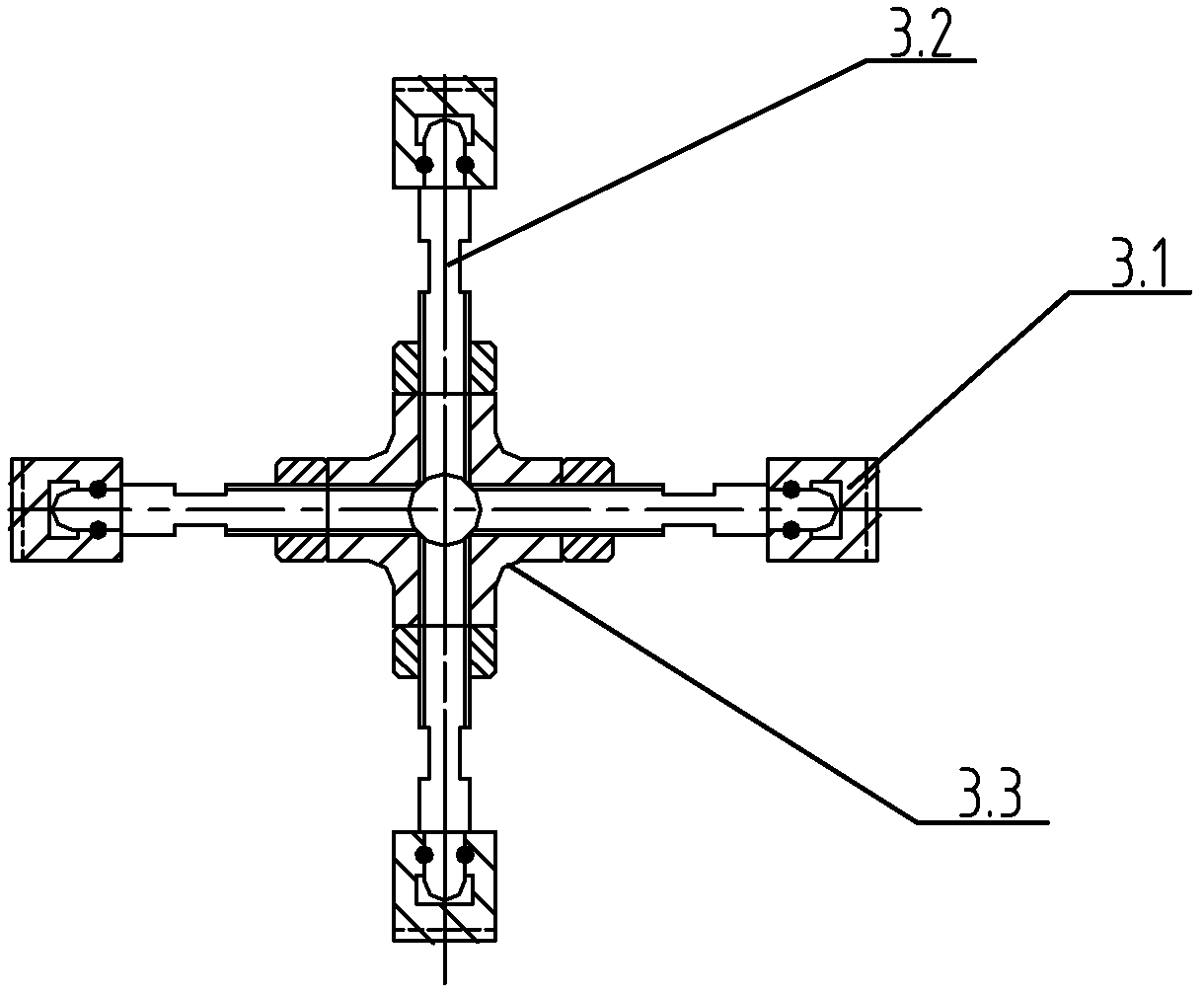

[0026] 2) Installation of special braces: Install the special braces 3 into the inner hole of the rear joint 2.4 at one end of the rear skirt 2.3 and tighten them. The special brac...

Embodiment 2

[0031] For an ultra-high-strength steel rocket combustion chamber shell with a size parameter of Φ1200mm×5600mm and a wall thickness of 4mm on an aircraft, the process control process of the skirt reference is as follows:

[0032]1) Shell clamping and alignment position identification and measurement: Taking a point on the outer circle of the front skirt 2.2 of the rocket combustion chamber shell 2 as a reference, divide the outer circle of the front skirt 2.2 and the front joint 2.1 into four equal parts , the outer circle of the rear skirt 2.3 and the rear joint 2.4 are equally divided into eight equal parts, and a linear mark with a length of 15mm is made at each equal part; the four diameters at the eighth equal parts of the outer circle of the rear skirt 2.3 are measured and marked as Record;

[0033] 2) Installation of special braces: Install the special braces 3 into the inner hole of the rear joint 2.4 at one end of the rear skirt 2.3 and tighten them. The special brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com