Processing method of nonmetal special-shaped rudder sheet and clamp for processing

A processing method, non-metallic technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as unguaranteed rudder shaft size, large product weight difference, poor surface roughness, etc., and achieve stable product quality , High processing precision, guarantee the effect of surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

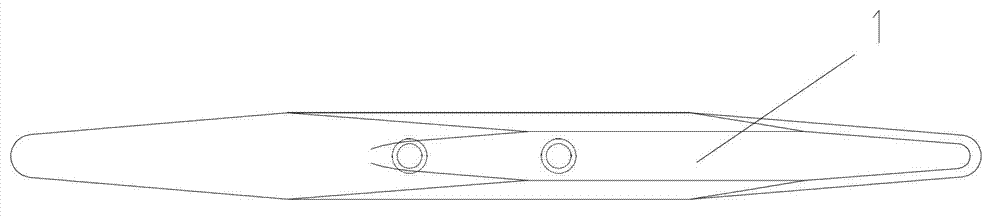

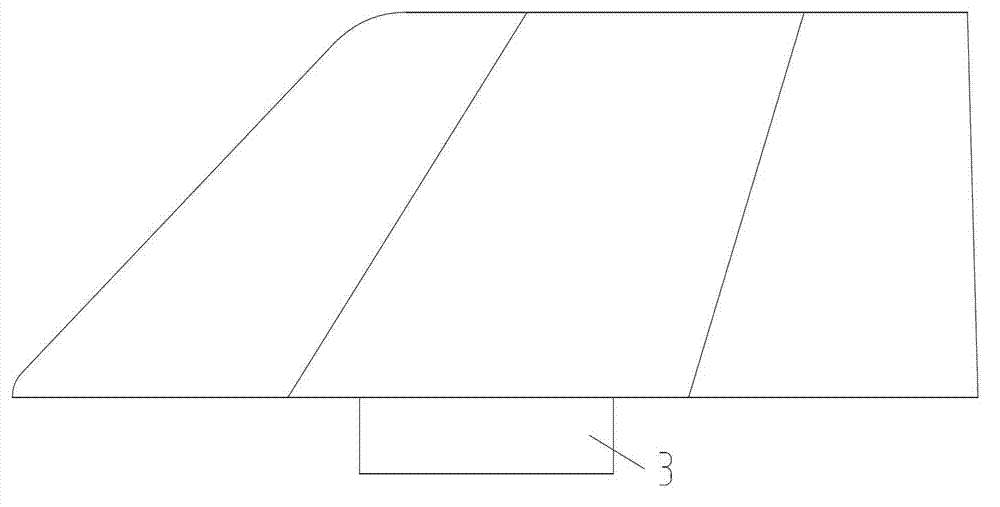

[0028] For a special-shaped rudder made of C / SiC ceramic material, the size of the rudder shaft is 16mm×21mm, the maximum length×width of the rudder is 198mm×95mm, the maximum thickness of the rudder is 17.5mm, and the minimum thickness is 9mm. The processing methods include the following step:

[0029] 1) Design the C / SiC ceramic rudder plate material according to the maximum external dimension of the product, leaving a machining allowance of 5~10mm on one side;

[0030] 2) Clamp the rudder blank vertically, and symmetrically grind the two datum surfaces of the rudder blank to ensure that the parallelism and flatness errors are within 0.06mm, and the thickness is left with a single-side machining allowance of 1~3mm;

[0031] 3) Clamp the rudder blank, rough mill the shape of the rudder blank, remove most of the machining allowance of the rudder blank, leave a single-sided machining allowance of 2~3mm on the rudder surface, and process the subsequent clamping on the 2nd part o...

Embodiment 2

[0037] For a special-shaped rudder made of SiC ceramic material, the size of the rudder shaft is φ18 mm, the maximum length × width of the rudder is 260 mm × 70 mm, the maximum thickness of the rudder is 12 mm, and the minimum thickness is 2 mm. The processing control process is as follows:

[0038] 1) Design the SiC ceramic rudder plate material according to the maximum external dimension of the product, leaving a machining allowance of 5~10mm on one side;

[0039] 2) Clamp the SiC ceramic rudder blank vertically, and symmetrically grind the two datum surfaces of the SiC ceramic rudder blank to ensure that the parallelism and flatness error of the two datum surfaces are within 0.06mm, and the thickness leaves a single-sided machining allowance of 1~ 3mm;

[0040] 3) Clamp the SiC ceramic rudder blank with flat scribing and milling to process the shape of the rudder, remove most of the machining allowance of the rudder blank, leave a single-sided machining allowance of 2~3mm o...

Embodiment 3

[0046] For a special-shaped rudder made of SiC ceramic material, the size of the rudder shaft is φ17 mm, the maximum length × width of the rudder is 230 mm × 80 mm, the maximum thickness of the rudder is 15 mm, and the minimum thickness is 4 mm. The processing control process is as follows:

[0047] 1) Design the SiC ceramic rudder plate material according to the maximum external dimension of the product, leaving a machining allowance of 5~10mm on one side;

[0048] 2) Clamp the SiC ceramic rudder blank vertically, and symmetrically grind the two datum surfaces of the SiC ceramic rudder blank to ensure that the parallelism and flatness error of the two datum surfaces are within 0.06mm, and the thickness leaves a single-sided machining allowance of 1~ 3mm;

[0049] 3) Clamp the SiC ceramic rudder blank with flat scribing and milling to process the shape of the rudder, remove most of the machining allowance of the rudder blank, leave a single-sided machining allowance of 2~3mm o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com