Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Uniform damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

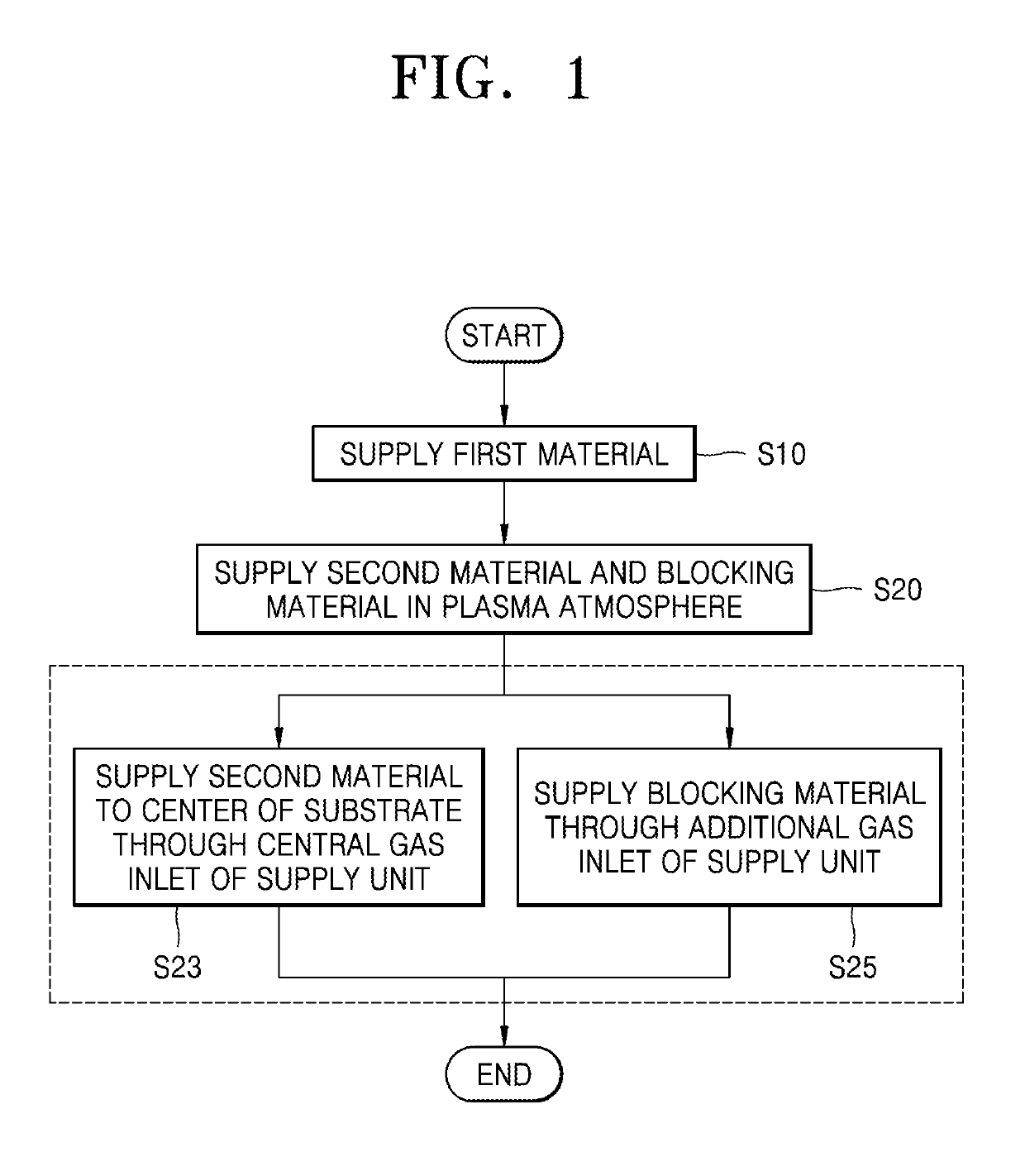

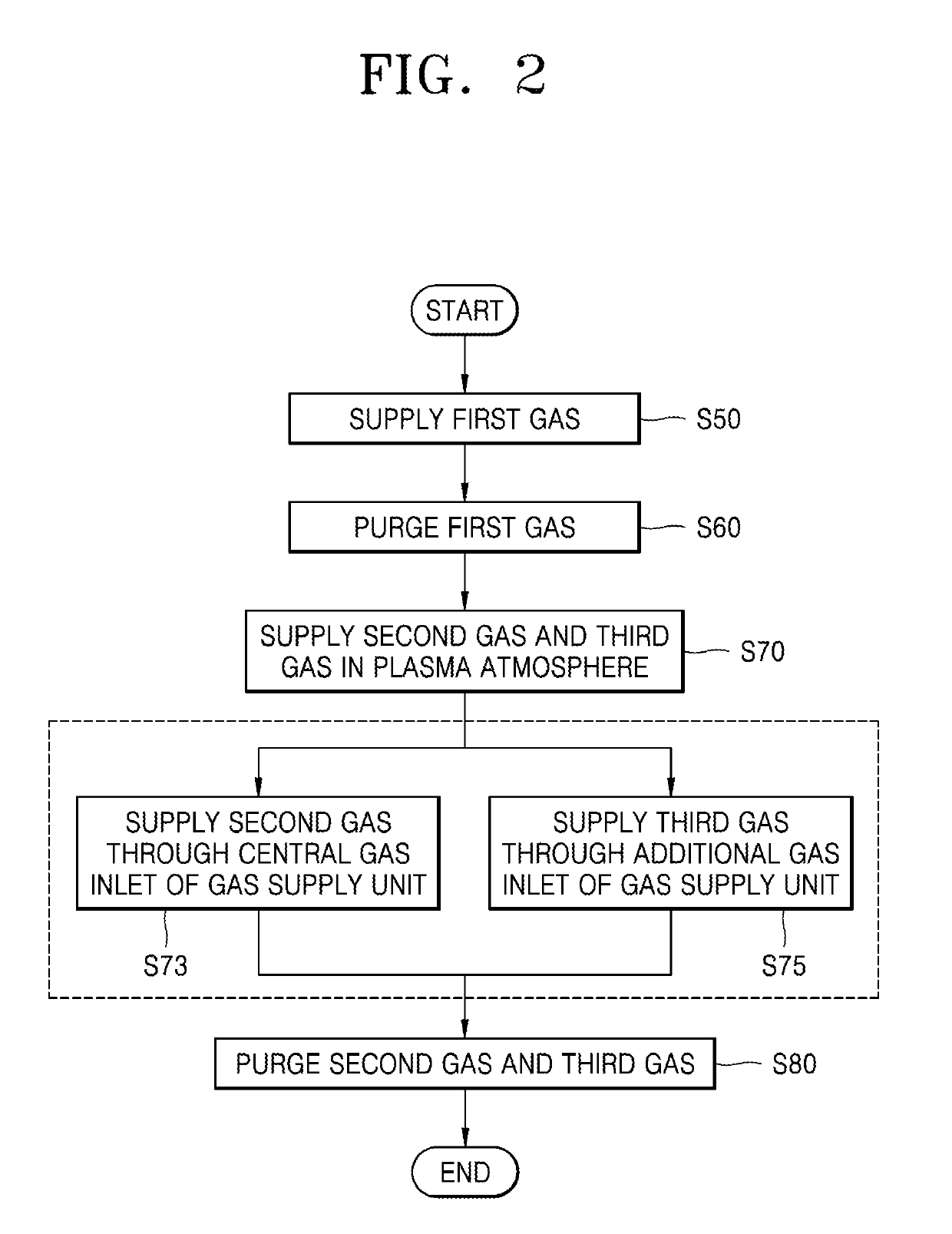

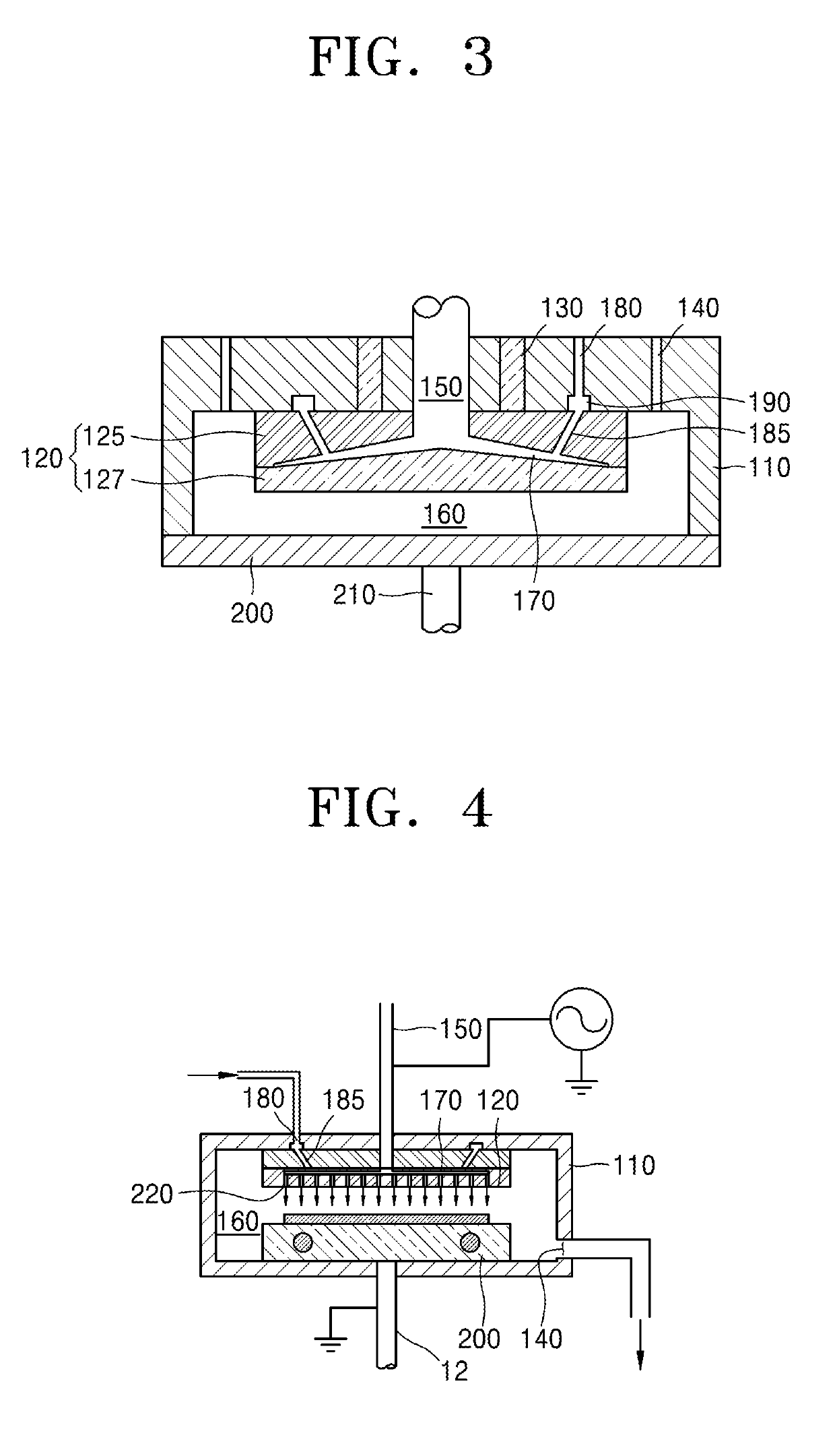

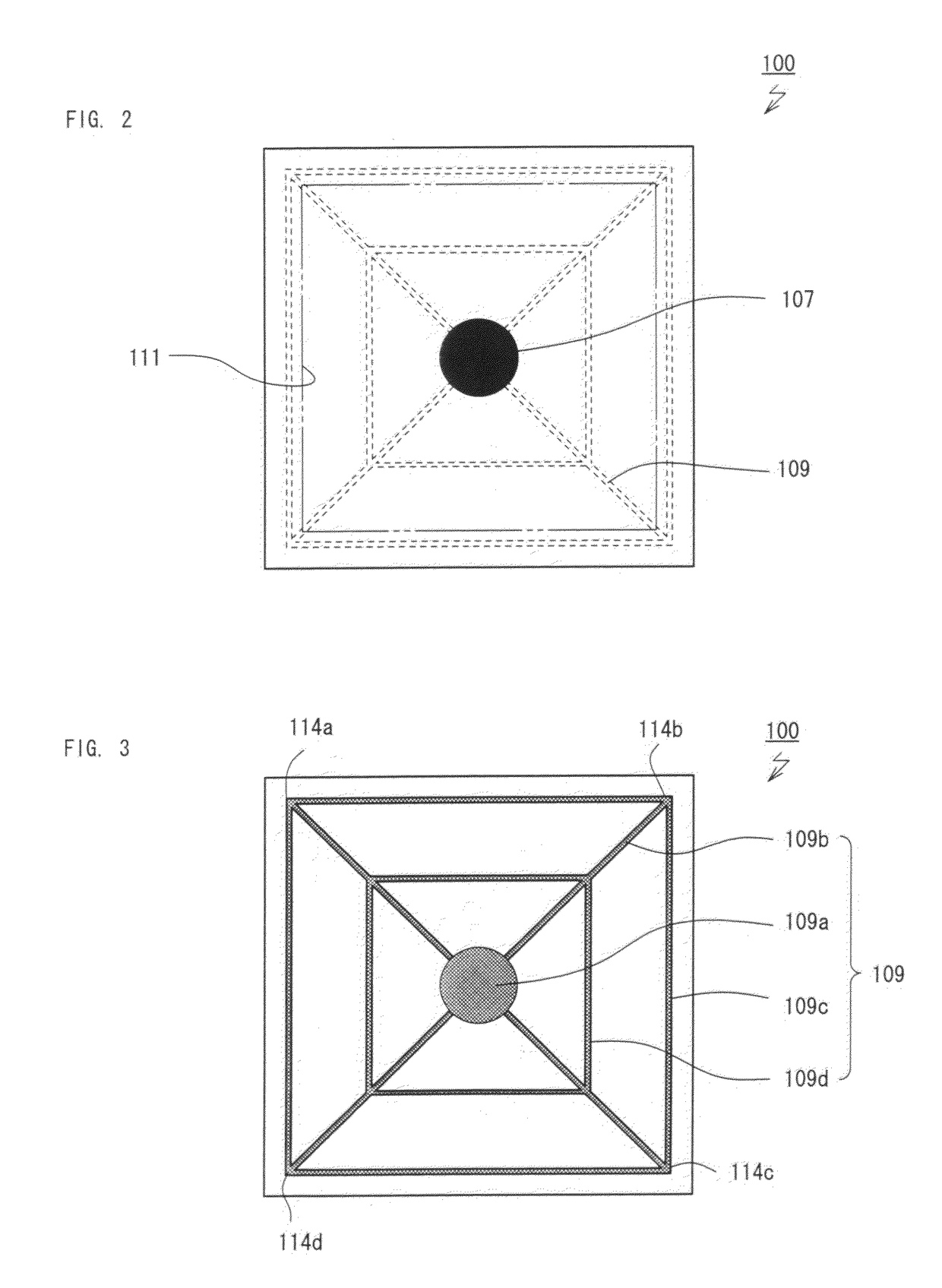

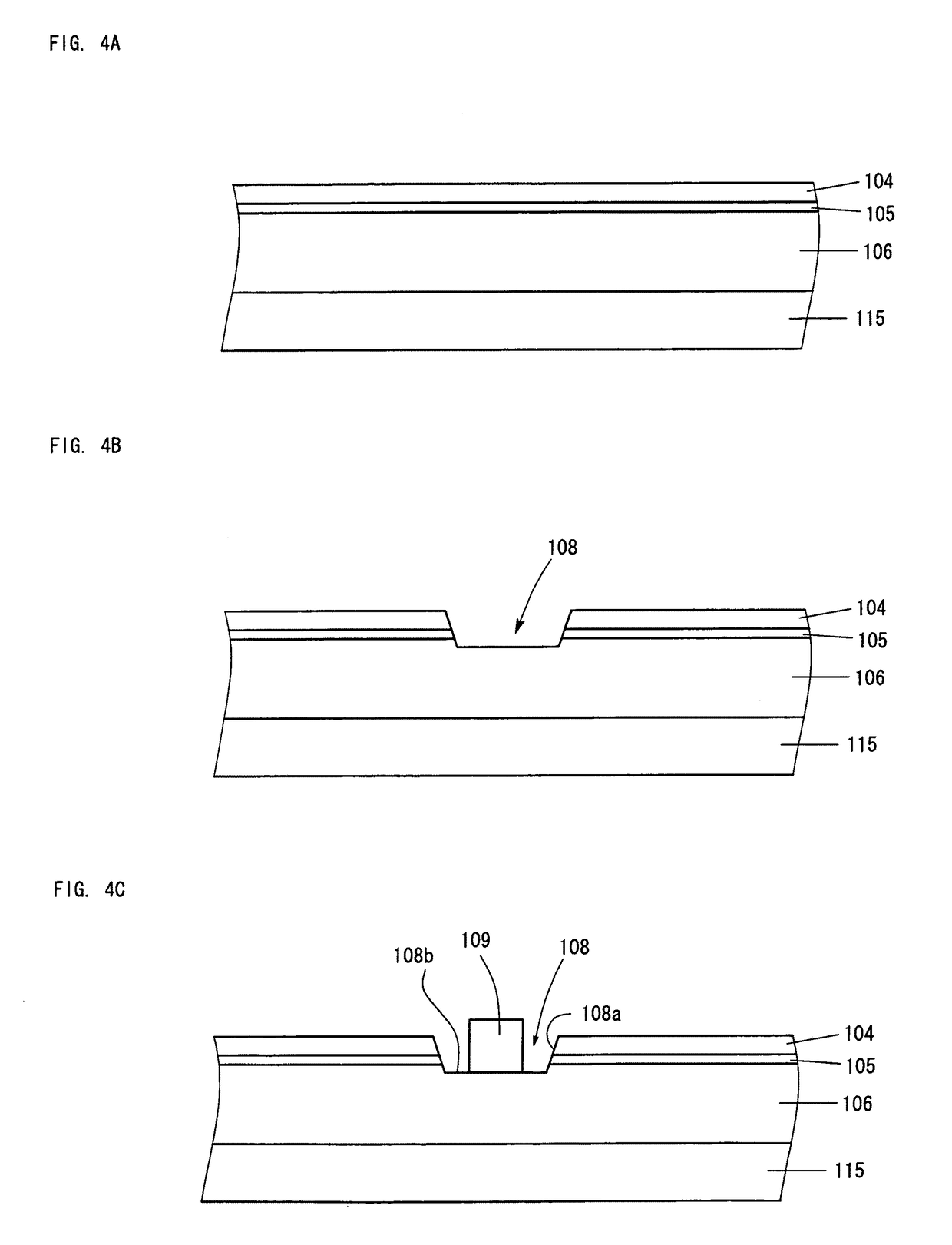

Substrate processing method

ActiveUS20190304776A1High densityUniform damageSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSource materialEngineering

A substrate processing method capable of uniformly maintaining damage to a pattern structure under a thin film formed on a substrate includes supplying a source material to a substrate on which a pattern structure that is reactive with a reactant is formed; and supplying the reactant through at least a central gas inlet of a supply unit in a plasma atmosphere, wherein, during the supplying of the reactant, a blocking material different from the reactant is supplied through an additional gas inlet that is spaced apart from the central gas inlet of the supply unit, and a flow of the blocking material at the edge of the substrate is increased, thereby increasing a radical density of the reactant near a center of the substrate.

Owner:ASM IP HLDG BV

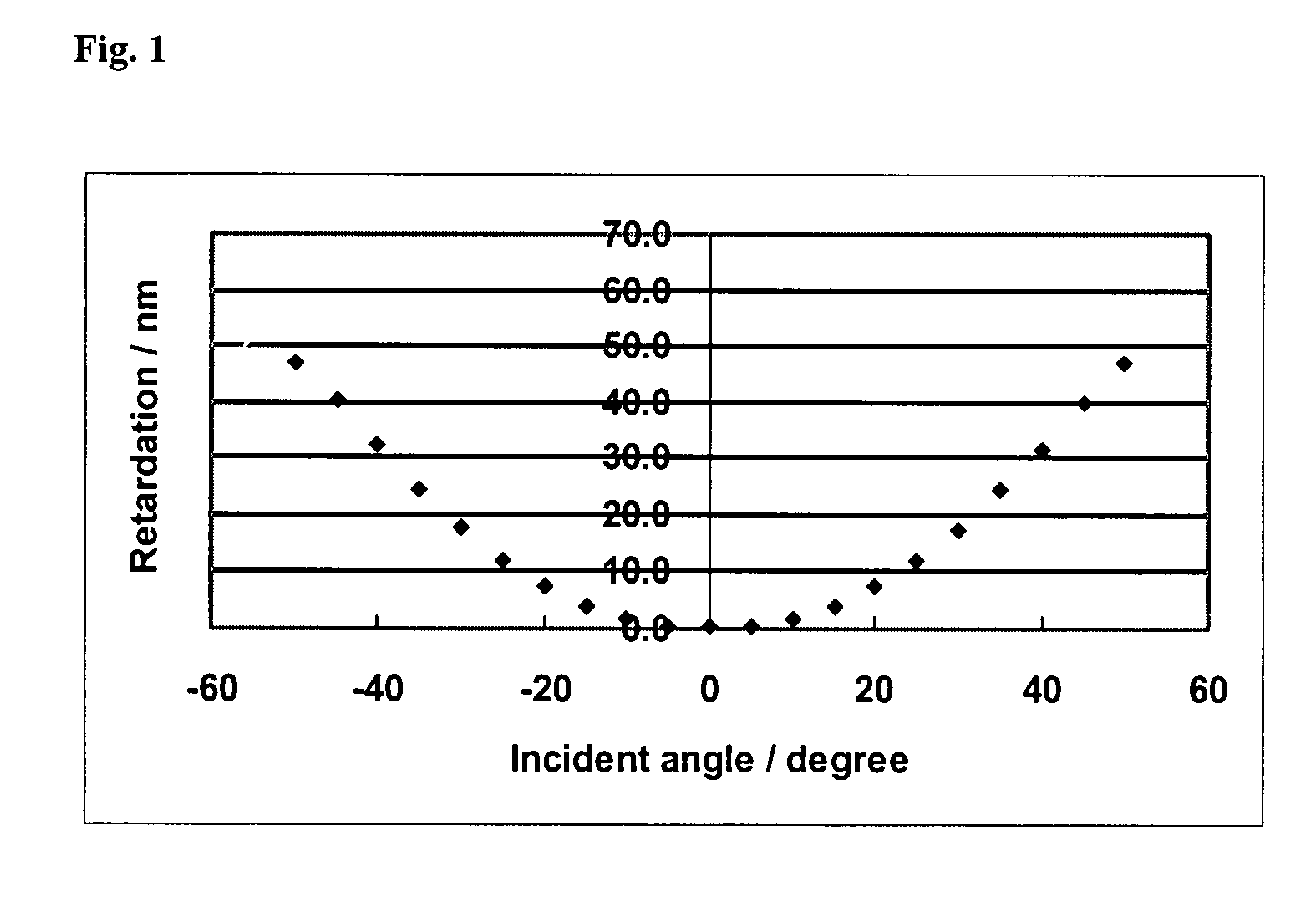

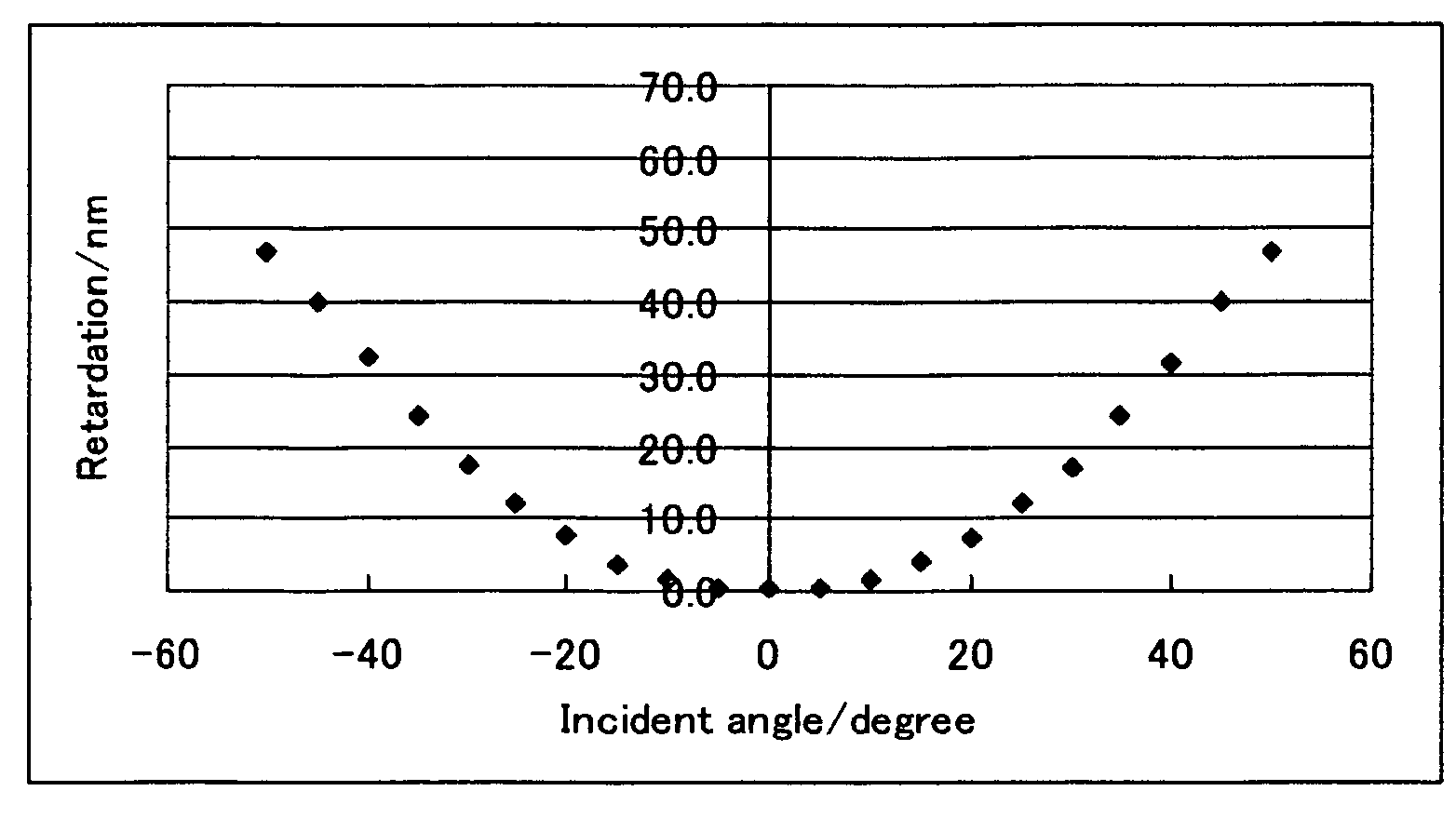

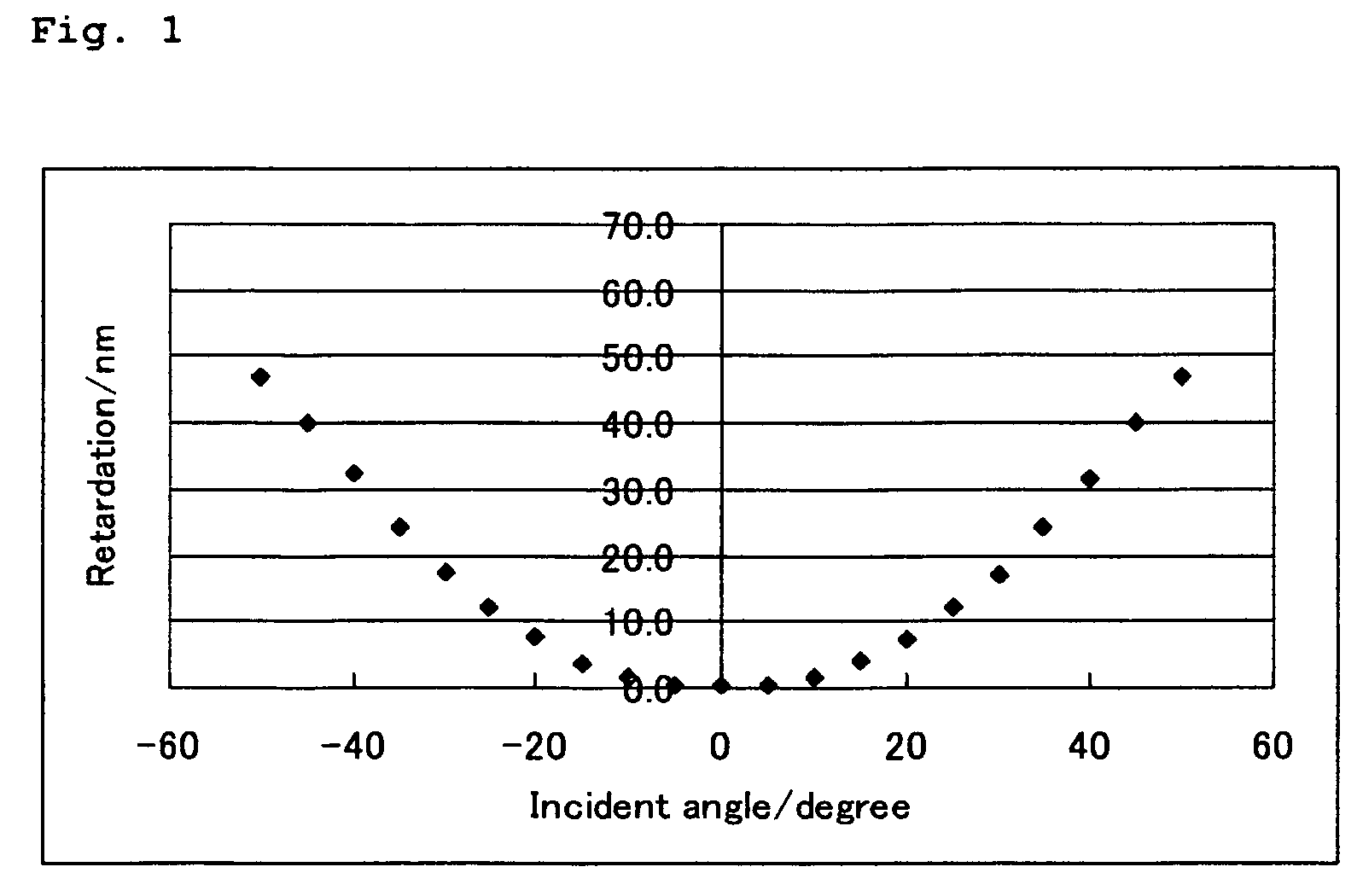

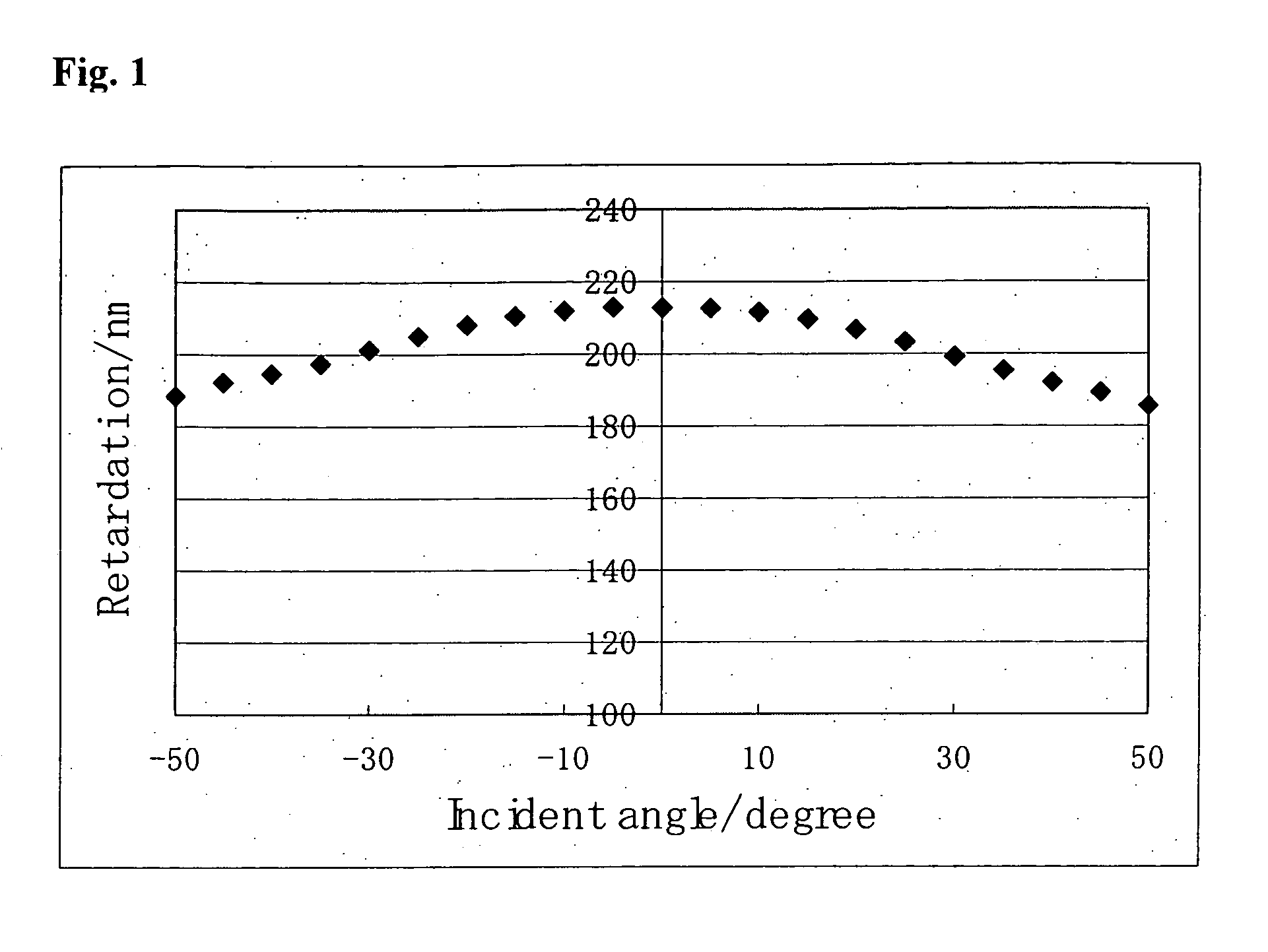

Polymerizable liquid crystal composition

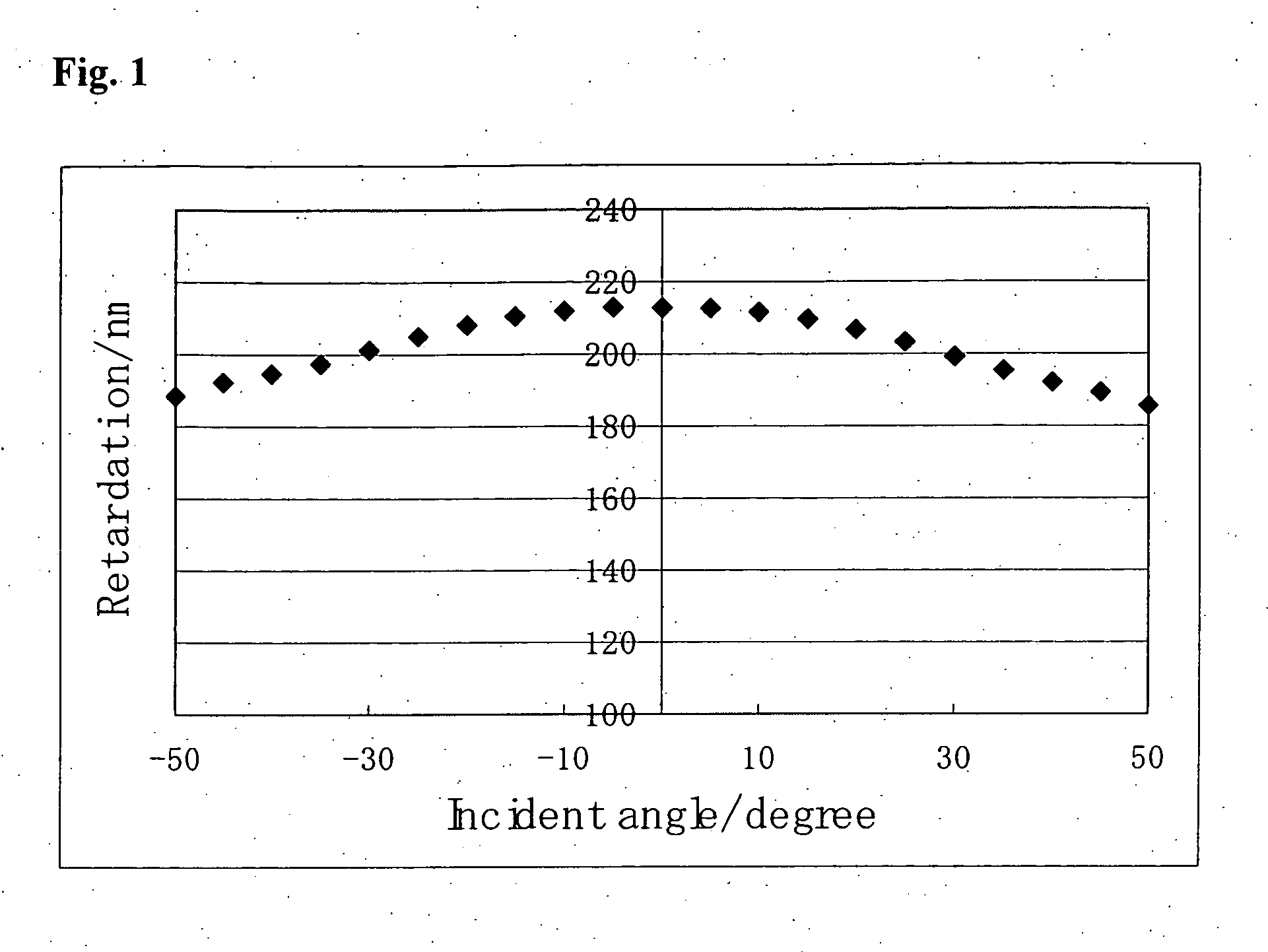

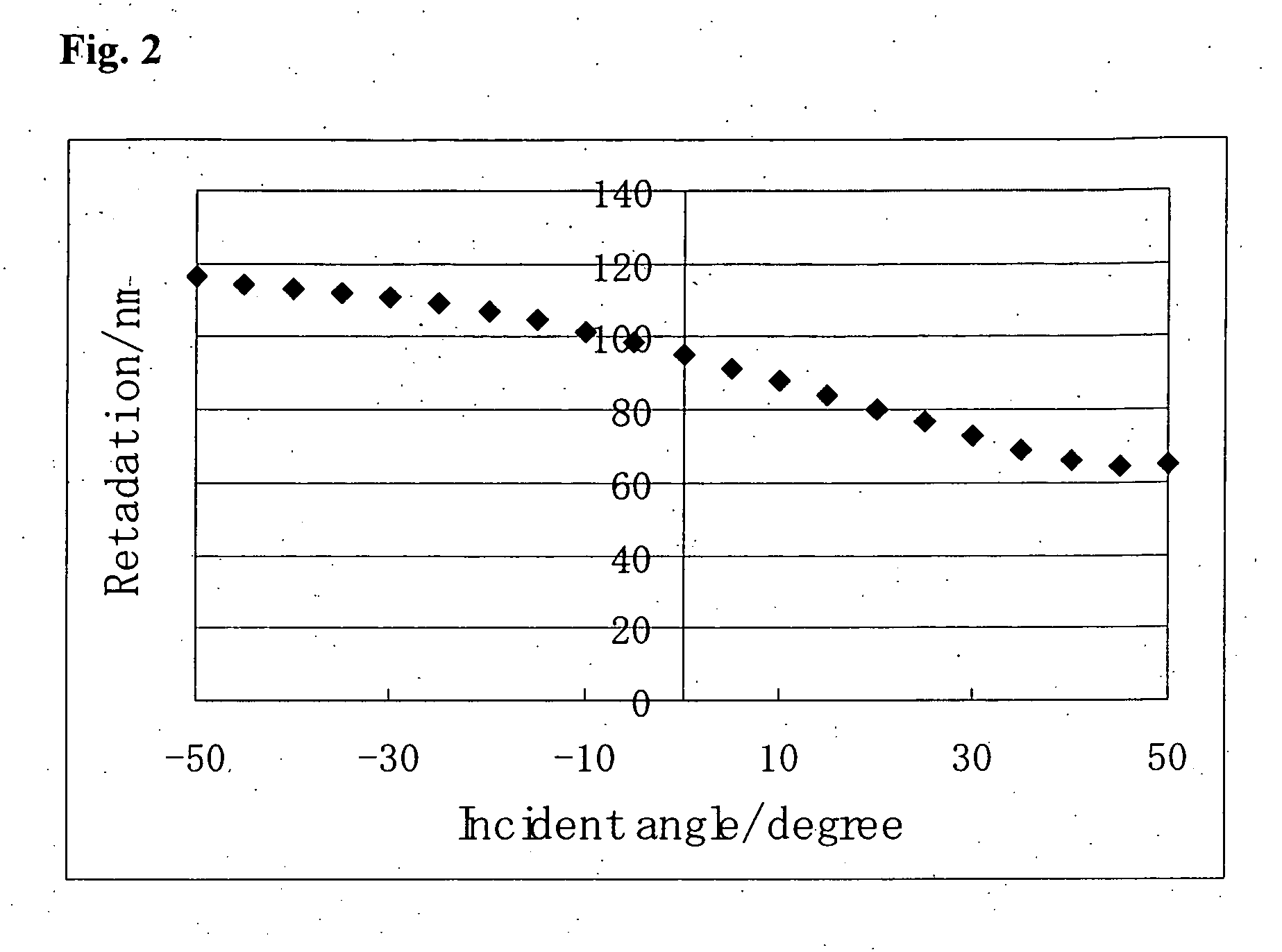

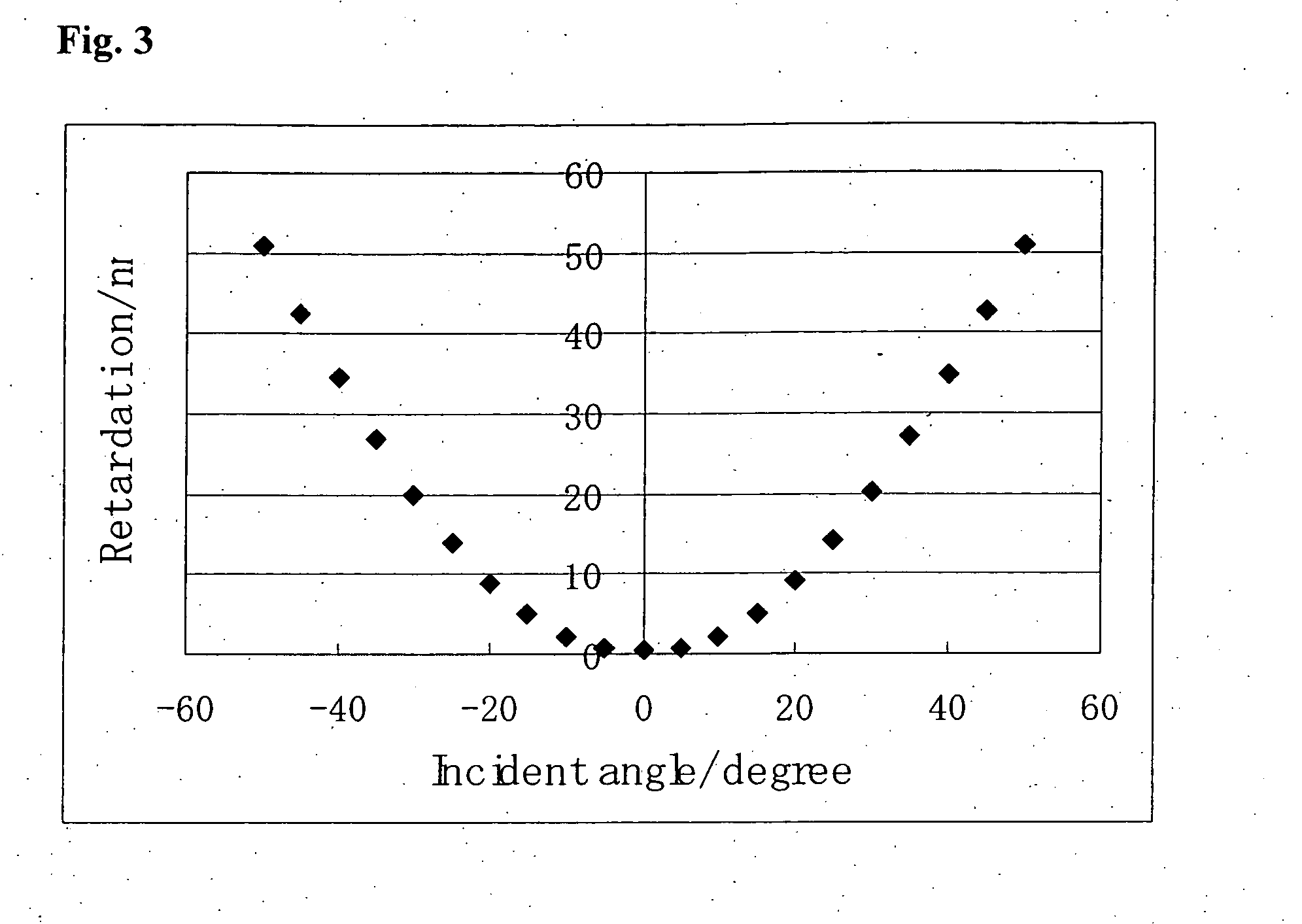

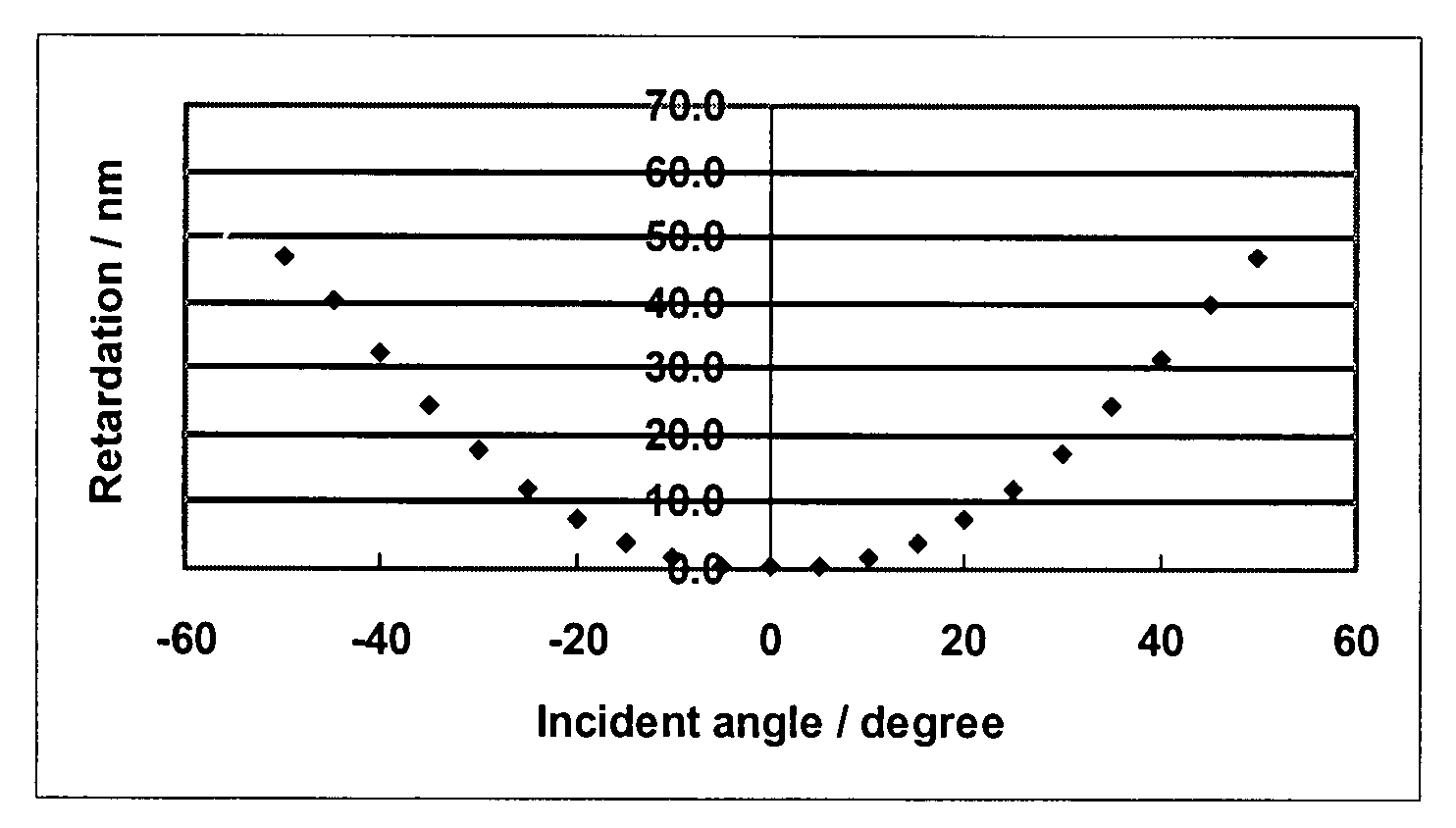

InactiveUS20080014374A1Uniform thicknessPrevent productivity being deterioratedLiquid crystal compositionsThin material handlingSolution stateBisphenol

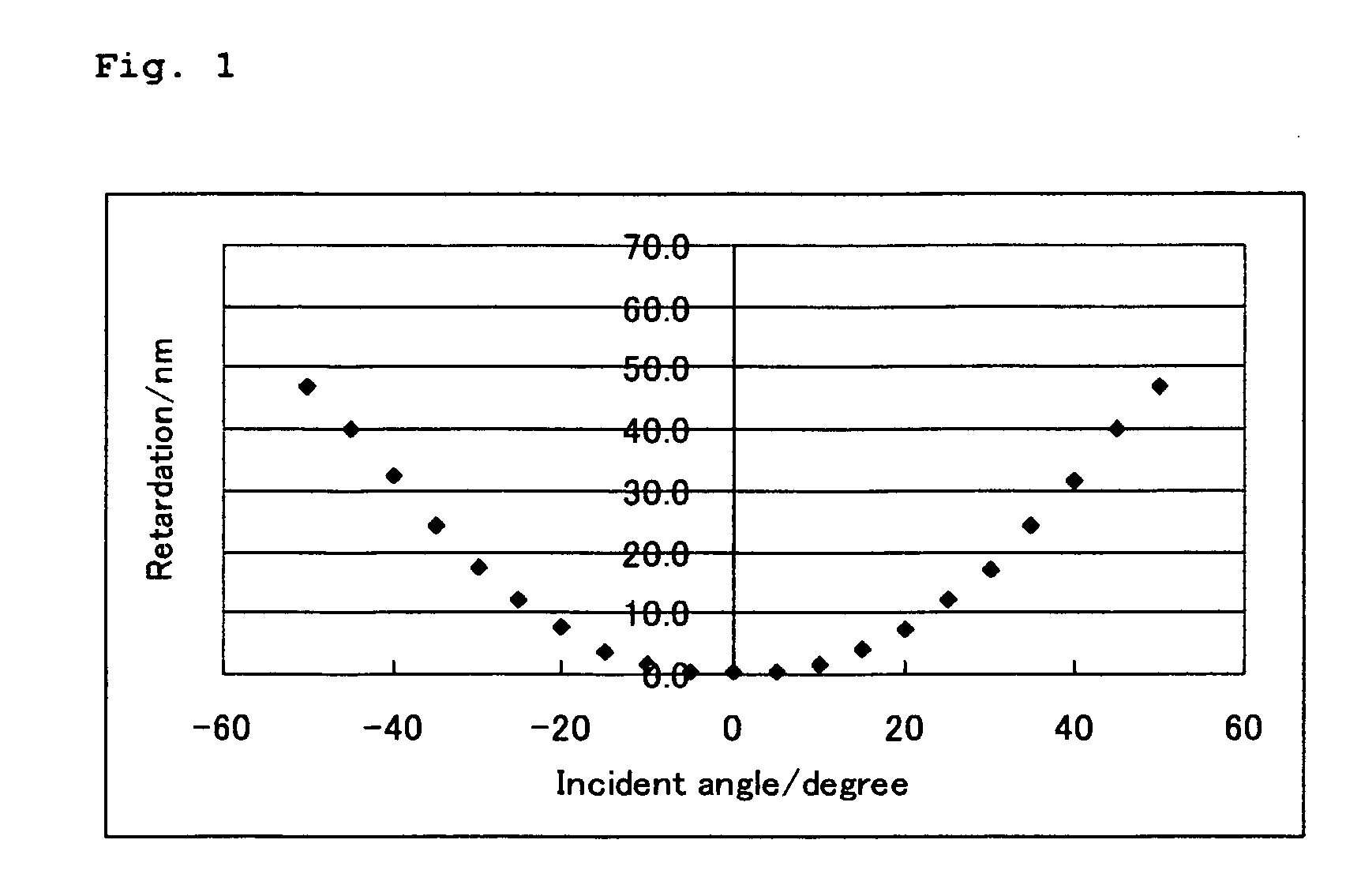

The invention is to provide such a polymerizable liquid crystal composition that is excellent in stability in a solution state, shows good coating property on a supporting substrate, and has uniform homeotropic alignment property. The polymerizable liquid crystal composition of the invention contains an acrylate compound and a bisphenol fluorene compound. The bisphenol fluorene compound is effective for controlling uniform homeotropic alignment of the polymerizable liquid crystal composition.

Owner:JNC PETROCHEM +1

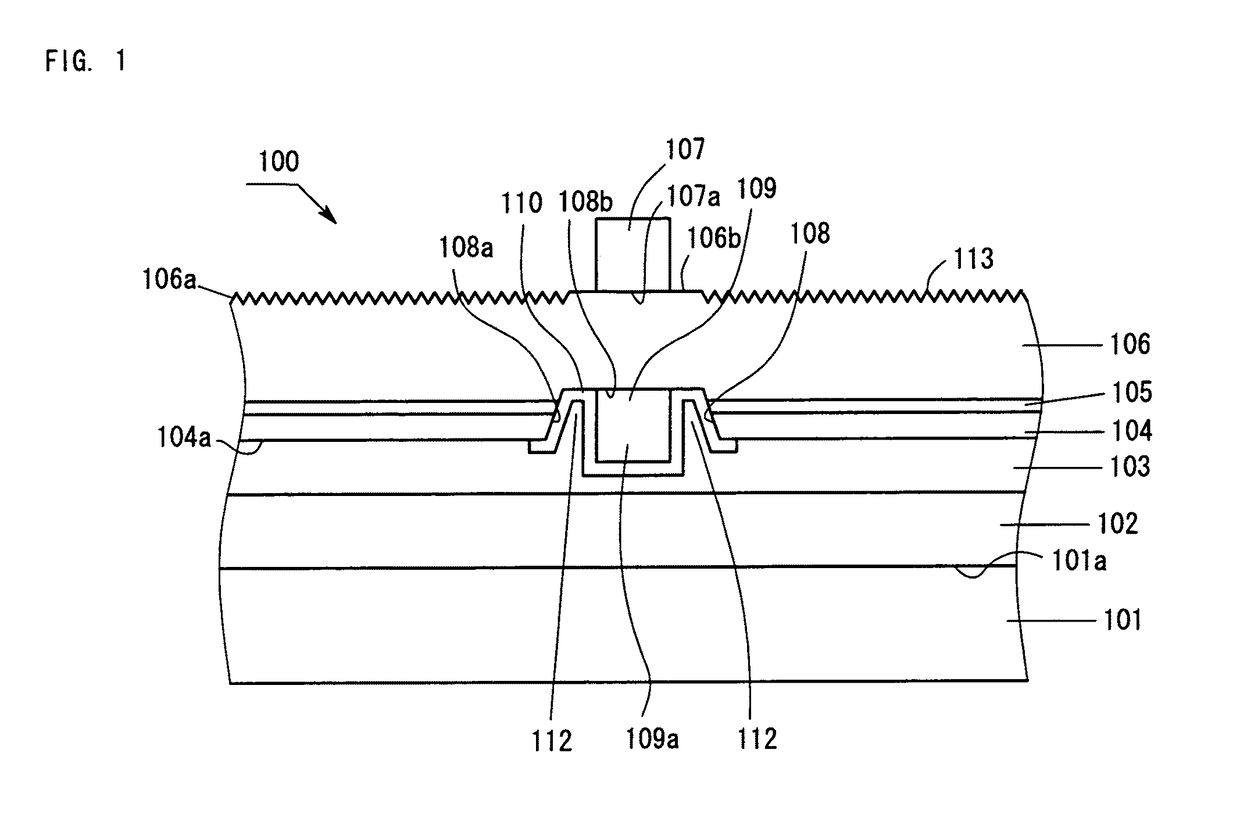

Group III nitride semiconductor light-emitting device

ActiveUS20110062488A1Reduce areaLight emission region be enlargeSolid-state devicesSemiconductor devicesAuxiliary electrodeElectrically conductive

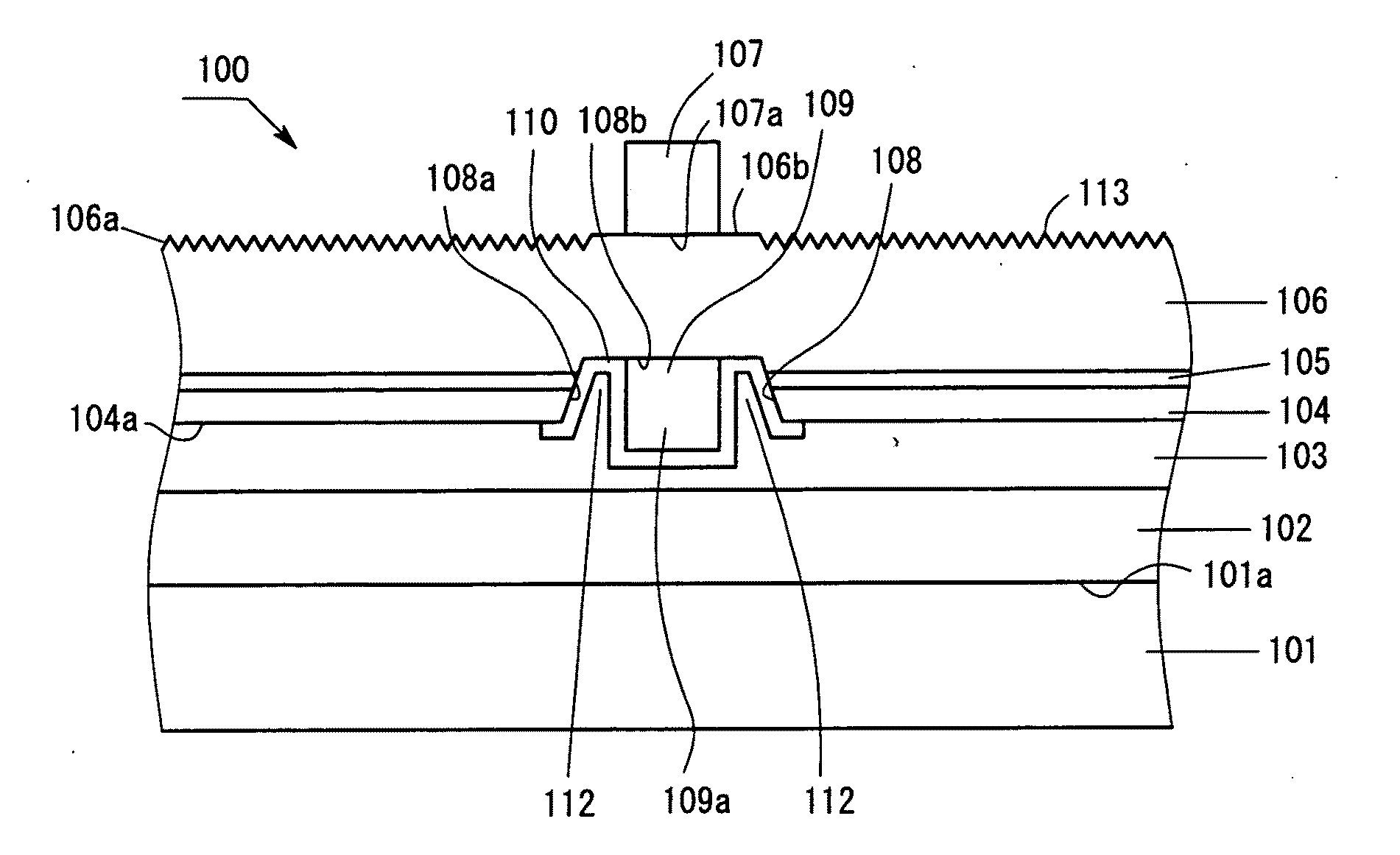

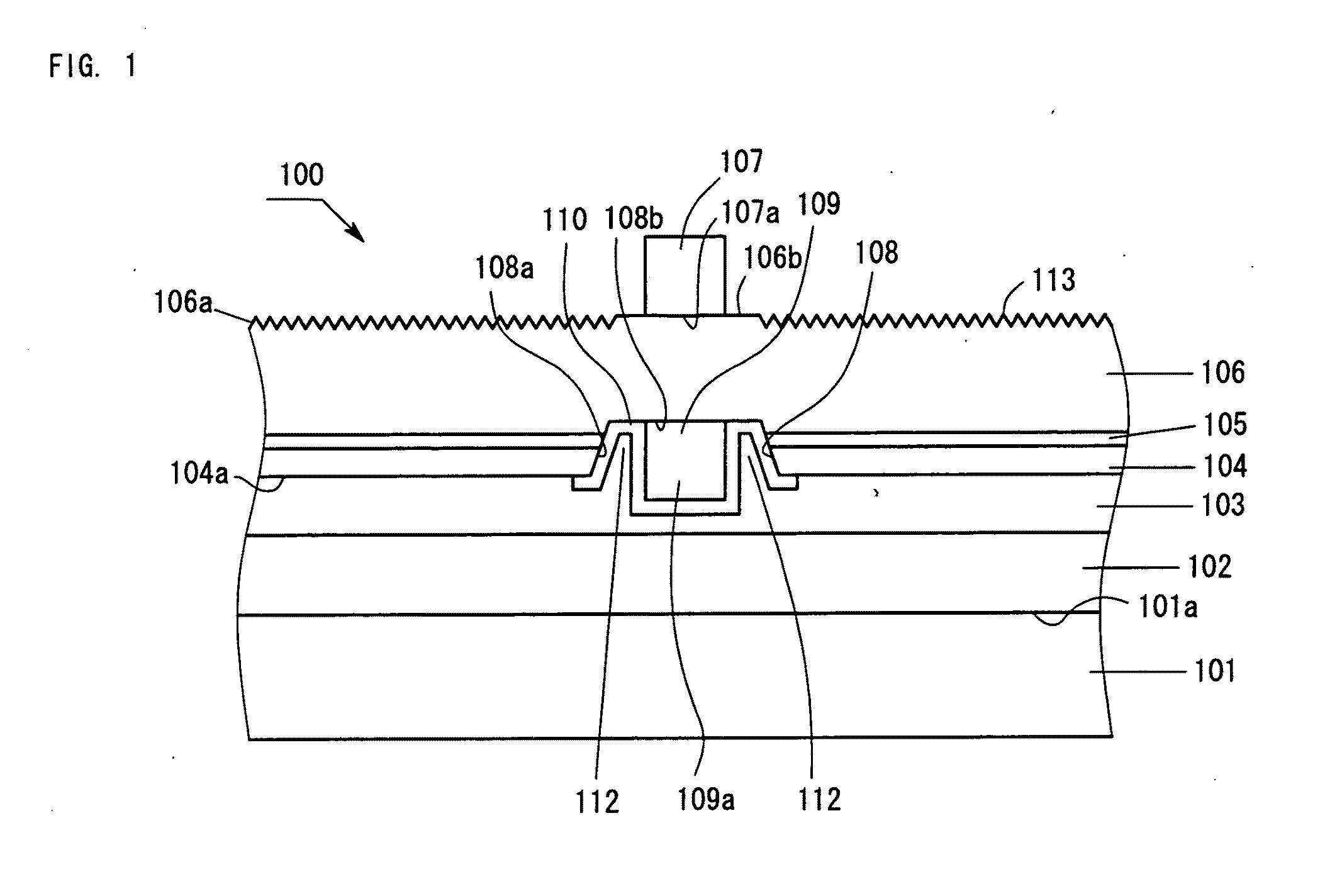

A Group III nitride semiconductor light-emitting device includes an electrically conductive support; a p-electrode provided on the support; a p-type layer, an active layer, and an n-type layer, which are formed of a Group III nitride semiconductor and are sequentially provided on the p-electrode; an n-electrode which is connected to the n-type layer; a first trench extending from the surface of the p-type layer on the p-electrode's side to reach the n-type layer; an auxiliary electrode which is in contact with the surface of the n-type layer serving as the bottom of the first trench, but is not in contact with the side walls of the first trench; and an insulating film which exhibits light permeability and covers the auxiliary electrode and the bottom and side walls of the first trench.

Owner:TOYODA GOSEI CO LTD

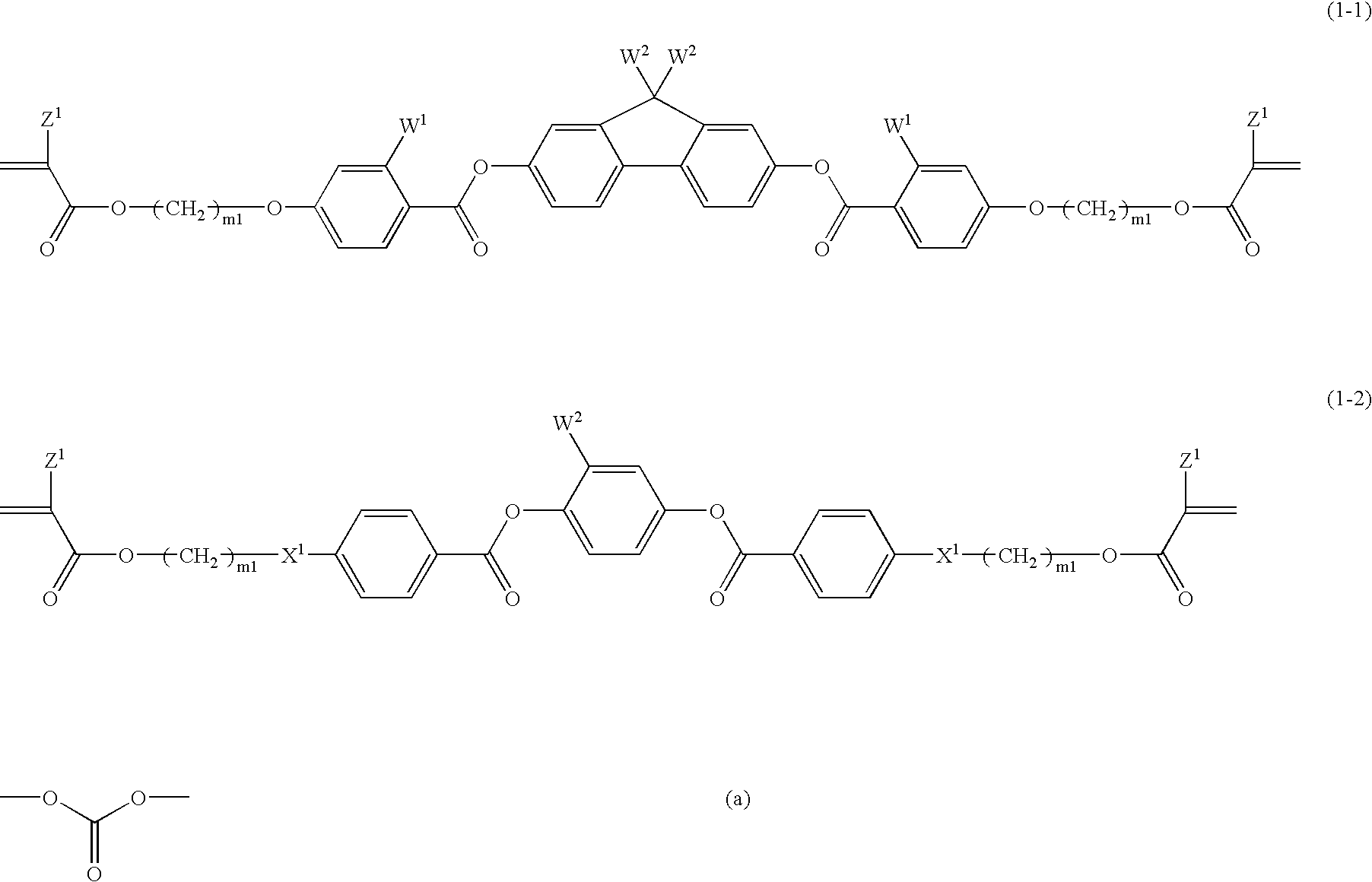

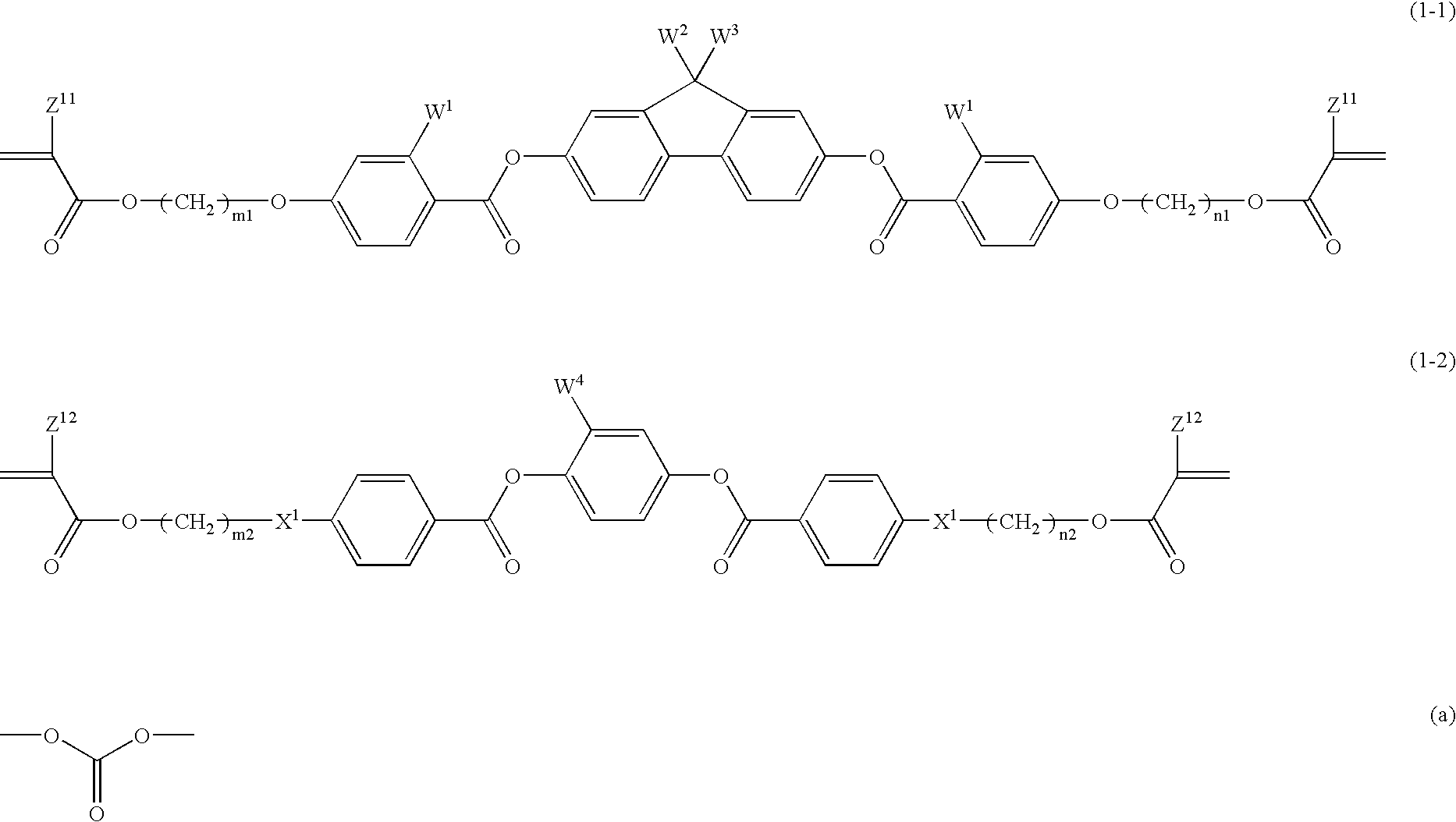

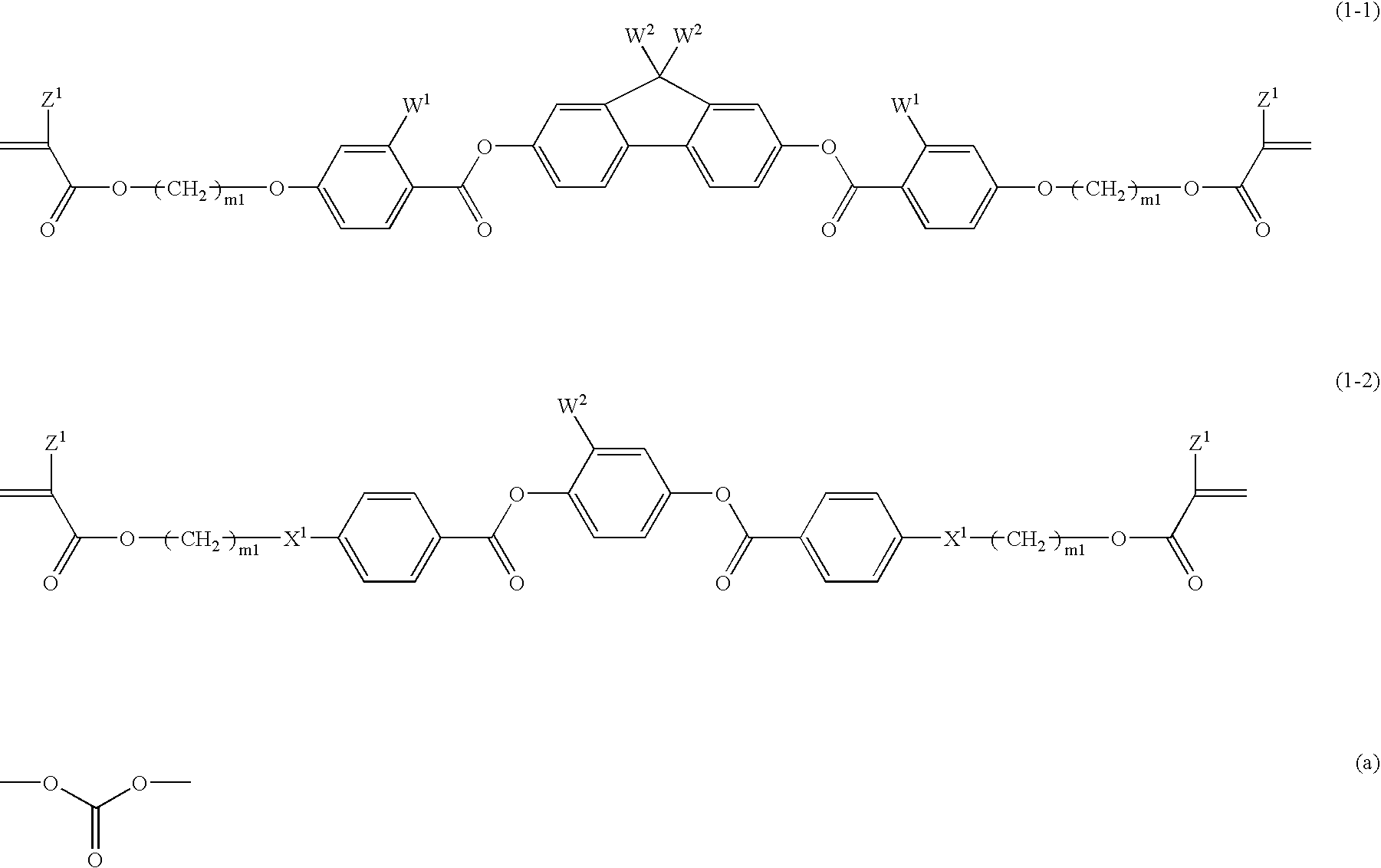

Polymerizable liquid crystal composition

ActiveUS20080241431A1Improve stabilityImprove adhesionLiquid crystal compositionsThin material handlingSolution stateOrganic chemistry

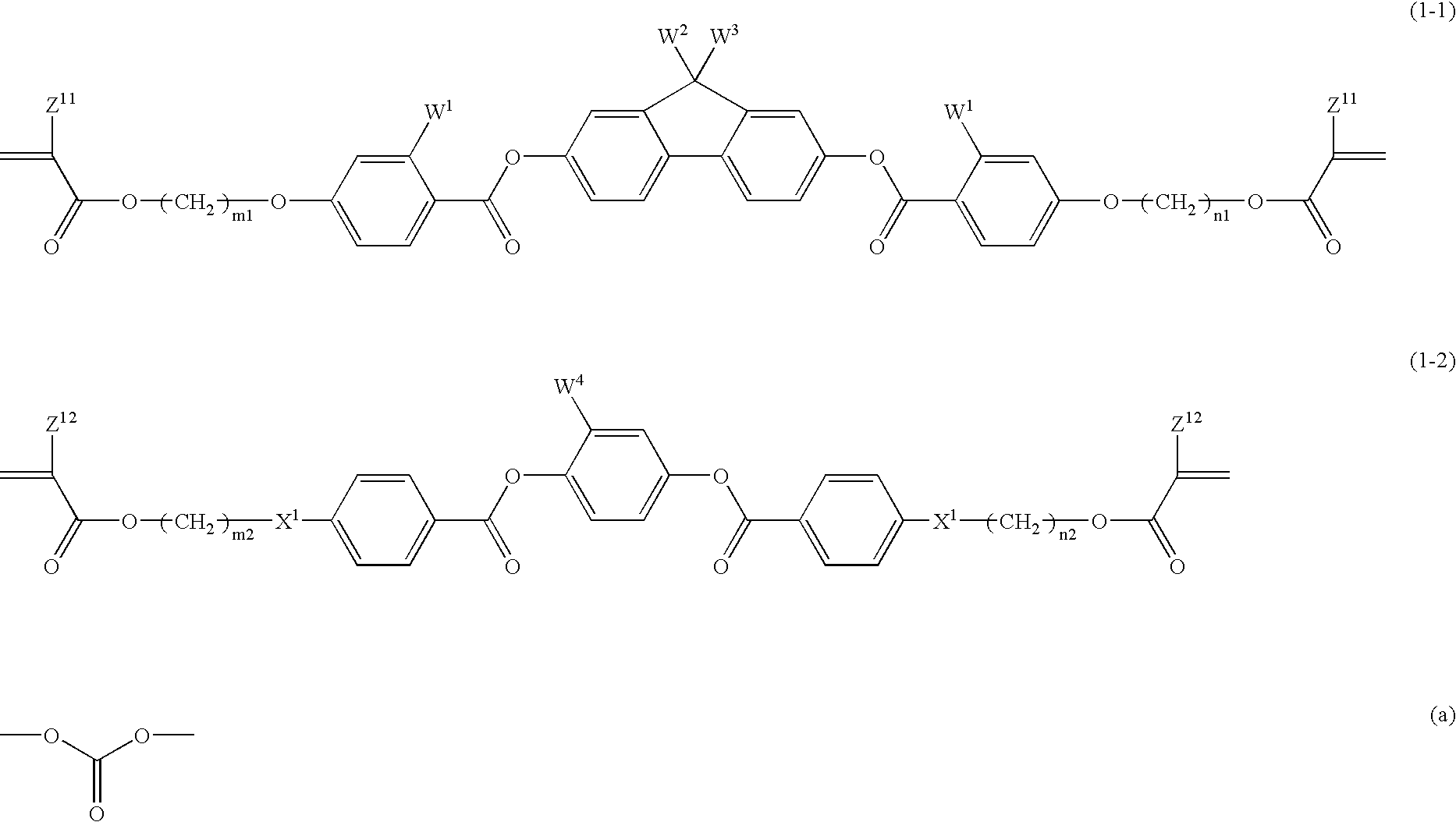

Such a polymerizable liquid crystal composition is to be provided that is excellent in stability in a solution state, shows good coating property on a supporting substrate, and has a uniform homeotropic alignment property. The polymerizable liquid crystal composition contains an acrylate compound, an epoxy compound and a bisphenol fluorene compound. The polymerizable liquid crystal composition contains a compound selected from a group of compounds represented by formulae (1-1) and (1-2) as a component (A), a compound selected from a group of compounds represented by formula (2) as a component (B), a compound selected from a group of compounds represented by formulae (3-1) to (3-3) as a component (C) and a compound selected from a group of compounds represented by formulae (4-1A), (4-1B), (4-2), (4-3), (4-4) and (4-5) as a component (D), and may optionally contain a compound selected from a group of compounds represented by formulae (5-1) and (5-2) as a component (E). The bisphenol fluorene compound is effective for controlling a uniform homeotropic alignment of the polymerizable liquid crystal composition.

Owner:JNC CORP +1

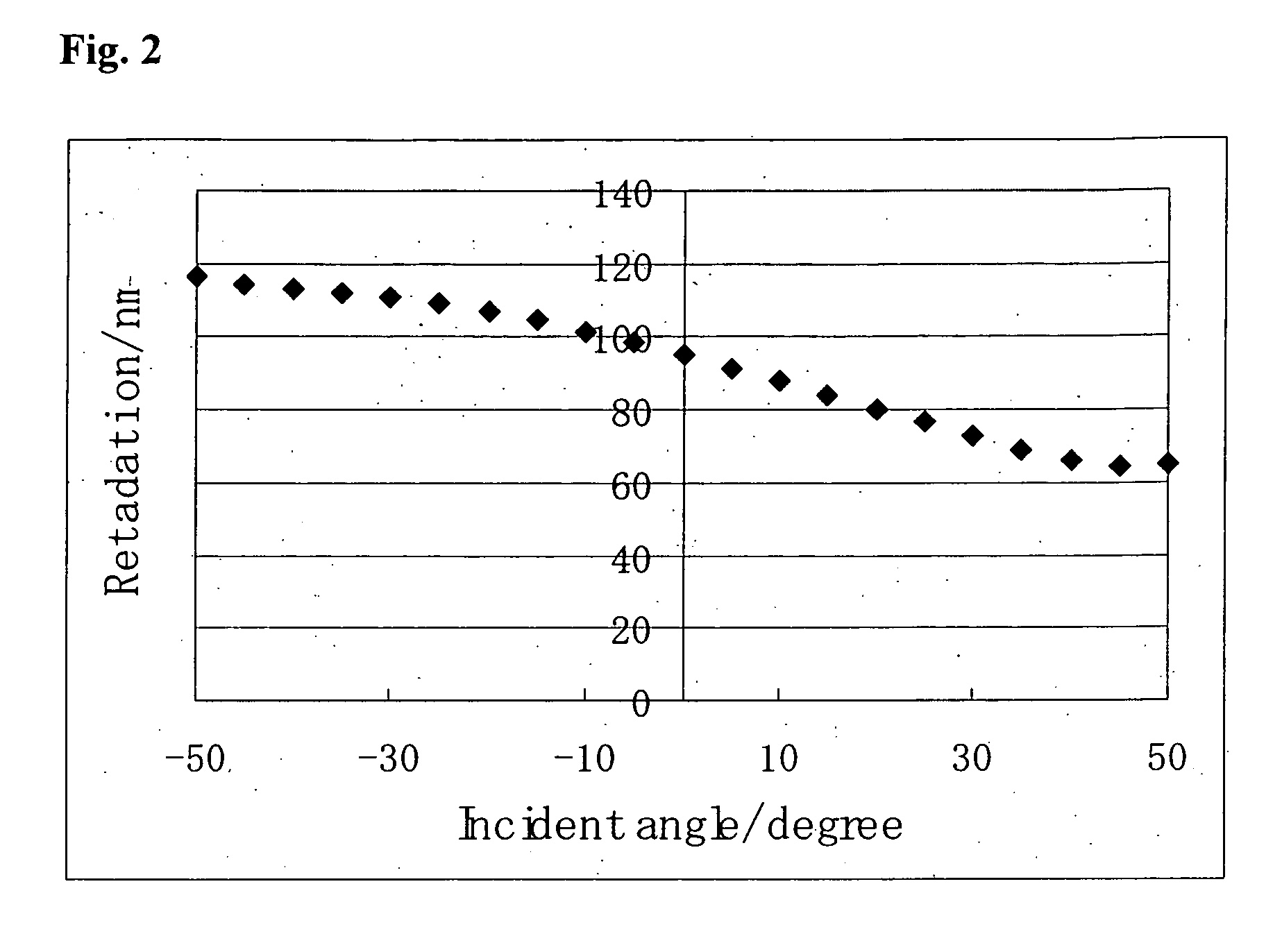

Polymerizable liquid crystal composition and optically anisotropic film using the same

InactiveUS20100051866A1Uniform thicknessPrevent productivity being deterioratedLiquid crystal compositionsThin material handlingSolubilitySolvent

A polymerizable liquid crystal composition is provided that has a wide range where a liquid crystal phase is exhibited, has excellent solubility in an organic solvent, and is facilitated in control of an alignment state. The use of the polymerizable liquid crystal composition provides a polymerizable liquid crystal composition that has good solubility in a solvent with high safety, such as PGMEA, and can control various alignment states. The polymerizable liquid crystal composition in one aspect contains a fluorenone derivative represented by the formula (1) and a compound having a bisphenol skeleton represented by the formula (2). In the formulae (1) and (2), W1 represents hydrogen, fluorine, chlorine, methyl or ethyl; X1 represents hydrogen, fluorine, methyl or trifluoromethyl; Z11 to Z14 are bonding groups; A1 represents a divalent cyclic group; Y1 represents alkylene having from 2 to 20 carbon atoms; A2 represents a divalent group having a bisphenol skeleton; X2 represents hydrogen, fluorine, methyl or trifluoromethyl; W2 represents hydrogen, halogen, alkyl or fluoroalkyl; Y2 independently represents a single bond, —CH═CH— or —(CH2)2—; and n2 independently represents an integer of from 2 to 15.

Owner:JNC PETROCHEM CORP +1

Polymerizable liquid crystal composition

InactiveUS7476423B2Impairs stabilityUniform damageLiquid crystal compositionsThin material handlingCrystallographyAcrylate ester

Owner:JNC PETROCHEM CORP +1

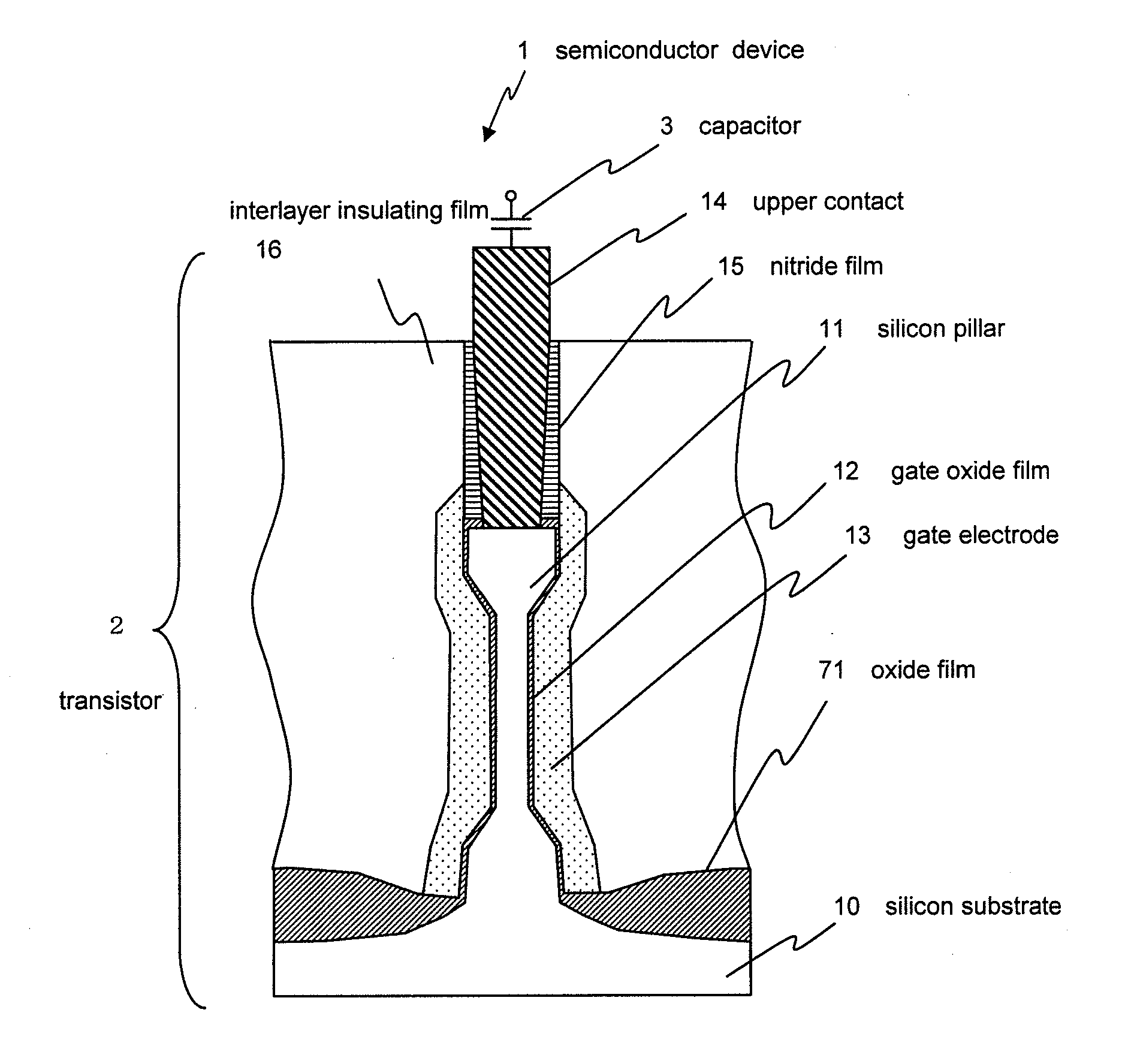

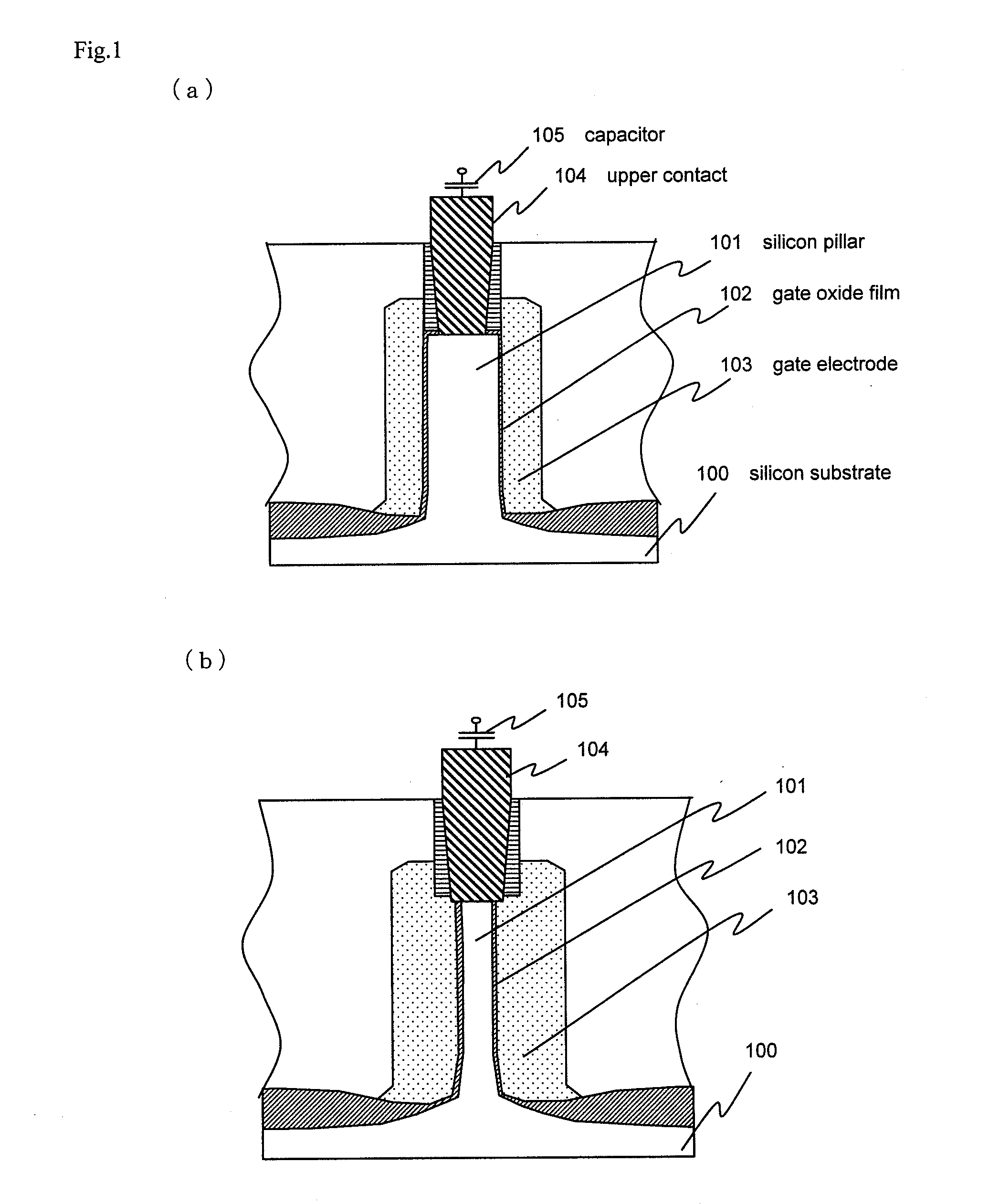

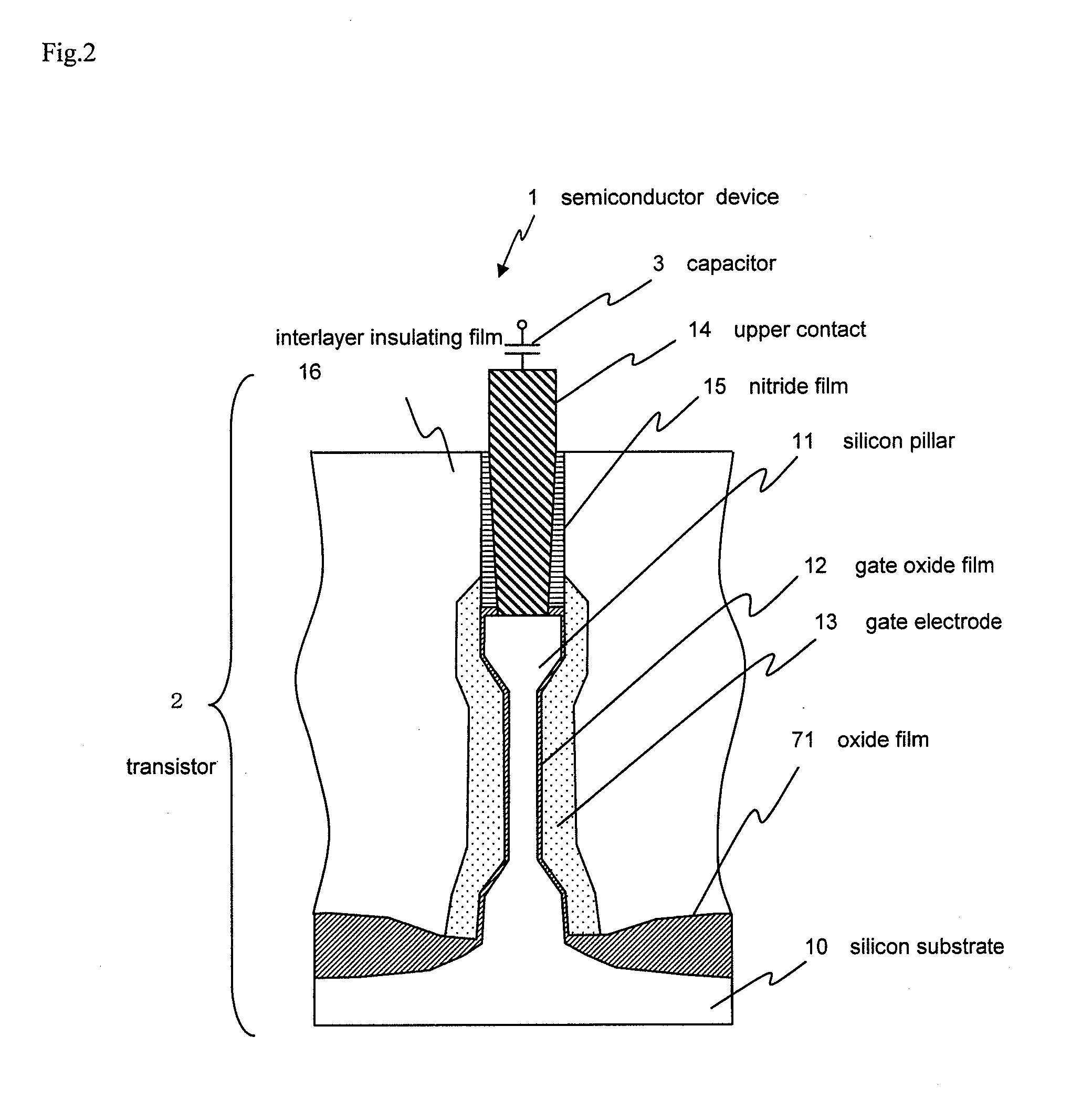

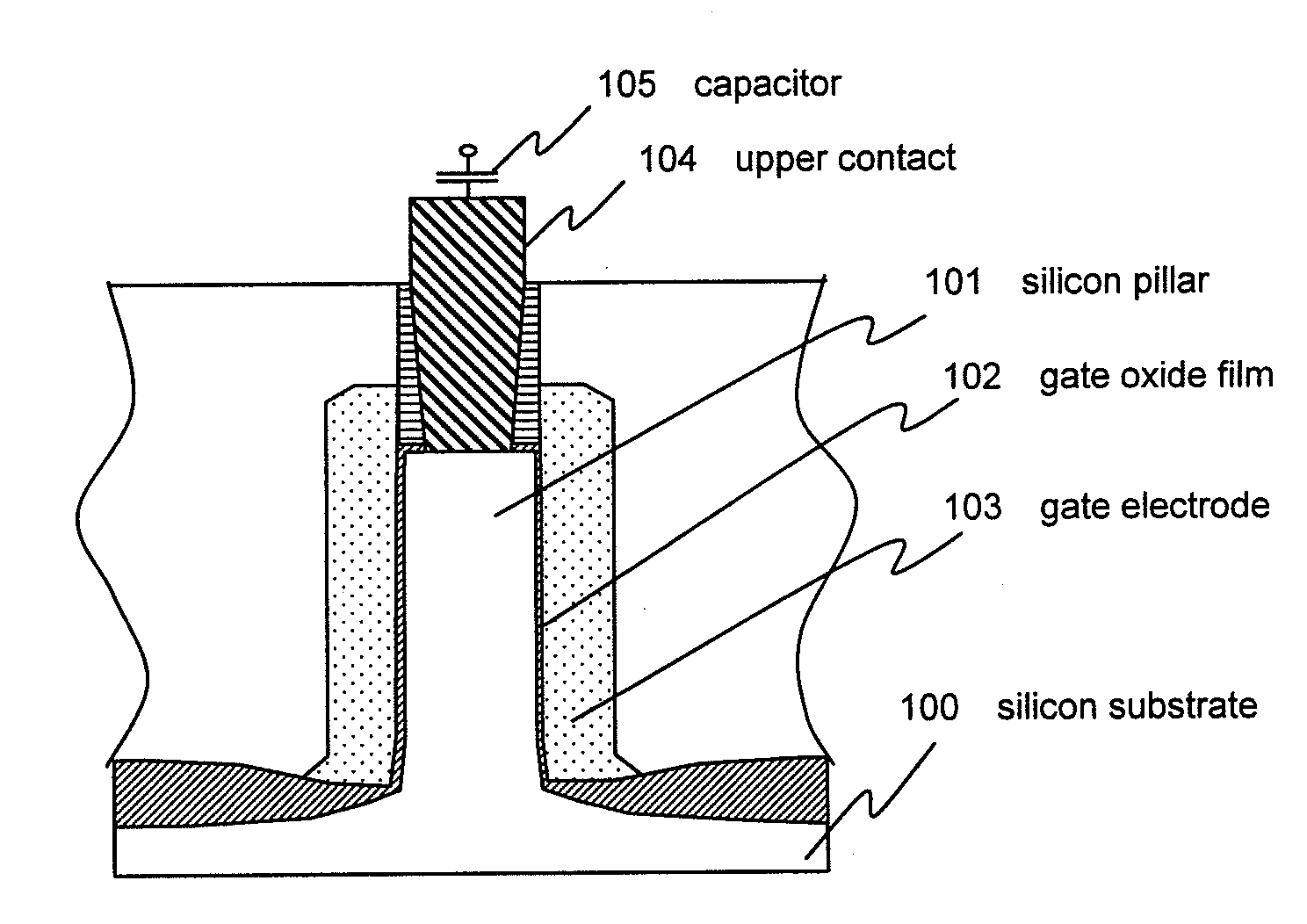

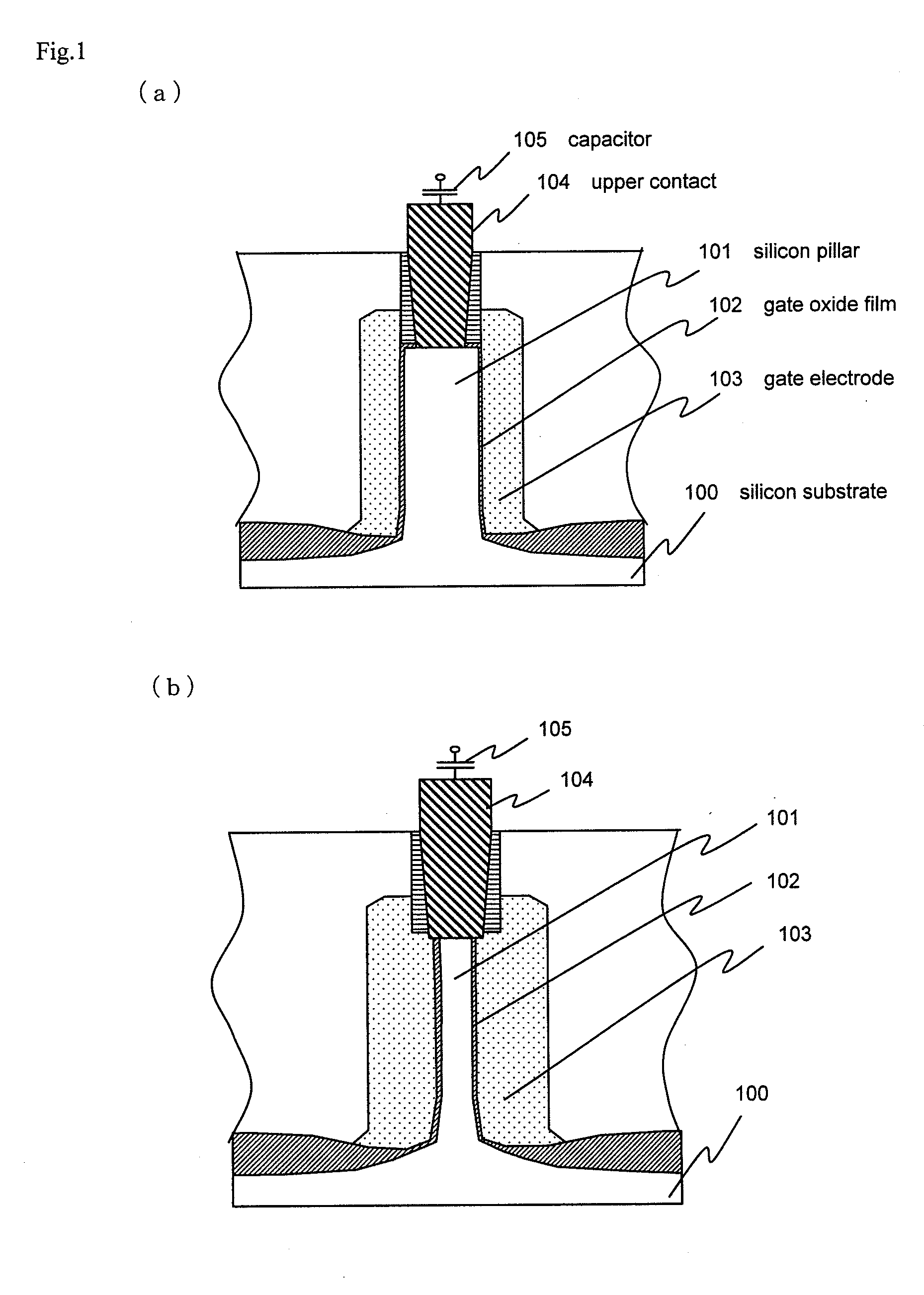

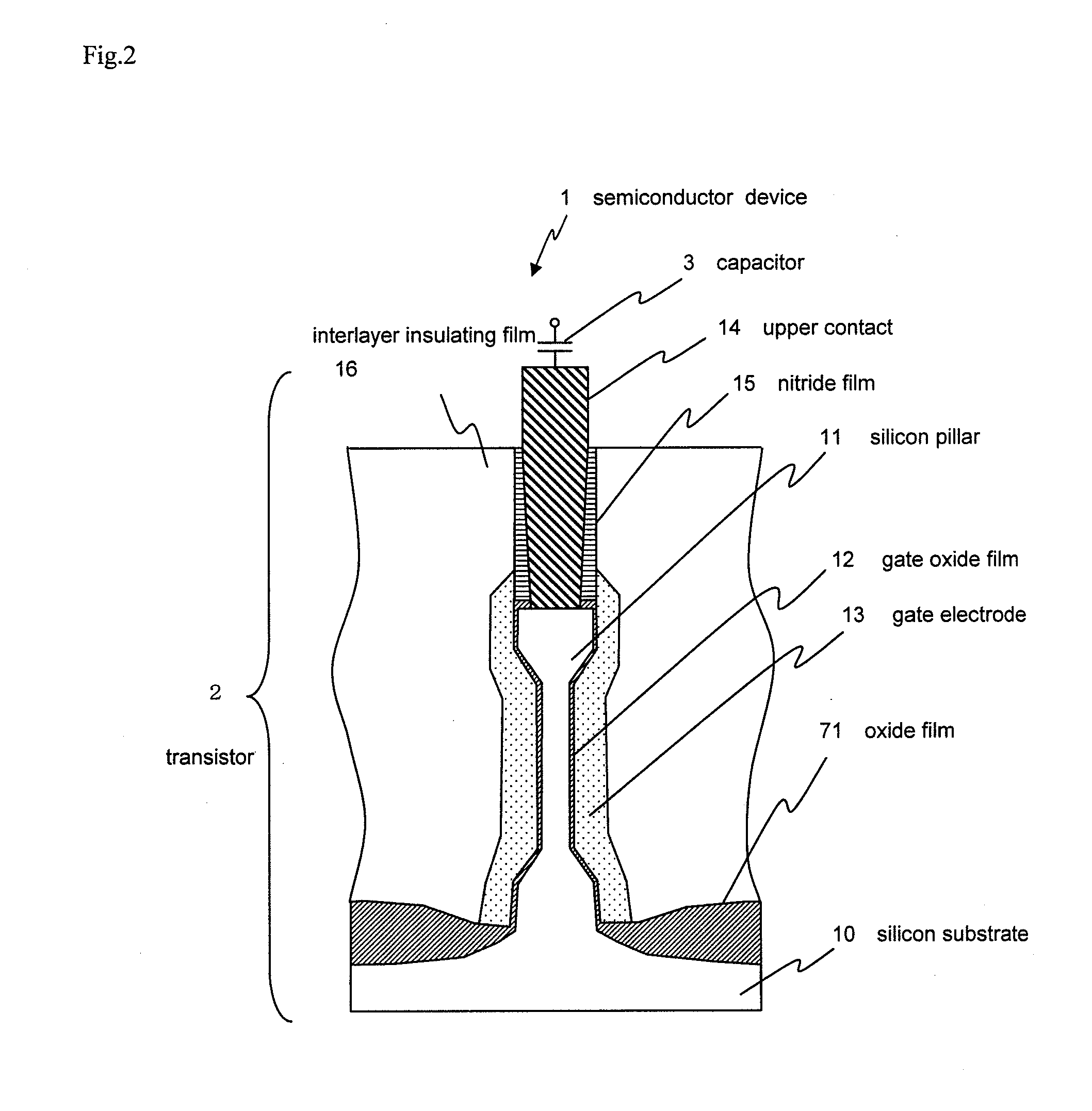

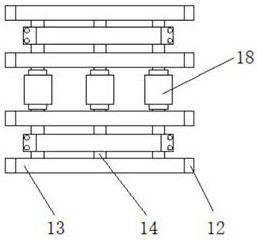

Semiconductor device and method of manufacturing the semiconductor device

InactiveUS20120025286A1Uniform damageSuppress mutationTransistorSolid-state devicesDevice materialEngineering

A method of manufacturing a semiconductor device includes forming silicon pillar 11 on substrate 10, forming a protective film which covers an upper end portion and a lower end portion of a side surface of silicon pillar 11, forming a constricted portion by anisotropic etching in a portion of the side surface of silicon pillar 11 which is not covered with the protective film after forming the protective film, removing the protective film after forming the constricted portion, forming gate oxide film 12 which covers the side surface of silicon pillar 11 in which the constricted portion is formed, and forming gate electrode 13 which covers gate oxide film 12.

Owner:PS4 LUXCO SARL

Polymerizable liquid crystal composition

ActiveUS7488519B2Impairs stabilityUniform damageLiquid crystal compositionsThin material handlingSolution stateBisphenol

Owner:JNC CORP +1

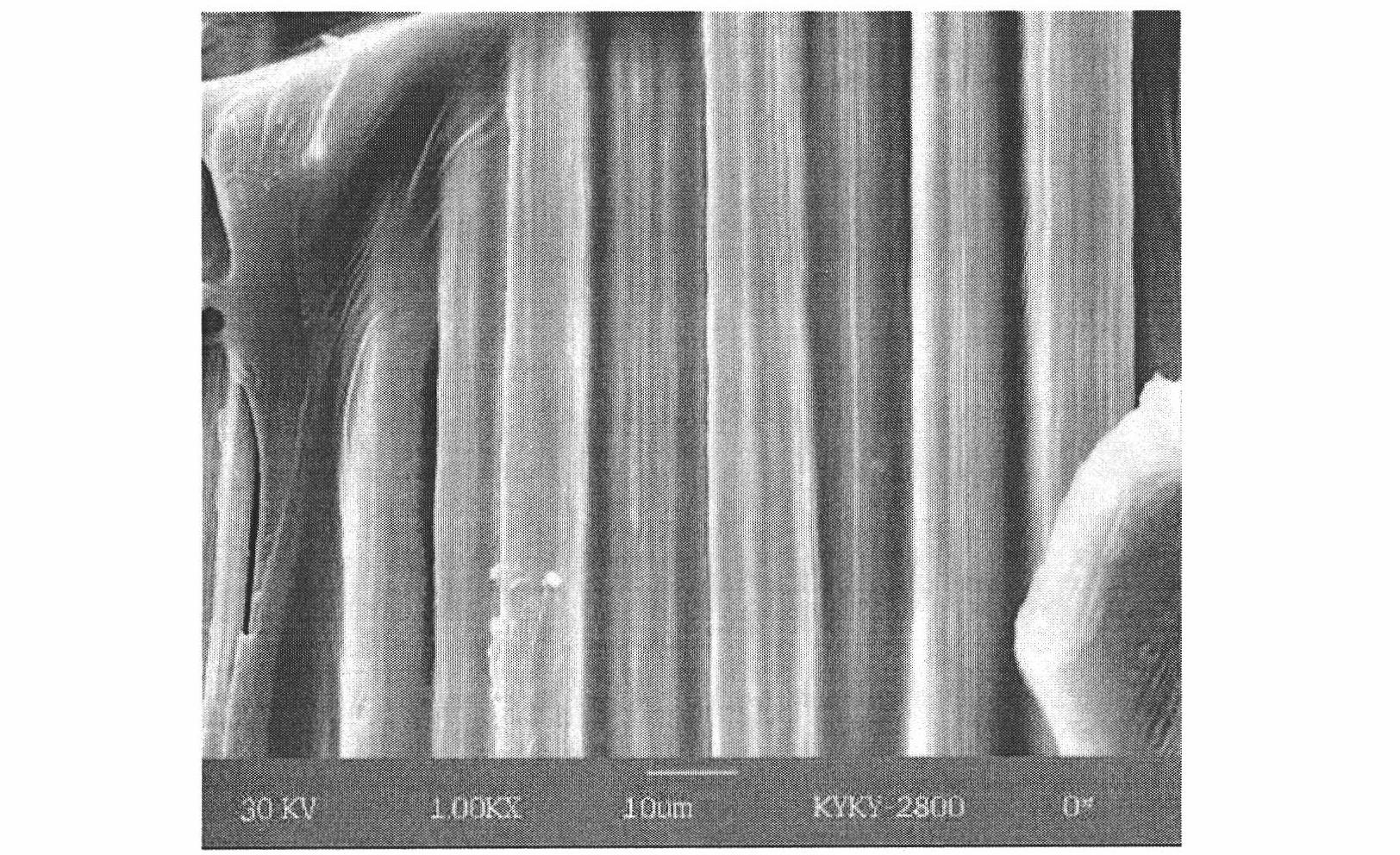

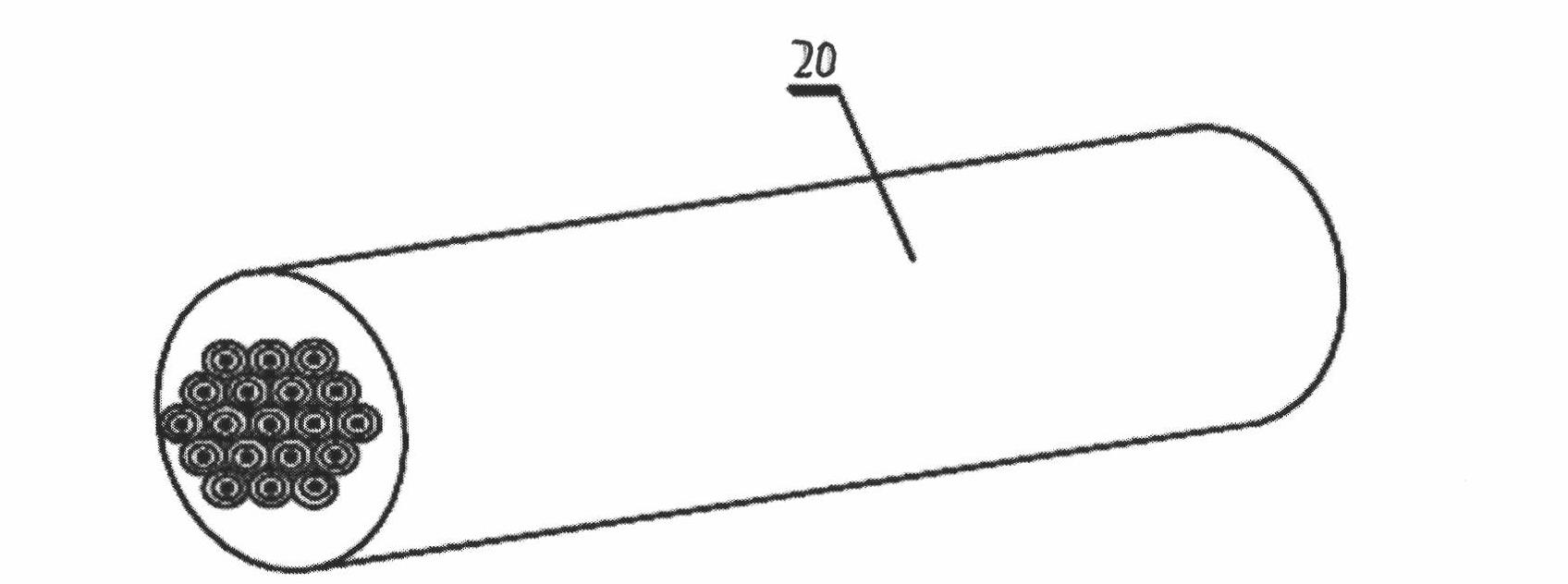

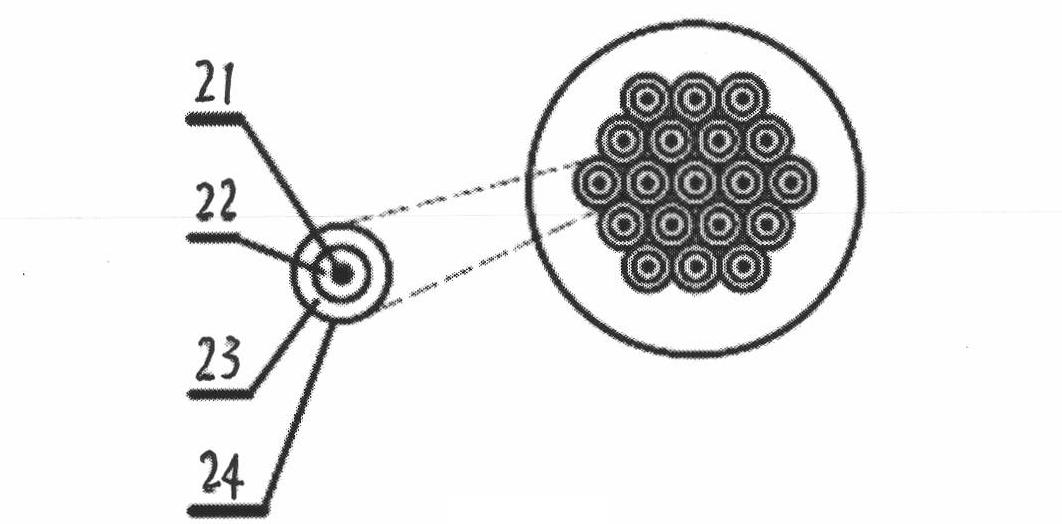

Preparation method of conductive plastics master batch containing stainless steel fibers

ActiveCN101840745AElectromagnetic shielding effect hasHas antistatic effectNon-conductive material with dispersed conductive materialCable/conductor manufactureElectromagnetic shieldingStainless steel fiber

The invention discloses a preparation method of a conductive plastics master batch containing stainless steel fibers. The stainless steel fibers in the plastics master batch are isolated by macromolecular materials and completely packed by the macromolecular materials. When the plastics master batch as raw materials is mixed with plastics for secondary granulation or a conductive plastic work-piece is formed, the stainless steel fibers can resist high shear force when the plastics are processed, and are easily and uniformly dispersed in the plastic work-piece and overlap to each other to form a three-dimensional conductive network. By adopting the conductive plastics master batch, the ideal antistatic and electromagnetic screen effects can be achieved under the circumstance of low content of the stainless steel fiber.

Owner:HUNAN HUITONG ADVANCED MATERIALS

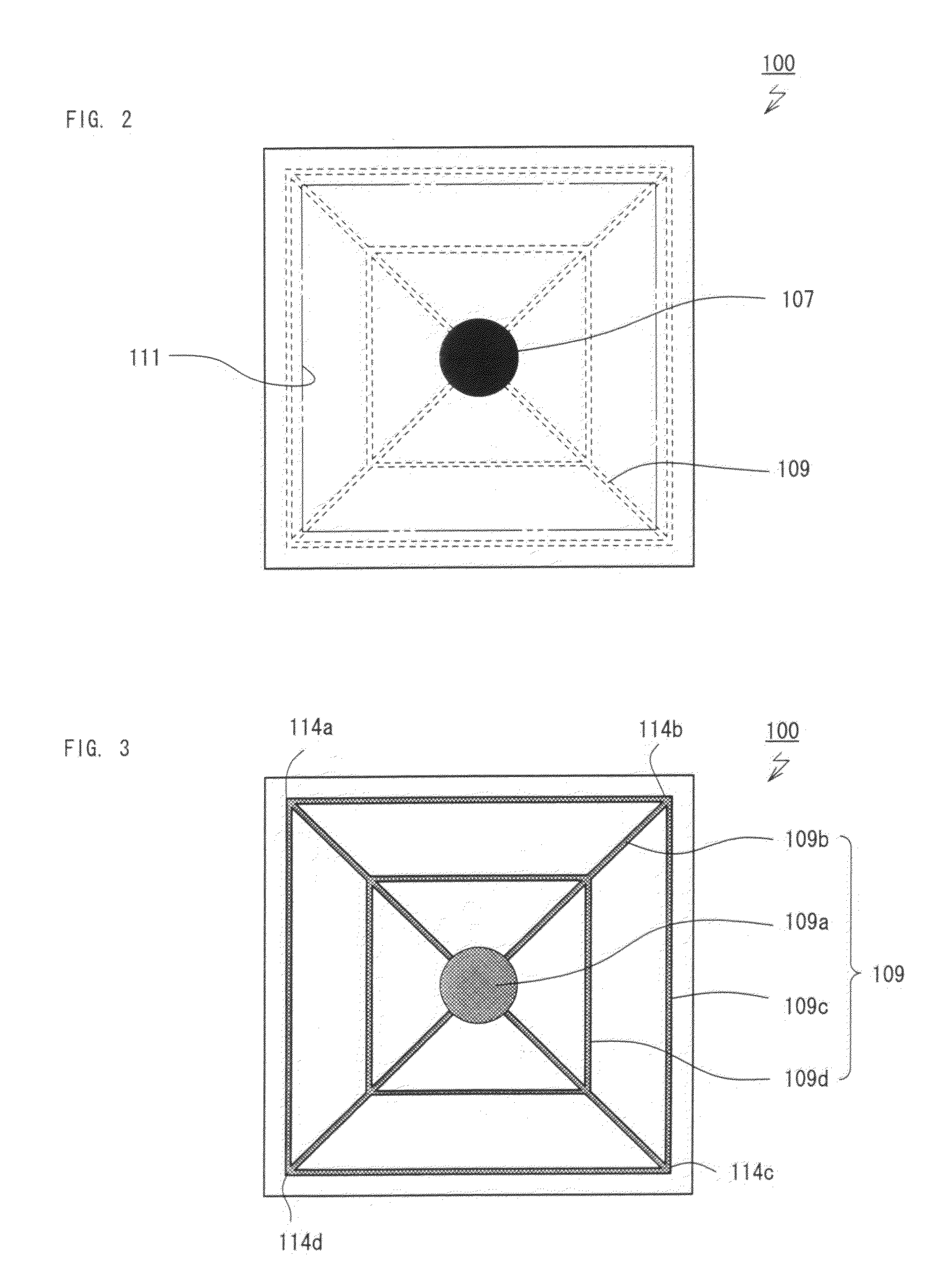

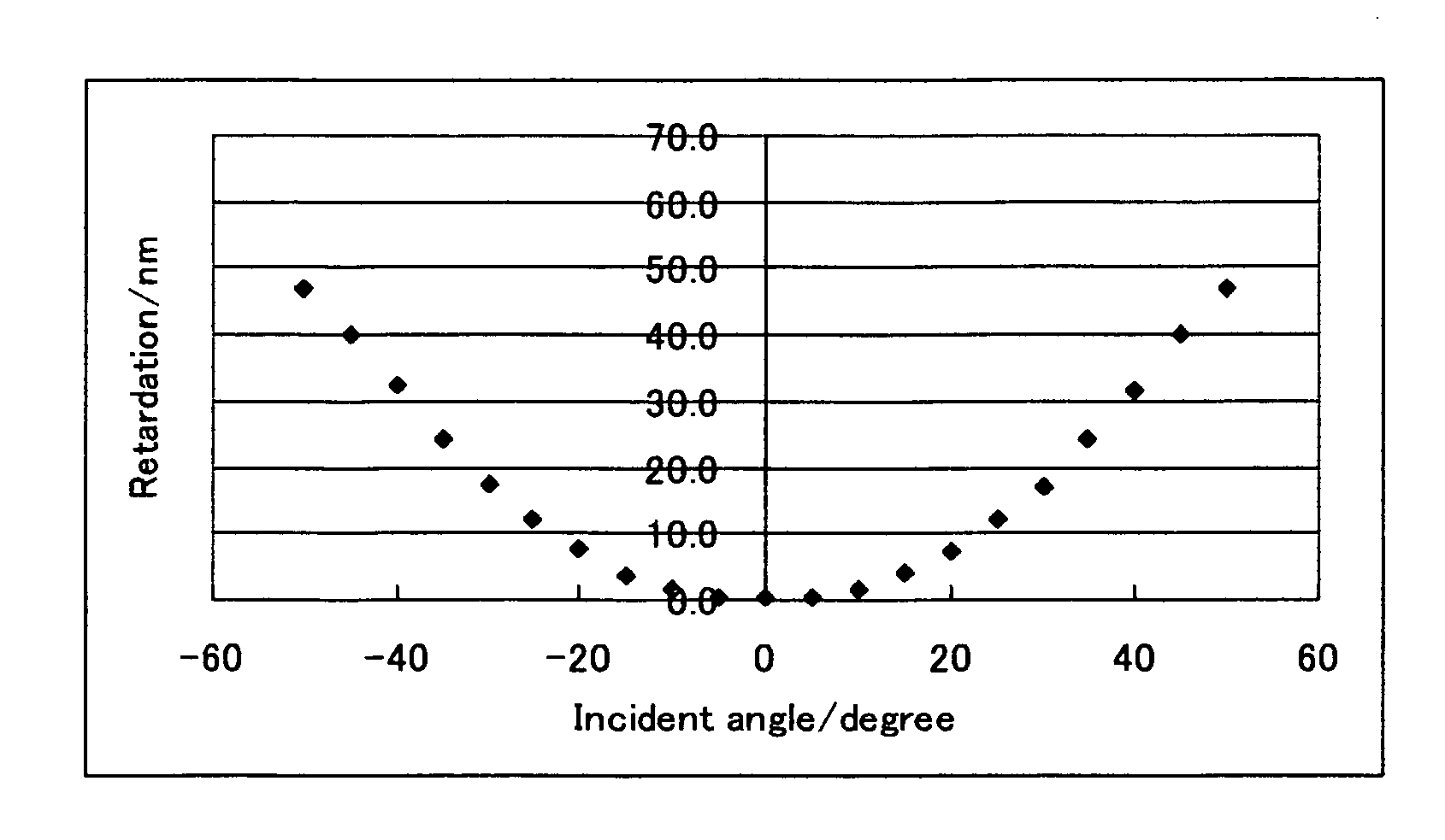

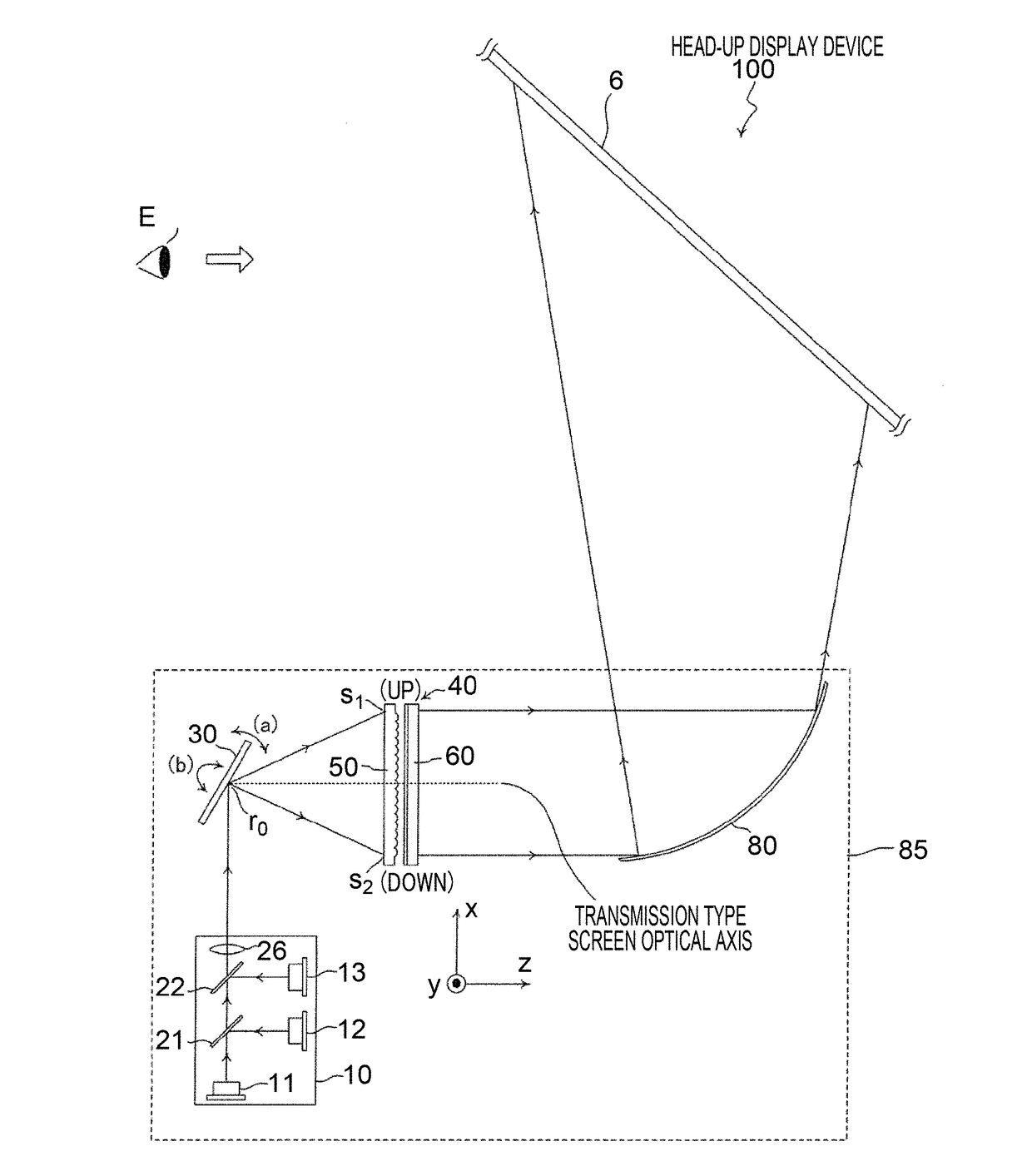

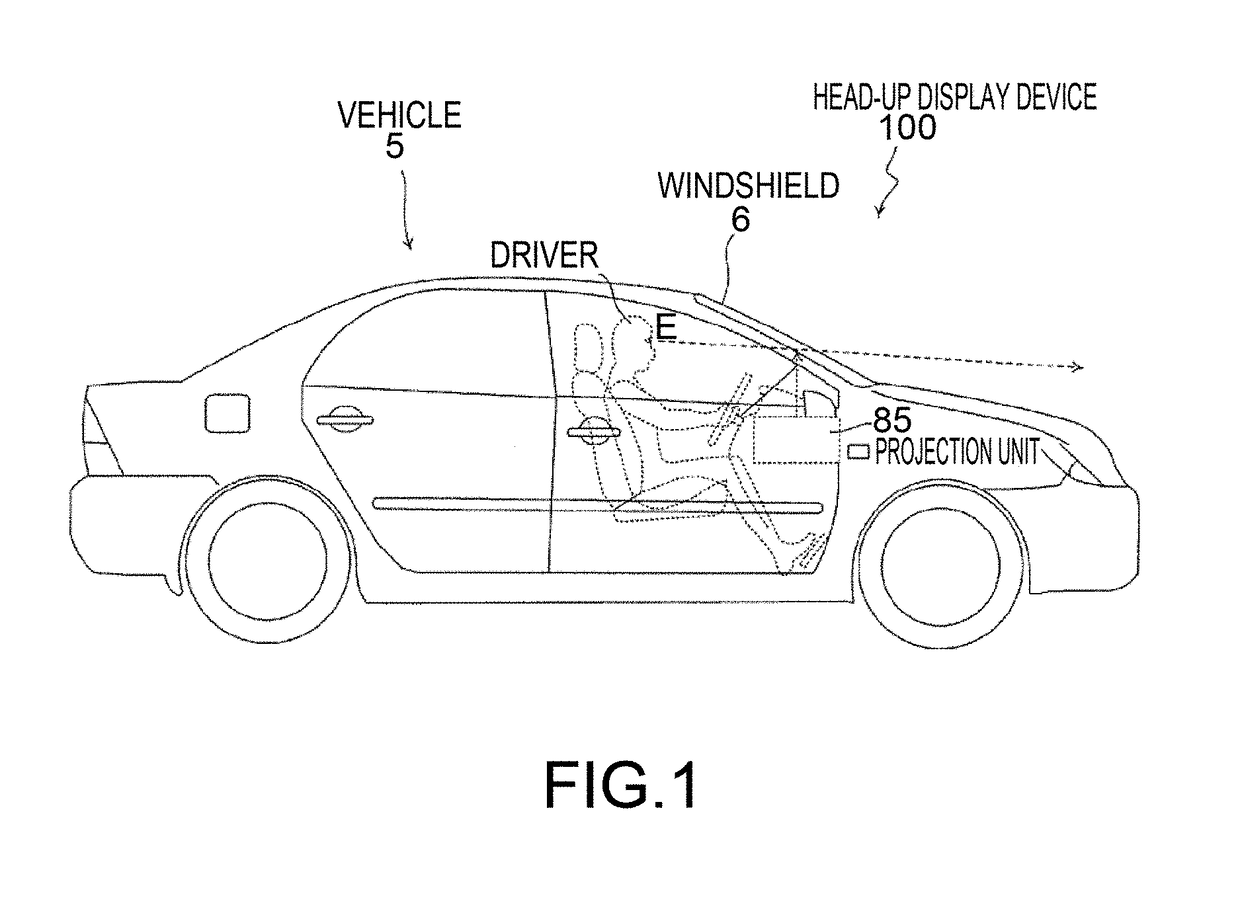

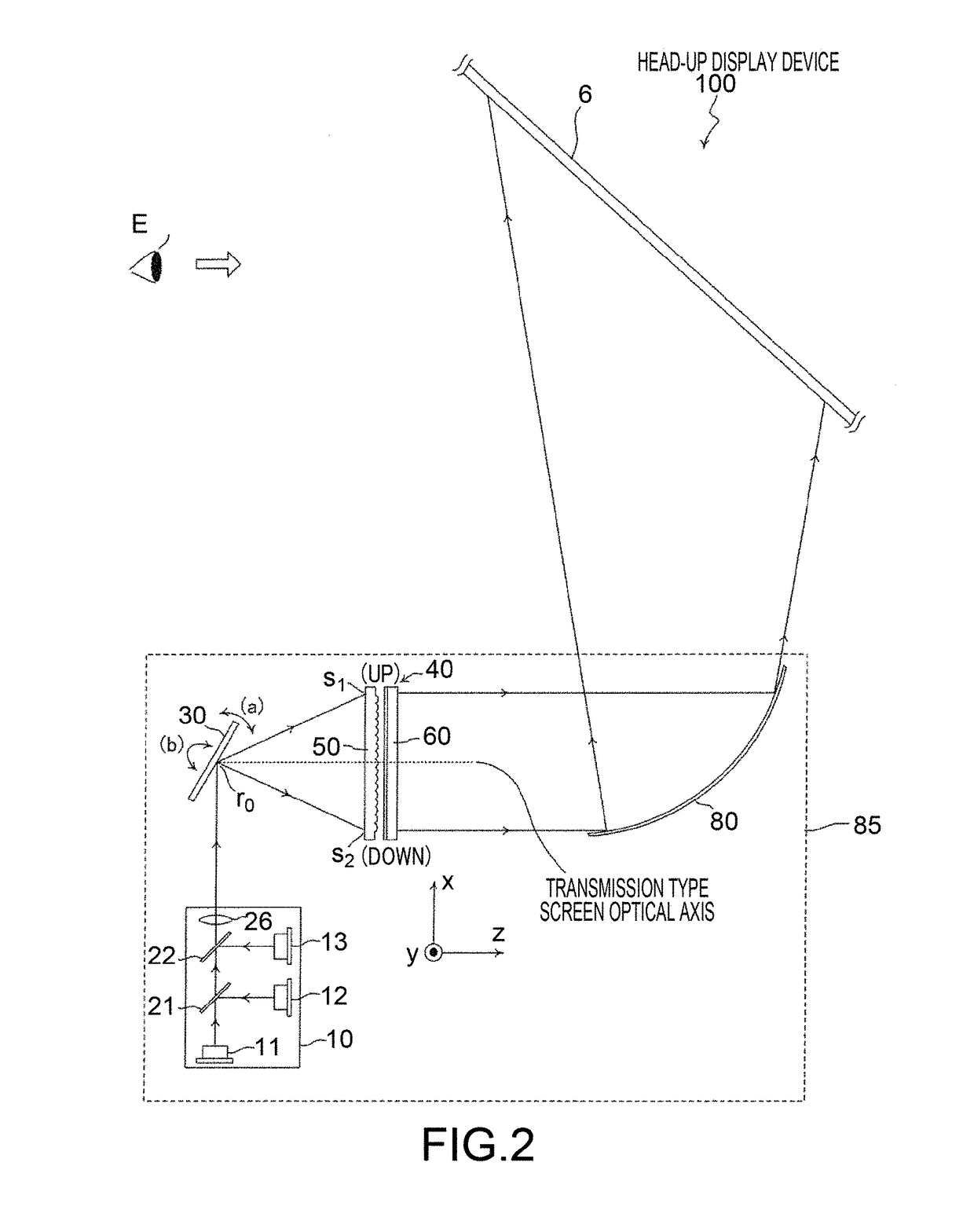

Transmission type screen and head-up display device using same

InactiveUS20180052322A1Maintain brightness sharpnessImpairing uniformity of imageDiffusing elementsBuilt-on/built-in screen projectorsHead-up displayDisplay device

In order to provide a transmission type screen capable of maintain sharpness of image without impairing uniformity of emergent light to be emitted therefrom, a transmission type screen 40 of the present invention includes a microlens array substrate 50 having a first surface 51 equipped with a microlens array 54 including a plurality of microlenses; and a light diffusion substrate 60 having a second surface 61 equipped with a light diffusion surface; wherein the first surface 51 of the microlens array substrate 50, which is equipped with the microlens array, and the second surface 61 of the light diffusion substrate 60, which is equipped with the light diffusion surface, are opposedly arranged.

Owner:DAI NIPPON PRINTING CO LTD

Semiconductor device and method of manufacturing the semiconductor device

InactiveUS20100140671A1Suppress mutationThickness variationTransistorSolid-state devicesDevice materialEngineering

A method of manufacturing a semiconductor device includes forming silicon pillar 11 on substrate 10, forming a protective film which covers an upper end portion and a lower end portion of a side surface of silicon pillar 11, forming a constricted portion by anisotropic etching in a portion of the side surface of silicon pillar 11 which is not covered with the protective film after forming the protective film, removing the protective film after forming the constricted portion, forming gate oxide film 12 which covers the side surface of silicon pillar 11 in which the constricted portion is formed, and forming gate electrode 13 which covers gate oxide film 12.

Owner:PS4 LUXCO SARL

Polymerizable liquid crystal composition and optically anisotropic film using the same

InactiveUS8246855B2Impairs stabilityUniform damageLiquid crystal compositionsThin material handlingSolubilitySolvent

A polymerizable liquid crystal composition is provided that has a wide range where a liquid crystal phase is exhibited, has excellent solubility in an organic solvent, and is facilitated in control of an alignment state. The use of the polymerizable liquid crystal composition provides a polymerizable liquid crystal composition that has good solubility in a solvent with high safety, such as PGMEA, and can control various alignment states. The polymerizable liquid crystal composition in one aspect contains a fluorenone derivative represented by the formula (1) and a compound having a bisphenol skeleton represented by the formula (2). In the formulae (1) and (2), W1 represents hydrogen, fluorine, chlorine, methyl or ethyl; X1 represents hydrogen, fluorine, methyl or trifluoromethyl; Z11 to Z14 are bonding groups; A1 represents a divalent cyclic group; Y1 represents alkylene having from 2 to 20 carbon atoms; A2 represents a divalent group having a bisphenol skeleton; X2 represents hydrogen, fluorine, methyl or trifluoromethyl; W2 represents hydrogen, halogen, alkyl or fluoroalkyl; Y2 independently represents a single bond, —CH═CH— or —(CH2)2—; and n2 independently represents an integer of from 2 to 15.

Owner:JNC PETROCHEM CORP +1

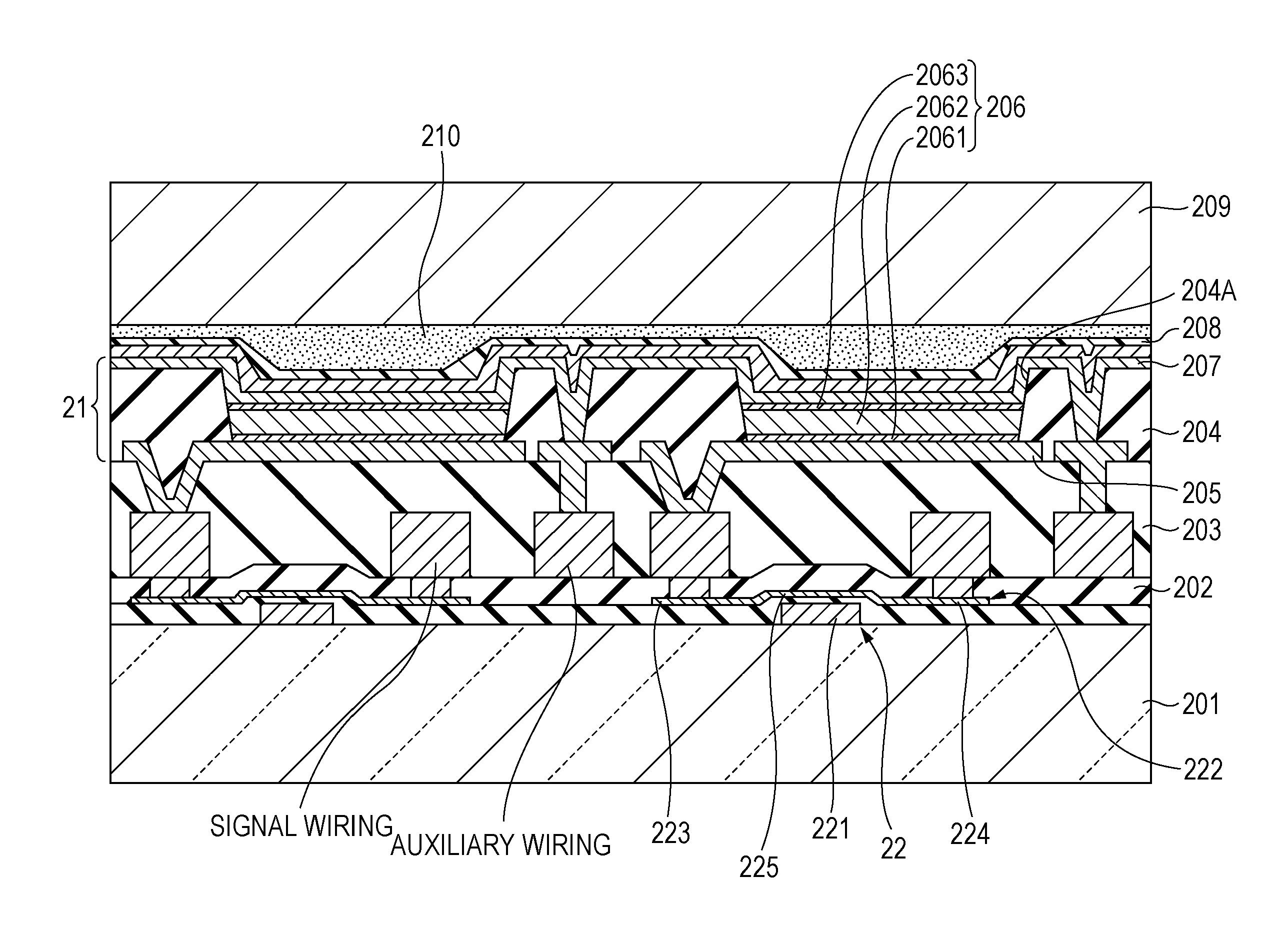

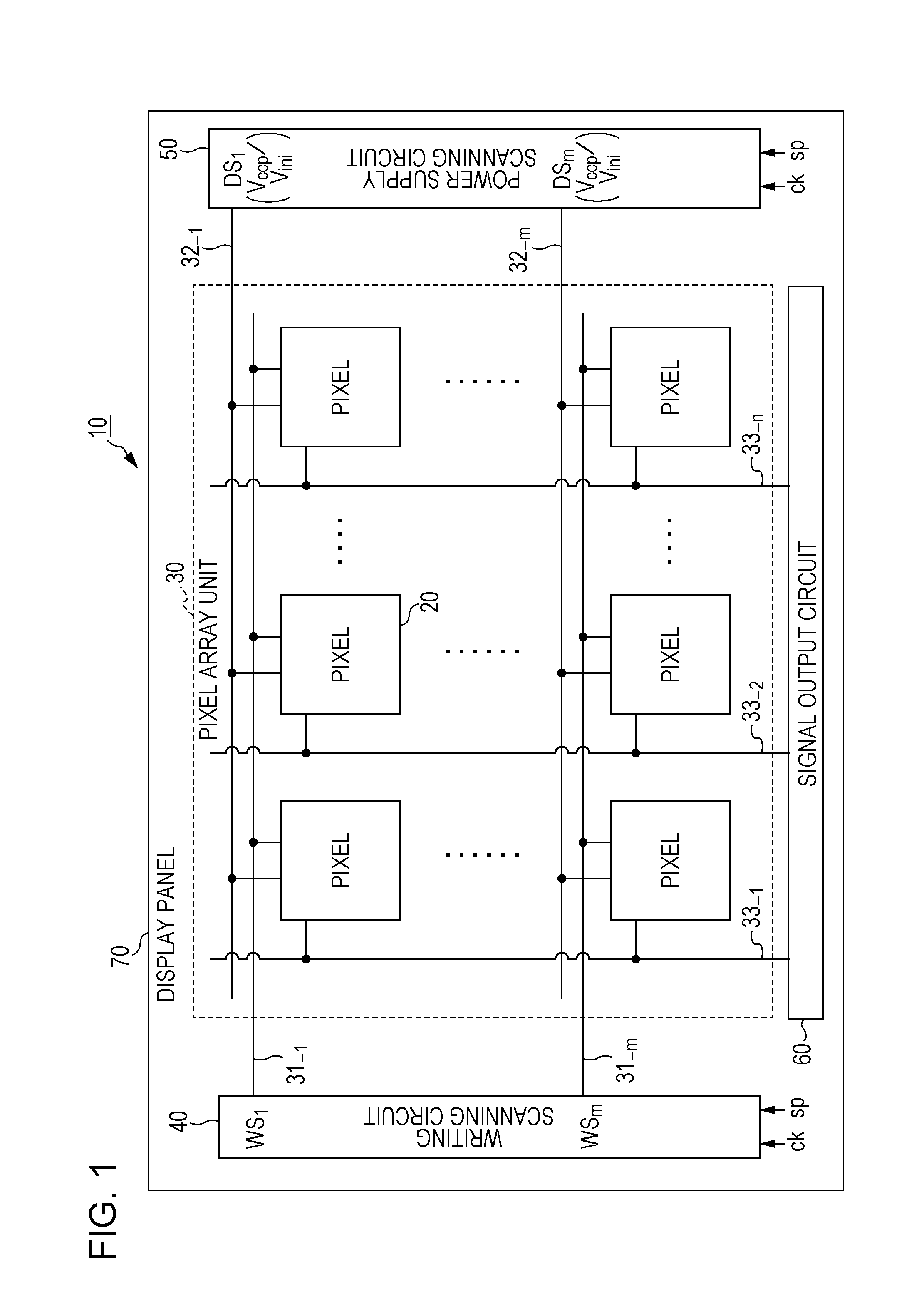

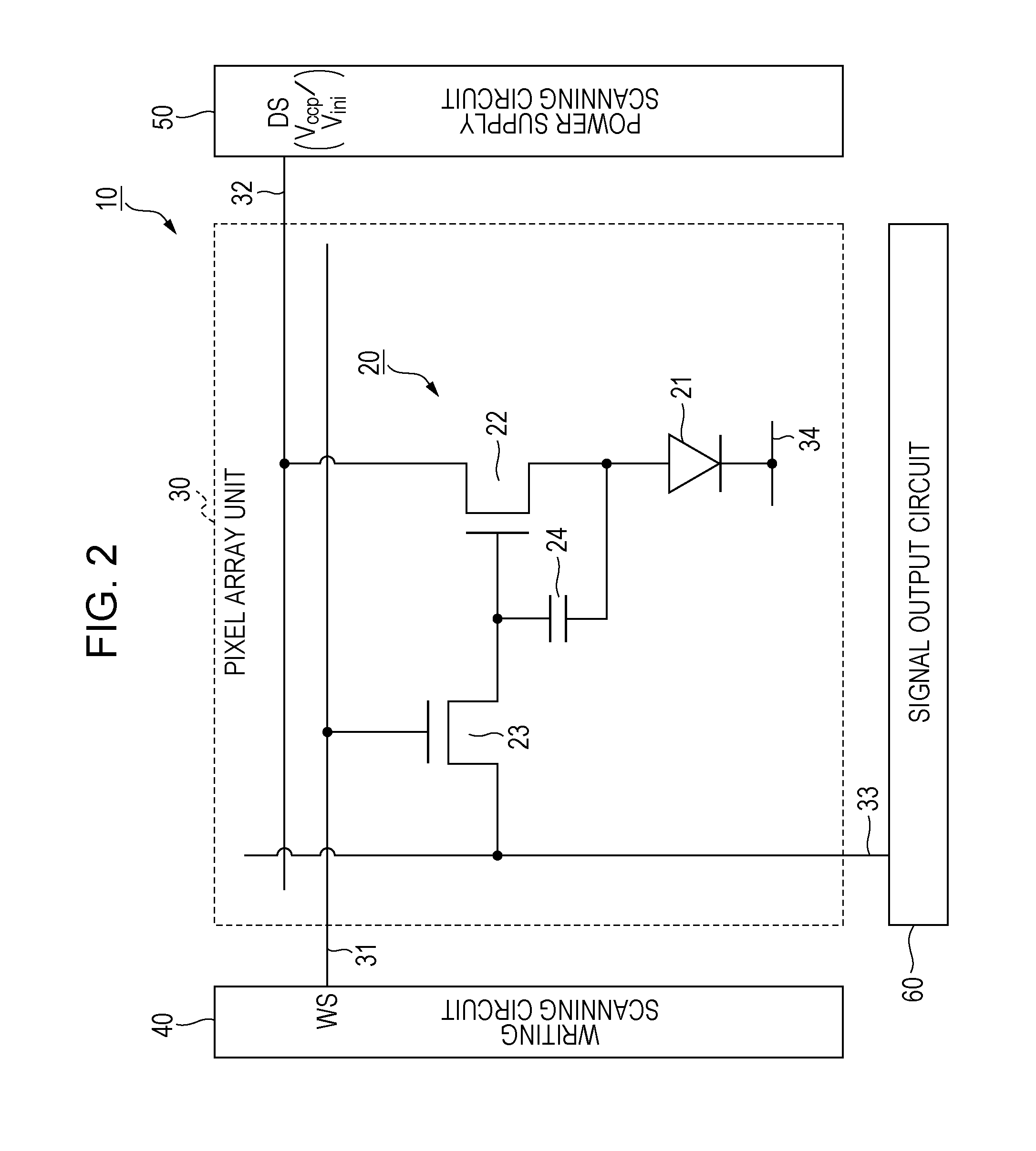

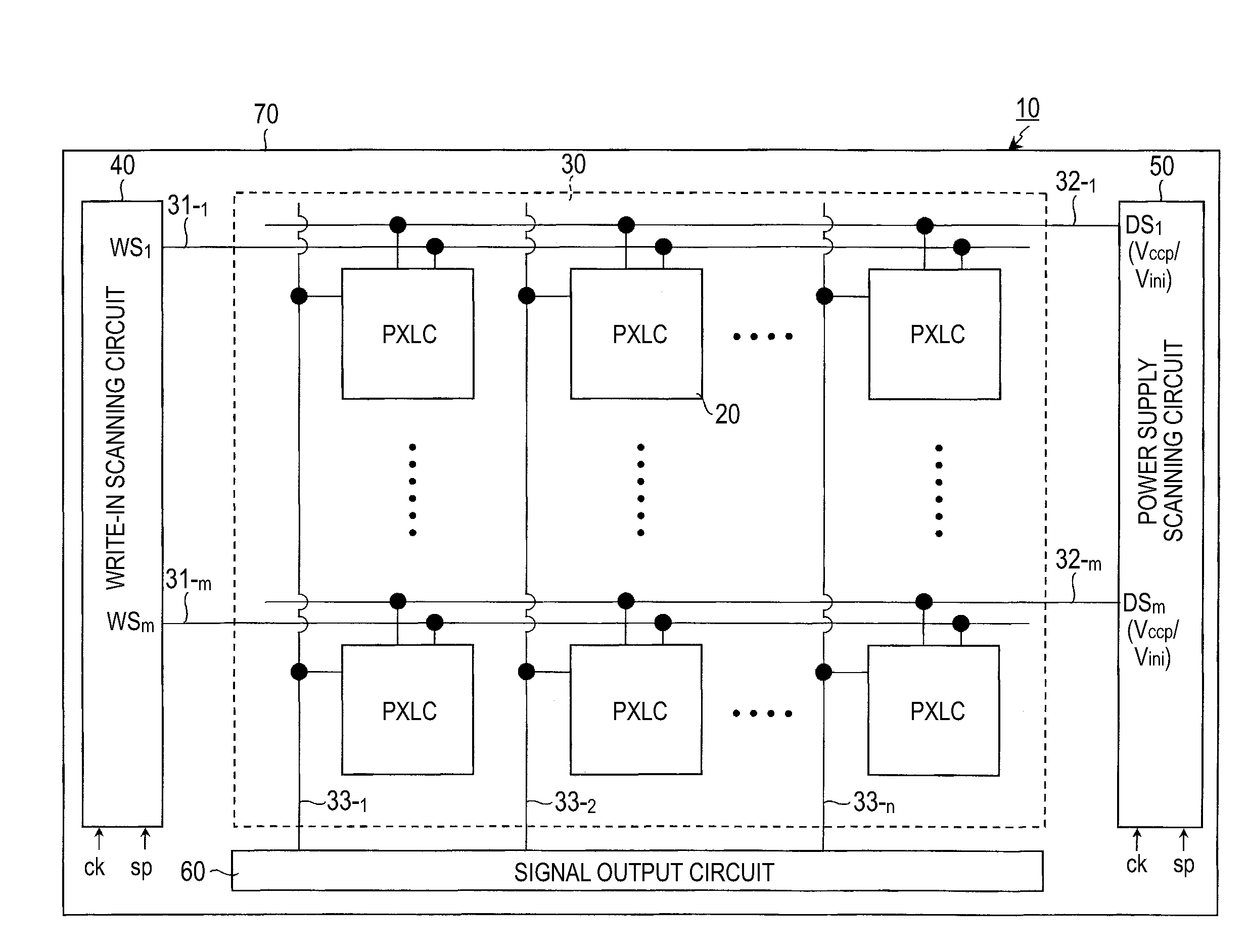

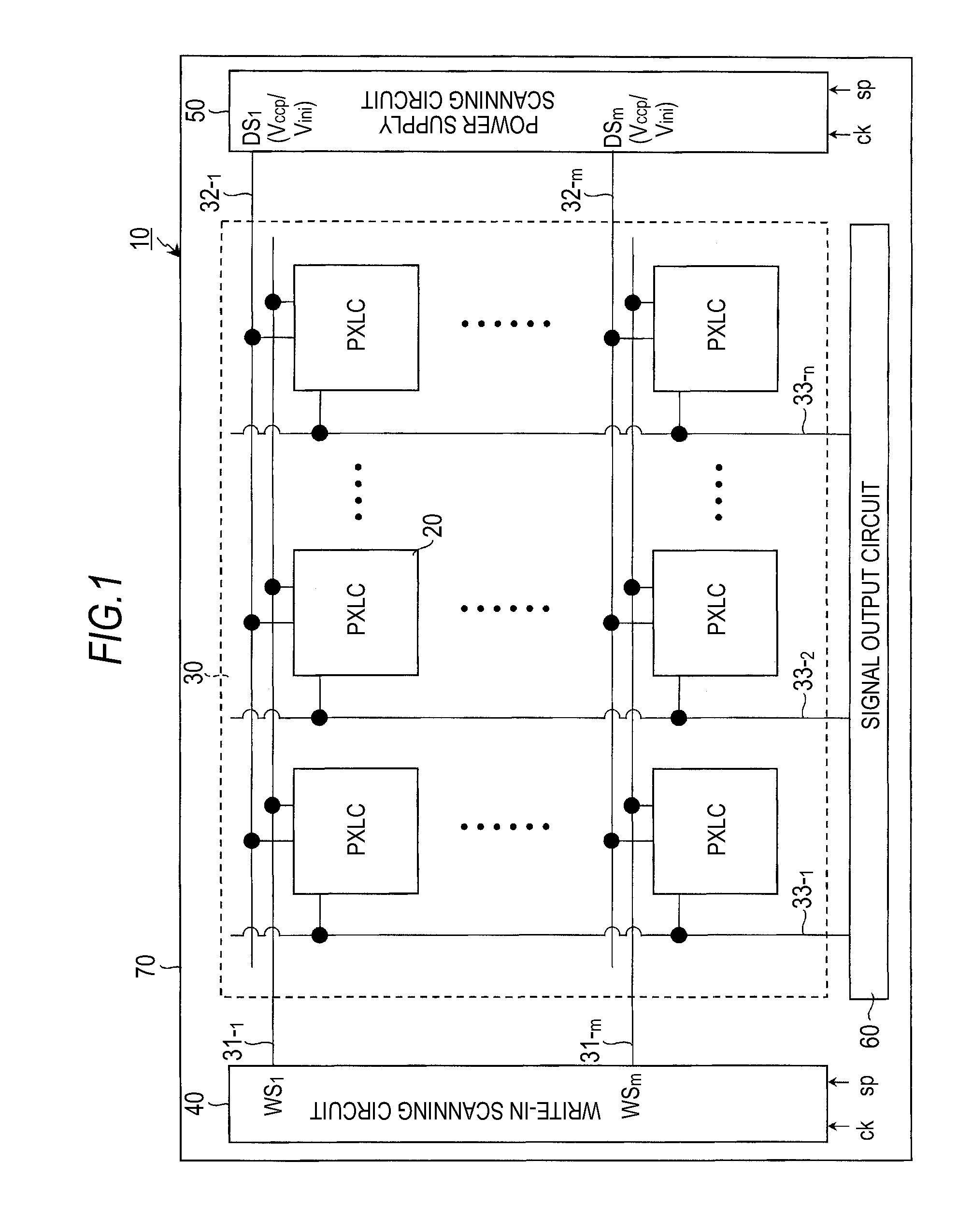

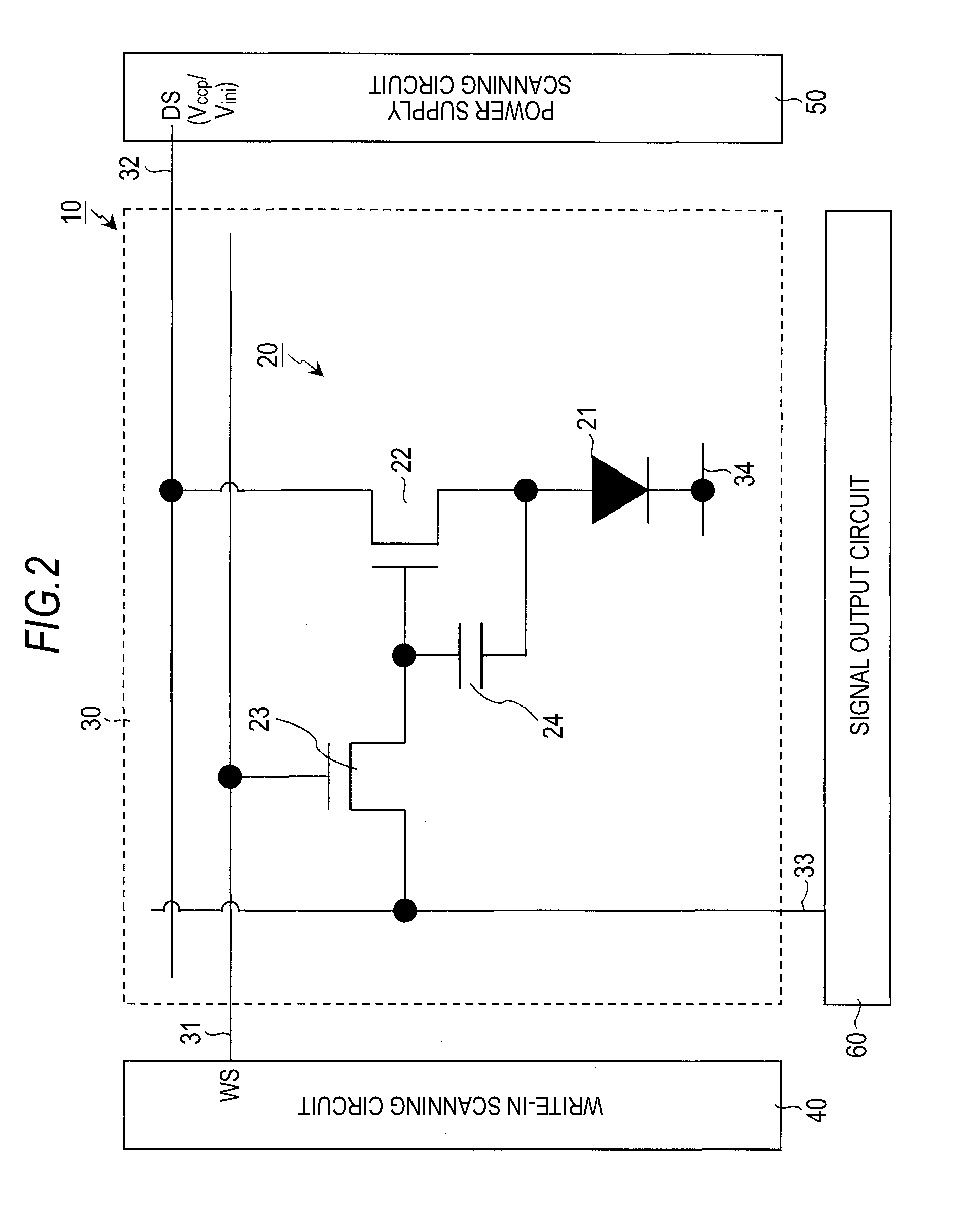

Display apparatus, method of manufacturing display apparatus, and electronic apparatus

ActiveUS20110241001A1Reduce capacitanceHigh-quality display imageStatic indicating devicesSolid-state devicesEngineeringCapacitor

A display apparatus includes a plurality of pixels each including an electro-optic element, a writing transistor writing a video signal into the pixel, a holding capacitor holding the video signal written by the writing transistor, and a driving transistor driving the electro-optic element based on the video signal held in the holding capacitor. The driving transistor includes a channel region, a gate electrode disposed opposite to the channel region, a first source / drain region closer to a power source, a second source / drain region closer to the electro-optic element, and impurity regions disposed between the channel region and the first and second source / drain regions and having a lower concentration than that of the corresponding source / drain region. The impurity region disposed between the channel region and the first source / drain region is formed in a region other than a region facing the gate electrode.

Owner:JOLED INC

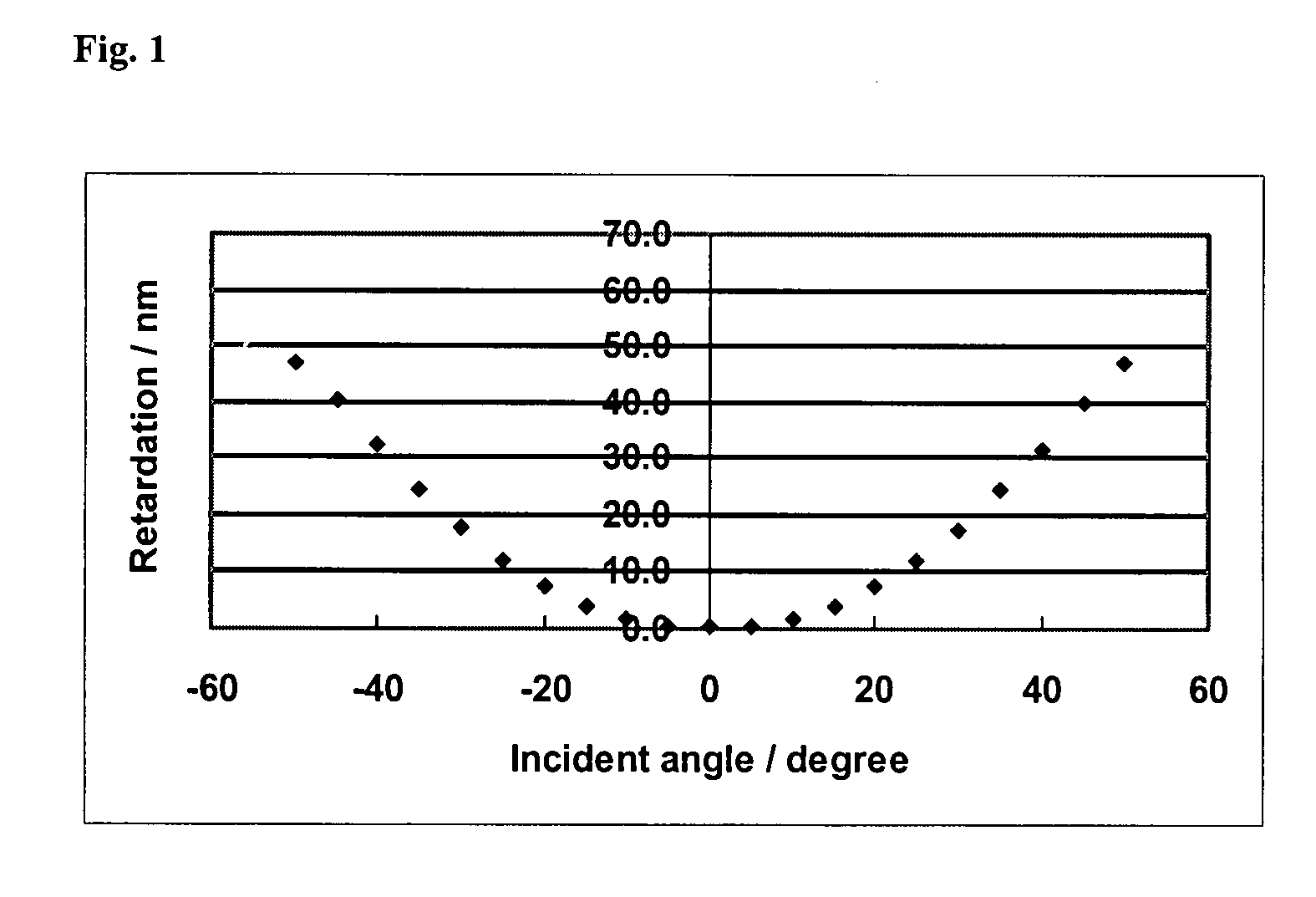

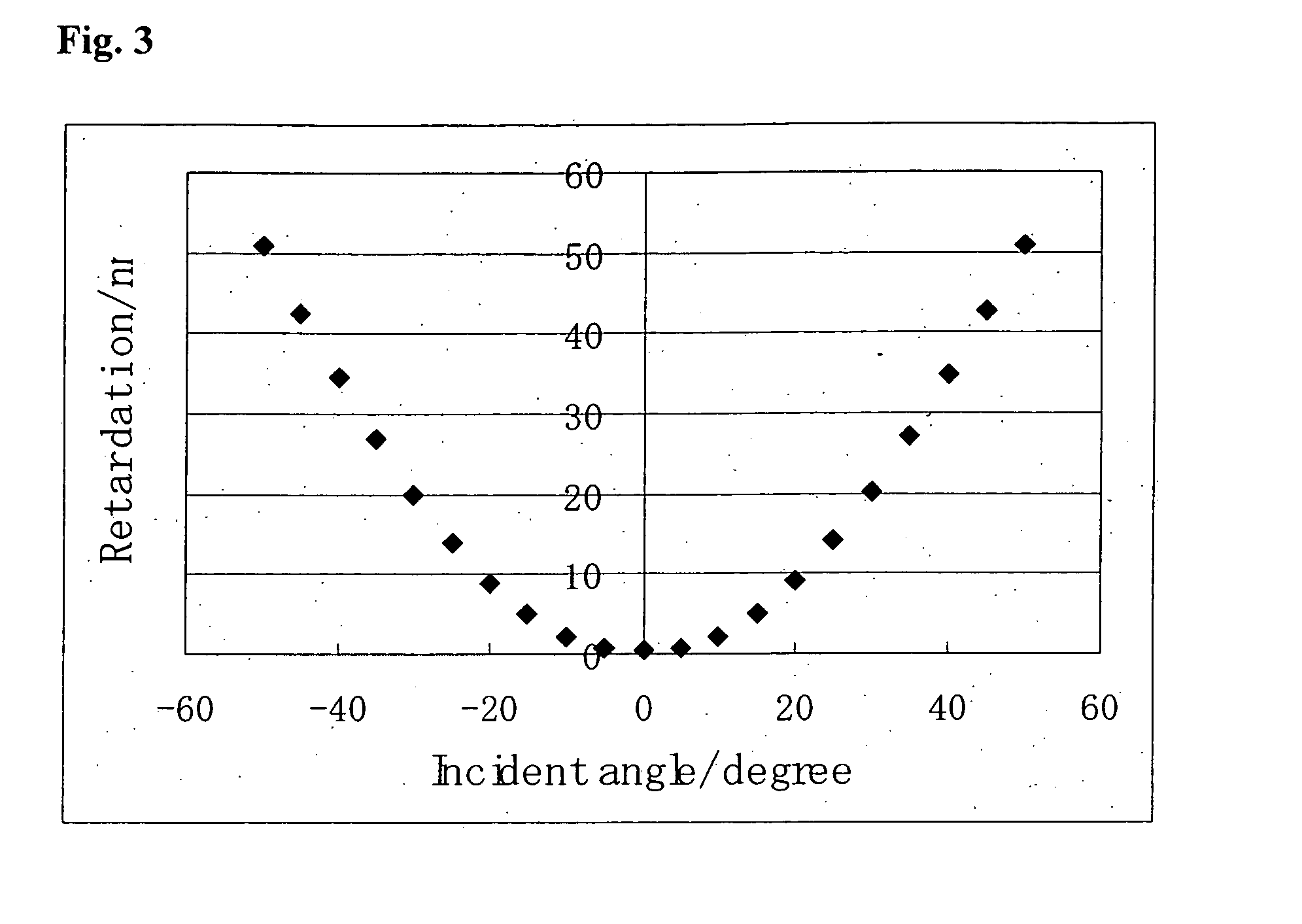

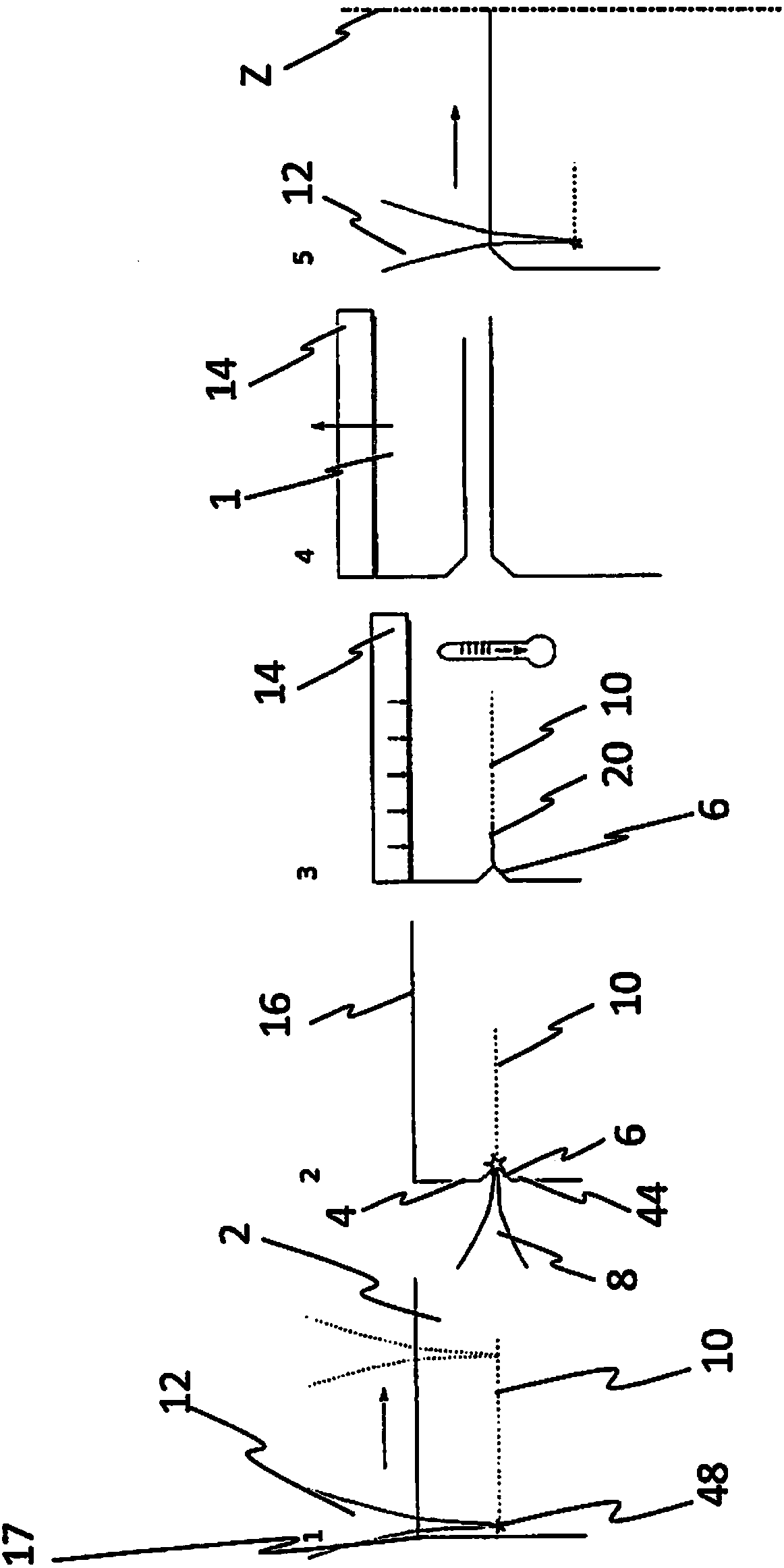

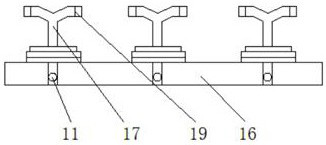

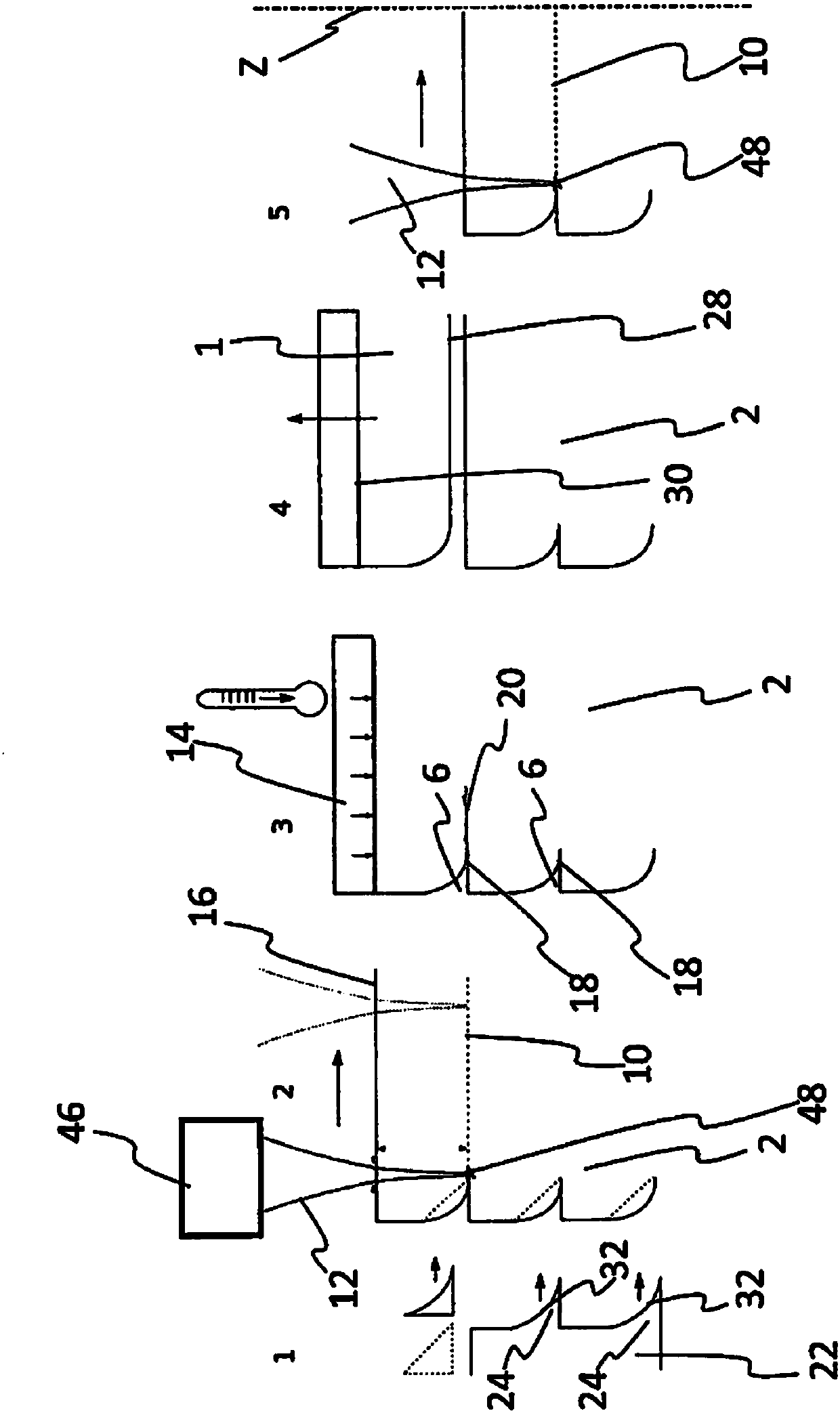

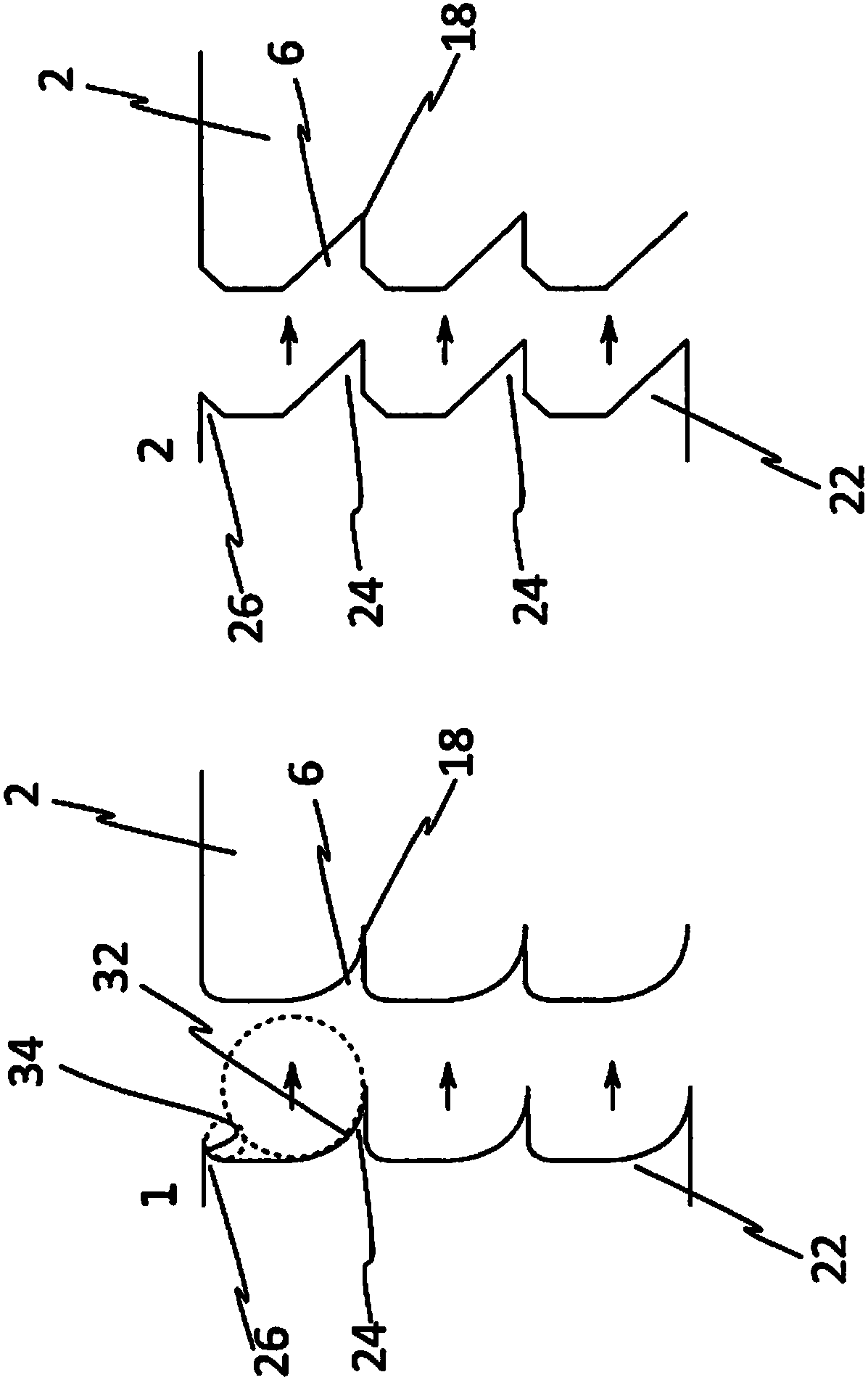

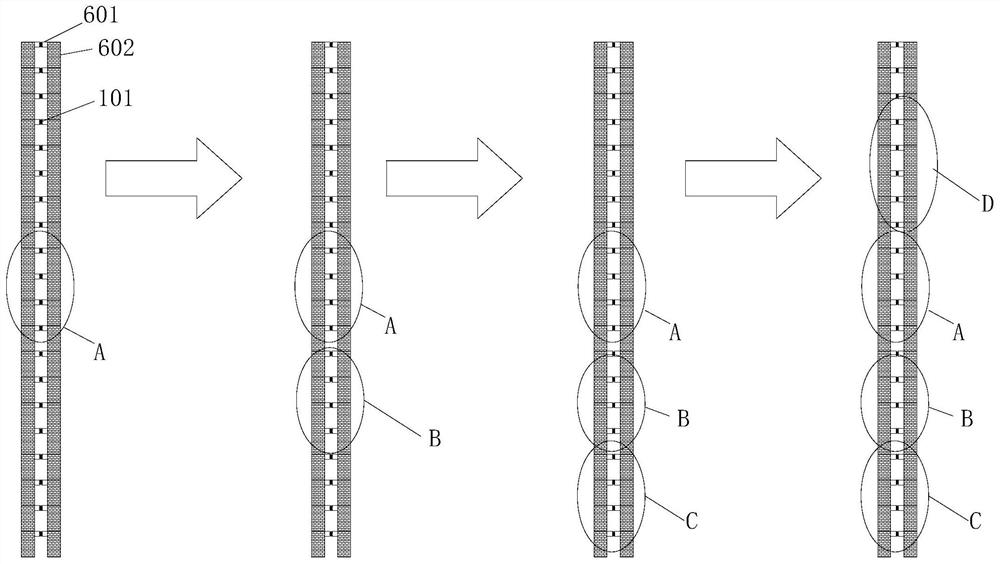

Method for guiding crack in edge portion of donor substrate by using inclined laser beam

ActiveCN107848067AUniform damageSemiconductor/solid-state device manufacturingFine working devicesStress inducedOptoelectronics

The invention relates to a method for cutting solids wafers (1) off a donor substrate (2). The method comprises the following steps of: providing the donor substrate (2); producing at least one modification (10) in the interior of the donor substrate (2) by means of at least one laser beam (12), wherein the laser beam (12) penetrates the donor substrate (2) via a flat surface (16) of the donor substrate (2). The laser beam (12) is inclined with respect to the flat surface (16) of the donor substrate (2) such that it penetrates the donor substrate at an angle of not equal to 0 degree or 180 degrees relative to the longitudinal axis of the donor substrate. The laser beam (12) is focused in order to produce the modification (10) in the donor substrate (2) and the solids wafer (1) detaches itself from the donor substrate (2) as a result of the modifications (10) produced. Or a stress-inducing layer (14) is produced in or arranged on the flat surface (16) of the donor substrate (2) and mechanical stress is produced in the donor substrate (2) by exposing the stress-inducing layer (14) to heat. The mechanical stress produces a crack (20) for separating a solids layer (1), and the crack propagates along the modifications (10).

Owner:SILTECTRA

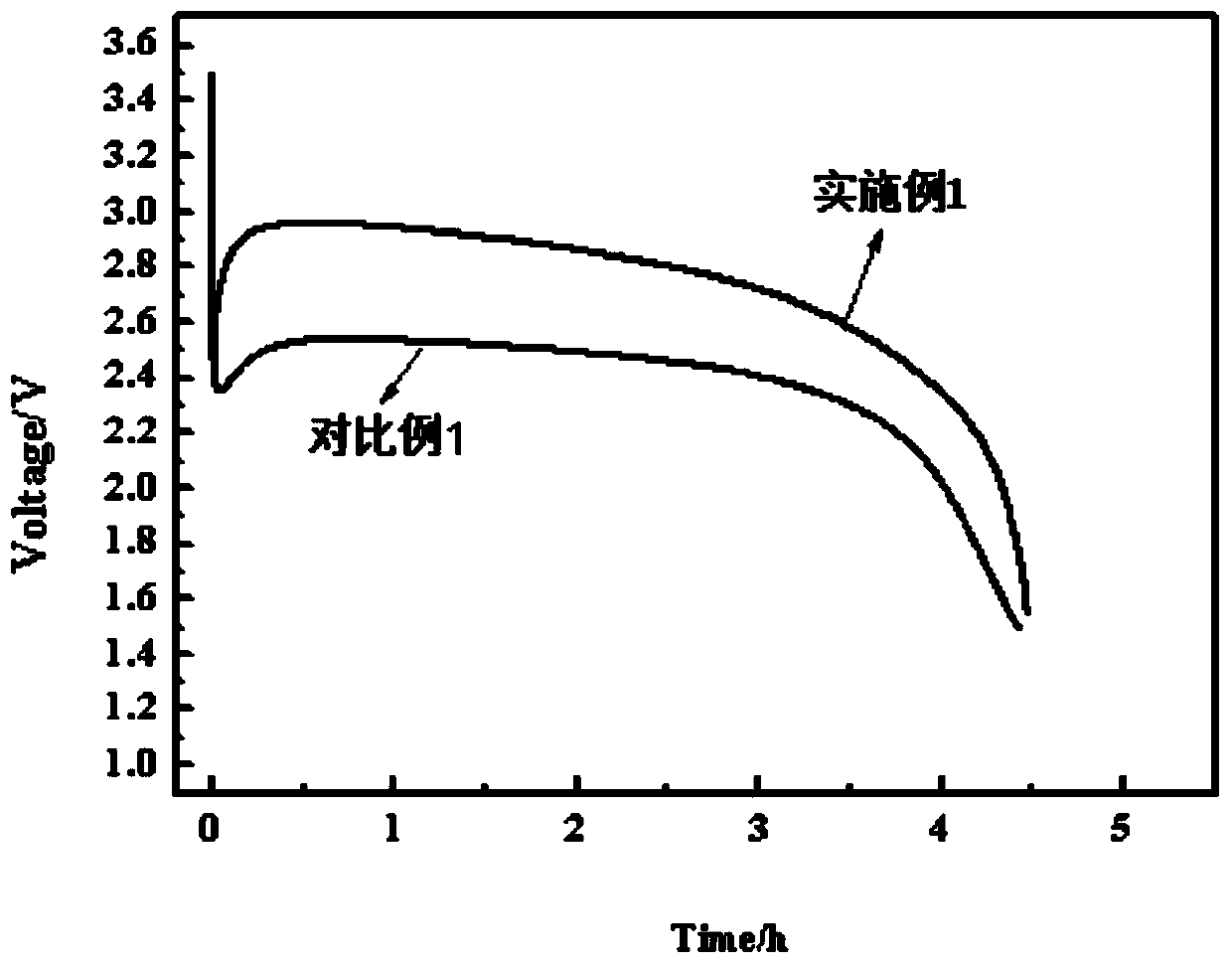

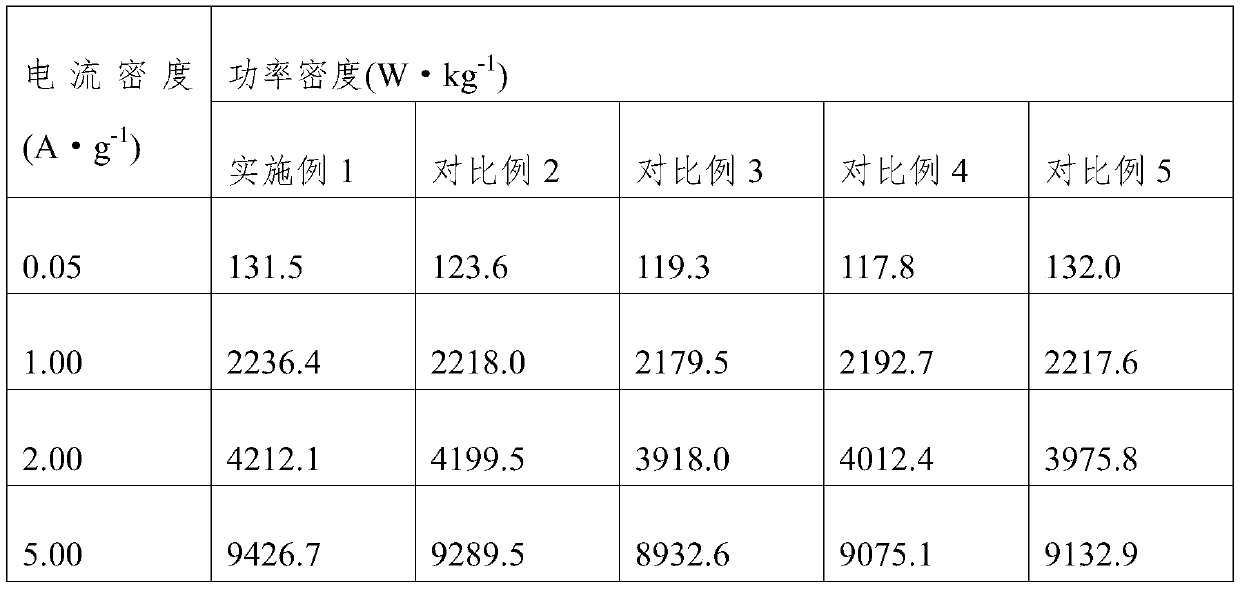

Nano-material modified carbon fluoride electrode material manufacturing method

ActiveCN110783522AImprove conductivityImprove voltage hysteresisMaterial nanotechnologyPrimary cell electrodesCarbon monofluorideModified carbon

The invention discloses a nano-material modified carbon fluoride electrode material manufacturing method. The method comprises the following steps of mixing a medium and carbon fluoride, adding a ferro-nickel alloy and mixing; adding a nano material, reacting, airing, carrying out vacuum drying, grinding, calcining in an argon atmosphere, and cooling to a room temperature; and grinding, and screening with a 100-200-mesh sieve to obtain a nano-material modified carbon fluoride electrode material. A mass ratio of the nano material to the carbon fluoride is (0.5-5):100. In the invention, a carbonfluoride material is modified by adopting the nano material, and the nano material is uniformly distributed on a surface of the carbon fluoride material so that conductivity of the carbon fluoride material is improved, problems of voltage lag and low-temperature performance of the carbon fluoride material are effectively solved, and a rate capability of a lithium carbon fluoride battery is improved.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Group III nitride semiconductor light-emitting device including an auxiliary electrode in contact with a back surface of an n-type layer

ActiveUS8471288B2Uniform damageImprove the extraction effectSolid-state devicesSemiconductor devicesAuxiliary electrodeActive layer

A Group III nitride semiconductor light-emitting device includes a support, a p-electrode provided on the support, a p-type layer including a Group III nitride semiconductor and provided on the p-electrode, an active layer including a Group III nitride semiconductor and provided on the p-type layer, an n-type layer including a Group III nitride semiconductor and provided on the active layer, an n-electrode which is connected to the n-type layer, a first trench having a depth extending from a back surface of the p-type layer on a side of the p-electrode to reach the n-type layer, an auxiliary electrode which is in contact with a back surface of the n-type layer at a bottom of the first trench, but is not in contact with side walls of the first trench, and an insulating film which exhibits light permeability.

Owner:TOYODA GOSEI CO LTD

Spraying and quenching device for steel pipe, petroleum well pipe and drill pipe medium frequency heat treatment system

ActiveCN101078045ARapid coolingRapid and uniform coolingFurnace typesHeat treatment process controlSteel tubeQuenching

This invention provides a kind of spray quenching equipment in the frequency treatment system of steel pipe, tube and drill pipe of oil well. The sprinkler is a circle distribution and the inlet pipe is connected with the pump. The spray quenching angle switch equipment is installed onto the sprinkler. Several muzzles are fixed to the sprinkler, which are distributed in taper or sector shape. All of the muzzles are symmetric set, the diameter of which is from 1.2mm to 4mm. The center line of the spray quenching equipment is coinciding with that of the steel pipe , tube and drill pipe. The advantages are: the continuum spray quenching process with product line can make the work pieces quenched properly. The average flatness of a 10-meters long work piece can come up to the US standard API, which is 0.2% of the total length from one end to the other. It couldn' t exceed 3.175 mm within 1524mm long. The spray pressure is controllable, the equipment can cool down quickly and the jam can be removed quickly. The angle of the muzzle is adjustable, which can reduce the backwater when the work pieces pass the spray quenching area.

Owner:朱兴发

Preparation method of pine needle-shaped carbon nanotube/carbon fiber composite carbon material

InactiveCN111217350AHigh degree of inkingIncrease distribution densityMulti-walled nanotubesSucroseReaction tube

The invention discloses a preparation method of a pine needle-shaped carbon nanotube / carbon fiber composite carbon material. The preparation method comprises the following steps: carrying out ultrasonic cleaning on carbon paper in isopropanol, drying, carrying out heat treatment, soaking in concentrated HNO3, rinsing, and drying; dissolving ferric nitrate and sucrose in a mixed solvent of acidic silica sol and ethanol, and stirring to obtain a metal iron catalyst precursor solution; and soaking the carbon paper into the solution, carrying out suction filtration, drying, placing on a porcelainboat, introducing Ar, heating to 280-290 DEG C, switching to H2, reducing, adjusting the flow of Ar and H2, heating to 745-755 DEG C, injecting a xylene ferrocene mixed solution into a reaction tube,reacting for 2-3 hours, closing H2, cooling the tubular furnace to 420-440 DEG C in an Ar atmosphere, calcining for 2.5-3.5 hours, and cooling to obtain the catalyst. According to the invention, multi-walled carbon nanotubes with high graphitization degree, high distribution density, large specific surface area and uniform tube diameter can be deposited on the pretreated carbon paper carbon fibers.

Owner:启东茂材实业有限公司

Agricultural anti-clogging farmland irrigation machine

InactiveCN111990041AEasily damagedEasy to installSpraying apparatusPressurised distribution of liquid fertiliserAgricultural engineeringStructural engineering

The invention discloses an agricultural anti-clogging farmland irrigation machine. The machine comprises a main body and a bottom plate; a push rod is fixed on the left side above the main body; a water tank is placed on the right side of the push rod; a spring is installed at the bottom of the water tank; a shaft core is arranged in the water tank; a shaft sleeve is installed on the outer wall ofthe shaft core; stirring cutters are arranged on the left side and the right side of the shaft sleeve; a slideway is formed in the inner wall of the right side of the water tank; a filter plate is placed at the bottom of the surface of the slideway; a port is formed in the right side of the water tank; a water pipe is connected to the right side of the port; a clamping groove is formed in the surface of the bottom plate; the bottom plate is located on the right side above the main body; a rolling shaft is placed in the clamping groove; and a bracket is placed above the bottom plate. The farmland irrigation machine is provided with the main body, the main body can provide a storage space for a whole irrigation device, the whole device can be placed together, simultaneous work is convenient, and the transportation and movement time is saved.

Owner:张雪燕

Method for guiding a crack in the peripheral region of a donor substrate

ActiveCN107820453AReduce spacingUniform damageSemiconductor/solid-state device manufacturingFine working devicesLaser beamsPhysics

The present invention relates to a method for separating solid wafers (1) from a donor substrate (2). The method comprises the steps of: creating modifications (10) within the donor substrate (2) by means of laser beams (12), wherein the modifications (10) define a detachment region along which separation of the solid layer (1) from the donor substrate (2) takes place, and removing material of thedonor substrate (2), starting from a surface (4) extending in the peripheral direction of the donor substrate (2), in the direction of the centre (Z) of the donor substrate (2), in particular for producing an encircling depression (6).

Owner:SILTECTRA

Ceramics sliding member for use in pure water

InactiveUS20130209777A1Easy to manufactureMinimize damagePump componentsAnimal housingCrystal structureCeramic

A ceramics sliding member for use in ultrapure water or pure water of the present invention is made of a non-continuous-pore SiC sintered body. The non-continuous-pore SiC sintered body includes β-SiC at a ratio of 20% by weight or more thereto and has an average crystal structure whose aspect ratio is 2 or greater.

Owner:EBARA CORP +1

Ceramics sliding member for use in pure water

InactiveUS20100130343A1Easy to manufactureMinimize damageEngine sealsBearing componentsCrystal structureCeramic

A ceramics sliding member for use in ultrapure water or pure water of the present invention is made of an SiC sintered body. The SiC sintered body includes β-SiC at a ratio of 20% or more thereto and has an average crystal structure whose aspect ratio is 2 or greater.

Owner:EBARA CORP +1

Medium-frequency furnace lining alumina-magnesia dry ramming material preparation and sintering process

InactiveCN109678474AImprove thermal shock resistanceGood chemical resistanceProcess efficiency improvementElectric furnaceMaterials preparationSpinel

The invention discloses a medium-frequency furnace lining alumina-magnesia dry ramming material preparation and sintering process, and relates to the technical field of steel metallurgy. A ramming material of the invention mainly comprises the following components in percentage by weight: 65%-75% of granules with the particle size being 0.5 mm-3 mm, 20%-45% of a powder material with the particle size less than or equal to 0.5 mm, 0.1%-0.5% of an admixture with the particle size less than or equal to 0.1 mm and 1%-3% of a high-temperature composite sintering accelerator with the particle size less than or equal to 0.005 mm. According to the method, the thermal shock resistance and the chemical corrosion resistance of the ramming material are improved through reasonable particle gradation, spinel is formed in use of a furnace lining in cooperation with a reasonable sintering process, generated expansion is matched with contraction generated by sintering, the sintering quality of the medium-frequency furnace lining after construction can be obviously improved, the overall strength of the furnace lining is excellent, the surface of the furnace lining is smooth, the damage is uniform, and the service life of the furnace lining is greatly prolonged.

Owner:浙江正锋实业有限公司

Display device and electronic appliance

InactiveUS20110242068A1Uniform damageImprove the bootstrap gainCathode-ray tube indicatorsInput/output processes for data processingDisplay deviceImage signal

A display device includes: a plurality of arranged pixels, each of which includes an electro-optical component, a write-in transistor writing an image signal in a pixel, a maintenance capacity maintaining the image signal written by the write-in transistor, and a driving transistor driving the electro-optical component based on the image signal maintained by the maintenance capacity; wherein the driving transistor has a sandwich gate structure in which a channel region is sandwiched between two gate electrodes, and the electro-optical component is formed so that at least a portion of one of the two gate electrodes and an anode electrode are opposite to each other.

Owner:SONY CORP

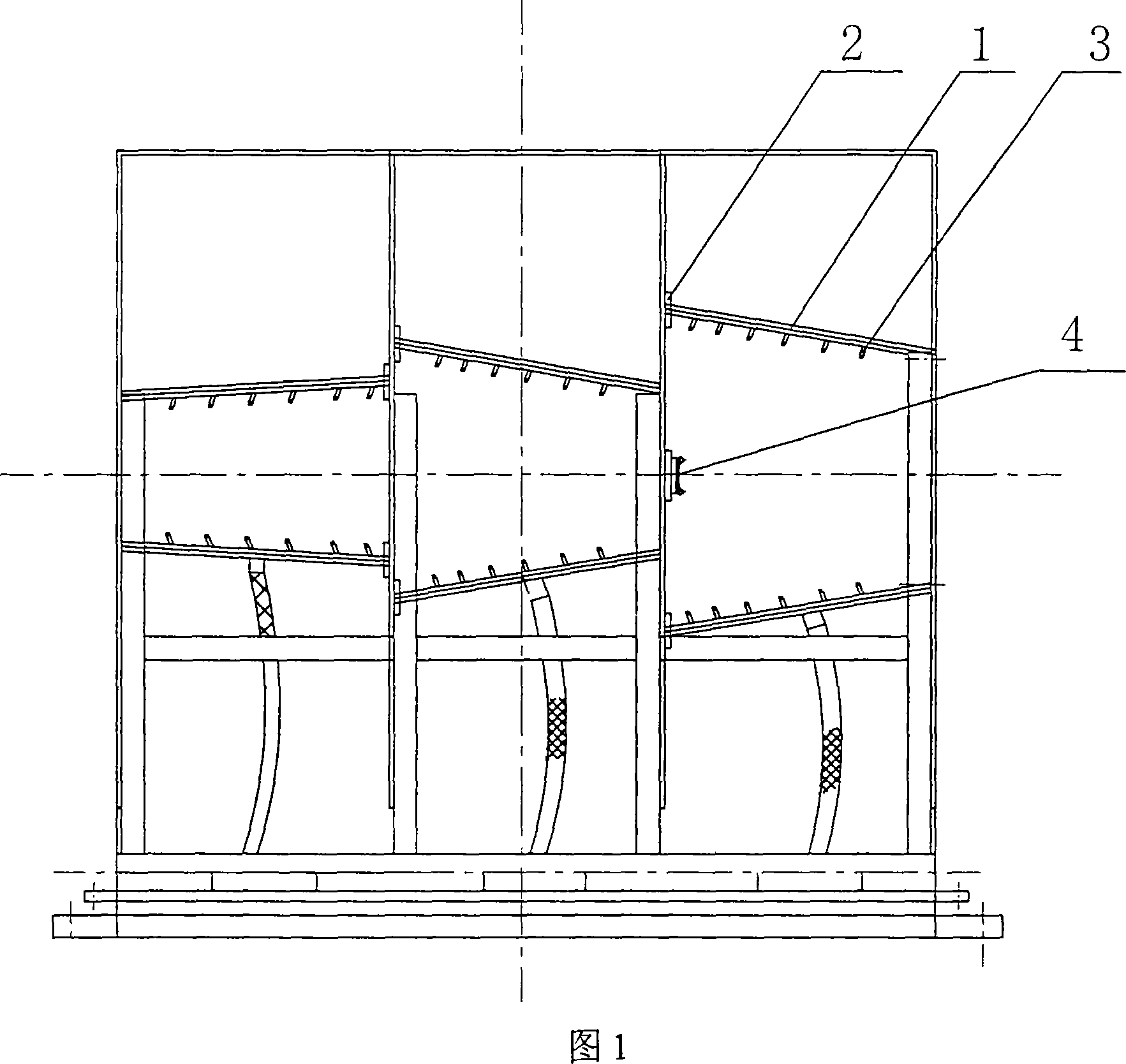

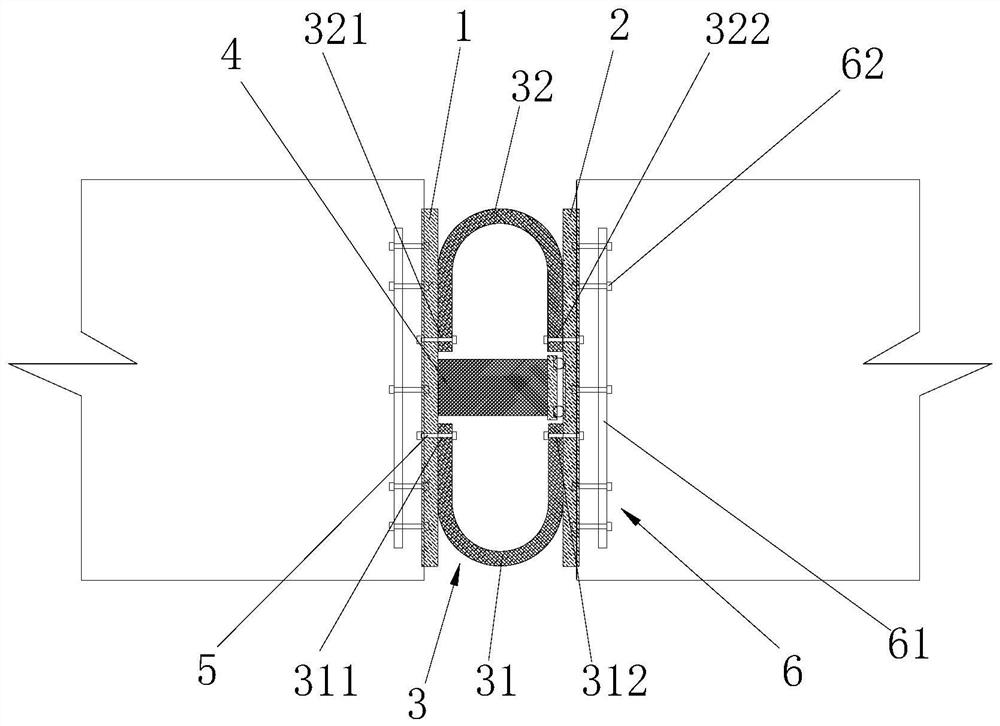

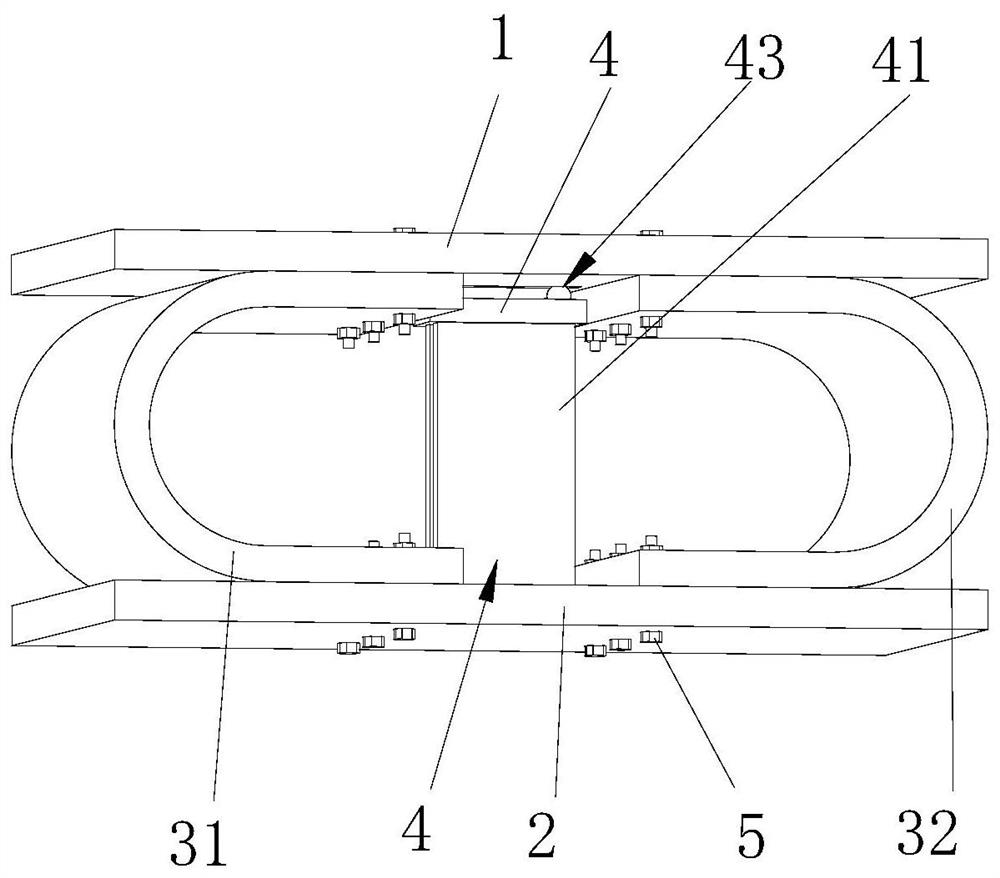

Second-order enhanced coupling beam type metal damping shock absorption system

ActiveCN112681552AAvoid replacementDamage does not accumulateHuman health protectionProtective buildings/sheltersEngineeringCoupling beam

The invention discloses a second-order enhanced coupling beam type metal damping shock absorption system. The second-order enhanced coupling beam type metal damping shock absorption system comprises a plurality of coupling beam soft steel dampers, the plurality of coupling beam soft steel dampers are distributed in a plurality of floors, and at least one coupling beam soft steel damper is arranged in each floor; each coupling beam soft steel damper comprises a first connecting plate and a second connecting plate, a first energy dissipation mechanism and a second energy dissipation mechanism are arranged between the first connecting plate and the second connecting plate, and the first energy dissipation mechanism comprises a first U-shaped energy dissipation plate and a second U-shaped energy dissipation plate; the second energy dissipation mechanism comprises a rectangular energy dissipation plate assembly; the first U-shaped energy dissipation plate and the second U-shaped energy dissipation plate are arranged on the two sides of the rectangular energy dissipation plate assembly; and the rectangular energy dissipation plate assembly is connected with the first connecting plate through a sliding support assembly. After the damping system is installed, the rigidity of lost parts of a building can be sequentially enhanced, the situation that the damage to the connecting beam damper part in a certain area is too large, and consequently an anti-seismic defense line is lost is avoided, and the overall structure is more convenient to replace and maintain.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

25-40mm specification Q235 pockmark control process

InactiveCN113369312AReduce the incidence of pittingReduce pittingRoll mill control devicesMetal rolling arrangementsThick plateStructural engineering

The invention discloses a 25-40mm specification Q235 pockmark control process, and relates to the technical field of steel production. The process comprises the steps that a Q235B steel type furnace charging plan is optimized and adjusted, and before Q235 steel type rolling, steel types with high surface quality requirements and thick plates with the specification being 40mm or above are not arranged; the condition of a rolling mill descaling header nozzle is replaced and checked regularly; according to the adjusted equipment condition, descaling processes of Q235B steel types with different thicknesses are redesigned; the Q235B steel types with different thicknesses are tracked, and the rolling control time is adjusted; and the surface quality conditions of steel plates under different finish rolling temperatures are analyzed, and the finish rolling starting process and the finish rolling process are adjusted according to the performance allowance of the steel plates. By adjusting the related rolling processes, 25-40mm specification Q235B surface pockmarks are reduced, the surface quality of the steel plates is improved, and the pockmark defects are reduced.

Owner:NANJING IRON & STEEL CO LTD

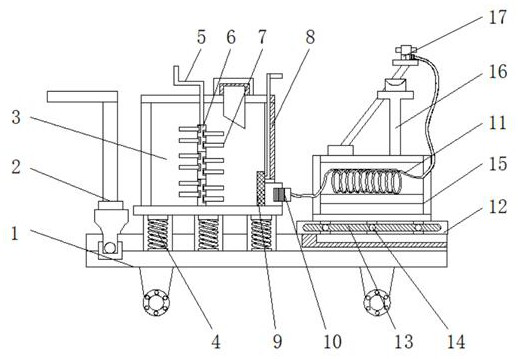

Tea leaf overturning apparatus

The invention relates to tea processing equipment, and concretely relates to a tea leaf overturning apparatus. The apparatus comprises a pedestal, a motor fixedly arranged on the pedestal, and a shake cage for receiving tea leaves, wherein the apparatus also comprises a transmission mechanism for connecting the motor with the shake cage, the transmission mechanism comprises an eccentric rod connected with the rotating shaft of the motor, a shake shaft connected with the eccentric rod through a first joint bearing, and a shake disc fixedly arranged at the free end of the shake rod, the shake shaft is connected with the pedestal through a second joint bearing, and the shake disc fixes the shake cage. The tea leaf overturning apparatus capable of overturning up and down and also capable of overturning from side to side to a certain degree is provided to solve the problem of poor overturning effect induced by insufficient overturning of tea leaves due to unable side-to-side overturning of present cylindrical rotating cages.

Owner:CHONGQING CITY CHANGSHOU DISTRICT DAJIAFU FRUIT PLANTING CO LTD

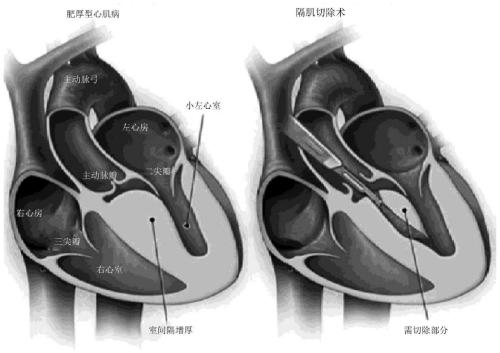

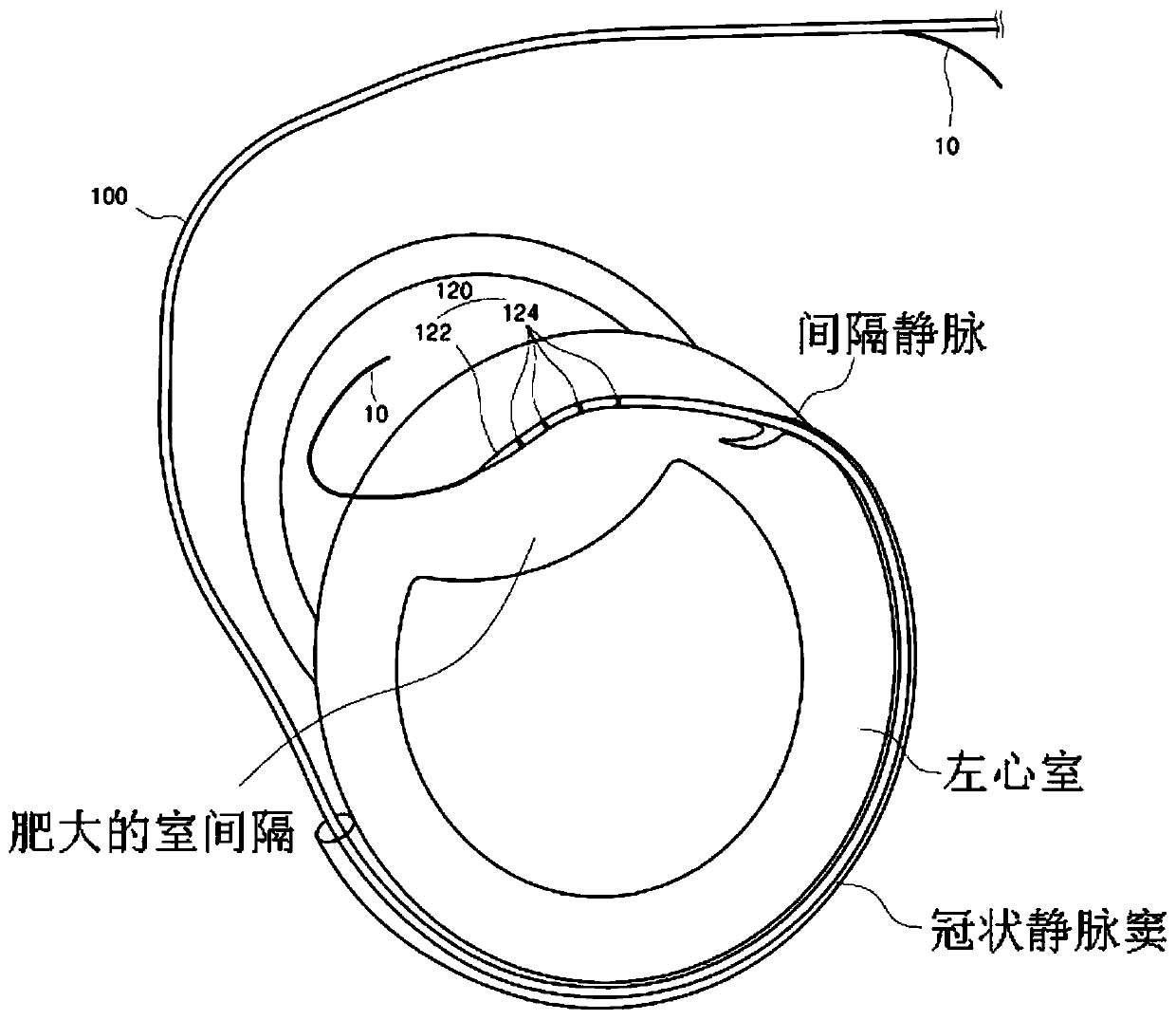

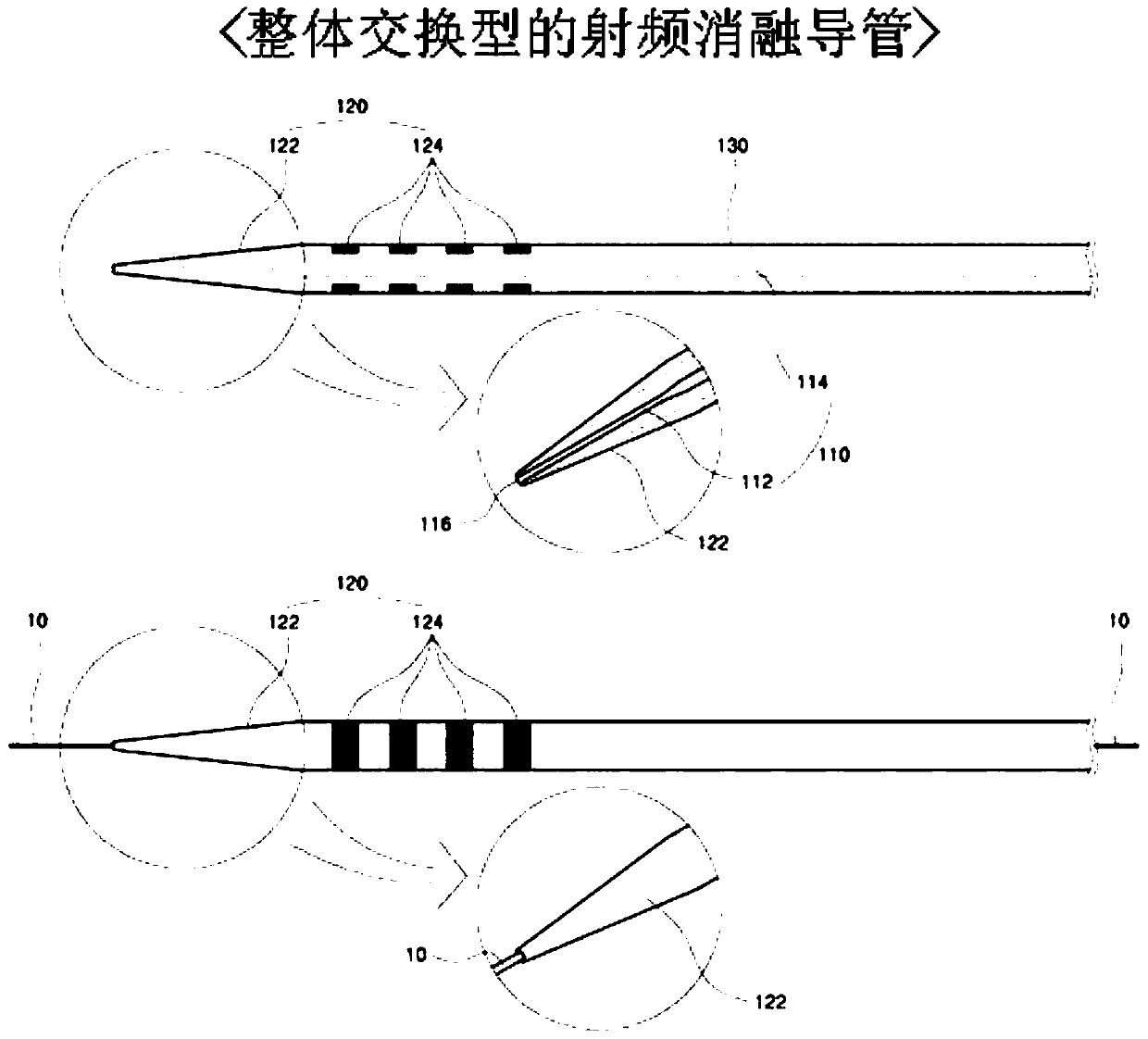

RF ablation catheter for treating hypertrophic cardiomyopathy

ActiveCN111202581ASmooth entryImplement securityElectrotherapyControlling energy of instrumentHypertrophic myocardiopathyRf ablation

An RF catheter for treating hypertrophic cardiomyopathy includes: a body part constituting a catheter body made of a flexible and soft material; and an intraseptal insertion part provided at a distalpart of the body part and having one or more electrodes, a tapered tip gradually becoming thinner toward an end thereof, and a guidewire lumen therein, into which a guidewire is inserted, so that during hypertrophic cardiomyopathy treatment, the intraseptal insertion part is inserted into the interventricular septum along the guidewire.

Owner:타우카디오인크

Sensitizing solution for electroless plating and electroless plating method

InactiveUS20110159191A1Excellent property of dissolving Sn compoundVariation of quality resultPretreated surfacesSemiconductor/solid-state device manufacturingAlcoholPhysical chemistry

Provided is a sensitizing solution for electroless plating which can easily dissolve an Sn compound therein without the use of acid, and thus can be used for a long period of time without impairing the uniformity of a metal plating coating. The sensitizing solution for electroless plating is a sensitizing solution for electroless plating including: an Sn compound; and a solvent, wherein the solvent contains 10 vol. % or more of a water-soluble alcohol. In addition, provided is an electroless plating method including: a pretreatment process of immersing a body to be plated into a pretreatment solution; and a plating process of immersing the body to be plated after being subjected to the pretreatment process into a plating solution, wherein the sensitizing solution for electroless plating according to the invention is used as the pretreatment solution.

Owner:SHOWA DENKO KK +1

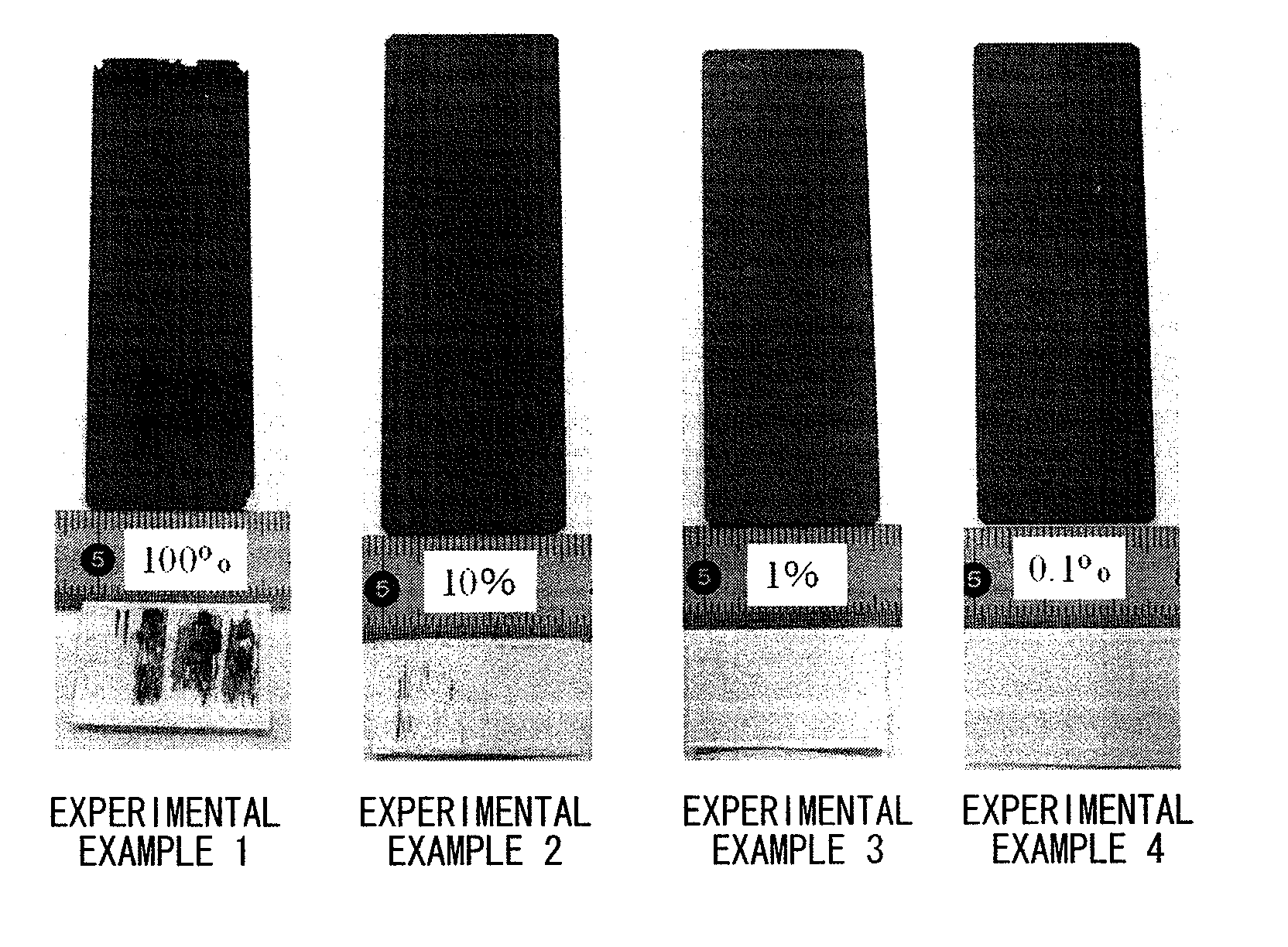

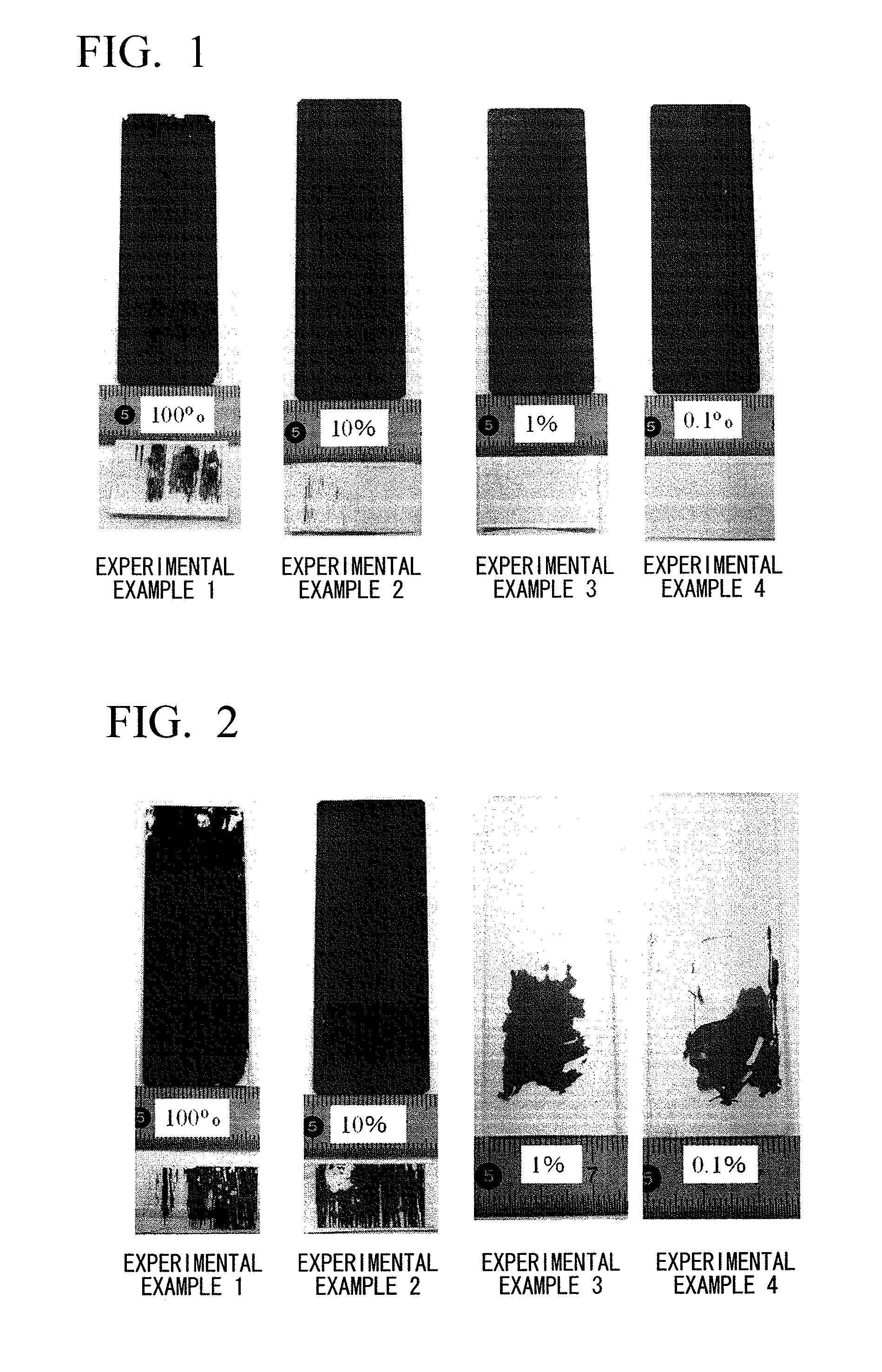

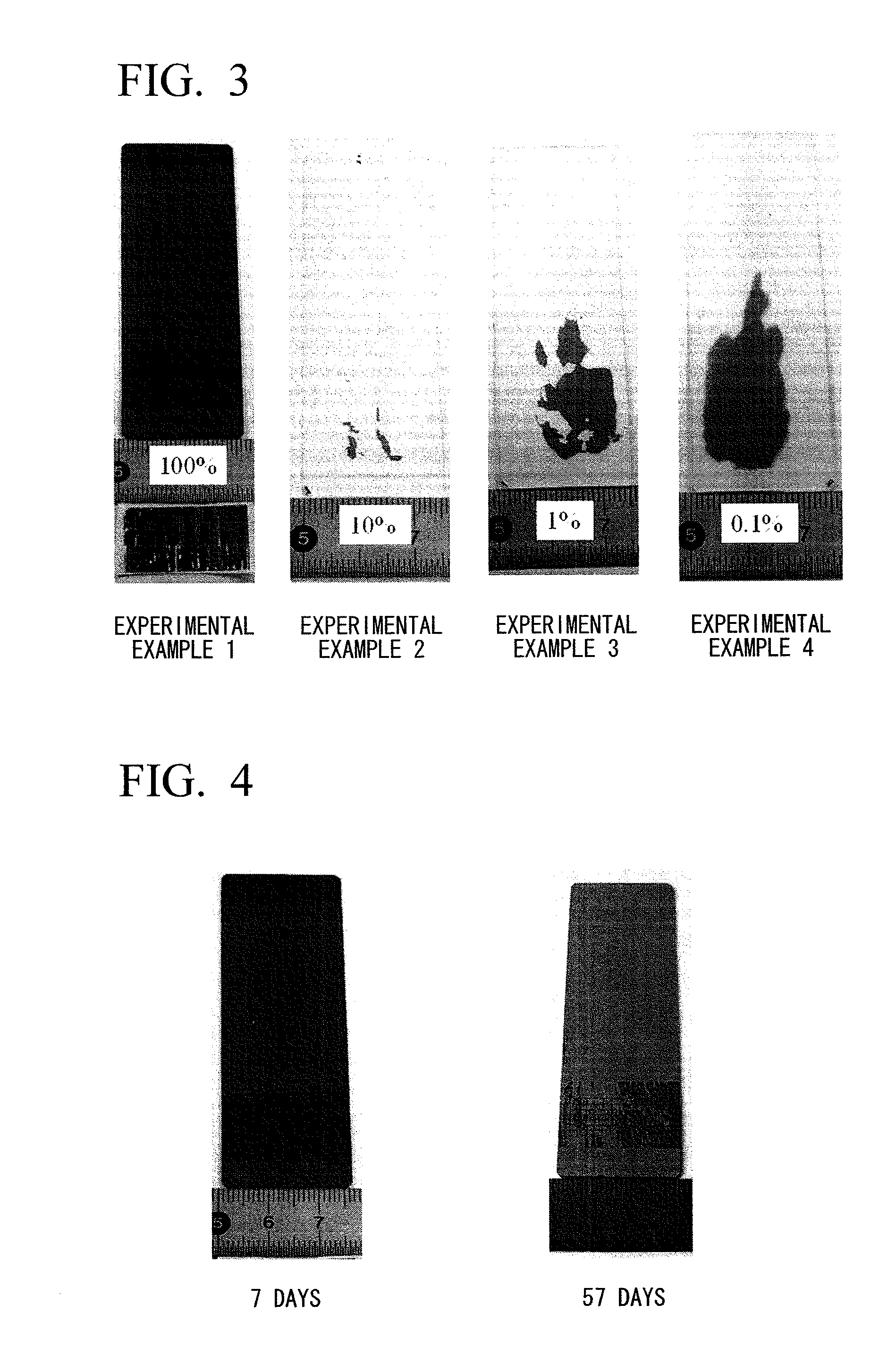

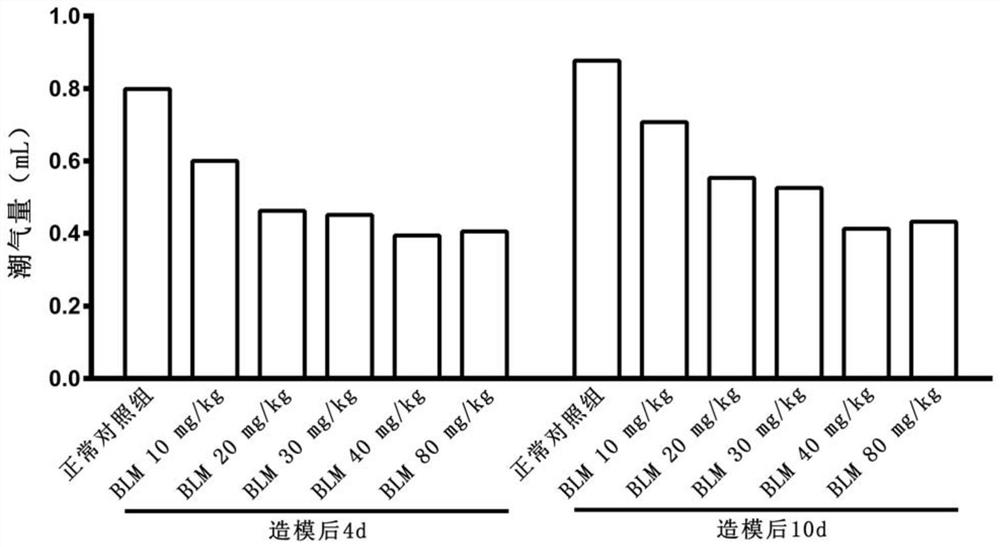

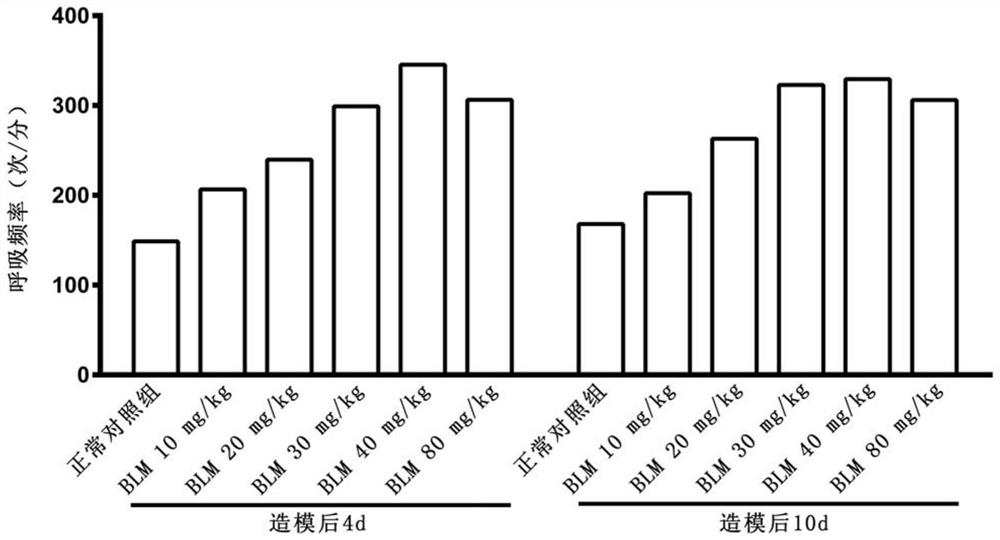

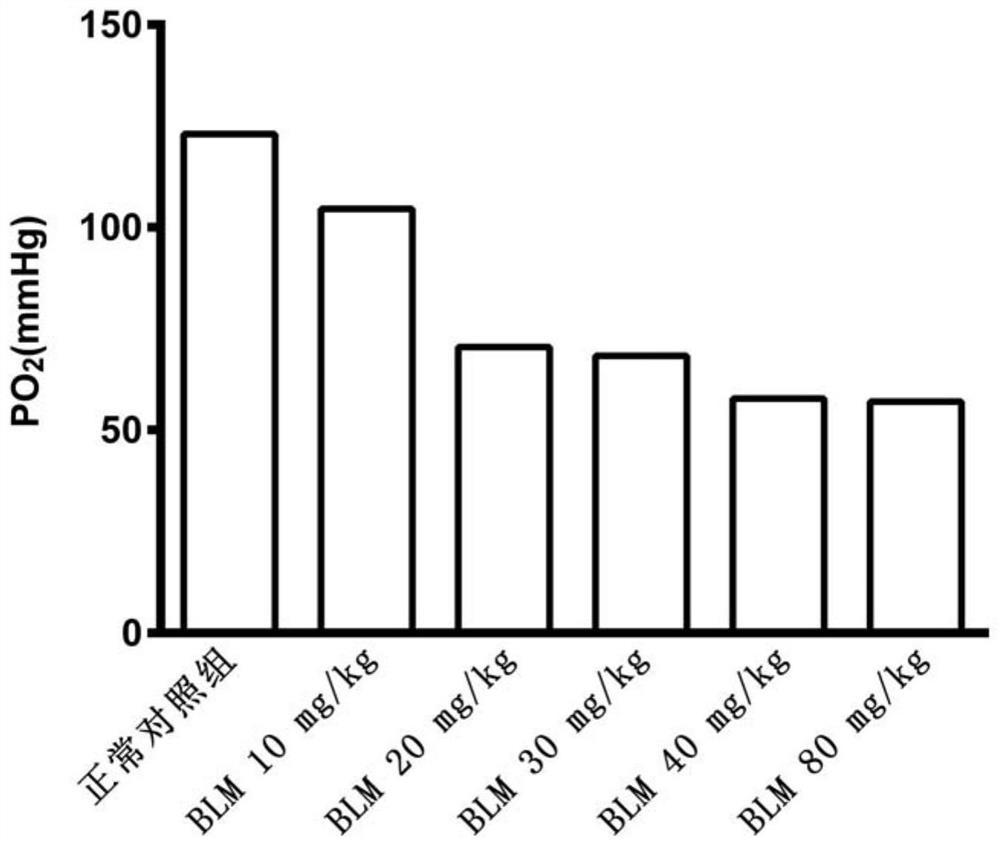

Rat lung injury model for different severity degrees and for achieving induction of different doses of bleomycin through tracheal inside spraying

InactiveCN112189625ASmall non-essential impactThe modeling process is simpleAnimal husbandryTongue rootBiology

The invention provides a rat lung injury model for different severity degrees and for achieving induction of different doses of bleomycin through tracheal inside spraying. The model comprises the following steps that rats are anesthetized, and after the rats reach the anesthetized state, the rats are immediately kept on an inclined face keeping table in a supine manner so that tracheal openings can be found smoothly through oral cavities of the rats; a cold light source is used for irradiating the lower jaws of the necks of the rats so as to obtain sufficient light during subsequent intraoraloperation; the tongues of the rats are pulled out, the tongue roots are pressed by tongue depressors, and the tracheal openings are found; and a tracheal inside atomizer is used, a needle-shaped headof the atomizer is directly inserted into the tracheas of the rats by 3-4 cm, the breathing rule of the rats is observed, bleomycin (10 mg / kg-80 mg / kg weight) of different doses is rapidly sprayed into the tracheas at the moment that the rats inhale, and then the rats are kept on the inclined face keeping table for 5-30 s. By means of the obtained rat lung injury model which is stable, controllable in death rate, better in consistency and capable of simulating different clinical severity degrees, a more reliable animal experiment material is provided for medical preclinical research.

Owner:苏州西山中科药物研究开发有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com