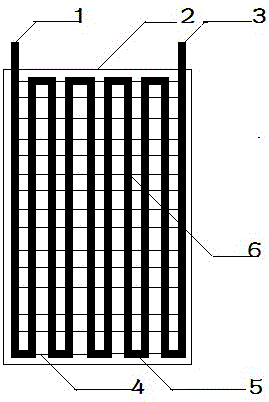

Lightweight aggregate concrete superposed slab integrating dual functions of load-bearing and heat radiation

A dual-function, lightweight aggregate technology, applied in building materials, building components, buildings, etc., can solve the problems of separate installation of heating systems, single load-bearing of building boards, poor energy-saving effect, etc., to improve load-bearing performance, good thermal insulation effect, good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

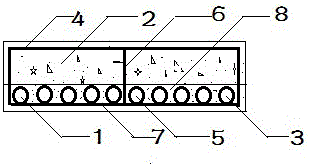

[0029] Embodiment 1: Taking a plate with a room size of 4800mm×3000mm as an example, the cooling pipe 5 is made of galvanized steel pipe. The galvanized steel pipes are machined in the factory with serpentine galvanized pipe meshes, and the cooling pipes 5 of each room panel correspond to four sets of galvanized steel pipe meshes, which are assembled on site. The size of the serpentine galvanized steel pipe mesh cooling pipe 5 is 3000mm×1200mm, that is, the length direction of the steel pipe is 3000mm. The total thickness of the plate ceramsite lightweight aggregate concrete 2 and the straw lightweight aggregate concrete 8 is 120 mm according to the requirements of thermal insulation performance and bearing capacity. At the position of the ring beam in the wall room where the masonry is completed, a connection inspection port is left, and a formwork is supported. The lower layer of steel wire mesh 7 is laid on the template, the steel wire diameter of the lower layer of steel ...

Embodiment 2

[0030] Embodiment 2: Taking a plate with a room size of 4800mm×3000mm as an example, the heat dissipation pipe 5 is made of polybutene pipe (PB). The cooling pipes 5 of each room board correspond to a group of polybutylene pipe (PB) mesh sheets, which are arranged in a serpentine shape on site. The heat pipe 5 in the whole room is not provided with a joint, and is connected with the heat pipe 5 in other rooms by setting a valve at the connecting inspection port, and the remaining parts are the same as in Embodiment 1.

Embodiment 3

[0031] Embodiment 3: Take a single-storey house as an example. After the lightweight aggregate concrete slabs in all rooms reach the design strength, the water inlet joint 1 of the heat dissipation pipe in the first room shall be connected with the corresponding joints of the system heating pipeline according to the design drawings; the first room slab The water outlet joint 3 of the inner heat dissipation pipe is connected with the water inlet joint 1 of the heat dissipation pipe of the second room plate by means of hot-melt joints. According to this method, according to the design requirements, the water outlet joint 3 of the heat dissipation pipe of the second room plate and the water inlet joint 1 of the heat dissipation pipe of the third room plate are connected by hot-melt joints until a circulation path connection is completed. In this way, the water inlet joint 1 of the plate cooling pipe in the first room is connected with the water supply pipe of this circulation pat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com