A continuous casting crystallizer for high-speed iron wire alloy copper rod and its production process

A casting crystallizer and production process technology, applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the uncontrollable length stability of the pulling copper rod, increase the cost and difficulty of the copper rod used for high-speed rail, and the uniformity of the inside of the copper rod To avoid problems such as inconsistency, to achieve the effect of easy regular replacement, maintain the quality of pulling, and the surface is smooth and scratch-free

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

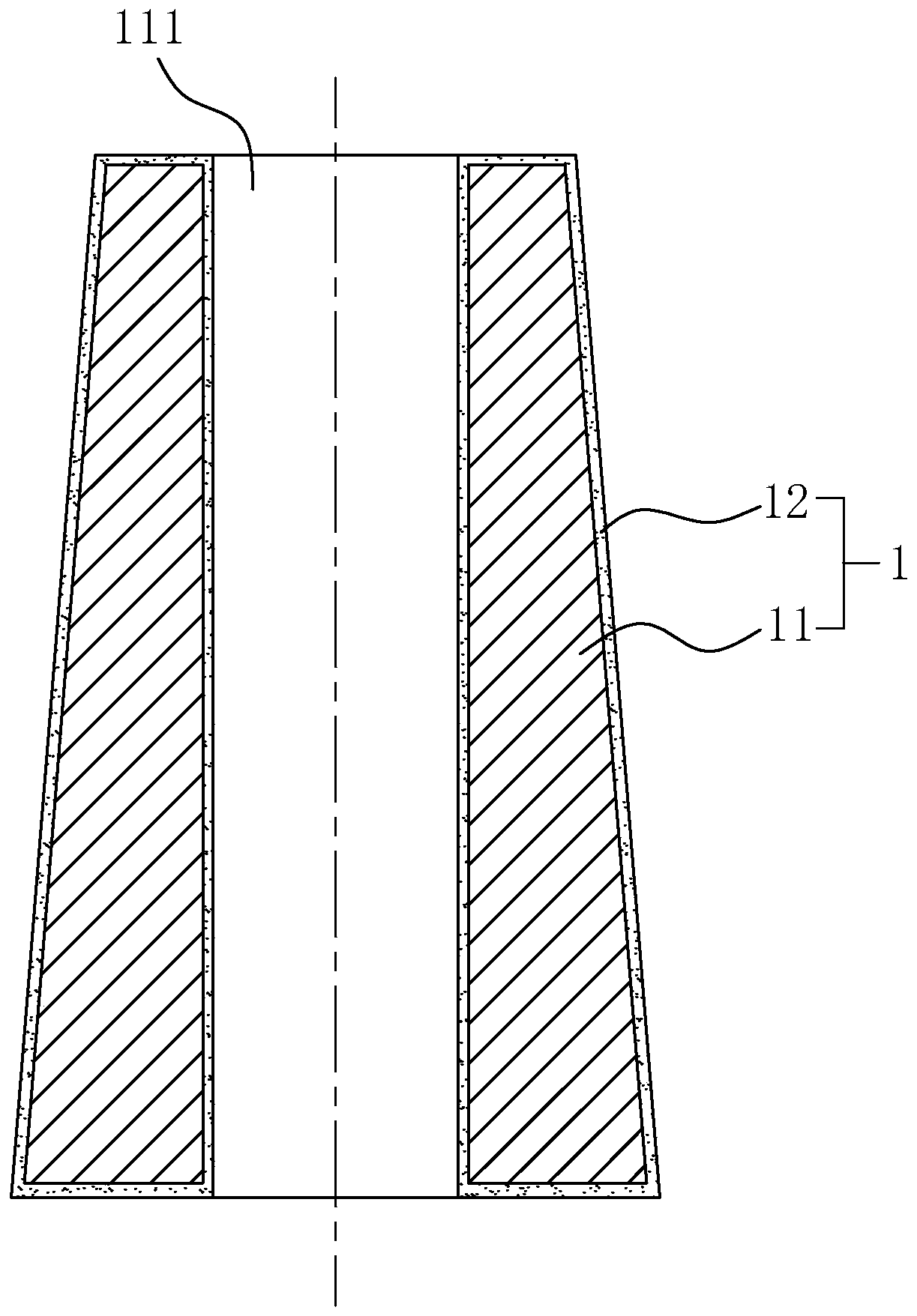

[0043] Embodiment one: a kind of high-iron wire alloy copper rod continuous casting crystallizer, such as figure 1 As shown, the graphite tube body 11 is included, and the graphite tube body 11 is provided with a cylindrical through-hole 111 of equal diameter along the axial direction, and the inner wall of the graphite tube body 11 is located in the through-hole 111 and is coated with a layer of 4-6um thick pyrolytic carbon coating. layer. According to needs, a layer of 4-6um thick pyrolytic carbon coating can also be coated on the two ends and the outer surface of the graphite tube body 11 . The graphite tube body 11 can be designed into a cylindrical shape as required, and the outer surface of one end of the cylindrical shape is provided with an external thread for threaded connection with the protective cover; the graphite tube body 11 can also be designed as a truncated cone to facilitate the cooperation of the crystallizer and the protective cover.

[0044] The graphite...

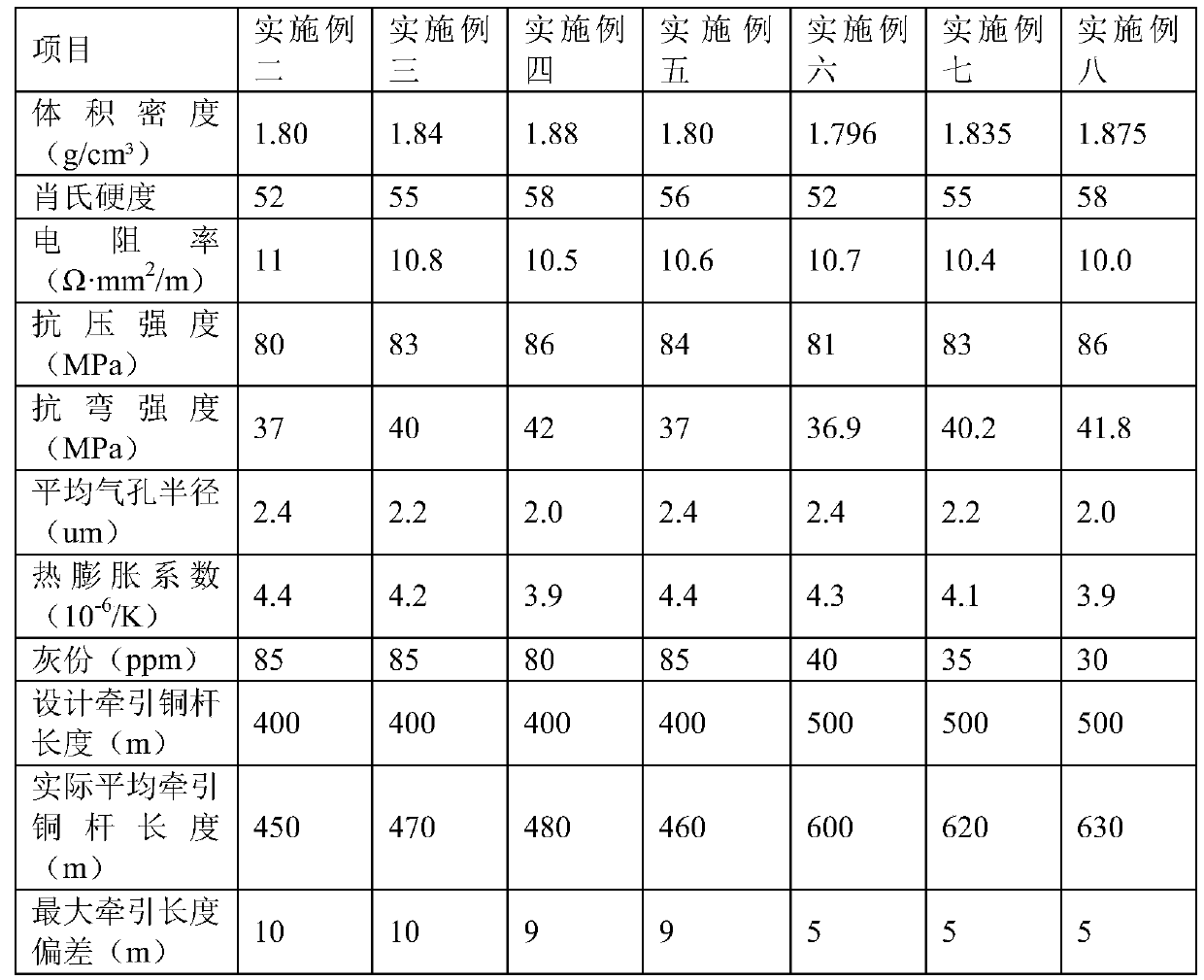

Embodiment 2

[0045] Embodiment two: a kind of production technology of high-iron wire alloy copper rod continuous casting crystallizer, such as figure 2 shown, including the following steps:

[0046] S1: Mix petroleum coke and pitch coke materials with a particle size of 15um to 25um, add molten pitch as a binder, and mold graphite blocks. The particle size of the petroleum coke can be 30-50 mesh, and the ash content of the petroleum coke is not more than 0.15%. Add graphite with a purity of 99.99%, mix evenly, put it into a mold and mold it, and obtain a cuboid or cylinder graphite block. The bulk density of the graphite block is controlled at 1.75g / cm 3 .

[0047] S2: The graphite block is sequentially subjected to primary roasting, primary dipping, secondary roasting, secondary dipping, triple roasting, triple dipping, and fourth roasting.

[0048] The roasting method is: put the graphite block into the vacuum furnace and slowly heat it to 1200°C at an average rate of ≤100°C / day, ke...

Embodiment 3

[0055] Embodiment three: a kind of production technique of continuous casting crystallizer of high-iron wire alloy copper rod, such as figure 2 shown, including the following steps:

[0056] S1: Mix petroleum coke and pitch coke materials with a particle size of 15um to 25um, add molten pitch as a binder, and mold graphite blocks. The particle size of the petroleum coke can be 30-50 mesh, and the ash content of the petroleum coke is not more than 0.15%. Add graphite with a purity of 99.99%, mix evenly, put it into a mold and mold it, and obtain a cuboid or cylinder graphite block. The bulk density of the graphite block is controlled at 1.73g / cm 3 .

[0057] S2: The graphite block is sequentially subjected to primary roasting, primary dipping, secondary roasting, secondary dipping, triple roasting, triple dipping, and fourth roasting.

[0058] The roasting method is: put the graphite block into the vacuum furnace and slowly heat it to 1200°C at an average rate of ≤100°C / day...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com