Sliding support arranged on 150 DEG C heat supply overhead pipeline and used for preventing heat bridge from transferring heat

A technology of sliding bearings and overhead pipelines, which is applied in the direction of heat insulation protection pipelines, pipeline protection, heat exchange equipment, etc., and can solve problems such as thermal bridge effects that are prone to occur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

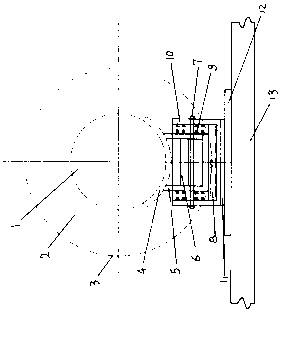

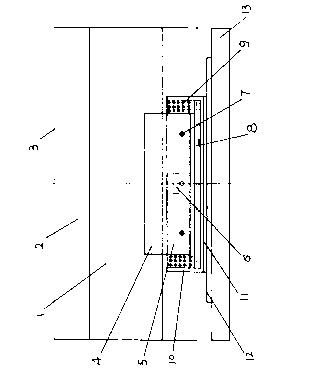

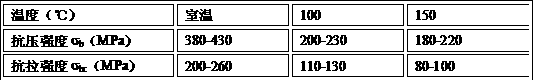

[0015] A sliding support for a 150°C heating overhead pipeline that prevents heat bridge transmission, including a pipeline support 13, an outer protective shell pipe 3, and a heat-transporting steel pipe 1. The heat-transporting steel pipe 1 is arranged in the outer protective shell pipe 3. 1 and the outer protective shell pipe 3 are provided with an insulating layer 2, a pre-embedded steel plate 12 is provided on the top surface of the pipe support 13, and an arc-shaped support plate 4 is fixedly arranged on the bottom arc-shaped outer surface of the heat-transporting steel pipe 1 , the arc-shaped supporting plate 4 is fixedly arranged on the arc-shaped top surface bracket 5, a reinforcing rib 6 is arranged on the arc-shaped top surface bracket 5, and a polytetrafluoroethylene plate 11 is movable on the embedded steel plate 12, A high-strength heat-insulating epoxy resin bracket 10 with pits is arranged on the polytetrafluoroethylene plate 11, and the arc-shaped top surface b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com