Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Same lifespan" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

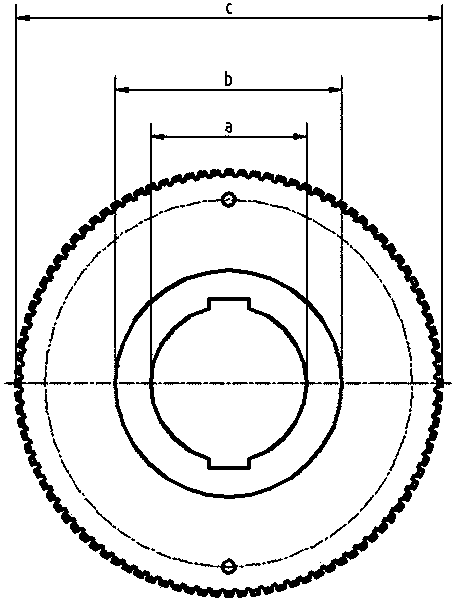

Processing method for nitrided gears

The invention discloses a processing method for nitrided gears which mainly solves the problem of deformation of parts in the course of processing a nitrided gear. The method comprises the following steps: I, rough turning the outer circle and the inner hole; II, performing heat treatment until the HBS reaches 260-300; III, finish turning parts; IV, tinning; V, milling the gear; VI, nitriding; VII, grinding the end surface; VIII, grinding the inner hole; IX, slotting and processing the key groove by utilizing a slotting tool; X, the lathing phi 160 (minus 0.05 / minus 0.20) hub outer circle b to be coaxial with the inner hole a by 0.015 mm, and lathing the two end faces to be perpendicular to the inner hole a by 0.015 mm; XI, grinding the gear tooth form; XII, marking a drilling hole, and finishing nitrided gear processing. The processing method for nitrided gears is used for preparing nitrided gears.

Owner:HARBIN TURBINE

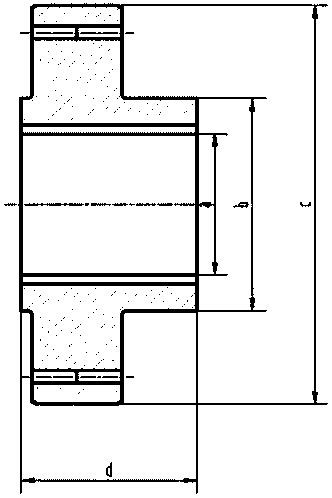

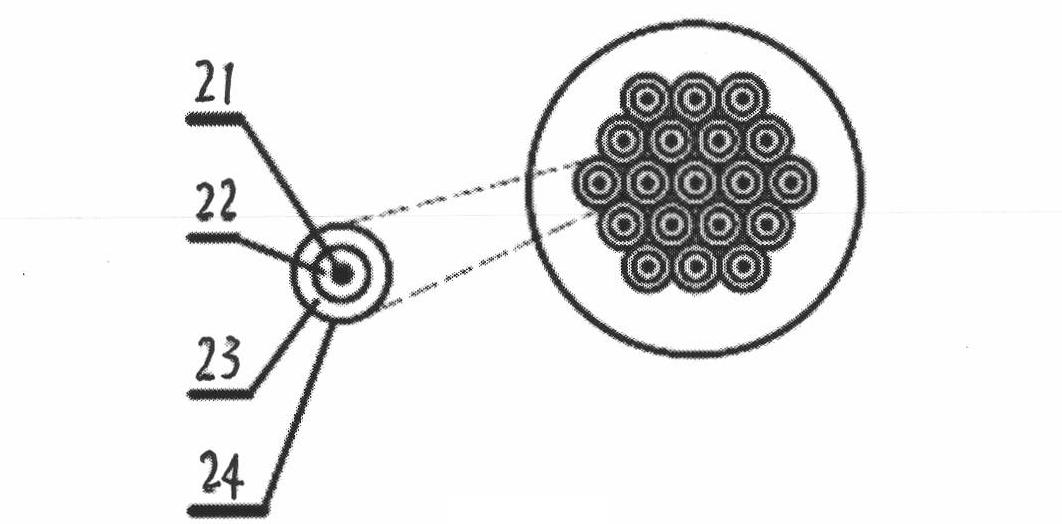

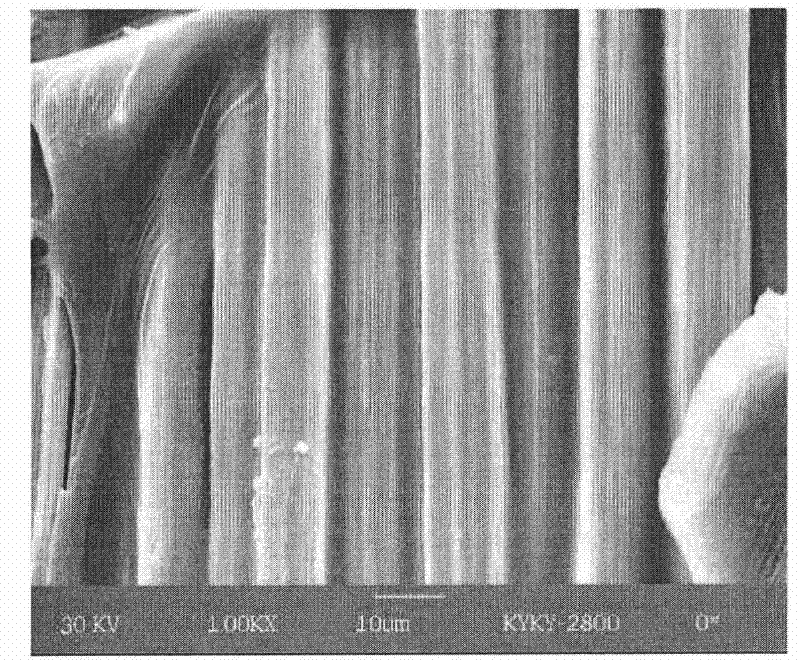

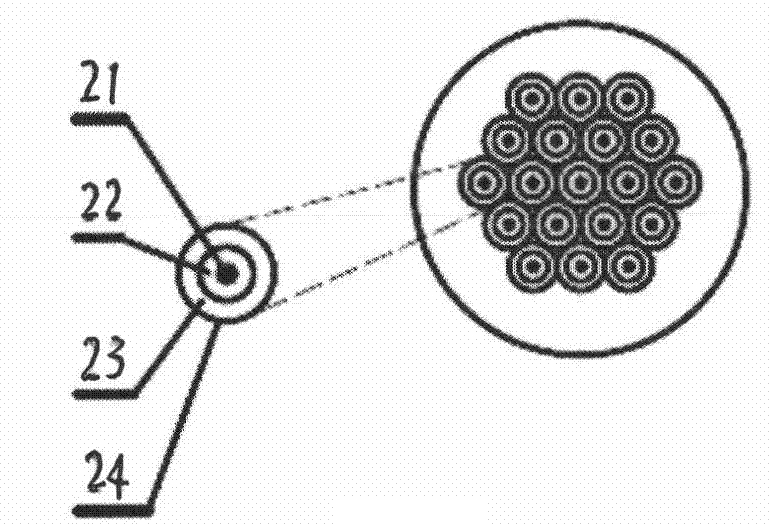

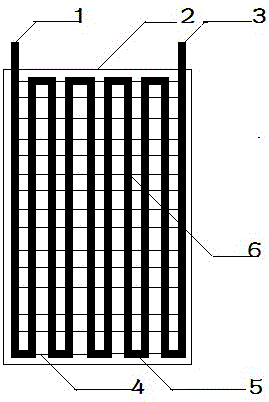

Preparation method of conductive plastics master batch containing stainless steel fibers

ActiveCN101840745AElectromagnetic shielding effect hasHas antistatic effectNon-conductive material with dispersed conductive materialCable/conductor manufactureElectromagnetic shieldingStainless steel fiber

The invention discloses a preparation method of a conductive plastics master batch containing stainless steel fibers. The stainless steel fibers in the plastics master batch are isolated by macromolecular materials and completely packed by the macromolecular materials. When the plastics master batch as raw materials is mixed with plastics for secondary granulation or a conductive plastic work-piece is formed, the stainless steel fibers can resist high shear force when the plastics are processed, and are easily and uniformly dispersed in the plastic work-piece and overlap to each other to form a three-dimensional conductive network. By adopting the conductive plastics master batch, the ideal antistatic and electromagnetic screen effects can be achieved under the circumstance of low content of the stainless steel fiber.

Owner:HUNAN HUITONG ADVANCED MATERIALS

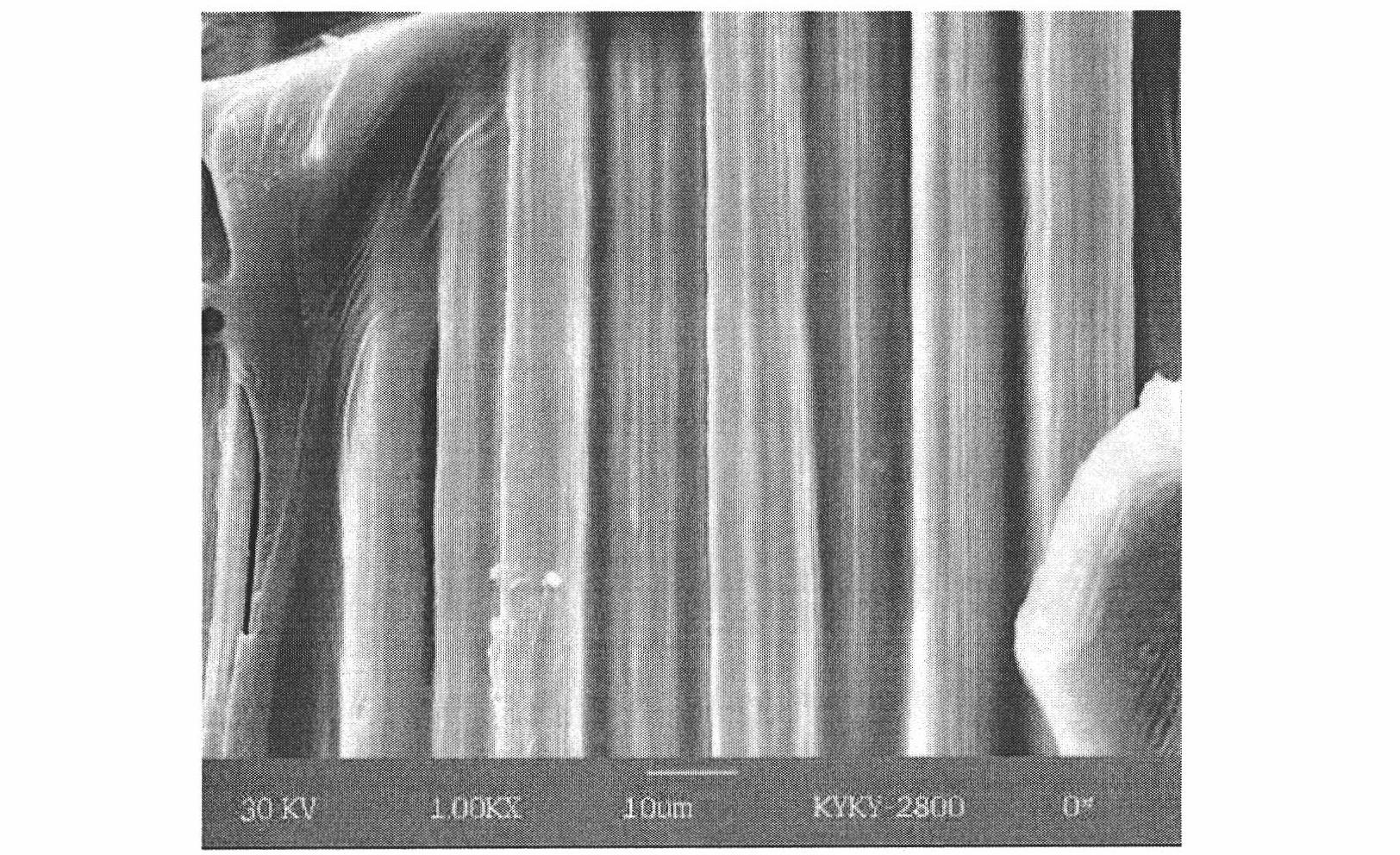

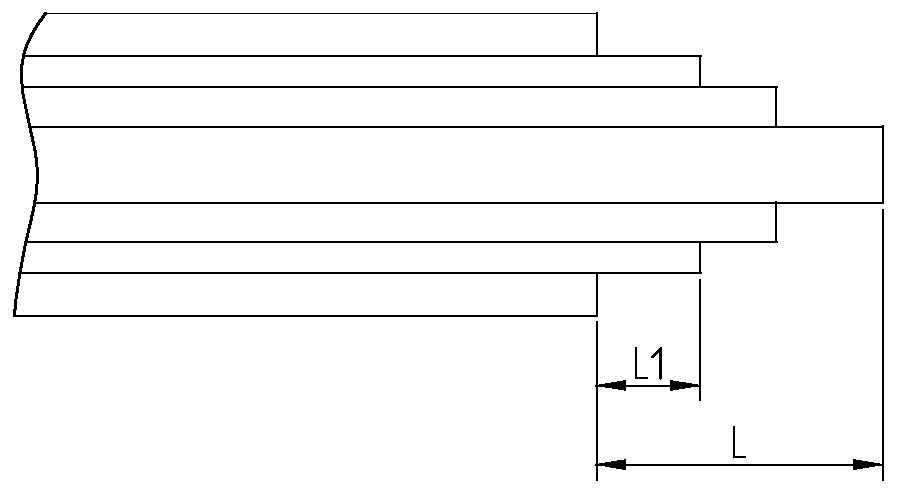

Method for extending length of cable

InactiveCN109861047AQuality improvementImprove reliabilityLine/current collector detailsInsulation layerElectrical conductor

The invention discloses a method for extending the length of a cable. The method comprises the following steps of: S1: cutting insulation layers at end portions of two cables to be connected to exposeconductors of the internal wires; S2: employing flame-retardant and fire-resistant cloth to fasten bodies, close to notches, of the two cables for protection; S3: allowing the mutual connection endsof the two cables to be made to adaptive anode head and cathode head, opening the cathode head layer by layer outwards to allow the wire in the innermost layer to be exposed, and performing welding from the wire in the innermost layer one by one and layer by layer; S4: performing molding for the insulation layers in the connected conductors through adoption of an injection molding method; and S5:performing molding for the outer sheaths of the connected conductors through adoption of an injection molding method. The silver materials with the electrical resistivity lower than these of the cables are employed layer by layer and one by one for brass soldering to allow the conductivity at the welding not to be lower than these of the conductor themselves; the connector insulation layer can bein fusion and cross-linkage with the insulation layer of an original cable well to allow the insulation layer at the connector and the insulation layer of the original cable to form an integrated structure, and the electrical properties of the connector are the same as these of the original cable.

Owner:嘉兴新缆电缆股份有限公司

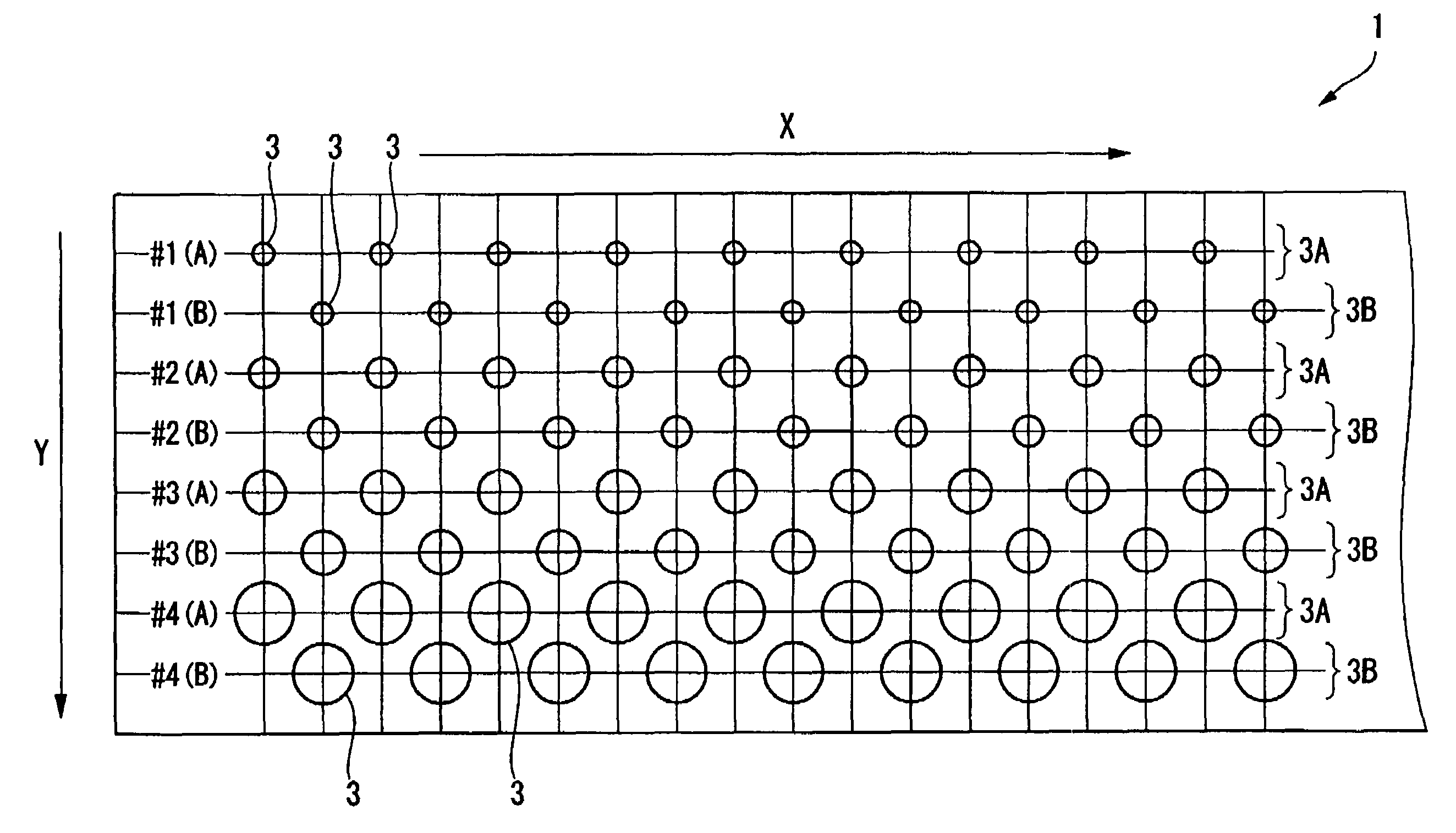

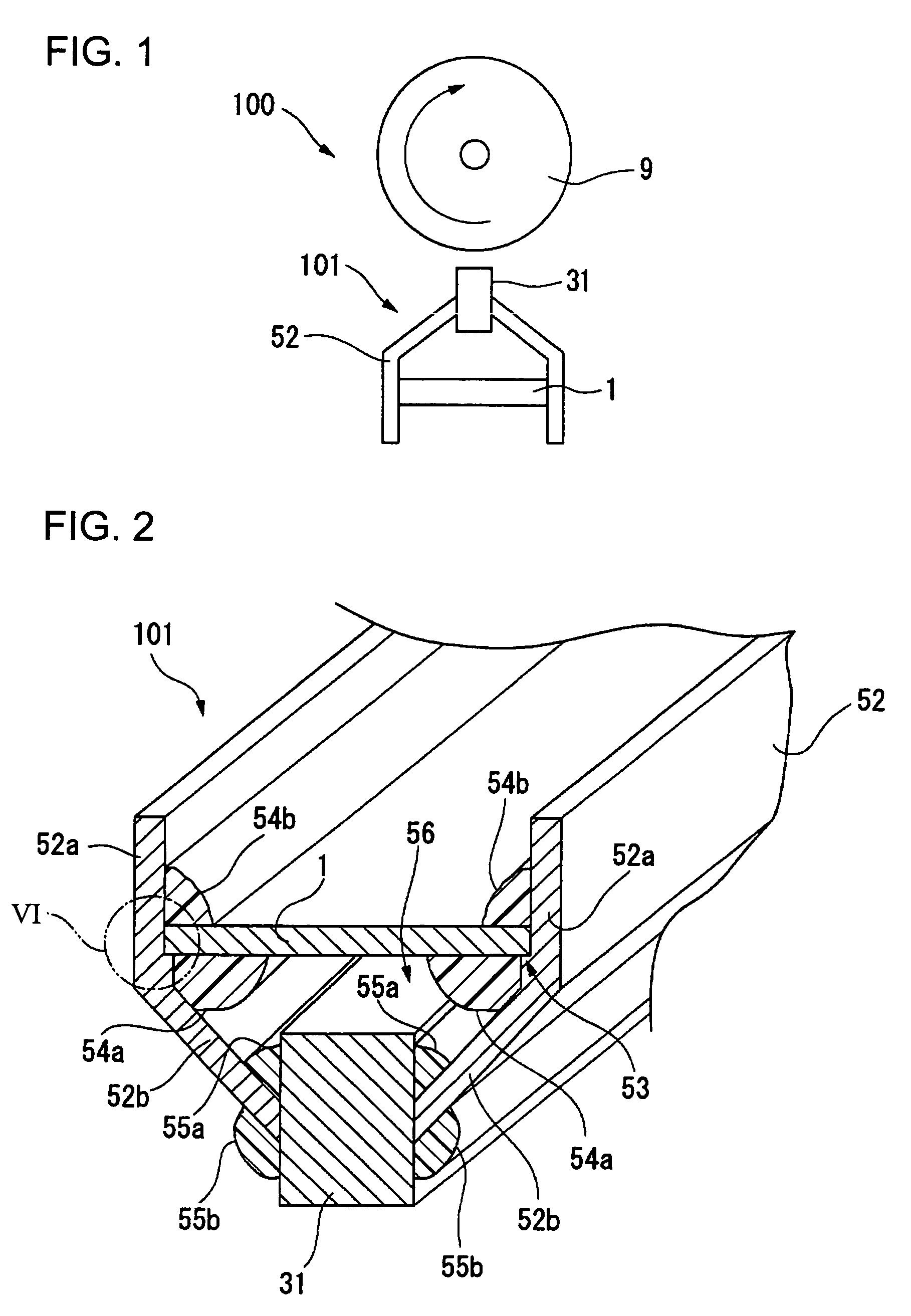

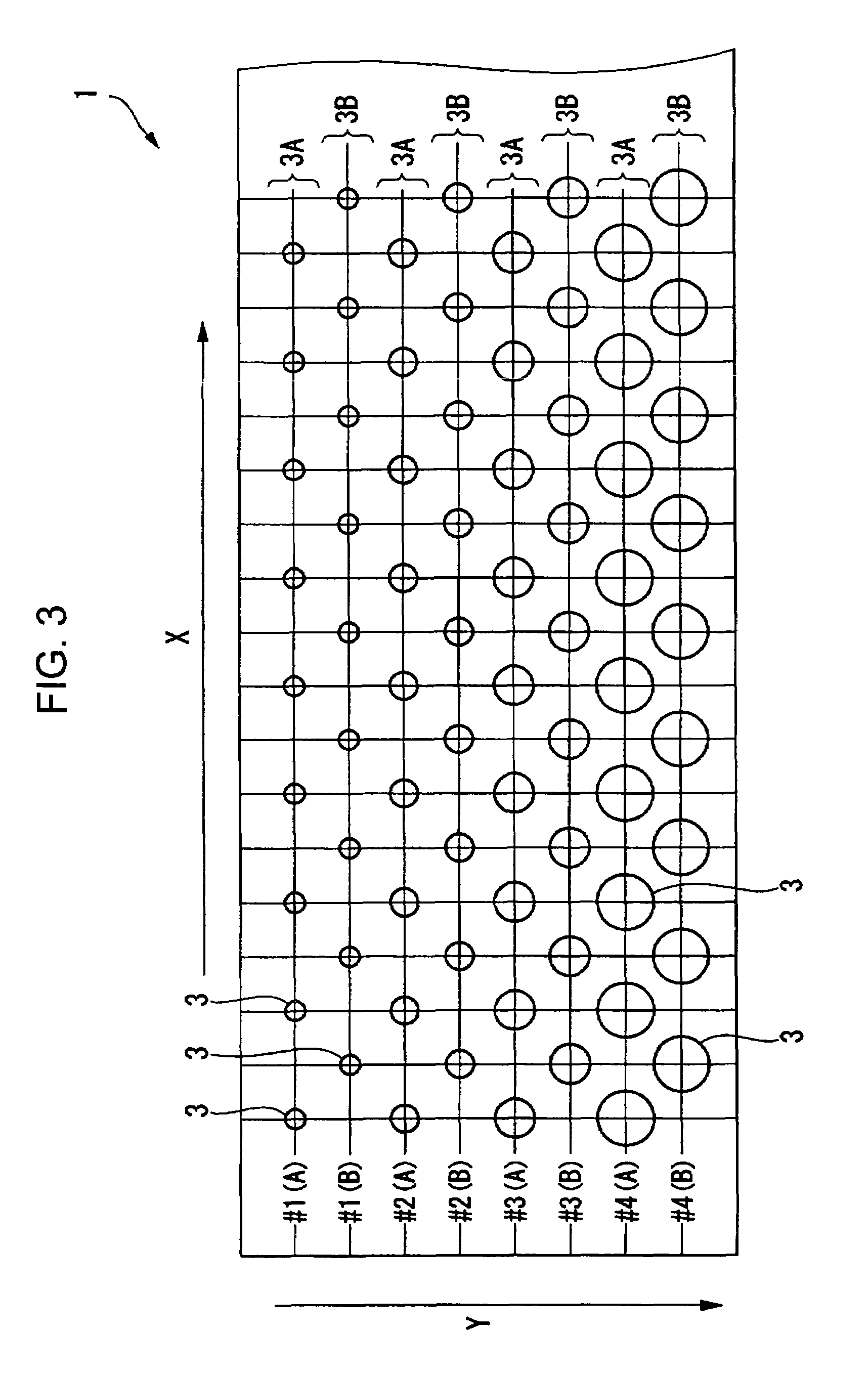

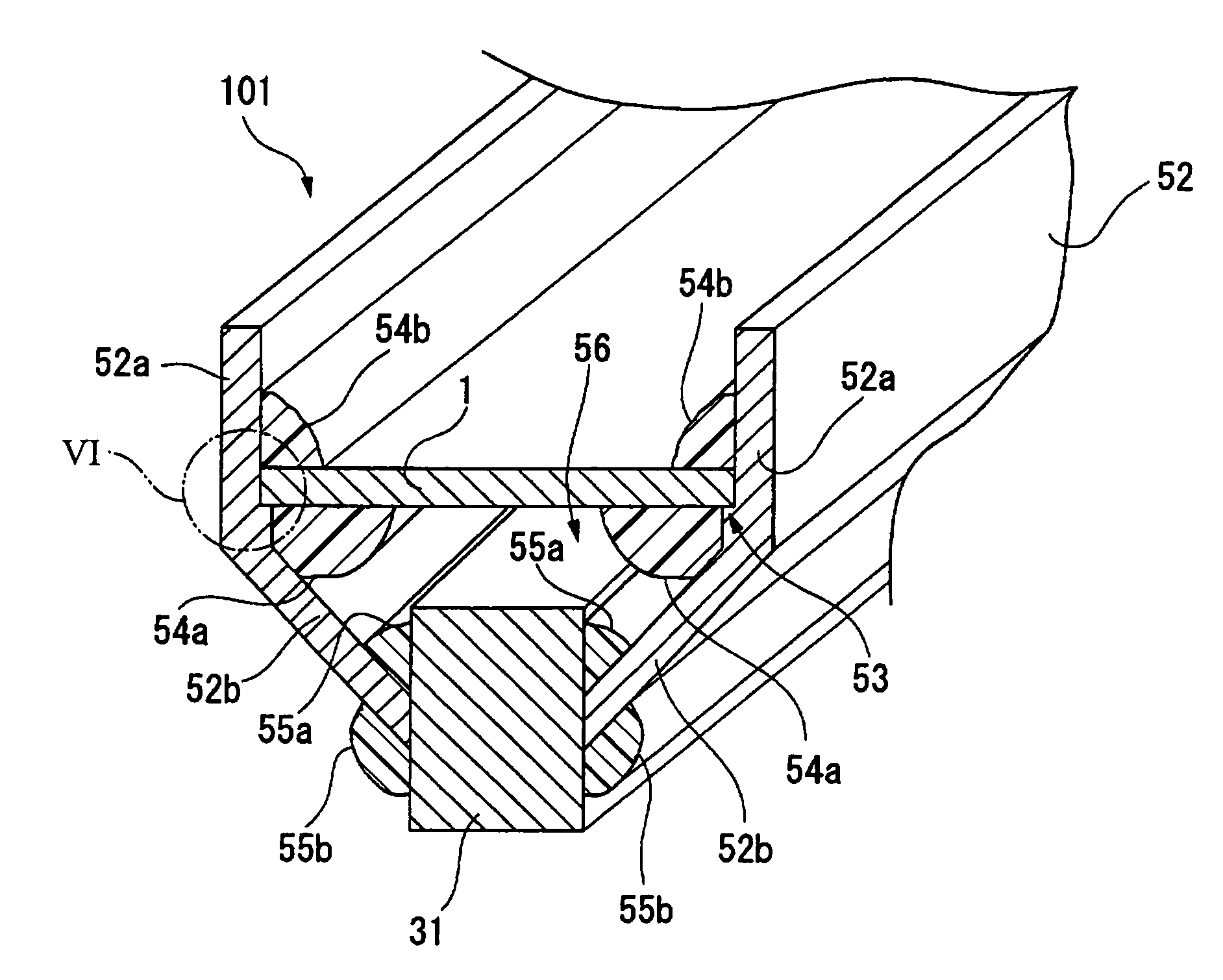

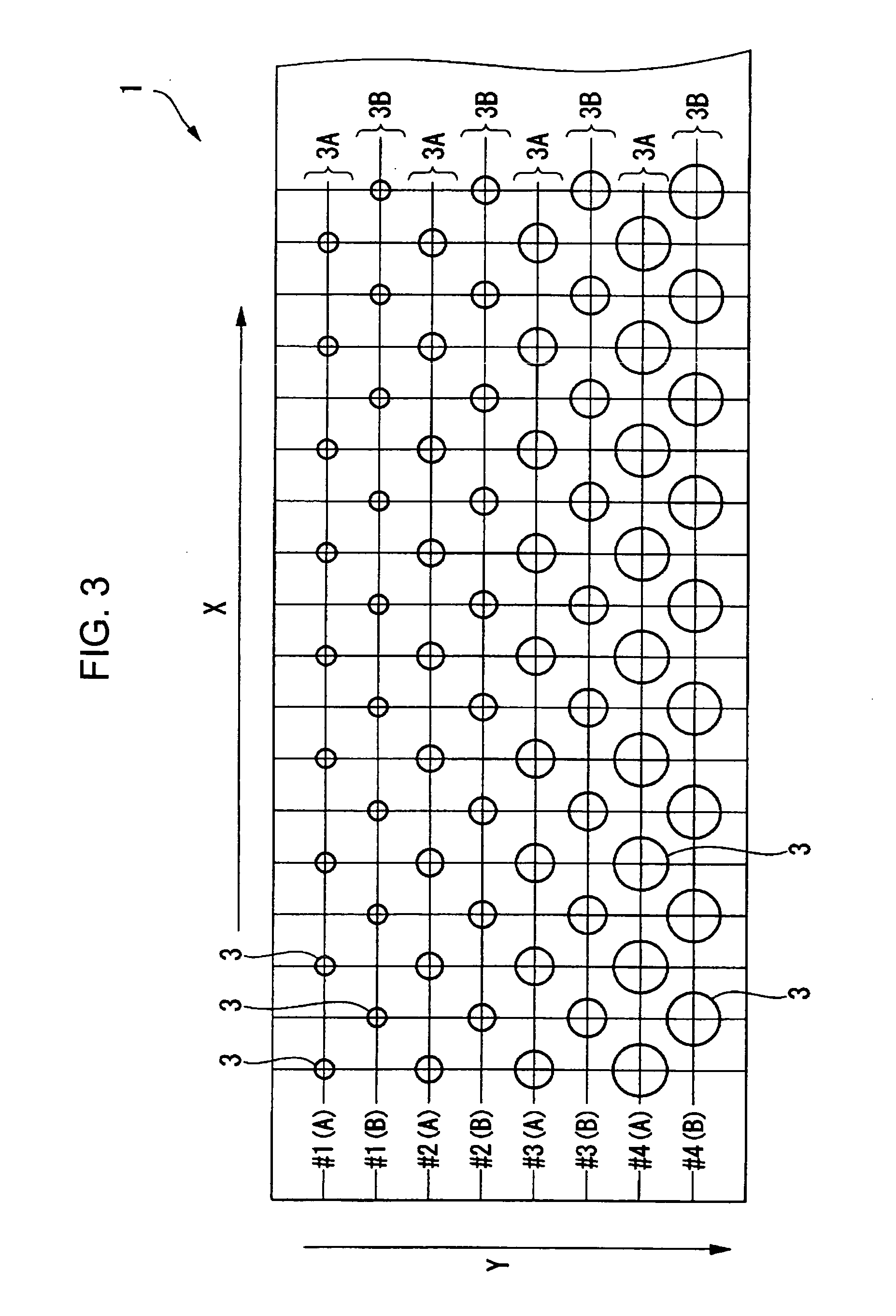

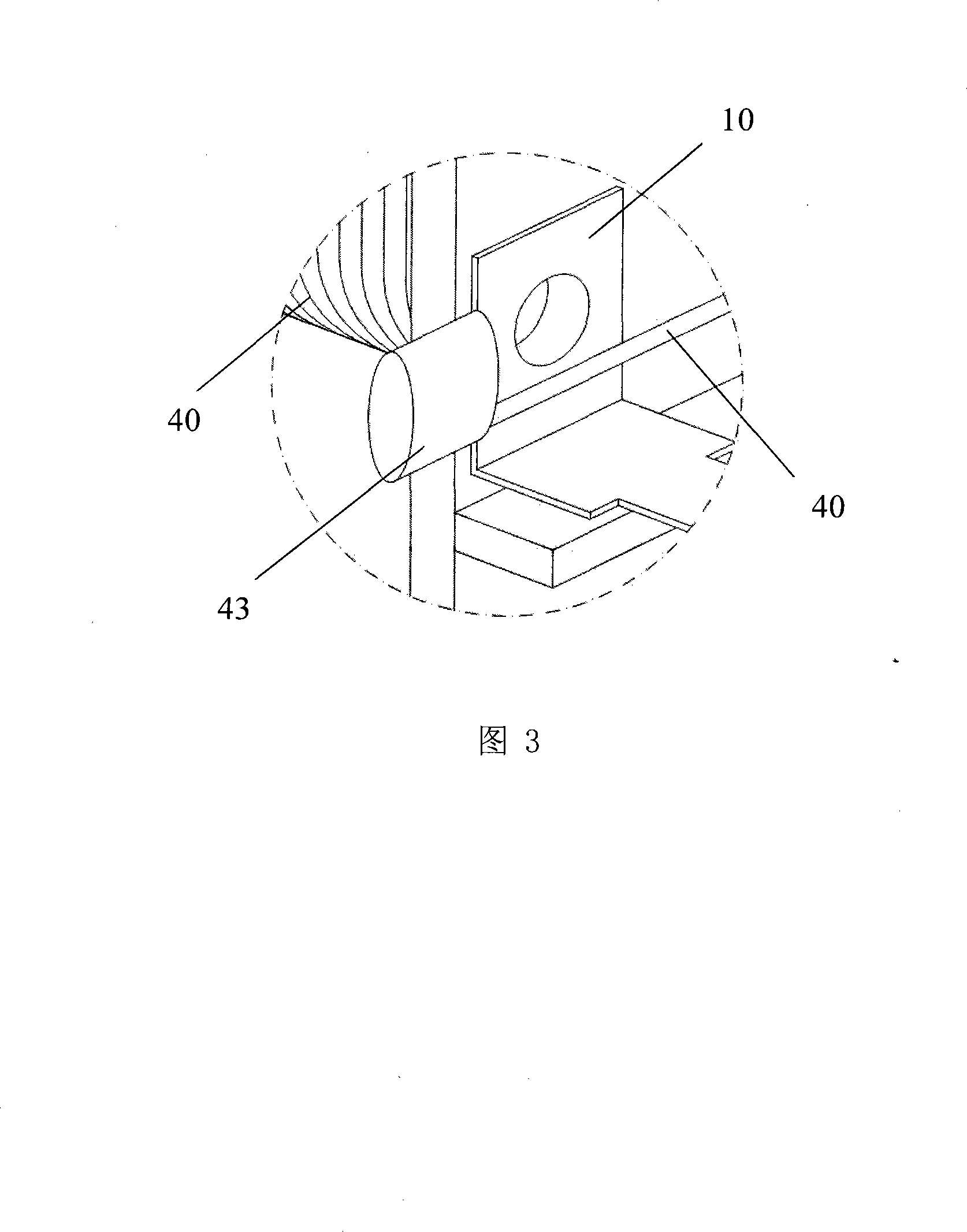

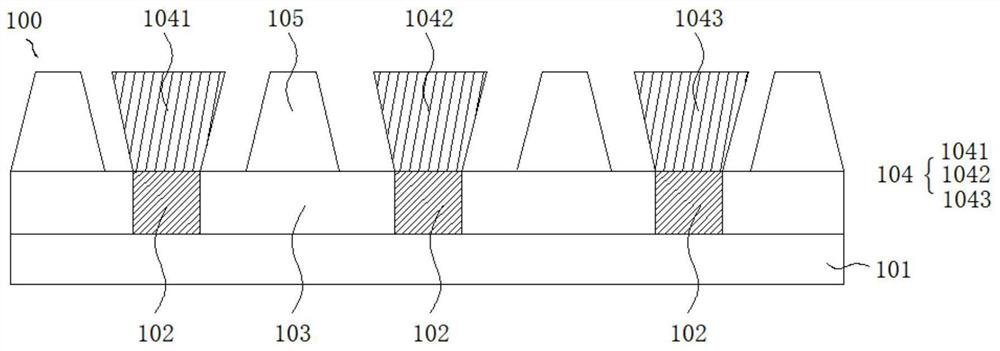

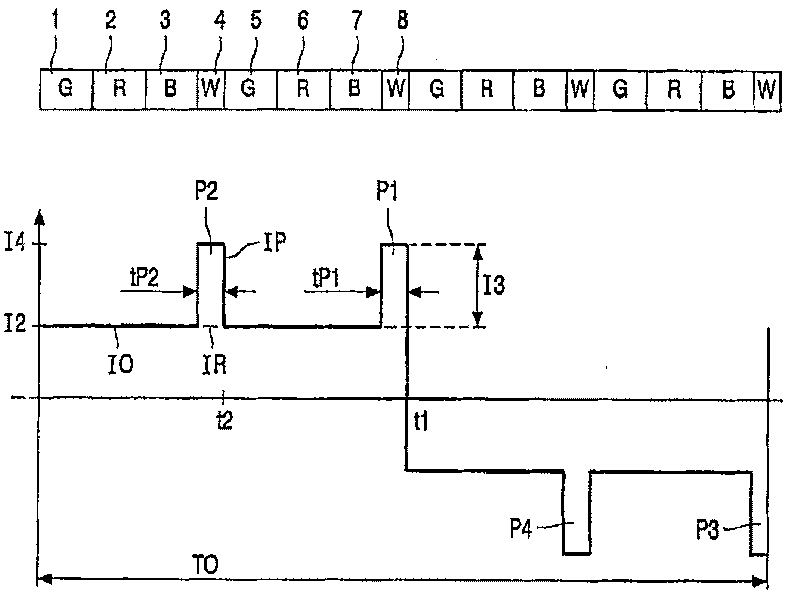

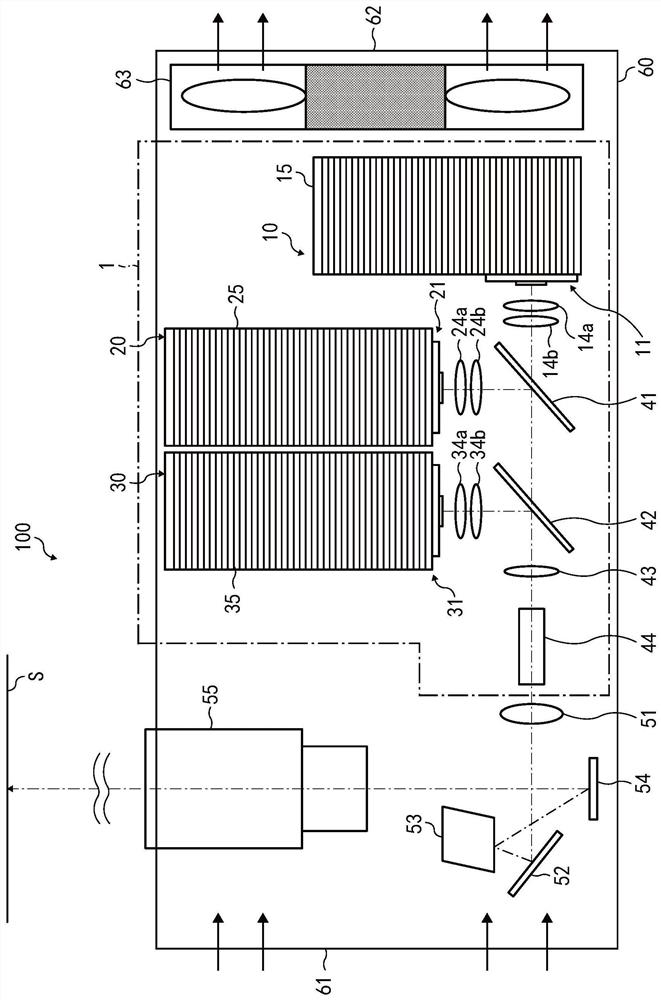

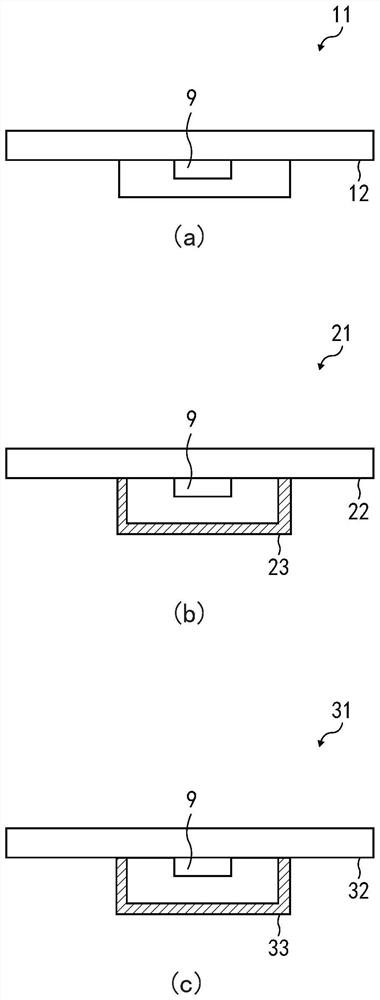

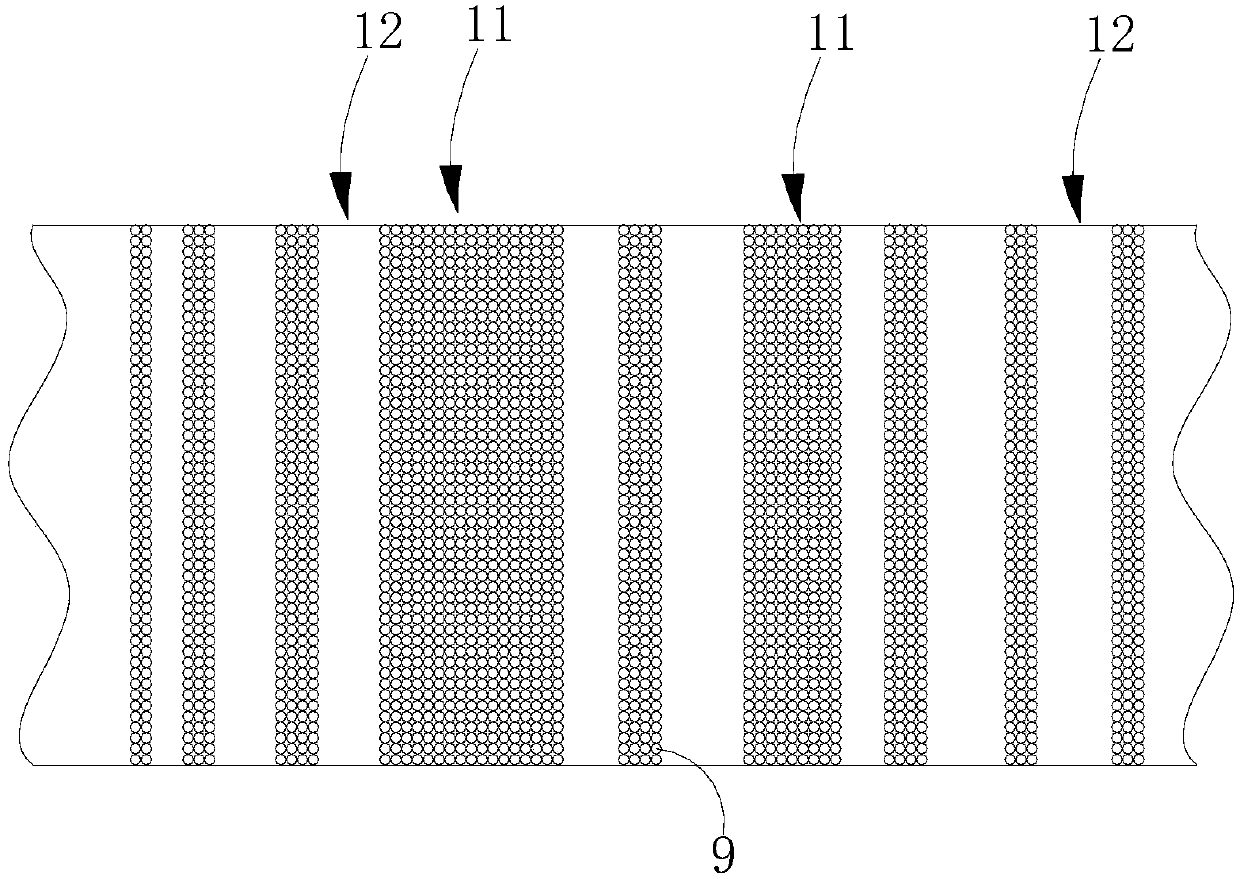

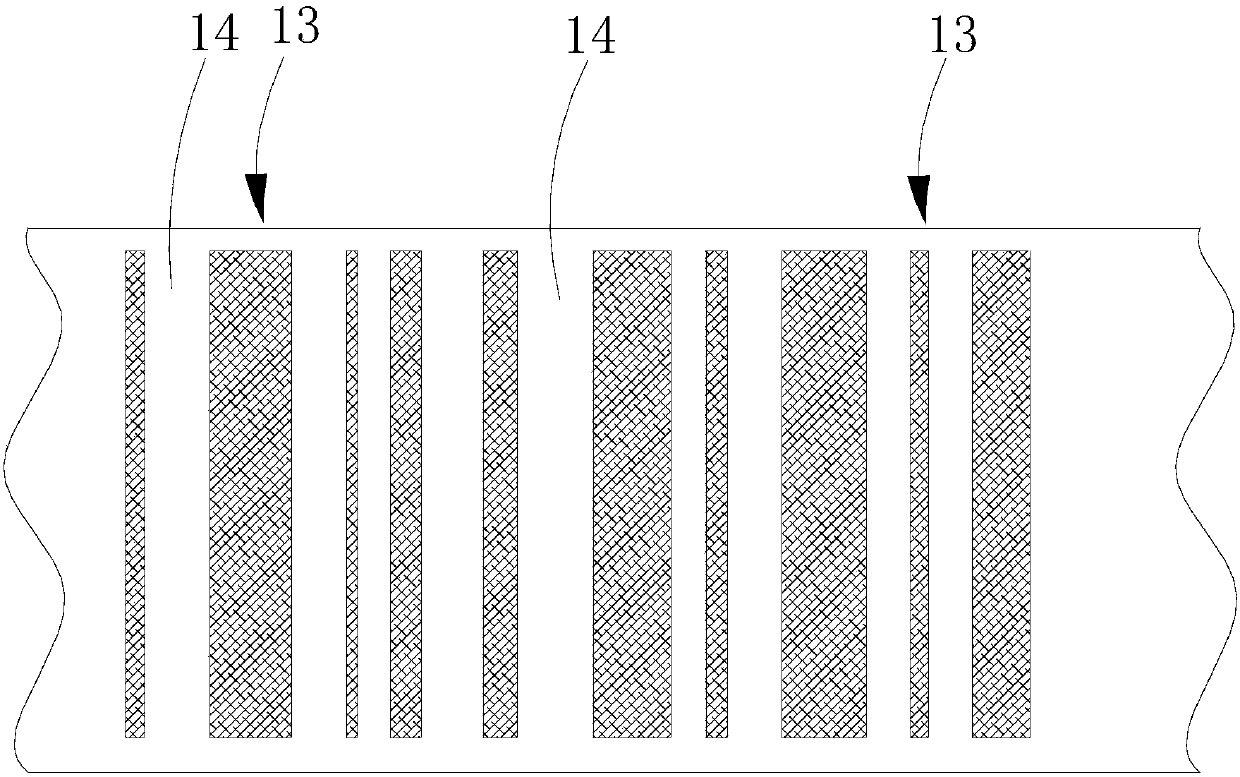

Exposure apparatus and image forming apparatus

InactiveUS7432945B2Easy to displaySame lifespanElectrographic process apparatusPrintingEngineeringElectrical and Electronics engineering

An exposure apparatus includes a line head and a rotatable photosensitive drum, which is exposed by light from the line head. The line head includes N (“N” being 2 or greater) EL element column. In each EL element column, the area S of a light-emitting pixel of the EL element is constant within a corresponding column. When the column number of the EL element columns is from 1 to N, the area of the light-emitting pixel of the EL element in each column is Si=S1 / (2n−1) (where, “i” is the column number of each EL element column and a natural number from 1 to N, and “S1” is the area of the light-emitting pixel of the EL element of a first column). One or more EL elements selected from N EL elements within the N EL element columns perform exposure on the same unit drawing region on the photosensitive drum.

Owner:SEIKO EPSON CORP

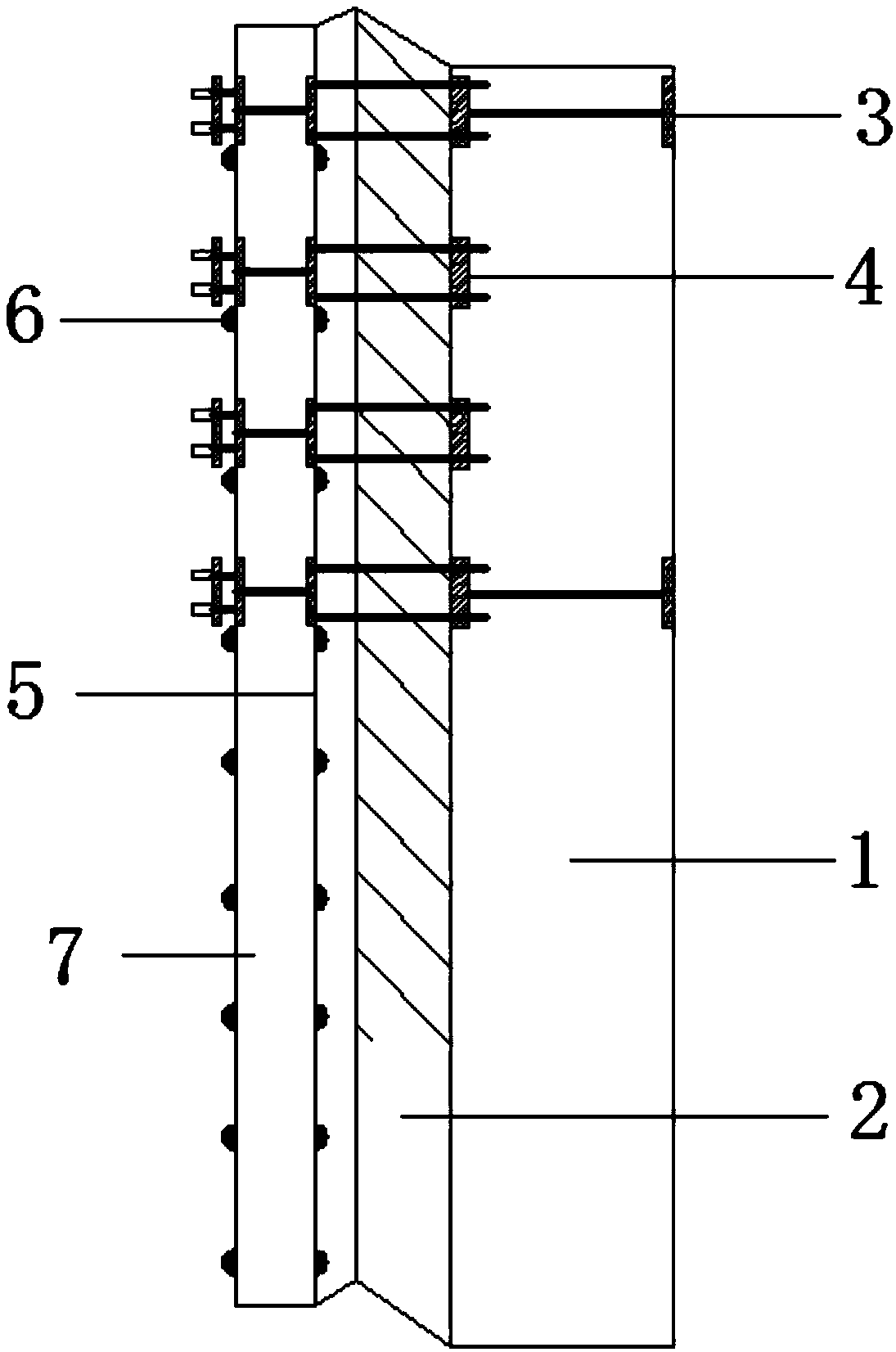

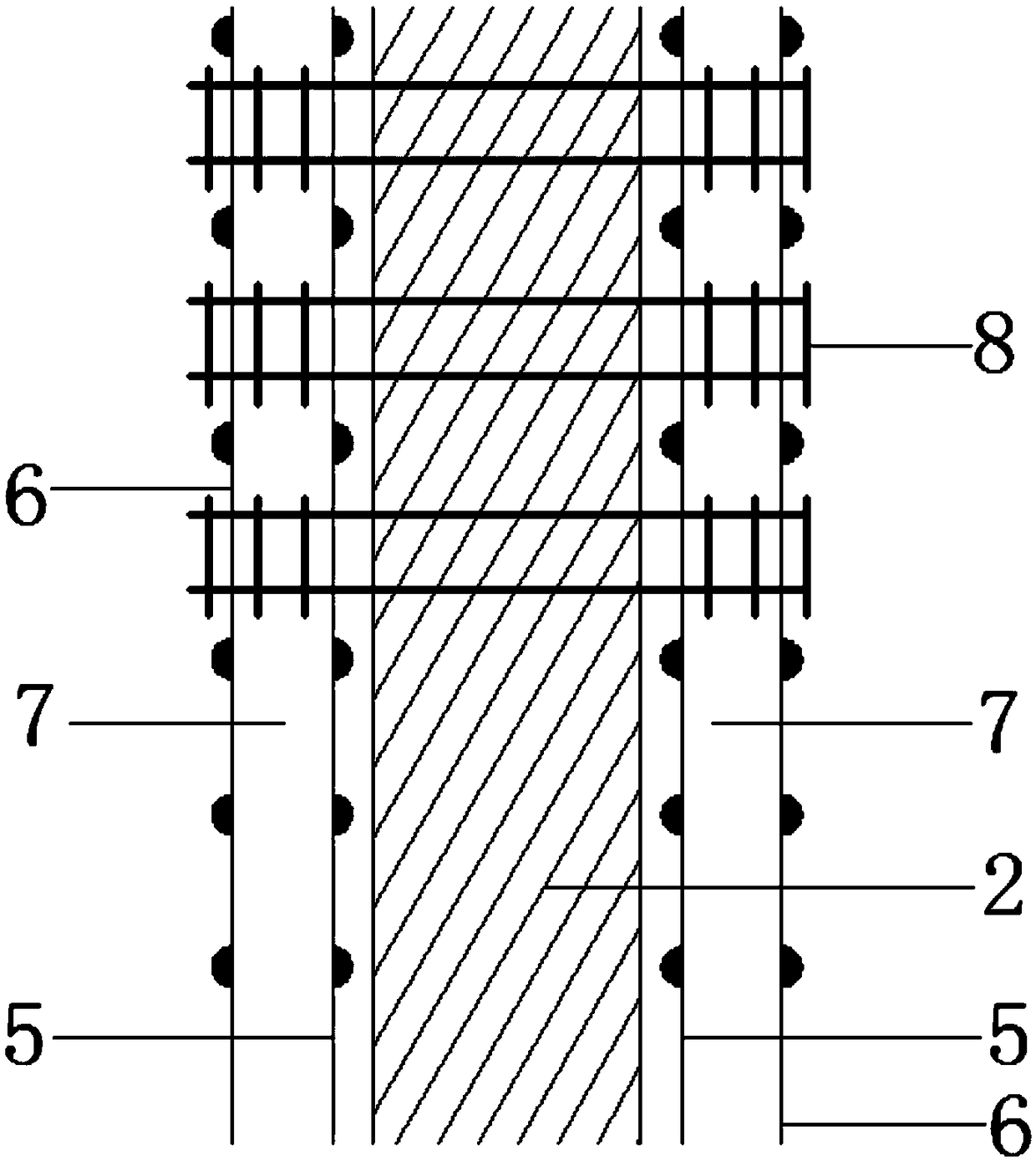

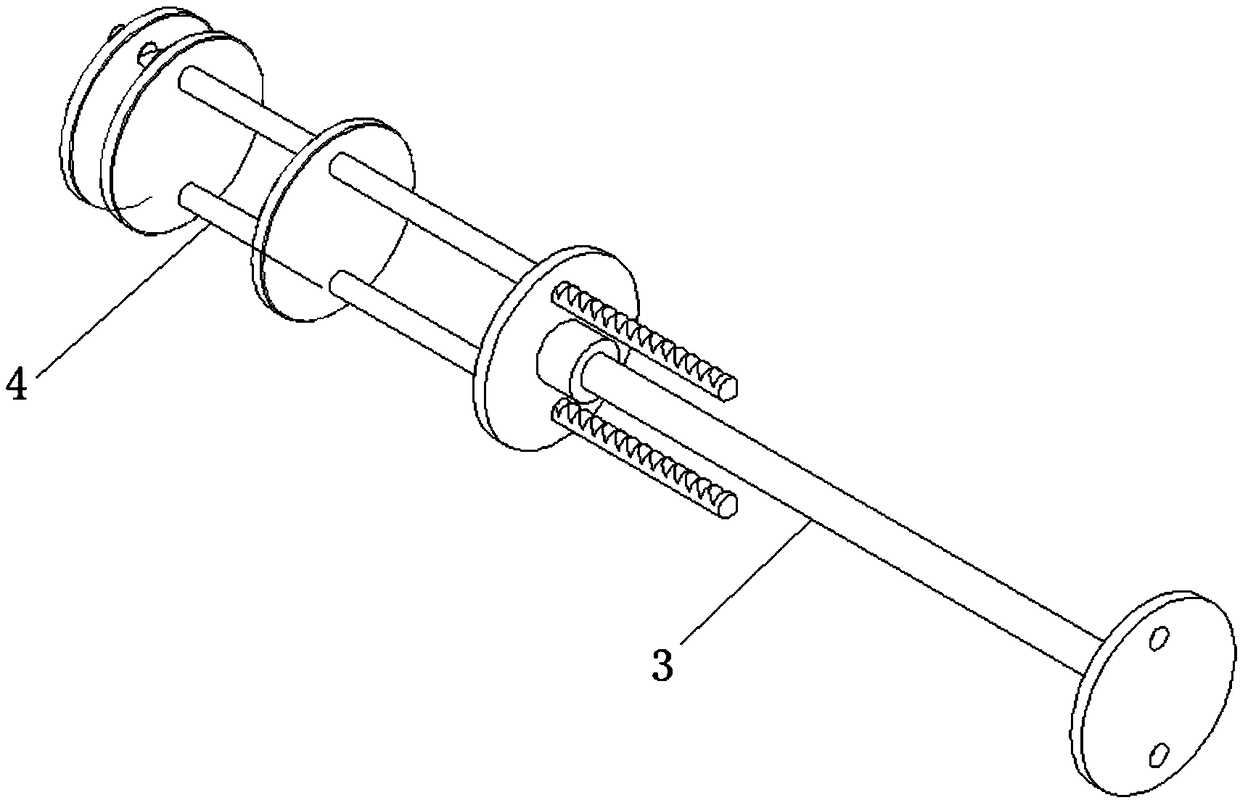

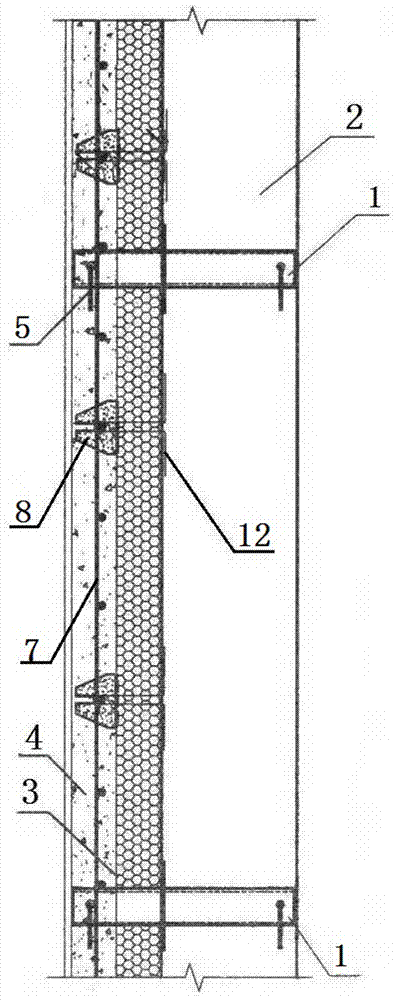

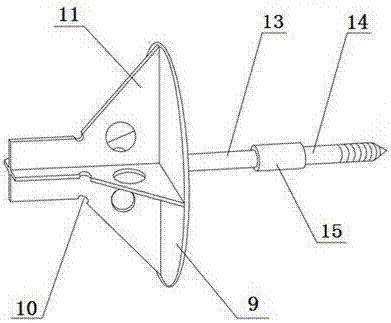

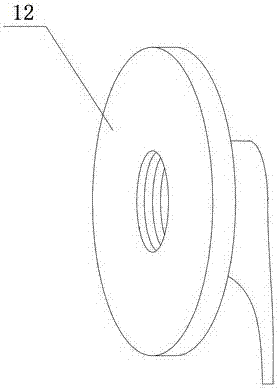

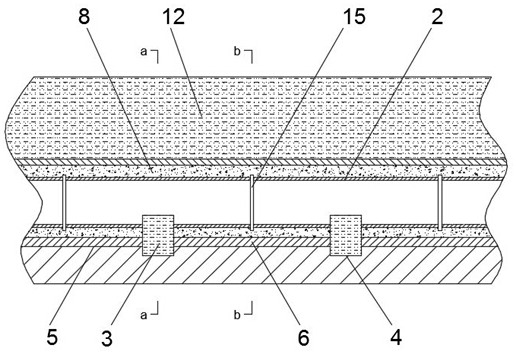

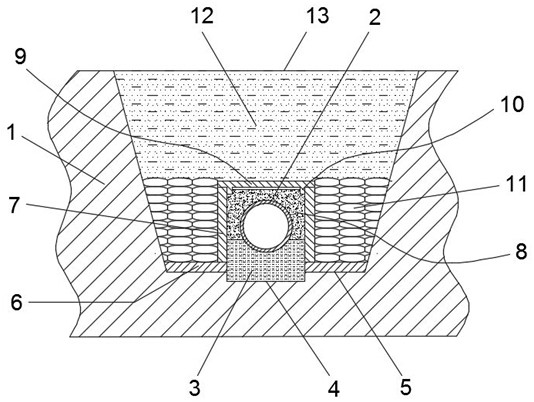

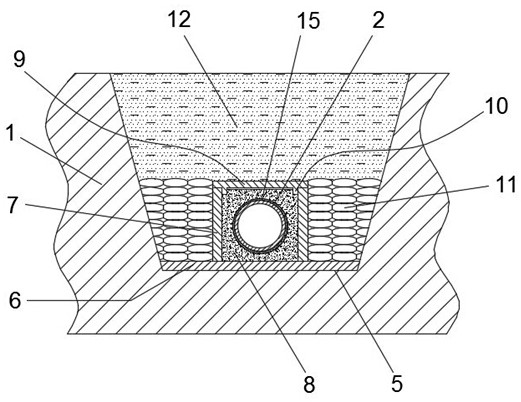

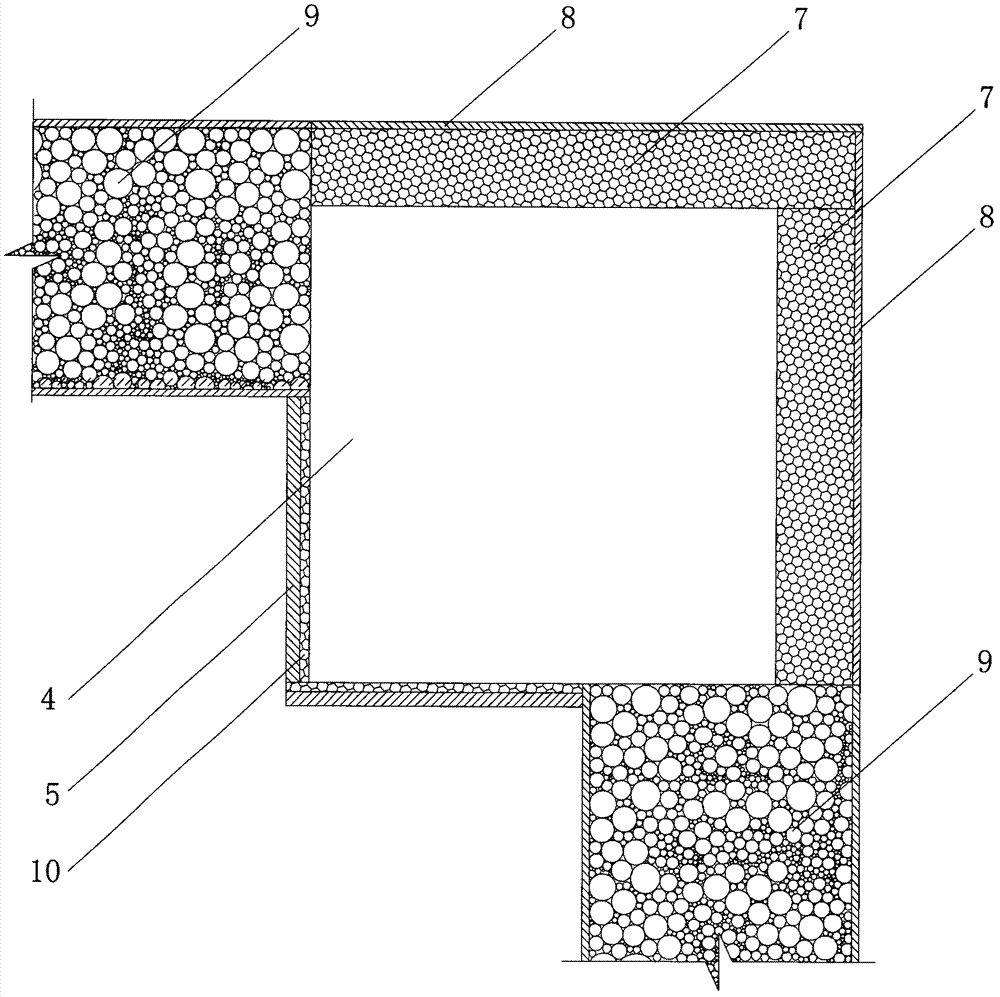

Modeling grid structure thermal insulation wall and construction method

PendingCN108915128AGuaranteed stabilityAvoid sheddingWallsHeat proofingThermal insulationScrew thread

The invention discloses a modeling grid structure thermal insulation wall and a construction method. The modeling grid structure thermal insulation wall comprises a shear wall and a filler wall, wherein a thermal insulation board is arranged on an outer layer of the shear wall; two layers of steel wire meshes are arranged on the outer side of the thermal insulation board of the shear wall, and twolayers of steel wire meshes are arranged on the inner side and the outer side of a thermal insulation board of the filler wall; the steel wire meshes comprise fixed steel wire meshes and anti-crack steel wire meshes, the fixed steel wire meshes are arranged outside the thermal insulation boards, the anti-crack steel wire meshes are arranged on outer layers of the fixed steel wire meshes, and thefixed steel wire meshes and the anti-crack steel wire meshes are connected by adopting mesh-frame-type connecting pieces; supporting pieces are installed at the inner side ends of the mesh-frame-typeconnecting pieces, and the supporting pieces are arranged on the mesh-frame-type connecting pieces in a penetrating mode; and the supporting pieces are connected to the inner sides of the mesh-frame-type connecting pieces through screw threads or clamping grooves in a fastening mode. The modeling grid structure thermal insulation wall and the construction method have a simple production process, agood thermal insulation effect, good fireproof performance, no falling off, fast construction progress and capability of maintaining the same technological life as a building.

Owner:陈红庆

Building external wall heat insulation structural system and safety degree evaluation method thereof

PendingCN107476450ACalculate securityAvoid quality problemsHeat proofingInsulation layerMoisture condensation

The invention discloses a building external wall heat insulation structural system and a safety degree evaluation method thereof. The building external wall heat insulation structural system and the safety degree evaluation method thereof aim to solve the problems that concentrated thermal bridge is generated because of a connecting piece, and the life of the building wall body is short. The structure of the building external wall heat insulation structural system comprises a concrete pavement, a load-bearing structural wall, a heat insulation layer, a positioning cushion block and a connecting component. The connecting component comprises a steel wire mesh sheet and a connecting piece fixed to the steel wire mesh sheet, the connecting piece penetrates through the heat insulation layer and is fixed to the structural wall and the concrete pavement, and the positioning cushion block is used for fixing the heat insulation layer and the steel wire mesh sheet to form a steel wire mesh frame plate. According to the building external wall heat insulation structural system and the safety degree evaluation method thereof, the method for evaluating the safety degree of the building external wall heat insulation system for the first time is provided, a heat insulation wall face with the appropriate thickness is selected to be put into use according to a result calculated through the method, and moisture condensation caused by concentrated thermal bridge of the connecting piece can be effectively overcome.

Owner:河南省华亿绿色建材有限公司

Exposure apparatus and image forming apparatus

InactiveUS20060146117A1Sufficient degreeReduced lifespanRecording apparatusElectrographic process apparatusRotational axisImage formation

An exposure apparatus includes a line head in which a plurality of EL elements are aligned and a rotatable photosensitive drum, which is exposed by light from the line head. The line head includes N (where, “N” is 2 or greater) EL element columns in which the alignment direction of the EL elements is parallel to the rotational axis of the photosensitive drum. In each of the EL element columns, the area of a light-emitting pixel of the EL element which emits light is constant within a corresponding column. When the column number of the EL element columns is from 1 to N, the area S of the light-emitting pixel of the EL element in each of the columns is Si=S1×2i−1 (where, “i” is the column number of each of the EL element columns and a natural number from 1 to N, and “S1” is the area of the light-emitting pixel of the EL element of a first column). One or a plurality of EL elements selected from N EL elements within the N EL element columns perform exposure on the same unit drawing region on the photosensitive drum.

Owner:SEIKO EPSON CORP

Self-modeling and self-heat preservation building

InactiveCN102587502ASame lifespanReduce construction proceduresHeat proofingConcrete beamsArchitectural engineering

The invention relates to a new building, in particular to a self-modeling and self-heat preservation building, which is a building realizing the self-modeling and self-heat preservation of concrete beams, plates and posts by changing a construction material, changing the construction sequence and adopting new sectional materials and a new construction sequence. The construction mode of the building is that a filled wall is firstly constructed at the relevant position of the designed building, the upper surface of the filled wall is used as a bottom die of a beam, templates with heat preservation layers are adopted at the both sides of the beam, the upper surface of the filled wall and the inner surfaces of the heat preservation layers are used as cavities of the beam, reinforcing steel bars are placed in the cavities, concrete is poured, thereby forming the beam with the heat preservation layers; the surface of the filled wall, which is connected with the post, has the functions of the templates, the templates with the heat preservation layers are adopted by other positions of the post, the side surface of the filled wall and the inner surface of the heat preservation layers of the templates of the posts are used as the cavities of the post, the reinforcing steel bars are placed in the cavities, the concrete is poured, and then the post with the heat preservation layers is formed; a floor plate adopts the template with the heat preservation layer, the density and the strength of the heat preservation layer needs to be properly increased so as to ensure that the heat preservation layer is not destroyed by the treading of constructors, the reinforcing steel bars are placed on the heat preservation layer, the concrete is poured, and then the floor plate with the heat preservation layer is formed; and the templates of the beam, the plate and the post are used as protection layers of the heat preservation layers.

Owner:杨怀君

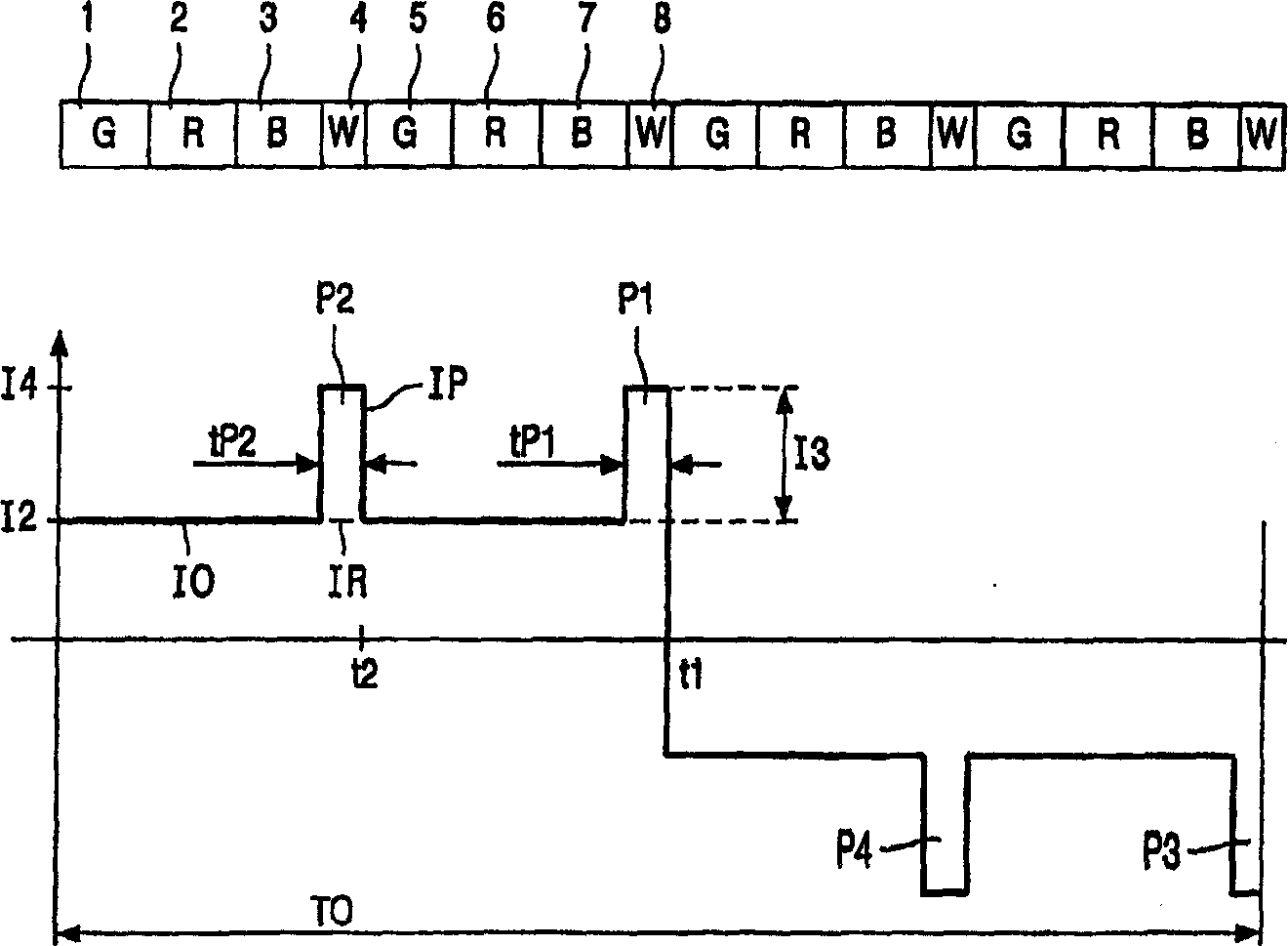

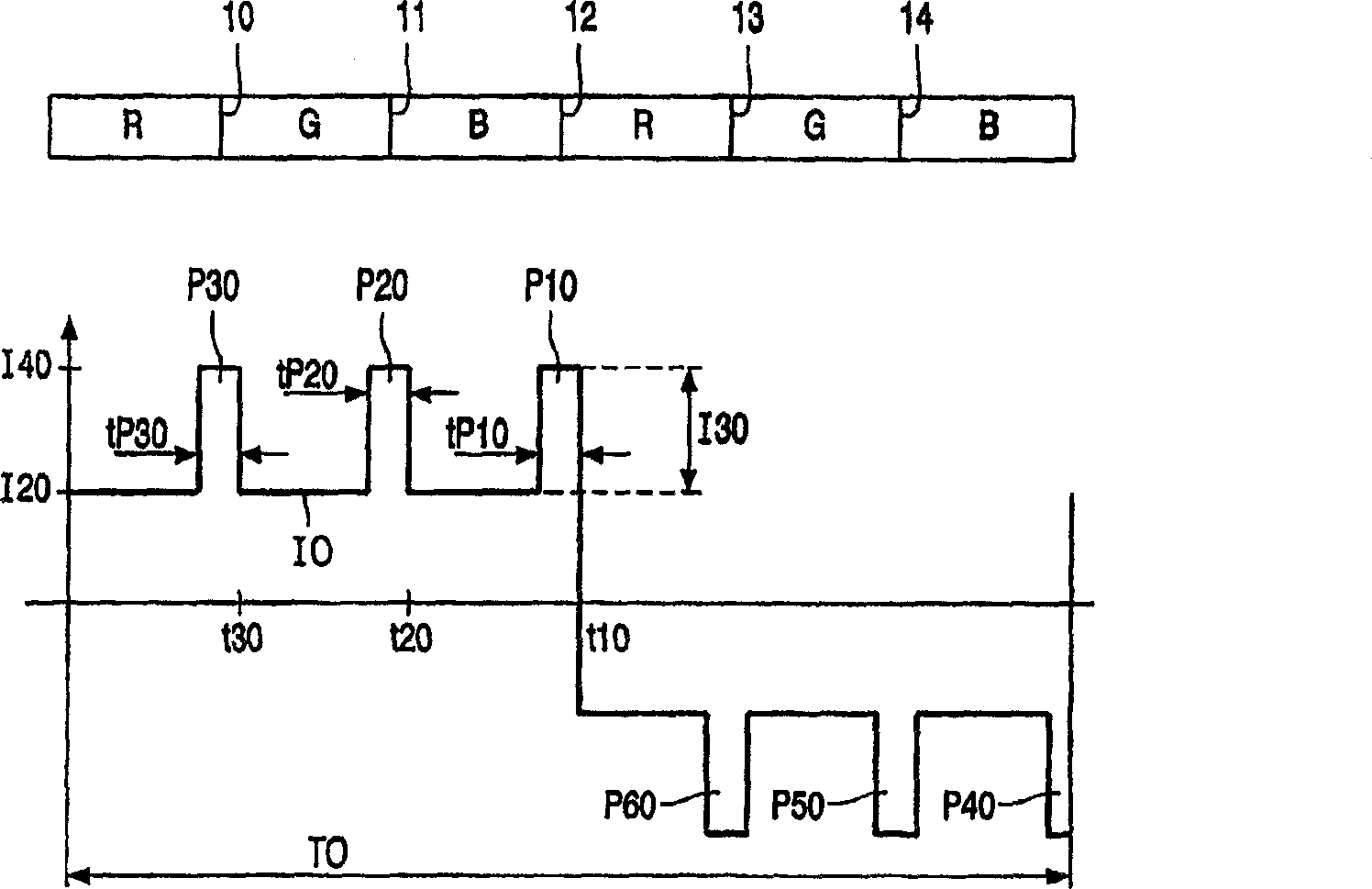

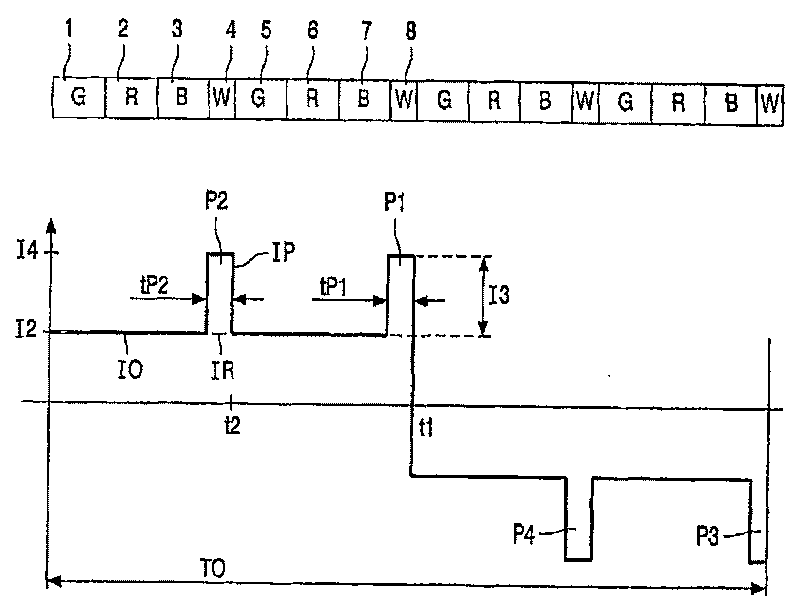

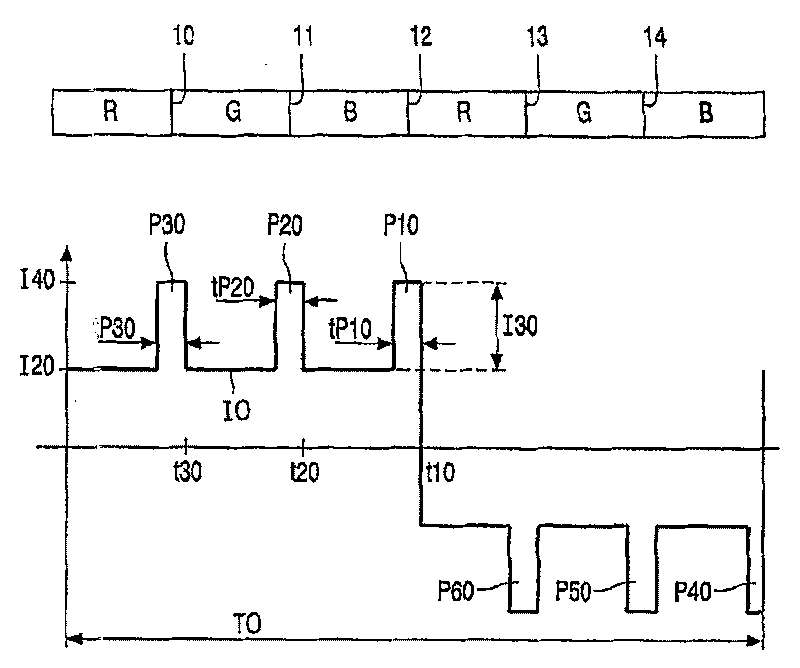

Method of representing a video image by means of a projector

InactiveCN1739300ASame lifespanNo low frequency visible effectElectric lighting sourcesPicture reproducers using projection devicesAC - Alternating currentElectrical polarity

The invention relates to a method of representing a video image based on a video signal by means of a projector which comprises an image display device and a high-pressure gas discharge lamp, which lamp is supplied with a square-wave alternating current (I 0 , I 10 ) on which a current pulse (P 1 , P 3 , P 10 , P 40 ) is superimposed before each phase reversal. According to the invention, the alternating current (I 0 , I 10 ) is superimposed with a second current pulse (P 2 , P 4 , P 20 , P 30 , P 50 , P 60 ) of the same polarity. A simple attunement of the alternating current frequency to the image frequency without image artifacts is made possible by the second pulses (P 2 , P 4 , P 20 , P 30 , P 50 , P 60 ).

Owner:SIGNIFY HLDG BV

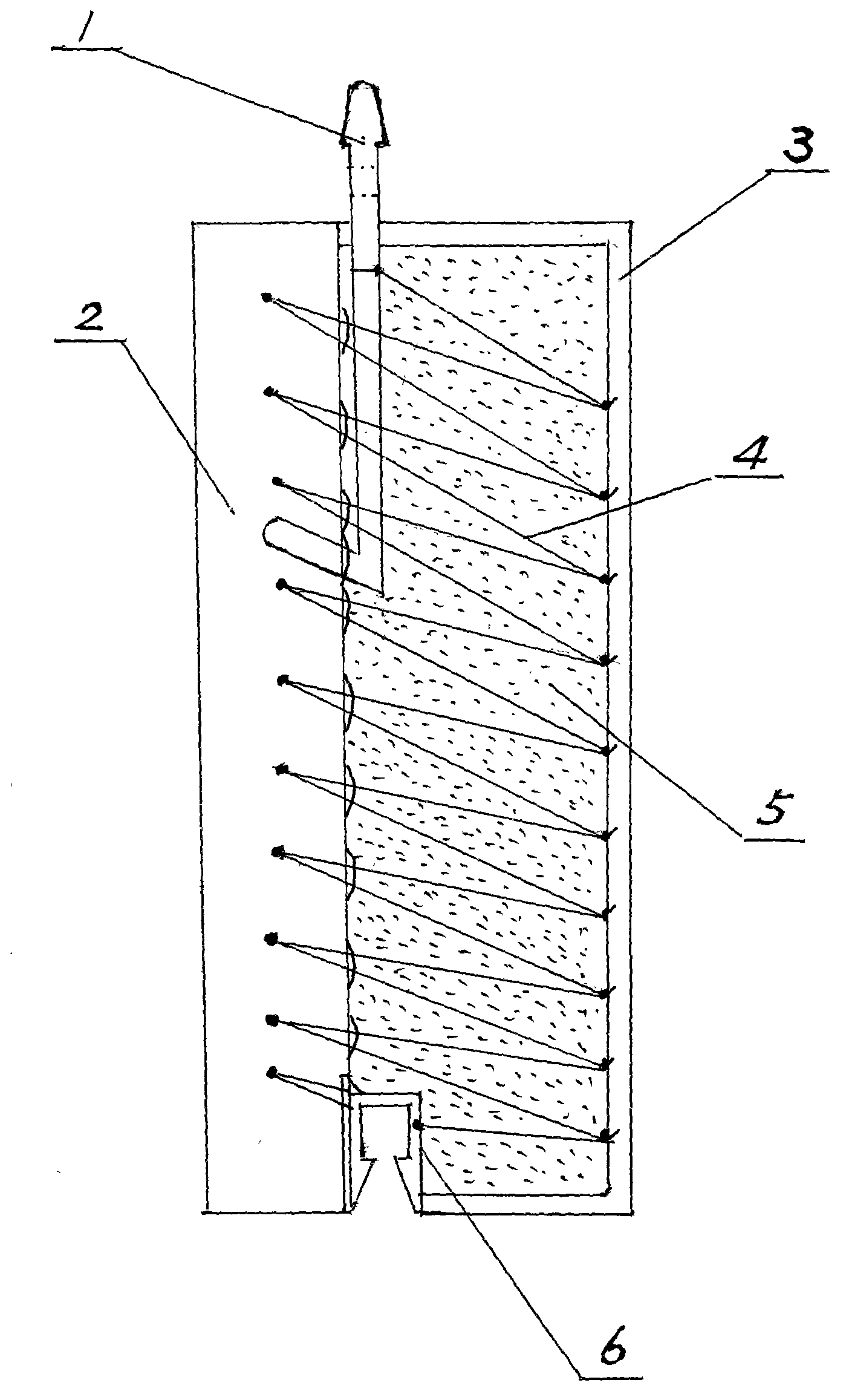

Large particle impact dust falling device for air inlet of electrostatic precipitator of boiler

InactiveCN102160946ASimple structureEasy to manufacture and installDispersed particle separationElectrostatic separation detailsElectricityEngineering

The invention discloses a large particle impact dust falling device for an air inlet of an electrostatic precipitator of a boiler, aiming at solving the problem that the air inlet of the existing electrostatic precipitator is not provided with a dust falling device for blocking large particle dust. The main body of the device is a rectangular conical structure consisting of impact plates, wherein a support device is arranged on the main body, and is fixedly connected with the air inlet of the electrostatic precipitator. The device has the advantages of simple structure, easiness for manufacture and assembly, long service life, wide applicability and remarkable effect of large particle dust removal.

Owner:崔兴云 +1

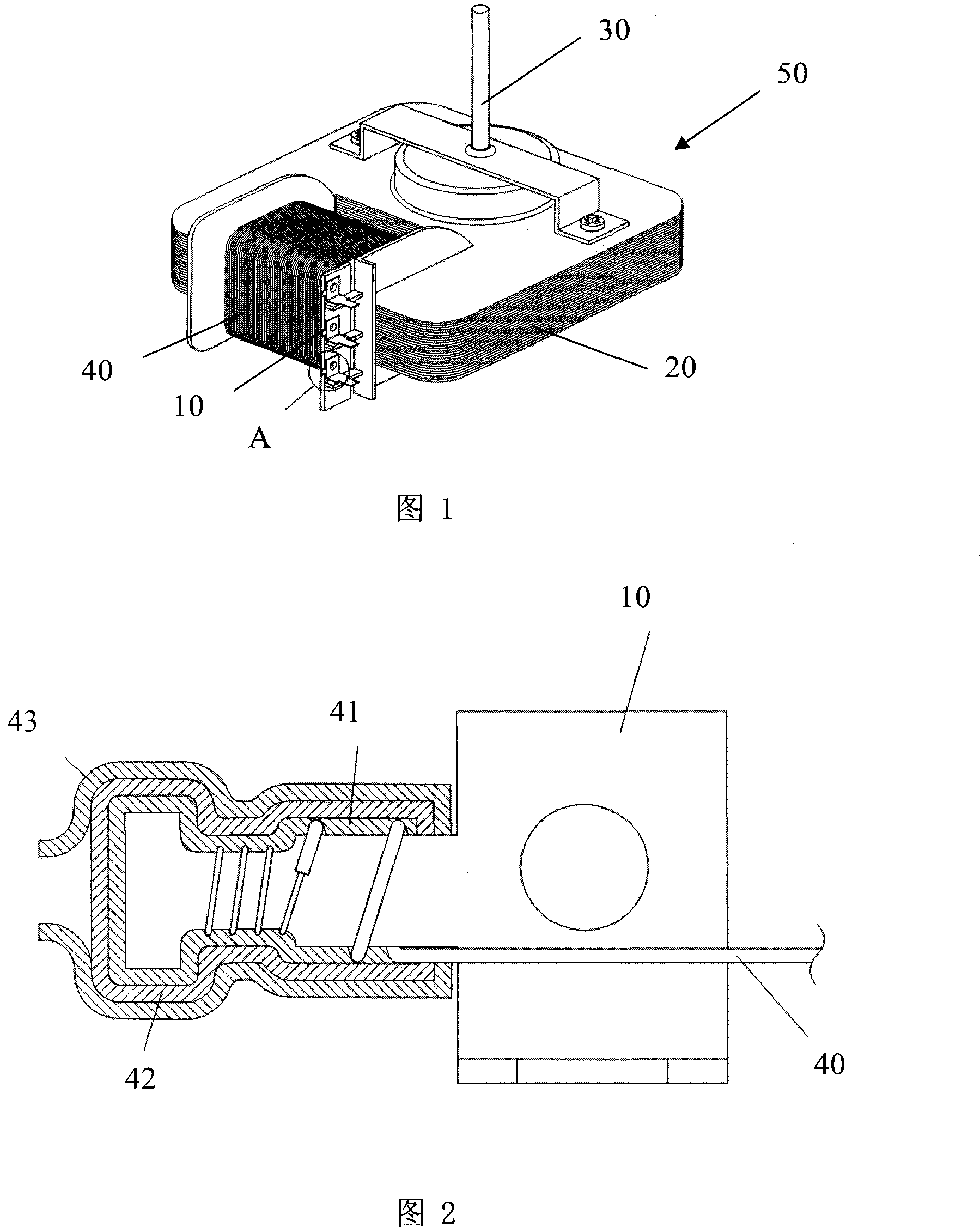

Aluminum coil connecting method of domestic electric machine

InactiveCN101227114ASolve sheddingIncreased durabilityWindingsManufacturing dynamo-electric machinesEpoxyElectric machine

The invention discloses a method for connecting aluminium coil of domestic appliances, wherein the method comprises welding the aluminium coil on terminal to form a welding portion, and then coating epoxy resin layer which has corrosion behavior on the welding portion, finally covering a cover which can cushion impact force which is acted on the epoxy resin layer and seal the epoxy resin layer on the outer portion of the epoxy resin layer. The invention provides the method for connecting aluminium coil of domestic appliance which utilizes the epoxy resin layer and a cover to protect the aluminium coil which is contacted with the terminal, therefore, the problem of abscission which is caused by corrosion and the external impact force of the aluminium coil can be prevented, so durability of the product can be increased. Furthermore, the cost of the aluminium coil is less than the copper coil, and a motor which uses the aluminium coil has the same service life as the motor which uses common copper coil, therefore the domestic appliance can be produced through adopting the aluminium coil which can not be used until now.

Owner:株式会社午星机电

Display panel and preparation method thereof

PendingCN113990997AImprove luminous efficiencyImprove efficiencySolid-state devicesSemiconductor devicesPhotoluminescenceEngineering

The invention provides a display panel and a preparation method thereof. The display panel comprises an array substrate, a near-infrared Micro-LED chip array located on the surface of the array substrate and a color conversion layer located on the surface of the near-infrared Micro-LED chip array. Materials of the color conversion layer comprise a conversion fluorescent material and a rare earth material doped in the conversion fluorescent material, the rare earth material is added to the conversion fluorescent material, and the rare earth material has low phonon energy, so that the non-radiative relaxation probability is greatly reduced, and the luminous efficiency of the conversion fluorescent material is effectively improved. Yb<3+> is serves as a sensitizing agent, Er<3+> serves as an activating agent, and effective near-infrared light-to-visible light up-conversion photoluminescence efficiency can be achieved through energy transfer from the Yb<3+> to the Er<3+>. The Er<3+> and Yb<3+> co-doped up-conversion fluorescent material has the advantages of being high in efficiency and high in color purity, near-infrared light is converted into pure red light, blue light and green light through the color conversion layer, the service life and performance of all near-infrared Micro-LED chips are the same, and a full-color scheme of the Micro-LED is satisfied.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

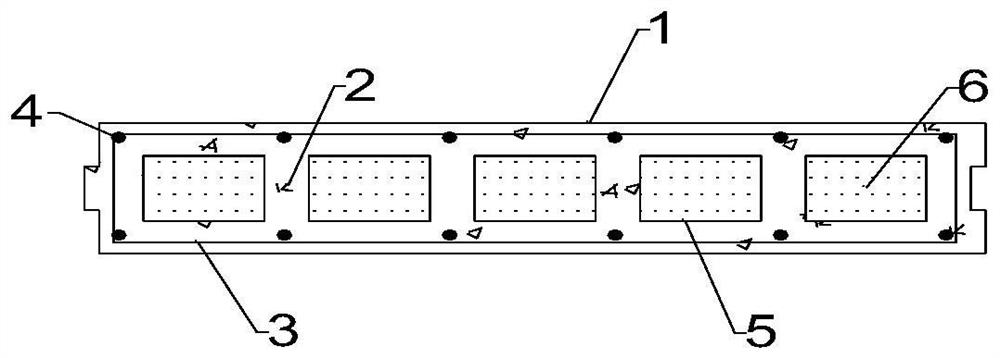

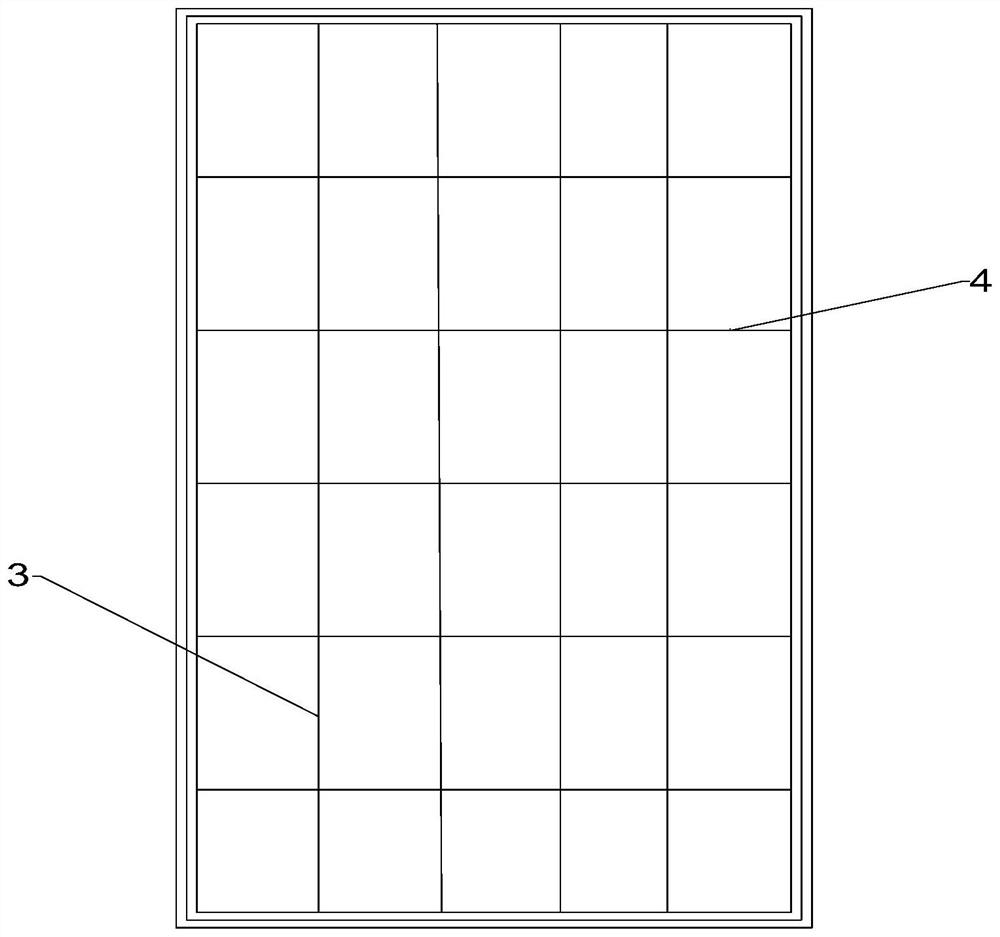

Granite solar power generation board

InactiveCN104120850AStrengthen the pulling forceBeautiful appearanceCovering/liningsBuilding materialEnvironmentally friendly

The invention discloses a granite solar power generation board which is an outer wall decorating building material capable of achieving power generation and heat preservation through solar energy. The granite solar power generation board comprises a stainless steel hanging plate, a granite plate, a glass fiber cement sheet, an infrared power generation grid, a heat preservation coating layer and an insertion hole. By the adoption of the granite solar power generation board, heat insulation and cold insulation of a house can be achieved, the maintaining time of heating or refrigerating of an air conditioner can be prolonged, electricity is saved, the granite solar power generation board has the power generation function and the heat preservation function, can not be burnt and is safe, capable of saving energy, environmentally friendly and free of pollution, and the service life of the granite solar power generation board is the same as that of the house; compared with a granite board on the market at present, the installation price is low, and the market prospect is good.

Owner:凌春林 +2

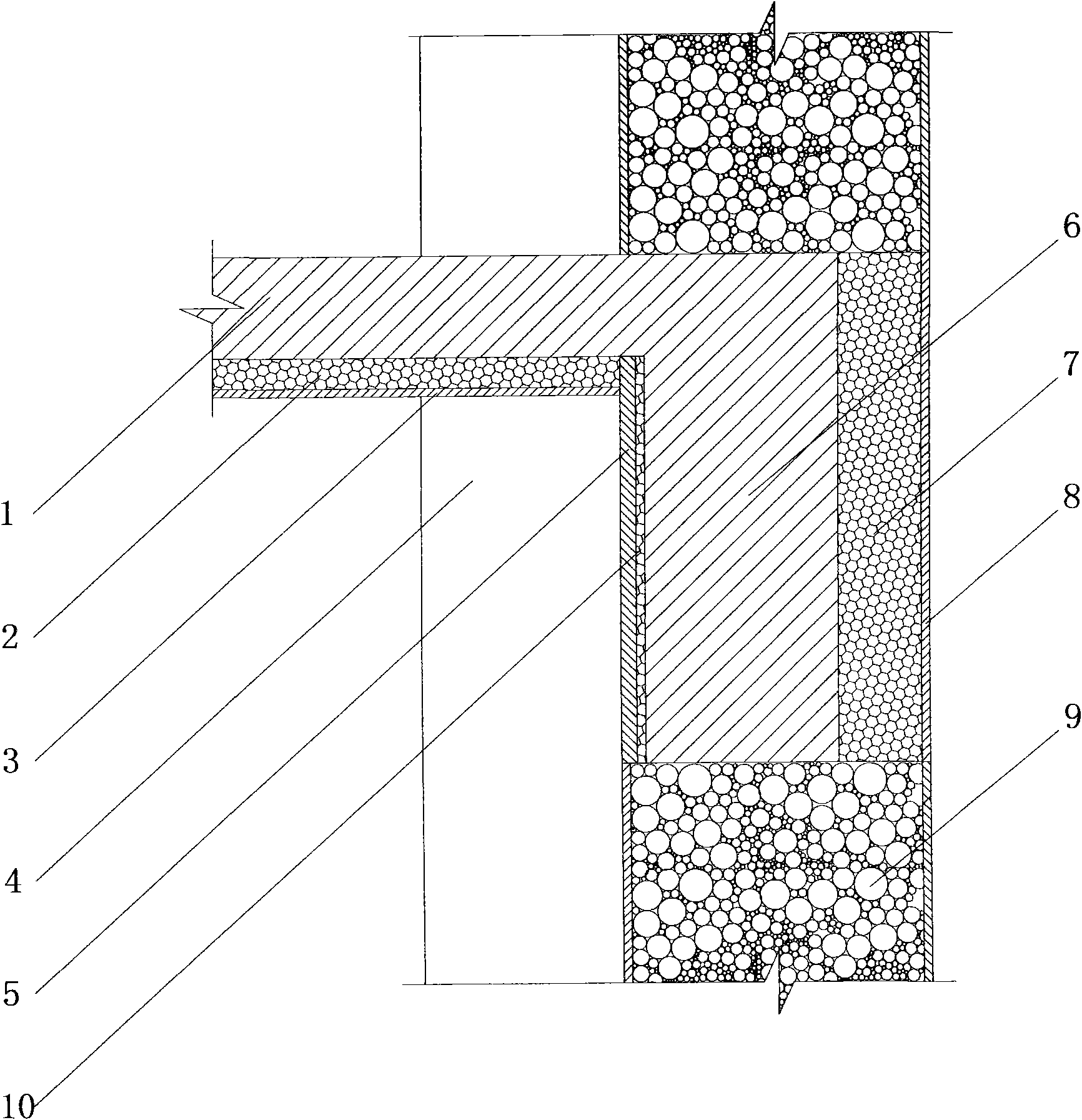

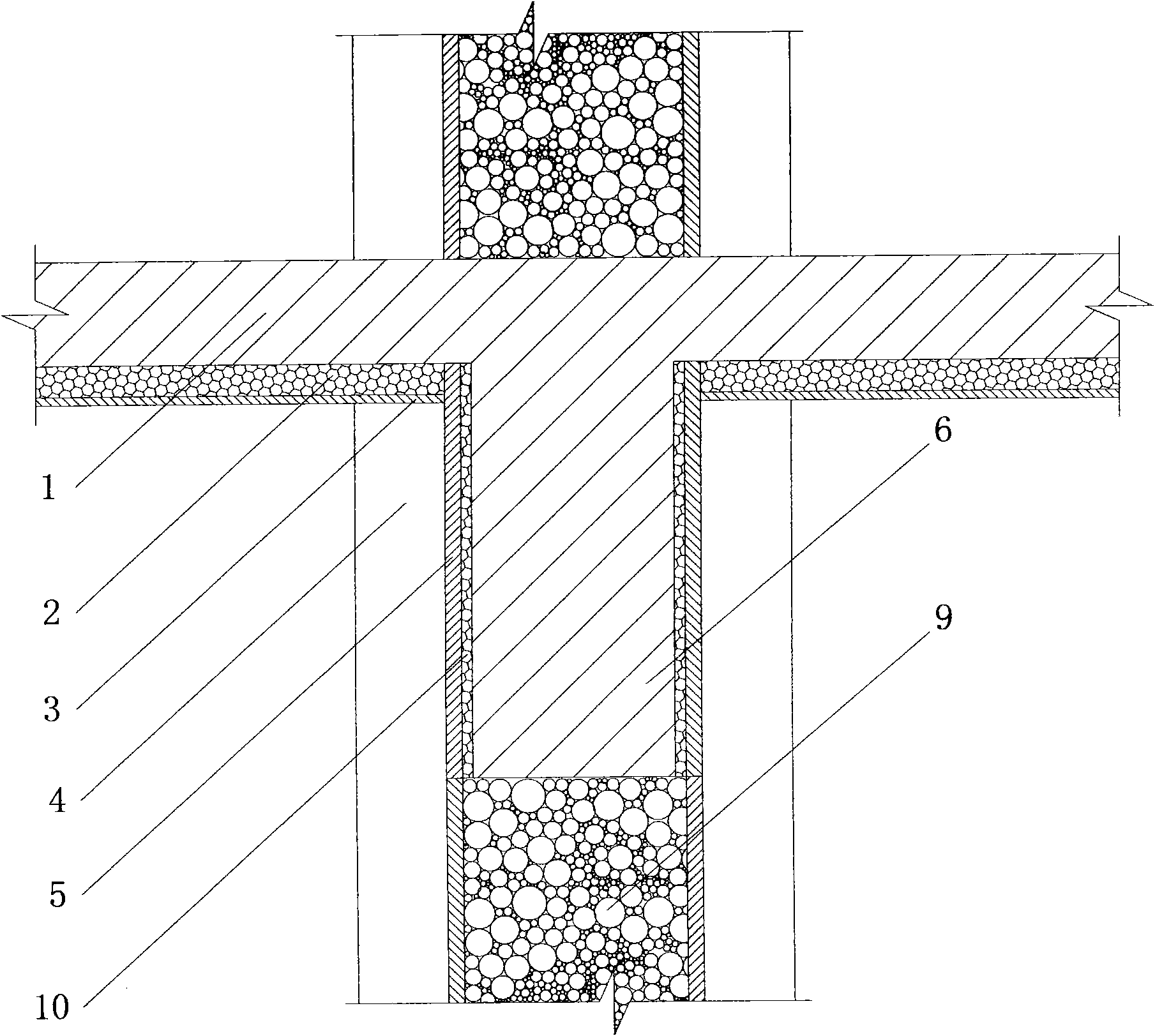

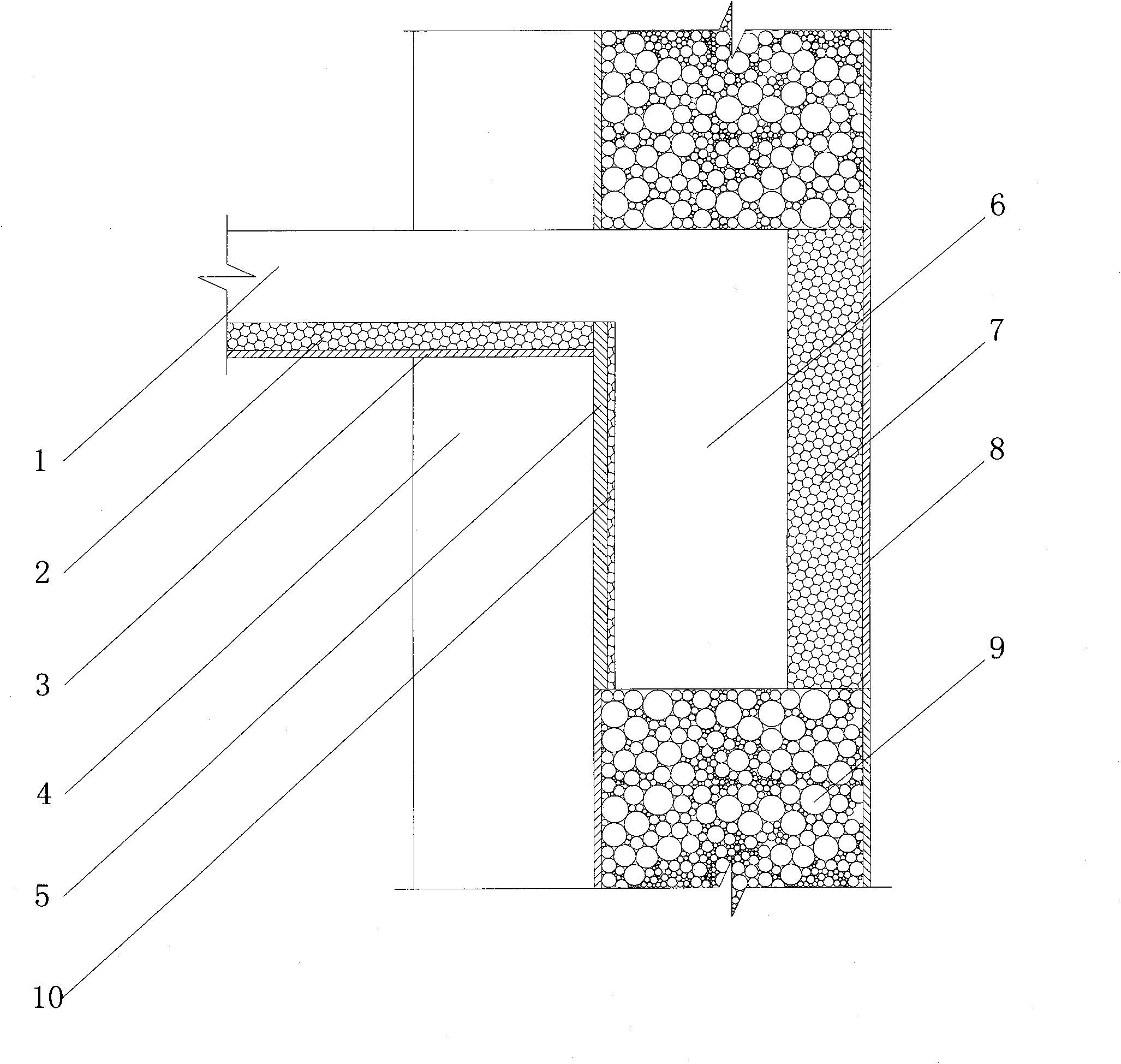

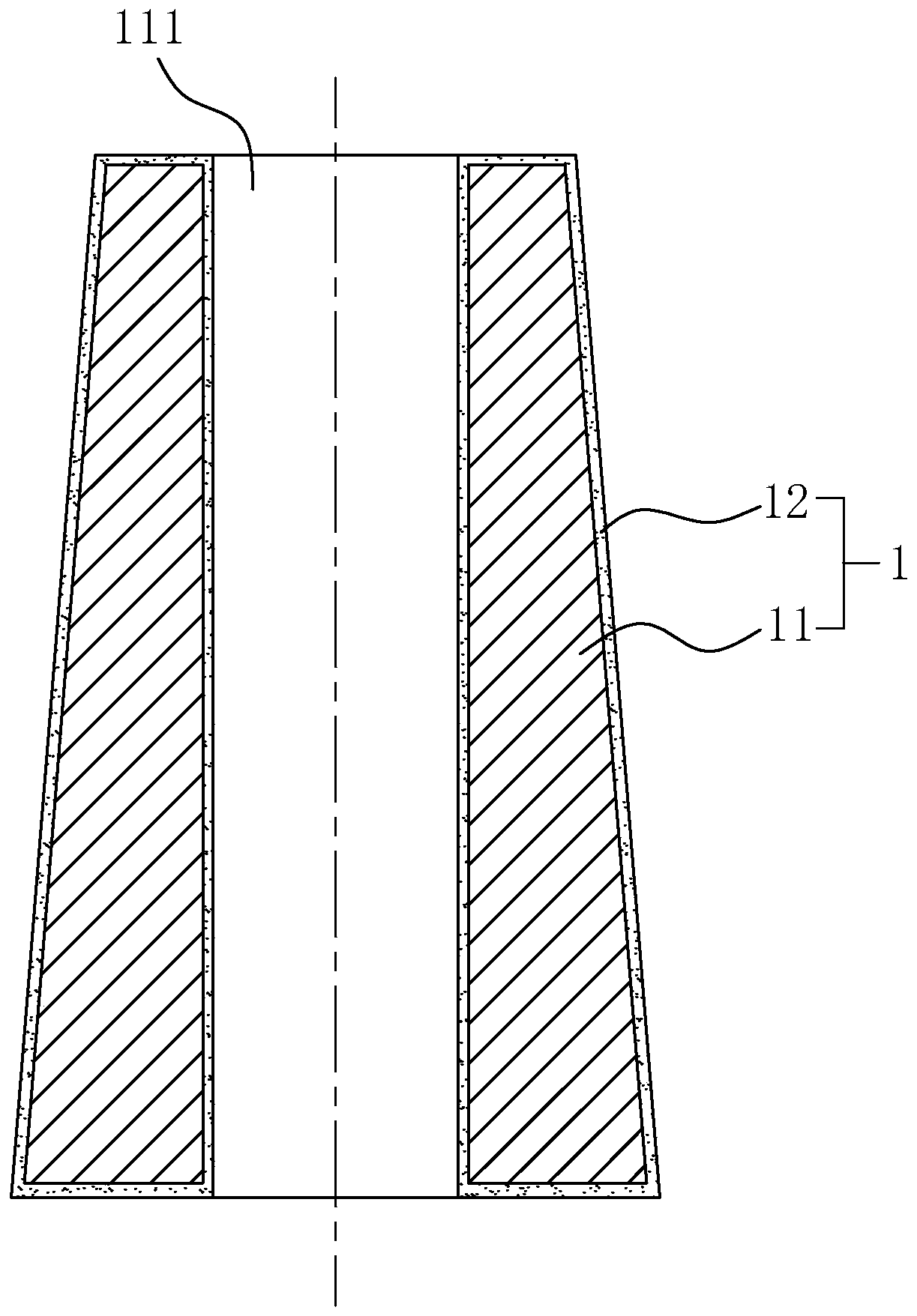

Novel outer wall beam for self-modeling self-insulation building

InactiveCN102758500AReduce construction proceduresImprove construction progressWallsGirdersEngineeringRebar

The invention relates to a novel outer wall beam for a self-modeling self-insulation building. The construction method of the beam includes: firstly, constructing a filling wall 9 which has functions of filling and insulation and can be realized by adopting a special self-insulation bar wallboard or other building materials, the upper surface of the filling wall 9 serves as a bottom mould, the bottom mould, a beam mould plate 5 and a mould plate 8 form a beam pouring groove 6, and a beam 6 is formed by placing steel bars and pouring concrete. A floor mould plate 3 with an insulation material 2 forms a floor mould plate, the upper surface of the insulation material 2 of the floor mould plate 3 flushes with the upper end of the beam mould plate 5, the upper surface of a hardened concrete floor plate flushes with a beam mould plate 8 with an insulation material 7 attitudinally, and a floor plate 1 is formed by placing steel bars and pouring concrete. The insulation material 7 blocks up a cold bridge at the beam 6, the beam mould plate 5 with an insulation material 10 blocks up a local cold bridge at an interface of the filling 9 and the beam 8, the filling wall 9, the insulation material 7, the insulation material 10 form an outer wall insulation system, the floor plate insulation material 2 realizes heat insulation of upper and lower floors, the filling wall 9, the insulation material 7, the insulation material 10 and the floor plate insulation material 2 form a self-insulation system, and the floor mould plate 3 with the insulation material 2, the beam mould plate 5 with the insulation material 10 and the beam mould plate 8 with the insulation material 7 are free of dismounting after mounted when concrete pouring is finished.

Owner:杨怀君

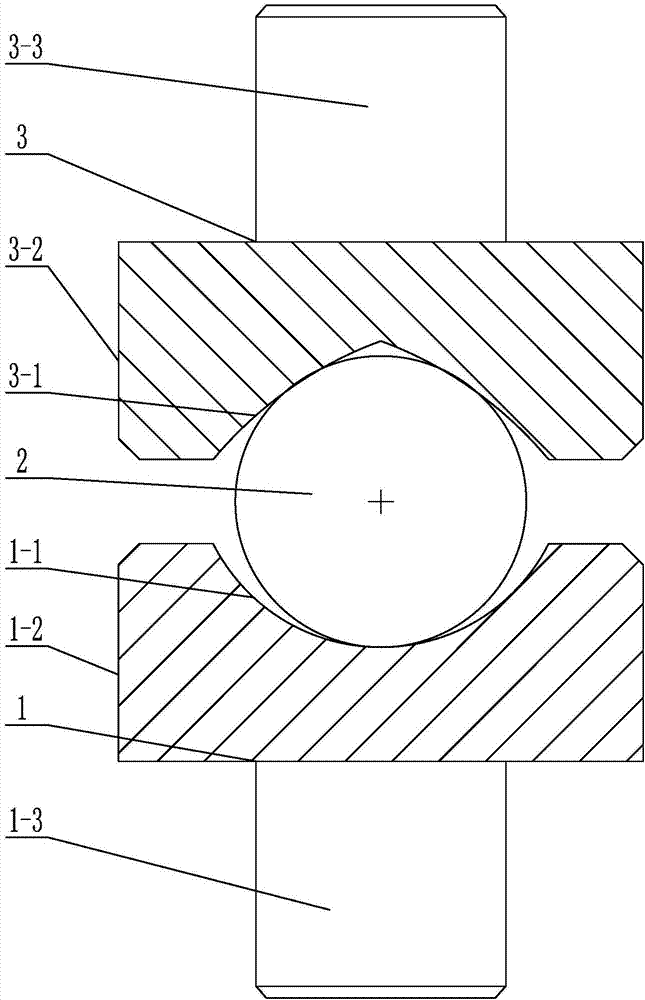

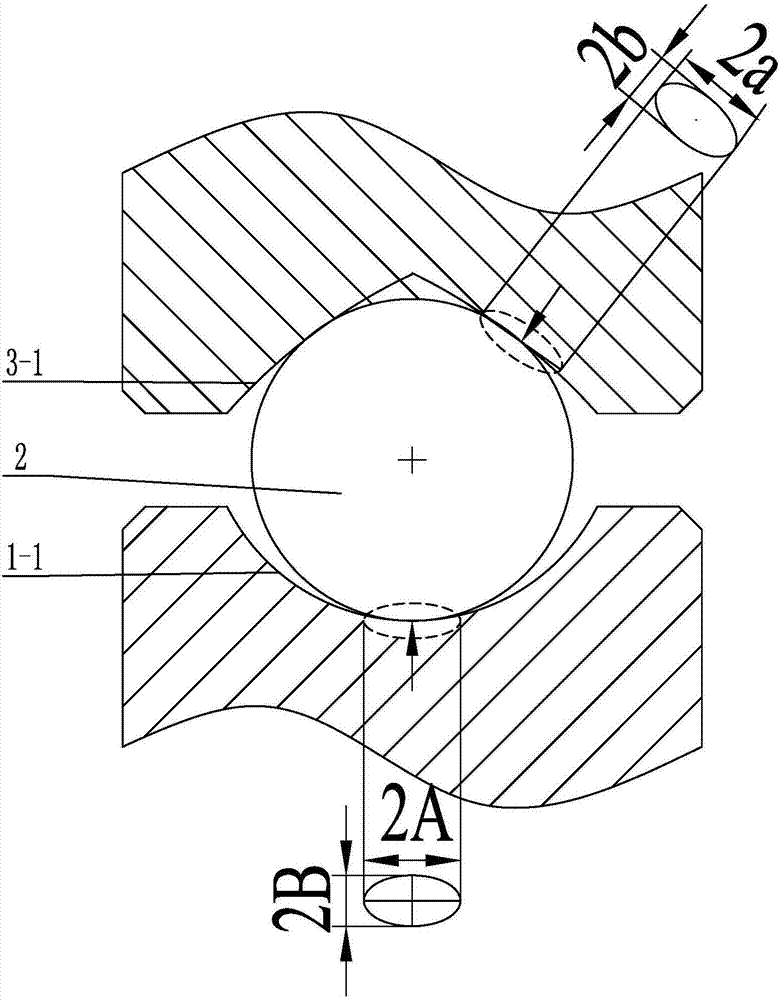

Gothic groove supporting device of mass center measurement equipment

InactiveCN107356371AReduce lateral forceHas full positioningStatic/dynamic balance measurementBiochemical engineeringMass center

The invention relates to a Gothic groove supporting device of mass center measurement equipment, relates to the measurement technology field and solves a problem of influence on measurement accuracy caused by poor stability of a supporting device of mass center measurement equipment in the prior art. The Gothic groove supporting device comprises a lower supporting body, a ball body and an upper supporting board which are sequentially arranged from up to down, the middle portion of an upper end surface of the lower supporting body is provided with a spherical groove, the middle portion of a lower end surface of the upper supporting body is provided with a groove in the horizontal direction, the groove bottom of the groove is a tip end, two side groove walls of the groove are arc-shaped structures, and the ball body is arranged between the spherical groove and the groove. The Gothic groove supporting device is applicable to object mass center measurement.

Owner:HARBIN INST OF TECH

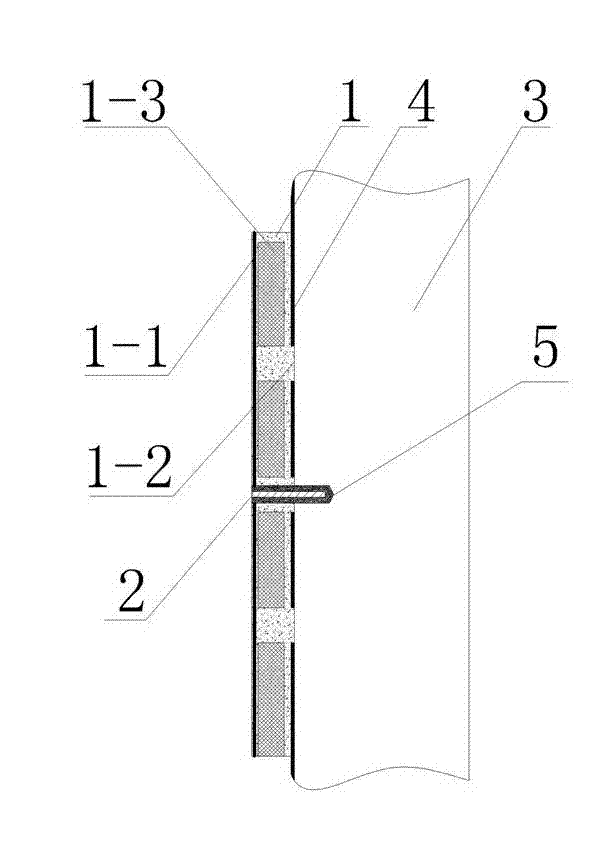

Wall insulation plate mounting structure and mounting method thereof

The invention relates to a wall insulation plate mounting structure and a mounting method thereof. The wall insulation plate mounting structure comprises an insulation plate sticking on the surface of a formed wall body. Column-shaped protrudes are arranged on the surface of the insulation plate at intervals, through holes are reserved on parts of the column-shaped protrudes. Cantilever beam reinforcing bars inserting inside blind holes reserved on the wall body penetrate through the through holes. Concrete is poured into the through holes and a gap between the insulation plate and the wall body. Portions of the cantilever beam reinforcing bars between ends in the through hole and the wall body are cover by the concrete tightly. The mounting method of the wall insulation plate mounting structure mainly includes drilling on the insulation plate, inserting the reinforcing bar, pouring the concrete and the like. The wall insulation plate mounting structure has the advantages of fixed mounting, capacity of sharing same service life with the wall body and the like.

Owner:SUZHOU SHIHAO BUILDING MATERIAL NEW TECH ENG

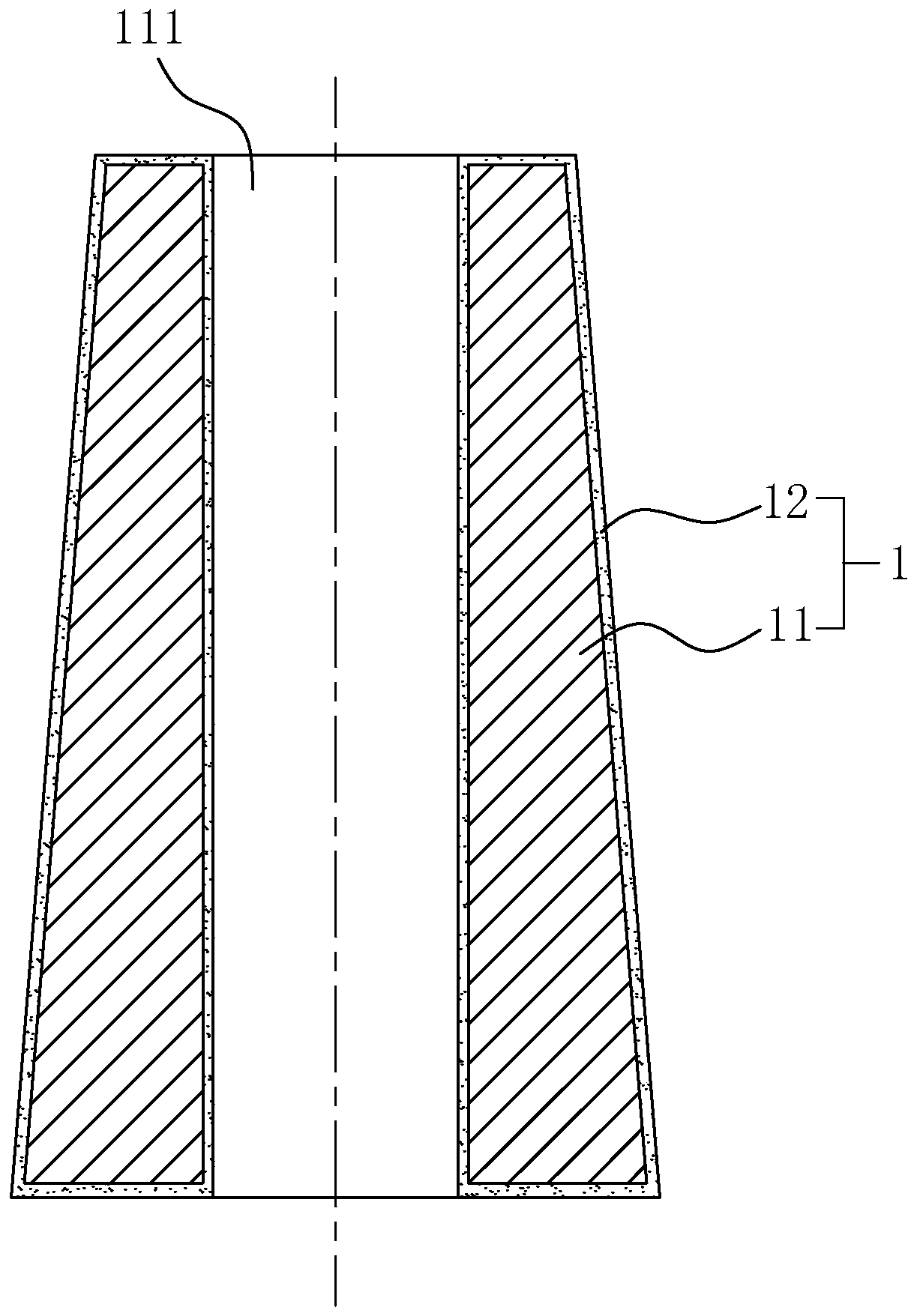

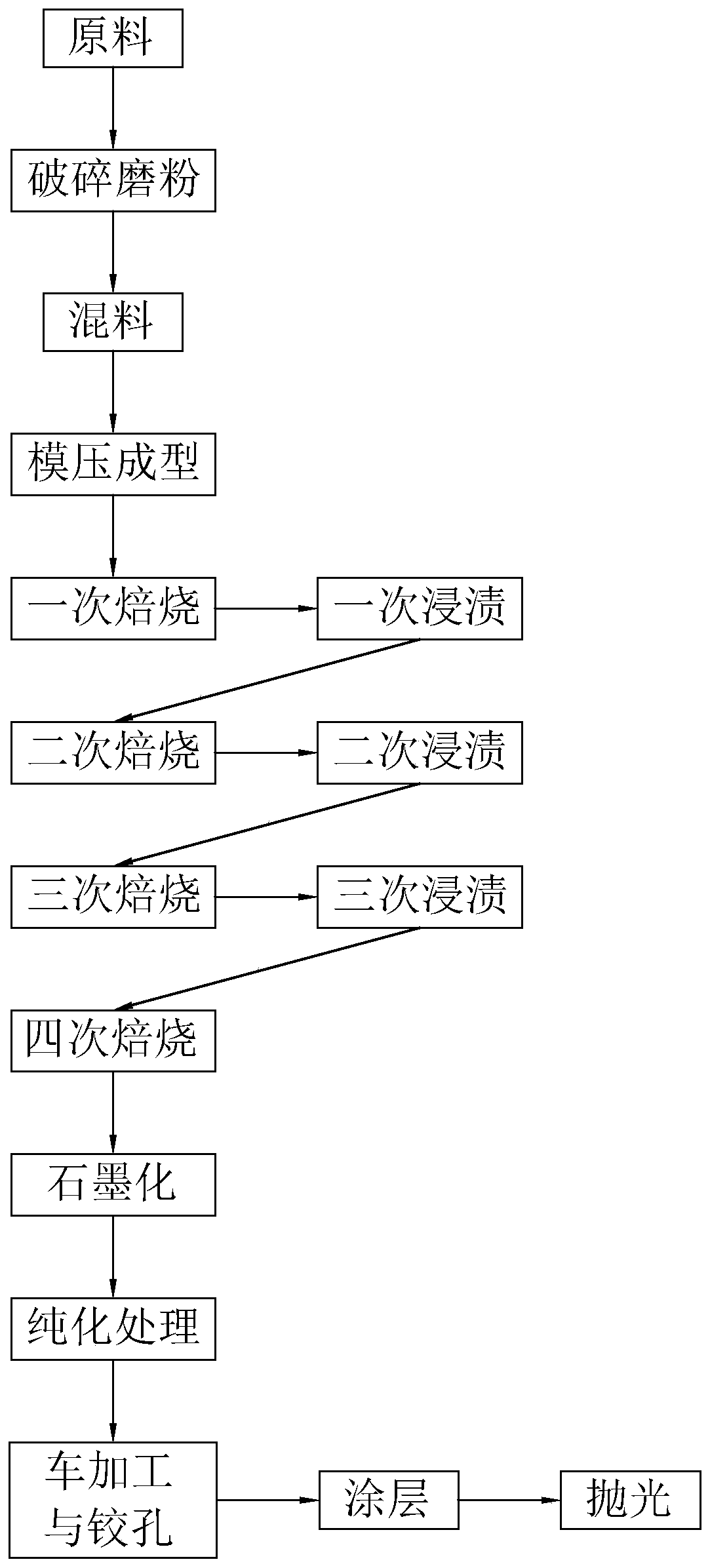

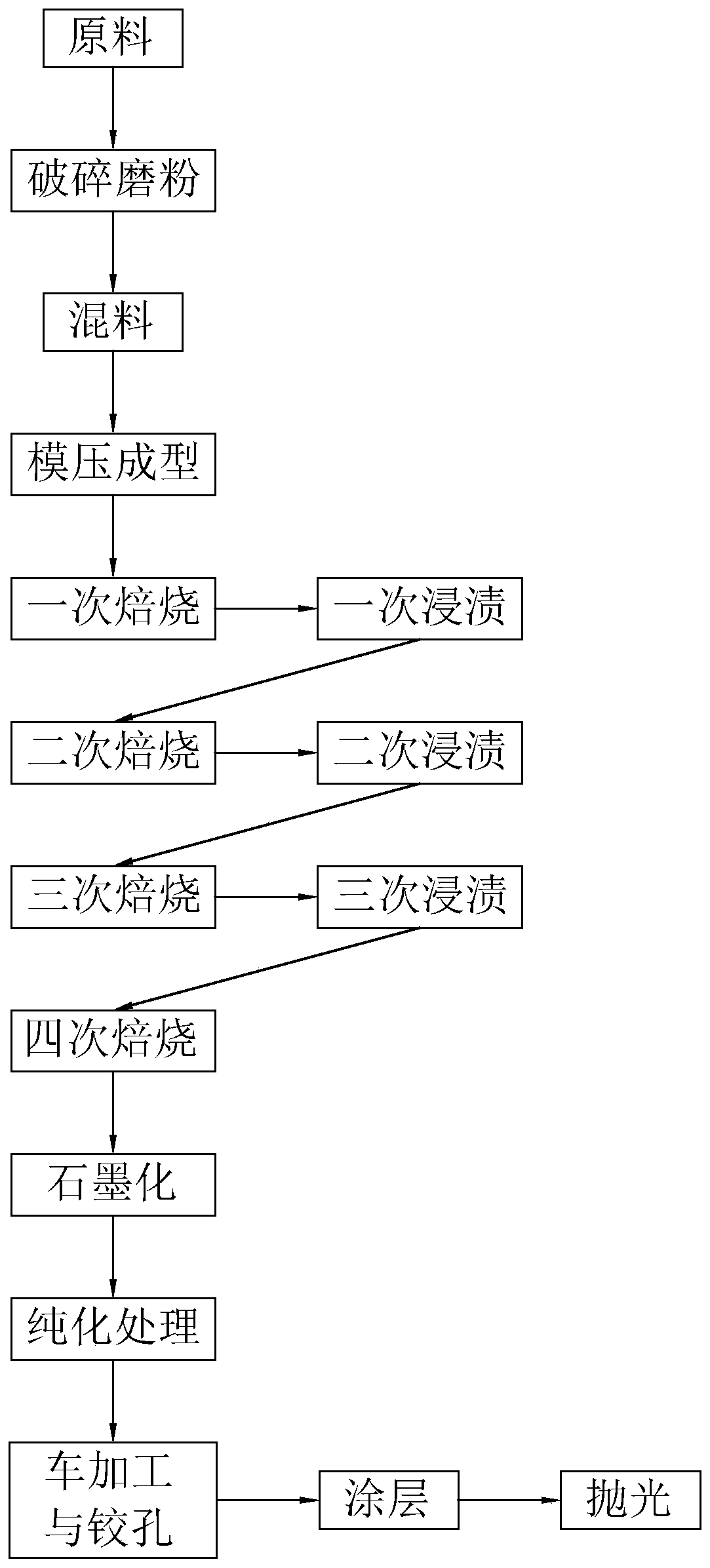

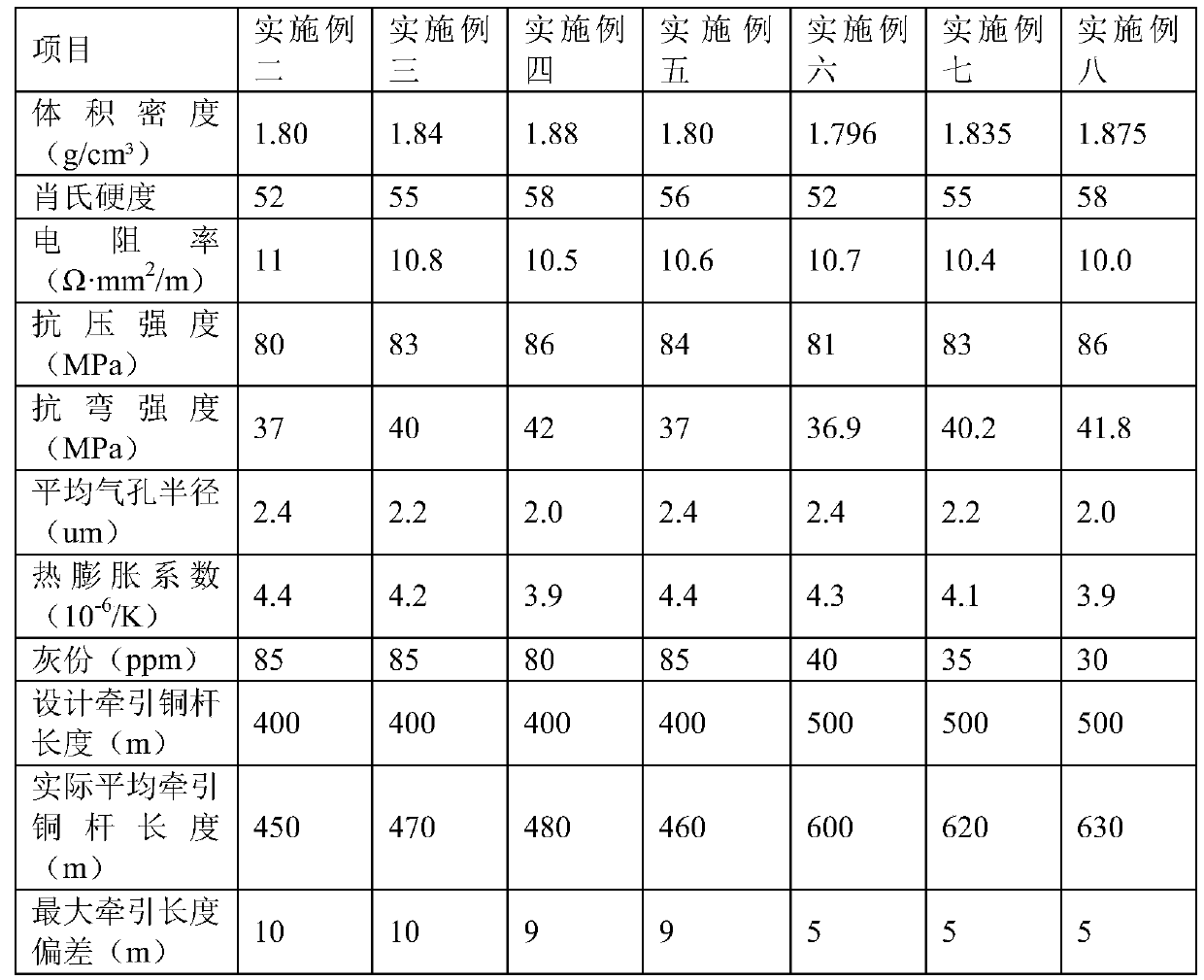

High-speed rail wire alloy copper rod continuous casting crystallizer and production process thereof

ActiveCN109702156AStable lifeEasy to change regularlyFoundry mouldsFoundry coresSurface roughnessGraphite

The invention discloses a high-speed rail wire alloy copper rod continuous casting crystallizer and a production process thereof, and relates to the technical field of crystallizers. According to thetechnical scheme, the crystallizer is characterized by comprising a graphite tube body, wherein the fixed carbon content of the graphite tube body is not lower than 99.95%, the density of the graphitetube body is 1.80-1.88 g / cm<3>, a through hole penetrating through the graphite tube body is formed in the axis, the roughness of the inner surface of the through hole is at least Ra 0.8, and a pyrolytic carbon coating with the thickness of 4-6 microns is coated on the side wall of the through hole of the graphite tube body. According to the high-speed rail wire alloy copper rod continuous casting crystallizer, the problem that due to the fact that the service life of an existing crystallizer for copper rod continuous casting is not stable, the production of a copper rod for the high-speed rail is affected is solved, three times of immersion, four times of baking and purification treatment are carried out on graphite, so that the service life of the graphite crystallizer is prolonged, andthe stability of the graphite crystallizer is improved.

Owner:青岛卓越碳素制品有限公司

Deformation protection structure of underground pipeline and construction method

PendingCN114150701AEffective protectionAvoid direct loadingCable installations on groundArtificial islandsArchitectural engineeringDeformation control

The invention discloses a deformation protection structure of an underground pipeline and a construction method, and aims to guarantee the safety of the buried underground pipeline under the conditions of ground overload and close soil disturbance, the protection structure comprises a small groove and a foundation cushion layer which are arranged at the bottom of a groove, a pipe seat pillow base is placed in the small groove, and a pipe seat is placed in the pipe seat pillow base. An underground pipeline is placed on the pipe seat pillow base, supporting retaining walls are arranged above the foundation cushion layer, the supporting retaining walls on the two sides and the foundation cushion layer form a cavity, foamed cement light soil is cast into the cavity in a cast-in-place mode to package the pipeline, geotechnical bags are fully laid between the supporting retaining walls and the groove side slope, and the structure further comprises a bearing top plate arranged above the supporting retaining walls in a covering mode. The protection system is mainly used for solving the problem that in the existing urban road construction process, nearby pipelines are deformed and damaged and are difficult to protect, effective deformation control and protection can be conducted on the nearby pipelines in road construction, and the protection system and a pipeline structure are the same in service life, construction is convenient and rapid, and certain waterproof and damping protection effects are achieved.

Owner:HUAHAI ENG CO LTD OF CREC SHANGHAI +2

Device of representing a video image based on video frequency signal

InactiveCN1739300BLifespan has no effectNo image artifactsElectric lighting sourcesPicture reproducers using projection devicesElectrical polarityHigh pressure

The invention relates to a method of representing a video image based on a video signal by means of a projector which comprises an image display device and a high-pressure gas discharge lamp, which lamp is supplied with a square-wave alternating current (I0, I10) on which a current pulse (P1, P3, P10, P40) is superimposed before each phase reversal. According to the invention, the alternating current (I0, I10) is superimposed with a second current pulse (P2, P4, P20, P30, P50, P60) of the same polarity. A simple attunement of the alternating current frequency to the image frequency without image artefacts is made possible by the second pulses (P2, P4, P20, P30, P50, P60).

Owner:SIGNIFY HLDG BV

Preparation method of conductive plastics master batch containing stainless steel fibers

ActiveCN101840745BElectromagnetic shielding effect hasHas antistatic effectNon-conductive material with dispersed conductive materialCable/conductor manufacturePolymer scienceElectromagnetic shielding

The invention discloses a preparation method of a conductive plastics master batch containing stainless steel fibers. The stainless steel fibers in the plastics master batch are isolated by macromolecular materials and completely packed by the macromolecular materials. When the plastics master batch as raw materials is mixed with plastics for secondary granulation or a conductive plastic work-piece is formed, the stainless steel fibers can resist high shear force when the plastics are processed, and are easily and uniformly dispersed in the plastic work-piece and overlap to each other to forma three-dimensional conductive network. By adopting the conductive plastics master batch, the ideal antistatic and electromagnetic screen effects can be achieved under the circumstance of low contentof the stainless steel fiber.

Owner:HUNAN HUITONG ADVANCED MATERIALS

Prefabricated coal gangue thermal insulation concrete shear wall plate

InactiveCN114562058AHarm reductionFriendly and unified developmentWallsClimate change adaptationThermal insulationEngineering

A prefabricated coal gangue heat preservation concrete shear wall plate is formed by pouring coal gangue concrete, longitudinal steel bars and stirrups, and square holes are formed in the shear wall in the height direction. The axes of the square holes in the coal gangue concrete hollow shear wall plate are consistent with the height direction, and the square holes are evenly distributed in the width direction. The square holes are filled with the heat preservation cotton, and the heat preservation effect can be achieved. The coal gangue concrete is adopted to replace common concrete, waste of coal gangue resources can be avoided, harm to the environment due to random stacking of coal gangue can be relieved, huge economic benefits and environmental benefits are created, and meanwhile the coal gangue concrete has great practical significance in resource recycling and environmental protection. And unified development of resource saving and environment friendliness is realized. According to the prefabricated coal gangue heat preservation concrete shear wall plate, a building heat preservation system and a structure have the same service life, the secondary heat preservation decoration cost of the structure is saved, the total cost is reduced, and good application prospects and economic values are achieved.

Owner:LIAONING TECHNICAL UNIVERSITY

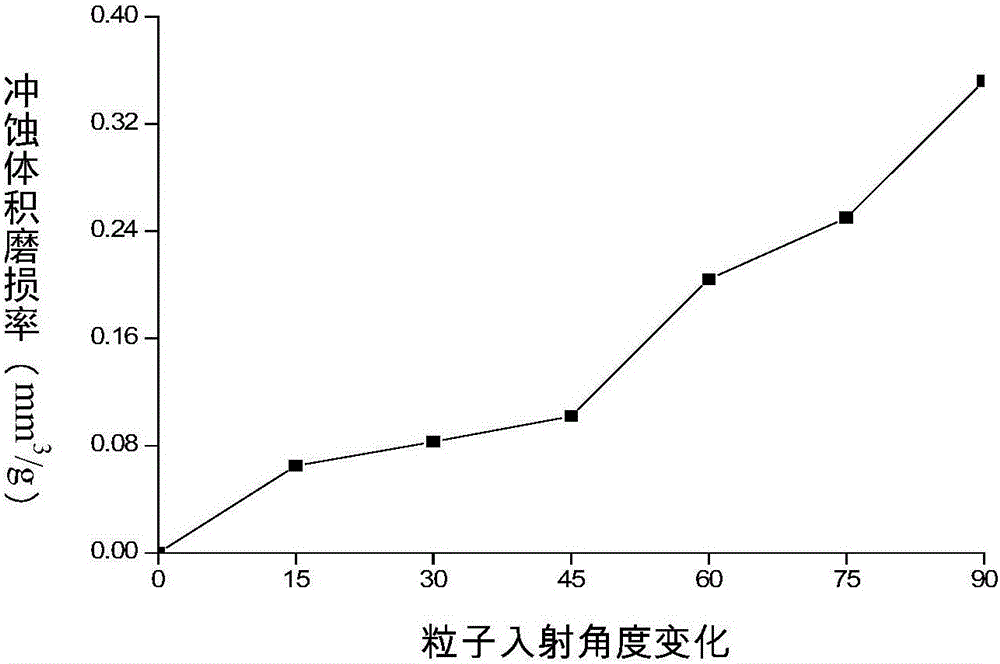

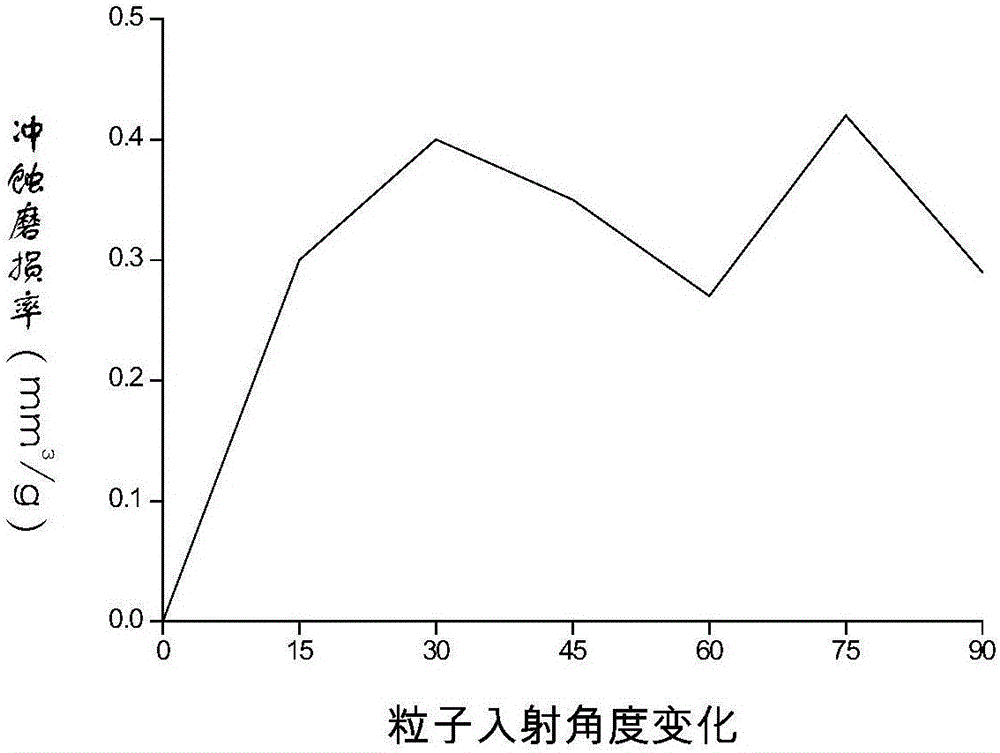

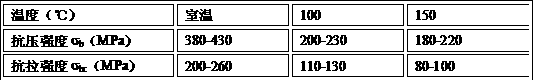

A kind of coating combination for motor car head

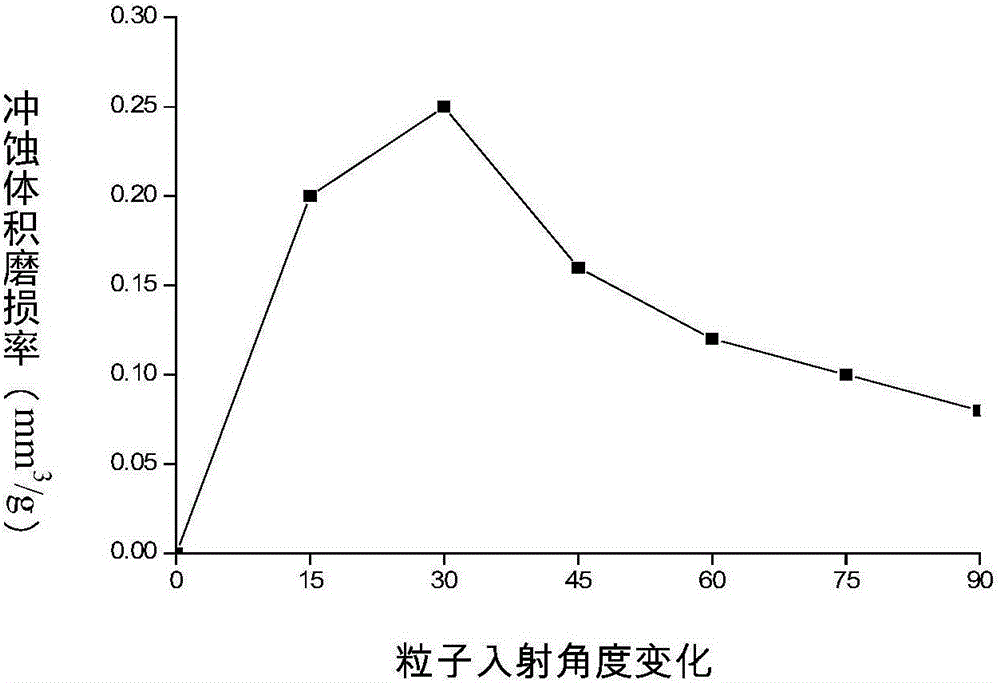

ActiveCN104530945BSame lifespanImprove frontal erosion resistanceMolten spray coatingAnti-corrosive paintsCeramic coatingHardness

The invention relates to an erosion-resistant coating combination for bullet train locomotives. The coating combination comprises a modified polyurethane resin composite coating sprayed at the tip of a locomotive, and a hard ceramic coating sprayed on the inclined plane of the locomotive. The spraying of the high toughness coating on the tip of the locomotive effectively improves the front side erosion resistance; the spraying of the high hardness coating on the inclined plane effectively improves the scratch resistance; the locomotive coating combination can guarantee that the life of the tip of the locomotive is basically same to the life of the coating of in the position of the inclined plane, and is suitable for unified replacement; and the service life of the locomotive coating is above 3 times higher than the service life of present coatings.

Owner:广东空天科技研究院(南沙)

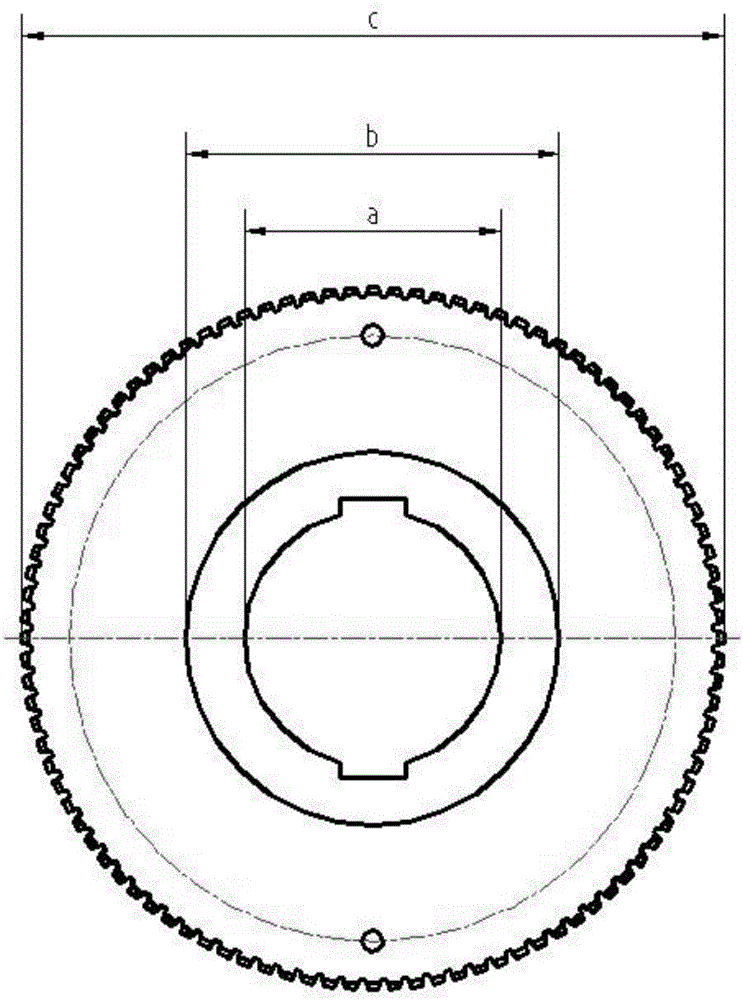

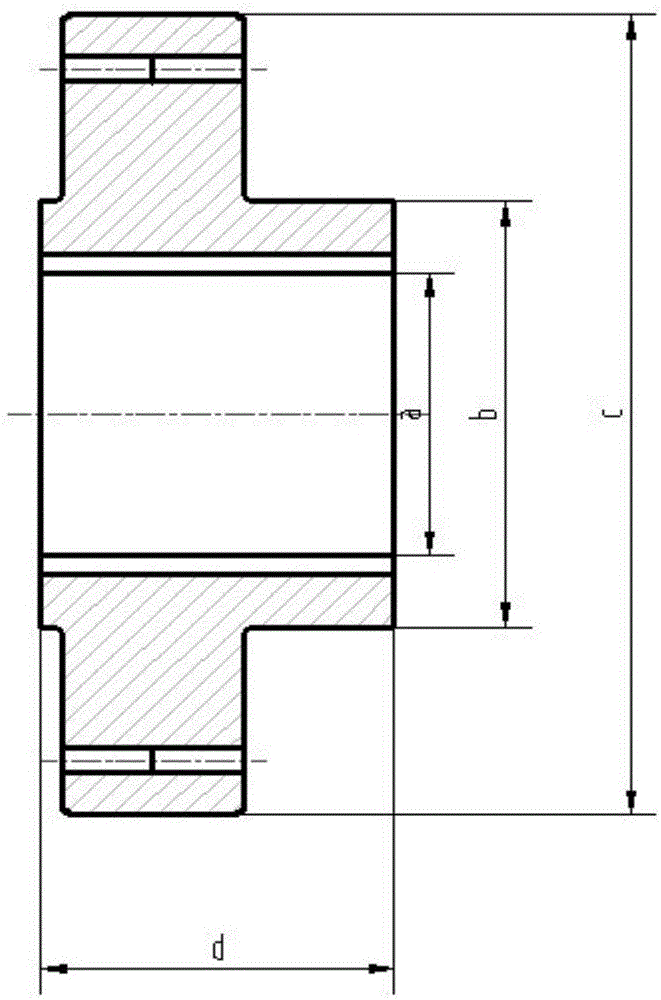

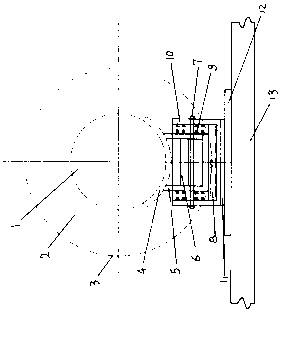

A kind of processing method of nitriding gear

The invention discloses a processing method for nitrided gears which mainly solves the problem of deformation of parts in the course of processing a nitrided gear. The method comprises the following steps: I, rough turning the outer circle and the inner hole; II, performing heat treatment until the HBS reaches 260-300; III, finish turning parts; IV, tinning; V, milling the gear; VI, nitriding; VII, grinding the end surface; VIII, grinding the inner hole; IX, slotting and processing the key groove by utilizing a slotting tool; X, the lathing phi 160 (minus 0.05 / minus 0.20) hub outer circle b to be coaxial with the inner hole a by 0.015 mm, and lathing the two end faces to be perpendicular to the inner hole a by 0.015 mm; XI, grinding the gear tooth form; XII, marking a drilling hole, and finishing nitrided gear processing. The processing method for nitrided gears is used for preparing nitrided gears.

Owner:HARBIN TURBINE

Wall insulation board installation structure and installation method

The invention relates to a wall insulation plate mounting structure and a mounting method thereof. The wall insulation plate mounting structure comprises an insulation plate sticking on the surface of a formed wall body. Column-shaped protrudes are arranged on the surface of the insulation plate at intervals, through holes are reserved on parts of the column-shaped protrudes. Cantilever beam reinforcing bars inserting inside blind holes reserved on the wall body penetrate through the through holes. Concrete is poured into the through holes and a gap between the insulation plate and the wall body. Portions of the cantilever beam reinforcing bars between ends in the through hole and the wall body are cover by the concrete tightly. The mounting method of the wall insulation plate mounting structure mainly includes drilling on the insulation plate, inserting the reinforcing bar, pouring the concrete and the like. The wall insulation plate mounting structure has the advantages of fixed mounting, capacity of sharing same service life with the wall body and the like.

Owner:SUZHOU SHIHAO BUILDING MATERIAL NEW TECH ENG

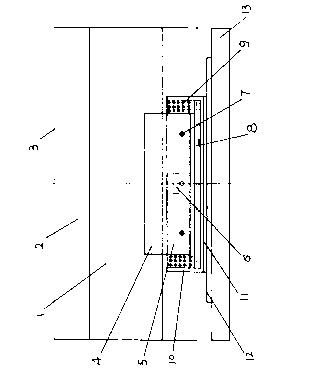

Sliding support arranged on 150 DEG C heat supply overhead pipeline and used for preventing heat bridge from transferring heat

InactiveCN103104784ASame lifespanAvoid heat transferThermal insulationPipe protection by thermal insulationEpoxyCalcium silicate

The invention discloses a sliding support arranged on a 150 DEG C heat supply overhead pipeline and used for preventing a heat bridge from transferring heat . The problem that a heat bridge effect easily happens in an existing device is solved. A polyfluortetraethylene plate (11) is movably placed on a pre-buried steel plate (12), a high-strength heat insulation epoxy resin bracket (10) with a pit is arranged on the polyfluortetraethylene plate (11), an arc-shaped top surface bracket (5) is arranged in the pit of the high-strength heat insulation epoxy resin bracket (10), a glass wool insulating layer (9) is placed between the outer side face of the arc-shaped top surface bracket (5) and the inner side face of the high-strength heat insulation epoxy resin bracket (10), and a calcium silicate hard heat insulation board (8) is placed between the pit bottom of the high-strength heat insulation epoxy resin bracket (10) and the outer bottom of the arc-shaped top surface bracket (5). According to the sliding support arranged on the 150 DEG C heat supply overhead pipeline and used for preventing the heat bridge from transferring the heat, heat transfer between a heat transferring steel pipe and the sliding support is effectively cut off.

Owner:CEEC SHANXI ELECTRIC POWER EXPLORATION & DESIGN INST

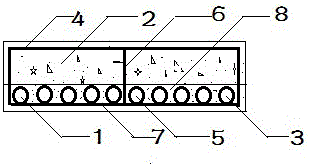

Lightweight aggregate concrete superposed slab integrating dual functions of load-bearing and heat radiation

InactiveCN106437008AHigh strengthImprove thermal conductivityConstruction materialExpanded clay aggregateMaterials processing

The invention relates to a lightweight aggregate concrete superposed slab integrating dual functions of load-bearing and heat radiation. The invention adopts the technical scheme that the lightweight aggregate concrete superposed slab comprises three stages: slab design, material processing and slab casting molding. Straw lightweight aggregate concrete is taken as upper-layer concrete for the slab, and lower-layer concrete adopts ordinary ceramsite lightweight aggregate concrete. After being subjected to overall pouring molding together with high-performance geothermal coils arranged in a snake shape or galvanized steel pipe meshes, the ceramsite lightweight aggregate concrete is superposed with the straw lightweight aggregate concrete on the upper layer, so that the straw lightweight aggregate concrete superposed slab integrating the dual functions of load-bearing and heat radiation is made. Each of heat radiation pipes in the slab has two functions of load-bearing and heat radiation; heat radiation pipe meshes not only are taken as tensile steel bars for the slab to jointly bear the load of the slab together with steel wires in steel wire meshes, but also are taken as the heat radiation pipes for a slab heat radiator, and the tensile steel bars and the heat radiation pipes are combined. The lightweight aggregate concrete superposed slab provided by the invention is simple to manufacture, convenient to mount and cost-saving and meanwhile has high comfort and an energy-saving effect.

Owner:QIQIHAR UNIVERSITY

Light source device, image projection device, installation method of light source device

ActiveCN107765496BStable light outputSame lifespanLight source combinationsLighting heating/cooling arrangementsEngineeringGreen-light

The present invention relates to a light source device, an image projection device, and an installation method of the light source device. An object of the present invention is to provide an image projection device that not only makes the lifespan of the light-emitting elements in the light sources of each light source unit substantially the same, but also stabilizes the light output of each light source unit and inhibits the A light source device with an enlarged frame and increased noise from the air blower. The light source device (1) is configured such that the blue light source portion (10), the red light source portion (20), and the green light source portion (30) that emit light in different wavelength bands have blue light source elements (9) of the same type that have substantially the same lifespan. When isochronous, the heat dissipation portion of each light source portion is provided as follows. That is, when the calorific value of the light source in each light source unit is set to Q, and the set temperature that the light-emitting element in the light source of each light source unit must not exceed in order to obtain the predetermined light intensity and life is set to T, according to the In order of increasing T / Q value, the heat dissipation parts of each light source part are arranged in order from the upstream to the downstream of the cooling air duct.

Owner:RICOH KK

Photovoltaic laminate and preparation method thereof, photovoltaic module and photovoltaic packaging structure

ActiveCN105609576BAging Unrecognized Risk AvoidanceSame lifespanFinal product manufactureSemiconductor/solid-state device detailsEngineeringBackplane

The invention relates to a photovoltaic lamination element. The photovoltaic lamination element comprises a transparent cover plate, a first sealing layer, a battery piece layer, a second sealing layer and a backplate, which are sequentially laminated, wherein the battery piece layer comprises a plurality of connected battery pieces, the photovoltaic lamination element also comprises a convergence strip, an insulation sheet and an identification code structure, and the identification code structure is formed on the convergence strip or the insulation sheet. In the above photovoltaic lamination element, the identification code structure is directly formed on the convergence strip or the insulation sheet, manual sticking is not needed, the formation of the identification code structure is automatically achieved by a machine, and the product cost is reduced; moreover, the identification code structure is difficult to age and cannot be layered, and the problem that the identification code structure cannot be identified is prevented; and the photovoltaic lamination element is attractive in appearance, and the product competiveness is enhanced. The invention also provides a fabrication method of the above photovoltaic lamination element and a photovoltaic module and a photovoltaic package structure containing the photovoltaic lamination element.

Owner:ZHANGJIAGANG GCL INTEGRATION TECH CO LTD

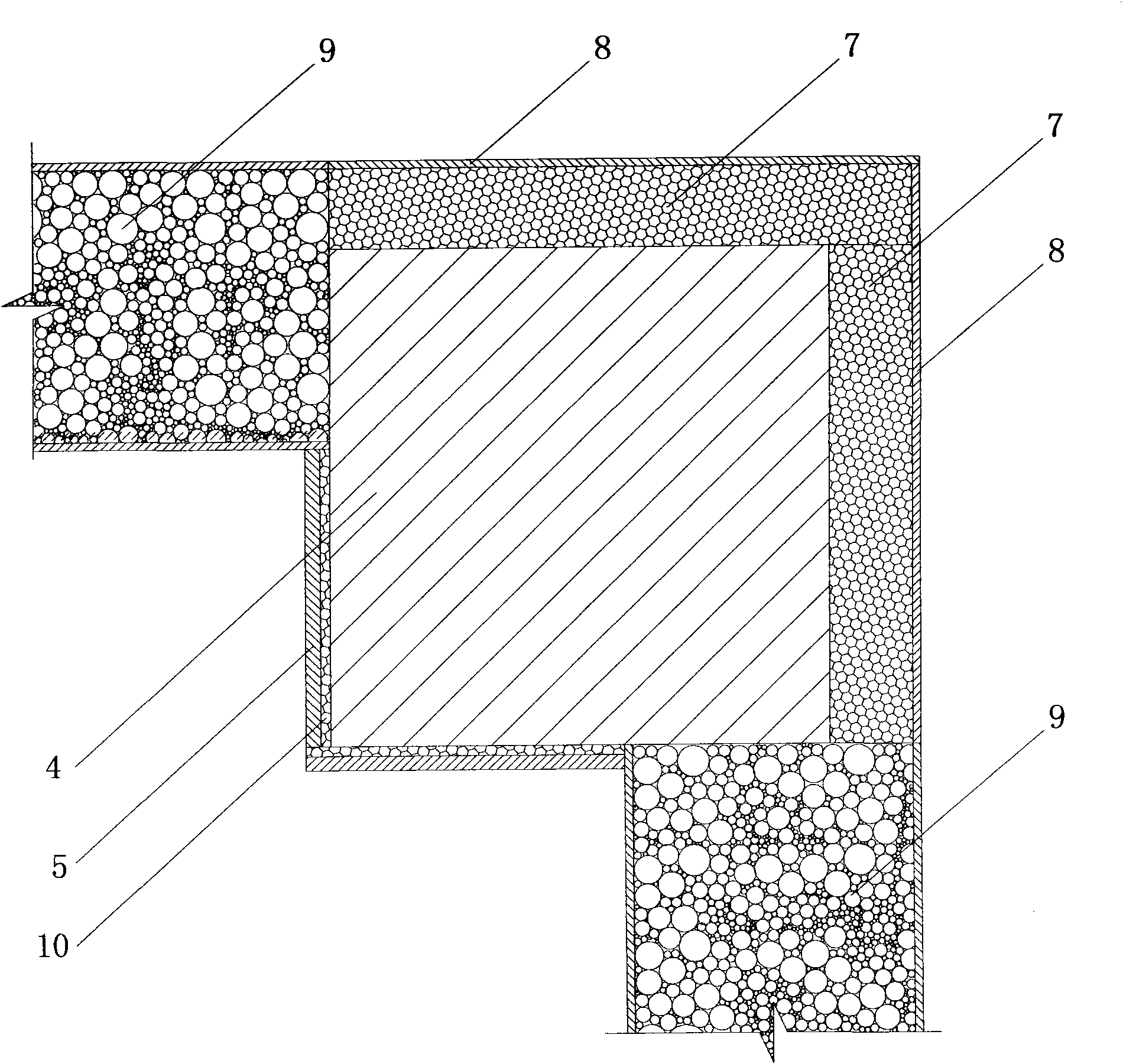

Novel self-molding self-insulation building corner column

InactiveCN102787694AReduce construction proceduresImprove construction progressStrutsWallsThermal insulationRebar

The invention discloses a novel self-molding self-insulation building corner column. An infilled wall 9 is built at first. The infilled wall 9 has functions of filling and heat preservation. The infilled wall 9 is a special self-insulation bar-type wall plate or other building material or a self-insulation infilled wall cast on site. Side surfaces of the infilled wall 9 are used as side molds. The side surfaces, a columnar mold plate 5 and a columnar mold plate 8 compose a columnar casting chamber 4. Rebars are put into the columnar casting chamber 4 and concrete is poured into the columnar casting chamber 4 so that a column 4 is obtained. A thermal insulation material 7 blocks a cold bridge at the column 4. The columnar mold plate 5 with a thermal insulation material 10 blocks a local cold bridge on a connection surface between the infilled wall 9 and the column 4. After mold plate installation and concrete casting, dismounting of the columnar mold plate 5 with the thermal insulation material 10 and the columnar mold plate 8 with the thermal insulation material 7 is avoided.

Owner:杨怀君

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com