Preparation method of conductive plastics master batch containing stainless steel fibers

A conductive plastic and stainless steel technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve the problems of surface hydrophilicity of materials, poor electromagnetic shielding effect of finished products, and difficult dispersion of fibers and other problems, to achieve excellent antistatic and electromagnetic shielding performance, suitable for large-scale production, and neat appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

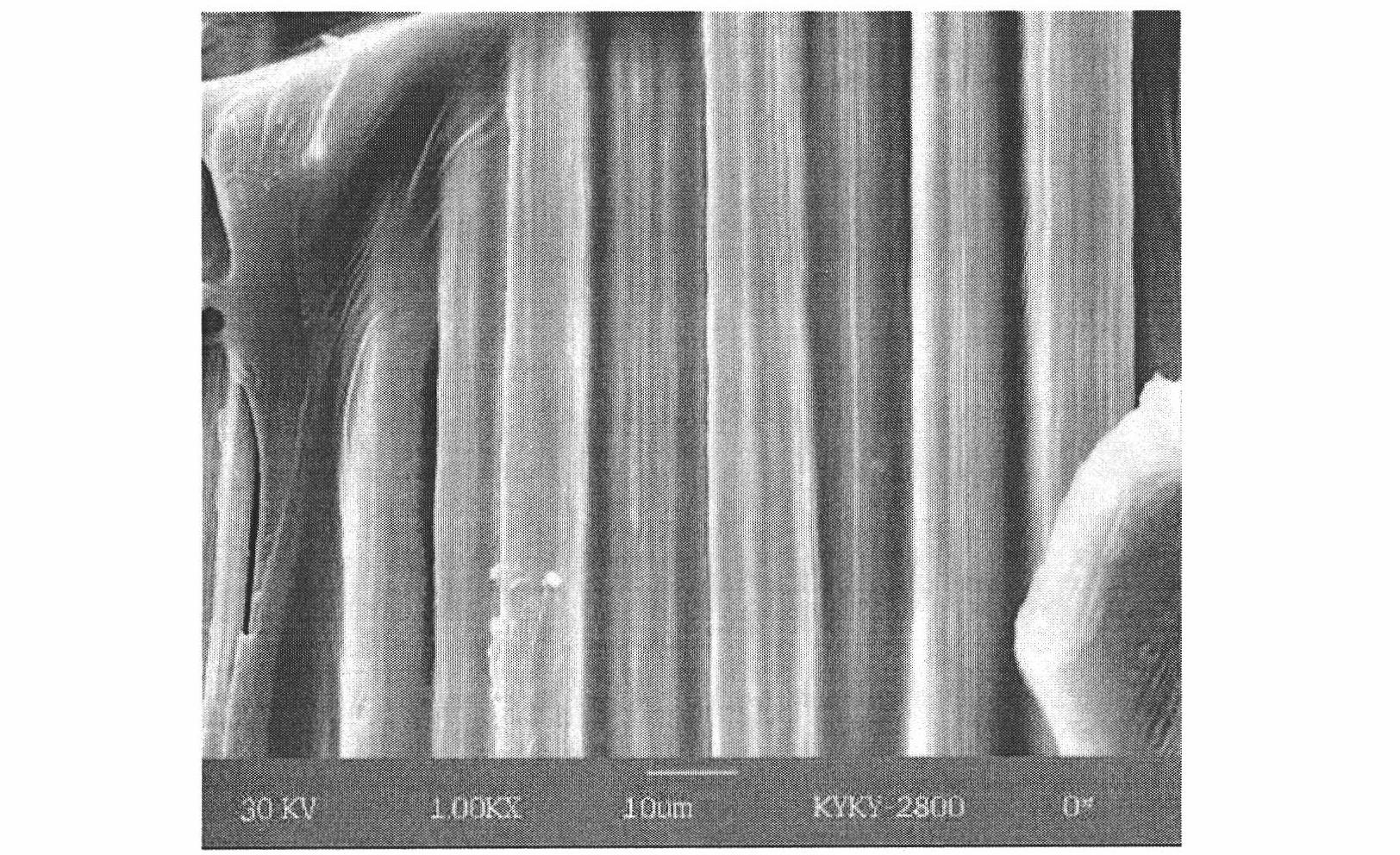

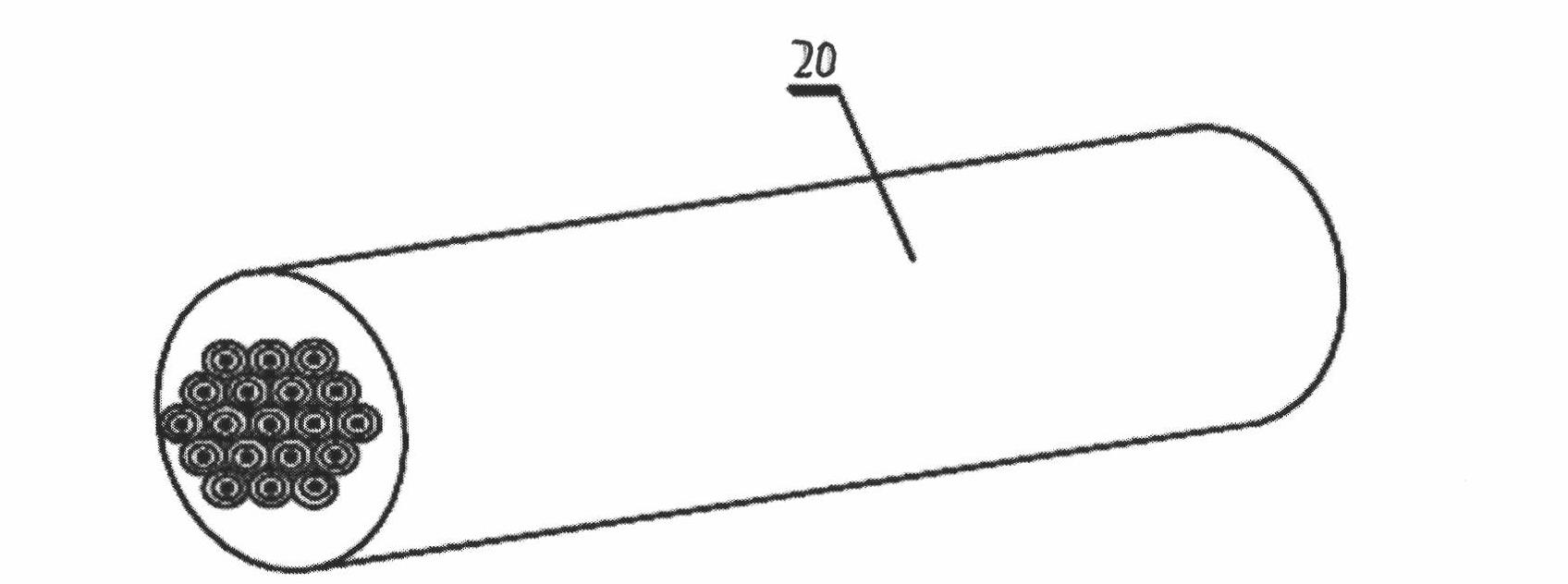

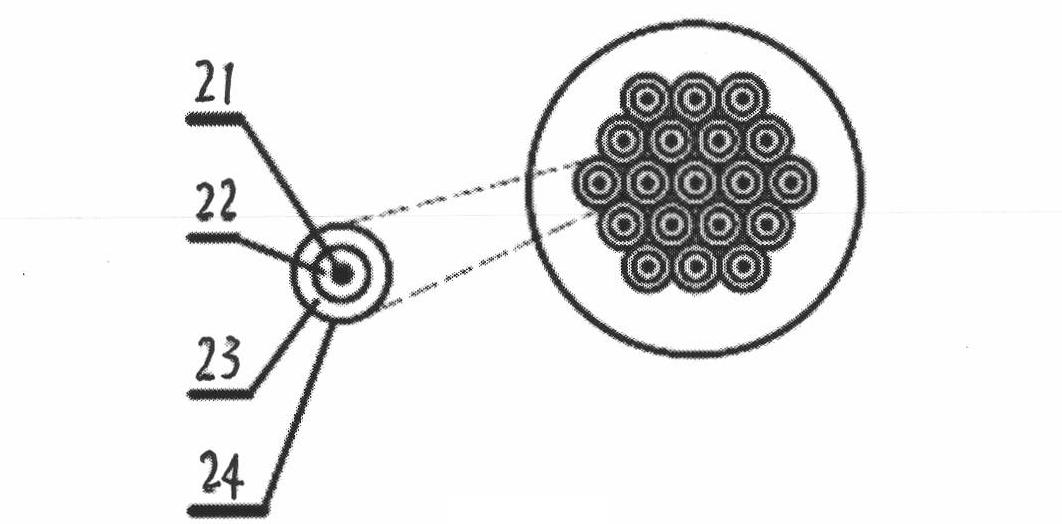

[0056] In the first embodiment, the diameter of the stainless steel fibers in the plastic masterbatch containing stainless steel fibers is 12 μm, the length is 6 mm, and the volume ratio of the stainless steel fibers is 25%. The specific production process is:

[0057] 1) A bundle of continuous stainless steel fibers is immersed in a 3% (Wt%) ethanol solution of tricosyl sodium salt of sulfosuccinate for coupling modification treatment, so that it has a lipophilic modified surface. On the premise of ensuring that the whole bundle of stainless steel fibers is fluffy and fully infiltrated, try to straighten the stainless steel fiber bundles. Dry the treated stainless steel fiber bundles.

[0058] 2) In step 1), the stainless steel fiber is introduced into a polyoxypropylene polyoxyethylene block type polyether ethanol solution (molecular weight is about 2600) with a concentration of 35% (Wt%) for coating, so that the polyoxypropylene polyoxyethylene block Segment polyether for...

Embodiment 2

[0067] Compared with Example 1, the diameter of the stainless steel fibers in the plastic masterbatch containing stainless steel fibers in Example 2 is also 12 μm, and the length is also 6 mm, the difference is that the stainless steel fiber content in the plastic masterbatch is 30v%. The specific production process is:

[0068] 1) A bundle of continuous stainless steel fibers is immersed in an aqueous solution of 3-aminopropyltriethoxysilane with a concentration of 3% (Wt%) for coupling modification treatment, so that it has a lipophilic modified surface. On the premise of ensuring that the whole bundle of stainless steel fibers is fluffy and fully infiltrated, try to straighten the stainless steel fiber bundles.

[0069] 2) The stainless steel fiber is introduced into the methoxybutyl ester solution of 30% (Wt%) propoxy bisphenol A fumaric acid resin with a concentration of 30% (Wt%) and coated, so that the propoxy bisphenol A fumaric acid resin is wrapped around the bundle ...

Embodiment 3

[0077] In the third embodiment, the diameter of the stainless steel fibers in the plastic masterbatch containing stainless steel fibers is 12 μm, the length is 6 mm, and the volume ratio of the stainless steel fibers is about 92%. The specific production process is:

[0078] 1) Immerse a bundle of continuous stainless steel fibers in a 5% (wt%) bis(dioctyloxypyrophosphate) ethylene titanate ethylene-propanol solution for coupling modification to make it lipophilic. sexual surface. On the premise of ensuring that the whole bundle of stainless steel fibers is fluffy and fully infiltrated, try to straighten the stainless steel fiber bundles. Dry the treated stainless steel fiber bundles.

[0079] 2) In step 1), the stainless steel fiber is introduced into a concentration of 30% (Wt%) propoxylated bisphenol A fumaric acid resin, and the methoxybutyl ester solution is coated to make the propoxylated bisphenol A fumaric acid resin The acid resin forms a covering layer on the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com