Processing method for nitrided gears

A processing method and gear technology, which is applied in the field of nitriding gear processing, can solve problems such as component deformation, achieve the effect of reducing deformation and ensuring processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific embodiment one: the processing method of a kind of nitriding gear of this embodiment is to carry out according to the following steps:

[0023] 1. Select a forging made of 42CrMo, and heat the forging at a temperature of 1100-1200°C for a heating time of 40min-80min to obtain the workpiece to be processed;

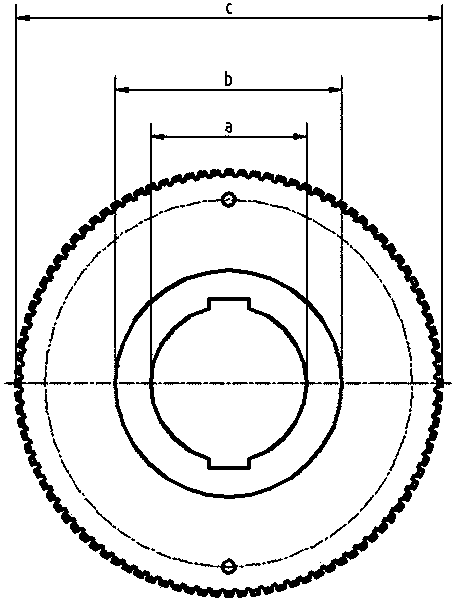

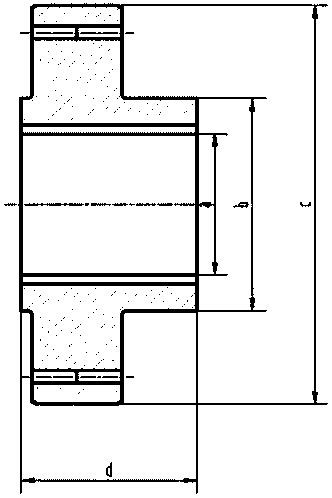

[0024] 2. Select the CNC machine tool, choose the outer circle turning tool and the inner hole boring tool for the tool, rough the outer circle b and inner hole a of the hub to be processed, the outer circle b of the hub, the inner hole a and the single-sided machining surplus of the two end faces The amount is 3mm, and the workpiece after rough turning is obtained; the cutting parameters are: speed 150r / min, feed rate 0.25mm / r, cutting depth 2mm;

[0025] 3. Put the rough-turned workpiece obtained in step 2 into a medium-temperature furnace, heat it for 60-120 minutes at a temperature of 920-940°C, then put it into an oil tank to cool to normal temperature...

specific Embodiment approach 2

[0037] Embodiment 2: This embodiment is different from Embodiment 1 in that: In step 1, the forging is heated at a temperature of 1150°C. Others are the same as the first embodiment.

specific Embodiment approach 3

[0038] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the heating time in step 1 is 60 minutes. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com