Prefabricated coal gangue thermal insulation concrete shear wall plate

A technology of coal gangue concrete and thermal insulation concrete, applied in thermal insulation, building thermal insulation materials, walls, etc., can solve the problems of less research, achieve good anti-corrosion performance, improve thermal insulation effect, and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

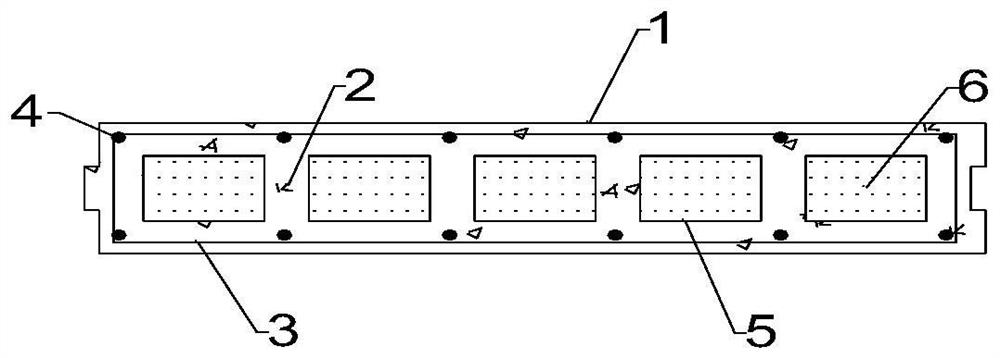

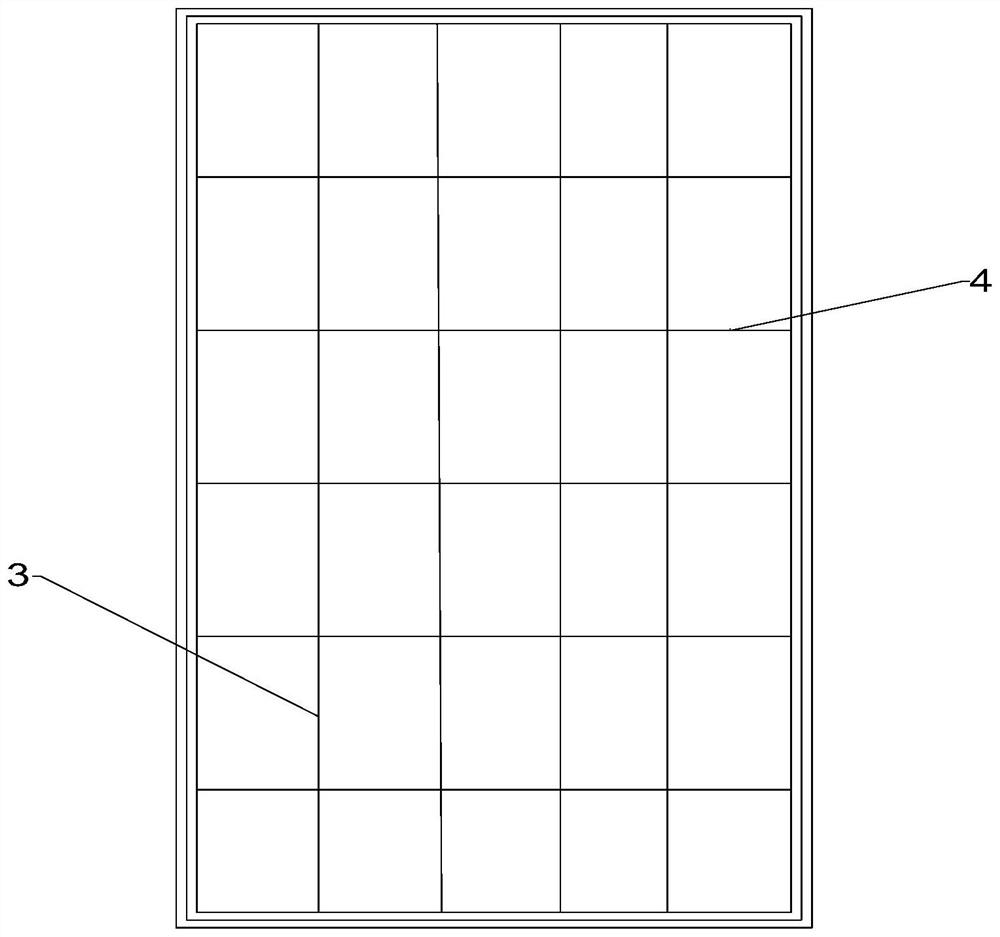

[0019] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0020] The present invention is because in the frame-shear wall structure, the cast-in-place concrete shear wall needs to bind the steel skeleton and pour concrete on site, which not only has a long construction period, but also is difficult to ensure good pouring quality; secondly, industrial wastes such as coal gangue are used. Coarse aggregate is used to replace ordinary concrete to produce prefabricated coal gangue shear wall panels, which realizes the advantages of recycling waste industrial materials, turning waste into treasure, promoting resource utilization, protecting the environment, and reducing occupation of agricultural land; at the same time, it will not be excessive Increase the weight of the structure and effectively improve the rigidity of the structure; the holes of the thermal insulation prefabricated coal gangue conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com